Experimental Study on the Compaction Characteristics and Evaluation Method of Coarse-Grained Materials for Subgrade

Abstract

:1. Introduction

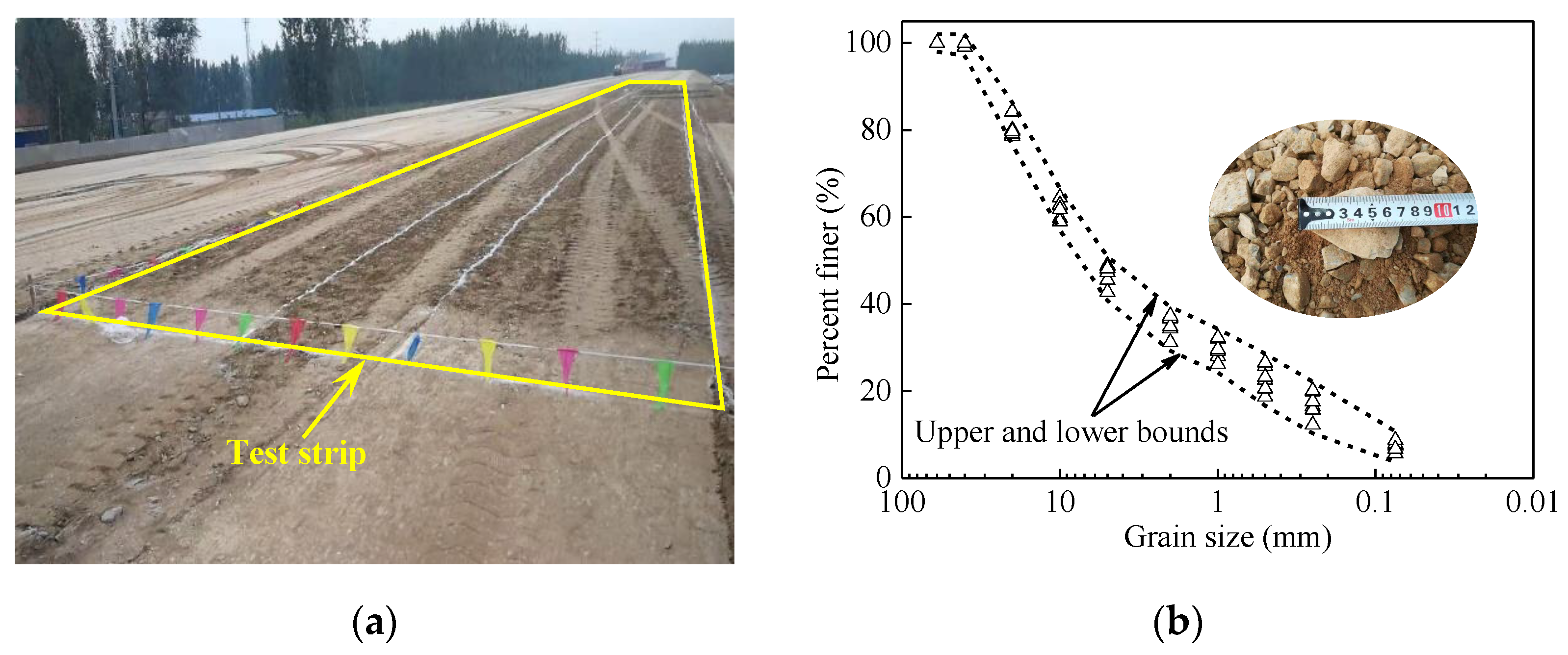

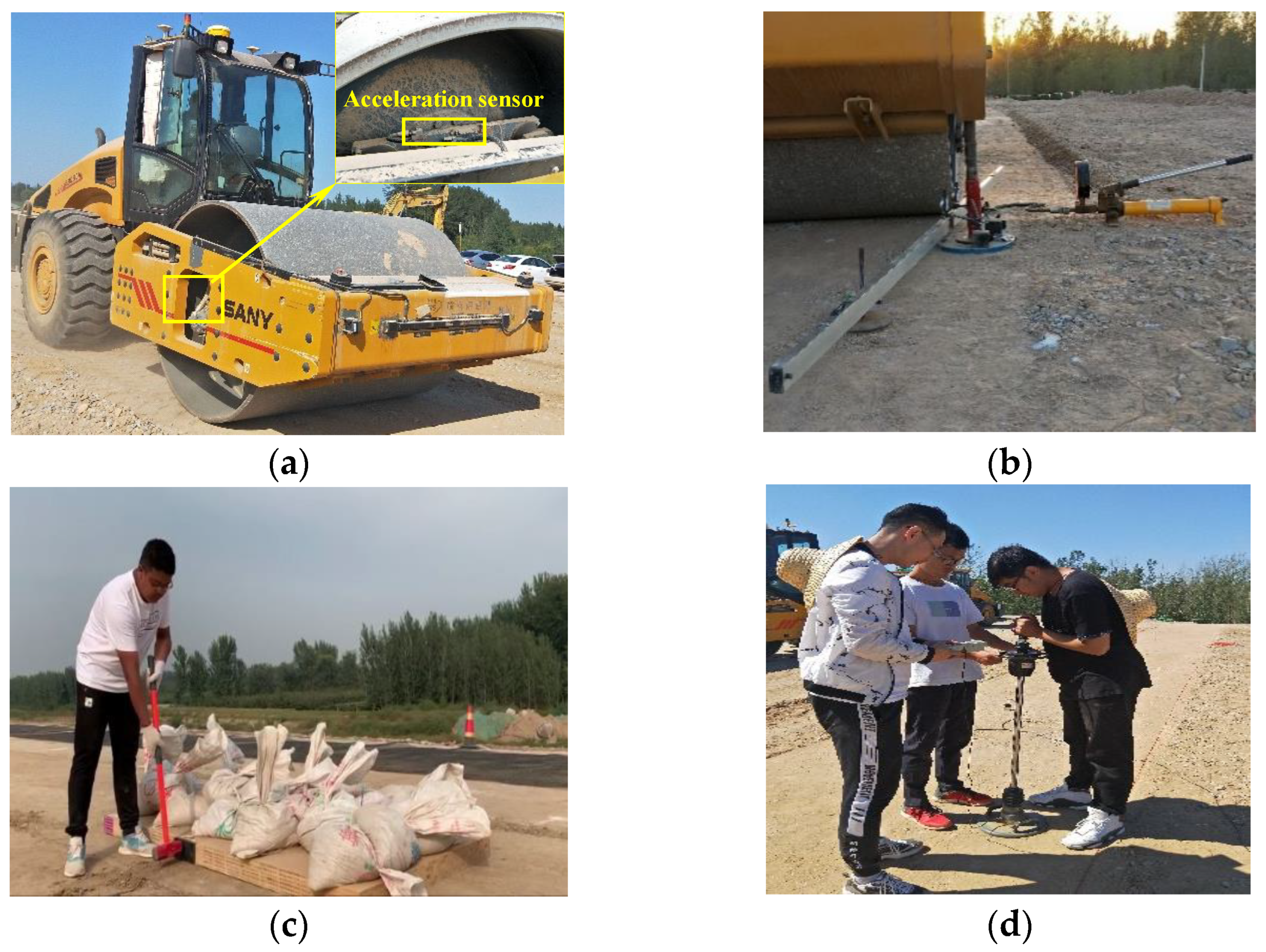

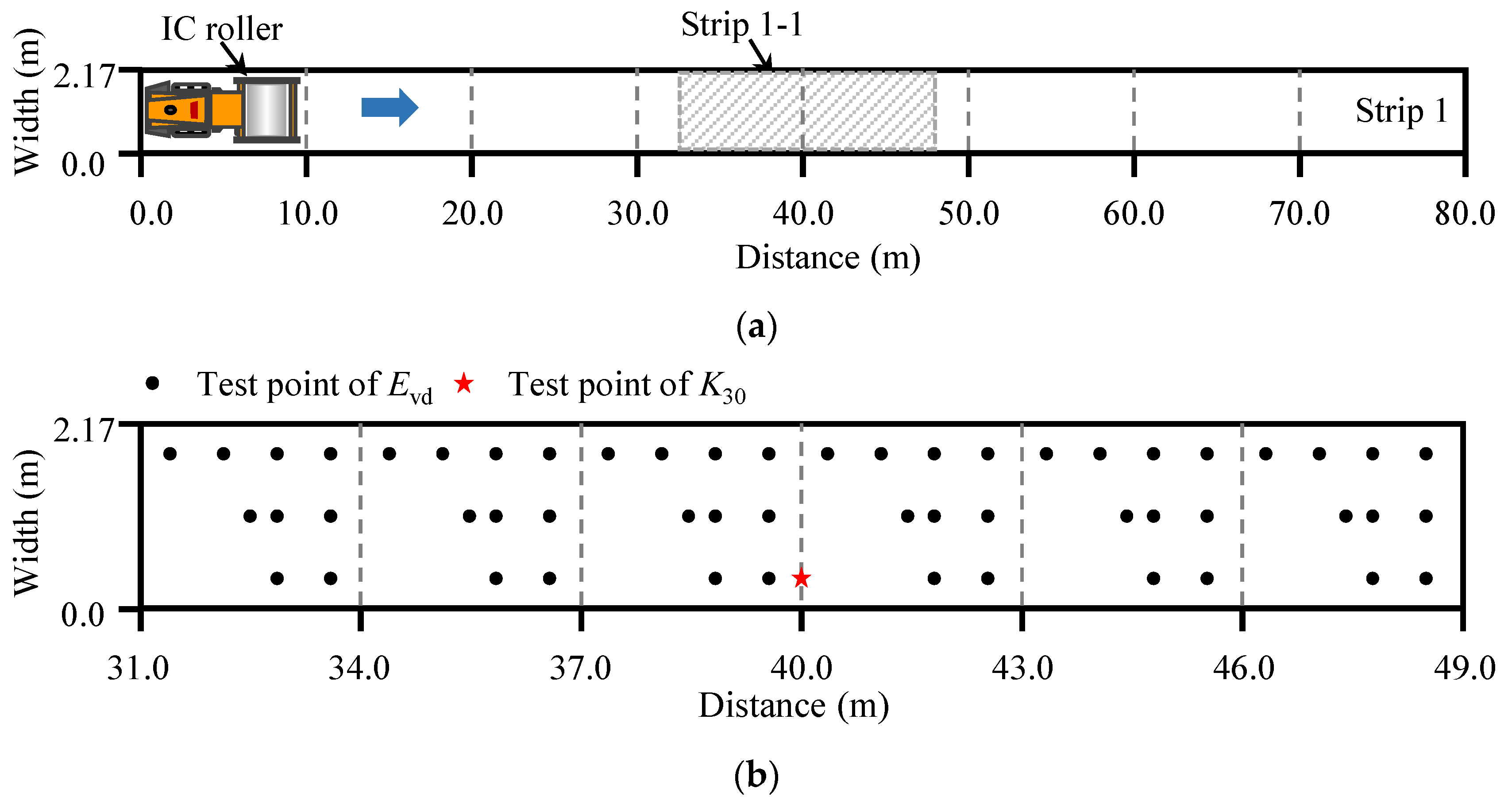

2. Field Compaction Experiment

2.1. Test Materials

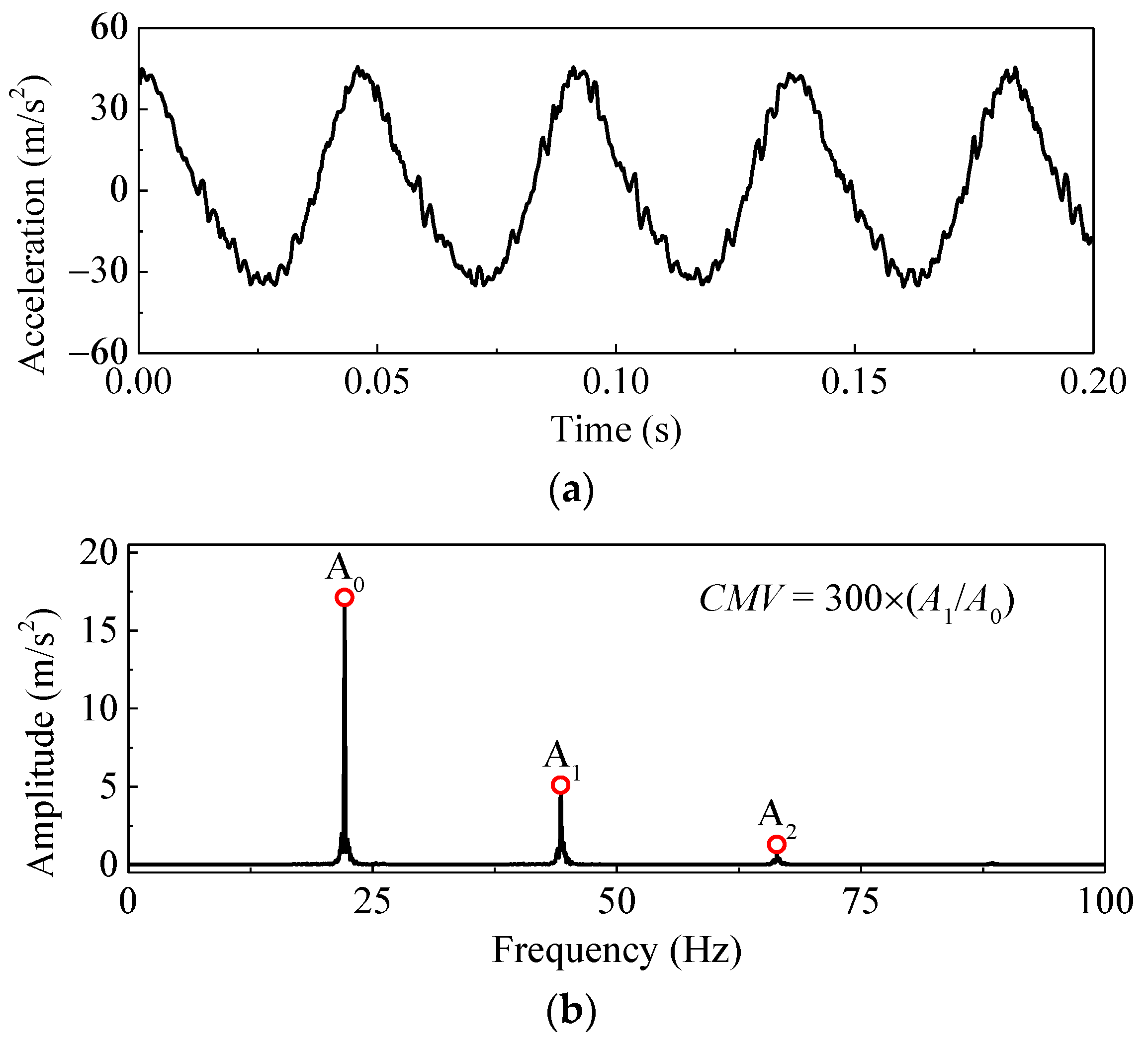

2.2. Measurement of Compaction Degree

3. Results and Analyses

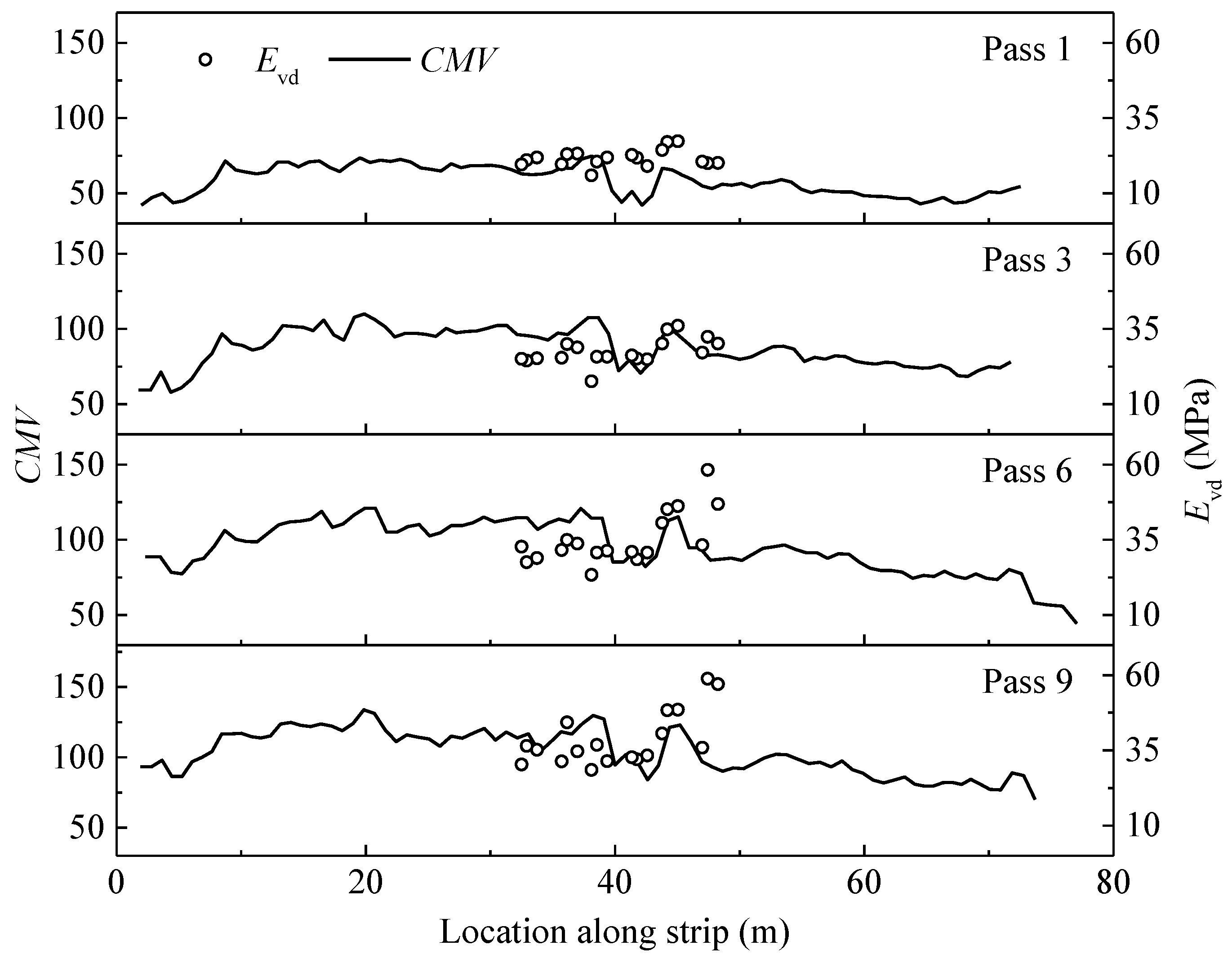

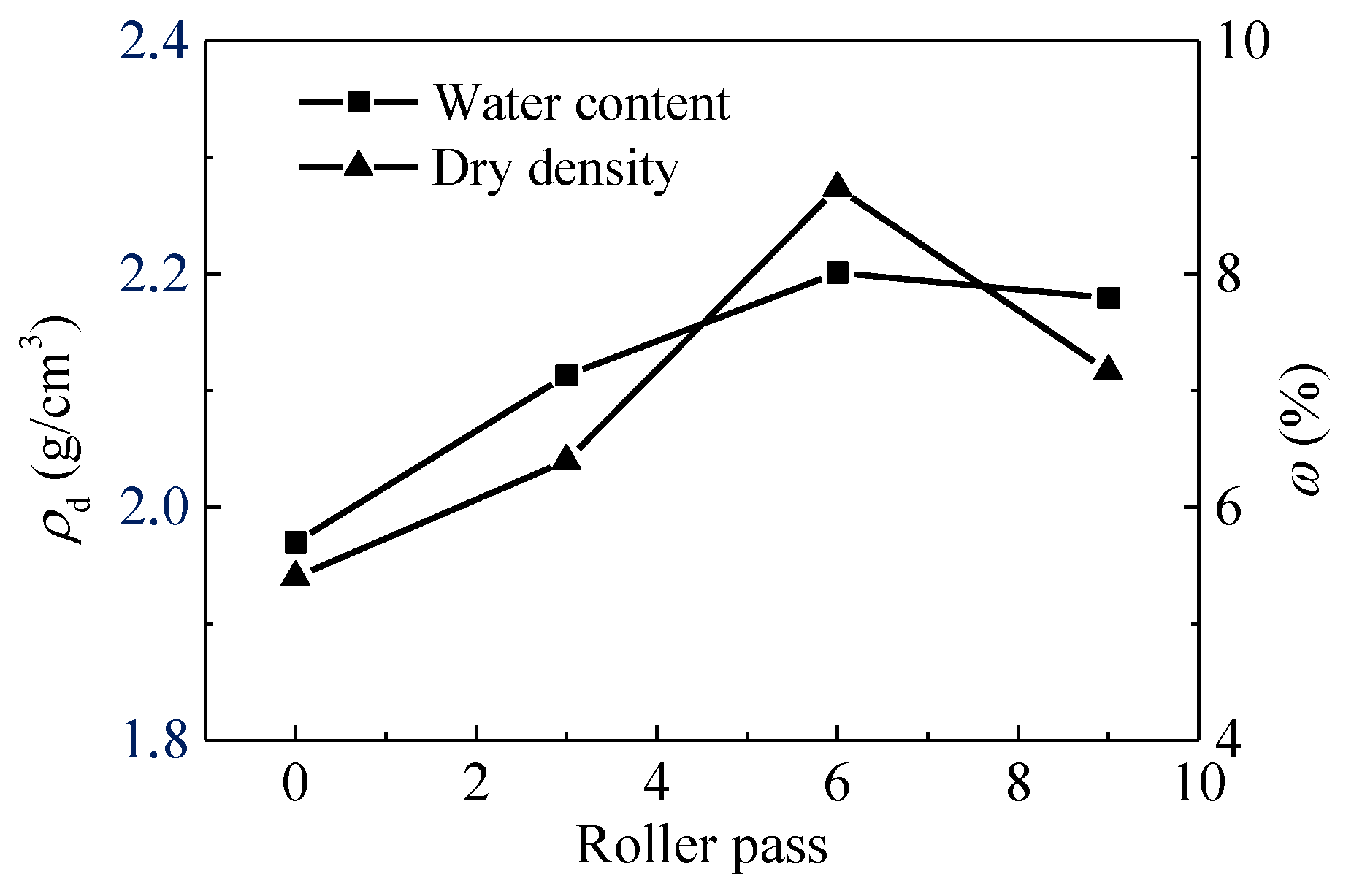

3.1. Practical Observations

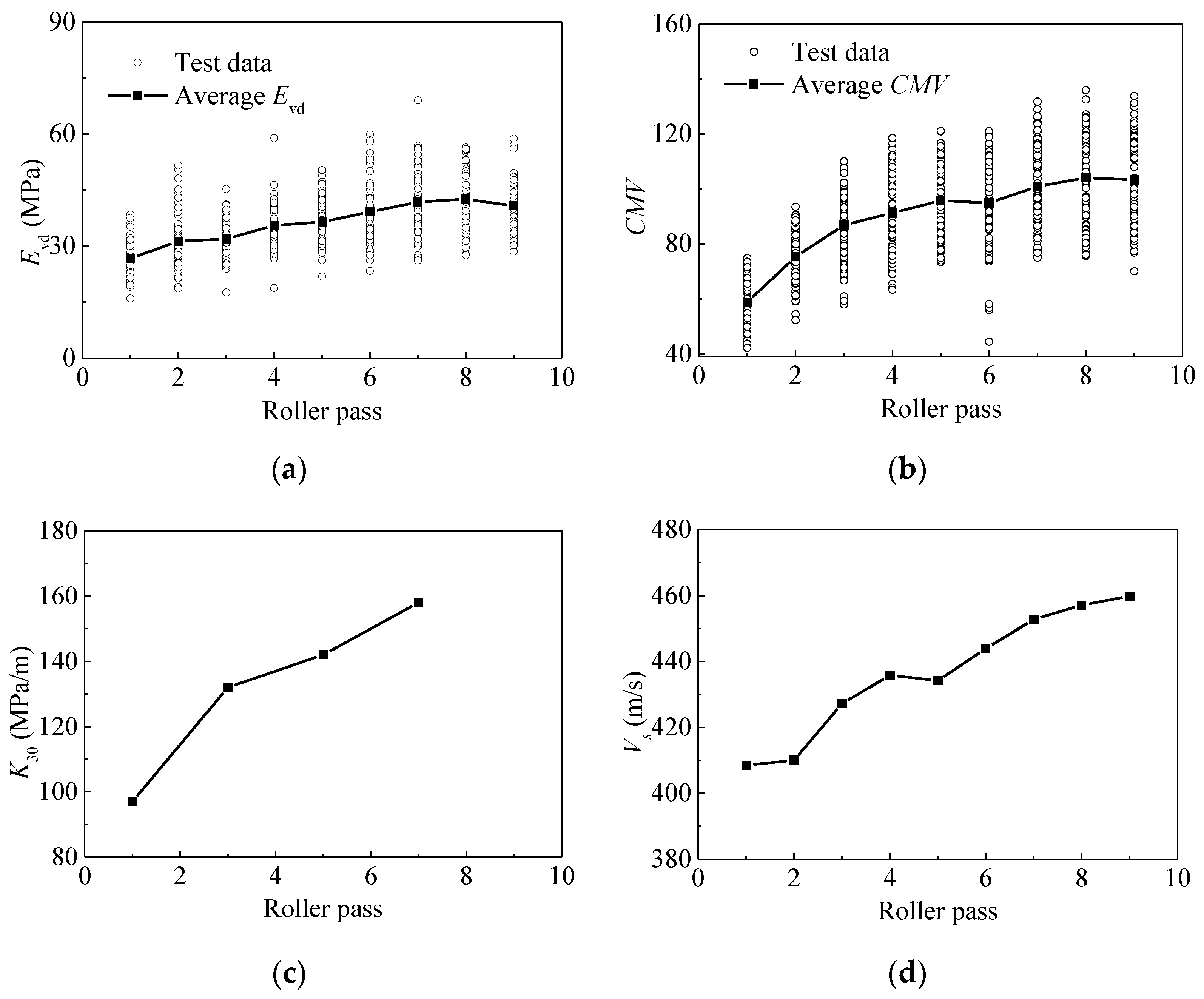

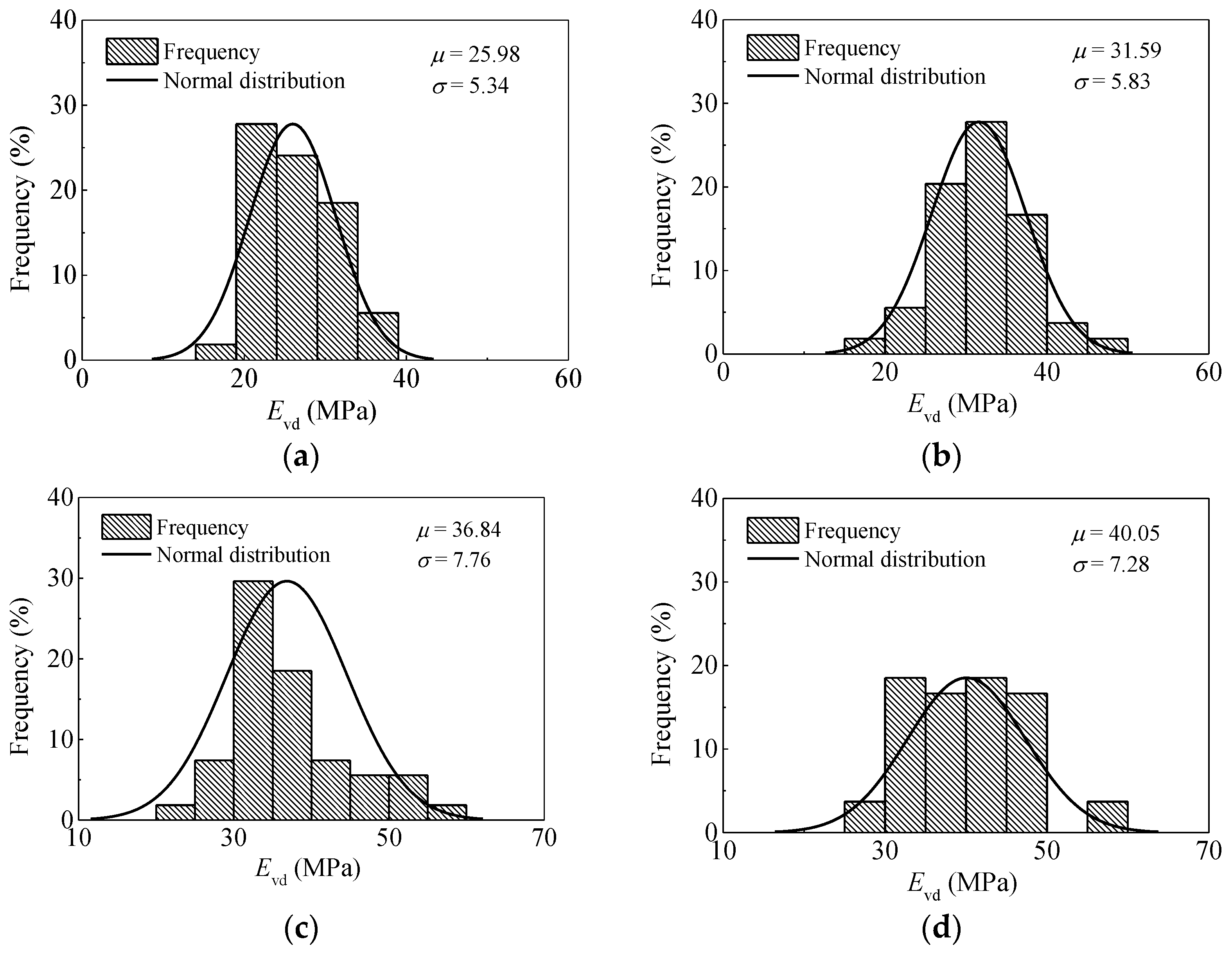

3.2. Statistical Analysis of Test Indexes

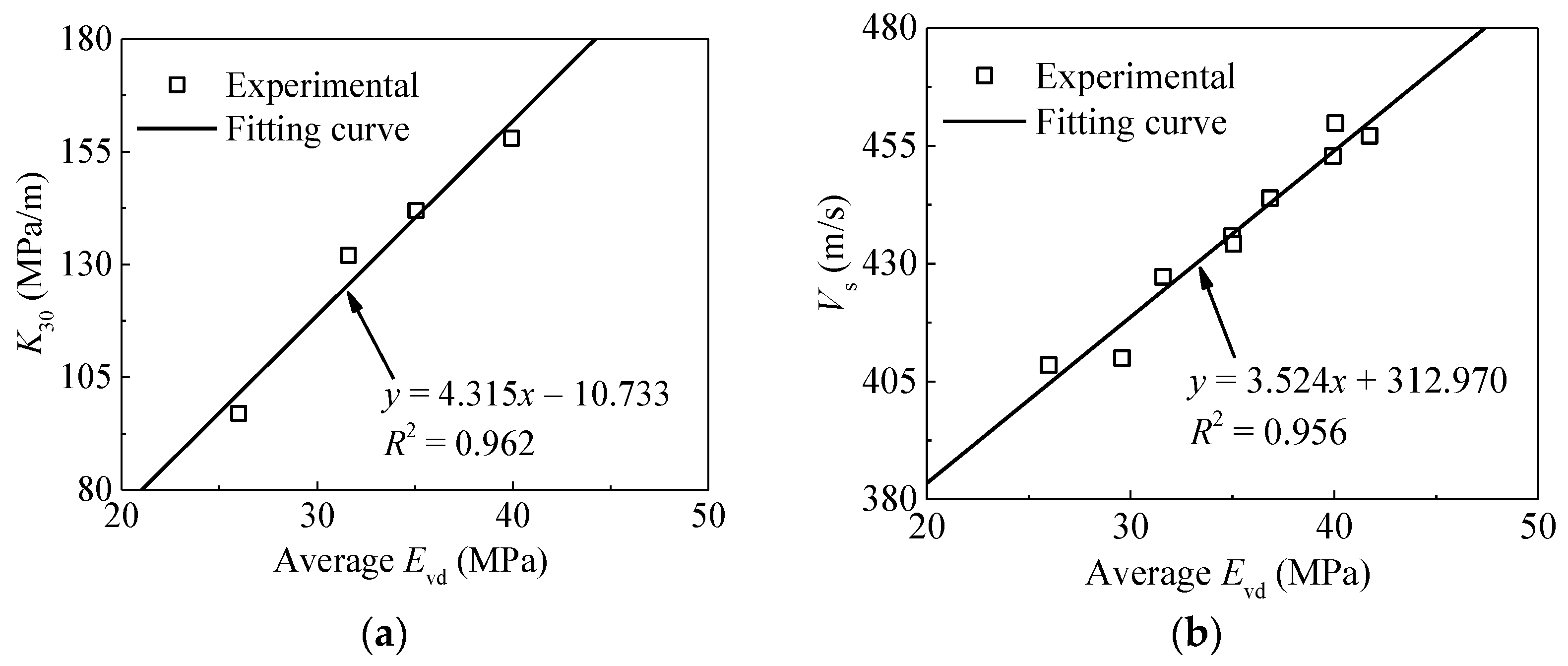

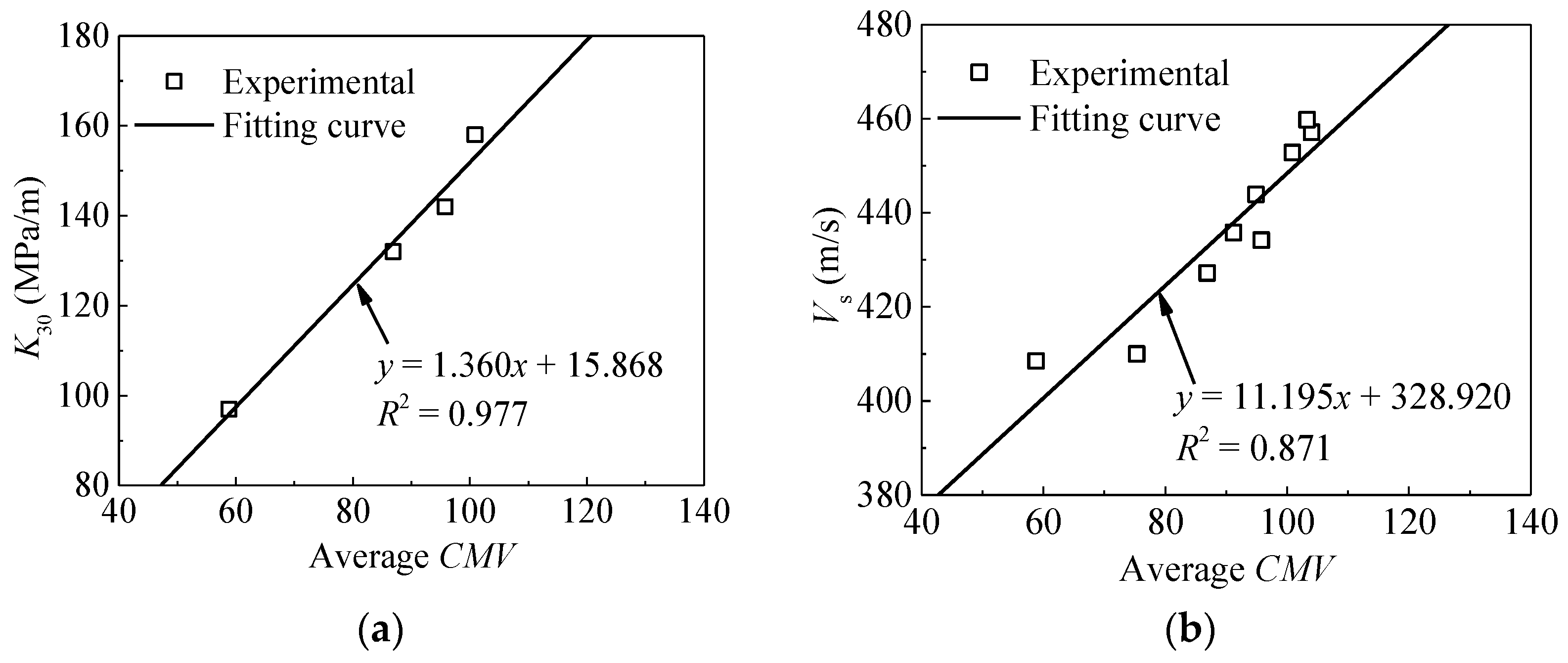

