Optical Losses of Frontal Layers in Superstrate CdS/CdTe Solar Cells Using OPAL2

Abstract

:1. Introduction

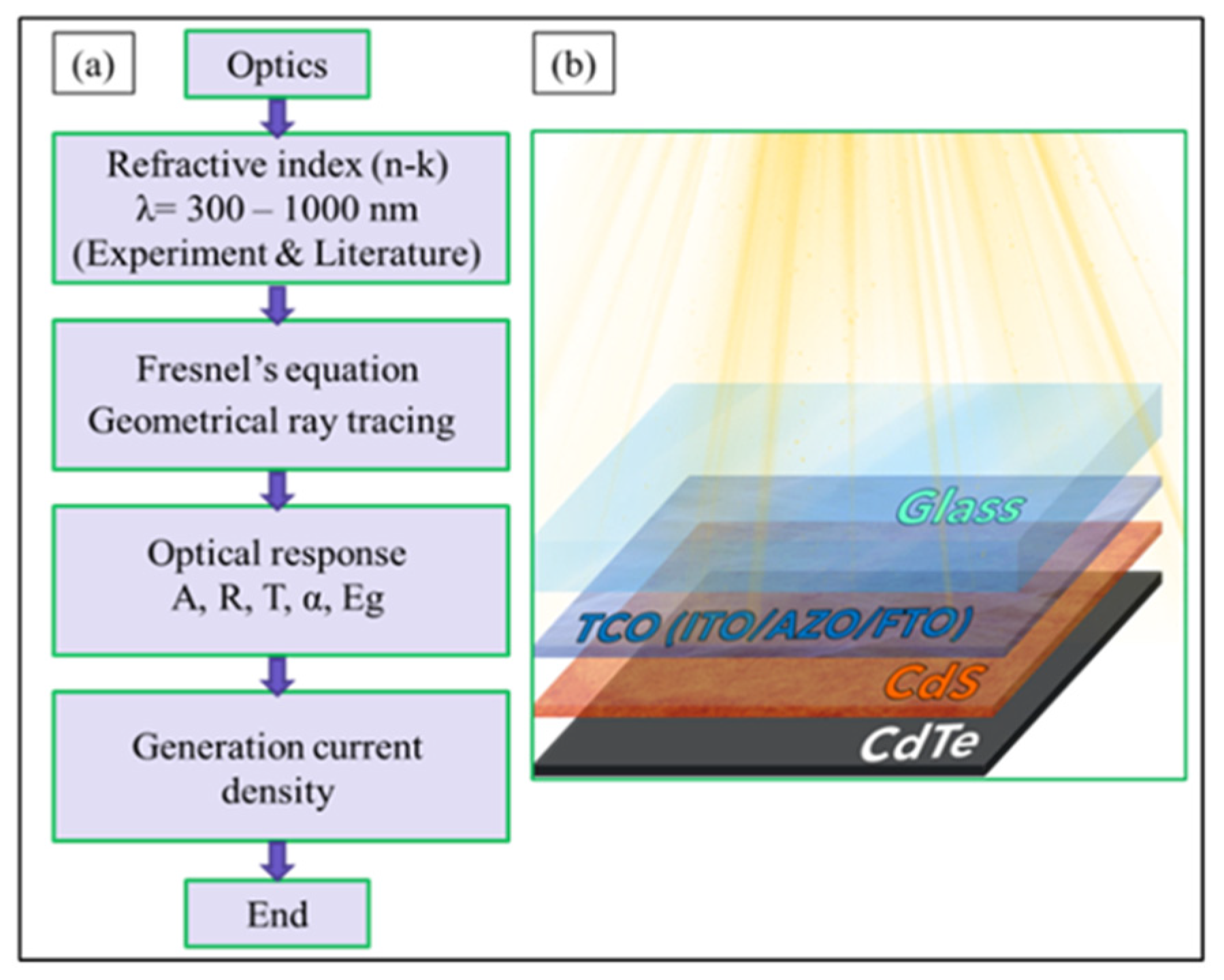

