Zero-Bias Visible to Near-Infrared Horizontal p-n-p TiO2 Nanotubes Doped Monolayer Graphene Photodetector

Abstract

1. Introduction

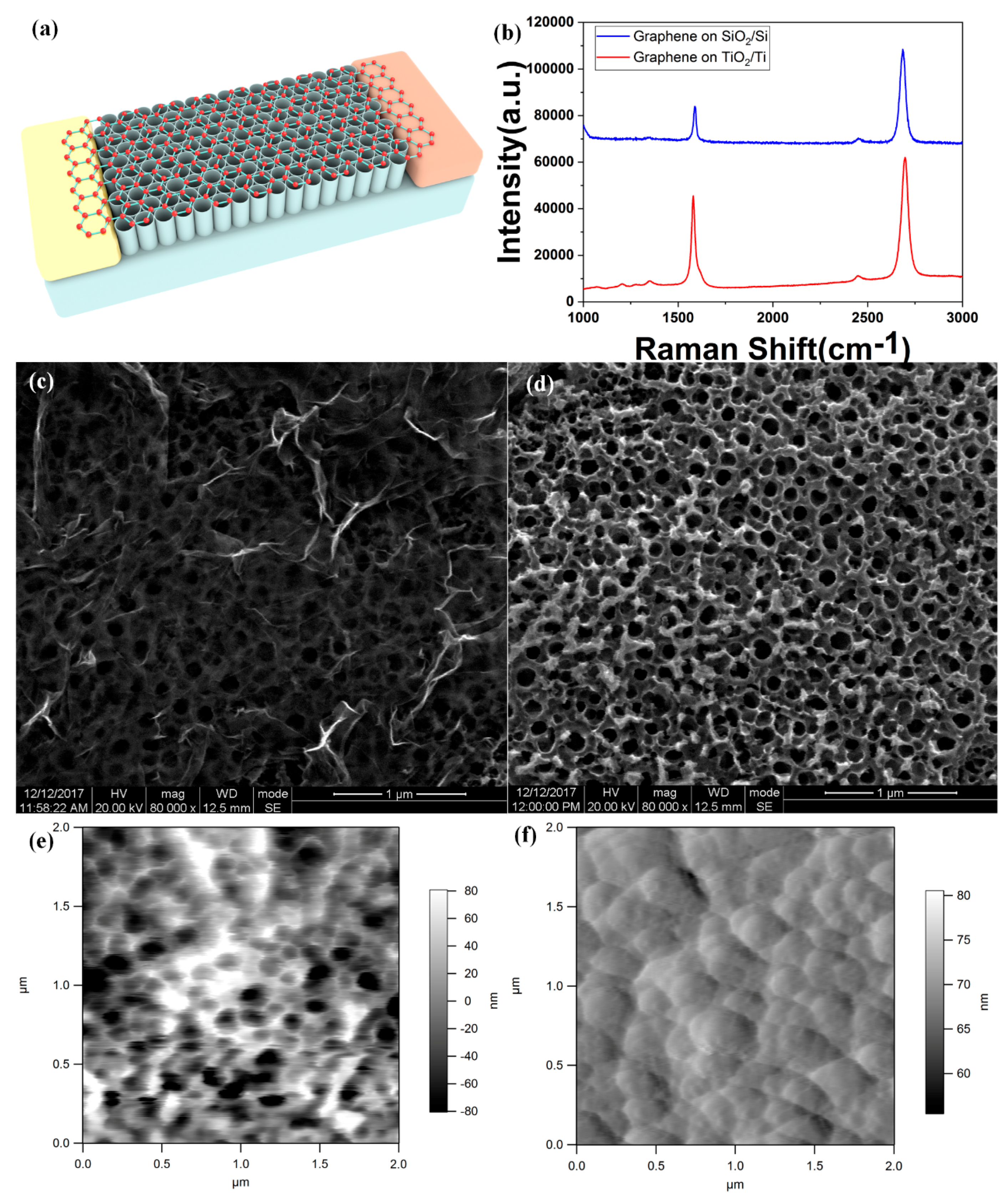

