Lignin from Hardwood and Softwood Biomass as a Lubricating Additive to Ethylene Glycol

Abstract

1. Introduction

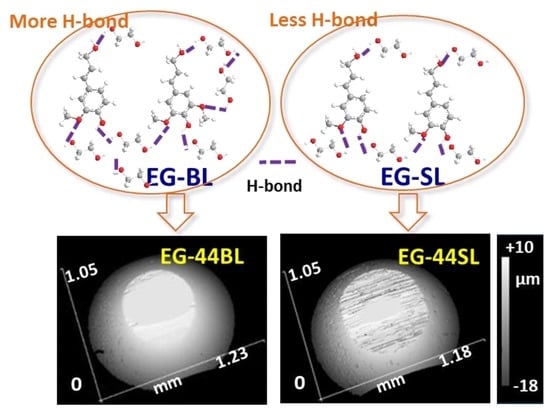

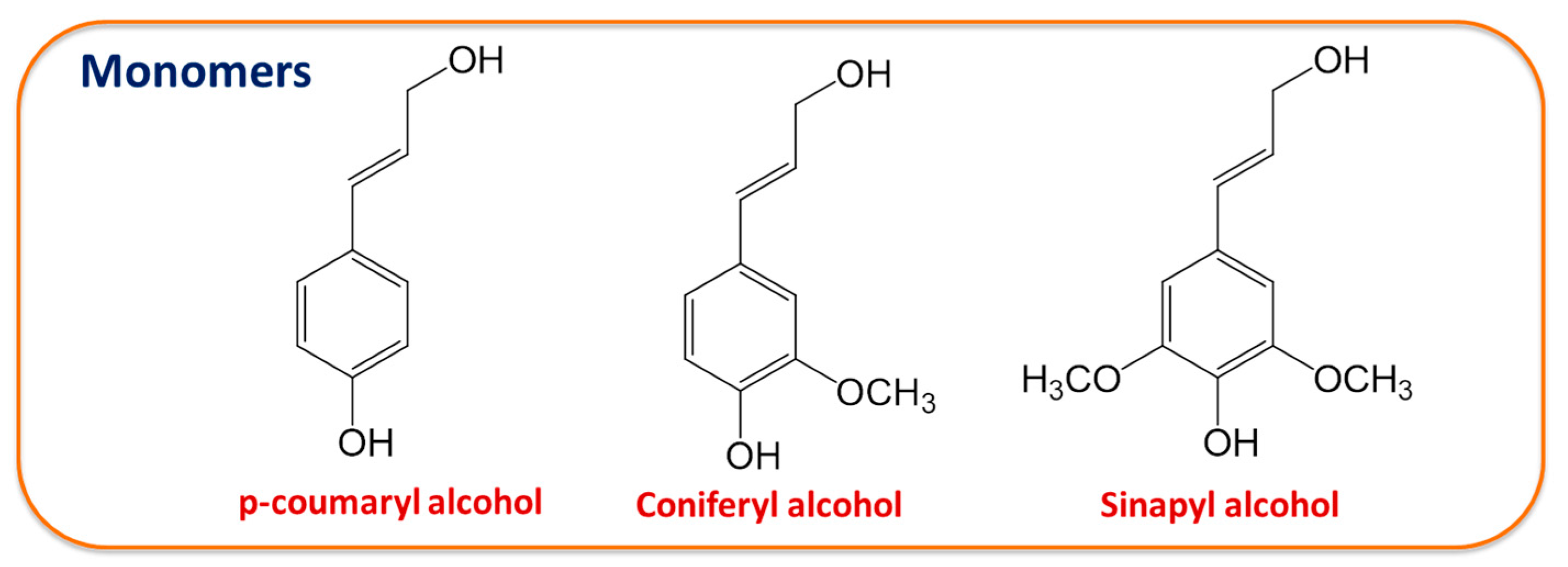

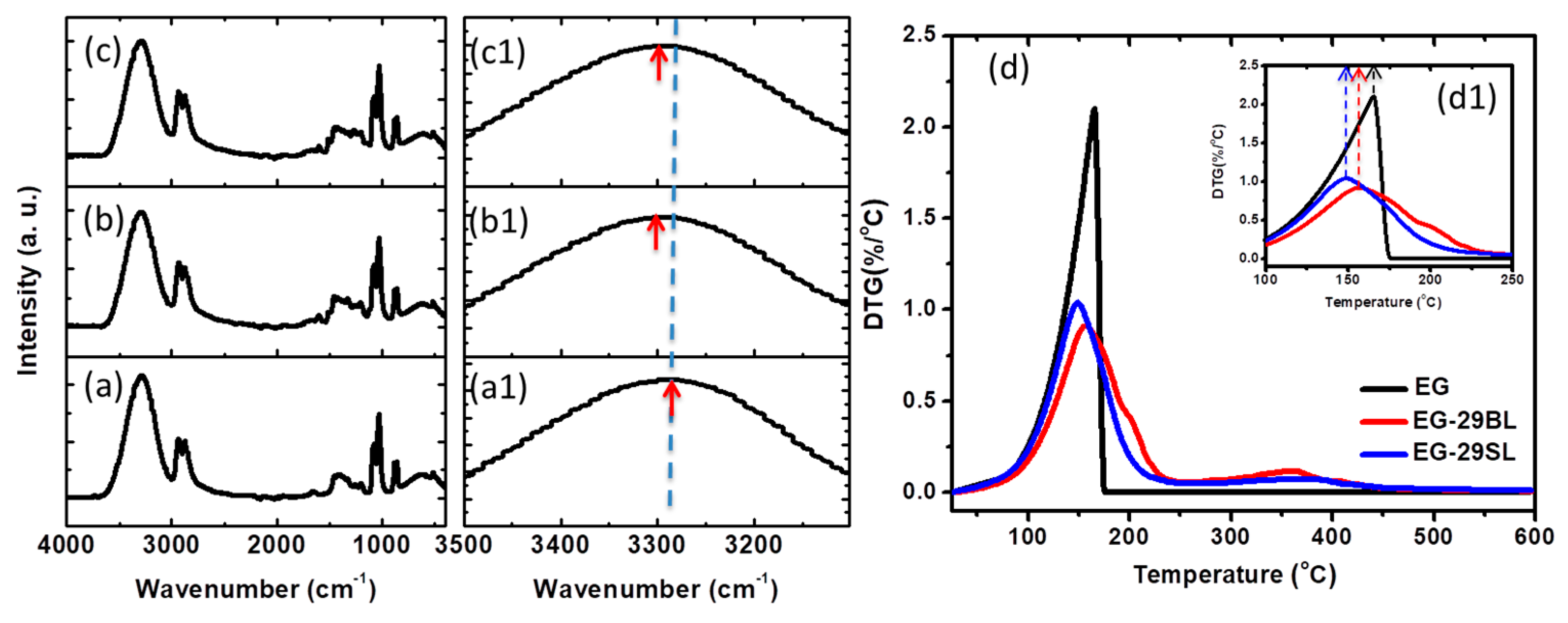

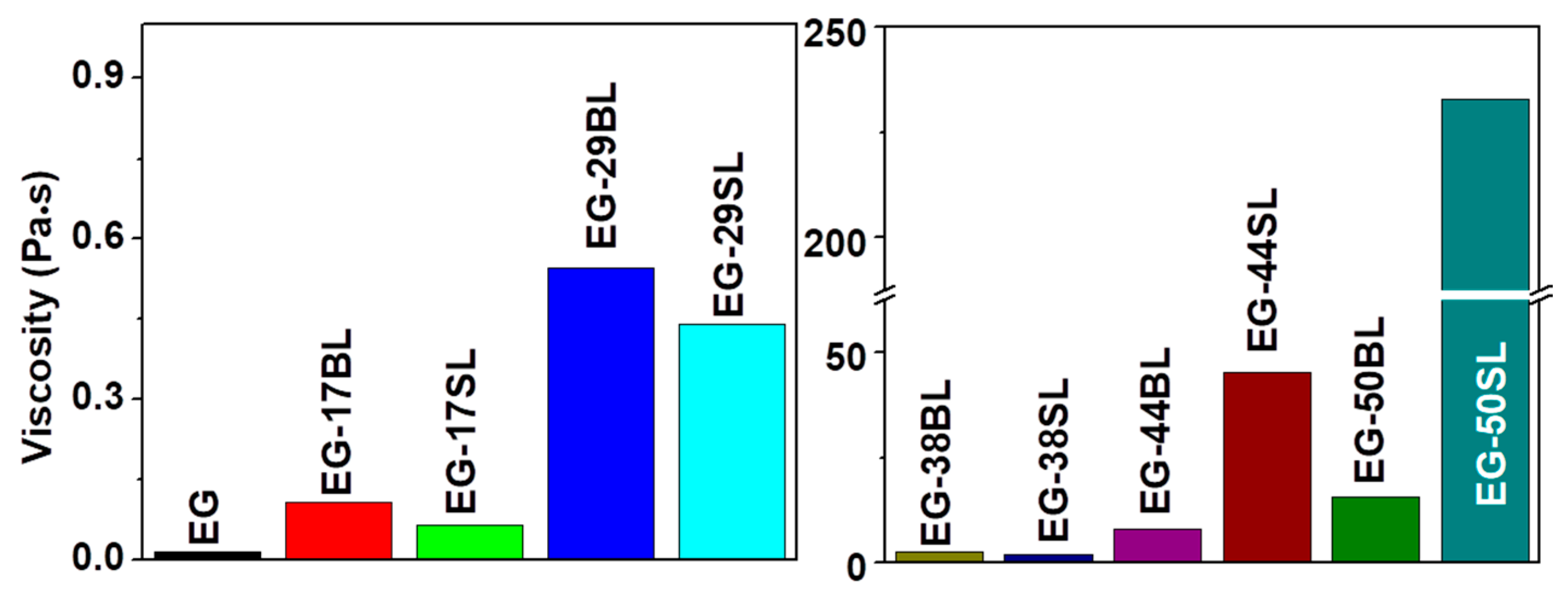

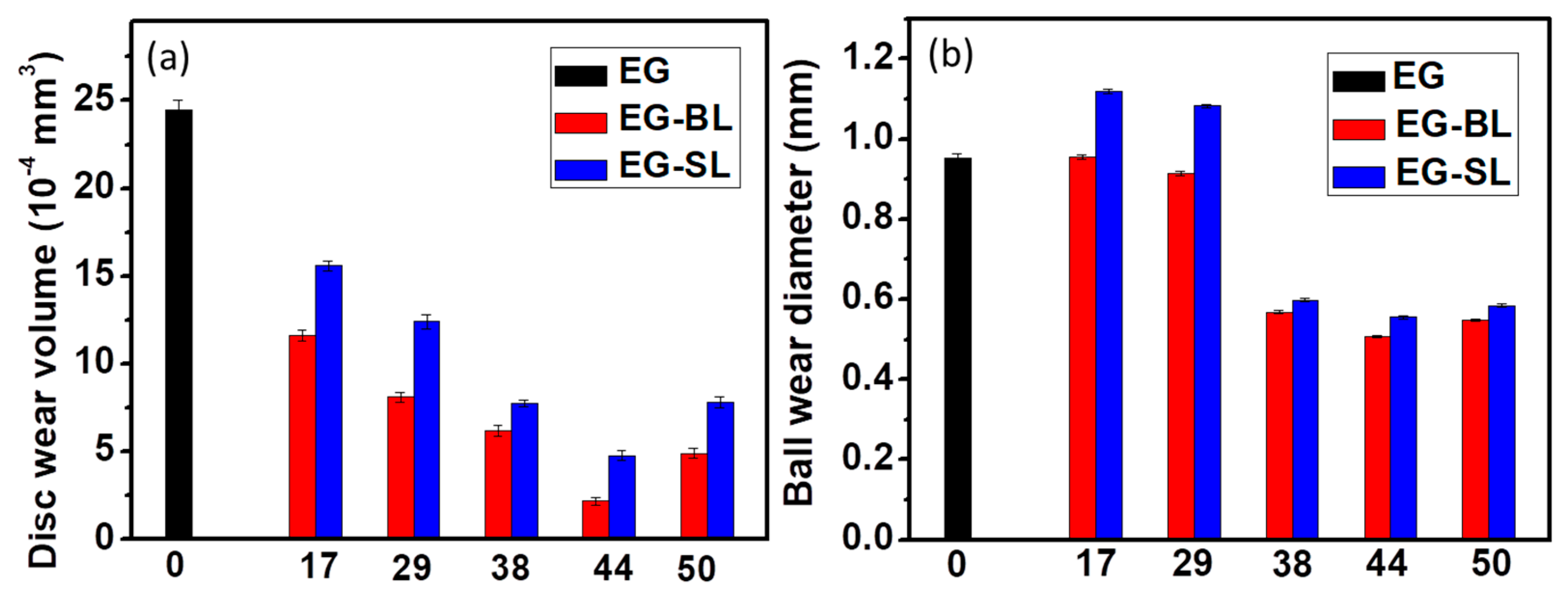

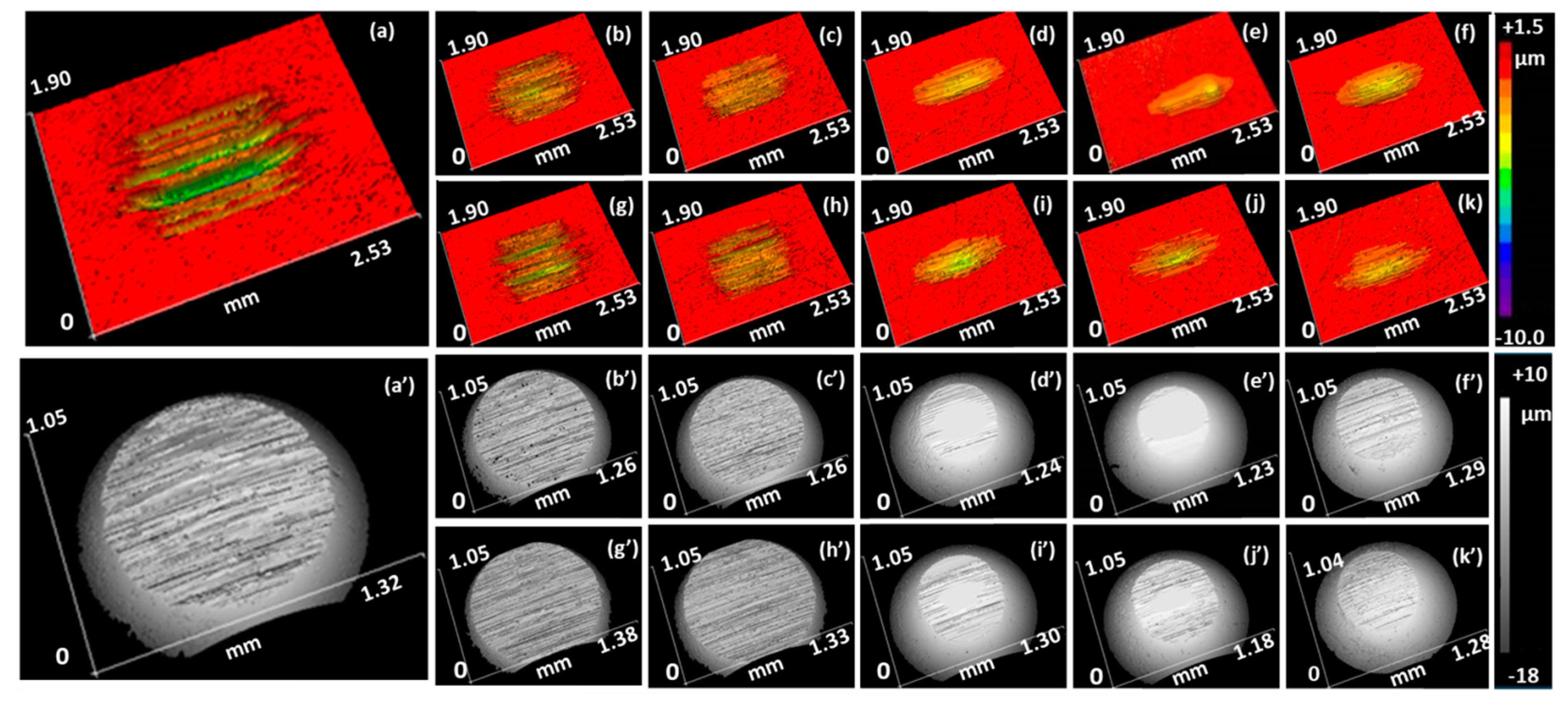

2. Results and Discussion

3. Experimental Section

3.1. Materials

3.2. Preparation of Lubricants