2. Simulation Method

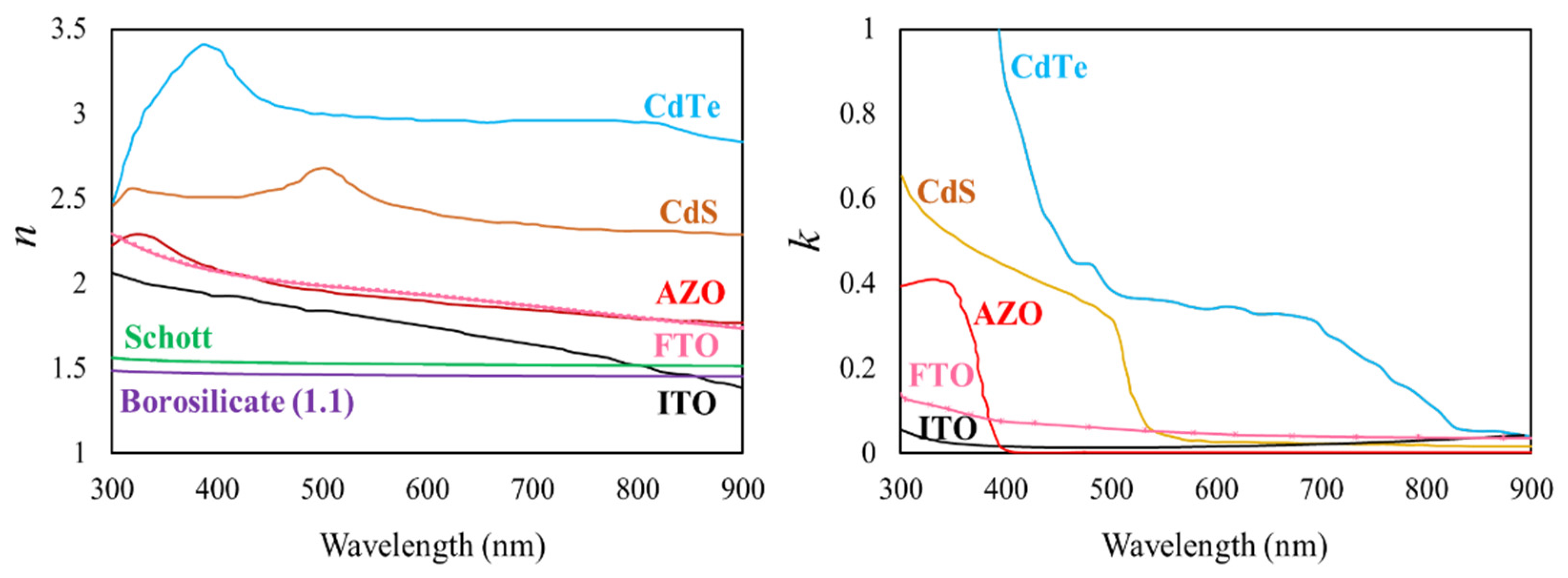

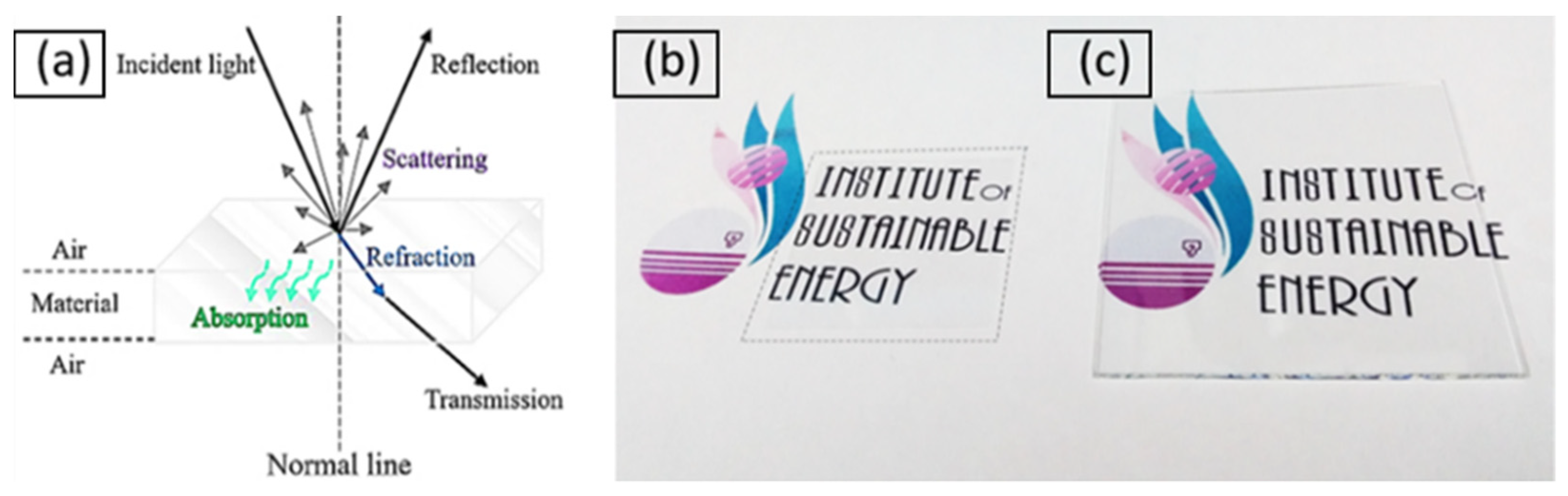

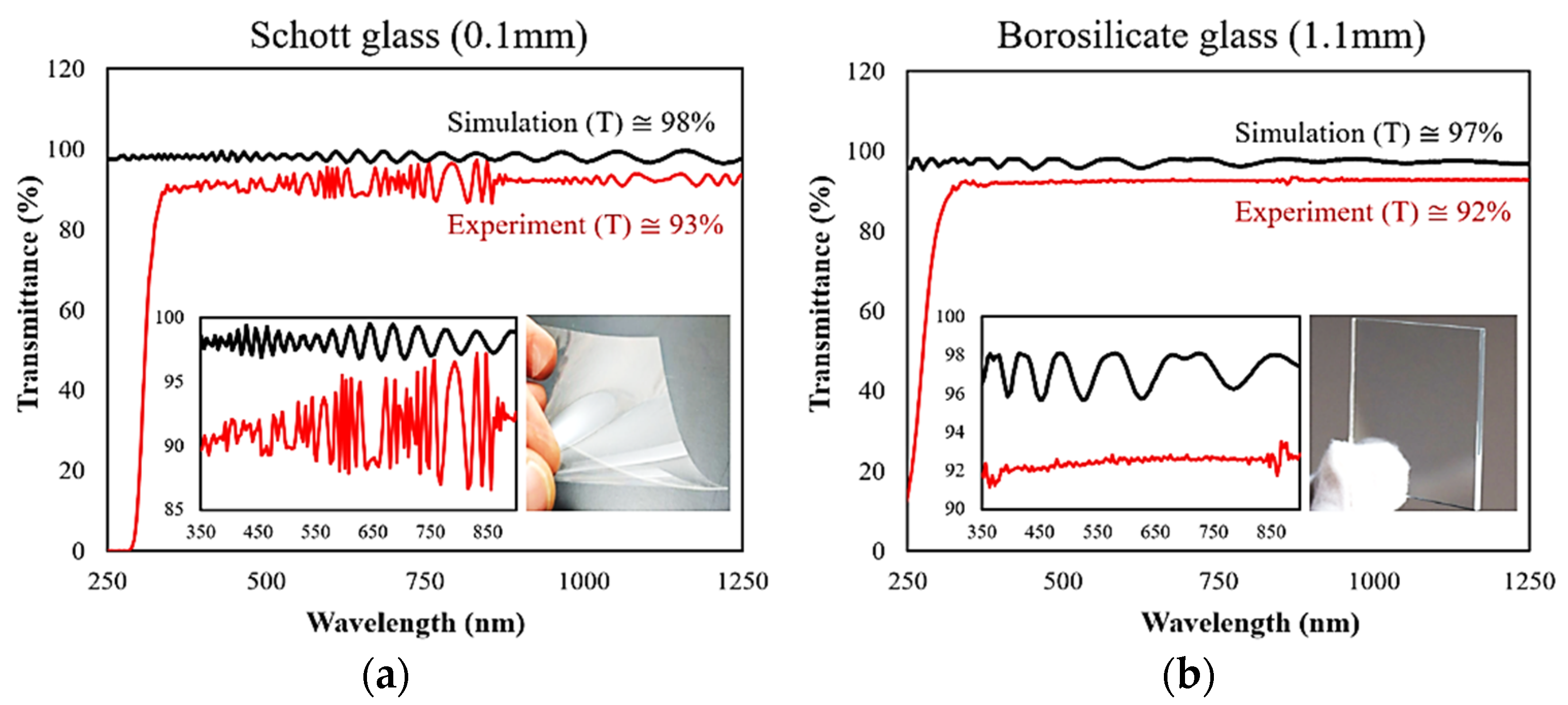

