Effect of H2O on the Pressure-Induced Amorphization of Hydrated AlPO4-17

Abstract

1. Introduction

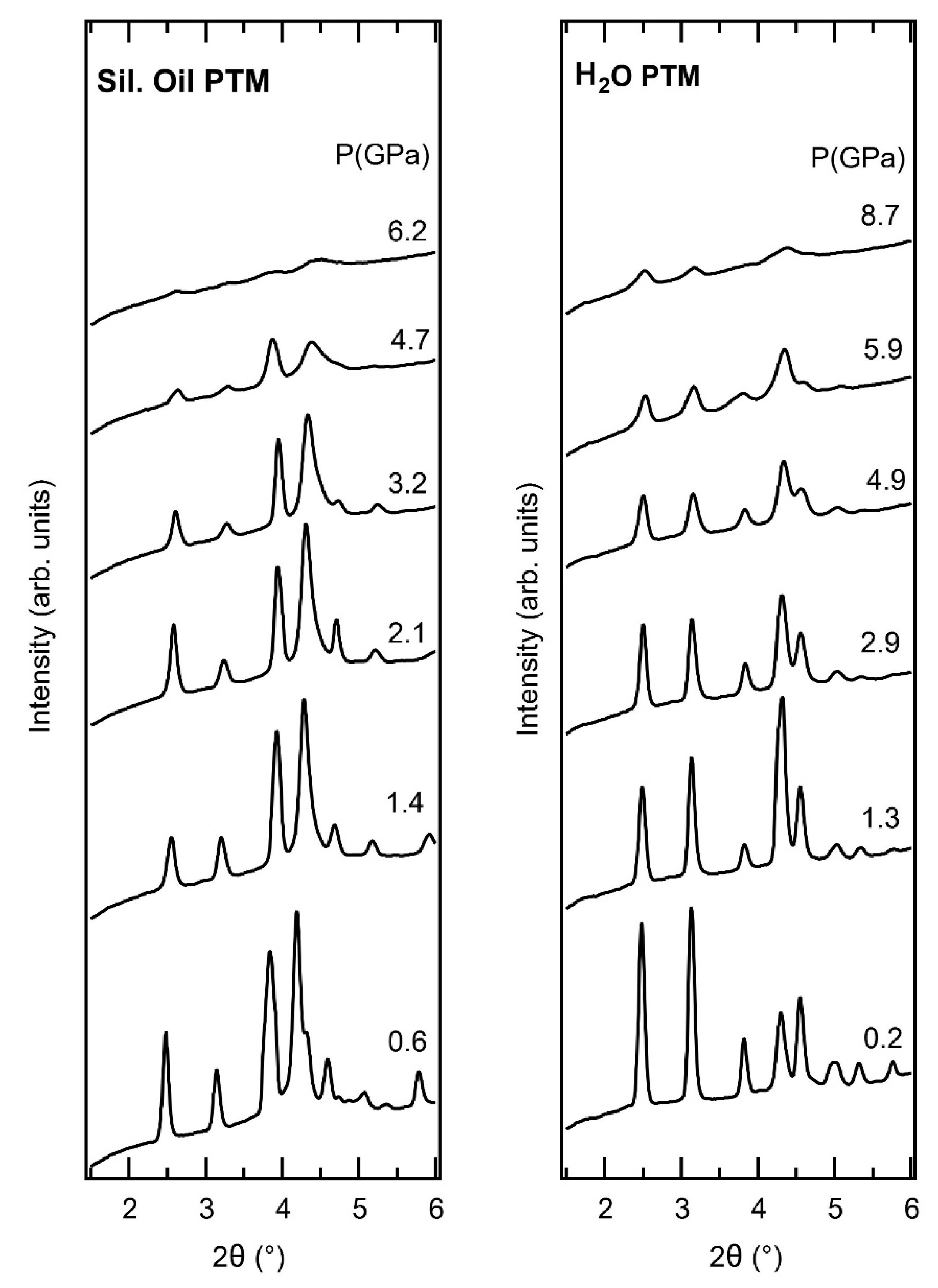

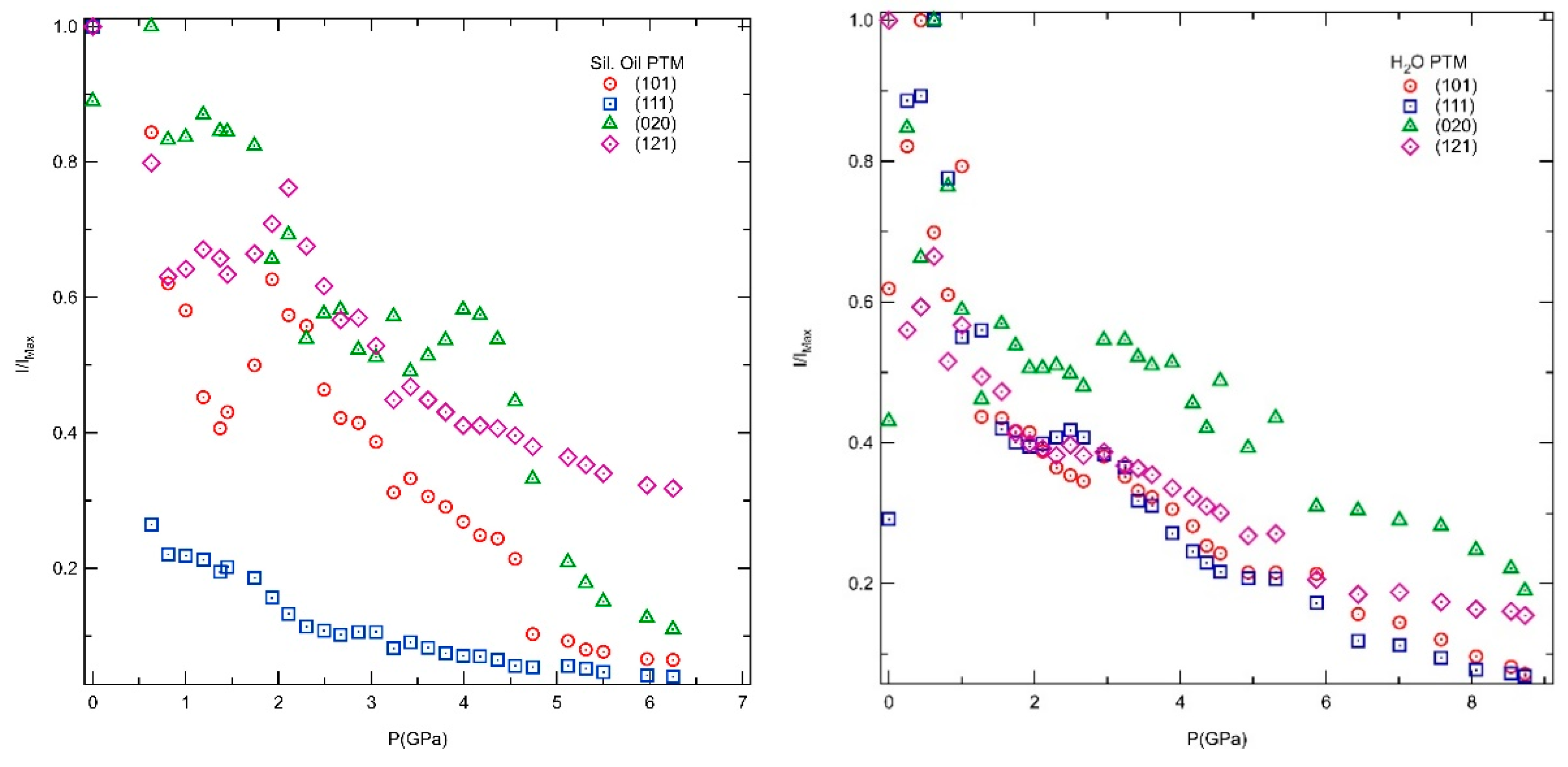

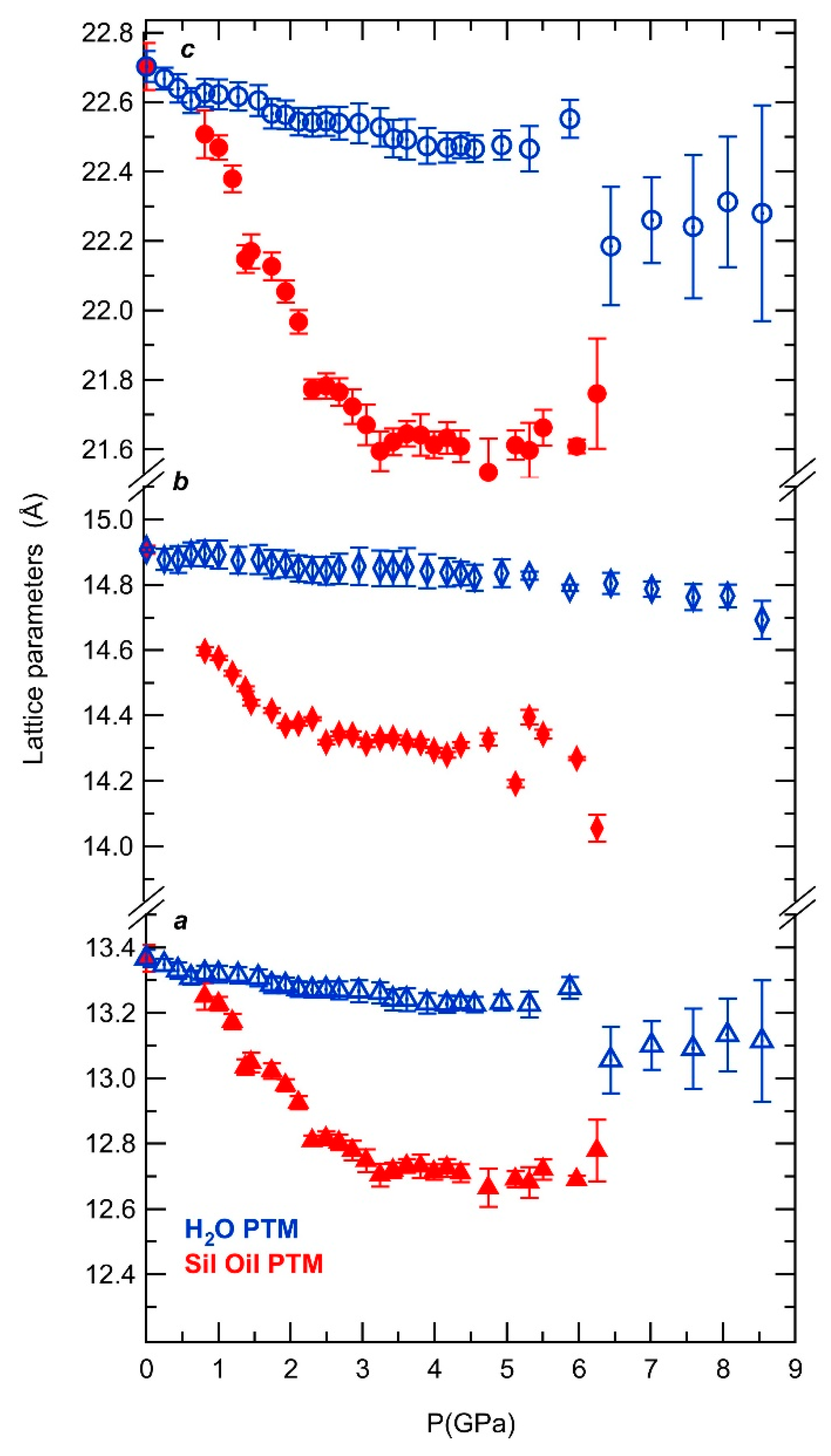

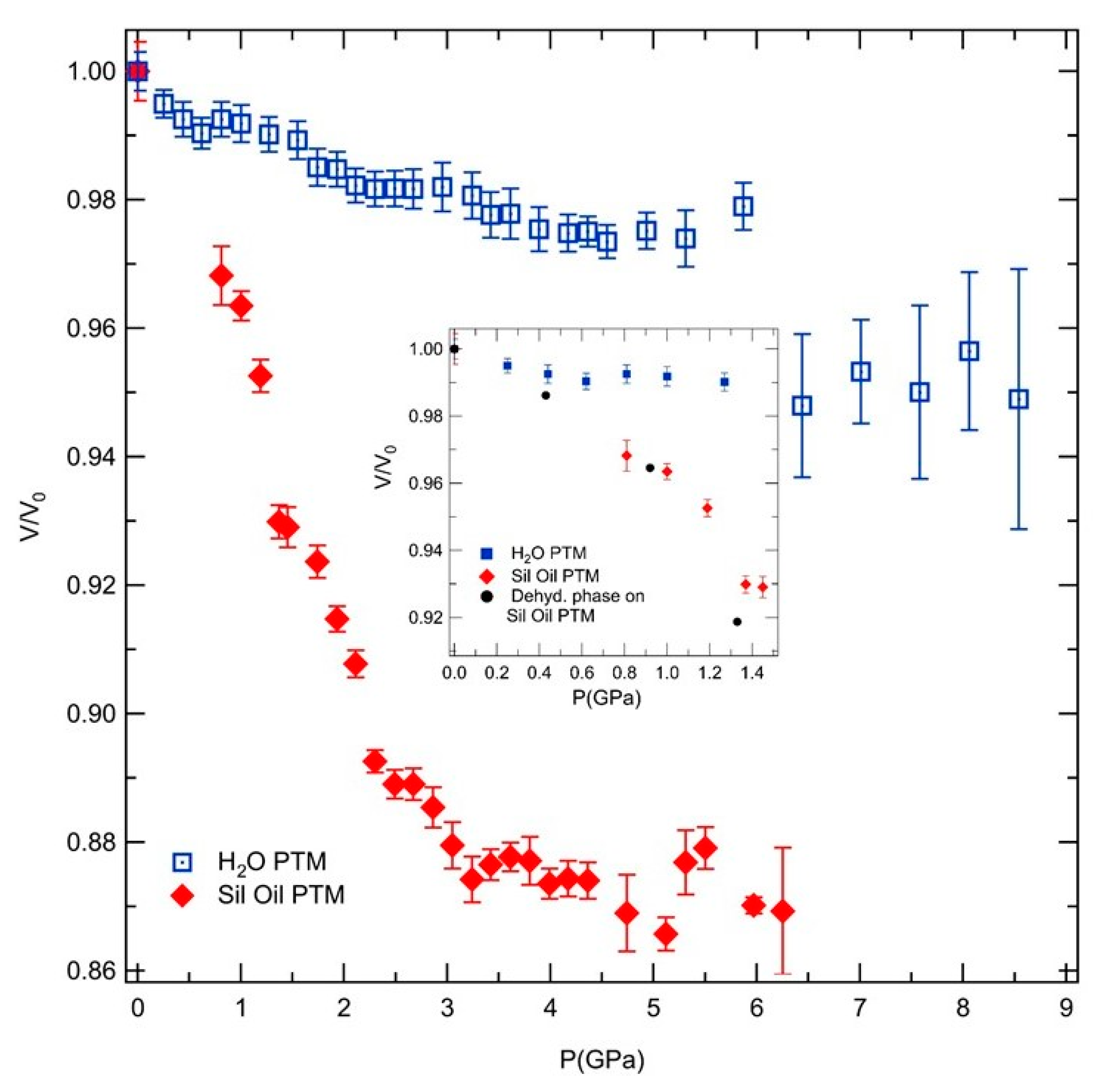

2. Results

3. Discussion

4. Materials and Methods

4.1. AlPO4-17•xH2O: Sample and Experiment

4.2. The Xpress Beamline