3.3. Relationships between Measured Parameters

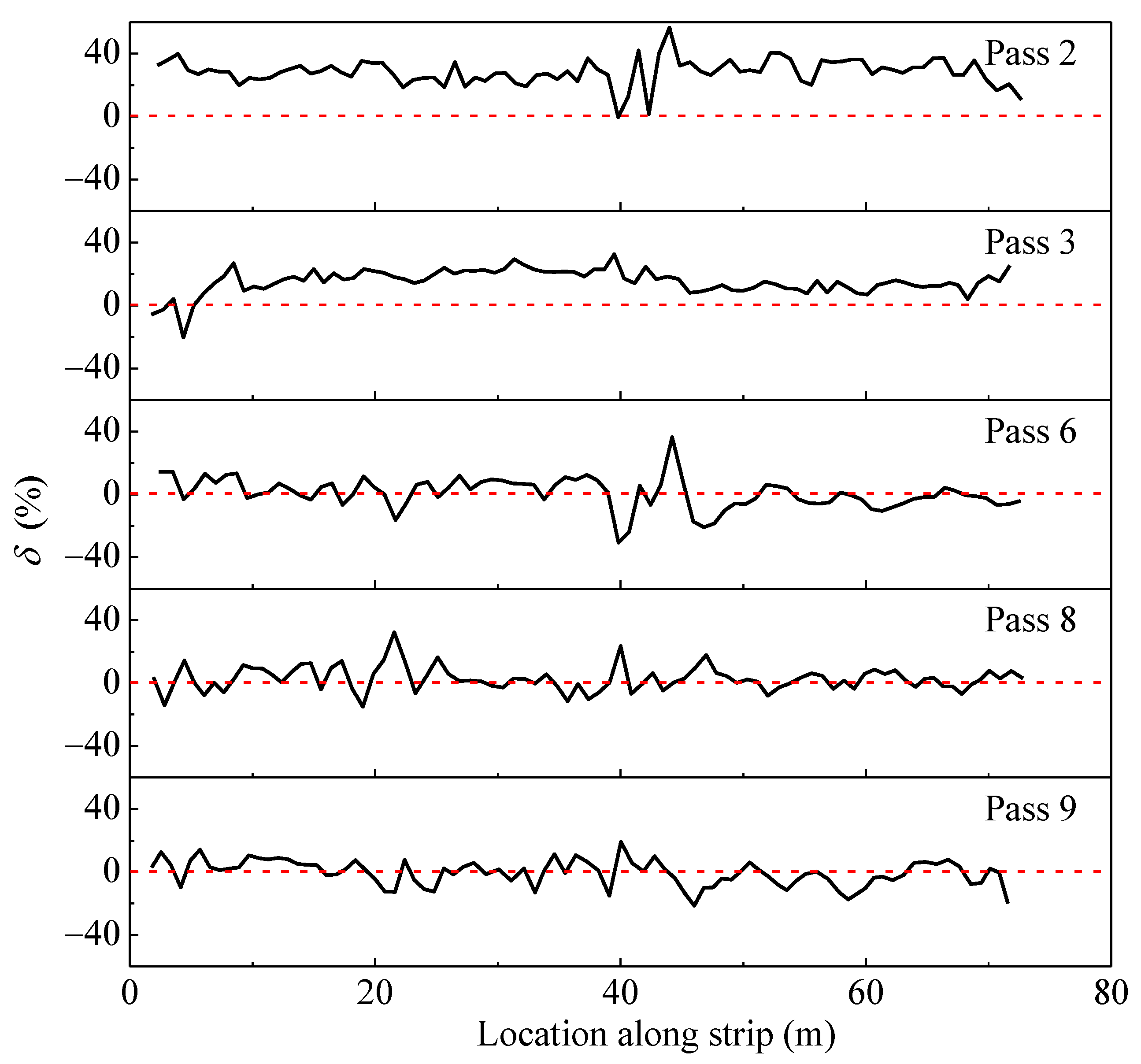

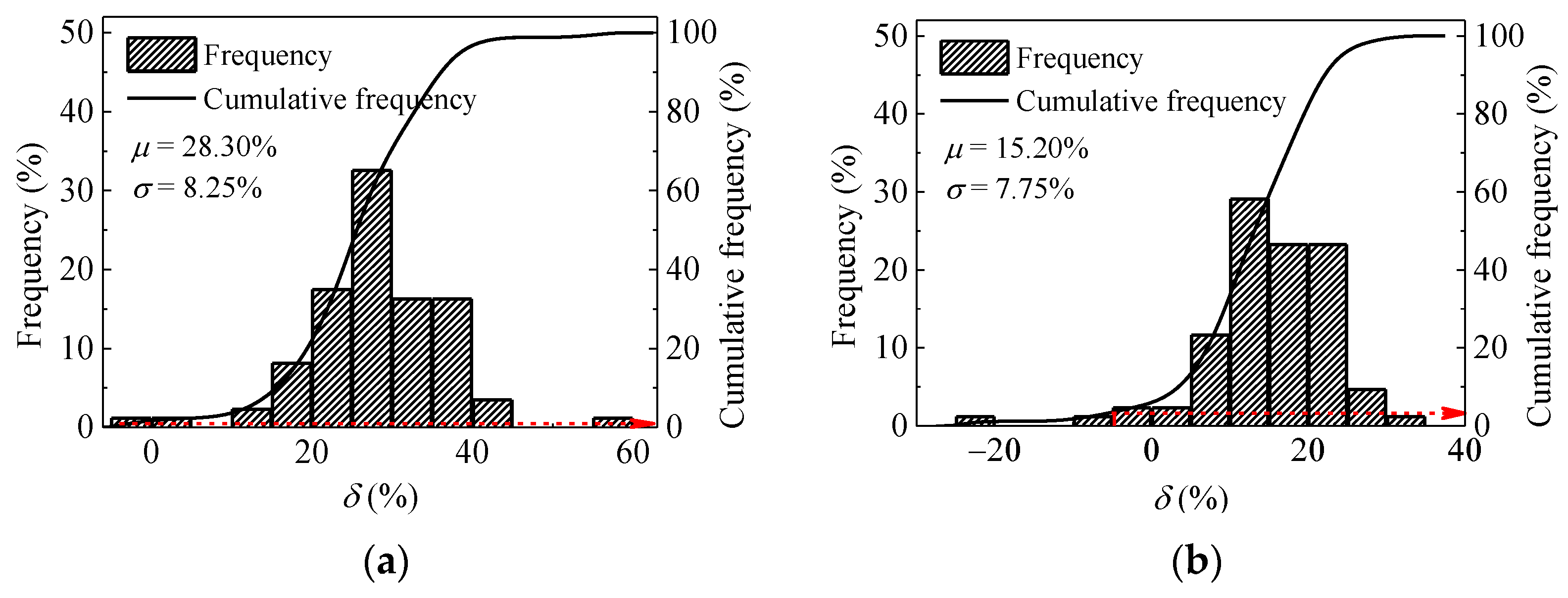

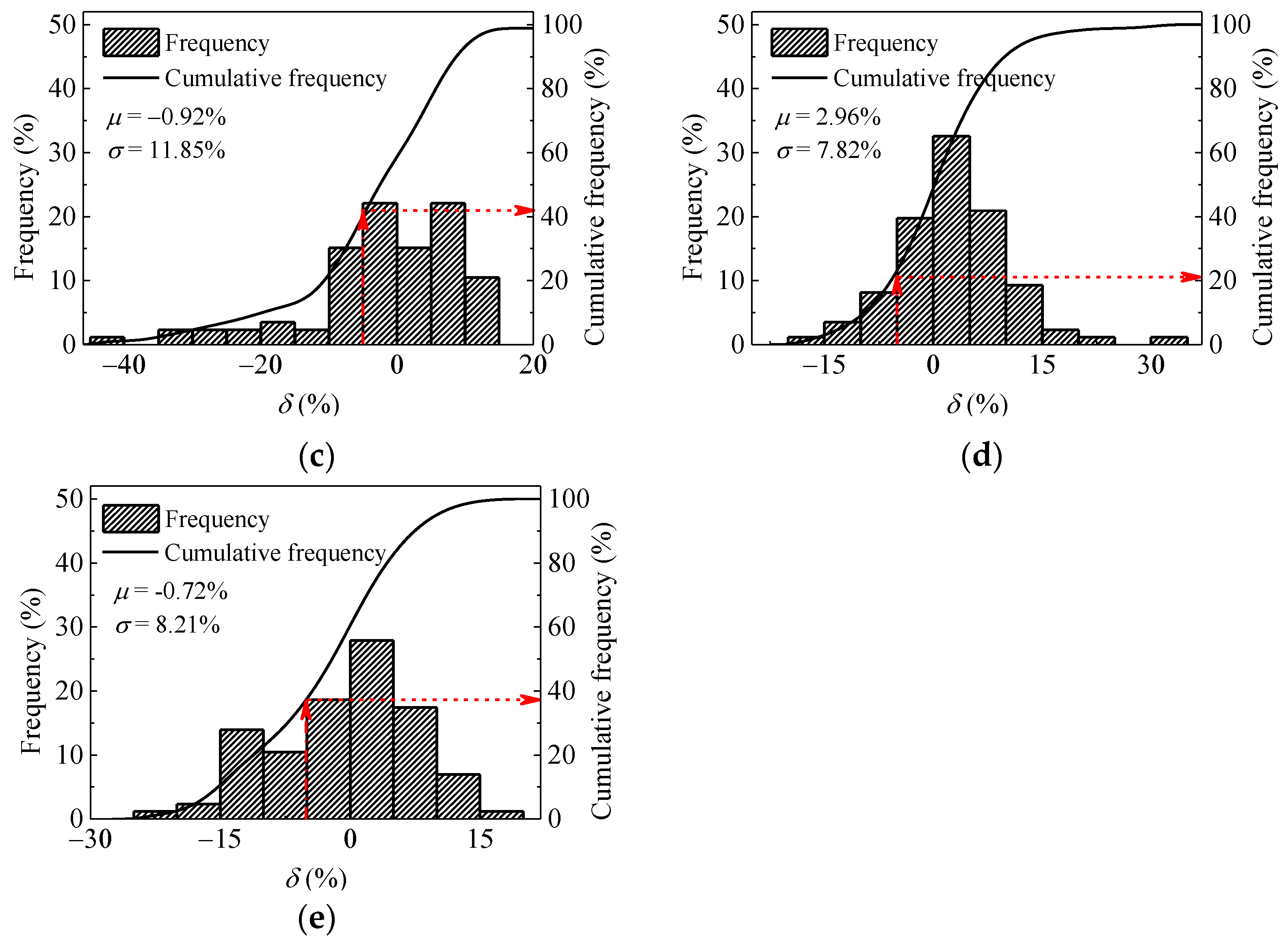

3.4. Compaction Stability

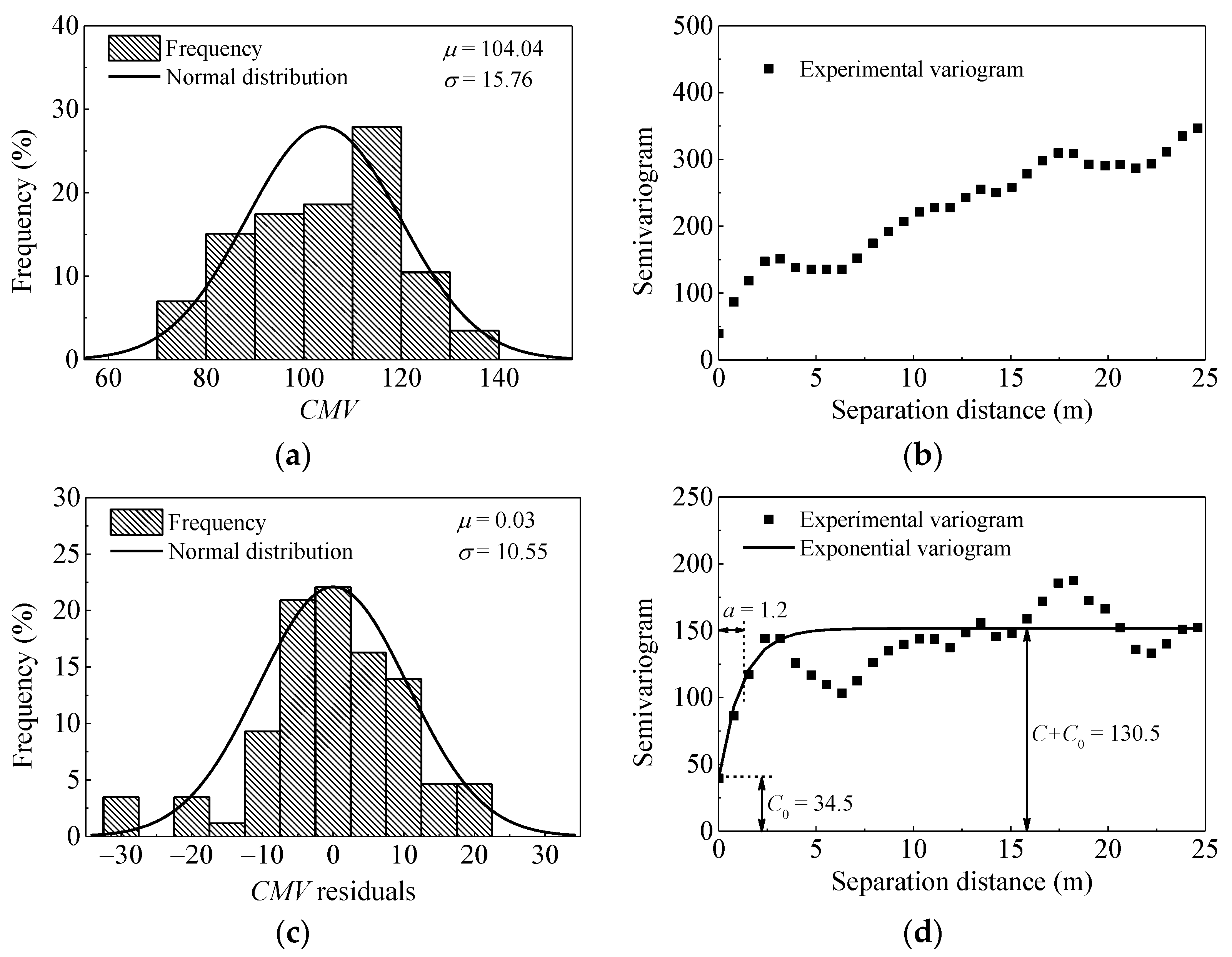

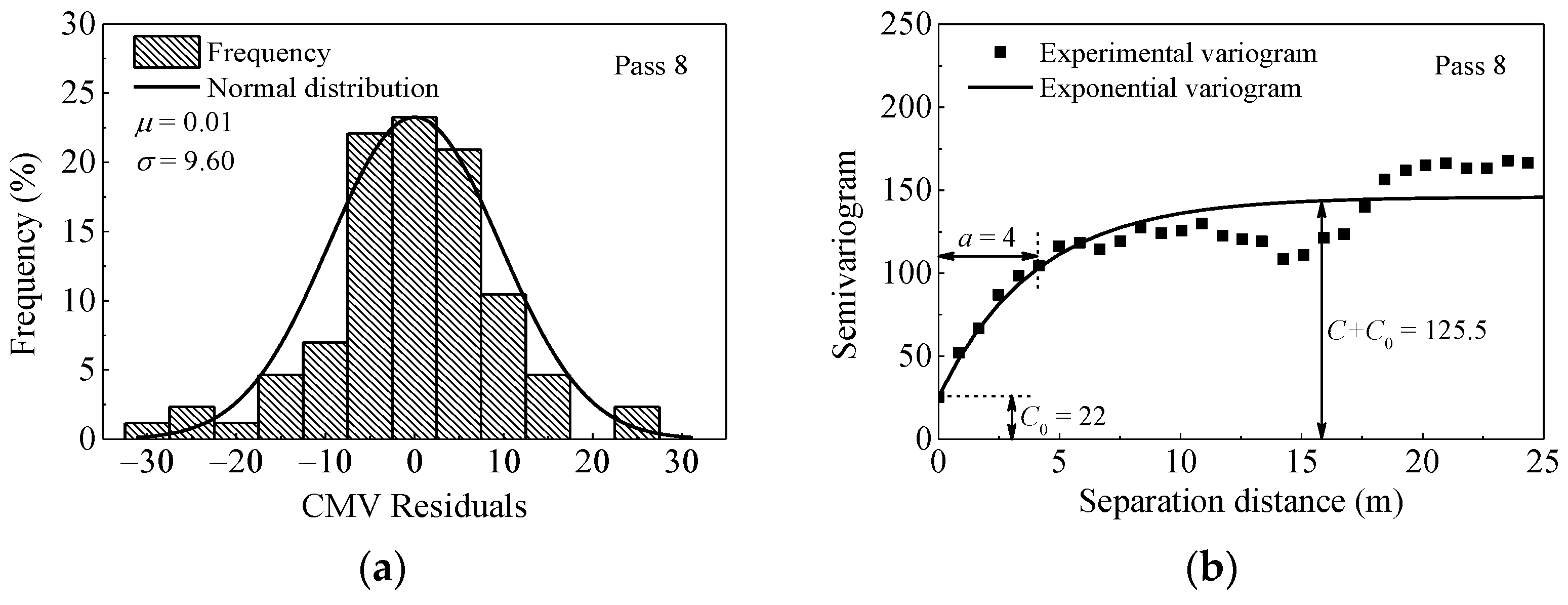

3.5. Spatial Uniformity of Compaction

4. Conclusions

- (1)

- The compaction trend is similar for both the traditional in situ and continuous compaction measurements. When the compaction number is up to a certain value (8th compaction in this study), a further increase in compaction effort could result in the decompaction of material. The dynamic deformation modulus Evd is observed to be more variable than CMV.

- (2)