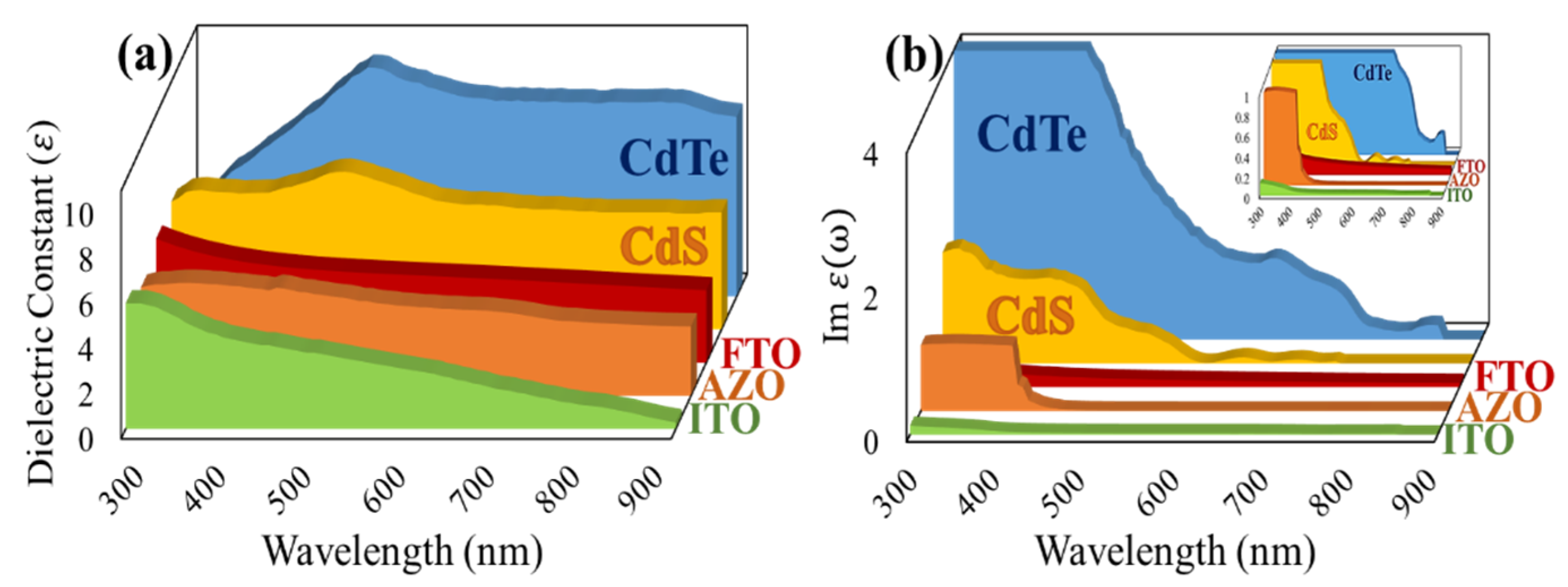

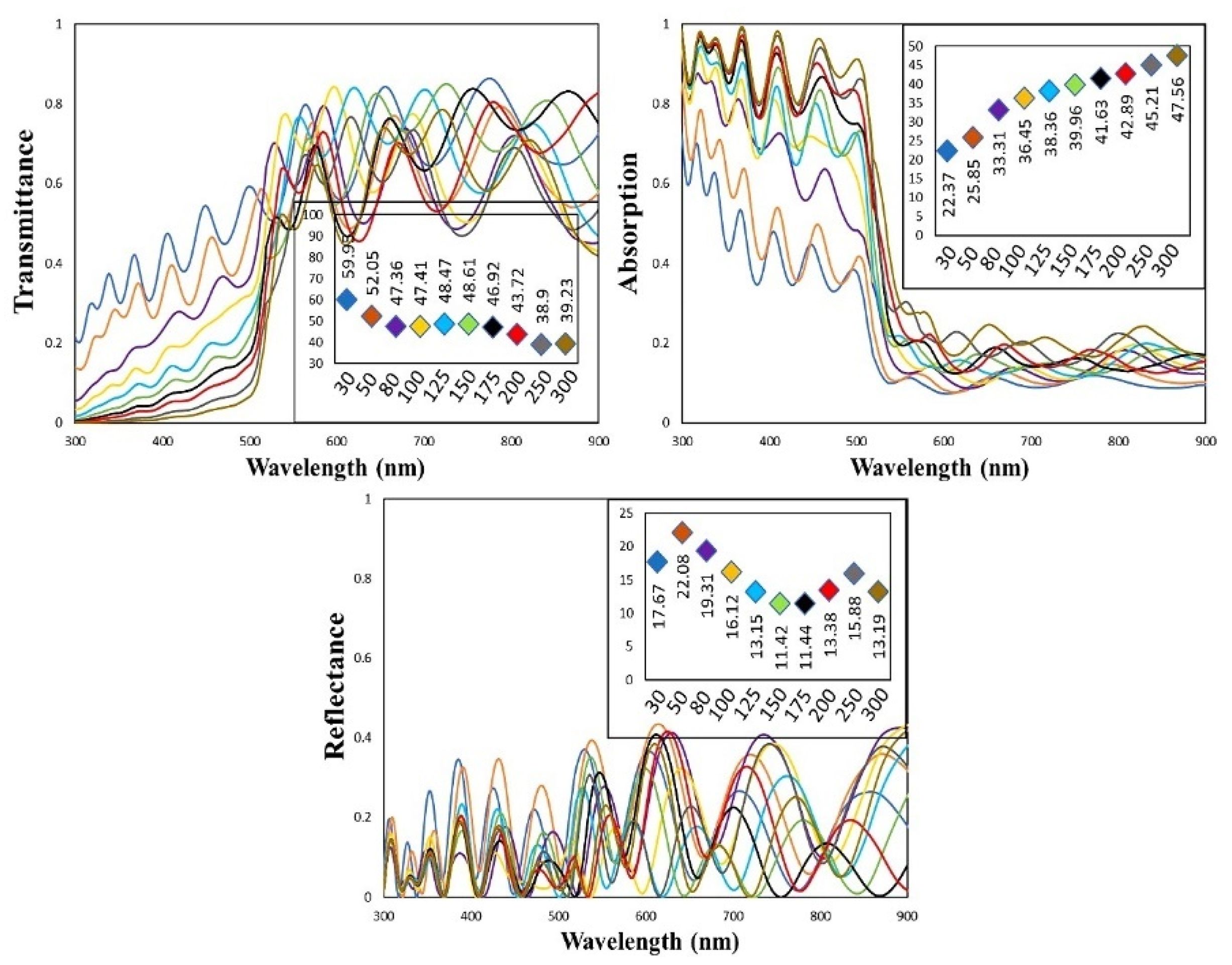

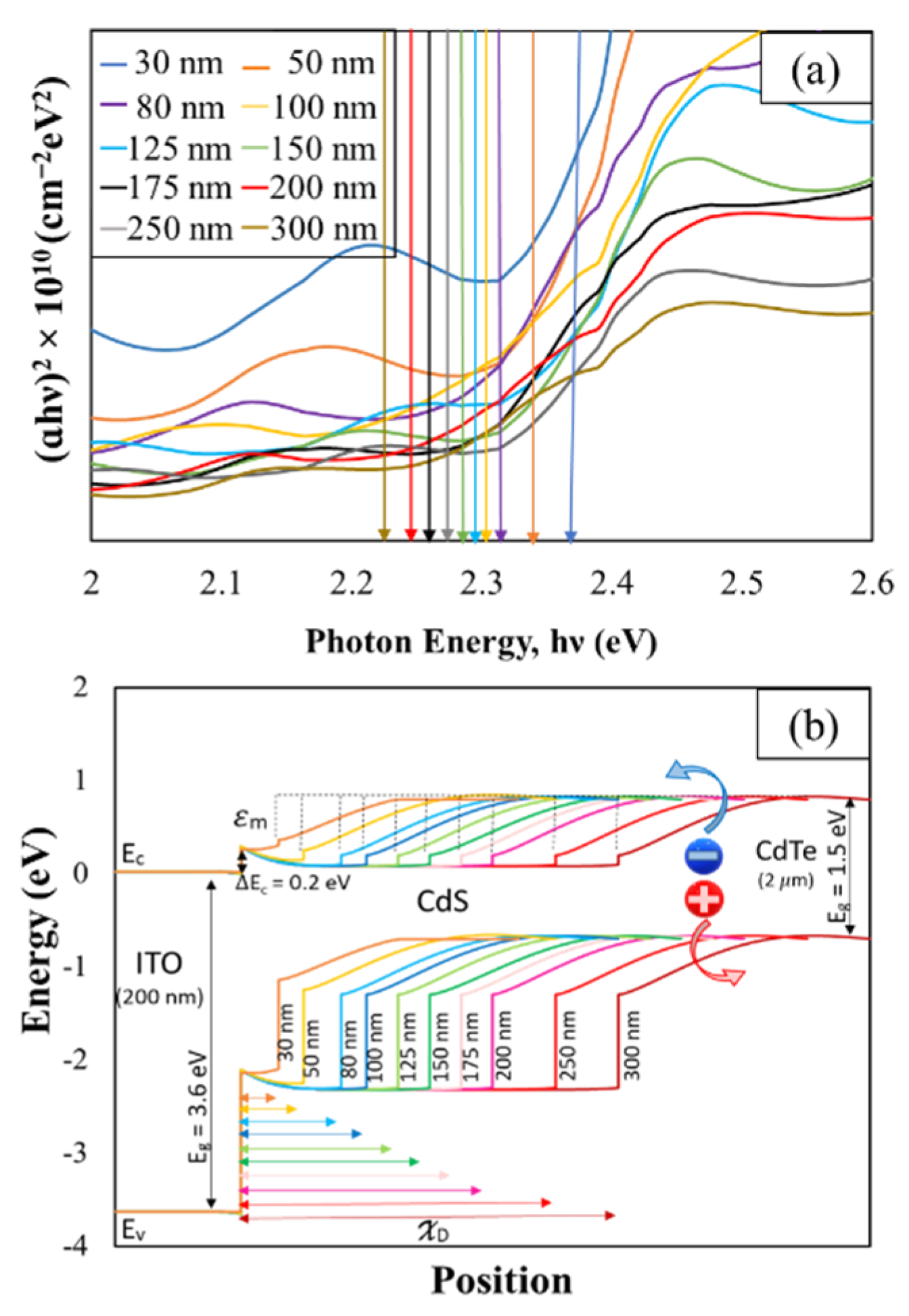

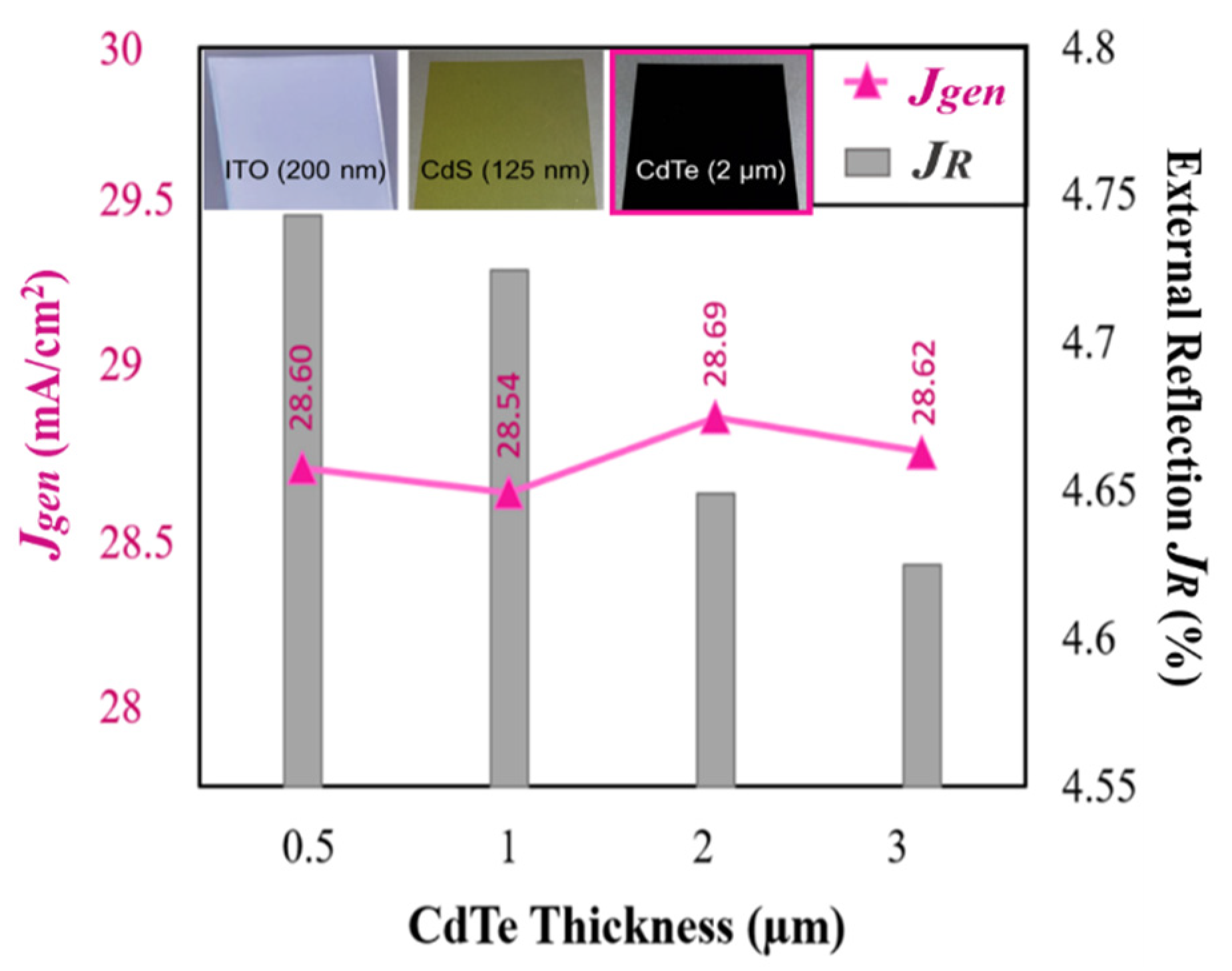