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Eroshenko, V.; Regis, R.C.; Soulard, M.; Patarin, J. Energetics: A New Field of Applications for Hydrophobic Zeolites. J. Am. Chem. Soc. 2001, 123, 8129–8130. [Google Scholar] [CrossRef] [PubMed]

- Haines, J.; Cambon, O.; Levelut, C.; Santoro, M.; Gorelli, F.; Garbarino, G. Deactivation of Pressure-Induced Amorphization in Silicalite Sio2 by Insertion of Guest Species. J. Am. Chem. Soc. 2010, 132, 8860–8861. [Google Scholar] [CrossRef] [PubMed]

- Hazen, R.M. Zeolite Molecular-Sieve 4a-Anomalous Compressibility and Volume Discontinuities at High-Pressure. Science 1983, 219, 1065–1067. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Lee, Y.; Hriljac, J.A.; Vogt, T.; Parise, J.B.; Artioli, G. First Structural Investigation of a Super-Hydrated Zeolite. J. Am. Chem. Soc. 2001, 123, 12732–12733. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Vogt, T.; Hriljac, J.A.; Parise, J.B.; Hanson, J.C.; Kim, S.J. Non-Framework Cation Migration and Irreversible Pressure-Induced Hydration in a Zeolite. Nature 2002, 420, 485–489. [Google Scholar] [CrossRef] [PubMed]