3.3. Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rahimi, A.; Ulbrich, A.; Coon, J.J.; Stahl, S.S. Formic-acid-induced depolymerization of oxidized lignin to aromatics. Nat. Lett. 2014, 515, 249–252. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhao, X.; Wang, A.; Huber, G.W.; Zhang, T. Catalytic Transformation of Lignin for the Production of Chemicals and Fuels. Chem. Rev. 2015, 115, 11559–11624. [Google Scholar] [CrossRef] [PubMed]

- Laurichesse, S.; Averous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Mu, L.; Shi, Y.; Chen, L.; Ji, T.; Yuan, R.; Wang, H.; Zhu, J. N-Methyl-2-pyrrolidone C1-C4 carboxylic acid: A novel solvent system with exceptional lignin solubility. Chem. Commun. 2015, 51, 13554–13557. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Arancon, R.A.D.; Labidi, J.; Luque, R. Lignin depolymerisation strategies: Towards valuable chemicals and fuels. Chem. Soc. Rev. 2014, 43, 7485–7500. [Google Scholar] [CrossRef] [PubMed]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M. Lignin Valorization: Improving Lignin Processing in the Biorefinery. Science 2014, 16, 1246843. [Google Scholar] [CrossRef] [PubMed]

- Constant, S.; Wienk, H.L.J.; Frissen, A.E.; Peinder, P.d.; Boelens, R.; van Es, D.S.; Grisel, R.J.H.; Weckhuysen, B.M.; Huijgen, W.J.J.; Gosselink, R.J.A. New insights into the structure and composition of technical lignins: A comparative characterisation study. Green Chem. 2016, 18, 2651–2665. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A.M. Strategies for the Conversion of Lignin to High-Value Polymeric Materials: Review and Perspective. Chem. Rev. 2016, 116, 2275–2306. [Google Scholar] [CrossRef] [PubMed]

- Sathitsuksanoh, N.; Holtman, K.M.; Yelle, D.J.; Morgan, T.; Stavila, V.; Pelton, J.; Blanch, H.; Simmons, B.A.; George, A. Lignin fate and characterization during ionic liquid biomass pretreatment for renewable chemicals and fuels production. Green Chem. 2014, 16, 1236–1247. [Google Scholar] [CrossRef]

- Karimi, K.; Taherzadeh, M.J. A critical review of analytical methods in pretreatment of lignocelluloses: Composition, imaging, and crystallinity. Bioresour. Technol. 2016, 200, 1008–1018. [Google Scholar] [CrossRef] [PubMed]