- The correlations between CMV and in-situ compaction measurements are strong and stable enough by using statistical averaging analysis. A regression formula between CMV and Evd is established to determine the target value of CMV.

- (3)

- The stability analysis proposed in this study will help to quantify the percentage of areas with acceptable compaction and identify the optimum compaction number. The geostatistical analysis reflects the spatial uniformity of compaction. Based on these two criteria, the optimum compaction number (pass 8) is obtained in strip 1.

- (4)

- The stability analysis and spatial uniformity analysis could aid the contractor in identifying poorly compacted areas or areas with highly non-uniform conditions that need additional compaction or other modification. These methods can help to improve the quality of construction, enhance the performance of pavements, and reduce the cost of construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Głuchowski, A.; Šadzevičius, R.; Skominas, R.; Sas, W. Compacted Anthropogenic Materials as Backfill for Buried Pipes. Materials 2021, 14, 717. [Google Scholar] [CrossRef] [PubMed]

- Tang, K.; Mao, X.-S.; Wu, Q.; Zhang, J.-X.; Huang, W.-J. Influence of Temperature and Sodium Sulfate Content on the Compaction Characteristics of Cement-Stabilized Macadam Base Materials. Materials 2020, 13, 3610. [Google Scholar] [CrossRef] [PubMed]

