Author Contributions

Conceptualization, V.D.Z. and I.B.S.; Methodology, V.D.Z., M.B., I.B.S. and T.A.; Software, M.B. and T.A.; Validation, M.B., I.B.S., V.D.Z., I.D., and T.A.; Formal Analysis, M.B. and T.A.; Investigation, I.B.S., I.D., V.D.Z., and T.A.; Resources, M.B., I.B.S., I.D., T.A., and V.D.Z.; Data Curation, M.B., I.B.S., V.D.Z., I.D., and T.A.; Writing—Original Draft Preparation, M.B., I.B.S., I.D. and V.D.Z.; Writing—Review and Editing, I.B.S., V.D.Z., I.D., M.B. and T.A.; Visualization, T.A.; Supervision, V.D.Z.; Project Administration, V.D.Z.; Funding Acquisition, V.D.Z.

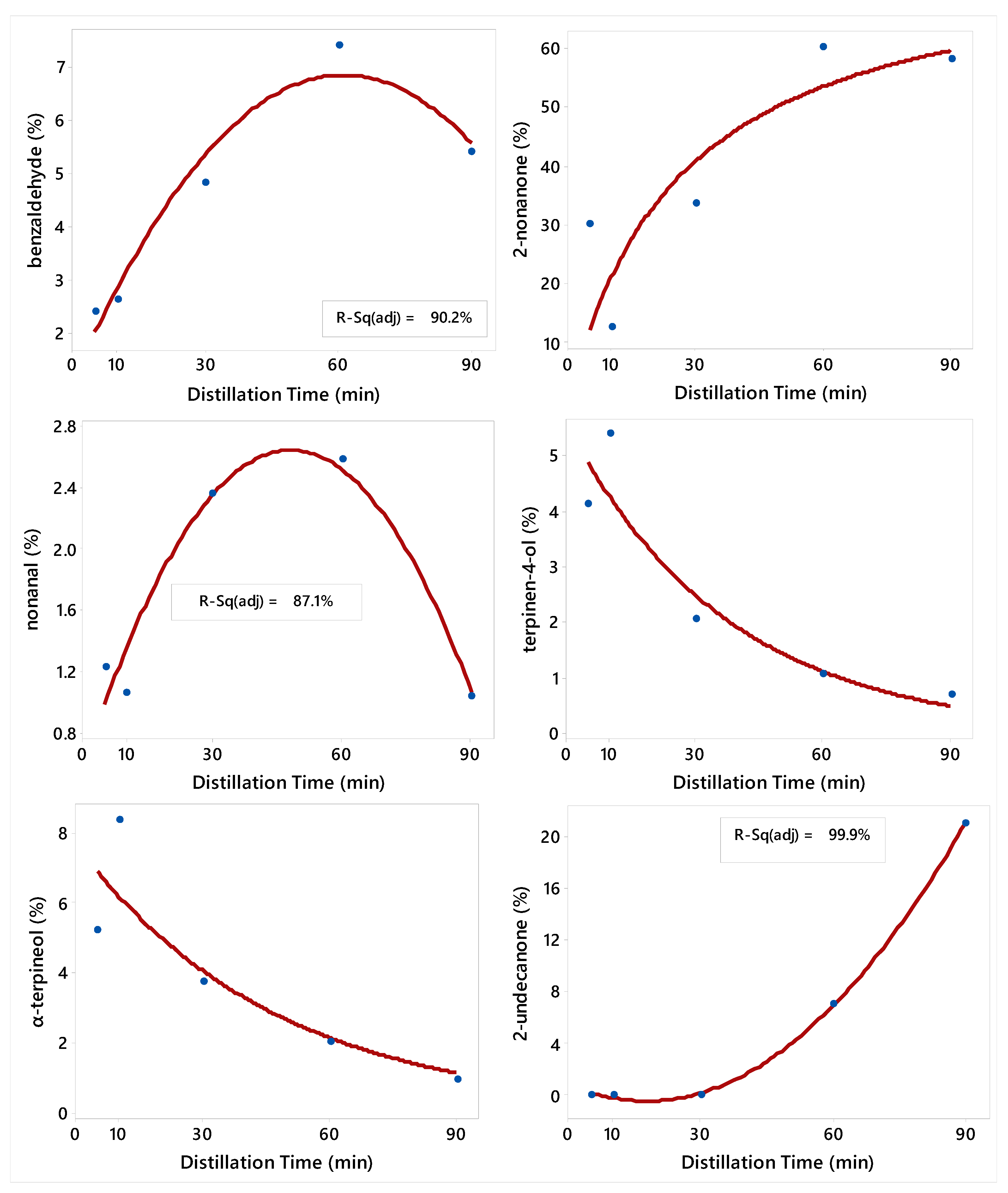

Figure 1.