- López, M.; Huerta-Pujol, O.; Martínez-Farré, F.X.; Soliva, M. Approaching compost stability from Klason lignin modified method: Chemical stability degree for OM and N quality assessment. Resour. Conserv. Recycl. 2010, 55, 171–181. [Google Scholar] [CrossRef]

- Shuai, L.; Amiri, M.T.; Questell-Santiago, Y.M.; Héroguel, F.; Li, Y.; Kim, H.; Meilan, R.; Chapple, C.; Ralph, J.; Luterbacher, J.S. Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science 2016, 354, 329. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Sun, J.-X.; Sun, R.; Fowler, P.; Baird, M.S. Comparative study of organosolv lignins from wheat straw. Ind. Crops Prod. 2006, 23, 180–193. [Google Scholar] [CrossRef]

- Feghali, E.; Carrot, G.; Thuery, P.; Genre, C.; Cantat, T. Convergent reductive depolymerization of wood lignin to isolated phenol derivatives by metal-free catalytic hydrosilylation. Energy Environ. Sci. 2015, 8, 2734–2743. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhao, S.; Yang, S.; Ding, S.-Y. Lignin plays a negative role in the biochemical process for producing lignocellulosic biofuels. Curr. Opin. Biotechnol. 2014, 27, 38–45. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sun, C.; Zhou, B.; He, Y. Determination of Hemicellulose, Cellulose and Lignin in Moso Bamboo by Near Infrared Spectroscopy. Sci. Rep. 2015, 5, 17210. [Google Scholar] [CrossRef] [PubMed]

- Nitsos, C.; Stoklosa, R.; Karnaouri, A.; Vörös, D.; Lange, H.; Hodge, D.; Crestini, C.; Rova, U.; Christakopoulos, P. Isolation and Characterization of Organosolv and Alkaline Lignins from Hardwood and Softwood Biomass. ACS Sustain. Chem. Eng. 2016, 4, 5181–5193. [Google Scholar] [CrossRef]

- Zhou, S.; Xue, Y.; Sharma, A.; Bai, X. Lignin Valorization through Thermochemical Conversion: Comparison of Hardwood, Softwood and Herbaceous Lignin. ACS Sustain. Chem. Eng. 2016, 4, 6608–6617. [Google Scholar] [CrossRef]

- Zhou, Y.; Qu, J. Ionic Liquids as Lubricant Additives: A Review. ACS Appl. Mater. Interface 2017, 9, 3209–3222. [Google Scholar] [CrossRef] [PubMed]

- Mu, L.; Shi, Y.; Guo, X.; Ji, T.; Chen, L.; Yuan, R.; Brisbin, L.; Wang, H.; Zhu, J. Non-corrosive green lubricants: Strengthened lignin-[choline][amino acid] ionic liquids interaction via reciprocal hydrogen bonding. RSC Adv. 2015, 5, 66067–66072. [Google Scholar] [CrossRef]

- Mu, L.; Shi, Y.; Guo, X.; Zhuang, W.; Chen, L.; Ji, T.; Hua, J.; Wang, H.; Zhu, J. Grafting heteroelement-rich groups on graphene oxide: Tuning polarity and molecular interaction with bio-ionic liquid for enhanced lubrication. J. Colloid Interface Sci. 2017, 498, 47–54. [Google Scholar] [CrossRef] [PubMed]

- Mu, L.; Shi, Y.; Ji, T.; Chen, L.; Yuan, R.; Wang, H.; Zhu, J. Ionic Grease Lubricants: Protic [Triethanolamine][Oleic Acid] and Aprotic [Choline][Oleic Acid]. ACS Appl. Mater. Interfaces 2016, 8, 4977–4984. [Google Scholar] [CrossRef] [PubMed]

- Mu, L.; Shi, Y.; Hua, J.; Zhuang, W.; Zhu, J. Engineering Hydrogen Bonding Interaction and Charge Separation in Bio-Polymers for Green Lubrication. J. Phys. Chem. B 2017, 121, 5669–5678. [Google Scholar] [CrossRef] [PubMed]

