Simultaneous Determination of Acrylamide and Hydroxymethylfurfural in Extruded Products by LC-MS/MS Method

Abstract

1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Chemicals and Consumables

3.2. Preparation of Corn Snack Products

3.3. Acrylamide and Hydroxymethylfurfural (HMF) Determination

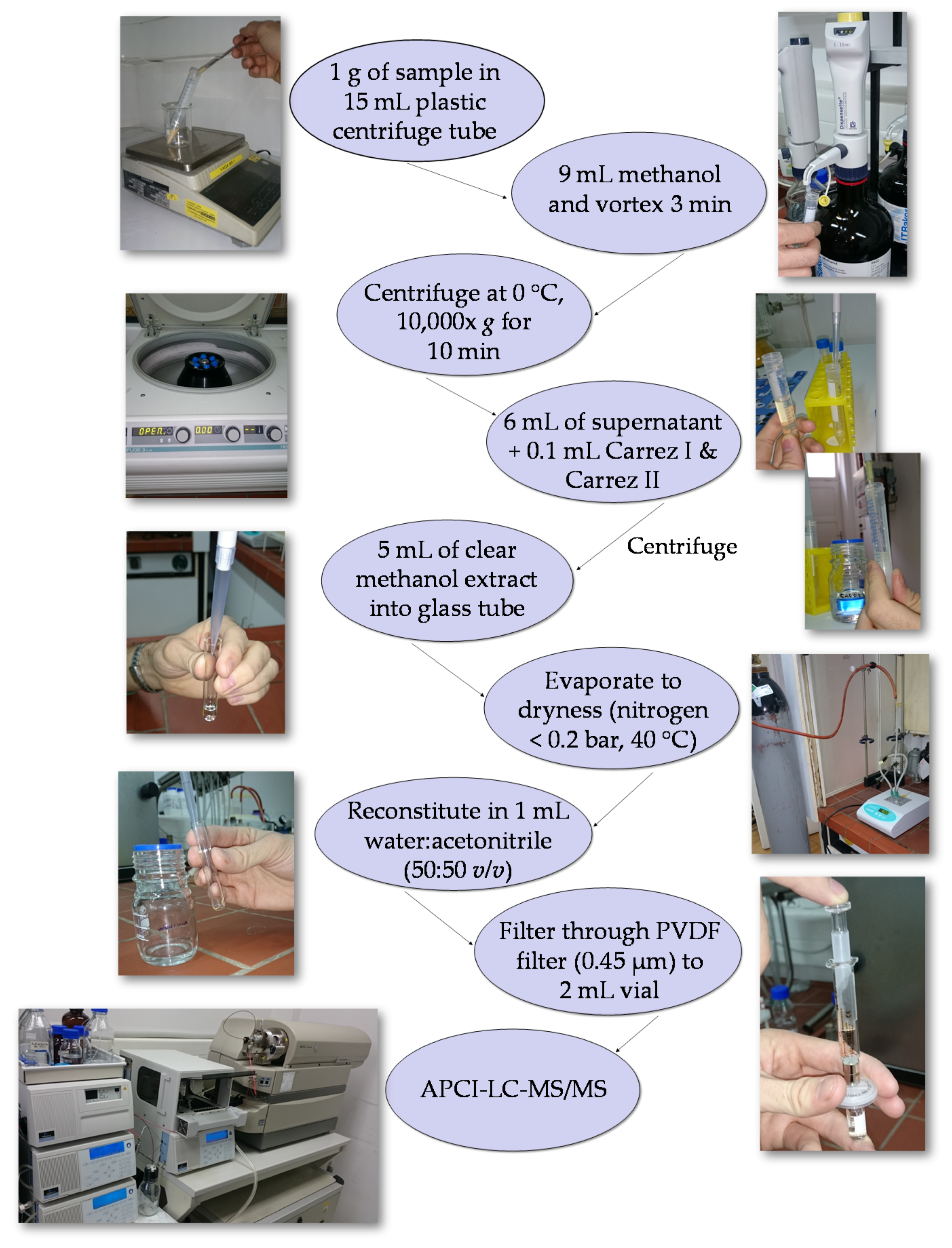

3.3.1. Sample Preparation

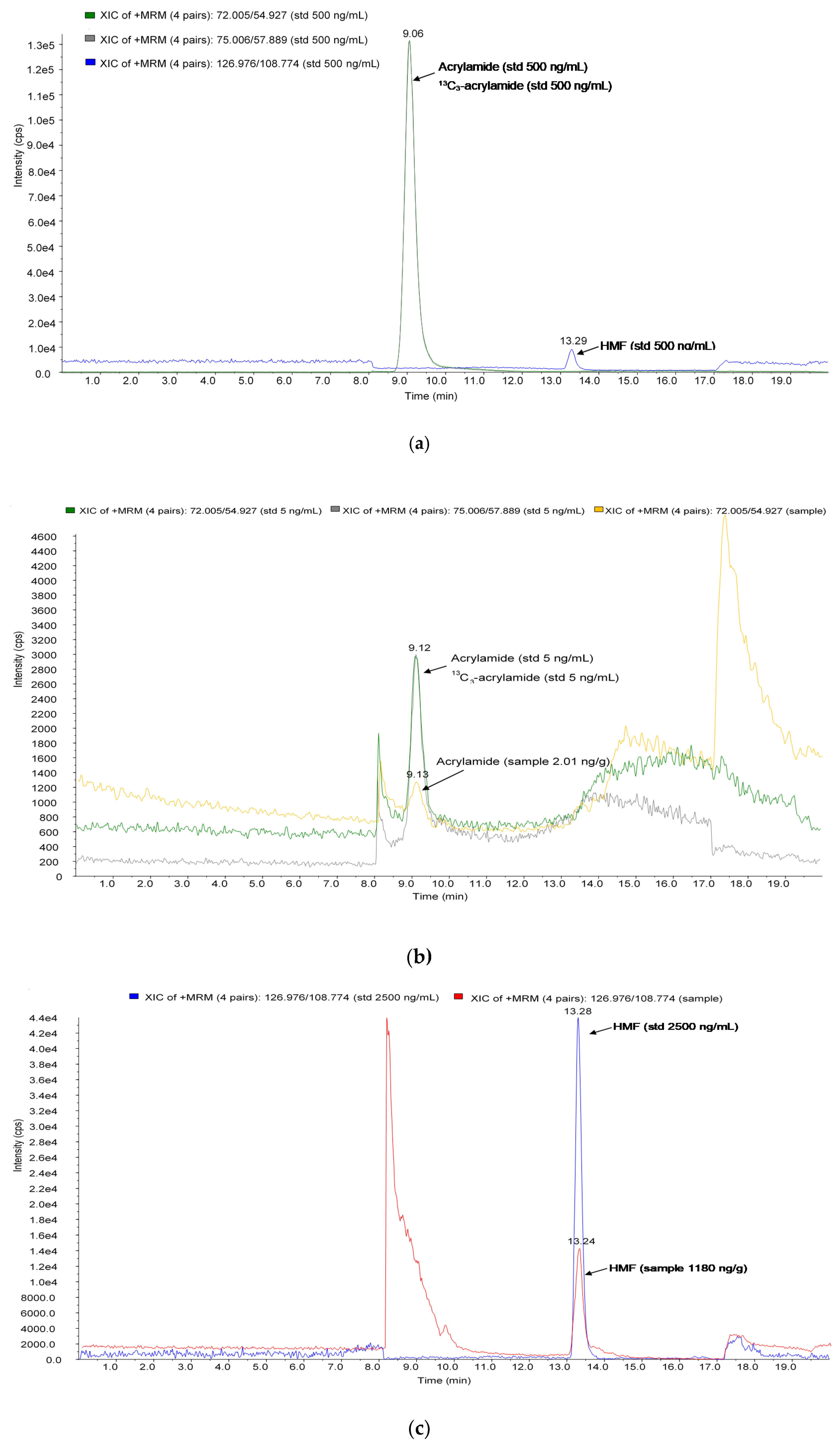

3.3.2. LC–MS/MS Analysis

3.3.3. Analytical Method Validation

3.4. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gökmen, V. Introduction: Potential Safety Risks Associated with Thermal Processing of Foods. In Acrylamide in Food; Gökmen, V., Ed.; Academic Press: London, UK, 2016. [Google Scholar]

- Capuano, E.; Ferrigno, A.; Acampa, I.; Serpen, A.; Açar, Ö.Ç.; Gökmen, V.; Fogliano, V. Effect of flour type on Maillard reaction and acrylamide formation during toasting of bread crisp model systems and mitigation strategies. Food Res. Int. 2009, 42, 1295–1302. [Google Scholar] [CrossRef]