Plot of Distillation Time (DT) vs. the concentrations of six constituents of R. graveolens fruit along with the fitted second-order polynomial, Michaelis–Menten, and Exponential regression models. Adjusted R2 is given only for the second-order polynomial model, which is linear. The fitted models are: (benzaldehyde), (2-nonanone), (nonanal), (terpinen-4-ol), (α-terpineol), and (2-undecanone).

Figure 1.

Plot of Distillation Time (DT) vs. the concentrations of six constituents of R. graveolens fruit along with the fitted second-order polynomial, Michaelis–Menten, and Exponential regression models. Adjusted R2 is given only for the second-order polynomial model, which is linear. The fitted models are: (benzaldehyde), (2-nonanone), (nonanal), (terpinen-4-ol), (α-terpineol), and (2-undecanone).

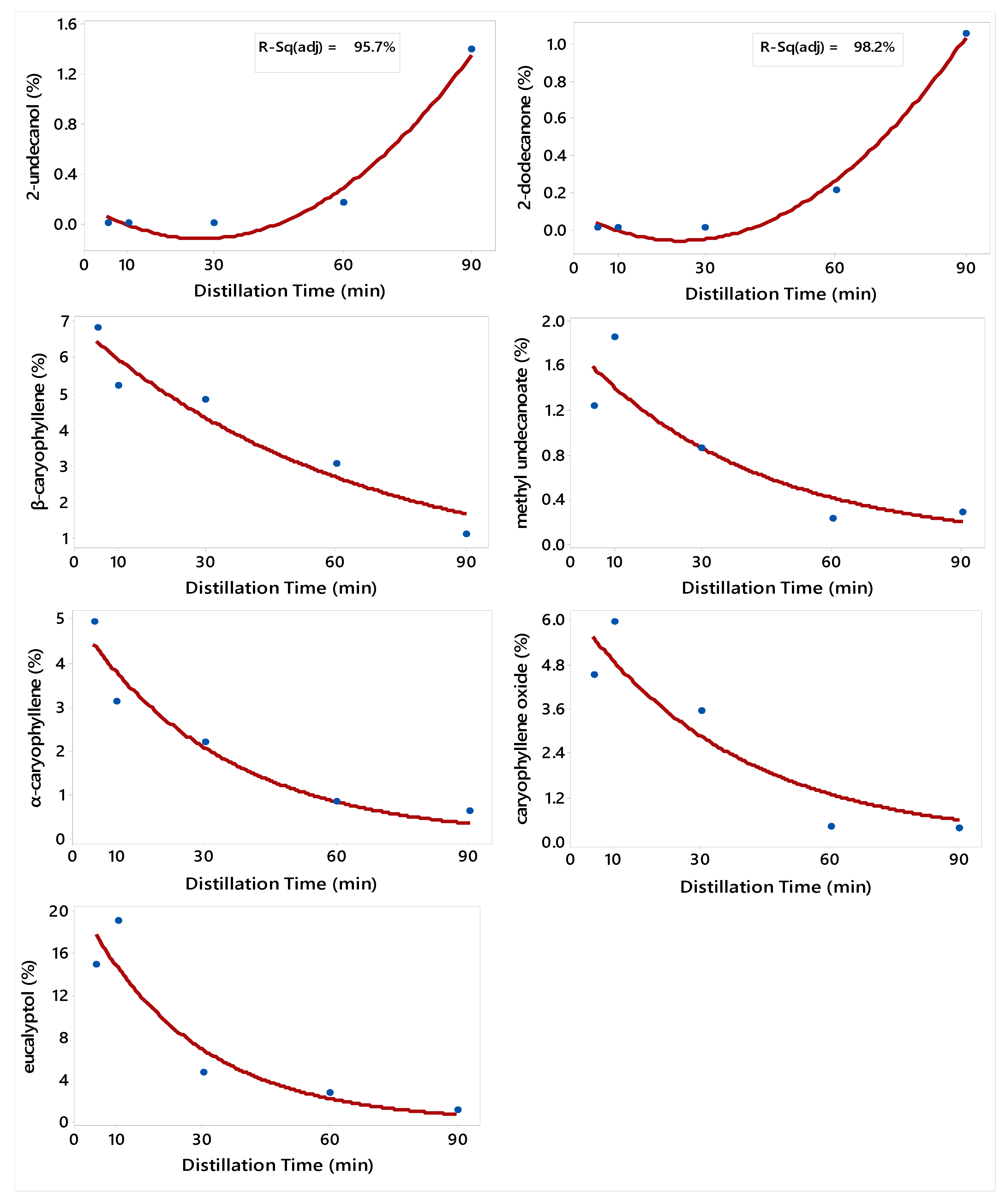

Figure 2.

Plot of Distillation Time (DT) vs. the concentrations of six constituents of R. graveolens fruit along with the fitted second-order polynomial and Exponential regression models. Adjusted R2 is given only for the second-order polynomial model, which is linear. The fitted models are: (2-undecanol), (2-dodecanone), (β-caryophyllene), (methyl undecanoate), (α-caryophyllene), (caryophyllene oxide), and (eucalyptol).

Figure 2.

Plot of Distillation Time (DT) vs. the concentrations of six constituents of R. graveolens fruit along with the fitted second-order polynomial and Exponential regression models. Adjusted R2 is given only for the second-order polynomial model, which is linear. The fitted models are: (2-undecanol), (2-dodecanone), (β-caryophyllene), (methyl undecanoate), (α-caryophyllene), (caryophyllene oxide), and (eucalyptol).

