Alpha-Mangostin-Rich Extracts from Mangosteen Pericarp: Optimization of Green Extraction Protocol and Evaluation of Biological Activity

Abstract

1. Introduction

2. Results and Discussion

2.1. Impact of Single Factors on α-Mangostin Content

2.2. Model and Response Surface Analysis

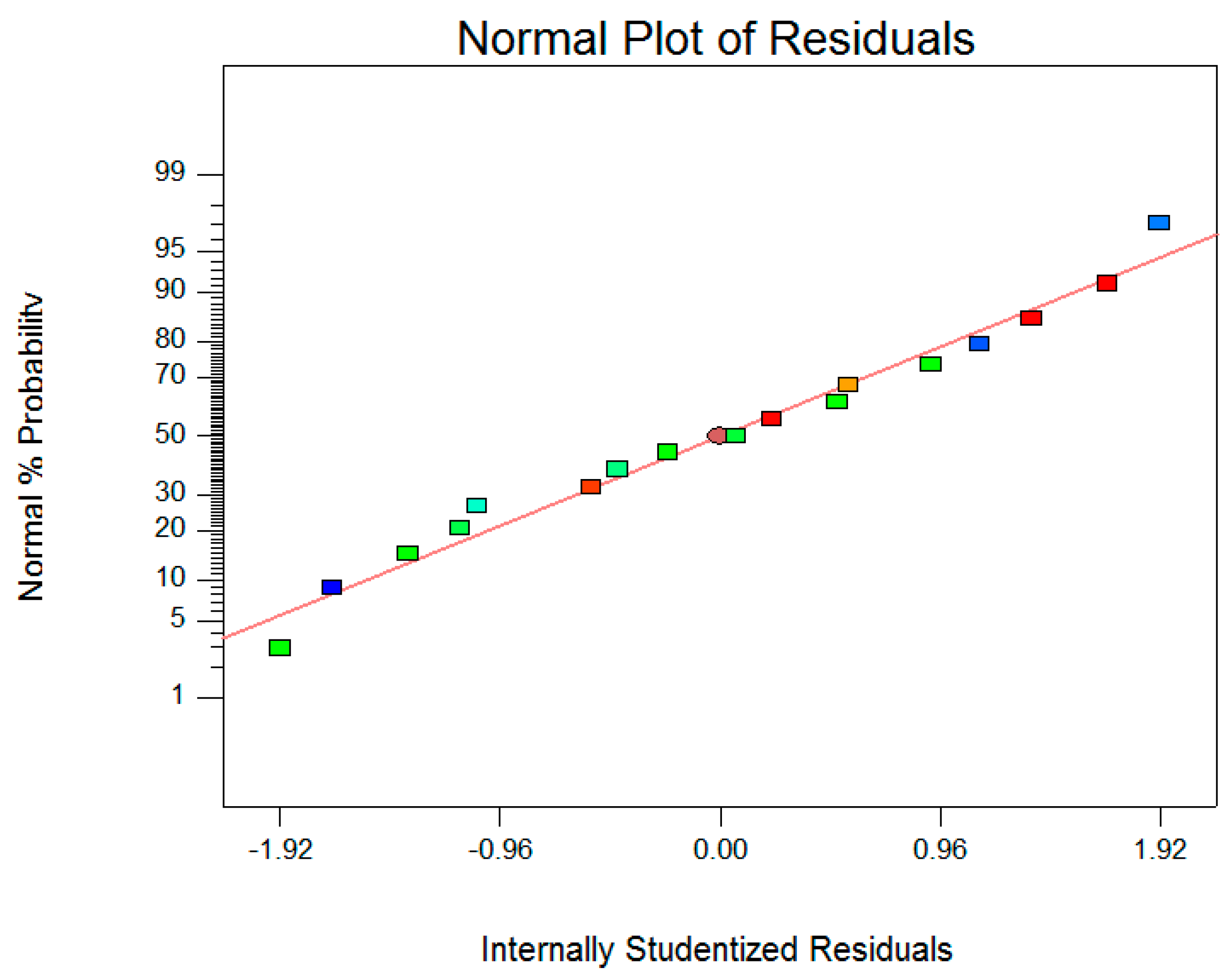

2.3. Model Fitting

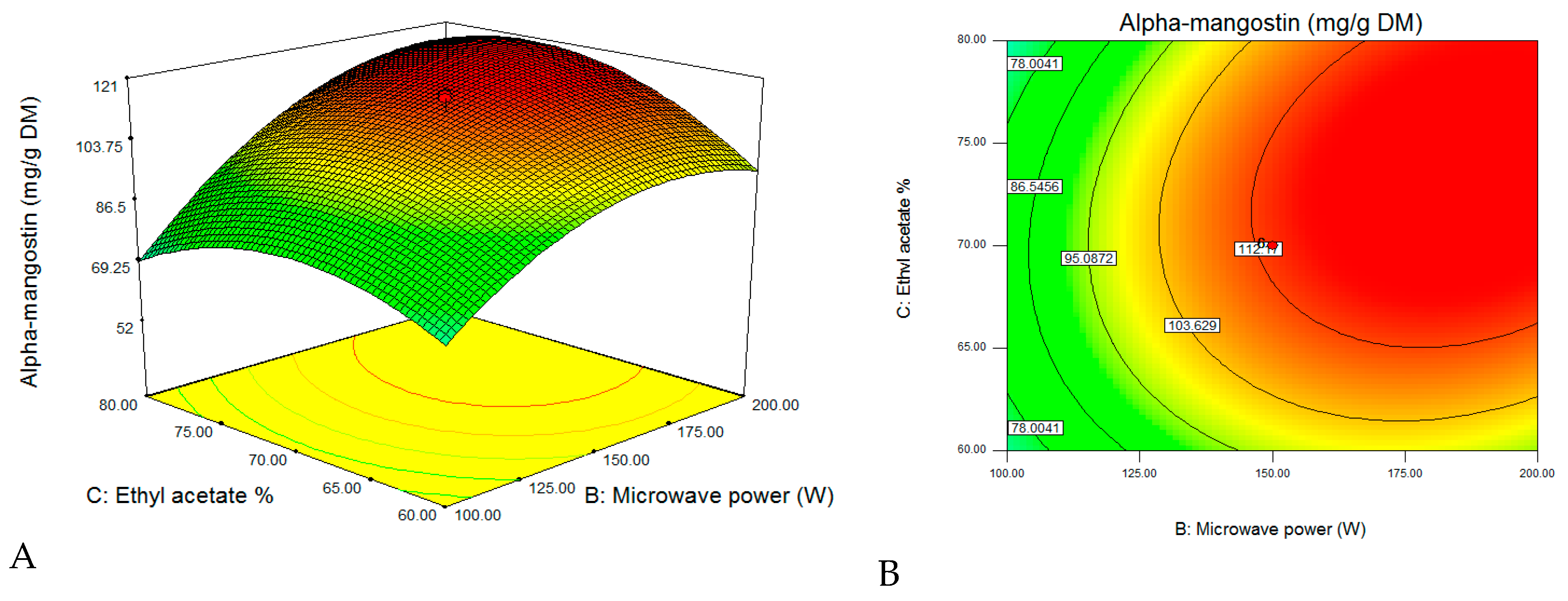

2.4. Response Surface Analysis of the α-Mangostin Concentration in Mangosteen Pericarp Extracts

2.5. Optimization and Prediction of Parameters

2.6. Optimal Condition Validation