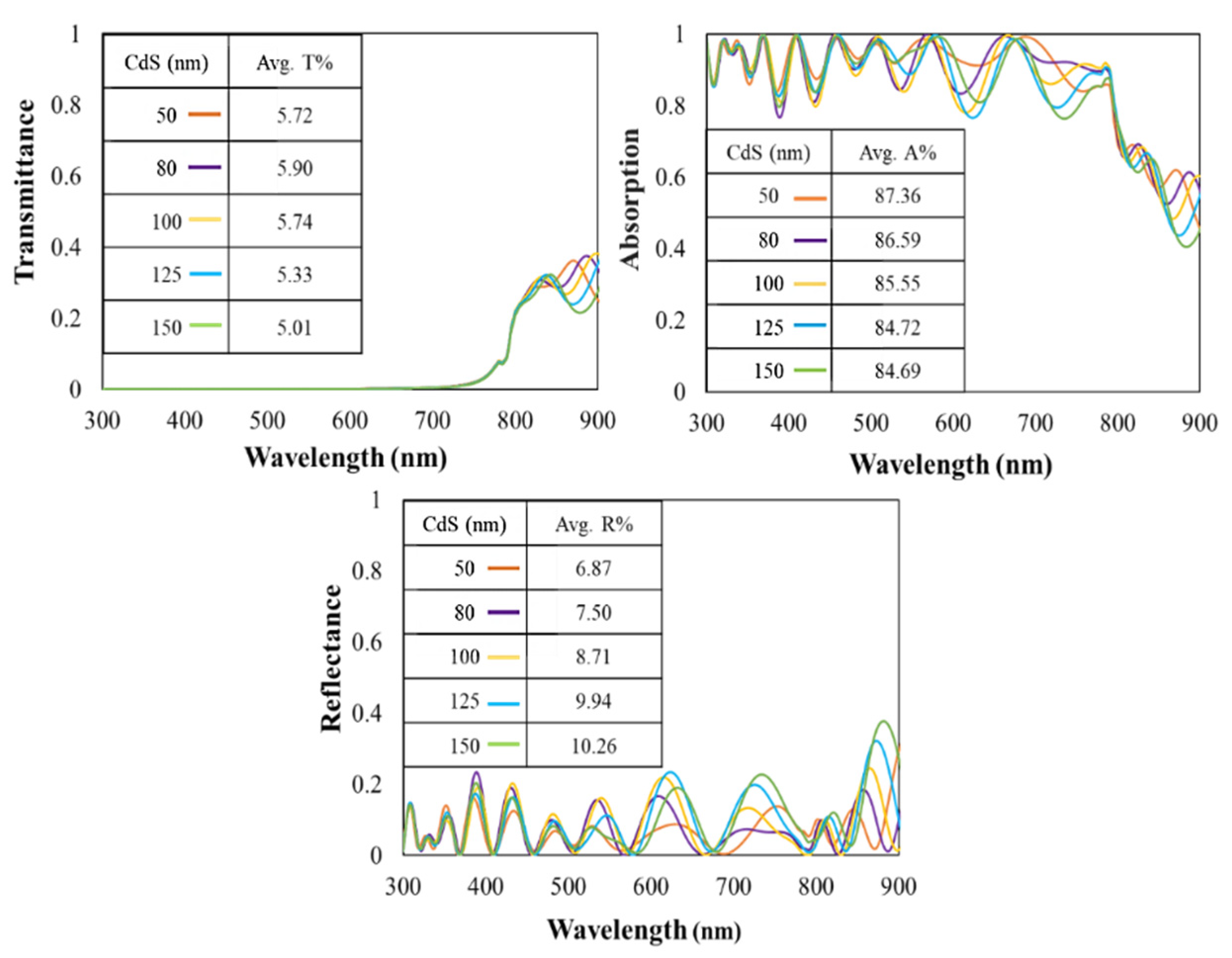

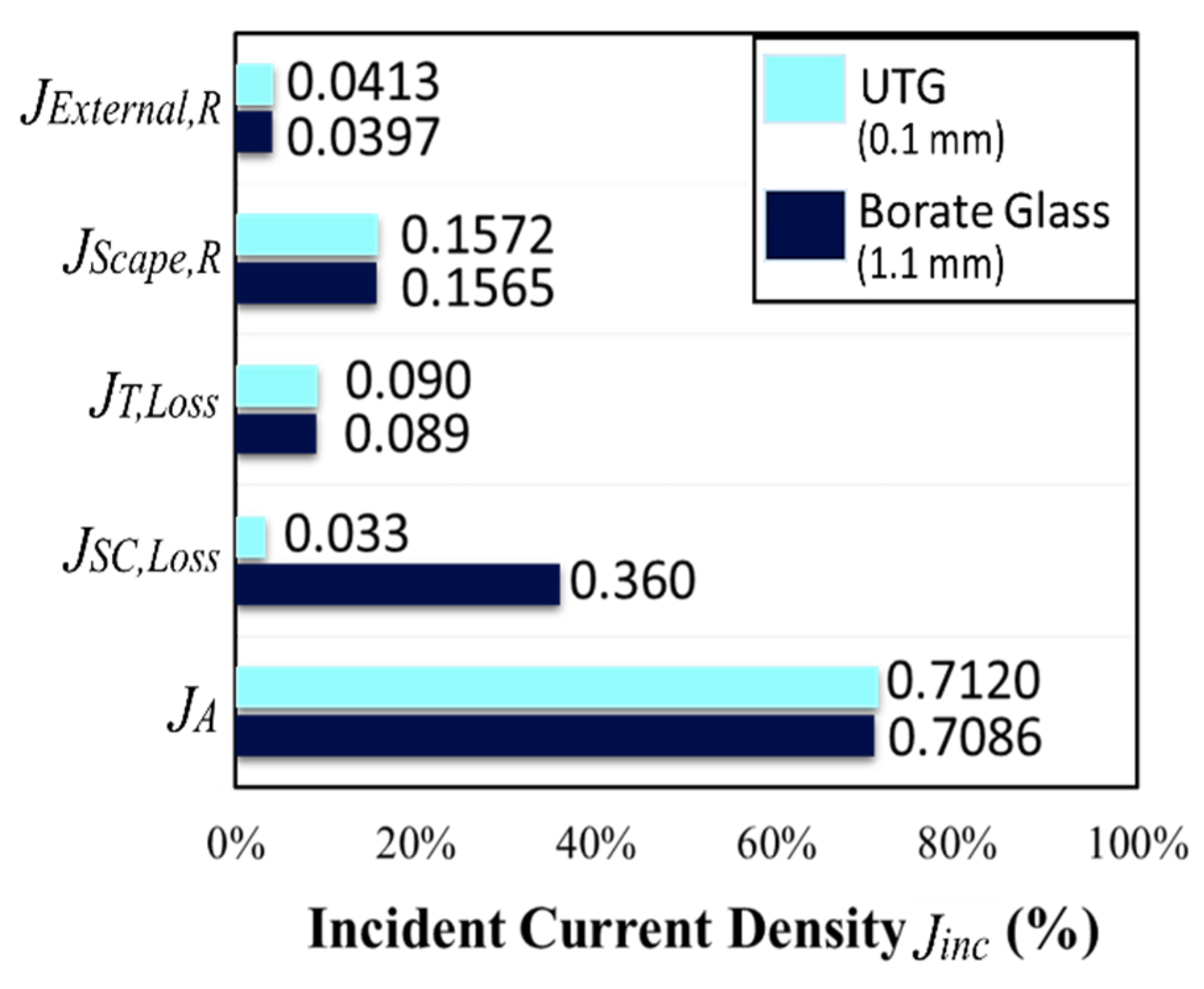

3. Modelling Procedure

- The simulation platform OPAL2 was implemented for the assessment of reflectance/absorption and transmission, optical spectrum characteristics of various product layers, respectively.