- Colligan, M.; Forster, P.M.; Cheetham, A.K.; Lee, Y.; Vogt, T.; Hriljac, J.A. Synchrotron X-Ray Powder Diffraction and Computational Investigation of Purely Siliceous Zeolite Y under Pressure. J. Am. Chem. Soc. 2004, 126, 12015–12022. [Google Scholar] [CrossRef]

- Colligan, M.; Lee, Y.; Vogt, T.; Celestian, A.J.; Parise, J.B.; Marshall, W.G.; Hriljac, J.A. High-Pressure Neutron Diffraction Study of Superhydrated Natrolite. J. Phys. Chem. B 2005, 109, 18223–18225. [Google Scholar] [CrossRef]

- Alabarse, F.G.; Rouquette, J.; Coasne, B.; Haidoux, A.; Paulmann, K.; Cambon, O.; Haines, J. Mechanism of H2O insertion and chemical bond formation in AlPO4-54•xH2O at high pressure. J. Am. Chem. Soc. 2015, 137, 584–587. [Google Scholar] [CrossRef]

- Sartbaeva, A.; Haines, J.; Cambon, O.; Santoro, M.; Gorelli, F.; Levelut, C.; Wells, S. Flexibility windows and compression of monoclinic and orthorombic silicalites. Phys. Rev. B 2012, 85, 064109. [Google Scholar] [CrossRef]

- Coasne, B.; Haines, J.; Levelut, C.; Cambon, O.; Santoro, M.; Gorelli, F.; Garbarino, G. Enhanced Mechanical Strength of Zeolites by Adsorption of Guest Molecules. Phys. Chem. Chem. Phys. 2011, 13, 20096–20099. [Google Scholar] [CrossRef]

- Alabarse, F.G.; Haines, J.; Cambon, O.; Levelut, C.; Bourgogne, D.; Haidoux, A.; Granier, D.; Coasne, B. Freezing of Water Confined at the Nanoscale. Phys. Rev. Lett. 2012, 109, 035701. [Google Scholar] [CrossRef] [PubMed]

- Alabarse, F.G.; Brubach, J.-B.; Roy, P.; Haidoux, A.; Levelut, C.; Bantignies, J.-L.; Cambon, O.; Haines, J. AlPO4-54-AlPO4-8 structural phase transition and amorphization under high pressure. J. Phys. Chem. C 2015, 199, 7771–7779. [Google Scholar] [CrossRef]

- Alabarse, F.G.; Silly, G.; Haidoux, A.; Levelut, C.; Bourgogne, D.; Flank, A.-M.; Lagarde, P.; Pereira, A.S.; Bantignies, J.-L.; Cambon, O.; et al. Effect of H2O on the Pressure-Induced Amorphization of AlPO4-54•xH2O. J. Phys. Chem. C 2014, 118, 3651–3663. [Google Scholar] [CrossRef]

- Attfield, P.; Sleight, A.W. Exceptional Negative Thermal Expansion in AlPO4-17. Chem. Mater. 1998, 10, 2013–2019. [Google Scholar] [CrossRef]

- Tuel, A.; Lorentz, C.; Gramlich, V.; Baerlocher, C. AlPO-ERI, an aluminophosphate with the ERI framework topology: Characterization and structure of the as-made and calcined rehydrated forms. C. R. Chim. 2005, 8, 531–540. [Google Scholar] [CrossRef]

- Alabarse, F.G.; Silly, G.; Brubach, J.-B.; Roy, P.; Haidoux, A.; Levelut, C.; Bantignies, J.L.; Kohara, S.; Le Floch, S.; Cambon, O.; et al. Anomalous Compressibility and Amorphization in AlPO4-17, the Oxide with the Highest Negative Thermal Expansion. J. Phys. Chem. C 2017, 121, 6852–6863. [Google Scholar] [CrossRef]

- Chapman, K.W.; Chupas, P.J. Pressure Enhancement of Negative Thermal Expansion Behavior and Induced Framework Softening in Zinc Cyanide. J. Am. Chem. Soc. 2007, 129, 10090–10091. [Google Scholar] [CrossRef]