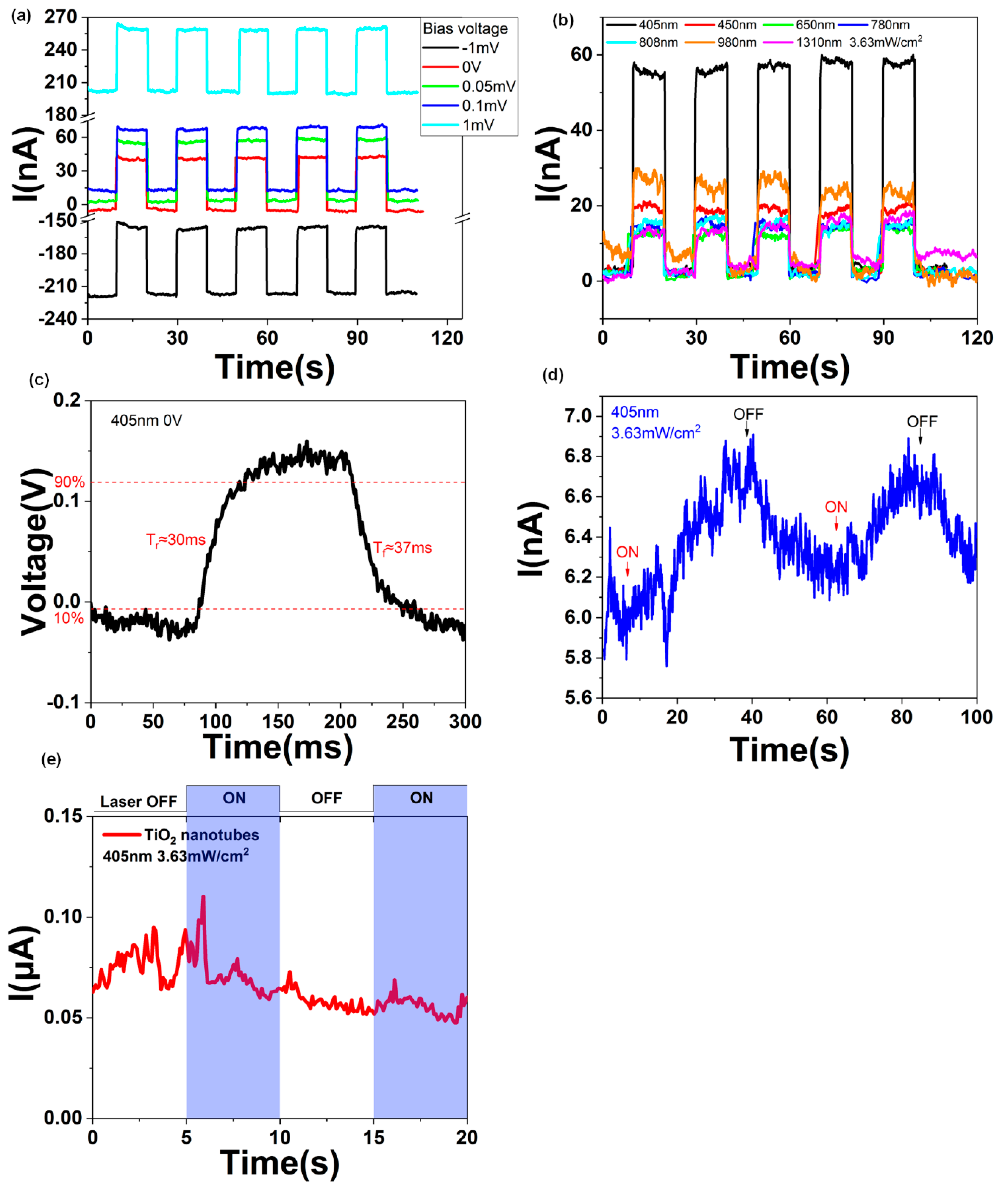

2. Experimental Section

2.1. Preparation of the Graphene/TiO2 Nanotubes Photodetector

2.2. Characterization Methods

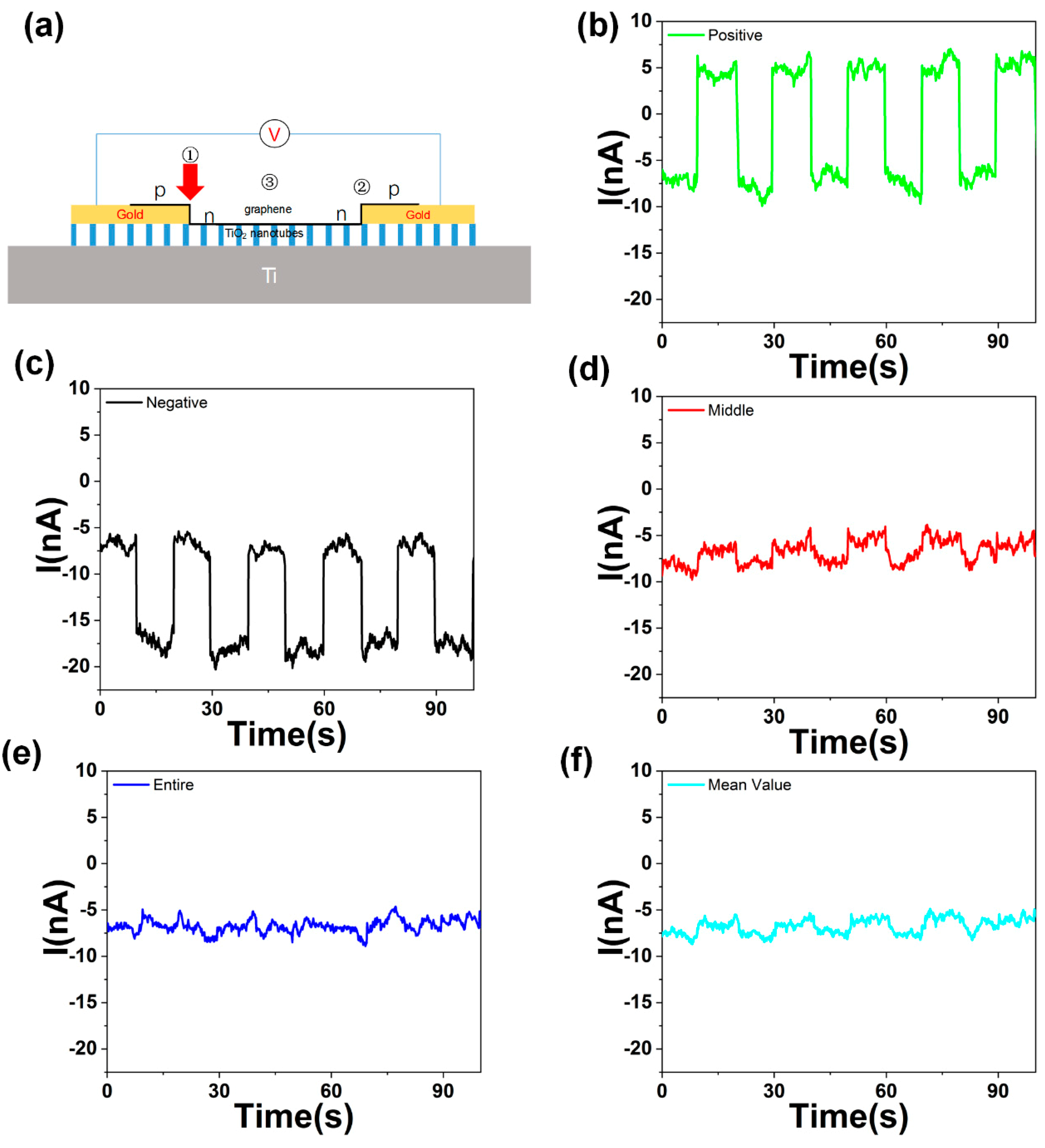