- Capuano, E.; Fogliano, V. Acrylamide and 5-hydroxymethylfurfural (HMF): A review on metabolism, toxicity, occurrence in food and mitigation strategies. LWT Food Sci. Technol. 2011, 44, 793–810. [Google Scholar] [CrossRef]

- Van Der Fels-Klerx, H.J.; Capuano, E.; Nguyen, H.T.; Ataç Mogol, B.; Kocadaǧli, T.; Göncüoǧlu Taş, N.; Hamzalıoğlu, A.; Van Boekel, M.A.J.S.; Gökmen, V. Acrylamide and 5-hydroxymethylfurfural formation during baking of biscuits: NaCl and temperature-time profile effects and kinetics. Food Res. Int. 2014, 57, 210–217. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Van der Fels-Klerx, H.J.; Van Boekel, M.A.J.S. Acrylamide and 5-hydroxymethylfurfural formation during biscuit baking. Part II: Effect of the ratio of reducing sugars and asparagine. Food Chem. 2017, 230, 14–23. [Google Scholar] [CrossRef]

- Teixidó, E.; Núñez, O.; Santos, F.J.; Galceran, T.M. 5-Hydroxymethylfurfural content in foodstuffs determined by micellar electrokinetic chromatography. Food Chem. 2011, 126, 1902–1908. [Google Scholar] [CrossRef]

- Gökmen, V.; Kocadağlı, T.; Göncüoğlu, N.; Mogol, B.A. Model studies on the role of 5-hydroxymethyl-2-furfural in acrylamide formation from asparagine. Food Chem. 2012, 132, 168–174. [Google Scholar] [CrossRef]

- Teixidó, E.; Moyano, E.; Santos, F.J.; Galceran, T.M. Liquid chromatography multi-stage mass spectrometry for the analysis of 5-hydroxymethylfurfural in foods. J. Chromatogr. A 2008, 1185, 102–108. [Google Scholar] [CrossRef]

- Gökmen, V.; Şenyuva, H.Z. Improved Method for the Determination of Hydroxymethylfurfural in Baby Foods Using Liquid Chromatography-Mass Spectrometry. J. Agric. Food Chem. 2006, 54, 2845–2849. [Google Scholar] [CrossRef]

- Rada-Mendoza, M.; Olano, A.; Villamiel, M. Determination of hydroxymethylfurfural in commercial jams and in fruit-based infant foods. Food Chem. 2002, 79, 513–516. [Google Scholar] [CrossRef]

- Spano, N.; Casula, L.; Panzanelli, A.; Pilo, M.I.; Piu, P.C.; Scanu, R.; Tapparo, A.; Sanna, G. An RP-HPLC determination of 5-hydroxymethylfurfural in honey: The case of strawberry tree honey. Talanta 2006, 68, 1390–1395. [Google Scholar] [CrossRef]

- Viegas, O.; Prucha, M.; Gökmen, V.; Ferreira, I.M.P.L.V.O. Parameters affecting 5-hydroxymethylfurfural exposure from beer. Food Addit. Contam. A 2018, 35, 1464–1471. [Google Scholar] [CrossRef] [PubMed]

- Codex Alimentarius Commission. Distribution of the Report of the Seventh Session of the codex Committee on Sugars (ALINORM 01/25); Codex Alimentarius Commission: Washington, DC, USA, 2001. [Google Scholar]

- European Commission. Directive 2001/110/EC. Off. J. Eur. Communities 2001, 47–52. [Google Scholar]

- Rufián-Henares, J.A.; Delgado-Andrade, C.; Morales, F.J. Non-enzymatic browning: The case of the Maillard reaction. In Assessing the Generation and Bioactivity of neoformed Compounds in Thermally Treated Foods; Delgado-Andrade, C., Rufián-Henares, J.A., Eds.; Editorial Atrio S.L.: Granada, Spain, 2009; pp. 9–32. [Google Scholar]

- The International Agency for Research on Cancer (IARC). Acrylamide. In Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Humans; IARC: Lyon, France, 1994; Volume 60, pp. 389–433. [Google Scholar]

- Swedish National Food Administration (SNFA). Information about Acrylamide in Food; SNFA: Stockholm, Sweden, 2002. [Google Scholar]

- Tareke, E.; Rydberg, P.; Karlsson, S.; Eriksson, M.; Törnqvist, M. Analysis of acrylamide, a carcinogen formed in heated foodstuffs. J. Agric. Food. Chem. 2002, 50, 4998–5006. [Google Scholar] [CrossRef]