2.7. Polyphenolic Compound Determinations of Optimized and Non-Optimized Extracts

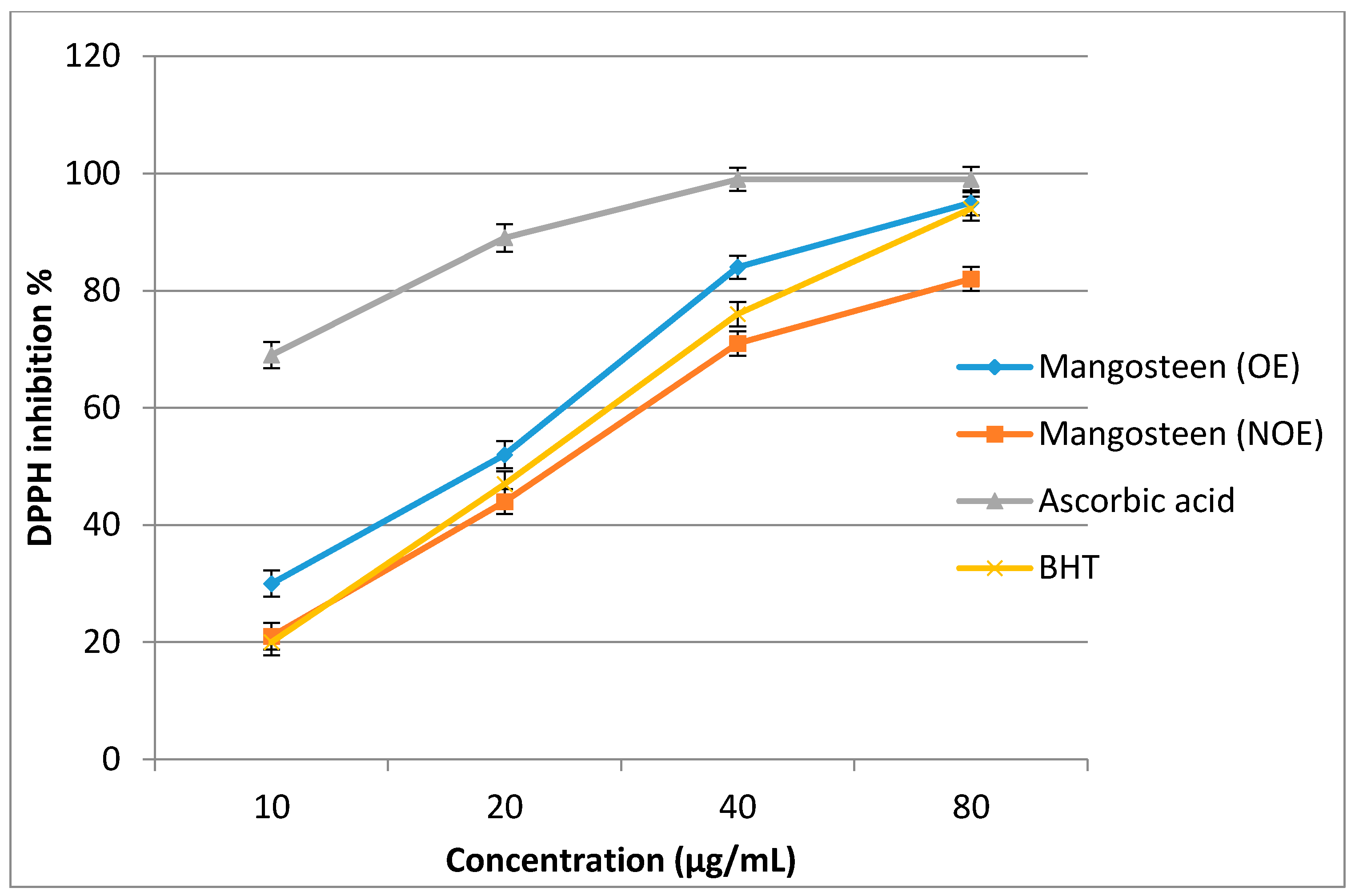

2.8. Antioxidant Activity of Optimized and Non-Optimized Extracts of Mangosteen

2.9. Antimicrobial Activity of Optimized and Non-Optimized Extracts

3. Materials and Methods

3.1. The Sampling of the Mangosteen Fruit

3.2. Extraction Parameters and Preliminary Study of Extraction Parameters

3.3. RSM Analysis

3.4. HPLC Analysis of α-Mangostin

3.5. HPLC Analysis of Phenolics and Flavonoids

3.6. Evaluation of Antioxidant Activity

3.6.1. DPPH Assay

3.6.2. Ferric Reducing Antioxidant Potential (FRAP) Assay

3.7. Antibacterial Test

3.8. Data Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Upaganlawar, A.B.; Badole, S.L. Mangosteen (Garcinia mangostana linn.): Role in prevention of skin disorders. In Bioactive Dietary Factors and Plant Extracts in Dermatology; Springer: Berlin, Germany, 2013; pp. 451–457. [Google Scholar]

- Burkill, I.H. A Dictionary of the Economic Products of the Malay Peninsula; Ministry of Agriculture & Co-operatives: Kuala Lumpur, Malaysia, 1966; Volume 2.