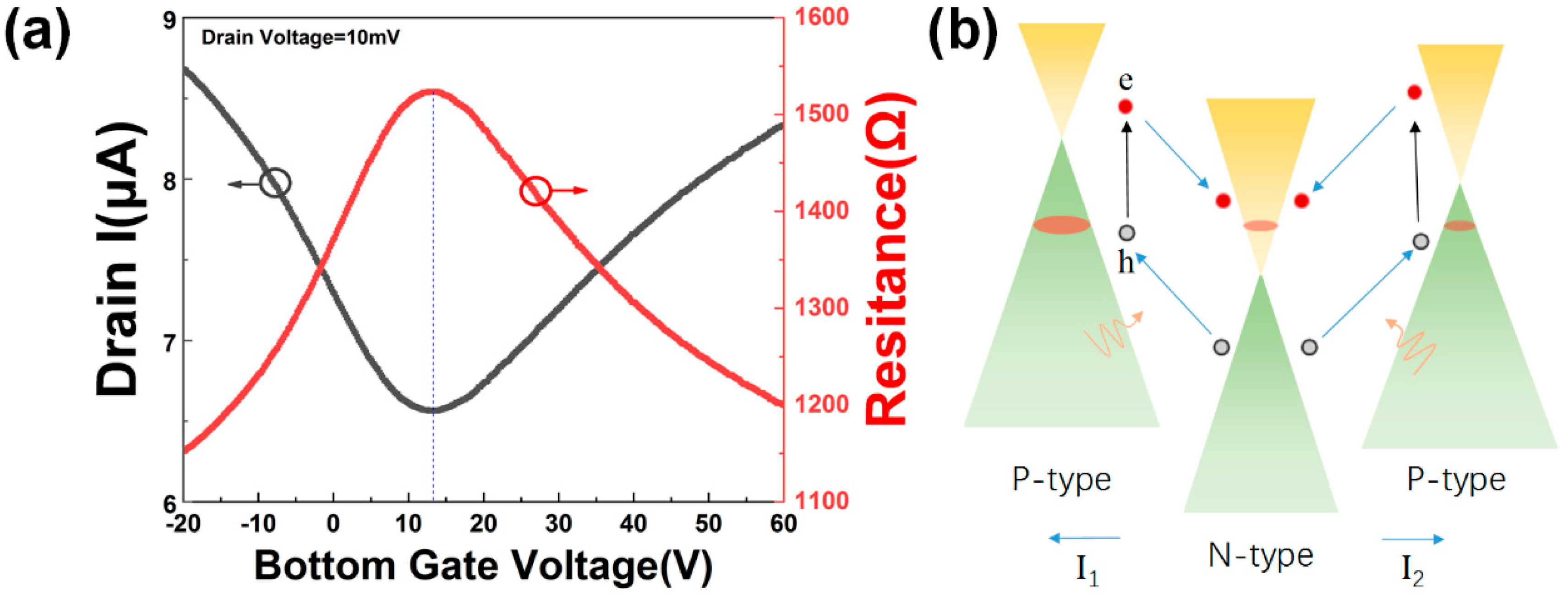

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liang, G.; Hu, X.; Yu, X.; Shen, Y.; Li, L.H.; Davies, A.G.; Linfield, E.H.; Liang, H.K.; Zhang, Y.; Yu, S.F.; et al. Integrated Terahertz Graphene Modulator with 100% Modulation Depth. ACS Photonics 2015, 2, 1559–1566. [Google Scholar] [CrossRef]