- Cai, G.; Liu, S. Compaction and mechanical characteristics and stabilization mechanism of carbonated reactive MgO-stabilized silt. KSCE J. Civ. Eng. 2017, 21, 2641–2654. [Google Scholar] [CrossRef]

- Wu, E.; Zhu, J.; Guo, W.; Zhang, Z. Effect of Gradation on the Compactability of Coarse-Grained Soils. KSCE J. Civ. Eng. 2020, 24, 356–364. [Google Scholar] [CrossRef]

- Nie, Z.H. Comparison Experimental Study on Subgrade Compaction Quality Test Methods. Appl. Mech. Mater. 2011, 71–78, 4679–4684. [Google Scholar] [CrossRef]

- Cai, J.; Gao, Q.; Chun, H.; Cai, H.; Nantung, T. Spatial Autocorrelation in Soil Compaction and Its Impact on Earthwork Acceptance Testing. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 332–342. [Google Scholar] [CrossRef]

- Hua, T.; Yang, Z.; Yang, X.; Huang, H.; Yao, Q.; Wu, G.; Li, H. Assessment of geomaterial compaction using the pressure-wave fundamental frequency. Transp. Geotech. 2020, 22, 100318. [Google Scholar] [CrossRef]

- Zhu, X.; Bai, S.; Xue, G.; Yang, J.; Cai, Y.; Hu, W.; Jia, X.; Huang, B. Assessment of compaction quality of multi-layer pavement structure based on intelligent compaction technology. Constr. Build. Mater. 2018, 161, 316–329. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Chen, J.; Zhang, Y. Intelligent compaction practice and development: A bibliometric analysis. Eng. Constr. Arch. Manag. 2019, 27, 1213–1232. [Google Scholar] [CrossRef]

- Pistrol, J.; Villwock, S.; Völkel, W.; Kopf, F.; Adam, D. Continuous Compaction Control (CCC) with Oscillating Rollers. Procedia Eng. 2016, 143, 514–521. [Google Scholar] [CrossRef] [Green Version]

- Herrera, C.; Costa, P.A.; Caicedo, B. Numerical modelling and inverse analysis of continuous compaction control. Transp. Geotech. 2018, 17, 165–177. [Google Scholar] [CrossRef]

- Pistrol, J.; Adam, D. Fundamentals of roller integrated compaction control for oscillatory rollers and comparison with conventional testing methods. Transp. Geotech. 2018, 17, 75–84. [Google Scholar] [CrossRef]

- Anderegg, R.; Kaufmann, K. Intelligent Compaction with Vibratory Rollers: Feedback Control Systems in Automatic Compaction and Compaction Control. Transp. Res. Rec. J. Transp. Res. Board 2004, 1868, 124–134. [Google Scholar] [CrossRef]