- Christendat, D.; Abraham, T.; Xu, Z.; Masliyah, J. Adhesion forces between functionalized probes and hydrophilic silica surfaces. J. Adhes. Sci. Technol. 2005, 19, 149–163. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Deng, M.; Luo, J. Investigations of the superlubricity of sapphire against ruby under phosphoric acid lubrication. Friction 2014, 2, 164–172. [Google Scholar] [CrossRef]

- Tan, Y.; Huang, W.; Wang, X. Molecular orbital indexes criteria for friction modifiers in boundary lubrication. Tribol. Int. 2002, 35, 381–384. [Google Scholar] [CrossRef]

- Mu, L.; Shi, Y.; Wang, H.; Zhu, J. Lignin in Ethylene Glycol and Poly(ethylene glycol): Fortified Lubricants with Internal Hydrogen Bonding. ACS Sustain. Chem. Eng. 2016, 4, 1840–1849. [Google Scholar] [CrossRef]

- Mu, L.; Shi, Y.; Guo, X.; Wu, J.; Ji, T.; Chen, L.; Feng, X.; Lu, X.; Hua, J.; Zhu, J. Enriching Heteroelements in Lignin as Lubricating Additives for Bioionic Liquids. ACS Sustain. Chem. Eng. 2016, 4, 3877–3887. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, N.; Panda, K.; Melvin, A.A.; Joshi, S.; Dash, S.; Tyagi, A.K. Effective Noncovalent Functionalization of Poly(ethylene glycol) to Reduced Graphene Oxide Nanosheets through γ-Radiolysis for Enhanced Lubrication. J. Phys. Chem. C 2016, 120, 2139–2148. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, N.; Panda, K.; Melvin, A.A.; Joshi, S.; Dash, S. Molecular-Pillar-Supported Functionalized Reduced Graphene-Oxide for Energy Efficient Lubrication. Adv. Mater. Interfaces 2016, 3, 1600161. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, N.; Panda, K.; Dash, S.; Tyagi, A.K. Energy efficient reduced graphene oxide additives: Mechanism of effective lubrication and antiwear properties. Sci. Rep. 2016, 6, 18372. [Google Scholar] [CrossRef] [PubMed]

- King, J.; Wei, L. Novel Lignin Based Composition. U.S. Patent 20,130,338,049 A1, 27 April 2011. [Google Scholar]

- Zhang, Y.; Jun, M.B.G. Feasibility of lignin as additive in metalworking fluids for micro-milling. J. Manuf. Process. 2014, 16, 503–510. [Google Scholar] [CrossRef]

- Liu, W.-J.; Jiang, H.; Yu, H.-Q. Thermochemical conversion of lignin to functional materials: A review and future directions. Green Chem. 2015, 17, 4888–4907. [Google Scholar] [CrossRef]

- Vieira, L.; Schennach, R.; Gollas, B. In situ PM-IRRAS of a glassy carbon electrode/deep eutectic solvent interface. Phys. Chem. Chem. Phys. 2015, 17, 12870–12880. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Painter, P.C.; Coleman, M.M.; Pearce, E.M.; Kwei, T.K. Equilibrium constants and predictions of miscibility windows and maps for polymer blends involving p-(hexafluoro-2-hydroxy-2-propyl)styrene with methacrylate and acetoxy groups. Macromolecules 1992, 25, 2156–2165. [Google Scholar] [CrossRef]

- Masser, K.A.; Zhao, H.; Painter, P.C.; Runt, J. Local Relaxation Behavior and Dynamic Fragility in Hydrogen Bonded Polymer Blends. Macromolecules 2010, 43, 9004–9013. [Google Scholar] [CrossRef]