- Wahyono, S.; Astuti, P.; Artaama, W. Characterisation of a bioactive substance and mangostin isolated from the hull of garicinia mangostana. Indones. J. Pharmacol. 1999, 10, 127–134. [Google Scholar]

- Yaacob, O.; Tindall, H.D. Mangosteen Cultivation; Food & Agriculture Org.: Quebec City, QC, Canada, 1995. [Google Scholar]

- Macmillan, H.F. Tropical Planting and Gardening with Sepcial Reference to Ceylon; Asian Educational Services: New Delhi, India, 1935. [Google Scholar]

- Tjahjani, S.; Widowati, W.; Khiong, K.; Suhendra, A.; Tjokropranoto, R. Antioxidant properties of Garcinia mangostana L (mangosteen) rind. Proced. Chem. 2014, 13, 198–203. [Google Scholar] [CrossRef]

- Zarena, A.; Sankar, K.U. Phenolic acids, flavonoid profile and antioxidant activity in mangosteen (Garcinia mangostana L.) pericarp. J. Food Biochem. 2012, 36, 627–633. [Google Scholar] [CrossRef]

- Geetha, R.; Roy, A.; Lakshmi, T. Evaluation of antibacterial activity of fruit rind extract of garcinia mangostana linn on enteric pathogens—An in vitro study. Asian J. Pharm. Clin. Res. 2011, 4, 115–118. [Google Scholar]

- Taher, M.; Zakaria, T.M.F.S.T.; Susanti, D.; Zakaria, Z.A. Hypoglycaemic activity of ethanolic extract of Garcinia mangostana linn. In normoglycaemic and streptozotocin-induced diabetic rats. BMC Complement. Altern. Med. 2016, 16, 135. [Google Scholar] [CrossRef] [PubMed]

- Moongkarndi, P.; Kosem, N.; Kaslungka, S.; Luanratana, O.; Pongpan, N.; Neungton, N. Antiproliferation, antioxidation and induction of apoptosis by Garcinia mangostana (mangosteen) on SKBR3 human breast cancer cell line. J. Ethnopharmacol. 2004, 90, 161–166. [Google Scholar] [CrossRef] [PubMed]

- Kosem, N.; Ichikawa, K.; Utsumi, H.; Moongkarndi, P. In vivo toxicity and antitumor activity of mangosteen extract. J. Nat. Med. 2013, 67, 255–263. [Google Scholar] [CrossRef] [PubMed]

- Zadernowski, R.; Czaplicki, S.; Naczk, M. Phenolic acid profiles of mangosteen fruits (Garcinia mangostana). Food Chem. 2009, 112, 685–689. [Google Scholar] [CrossRef]

- Hemshekhar, M.; Sunitha, K.; Santhosh, M.S.; Devaraja, S.; Kemparaju, K.; Vishwanath, B.; Niranjana, S.; Girish, K. An overview on genus garcinia: Phytochemical and therapeutical aspects. Phytochem. Rev. 2011, 10, 325–351. [Google Scholar] [CrossRef]

- Gutierrez-Orozco, F.; Failla, M.L. Biological activities and bioavailability of mangosteen xanthones: A critical review of the current evidence. Nutrients 2013, 5, 3163–3183. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.Y.; Hashim, N.M.; Mariod, A.A.; Mohan, S.; Abdulla, M.A.; Abdelwahab, S.I.; Arbab, I.A. α-Mangostin from Garcinia mangostana linn: An updated review of its pharmacological properties. Arab. J. Chem. 2016, 9, 317–329. [Google Scholar] [CrossRef]