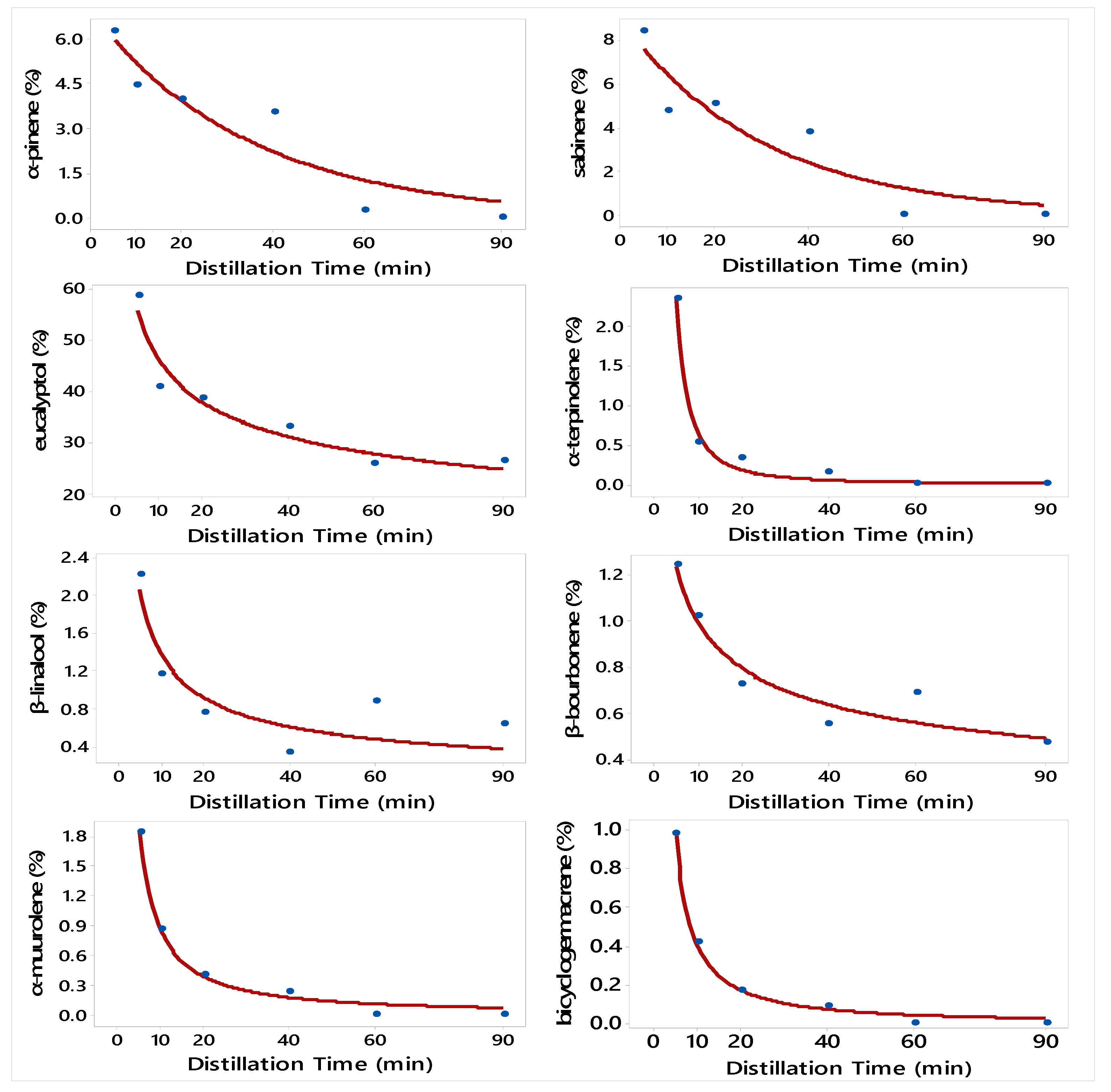

Figure 3.

Plot of Distillation Time vs. the concentrations of eight constituents of H. officinalis subsp. aristatus along with the fitted Exponential and Power nonlinear regression models. The fitted models are: (α-pinene), (sabinene), (eucalyptol), (α-terpinolene), (β-linalool), (β-bourbonene), (α-muurolene), and (bicyclogermacrene).

Figure 3.

Plot of Distillation Time vs. the concentrations of eight constituents of H. officinalis subsp. aristatus along with the fitted Exponential and Power nonlinear regression models. The fitted models are: (α-pinene), (sabinene), (eucalyptol), (α-terpinolene), (β-linalool), (β-bourbonene), (α-muurolene), and (bicyclogermacrene).

Table 1.

Essential oil yield (%) of Ruta graveolens fruits and Hyssopus officinalis subsp. aristatus biomass.

Table 1.

Essential oil yield (%) of Ruta graveolens fruits and Hyssopus officinalis subsp. aristatus biomass.

| DT(min) | EO Yield % | DT (min) | EO Yield % |