- Glass, J.E.; Schulz, D.N.; Zukoski, C.F. Polymers as Rheology Modifiers. In Polymers as Rheology Modifiers; American Chemical Society: Washington, DC, USA, 1991; Volume 462, pp. 2–17. ISBN 9780841220096. [Google Scholar]

- Lopez, C.G.; Colby, R.H.; Graham, P.; Cabral, J.T. Viscosity and Scaling of Semiflexible Polyelectrolyte NaCMC in Aqueous Salt Solutions. Macromolecules 2017, 50, 332–338. [Google Scholar] [CrossRef]

- Xiao, H.; Dai, W.; Kan, Y.; Clearfield, A.; Liang, H. Amine-intercalated α-zirconium phosphates as lubricant additives. Appl. Surf. Sci. 2015, 329, 384–389. [Google Scholar] [CrossRef]

- Zhou, F.; Liang, Y.; Liu, W. Ionic liquid lubricants: Designed chemistry for engineering applications. Chem. Soc. Rev. 2009, 38, 2590–2599. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Liang, Y.; Fan, M.; Zhou, F.; Liu, W. Ionic liquids from amino acids: Fully green fluid lubricants for various surface contacts. RSC Adv. 2014, 4, 19396–19402. [Google Scholar] [CrossRef]

- Naveira-Suarez, A.; Tomala, A.; Pasaribu, R.; Larsson, R.; Gebeshuber, I.C. Evolution of ZDDP-derived reaction layer morphology with rubbing time. Scanning 2010, 32, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Shen, B.; Groll, E.A. Review Article: A Critical Review of the Influence of Lubricants on the Heat Transfer and Pressure Drop of Refrigerants, Part 1: Lubricant Influence on Pool and Flow Boiling. HVAC&R Res. 2005, 11, 341–359. [Google Scholar]

- Ostberg, J.R.; Barth, R.K.; Frelinger, J.G. The Roman god Janus: A paradigm for the function of CD43. Immunol. Today 1998, 19, 546–550. [Google Scholar] [CrossRef]

- Gurney, R.; Henry, A.; Schach, R.; Lindner, A.; Creton, C. Molecular Weight Dependence of Interdiffusion and Adhesion of Polymers at Short Contact Times. Langmuir 2017, 33, 1670–1678. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are available from the Prof. Yijun Shi. |

| BL | SL | |

|---|---|---|

| Mw (Da) | 1855 | 2226 |

| Mn (Da) | 587 | 846 |

| PDI | 3.2 | 2.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, L.; Wu, J.; Matsakas, L.; Chen, M.; Vahidi, A.; Grahn, M.; Rova, U.; Christakopoulos, P.; Zhu, J.; Shi, Y. Lignin from Hardwood and Softwood Biomass as a Lubricating Additive to Ethylene Glycol. Molecules 2018, 23, 537. https://doi.org/10.3390/molecules23030537

Mu L, Wu J, Matsakas L, Chen M, Vahidi A, Grahn M, Rova U, Christakopoulos P, Zhu J, Shi Y. Lignin from Hardwood and Softwood Biomass as a Lubricating Additive to Ethylene Glycol. Molecules. 2018; 23(3):537. https://doi.org/10.3390/molecules23030537

Chicago/Turabian StyleMu, Liwen, Jian Wu, Leonidas Matsakas, Minjiao Chen, Alireza Vahidi, Mattias Grahn, Ulrika Rova, Paul Christakopoulos, Jiahua Zhu, and Yijun Shi. 2018. "Lignin from Hardwood and Softwood Biomass as a Lubricating Additive to Ethylene Glycol" Molecules 23, no. 3: 537. https://doi.org/10.3390/molecules23030537

APA StyleMu, L., Wu, J., Matsakas, L., Chen, M., Vahidi, A., Grahn, M., Rova, U., Christakopoulos, P., Zhu, J., & Shi, Y. (2018). Lignin from Hardwood and Softwood Biomass as a Lubricating Additive to Ethylene Glycol. Molecules, 23(3), 537. https://doi.org/10.3390/molecules23030537