- A beam divides into a sequence of rays, such that the whole distance of the light window is filled by the number of rays.

- The software addresses discontinuities in the limits of the unit dynamically as the beam is split.

- Rays are also split into the emitted ray and the reflected ray at interfaces between the layers.

4. Modelling Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shah, A. Thin-Film Silicon Solar Cells; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Ojo, A.A.; Cranton, W.M.; Dharmadasa, I.M. Next Generation Multilayer Graded Bandgap Solar Cells; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Krc, J. Optical Modeling and Simulation of Thin-Film Photovoltaic Devices; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Daniel, M.M.; Matthew, O.R.; Charles, W.W.; Ali, A.; James, M.B.; Hasitha, P.M.; Wyatt, K.M.; John, M.W.; Mark, C.L.; Teresa, M.B.; et al. Evolution of oxygenated cadmium sulfide (CdS:O) during high-temperature CdTe solar cell fabrication. Sol. Energy Mater. Sol. Cells 2016, 157, 276–285. [Google Scholar]

- Bosio, A.; Pasini, S.; Romeo, N. The history of photovoltaics with emphasis on CdTe solar cells and modules. Coatings 2020, 10, 344. [Google Scholar] [CrossRef] [Green Version]

- Kranz, L.; Schmitt, R.; Gretener, C.; Perrenoud, J.; Pianezzi, F.; Uhl, A.R.; Keller, D.; Buecheler, S.; Tiwari, A.N. Progress towards 14% efficient CdTe solar cells in substrate configuration. In Proceedings of the 39th IEEE Photovoltaics Specialists Conference, Tampa, FL, USA, 16–21 June 2013; pp. 1644–1648. [Google Scholar]

- Mohamed, H.; Hadia, N. Theoretical analysis of ZnO and ZnO based alloys as front electrode in CdS/CdTe solar cells. Optics 2015, 126, 1976–1980. [Google Scholar] [CrossRef]

- Drăgan, F.; Nordseth, Ø.; Fara, L.; Dumitru, C.; Crăciunescu, D.; Muscurel, V.; Sterian, P. Optical modeling and simulation of tandem metal oxide solar cells. Ann. West Univ. Timisoara. Phys. Ser. 2018, 60, 56–66. [Google Scholar] [CrossRef] [Green Version]

- Rance, W.L.; Burst, J.M.; Meysing, D.M.; Wolden, C.A.; Reese, M.O.; Gessert, T.A.; Metzger, W.K.; Garner, S.; Cimo, P.; Barnes, T.M. 14%-efficient flexible CdTe solar cells on ultra-thin glass substrates. Appl. Phys. Lett. 2014, 104, 143903. [Google Scholar] [CrossRef]

- Salavei, A.; Menossi, D.; Piccinelli, F.; Kumar, A.; Mariotto, G.; Barbato, M.; Meneghini, M.; Meneghesso, G.; Di Mare, S.; Artegiani, E.; et al. Comparison of high efficiency flexible CdTe solar cells on different substrates at low temperature deposition. Sol. Energy 2016, 139, 13–18. [Google Scholar] [CrossRef]

- Hojo, J. Materials Chemistry of Ceramics; Springer Nature: Fukuoka, Singapore, 2019. [Google Scholar]

- Brusberg, L.; Henning, S.; Michael, T.; Herbert, R. Photonic system-in-package technologies using thin glass substrates. In Proceedings of the 11th Electronics Packaging Technology Conference, Singapore, 9–11 December 2009; pp. 930–935. [Google Scholar]

- Cvecek, K.; Johannes, H.; Isamu, M.; Michael, B. Dominique de, L.; Michael, S. On-line interferometric observation of thermomechanically induced refractive index changes during glass welding by ultra-short laser pulses. J. Laser Micro Nanoeng. 2018, 13, 301–308. [Google Scholar]

- Ikhmayies, S.J. Transparent conducting oxides for solar cell applications. In Mediterranean Green Buildings & Renewable Energy; Springer: Berlin/Heidelberg, Germany, 2017; pp. 899–907. [Google Scholar]

- Ferekides, C.S.; Mamazza, R.; Balasubramanian, U.; Morel, D.L. Transparent conductors and buffer layers for CdTe solar cells. Thin Solid Film. 2005, 480, 224–229. [Google Scholar] [CrossRef]

- Coutts, T.J.; Young, D.L.; Gessert, T.A. Modeling, characterization, and properties of transparent conducting oxides. In Handbook of Transparent Conductors; Springer: Boston, MA, USA, 2011. [Google Scholar]

- Ngamsinlapasathian, S.; Sreethawong, T.; Suzuki, Y.; Yoshikawa, S. Doubled layered ITO/SnO2 conducting glass for substrate of dye-sensitized solar cells. Sol. Energy Mater. Sol. Cells 2006, 90, 2129–2140. [Google Scholar] [CrossRef]

- Kumar, S.G.; Rao, K.R.S.K. Physics and chemistry of CdTe/CdS thin film heterojunction photovoltaic devices: Fundamental and critical aspects. Energy Environ. Sci. 2014, 7, 45–102. [Google Scholar] [CrossRef]

- Khusayfan, N.M.; El-Nahass, M.M. Study of Structure and electro-optical characteristics of indium tin oxide thin films. Adv. Condens. Matter Phys. 2013, 2013, 408182. [Google Scholar] [CrossRef] [Green Version]

- Parsianpour, E.; Raoufi, D.; Roostaei, M.; Sohrabi, B.; Samavat, F. Characterization and structural property of indium tin oxide thin films. Adv. Mater. Phys. Chem. 2017, 7, 42–57. [Google Scholar] [CrossRef] [Green Version]

- Kurdesau, F.; Khripunov, G.; da Cunha, A.; Kaelin, M.; Tiwari, A. Comparative study of ITO layers deposited by DC and RF magnetron sputtering at room temperature. J. Non Cryst. Solids 2006, 352, 1466–1470. [Google Scholar] [CrossRef]

- John, K.A.; Philip, R.R.; Sajan, P.; Manju, T. In situ crystallization of highly conducting and transparent ITO thin films deposited by RF magnetron sputtering. Vacuum 2016, 132, 91–94. [Google Scholar] [CrossRef]

- Gordon, R.G. Criteria for choosing transparent conductors. MRS Bull. 2000, 25, 52–57. [Google Scholar] [CrossRef] [Green Version]

- Natarajan, P.; Vaiude, D.; Rao, B. Development/study of thin films for electroluminescent flat panel display. Microelectron. Int. 1992, 9, 28–32. [Google Scholar] [CrossRef]