|---|

| R. graveolens Fruits | H. officinalis subsp. aristatus Biomass |

|---|

| 0–5 | 0.04 b | 0–5 | 0.44 b |

| 5–10 | 0.10 b | 5–10 | 0.15 bc |

| 10–30 | 0.04 b | 10–20 | 0.24 bc |

| 30–60 | 0.12 b | 20–40 | 0.24 bc |

| 60–90 | 0.03 b | 40–60 | 0.05 c |

| Control | 0.39 a | 60–90 | 0.20 bc |

| | | Control | 1.12a |

Table 2.

Chemical families of Ruta graveolens fruit essential oil (EO) constituents as a function of their extraction during hydrodistillation timeframes (DT).

Table 2.

Chemical families of Ruta graveolens fruit essential oil (EO) constituents as a function of their extraction during hydrodistillation timeframes (DT).

| DT (min) | Control (0–90) | 0–5 | 5–10 | 10–30 | 30–60 | 60–90 |

|---|

| Alkyl aldehyde | 0.44 | 2.72 | 3.67 | 4.67 | 3.75 | 1.07 |

| aromatic aldehyde | 0.11 | 2.44 | 2.65 | 4.89 | 7.27 | 5.45 |

Monoterpenes

(acyclic, phenolic, monocyclic, bicyclic) | 2.79 | 36.5 | 47.5 | 24.1 | 6.30 | 3.5 |