- Schügerl, K. Solvent Extraction in Biotechnology: Recovery of Primary and Secondary Metabolites; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Ghasemzadeh, A.; Jaafar, H.Z. Optimization of reflux conditions for total flavonoid and total phenolic extraction and enhanced antioxidant capacity in pandan (Pandanus amaryllifolius Roxb.) using response surface methodology. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef] [PubMed]

- Ghasemzadeh, A.; Jaafar, H.Z.; Rahmat, A. Optimization protocol for the extraction of 6-gingerol and 6-shogaol from zingiber officinale var. Rubrum theilade and improving antioxidant and anticancer activity using response surface methodology. BMC Complement. Altern. Med. 2015, 15, 258. [Google Scholar] [CrossRef] [PubMed]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Tang, Q.; Jin, D.; Wang, X.; Zhang, L. Optimize technique of extracting α-mangostin from pericarp of Garcinia mangostana by supersonic wave using central composite design-response surface methodology. J. Chin. Med. Mater. 2012, 35, 973–977. [Google Scholar]

- Abdul Hamid, M.; Abu Bakar, N.; Seo Park, C.; Ramli, F.; Rosli Wan, W. Optimisation of α mangostin extraction using supercritical CO2 from Garcinia mangostana. Chem. Eng. Trans. 2018, 63, 577–582. [Google Scholar]

- Filly, A.; Fernandez, X.; Minuti, M.; Visinoni, F.; Cravotto, G.; Chemat, F. Solvent-free microwave extraction of essential oil from aromatic herbs: From laboratory to pilot and industrial scale. Food Chem. 2014, 150, 193–198. [Google Scholar] [CrossRef] [PubMed]

- Dahmoune, F.; Nayak, B.; Moussi, K.; Remini, H.; Madani, K. Optimization of microwave-assisted extraction of polyphenols from Myrtus communis L. Leaves. Food Chem. 2015, 166, 585–595. [Google Scholar] [CrossRef] [PubMed]

- Ghasemzadeh, A.; Jaafar, H.Z.; Rahmat, A.; Swamy, M.K. Optimization of microwave-assisted extraction of zerumbone from Zingiber zerumbet L. Rhizome and evaluation of antiproliferative activity of optimized extracts. Chem. Cent. J. 2017, 11, 5. [Google Scholar] [CrossRef] [PubMed]

- Pothitirat, W.; Chomnawang, M.T.; Supabphol, R.; Gritsanapan, W. Free radical scavenging and anti-acne activities of mangosteen fruit rind extracts prepared by different extraction methods. Pharm. Biol. 2010, 48, 182–186. [Google Scholar] [CrossRef] [PubMed]

- Bundeesomchok, K.; Filly, A.; Rakotomanomana, N.; Panichayupakaranant, P.; Chemat, F. Extraction of α-mangostin from Garcinia mangostana L. Using alternative solvents: Computational predictive and experimental studies. LWT-Food Sci. Technol. 2016, 65, 297–303. [Google Scholar] [CrossRef]

- Pan, X.; Liu, H.; Jia, G.; Shu, Y.Y. Microwave-assisted extraction of glycyrrhizic acid from licorice root. Biochem. Eng. J. 2000, 5, 173–177. [Google Scholar] [CrossRef]

- Camel, V. Microwave-assisted solvent extraction of environmental samples. TrAC Trends Anal. Chem. 2000, 19, 229–248. [Google Scholar] [CrossRef]

- Veggi, P.C.; Martinez, J.; Meireles, M.A.A. Fundamentals of microwave extraction. In Microwave-Assisted Extraction for Bioactive Compounds; Springer: Berlin, Germany, 2012; pp. 15–52. [Google Scholar]

- Alipieva, K.; Petreska, J.; Gil-Izquierdo, A.; Stefova, M.; Evstatieva, L.; Bankova, V. Influence of the extraction method on the yield of flavonoids and phenolics from Sideritis spp.(Pirin Mountain tea). Nat. Prod. Commun. 2010, 5, 51–54. [Google Scholar] [PubMed]