- Junghähnel, M.; Weller, S.; Gebel, T. P-65: Advanced processing of ITO and IZO thin films on flexible glass. In Proceedings of the SID Symposium Digest of Technical Papers, San Jose, CA, USA, 21 May–5 June 2015; pp. 1378–1381. [Google Scholar]

- Yoo, J.-H.; Matthews, M.; Ramsey, P.; Barrios, A.C.; Carter, A.; Lange, A.; Bude, J.; Elhadj, S. Thermally ruggedized ITO transparent electrode films for high power optoelectronics. Opt. Express 2017, 25, 25533–25545. [Google Scholar] [CrossRef]

- Winkler, M.T.; Wei, W.; Gunawan, O.; Hovel, H.J.; Todorov, T.K.; Mitzi, D.B. Optical designs that improve the efficiency of Cu2 ZnSn(S,Se)4 solar cells. Energy Environ. Sci. 2014, 7, 1029–1036. [Google Scholar] [CrossRef]

- Benoy, M.; Mohammed, E.; Babu, M.S.; Binu, P.; Pradeep, B. Thickness dependence of the properties of indium tin oxide (ITO) FILMS prepared by activated reactive evaporation. Braz. J. Phys. 2009, 39, 629–632. [Google Scholar] [CrossRef] [Green Version]

- Cozza, D.; Ruiz, C.M.; Duché, D.; Giraldo, S.; Saucedo, E.; Simon, J.J.; Escoubas, L. Optical modeling and optimizations of Cu2ZnSnSe4 solar cells using the modified transfer matrix method. Opt. Express 2016, 24, A1201–A1209. [Google Scholar] [CrossRef]

- Cozza, D. Modeling and Physical Studies of Kesterite Solar Cells. Ph.D. Thesis, Aix Marseille, Marseille, France, 2016. [Google Scholar]

- McIntosh, K.R.; Abbott, M.D.; Sudbury, B.A.; Manzoor, S.; Yu, Z.J.; Mehdi, L.; Shi, J.; Holman, Z.C. Absorption in each layer of a silicon heterojunction solar cell. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 1322–1328. [Google Scholar]

- Holman, Z.C.; Filipič, M.; Lipovšek, B.; De Wolf, S.; Smole, F.; Topic, M.; Ballif, C. Parasitic absorption in the rear reflector of a silicon solar cell: Simulation and measurement of the sub-bandgap reflectance for common dielectric/metal reflectors. Sol. Energy Mater. Sol. Cells 2014, 120, 426–430. [Google Scholar] [CrossRef]

- Barraud, L.; Holman, Z.C.; Badel, N.; Reiss, P.; Descoeudres, A.; Battaglia, C.; De Wolf, S.; Ballif, C. Hydrogen-doped indium oxide/indium tin oxide bilayers for high-efficiency silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 2013, 115, 151–156. [Google Scholar] [CrossRef] [Green Version]

- Sabory-Garcia, R.A.; Leal-Cruz, A.L.; Vera-Marquina, A.; Garcia-Delgado, L.A.; Garcia-Juarez, A.; Rojas-Hernandez, A.G. modeling and analytical study for efficiency improvement for thin film solar cells based on CdS/PbS, CdS/CdTe, AND CdS/CdSe. Chalcogenide Lett. 2018, 15, 625–638. [Google Scholar]

- McIntosh, K.R.; Baker-Finch, S.C. OPAL 2: Rapid optical simulation of silicon solar cells. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 265–271. [Google Scholar]

- Valencia, H.; Moreno, L.; Ardila, A. Structural, electrical and optical analysis of ITO thin films prepared by sol–gel. Microelectron. J. 2008, 39, 1356–1357. [Google Scholar] [CrossRef]

- Coutts, T.J.; Young, D.L.; Li, X. Characterization of transparent conducting oxides. MRS Bull. 2000, 25, 58–65. [Google Scholar] [CrossRef]

- Li, Q.H.; Zhu, D.; Liu, W.; Liu, Y.; Ma, X.C. Optical properties of Al-doped ZnO thin films by ellipsometry. Appl. Surf. Sci. 2008, 254, 2922–2926. [Google Scholar] [CrossRef]

- Winter, M.; Vogt, M.R.; Holst, H.; Altermatt, P.P. Combining structures on different length scales in ray tracing: Analysis of optical losses in solar cell modules. Opt. Quantum Electron. 2015, 47, 1373–1379. [Google Scholar] [CrossRef]

- Rashwan, O.; Newill, A.; Najan, N.K.K. Optimization of the light trapping nano structures in CdTe thin film solar cells. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 6 February 2020; pp. 911–914. [Google Scholar]

- Nykyruy, L.; Yavorskyi, R.; Zapukhlyak, Z.; Wisz, G.; Potera, P. Evaluation of CdS/CdTe thin film solar cells: SCAPS thickness simulation and analysis of optical properties. Opt. Mater. 2019, 92, 319–329. [Google Scholar] [CrossRef]

- Khan, M.R.; Wang, X.; Alam, M.A. Fundamentals of PV efficiency: Limits for light absorption. arXiv 2012, arXiv:1212:2879. [Google Scholar]

- Slauch, I.M.; Deceglie, M.G.; Silverman, T.J.; Ferry, V.E. Two-layer anti-reflection coatings with optimized sub-bandgap reflection for solar modules. In New Concepts in Solar and Thermal Radiation Conversion and Reliability; International Society for Optics and Photonics: San Diego, CA, USA, 2018; Volume 10759, p. 1075911. [Google Scholar]

- Li, Y.; Li, Z.; Lu, Z.; Cui, J.; Ouyang, Z.; Lennon, A. Optical modelling for multilayer and geometric light-trapping structures for crystalline silicon solar cells. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 1223–1226. [Google Scholar]

- Babkair, S.S.; Al-Twarqi, M.N.; Ansari, A.A. Optical characterization of CdTe films for solar cell applications. Karachi Univ. J. Sci. 2011, 39, 1–5. [Google Scholar]

- Kosyachenko, L.A. Possibilities to decrease the absorber thickness reducing optical and recombination losses in CdS/CdTe solar cells. Mater. Renew. Sustain. Energy 2013, 2, 14. [Google Scholar] [CrossRef] [Green Version]

- Fleischer, K.; Norton, E.; Mullarkey, D.; Caffrey, D.; Shvets, I.V. Quantifying the performance of P-type transparent conducting oxides by experimental methods. Materials 2017, 10, 1019. [Google Scholar] [CrossRef] [Green Version]

- Baker-Finch, S.C.; McIntosh, K.R. A freeware program for precise optical analysis of the front surface of a solar cell. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 1 November 2010; pp. 002184–002187. [Google Scholar]

- Sentaurus Device Monte Carlo/S-Band Version K-2015.06 User’s Manual, Synopsys, Inc., 2015. Available online: http://www.synopsys.com (accessed on 7 April 2021).