- Vennapusa, P.K.R.; White, D.J.; Morris, M.D. Geostatistical Analysis for Spatially Referenced Roller-Integrated Compaction Measurements. J. Geotech. Geoenviron. Eng. 2010, 136, 813–822. [Google Scholar] [CrossRef] [Green Version]

- Hu, W.; Huang, B.; Shu, X.; Woods, M. Utilising intelligent compaction meter values to evaluate construction quality of asphalt pavement layers. Road Mater. Pavement Des. 2017, 18, 980–991. [Google Scholar] [CrossRef]

- Vennapusa, P.K.R.; White, D.J.; Schram, S. Roller-Integrated Compaction Monitoring for Hot-Mix Asphalt Overlay Construction. J. Transp. Eng. 2013, 139, 1164–1173. [Google Scholar] [CrossRef]

- Thompson, M.J.; Schmitt, R.L. Calibration of Roller-Integrated Machine Drive Power Measurements Using Soil Compaction Forecasting Model. Geotech. Test. J. 2013, 36, 626–636. [Google Scholar] [CrossRef]

- White, D.J.; Jaselskis, E.J.; Schaefer, V.R.; Cackler, E.T. Real-Time Compaction Monitoring in Cohesive Soils from Machine Response. Transp. Res. Rec. J. Transp. Res. Board 2005, 1936, 172–180. [Google Scholar] [CrossRef]

- Liu, D.; Li, Z.; Lian, Z. Compaction quality assessment of earth-rock dam materials using roller-integrated compaction monitoring technology. Autom. Constr. 2014, 44, 234–246. [Google Scholar] [CrossRef]

- Liu, D.; Lin, M.; Li, S. Real-Time Quality Monitoring and Control of Highway Compaction. Autom. Constr. 2016, 62, 114–123. [Google Scholar] [CrossRef]

- White, D.J.; Thompson, M.J.; Vennapusa, P.; Siekmeier, J. Implementing Intelligent Compaction Specification on Minnesota TH-64. Transp. Res. Rec. J. Transp. Res. Board 2008, 2045, 1–9. [Google Scholar] [CrossRef]

- Cai, H.; Kuczek, T.; Dunston, P.S.; Li, S. Correlating Intelligent Compaction Data to In Situ Soil Compaction Quality Measurements. J. Constr. Eng. Manag. 2017, 143, 04017038. [Google Scholar] [CrossRef]

- Thompson, M.J.; White, D.J. Field Calibration and Spatial Analysis of Compaction-Monitoring Technology Measurements. Transp. Res. Rec. J. Transp. Res. Board 2007, 2004, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Chang, G.K.; Gallivan, V.L. Development of a systematic method for intelligent compaction data analysis and management. Constr. Build. Mater. 2012, 37, 470–480. [Google Scholar] [CrossRef]

- Xu, Q.; Chang, G.K. Evaluation of intelligent compaction for asphalt materials. Autom. Constr. 2013, 30, 104–112. [Google Scholar] [CrossRef]

- Grabe, J. Spatial variation of soil stiffness: Spectral density approach. Soil Dyn. Earthq. Eng. 1994, 13, 25–29. [Google Scholar] [CrossRef]

- Facas, N.W.; Mooney, M.A.; Furrer, R. Anisotropy in the Spatial Distribution of Roller-Measured Soil Stiffness. Int. J. Géoméch. 2010, 10, 129–135. [Google Scholar] [CrossRef]

- Elsamee, W.N.A. An Experimental Study on the Effect of Foundation Depth, Size and Shape on Subgrade Reaction of Cohessionless Soil. Engineering 2013, 05, 785–795. [Google Scholar] [CrossRef] [Green Version]

- Ryden, N.; Mooney, M.A. Analysis of surface waves from the light weight deflectometer. Soil Dyn. Earthq. Eng. 2009, 29, 1134–1142. [Google Scholar] [CrossRef]

- Park, C.S.; Park, I.B.; Mok, Y.J. Evaluation of resilient moduli for recycled crushed-rock-soil-mixtures using in-situ seismic techniques and large-scale resonant column tests. KSCE J. Civ. Eng. 2014, 19, 1647–1655. [Google Scholar] [CrossRef]

- Liu, X.; Qin, H.; Lan, H. On the relationship between soil strength and wave velocities of sandy loess subjected to freeze-thaw cycling. Soil Dyn. Earthq. Eng. 2020, 136, 106216. [Google Scholar] [CrossRef]

- Kim, K.; Chun, S. Finite element analysis to simulate the effect of impact rollers for estimating the influence depth of soil compaction. KSCE J. Civ. Eng. 2016, 20, 2692–2701. [Google Scholar] [CrossRef]

- White, D.J.; Thompson, M.J. Relationships between In Situ and Roller-Integrated Compaction Measurements for Granular Soils. J. Geotech. Geoenviron. Eng. 2008, 134, 1763–1770. [Google Scholar] [CrossRef]

- National Railway Administration of The People’s Republic of China. Code for Design of High Speed Railway; China Railway Publishing House: Beijing, China, 2015. [Google Scholar]

- Kumar, S.A.; Aldouri, R.; Nazarian, S.; Si, J. Accelerated assessment of quality of compacted geomaterials with intelligent compaction technology. Constr. Build. Mater. 2016, 113, 824–834. [Google Scholar] [CrossRef]

- Hu, W.; Shu, X.; Jia, X.; Huang, B. Geostatistical analysis of intelligent compaction measurements for asphalt pavement compaction. Autom. Constr. 2018, 89, 162–169. [Google Scholar] [CrossRef]

- Gringarten, E.; Deutsch, C.V. Teacher’s Aide Variogram Interpretation and Modeling. Math. Geol. 2001, 33, 507–534. [Google Scholar] [CrossRef]

| Pass No. | Evd | CMV | ||||

|---|---|---|---|---|---|---|

| Average Value (MPa) | Standard Deviation (MPa) | Variation Parameter COV (%) | Average Value | Standard Deviation | Variation Parameter COV (%) | |

| 1 | 25.98 | 5.34 | 20.55 | 58.80 | 9.72 | 16.53 |

| 2 | 29.58 | 6.10 | 20.62 | 75.42 | 9.56 | 12.68 |

| 3 | 31.59 | 5.83 | 18.46 | 86.88 | 12.76 | 14.69 |

| 4 | 34.99 | 6.97 | 19.92 | 91.18 | 14.60 | 16.01 |

| 5 | 35.05 | 6.22 | 17.75 | 95.78 | 13.21 | 13.79 |

| 6 | 36.84 | 7.76 | 21.06 | 94.90 | 16.85 | 17.76 |

| 7 | 39.93 | 8.86 | 22.19 | 100.88 | 14.97 | 14.84 |

| 8 | 41.73 | 7.87 | 18.86 | 104.04 | 15.76 | 15.15 |

| 9 | 40.05 | 7.28 | 18.18 | 103.28 | 15.98 | 15.47 |

| Pass No. | Mean Value, μ (%) | Standard Deviation, σ (%) | Acceptable Compaction Percentage (%) |

|---|---|---|---|

| 2 | 28.30 | 8.25 | 100 |

| 3 | 15.20 | 7.75 | 97.68 |

| 4 | 4.52 | 6.72 | 86.46 |

| 5 | 4.40 | 3.91 | 89.58 |

| 6 | −0.92 | 11.85 | 58.62 |

| 7 | 5.97 | 12.33 | 78.43 |

| 8 | 2.96 | 7.82 | 78.58 |

| 9 | −0.72 | 8.21 | 62.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Ye, Y.; Tang, L.; Cai, D.; Tian, S.; Ling, X. Experimental Study on the Compaction Characteristics and Evaluation Method of Coarse-Grained Materials for Subgrade. Materials 2021, 14, 6972. https://doi.org/10.3390/ma14226972

Li S, Ye Y, Tang L, Cai D, Tian S, Ling X. Experimental Study on the Compaction Characteristics and Evaluation Method of Coarse-Grained Materials for Subgrade. Materials. 2021; 14(22):6972. https://doi.org/10.3390/ma14226972

Chicago/Turabian StyleLi, Shanzhen, Yangsheng Ye, Liang Tang, Degou Cai, Shuang Tian, and Xianzhang Ling. 2021. "Experimental Study on the Compaction Characteristics and Evaluation Method of Coarse-Grained Materials for Subgrade" Materials 14, no. 22: 6972. https://doi.org/10.3390/ma14226972