- Mottram, D.S.; Wedzicha, B.L.; Dodson, A.T. Acrylamide is formed in the Maillard reaction. Nature 2002, 419, 448–449. [Google Scholar] [CrossRef] [PubMed]

- Stadler, R.H.; Blank, I.; Varga, N.; Robert, F.; Hau, J.; Guy, P.A.; Robert, M.-C.; Riediker, S. Food chemistry: Acrylamide from Maillard reaction products. Nature 2002, 419, 449–450. [Google Scholar] [CrossRef]

- Yaylayan, V.A.; Wnorowski, A.; Perez Locas, C. Why asparagine needs carbohydrates to generate acrylamide. J. Agric. Food Chem. 2003, 51, 1753–1757. [Google Scholar] [CrossRef]

- Zyzak, D.V.; Sanders, R.A.; Stojanovic, M.; Tallmadge, D.H.; Eberhart, B.L.; Ewald, D.K.; Gruber, D.C.; Morsch, T.R.; Strothers, M.A.; Rizzi, G.P.; et al. Acrylamide formation in heated foods. J. Agric. Food Chem. 2003, 51, 4782–4787. [Google Scholar] [CrossRef]

- Claus, A.; Carle, R.; Schieber, A. Acrylamide in cereal products: A review. J. Cereal Sci. 2008, 47, 118–133. [Google Scholar] [CrossRef]

- Mulla, M.Z.; Bharadway, V.R.; Annapure, U.S.; Singhal, R.S. Effect of formulation and processing parameters on acrylamide formation: A case study on extrusion of blends of potato flour and semolina. LWT Food Sci. Technol. 2011, 44, 1643–1648. [Google Scholar] [CrossRef]

- Pedreschi, F.; Kaack, K.; Granby, K. The effect of asparaginase on acrylamide formation in French fries. Food Chem. 2008, 109, 386–392. [Google Scholar] [CrossRef]

- Masatcioglu, M.T.; Gökmen, V.; Ng, P.K.W.; Köksel, H. Effects of formulation, extrusion cooking conditions, and CO2 injection on the formation of acrylamide in corn extrudates. J. Sci. Food. Agric. 2014, 94, 2562–2568. [Google Scholar] [CrossRef]

- European Commission. Commission recommendations of 3 May 2007 on the monitoring of acrylamide levels in food. Off. J. Eur. Union 2007, 123, 33–39. [Google Scholar]

- European Commission. Commission recommendations of 2 June 2010 on the monitoring of acrylamide levels in food. Off. J. Eur. Union 2010, 137, 4–10. [Google Scholar]

- European Commission. Commission recommendations of 8 November 2013 on the monitoring of acrylamide levels in food. Off. J. Eur. Union 2013, 301, 15–17. [Google Scholar]

- European Commission. Commission regulation (EU) 2017/2158 of 20 November 2017 establishing mitigation measures and benchmark levels for the reduction of the presence of acrylamide in food. Off. J. Eur. Union 2017, 304, 24–44. [Google Scholar]

- European Food Safety Authority (EFSA). Update on acrylamide levels in food from monitoring years 2007 to 2010. EFSA J. 2012, 10, 2938. [Google Scholar] [CrossRef]

- EFSA Panel on Contaminants in the Food Chain (CONTAM). Scientific Opinion on acrylamide in food. EFSA J. 2015, 13, 4104. [Google Scholar] [CrossRef]

- Rufián-Henares, J.A.; Morales, F.J. Determination of acrylamide in potato chips by a reversed-phase LC–MS method based on a stable isotope dilution assay. Food Chem. 2006, 97, 555–562. [Google Scholar] [CrossRef]

- Oracz, J.; Nebesny, E.; Żyżelewicz, D. New trends in quantification of acrylamide in food products. Talanta. 2011, 86, 23–34. [Google Scholar] [CrossRef]

- Keramat, J.; LeBail, A.; Prost, C.; Soltanizadeh, N. Acrylamide in Foods: Chemistry and Analysis. A Review. Food Bioprocess Technol. 2011, 4, 340–363. [Google Scholar] [CrossRef]