- Gfrerer, M.; Lankmayr, E. Screening, optimization and validation of microwave-assisted extraction for the determination of persistent organochlorine pesticides. Anal. Chim. Acta 2005, 533, 203–211. [Google Scholar] [CrossRef]

- Xiao, W.; Han, L.; Shi, B. Microwave-assisted extraction of flavonoids from radix astragali. Sep. Purif. Technol. 2008, 62, 614–618. [Google Scholar] [CrossRef]

- Montes, I.; Lai, C.; Sanabria, D. Like dissolves like: A guided inquiry experiment for organic chemistry. J. Chem. Educ. 2003, 80, 447. [Google Scholar] [CrossRef]

- Zhang, Z.-S.; Li, D.; Wang, L.-J.; Ozkan, N.; Chen, X.D.; Mao, Z.-H.; Yang, H.-Z. Optimization of ethanol-water extraction of lignans from flaxseed. Sep. Purif. Technol. 2007, 57, 17–24. [Google Scholar] [CrossRef]

- Wang, L.; Weller, C.L. Recent advances in extraction of nutraceuticals from plants. Trends Food Sci. Technol. 2006, 17, 300–312. [Google Scholar] [CrossRef]

- Pan, X.; Niu, G.; Liu, H. Microwave-assisted extraction of tea polyphenols and tea caffeine from green tea leaves. Chem. Eng. Process. 2003, 42, 129–133. [Google Scholar] [CrossRef]

- Kubrakova, I.; Toropchenova, E. Microwave heating for enhancing efficiency of analytical operations. Inorg. Mater. 2008, 44, 1509–1519. [Google Scholar] [CrossRef]

- Mandal, V.; Mohan, Y.; Hemalatha, S. Microwave assisted extraction—an innovative and promising extraction tool for medicinal plant research. Pharmacogn. Rev. 2007, 1, 7–18. [Google Scholar]

- Hassan, A.; Hawa, S.; Fry, J.R.; Bakar, A.; Fadzelly, M. Phytochemicals content, antioxidant activity and acetylcholinesterase inhibition properties of indigenous garcinia parvifolia fruit. Biomed Res. Int. 2013, 2013. [Google Scholar] [CrossRef]

- Suttirak, W.; Manurakchinakorn, S. In vitro antioxidant properties of mangosteen peel extract. J. Food Sci. Technol. 2014, 51, 3546–3558. [Google Scholar] [CrossRef] [PubMed]

- Ghasemzadeh, A.; Jaafar, H.Z.; Bukhori, M.F.M.; Rahmat, M.H.; Rahmat, A. Assessment and comparison of phytochemical constituents and biological activities of bitter bean (parkia speciosa hassk.) collected from different locations in malaysia. Chem. Cent. J. 2018, 12, 12. [Google Scholar] [CrossRef] [PubMed]

- Murthy, H.N.; Lee, E.-J.; Paek, K.-Y. Production of secondary metabolites from cell and organ cultures: Strategies and approaches for biomass improvement and metabolite accumulation. Plant Cell Tissue Organ Cult. PCTOC 2014, 118, 1–16. [Google Scholar] [CrossRef]

- Jaakola, L.; Hohtola, A. Effect of latitude on flavonoid biosynthesis in plants. Plant Cell Environ. 2010, 33, 1239–1247. [Google Scholar] [CrossRef] [PubMed]

- Palakawong, C.; Sophanodora, P.; Toivonen, P.; Delaquis, P. Optimized extraction and characterization of antimicrobial phenolic compounds from mangosteen (Garcinia mangostana L.) cultivation and processing waste. J. Sci. Food Agric. 2013, 93, 3792–3800. [Google Scholar] [CrossRef] [PubMed]

- Palakawong, C.; Sophanodora, P.; Pisuchpen, S.; Phongpaichit, S. Antioxidant and antimicrobial activities of crude extracts from mangosteen (Garcinia mangostana L.) parts and some essential oils. Int. Food Res. J. 2010, 17, 583–589. [Google Scholar]