- Withers, F.; Bointon, T.H.; Craciun, M.F.; Russo, S. All-graphene photodetectors. ACS Nano 2013, 7, 5052–5057. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhang, M.; Chen, D.; Guo, Q.; Feng, X.; Niu, T.; Liu, X.; Li, A.; Lai, J.; Sun, D.; et al. Seamless lateral graphene p-n junctions formed by selective in situ doping for high-performance photodetectors. Nat. Commun. 2018. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Han, J.; Chen, X.; Wang, X. Design strategies for two–dimensional material photodetectors to enhance device performance. InfoMat 2019. [Google Scholar] [CrossRef]

- Mai, S.; Syzranov, S.V.; Efetov, K.B. Photocurrent in a visible-light graphene photodiode. Phys. Rev. 2011. [Google Scholar] [CrossRef]

- Lockwood, D.J.; Pavesi, L. Silicon fundamentals for photonics applications. In Silicon Photonics; Springer: Cham, Switzerland, 2004; pp. 1–50. [Google Scholar]

- Lin, L.; Liao, L.; Yin, J.; Peng, H.; Liu, Z. Building graphene p–n junctions for next-generation photodetection. Nano Today 2015, 10, 701–716. [Google Scholar] [CrossRef]

- Kinch, M.A. Fundamentals of Infrared Detector Materials; SPIE Press: Bellingham, WA, USA, 2007; Volume 76. [Google Scholar]

- Xia, F.; Mueller, T.; Lin, Y.M.; Valdes-Garcia, A.; Avouris, P. Ultrafast graphene photodetector. Nat. Nanotechnol. 2009, 839–843. [Google Scholar] [CrossRef] [PubMed]

- Mueller, T.; Xia, F.N.A.; Avouris, P. Graphene photodetectors for high-speed optical communications. Nat. Photonics 2010, 4, 297–301. [Google Scholar] [CrossRef]

- Spirito, D.; Coquillat, D.; De Bonis, S.L.; Lombardo, A.; Bruna, M.; Ferrari, A.C.; Pellegrini, V.; Tredicucci, A.; Knap, W.; Vitiello, M.S. High performance bilayer-graphene terahertz detectors. Appl. Phys. Lett. 2014. [Google Scholar] [CrossRef]

- Shin, D.H.; Choi, S.H. Graphene-Based Semiconductor Heterostructures for Photodetectors. Micromachines 2018, 9, 350. [Google Scholar] [CrossRef]

- Liu, N.; Tian, H.; Schwartz, G.; Tok, J.B.; Ren, T.L.; Bao, Z. Large-area, transparent, and flexible infrared photodetector fabricated using P-N junctions formed by N-doping chemical vapor deposition grown graphene. Nano Lett. 2014, 14, 3702–3708. [Google Scholar] [CrossRef]

- De Sanctis, A.; Jones, G.F.; Wehenkel, D.J.; Bezares, F.; Koppens, F.H.L.; Craciun, M.F.; Russo, S. Extraordinary linear dynamic range in laser-defined functionalized graphene photodetectors. Sci. Adv. 2017, 3, e1602617. [Google Scholar] [CrossRef] [PubMed]