| Alkyl ketone; ketone | 69.2 | 30.2 | 13.5 | 34.0 | 67.4 | 80.0 |

| Alkyl aldehyde | 0.14 | 1.25 | 1.08 | 2.40 | 2.61 | 1.06 |

| Fatty alcohol | 0.92 | 3.18 | 3.37 | 7.49 | 1.70 | 2.31 |

Sesquiterpenes (bicyclic,

tricyclic, monocyclic; bicyclic sesquiterpenoid) | 8.08 | 17.8 | 19.6 | 19.0 | 8.09 | 3.64 |

| Fatty acid ester | 7.56 | 1.25 | 1.74 | 0.87 | 0.22 | 0.28 |

| Acyclic diterpenoids | 3.43 | 4.39 | 6.02 | 3.39 | 0.42 | 0.35 |

| Straight-chain saturated hydrocarbon | 1.65 | nd | nd | nd | nd | nd |

Table 3.

The mean concentrations (%) of Ruta graveolens fruit EO (benzaldehyde, 2-nonanone, 2-nonanol, nonanal, 2-undecanone, 2-undecanol, 2-dodecanone, and methyl undecanoate) obtained from the six distillation times (DT). Control = nonstop 0–90 min.

Table 3.

The mean concentrations (%) of Ruta graveolens fruit EO (benzaldehyde, 2-nonanone, 2-nonanol, nonanal, 2-undecanone, 2-undecanol, 2-dodecanone, and methyl undecanoate) obtained from the six distillation times (DT). Control = nonstop 0–90 min.

| DT (min) | Benzaldehyde | 2-Nonanone | 2-Nonanol | Nonanal | 2-Undecanone | 2-Undecanol | 2-Dodecanone | Methyl Undecanoate |

|---|

| 0–5 | 2.41 d | 29.9 d | 2.38 b | 1.23 c | 0.00 d | 0.00 c | 0.00 d | 1.23 b |

| 5–10 | 2.62 d | 12.6 f | 2.07 c | 1.07 d | 0.00 d | 0.00 c | 0.00 d | 1.85 a |

| 10–30 | 4.80 c | 33.5 c | 4.58 a | 2.36 b | 0.00 d | 0.00 c | 0.00 d | 0.86 c |

| 30–60 | 7.38 a | 60.1 a | 1.51 d | 2.57 a | 6.96 c | 0.17 c | 0.21 c | 0.22 d |

| 60–90 | 5.38 b | 57.9 b | 0.90 e | 1.05 d | 21.1 b | 1.39 b | 1.05 b | 0.27 d |

| Control | 0.11 e | 25.1 e | 0.67 f | 0.14 e | 35.0 a | 5.19 a | 2.34 a | 2.12 a |

Table 4.

Mean concentrations (%) of Ruta graveolens fruit EO (terpinen-4-ol, α-terpineol, trans-pinocarveol, nopinone, and eucalyptol) obtained from the six distillation times (DT). Control = nonstop 0–90 min.

Table 4.

Mean concentrations (%) of Ruta graveolens fruit EO (terpinen-4-ol, α-terpineol, trans-pinocarveol, nopinone, and eucalyptol) obtained from the six distillation times (DT). Control = nonstop 0–90 min.

| DT (min) | Terpinen-4-ol | α-Terpineol | trans-Pinocarveol | Nopinone | Eucalyptol |

|---|

| 0–5 | 4.12 b | 5.22 b | 2.04 b | 2.69 c | 14.95 b |

| 5–10 | 5.37 a | 8.35 a | 1.60 c | 3.03 b | 19.04 a |

| 10–30 | 2.05 c | 3.73 c | 3.54 a | 3.75 a | 4.65 c |

| 30–60 | 1.06 d | 2.02 d | 0.00 d | 0.00 d | 2.67 d |

| 60–90 | 0.71 e | 0.93 e | 0.00 d | 0.00 d | 1.03 e |

| Control | 0.62 e | 0.57 f | 0.00 d | 0.00 d | 0.29 e |

Table 5.

Mean concentrations (%) of Ruta graveolens fruit EO (α-caryophyllene, δ-cadinene, caryophyllene oxide, tau-cadinol, tau-muurolol, β-caryophyllene, manoyl oxide) obtained from the six distillation times (DT). Control = nonstop 0–90 min.