- Manasathien, J. Antioxidant and cytotoxic activities of mangosteen garcinia mangostana pericarp extracts. Asia-Pac. J. Sci. Technol. 2015, 20, 381–392. [Google Scholar]

- Dharmaratne, H.; Sakagami, Y.; Piyasena, K.; Thevanesam, V. Antibacterial activity of xanthones from Garcinia mangostana (L.) and their structure–activity relationship studies. Nat. Prod. Res. 2013, 27, 938–941. [Google Scholar] [CrossRef] [PubMed]

- Sakagami, Y.; Iinuma, M.; Piyasena, K.; Dharmaratne, H. Antibacterial activity of α-mangostin against vancomycin resistant Enterococci (VRE) and synergism with antibiotics. Phytomedicine 2005, 12, 203–208. [Google Scholar] [CrossRef] [PubMed]

- Waitz, J.A. Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria that Grow Aerobically; National Committee for Clinical Laboratory Standards: Wayne, PA, USA, 1990. [Google Scholar]

Sample Availability: Samples of the dry mangosteen and the crude extracts are available from the authors. |

| Run | Independent Variables | α-Mangostin Content (mg/g DM) | |||

|---|---|---|---|---|---|

| Time (min) | Microwave Power (W) | Ethyl Acetate (%) | Experimental | Predicted | |