- Chapman, K.W.; Halder, G.J.; Chupas, P.J. Pressure-Induced Amorphization and Porosity Modification in a Metal-Organic Framework. J. Am. Chem. Soc. 2009, 131, 17546–17547. [Google Scholar] [CrossRef]

- Fang, H.; Dove, M.T. Pressure-induced softening as a common feature of framework structures with negative thermal expansion. Phys. Rev. B 2013, 87, 214109. [Google Scholar] [CrossRef]

- Greaves, G.N.; Meneau, F. Probing the dynamics of instability in zeolitic materials. J. Phys. Condens Matter 2004, 16, S3459–S3472. [Google Scholar] [CrossRef]

- Greaves, G.N.; Meneau, F.; Kargl, F.; Ward, D.; Holliman, P.; Albergamo, F. Zeolite collapse and polyamorphism. J. Phys. Condens Matter 2007, 19, 415102. [Google Scholar] [CrossRef]

- Christie, D.M.; Chelikowsky, J.R. Structural properties of α-berlinite (AlPO4). Phys. Chem. Miner. 1998, 25, 222–226. [Google Scholar] [CrossRef]

- Haines, J.; Levelut, C.; Isambert, A.; Hébert, P.; Kohara, S.; Keen, D.A.; Hammouda, T.; Andrault, D. Topologically Ordered Amorphous Silica Obtained from the Collapsed Siliceous Zeolite, Silicalite-1-F: A Step toward “Perfect” Glasses. J. Am. Chem. Soc. 2009, 131, 12333–12338. [Google Scholar] [CrossRef]

- Fu, Y.; Song, Y.; Huang, Y. An Investigation of the Behavior of Completely Siliceous Zeolite ZSM-5 under High External Pressures. J. Phys. Chem. 2012, 116, 2080–2089. [Google Scholar] [CrossRef]

- Evans, J.S.O.; Hu, Z.; Jorgensen, J.D.; Argyriou, D.N.; Short, S.; Sleight, A.W. Compressibility, phase transitions, and oxygen migration in zirconium tungstate. Science 1997, 275, 61. [Google Scholar] [CrossRef]

- Mao, H.K.; Xu, J.; Bell, P.M. Calibration of the Ruby Pressure Gauge to 800 kbar under quasi-hydrostatic conditions. J. Geophys. Res. 1986, 91, 4673–4676. [Google Scholar] [CrossRef]

- Hammersley, A.P.; Svensson, S.O.; Hanfland, M.; Fitch, A.N.; Häusermann, D. Two Dimensional Detector Software: From Real Detector to Idealised Image or Two-Theta Scan. High Press. Res. 1996, 14, 235–248. [Google Scholar] [CrossRef]

- Prescher, C.; Prakapenka, V.B. DIOPTAS: A program for reduction of two-dimensional X-ray diffraction data and data exploration. High Press. Res. 2015, 35, 223–230. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. Recent Developments of the Program FULLPROF. Comm. Powder Diffr. Newsl. 2001, 26, 12–19. [Google Scholar]

Sample Availability: Powder and single crystals of hydrated AlPO4-17 are available from the authors. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alabarse, F.G.; Joseph, B.; Lausi, A.; Haines, J. Effect of H2O on the Pressure-Induced Amorphization of Hydrated AlPO4-17. Molecules 2019, 24, 2864. https://doi.org/10.3390/molecules24162864

Alabarse FG, Joseph B, Lausi A, Haines J. Effect of H2O on the Pressure-Induced Amorphization of Hydrated AlPO4-17. Molecules. 2019; 24(16):2864. https://doi.org/10.3390/molecules24162864

Chicago/Turabian StyleAlabarse, Frederico G., Boby Joseph, Andrea Lausi, and Julien Haines. 2019. "Effect of H2O on the Pressure-Induced Amorphization of Hydrated AlPO4-17" Molecules 24, no. 16: 2864. https://doi.org/10.3390/molecules24162864

APA StyleAlabarse, F. G., Joseph, B., Lausi, A., & Haines, J. (2019). Effect of H2O on the Pressure-Induced Amorphization of Hydrated AlPO4-17. Molecules, 24(16), 2864. https://doi.org/10.3390/molecules24162864