Table 5.

Mean concentrations (%) of Ruta graveolens fruit EO (α-caryophyllene, δ-cadinene, caryophyllene oxide, tau-cadinol, tau-muurolol, β-caryophyllene, manoyl oxide) obtained from the six distillation times (DT). Control = nonstop 0–90 min.

| DT (min) | α-Caryophyllene | δ-Cadinene | Caryophyllene Oxide | β-Caryophyllene | tau-Cadinol | tau-Muurolol | Manoyl Oxide |

|---|

| 0–5 | 4.90 a | 1.77 c | 4.49 b | 6.81 a | 0.72 b | 0.93 c | 1.52 c |

| 5–10 | 3.11 b | 2.73 b | 5.95 a | 5.20 b | 0.96 a | 1.28 b | 6.48 a |

| 10–30 | 2.16 c | 3.74 a | 3.53 c | 4.82 c | 0.95 a | 2.02 a | 4.16 b |

| 30–60 | 0.84 d | 1.38 d | 0.42 d | 3.05 d | 0.00 d | 0.00 e | 1.03 cd |

| 60–90 | 0.60 d | 0.80 e | 0.35 d | 1.10 e | 0.00 d | 0.00 e | 0.40 d |

| Control | 0.23 e | 1.06 de | 0.46 d | 0.83 e | 0.46 c | 0.45 d | 0.95 cd |

Table 6.

Chemical families of Hyssopus officinalis subsp. aristatus essential oil (EO) constituents as a function of their release during hydrodistillation time frames.

Table 6.

Chemical families of Hyssopus officinalis subsp. aristatus essential oil (EO) constituents as a function of their release during hydrodistillation time frames.

| DT (min) | Control (0–90) | 0–5 | 5–10 | 10–20 | 20–40 | 40–60 | 60–90 |

|---|

| Class Compounds |

|---|

| Total Monoterpenes | 84.5 | 88.2 | 93.9 | 95.1 | 91.9 | 95.3 | 96.3 |

| Bicyclic monoterpenes monoterpenoids | 69.6 | 73.9 | 83.5 | 86.6 | 78.6 | 82.6 | 84.8 |

| Acyclic monoterpenes | 3.70 | 3.90 | 3.57 | 3.25 | 2.39 | 0.89 | 0.65 |

| Phenolic monoterpenoids | 0.58 | 0.37 | 0.15 | 0.11 | 0.92 | nd | nd |

| Monocyclic monoterpenes | 10.5 | 10.0 | 6.76 | 5.14 | 9.95 | 11.9 | 10.8 |

| Total Sesquiterpenes | 12 | 7.97 | 3.56 | 1.91 | 3.52 | 2.02 | 1.6 |

| Monocyclic sesquiterpenes | 0.19 | 0.24 | 0.10 | nd | nd | nd | nd |

| Tricyclic sesquiterpenes | 2.57 | 1.89 | 1.48 | 0.96 | 0.34 | 0.70 | 0.49 |

| Bicyclic sesquiterpenes | 6.11 | 4.64 | 1.47 | 0.65 | 3.18 | 1.32 | 1.11 |

| Tricyclic sesquiterpenoids | 3.1 | 1.2 | 0.51 | 0.30 | nd | nd | nd |

| Straight-chain saturated hydrocarbons | 0.80 | 0.67 | nd | nd | nd | nd | nd |

Table 7.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (α-pinene, sabinene, β-pinene, β-myrcene, and eucalyptol) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

Table 7.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (α-pinene, sabinene, β-pinene, β-myrcene, and eucalyptol) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

| DT (min) | α-Pinene | Sabinene | β-Pinene | β-Myrcene | Eucalyptol |

|---|

| 0–5 | 6.28 a | 8.45 a | 7.90 d | 0.32 e | 58.6 a |

| 5–10 | 4.46 b | 4.79 b | 10.8 c | 1.33 c | 40.8 c |

| 10–20 | 3.99 bc | 5.12 b | 12.7 b | 1.72 a | 38.6 d |

| 20–40 | 3.56 c | 3.82 c | 15.2 a | 1.43 b | 32.9 e |

| 40–60 | 0.27 d | 0.00 d | 0.44 e | 0.00 f | 25.8 f |

| 60–90 | 0.00 d | 0.00 d | 0.00 e | 0.00 f | 26.3 f |

| Control | 6.58 a | 9.07 a | 7.53 d | 0.65 d | 55.9 b |

Table 8.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (α-terpinolene, β-linalool, trans-pinocarveol, cis-verbenol, pinocarvone, and cis-3-pinanone) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