- Šarkanj, B.; Ezekiel, N.C.; Turner, C.P.; Abia, A.W.; Rychlik, M.; Krska, R.; Sulyok, M.; Warth, B. Ultra-sensitive, stable isotope assisted quantification of multiple urinary mycotoxin exposure biomarkers. Anal. Chim. Acta 2018, 1019, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Jozinović, A.; Panak Balentić, J.; Ačkar, Đ.; Babić, J.; Pajin, B.; Miličević, B.; Guberac, S.; Vrdoljak, A.; Šubarić, D. Cocoa husk application in the enrichment of extruded snack products. J. Food Process Pres. 2019, 43, e13866. [Google Scholar] [CrossRef]

- Ačkar, Đ.; Jozinović, A.; Babić, J.; Miličević, B.; Panak Balentić, J.; Šubarić, D. Resolving the problem of poor expansion in corn extrudates enriched with food industry by-products. Innov. Food. Sci. Emerg. Technol. 2018, 47, 517–524. [Google Scholar] [CrossRef]

- Teixidó, E.; Santos, F.J.; Puignou, L.; Galceran, M.T. Analysis of 5-hydroxymethylfurfural in foods by gas chromatography–mass spectrometry. J. Chromatogr. A 2006, 1135, 85–90. [Google Scholar] [CrossRef] [PubMed]

- Gökmen, V.; Morales, F.J.; Ataç, B.; Serpen, A.; Arribas-Lorenzo, G. Multiple-stage extraction strategy for the determination of acrylamide in foods. J. Food Compost. Anal. 2009, 22, 142–147. [Google Scholar] [CrossRef]

- Gökmen, V.; Şenyuva, H.Z. Study of colour and acrylamide formation in coffee, wheat flour and potato chips during heating. Food Chem. 2006, 99, 238–243. [Google Scholar] [CrossRef]

- Spanic, V.; Marcek, T.; Abicic, I.; Sarkanj, B. Effects of Fusarium Head Blight on Wheat Grain and Malt Infected by Fusarium culmorum. Toxins 2018, 10, 17. [Google Scholar] [CrossRef]

- Malachová, A.; Sulyok, M.; Beltrán, E.; Berthiller, F.; Krska, R. Optimization and validation of a quantitative liquid chromatography-tandem mass spectrometric method covering 295 bacterial and fungal metabolites including all regulated mycotoxins in four model food matrices. J. Chrom. A 2014, 1362, 145–156. [Google Scholar] [CrossRef] [PubMed]

- Stadler, D.; Sulyok, M.; Schuhmacher, R.; Berthiller, F.; Krska, R. The contribution of lot-to-lot variation to the measurement uncertainty of an LC-MS-based multi-mycotoxin assay. Anal. Bioanal. Chem. 2018, 410, 4409–4418. [Google Scholar] [CrossRef]

- Shrivastava, A.; Gupta, V.B. Methods for the determination of limit of detection and limit of quantitation of the analytical methods. Chron. Young. Sci. 2011, 2, 21–25. [Google Scholar] [CrossRef]

- Masatcioglu, M.T.; Ng, P.K.W.; Köksel, H. Effects of formulation and extrusion cooking conditions on furfural and hydroxymethylfurfural content. J. Cereal Sci. 2015, 65, 32–38. [Google Scholar] [CrossRef]

- Validation of analytical procedures: Text and Methodology. In International Conference on Harmonization (ICH) of Technical Requirements for the Registration of Pharmaceuticals for Human Use; ICH: Geneva, Switzerland, 2005.

Sample Availability: Samples of the compounds are not available from the authors. |

| Validation Parameters * | Acrylamide | 13C3-acrylamide | HMF | |

|---|---|---|---|---|

| Calibration curve equation | y = 6421.6x − 2739.3 | y = 7114.5x − 2567.8 | y = 205.38x + 6249.7 | |