- Dang, V.Q.; Trung, T.Q.; Kim, D.I.; Duy le, T.; Hwang, B.U.; Lee, D.W.; Kim, B.Y.; Toan le, D.; Lee, N.E. Ultrahigh Responsivity in Graphene-ZnO Nanorod Hybrid UV Photodetector. Small 2015, 11, 3054–3065. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.-Z.; Liang, F.-X.; Nie, B.; Zeng, L.-H.; Zheng, L.-X.; Lv, P.; Yu, Y.-Q.; Xie, C.; Li, Y.Y.; Luo, L.-B. TiO2Nanotube Array/Monolayer Graphene Film Schottky Junction Ultraviolet Light Photodetectors. Part. Part. Syst. Charact. 2013, 30, 630–636. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Z.; Zhang, X.; Yang, L.; Zhang, N.; Pan, G.; Yin, S.; Chen, Y.; Wei, J. Polymer Photovoltaic Cells Based on Solution-Processable Graphene and P3HT. Adv. Funct. Mater. 2009, 19, 894–904. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, Z.; Li, J.; Tai, G.A.; Lau, S.P.; Yan, F. Infrared photodetectors based on CVD-grown graphene and PbS quantum dots with ultrahigh responsivity. Adv. Mater. 2012, 24, 5878–5883. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Wang, J. Photodetectors based on two-dimensional materials and organic thin-film heterojunctions. Chin. Phys. B 2019. [Google Scholar] [CrossRef]

- Yang, M.; Wang, J.; Zhao, Y.; He, L.; Ji, C.; Liu, X.; Zhou, H.; Wu, Z.; Wang, X.; Jiang, Y. Three-Dimensional Topological Insulator Bi2Te3/Organic Thin Film Heterojunction Photodetector with Fast and Wideband Response from 450 to 3500 Nanometers. ACS Nano 2019, 13, 755–763. [Google Scholar] [CrossRef]

- Lemme, M.C.; Koppens, F.H.; Falk, A.L.; Rudner, M.S.; Park, H.; Levitov, L.S.; Marcus, C.M. Gate-activated photoresponse in a graphene p-n junction. Nano Lett. 2011, 11, 4134–4137. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Shi, J.; Yu, Y. One-dimensional titanium dioxide nanomaterials: Nanowires, nanorods, and nanobelts. Chem. Rev. 2014, 114, 9346–9384. [Google Scholar] [CrossRef]

- Ghosh, M.; Lohrasbi, M.; Chuang, S.S.; Jana, S.C. Mesoporous titanium dioxide nanofibers with a significantly enhanced photocatalytic activity. ChemCatChem 2016, 8, 2525–2535. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Ge, C.W.; Wang, J.Z.; Zhang, T.F.; Wu, Y.C.; Liang, F.X. Single-layer graphene-TiO2 nanotubes array heterojunction for ultraviolet photodetector application. Appl. Surf. Sci. 2016, 387, 1162–1168. [Google Scholar] [CrossRef]

- Wei, X.; Wu, T.; Pang, H.; Lv, G.; Yang, X.; Wu, S.; Li, S.; Chen, Z. Controllable preparation of TiO2 nanotube arrays on Ti foil substrates. Integr. Ferroelectr. 2017, 182, 127–133. [Google Scholar] [CrossRef]

- Gohler, D.; Stintz, M. Granulometric characterization of airborne particulate release during spray application of nanoparticle-doped coatings. J. Nanopart. Res. 2014. [Google Scholar] [CrossRef] [PubMed]

- Bressot, C.; Shandilya, N.; Jayabalan, T.; Fayet, G.; Voetz, M.; Meunier, L.; Le Bihan, O.; Aguerre-Chariol, O.; Morgeneyer, M. Exposure assessment of Nanomaterials at production sites by a Short Time Sampling (STS) approach. Process Saf. Environ. 2018, 116, 324–332. [Google Scholar] [CrossRef]

- Warheit, D.B. Hazard and risk assessment strategies for nanoparticle exposures: How far have we come in the past 10 years? F1000Res 2018. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef]

- Tan, Z.; Wu, Y.; Hong, H.; Yin, J.; Zhang, J.; Lin, L.; Wang, M.; Sun, X.; Sun, L.; Huang, Y.; et al. Two-Dimensional (C4H9NH3)2PbBr4 Perovskite Crystals for High-Performance Photodetector. J. Am. Chem. Soc. 2016, 138, 16612–16615. [Google Scholar] [CrossRef]