Table 8.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (α-terpinolene, β-linalool, trans-pinocarveol, cis-verbenol, pinocarvone, and cis-3-pinanone) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

| DT (min) | α-Terpinolene | β-Linalool | trans-Pinocarveol | cis-Verbenol | Pinocarvone | cis-3-Pinanone |

|---|

| 0–5 | 2.35 a | 2.21 a | 2.85 bc | 3.49 a | 2.91 b | 12.78 d |

| 5–10 | 0.53 c | 1.16 c | 1.83 d | 2.16 c | 2.46 c | 16.67 b |

| 10–20 | 0.32 d | 0.76 de | 1.49 e | 1.52 d | 1.80 d | 18.81 a |

| 20–40 | 0.15 e | 0.34 f | 1.27 e | 0.29 e | 1.24 e | 20.06 a |

| 40–60 | 0.00 f | 0.88 d | 3.11 b | 3.47 a | 2.70 bc | 14.09 c |

| 60–90 | 0.00 f | 0.64 e | 2.80 c | 3.02 b | 2.57 c | 15.81 b |

| Control | 1.29 b | 1.80 b | 3.62 a | 2.37 c | 3.24 a | 8.61 e |

Table 9.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (terpinen-4-ol, cryptone, α-terpineol, verbenone, trans-carveol, and cis-carveol) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

Table 9.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (terpinen-4-ol, cryptone, α-terpineol, verbenone, trans-carveol, and cis-carveol) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

| DT (min) | Terpinen-4-ol | Cryptone | α-Terpineol | Verbenone | trans-Carveol | cis-Carveol |

|---|

| 0–5 | 1.49 c | 1.69 b | 2.91 bc | 0.31 d | 0.70 d | 0.37 d |

| 5–10 | 1.29 d | 0.98 c | 2.54 c | 0.22 de | 0.63 de | 0.24 e |

| 10–20 | 0.92 e | 0.42 d | 1.93 d | 0.19 e | 0.55 e | 0.16 f |

| 20–40 | 1.90 b | 1.65 b | 5.32 a | 0.16 e | 0.42 f | 0.11 f |

| 40–60 | 2.13 a | 2.24 a | 3.35 b | 3.05 a | 2.41 a | 1.63 a |

| 60–90 | 2.12 a | 2.23 a | 3.07 b | 2.34 b | 2.07 b | 1.11 b |

| Control | 1.74 b | 2.30 a | 2.94 bc | 0.42 c | 0.86 c | 0.55 c |

Table 10.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (β-bourbonene, α-muurolene, bicyclogermacrene, (-)-spathulenol, and caryophyllene oxide) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

Table 10.

Mean concentrations (%) of Hyssopus officinalis subsp. aristatus EO (β-bourbonene, α-muurolene, bicyclogermacrene, (-)-spathulenol, and caryophyllene oxide) obtained from the seven distillation times (DT). Control = nonstop 0–90 min.

| DT (min) | β-Bourbonene | α-Muurolene | Bicyclogermacrene | (-)-Spathulenol | Caryophyllene Oxide |

|---|

| 0–5 | 1.24 b | 1.84 b | 0.99 b | 0.96 c | 0.72 c |

| 5–10 | 1.02 c | 0.86 c | 0.43 c | 0.52 d | 0.68 c |

| 10–20 | 0.73 d | 0.41 d | 0.17 d | 0.30 d | 0.22 d |

| 20–40 | 0.56 de | 0.24 e | 0.09 e | 3.11 a | 1.57 a |

| 40–60 | 0.69 d | 0.00 f | 0.00 f | 1.31 b | 0.00 e |

| 60–90 | 0.48 e | 0.00 f | 0.00 f | 1.09 bc | 0.00 e |

| Control | 1.57 a | 2.48 a | 2.23 a | 2.92 a | 1.14 b |