| R2 | 0.997 | 0.998 | 0.999 | |

| LOD (ng/g) | 0.62 | 0.58 | 18.9 | |

| LOQ (ng/g) | 1.89 | 1.75 | 57.5 | |

| Retention time (min) | 9.10 ± 0.07 | 9.10 ± 0.06 | 13.3 ± 0.08 | |

| RA (%) | Lower concentration | 91.2 | 91.9 | 90.0 |

| Higher concentration | 91.6 | 92.3 | 90.9 | |

| Average | 91.4 | 92.1 | 90.4 | |

| RE (%) | Lower concentration | 92.7 | 93.1 | 91.2 |

| Higher concentration | 93.0 | 93.9 | 94.2 | |

| Average | 92.8 | 93.5 | 92.7 | |

| SSE (%) | Lower concentration | 98.5 | 98.8 | 98.7 |

| Higher concentration | 98.5 | 98.3 | 96.5 | |

| Average | 98.5 | 98.5 | 97.6 | |

| RSD Intraday (%) | Lower concentration | 2.89 | 2.77 | 3.17 |

| Higher concentration | 2.86 | 2.91 | 3.15 | |

| Average | 2.88 | 2.84 | 3.16 | |

| RSD Interday (%) | Lower concentration | 3.12 | 3.01 | 3.36 |

| Higher concentration | 3.06 | 3.08 | 3.43 | |

| Average | 3.09 | 3.05 | 3.40 | |

| Sample * | Acrylamide (ng/g) | HMF (ng/g) |

|---|---|---|

| Corn grits | <LOD | 63.0 ± 3.00 a |

| BSG | <LOD | 5634 ± 11.0 a |

| SBP | <LOD | 658 ± 15.8 a |

| AP | <LOD | 16,019 ± 978 b |

| Sample* | Non-Extruded | Extruded | ||

|---|---|---|---|---|

| Acrylamide (ng/g) | HMF (ng/g) | Acrylamide (ng/g) | HMF (ng/g) | |

| Corn grits | <LOD | 63.0 ± 3.00 a | 2.25 ± 0.29 a | 174 ± 2.21 a |

| Corn + 5% BSG | <LOD | 68.2 ± 3.31 a | 2.74 ± 0.02 a,b | 192 ± 5.36 a |

| Corn + 10% BSG | <LOD | 78.4 ± 4.89 a | 2.86 ± 0.05 a,b | 290 ± 18.9 a |

| Corn + 15% BSG | <LOD | 83.8 ± 4.89 a | 3.13 ± 0.23 b | 301 ± 12.6 a |

| Corn + 5% SBP | <LOD | 86.0 ± 0.47 a | 2.59 ± 0.02 a,b | 173 ± 11.2 a |

| Corn + 10% SBP | <LOD | 88.1 ± 1.26 a | 2.68 ± 0.07 a,b | 224 ± 30.5 a |

| Corn + 15% SBP | <LOD | 90.6 ± 0.32 a | 3.00 ± 0.21 b | 317 ± 9.47 a |

| Corn + 5% AP | <LOD | 421 ± 20.5 b | 3.98 ± 0.07 c | 971 ± 85.2 b |

| Corn + 10% AP | <LOD | 801 ± 37.9 c | 4.93 ± 0.71 d | 2622 ± 110 c |

| Corn + 15% AP | <LOD | 1277 ± 11.0 d | 5.37 ± 0.50 d | 6069 ± 789 d |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jozinović, A.; Šarkanj, B.; Ačkar, Đ.; Panak Balentić, J.; Šubarić, D.; Cvetković, T.; Ranilović, J.; Guberac, S.; Babić, J. Simultaneous Determination of Acrylamide and Hydroxymethylfurfural in Extruded Products by LC-MS/MS Method. Molecules 2019, 24, 1971. https://doi.org/10.3390/molecules24101971

Jozinović A, Šarkanj B, Ačkar Đ, Panak Balentić J, Šubarić D, Cvetković T, Ranilović J, Guberac S, Babić J. Simultaneous Determination of Acrylamide and Hydroxymethylfurfural in Extruded Products by LC-MS/MS Method. Molecules. 2019; 24(10):1971. https://doi.org/10.3390/molecules24101971

Chicago/Turabian StyleJozinović, Antun, Bojan Šarkanj, Đurđica Ačkar, Jelena Panak Balentić, Domagoj Šubarić, Tanja Cvetković, Jasmina Ranilović, Sunčica Guberac, and Jurislav Babić. 2019. "Simultaneous Determination of Acrylamide and Hydroxymethylfurfural in Extruded Products by LC-MS/MS Method" Molecules 24, no. 10: 1971. https://doi.org/10.3390/molecules24101971

APA StyleJozinović, A., Šarkanj, B., Ačkar, Đ., Panak Balentić, J., Šubarić, D., Cvetković, T., Ranilović, J., Guberac, S., & Babić, J. (2019). Simultaneous Determination of Acrylamide and Hydroxymethylfurfural in Extruded Products by LC-MS/MS Method. Molecules, 24(10), 1971. https://doi.org/10.3390/molecules24101971