- Liang, F.-X.; Wang, J.-Z.; Wang, Y.; Lin, Y.; Liang, L.; Gao, Y.; Luo, L.-B. Single-layer graphene/titanium oxide cubic nanorods array/FTO heterojunction for sensitive ultraviolet light detection. Appl. Surf. Sci. 2017, 391–398. [Google Scholar] [CrossRef]

- Grimes, C.A. Synthesis and application of highly ordered arrays of TiO2 nanotubes. J. Mater. Chem. 2007, 17, 1451–1457. [Google Scholar] [CrossRef]

- Ghicov, A.; Schmuki, P. Self-ordering electrochemistry: A review on growth and functionality of TiO2 nanotubes and other self-aligned MO(x) structures. Chem. Commun. (Camb.) 2009, 20, 2791–2808. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97. [Google Scholar] [CrossRef] [PubMed]

- Ren, D.; Meng, X.; Rong, Z.; Cao, M.; Farrell, A.C.; Somasundaram, S.; Azizur-Rahman, K.M.; Williams, B.S.; Huffaker, D.L. Uncooled photodetector at short-wavelength infrared using InAs nanowire photoabsorbers on InP with p–n heterojunctions. Nano Lett. 2018, 18, 7901–7908. [Google Scholar] [CrossRef]

- Ren, D.; Azizur-Rahman, K.M.; Rong, Z.; Juang, B.-C.; Somasundaram, S.; Shahili, M.; Farrell, A.C.; Williams, B.S.; Huffaker, D.L. Room-Temperature Midwavelength Infrared InAsSb Nanowire Photodetector Arrays with Al2O3 Passivation. Nano. Lett. 2019, 19, 2793–2802. [Google Scholar] [CrossRef] [PubMed]

- Chan, J.; Venugopal, A.; Pirkle, A.; McDonnell, S.; Hinojos, D.; Magnuson, C.W.; Ruoff, R.S.; Colombo, L.; Wallace, R.M.; Vogel, E.M. Reducing Extrinsic Performance-Limiting Factors in Graphene Grown by Chemical Vapor Deposition. ACS Nano 2012, 6, 3224–3229. [Google Scholar] [CrossRef] [PubMed]

- De Sanctis, A.; Mehew, J.D.; Craciun, M.F.; Russo, S. Graphene-Based Light Sensing: Fabrication, Characterisation, Physical Properties and Performance. Materials 2018, 11, 1762. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Ji, C.; Cheng, L.; Han, J.; Yang, M.; Wei, X.; Jiang, Y.; Wang, J. Zero-Bias Visible to Near-Infrared Horizontal p-n-p TiO2 Nanotubes Doped Monolayer Graphene Photodetector. Molecules 2019, 24, 1870. https://doi.org/10.3390/molecules24101870

Huang Z, Ji C, Cheng L, Han J, Yang M, Wei X, Jiang Y, Wang J. Zero-Bias Visible to Near-Infrared Horizontal p-n-p TiO2 Nanotubes Doped Monolayer Graphene Photodetector. Molecules. 2019; 24(10):1870. https://doi.org/10.3390/molecules24101870

Chicago/Turabian StyleHuang, Zehua, Chunhui Ji, Luhua Cheng, Jiayue Han, Ming Yang, Xiongbang Wei, Yadong Jiang, and Jun Wang. 2019. "Zero-Bias Visible to Near-Infrared Horizontal p-n-p TiO2 Nanotubes Doped Monolayer Graphene Photodetector" Molecules 24, no. 10: 1870. https://doi.org/10.3390/molecules24101870

APA StyleHuang, Z., Ji, C., Cheng, L., Han, J., Yang, M., Wei, X., Jiang, Y., & Wang, J. (2019). Zero-Bias Visible to Near-Infrared Horizontal p-n-p TiO2 Nanotubes Doped Monolayer Graphene Photodetector. Molecules, 24(10), 1870. https://doi.org/10.3390/molecules24101870