| 1 | 2.0 | 200.0 | 60.0 | 77.6 | 79.1 |

| 2 | 1.3 | 150.0 | 70.0 | 81.5 | 82.4 |

| 3 | 3.0 | 150.0 | 86.8 | 90.4 | 90.8 |

| 4 | 3.0 | 66.0 | 70.0 | 50.7 | 52.1 |

| 5 | 3.0 | 150.0 | 53.1 | 80.1 | 84.6 |

| 6 | 3.0 | 150.0 | 70.0 | 98.8 | 99.5 |

| 7 | 4.6 | 150.0 | 70.0 | 101.5 | 102.7 |

| 8 | 4.0 | 200.0 | 80.0 | 110.5 | 113.8 |

| 9 | 4.0 | 100.0 | 60.0 | 74.3 | 75.9 |

| 10 | 2.0 | 200.0 | 80.0 | 100.6 | 102.1 |

| 11 | 3.0 | 150.0 | 70.0 | 115.7 | 116.5 |

| 12 | 3.0 | 150.0 | 70.0 | 116.8 | 115. 9 |

| 13 | 2.0 | 100.0 | 60.0 | 46.6 | 47.2 |

| 14 | 3.0 | 150.0 | 70.0 | 116.4 | 115.0 |

| 15 | 3.0 | 150.0 | 70.0 | 115.7 | 115.4 |

| 16 | 2.0 | 100.0 | 80.0 | 52.5 | 54. 9 |

| 17 | 4.0 | 200.0 | 60.0 | 93.6 | 94.6 |

| 18 | 3.0 | 234.0 | 70.0 | 106.4 | 105.8 |

| 19 | 4.0 | 100.0 | 80.0 | 62.9 | 64.2 |

| 20 | 3.0 | 150.0 | 70.0 | 115.4 | 116.0 |

| Source | Sum of Squares | df | Mean of Square | F-Value | p-Value (Prob > F) |

|---|---|---|---|---|---|

| Model | 7699.587 | 9 | 855.5097 | 12.25099 | 0.0016 ** |

| X1 | 72 | 1 | 72 | 1.031047 | 0.3437 |

| X2 | 607.7841 | 1 | 607.7841 | 8.703531 | 0.0214 * |

| X3 | 2931.865 | 1 | 2931.865 | 41.98461 | 0.0003 ** |

| X1X2 | 34.04723 | 1 | 34.04723 | 0.48756 | 0.5075 |

| X1X3 | 27.61503 | 1 | 27.61503 | 0.39545 | 0.5494 |

| X2X3 | 350.4384 | 1 | 350.4384 | 5.018314 | 0.0401 * |

| X12 | 39.6321 | 1 | 39.6321 | 0.567536 | 0.4758 |

| X22 | 3139.328 | 1 | 3139.328 | 44.9555 | 0.0003 ** |

| X32 | 606.7706 | 1 | 606.7706 | 8.689018 | 0.0215 * |

| Residual | 488.8233 | 7 | 69.8319 | ||

| Lack of Fit | 351.762 | 3 | 117.254 | 3.421943 | 0.1328 n.s |

| Pure Error | 137.0613 | 4 | 34.26533 | ||

| R2 | 0.983 | ||||

| Adj R2 | 0.970 | ||||

| CV% | 3.481 | ||||

| Cor Total | 8188.41 | 16 |

| Microwave Power (W) | Time (min) | Solvent Percentage (%) | Desirability | α-Mangostin (mg/g DM) | |

|---|---|---|---|---|---|

| Predicted | Experimental | ||||

| 189.20 | 3.16 | 72.40 | 1 | 121.01 | 120.68 |

| Secondary Metabolites | Optimized | Non-Optimized |

|---|---|---|

| TPC | 368.2 ± 21.06 a | 311.72 ± 19.55 b |

| trans-ferulic acid | 148.91 ± 17.69 a | 112.41 ± 16.53 b |

| cinnamic acid | 82.54 ± 9.21 a | 56.74 ± 9.21 b |

| caffeic acid | 55.06 ± 6.25 a | 41.42 ± 6.18 b |

| TFC | 279.19 ± 19.55 a | 192.5 ± 17.28 b |

| rutin | 34.73 ± 7.06 a | 30.16 ± 5.44 b |

| catechin | 78.61 ± 9.18 a | 42.71 ± 5.92 b |

| quercetin | 40.15 ± 8.55 a | 36.22 ± 6.11 a |

| Samples | FRAP (μM of Fe (II)/g DM) |

|---|---|

| NOE | 344.60 ± 8.61 d |

| OE | 497.42 ± 12.73 b |

| Ascorbic acid | 783.27 ± 16.28 a |

| BHT | 421.91 ± 10.33 c |

| Bacterial Strains | ID (mm) | |||

|---|---|---|---|---|

| Negative Control | Positive Control | OE | NOE | |

| Listeria ivanovii | − | 18 | 17 | 14 |

| Staphylococcus aureus | − | 16 | 18 | 14 |

| Mycobacterium smegmatis | − | 17 | 16 | 12 |

| Streptococcus uberis | − | 18 | 14 | 14 |

| Vibrio parahaemolyticus | − | 14 | 12 | 10 |

| Enterobacter cloacae | − | 15 | 12 | 8 |

| Escherichia coli | − | 15 | 10 | 6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghasemzadeh, A.; Jaafar, H.Z.E.; Baghdadi, A.; Tayebi-Meigooni, A. Alpha-Mangostin-Rich Extracts from Mangosteen Pericarp: Optimization of Green Extraction Protocol and Evaluation of Biological Activity. Molecules 2018, 23, 1852. https://doi.org/10.3390/molecules23081852

Ghasemzadeh A, Jaafar HZE, Baghdadi A, Tayebi-Meigooni A. Alpha-Mangostin-Rich Extracts from Mangosteen Pericarp: Optimization of Green Extraction Protocol and Evaluation of Biological Activity. Molecules. 2018; 23(8):1852. https://doi.org/10.3390/molecules23081852

Chicago/Turabian StyleGhasemzadeh, Ali, Hawa Z. E. Jaafar, Ali Baghdadi, and Amin Tayebi-Meigooni. 2018. "Alpha-Mangostin-Rich Extracts from Mangosteen Pericarp: Optimization of Green Extraction Protocol and Evaluation of Biological Activity" Molecules 23, no. 8: 1852. https://doi.org/10.3390/molecules23081852

APA StyleGhasemzadeh, A., Jaafar, H. Z. E., Baghdadi, A., & Tayebi-Meigooni, A. (2018). Alpha-Mangostin-Rich Extracts from Mangosteen Pericarp: Optimization of Green Extraction Protocol and Evaluation of Biological Activity. Molecules, 23(8), 1852. https://doi.org/10.3390/molecules23081852