- Manzoor, S.; Zhengshan, J.Y.; Ali, A.; Ali, W.; Bush, K.A.; Palmstrom, A.F.; Bent, S.F.; McGehee, M.D.; Holman, Z.C. Improved light management in planar silicon and perovskite solar cells using PDMS scattering layer. Sol. Energy Mater. Sol. Cells 2017, 173, 59–65. [Google Scholar] [CrossRef]

- Product Variants of D263. Available online: https://www.schott.com/en-us/search?q=Product%20variants%20of%20D263 (accessed on 20 May 2020).

- Rangel-Cárdenas, J.; Sobral, H. Optical absorption enhancement in CdTe thin films by microstructuration of the silicon substrate. Materials 2017, 10, 607. [Google Scholar] [CrossRef] [Green Version]

- Khomyak, V.V.; Slyotov, O.M.; Chupyra, S.M. Optical and photoluminescence properties of ZnO1−xSex thin films. Appl. Opt. 2014, 53, B110–B115. [Google Scholar] [CrossRef] [PubMed]

- Arfsten, N. Sol-gel derived transparent IR-reflecting ITO semiconductor coatings and future applications. J. Non Cryst. Solids 1984, 63, 243–249. [Google Scholar] [CrossRef]

- Tehrani, F.S.; Fakhredin, M.; Tafreshi, M.J. The optical properties of silicon carbide thin films prepared by HWCVD from pure silane and methane under various total gas partial pressure. Mater. Res. Express 2019, 6, 086469. [Google Scholar] [CrossRef]

- Laureto, E.; da Silva, M.A.T.; Fernandes, R.V.; Duarte, J.L.; Dias, I.F.L.; Marletta, A. Thickness effects on the optical properties of layer-by-layer poly (p-phenylene vinylene) thin films and their use in energy-modulated structures. Curr. Appl. Phys. 2012, 12, 870–874. [Google Scholar] [CrossRef]

- Ikhmayies, S.J. Thickness Dependence of the optical parameters of spray-deposited SnO2:F thin films. In Proceedings of the TMS 2015 144th Annual Meeting & Exhibition, Orlando, FL, USA; 2015; pp. 593–600. [Google Scholar]

- Asl, H.Z.; Rozati, S.M. High-quality spray-deposited fluorine-doped tin oxide: Effect of film thickness on structural, morphological, electrical, and optical properties. Appl. Phys. A 2019, 125, 689. [Google Scholar] [CrossRef]

- Emam-Ismail, M.; El-Hagary, M.; Shaaban, E.; Al-Hedeib, A. Microstructure and optical studies of electron beam evaporated ZnSe1−xTex nanocrystalline thin films. J. Alloy. Compd. 2012, 532, 16–24. [Google Scholar] [CrossRef]

- Vasiliev, M.; Belotelov, V.; Alameh, K. Properties of ferrite garnet (Bi,Lu,Y)3(Fe,Ga)5O12 thin film materials prepared by RF magnetron sputtering. Nanomaterials 2018, 8, 355. [Google Scholar]

- Ghorannevis, Z.; Akbarnejad, E.; Ghoranneviss, M. Structural and morphological properties of ITO thin films grown by magnetron sputtering. J. Theor. Appl. Phys. 2015, 9, 285–290. [Google Scholar] [CrossRef] [Green Version]

- Han, X.; Mendes, S.B. Spectroelectrochemical properties of ultra-thin indium tin oxide films under electric potential modulation. Thin Solid Films 2016, 603, 230–237. [Google Scholar] [CrossRef] [Green Version]

- Rabeh, M.B.; Khedmi, N.; Fodha, M.A.; Kazari, M. The effect of thickness on optical band gap and N-type conductivity of CuInS2 thin films annealed in air atmosphere. Energy Procedia 2014, 44, 52–60. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.C.-J.; Lin, R.; Lin, Z.; Zhang, T.; Wu, L.; Jia, X.; Puthen-Veettil, B.; Perez-Wurfl, I.; Conibeer, G. Investigation into high temperature post-annealing of ZNO:Al as a prospective transparent conductive oxide window layer for superstrate silicon nanostructure solar cells. In Proceedings of the 1BV.7 New Materials and Concepts for Cells, Amsterdam, The Netherlands, 23 September 2014. [Google Scholar]

- Yan, X.; Mont, F.W.; Poxson, D.J.; Schubert, M.F.; Kim, J.K.; Cho, J.; Schubert, E.F. Refractive-index-matched indium–tin-oxide electrodes for liquid crystal displays. Jpn. J. Appl. Phys. 2009, 48, 120203. [Google Scholar] [CrossRef]

- Aperador, W.; Yate, L.; Pinzón, M.; Caicedo, J. Optical and semiconductive properties of binary and ternary thin films from the Nb-Ti-O system. Results Phys. 2018, 9, 328–336. [Google Scholar] [CrossRef]

- Das, S.K.; Alamgir, B.; Das, P.; Khandaker, J.I.; Ahmed, F. Simulation study of optical properties of transparent CdS thin film using the Sellmeier empirical dispersion formula. Int. J. Photon. Opt. Tech. 2019, 5, 4. [Google Scholar]

- Wang, Z.; Chen, C.; Wu, K.; Chong, H.; Ye, H. Transparent conductive oxides and their applications in near infrared plasmonics. Phys. Status Solidi 2019, 216, 1700794. [Google Scholar] [CrossRef]

- de Carvalho, C.N.; Luis, A.; Lavareda, G.; Fortunato, E.; Amaral, A.; DE Carvalho, C.A.N. Effect of thickness on the properties of ITO thin films deposited by RF-PERTE on unheated, flexible, transparent substrates. Surf. Coat. Technol. 2002, 151–152, 252–256. [Google Scholar] [CrossRef]

- Alamri, S.N.; Brinkman, A.W. The effect of the transparent conductive oxide on the performance of thin film CdS/CdTe solar cells. J. Phys. D Appl. Phys. 1999, 33, L1–L4. [Google Scholar] [CrossRef]

- Zeng, G.; Zhang, J.; Wang, W.; Feng, L. Correlation of interfacial transportation properties of CdS/CdTe heterojunction and performance of CdTe polycrystalline thin-film solar cells. Int. J. Photoenergy 2015, 2015, 519386. [Google Scholar] [CrossRef] [Green Version]

- Bass, M.; Mahajan, V.N. Handbook of Optics: Volume I: Geometrical and Physical Optics, Polarized Light, Components and Instruments; McGraw-Hill Education: Orlando, FL, USA, 2010. [Google Scholar]

- Richards, B.; McIntosh, K. Overcoming the poor short wavelength spectral response of CdS/CdTe photovoltaic modules via luminescence down-shifting: Ray-tracing simulations. Prog. Photovolt. Res. Appl. 2006, 15, 27–34. [Google Scholar] [CrossRef]

- Parashar, D.; Krishna, V.S.G.; Moger, S.N.; Keshav, B.; Mahesha, M.G. Thickness optimization of ZnO/CdS/CdTe solar cell by numerical simulation. Trans. Electr. Electron. Mater. 2020, 21, 587–593. [Google Scholar] [CrossRef]

- Klein, A. Energy band alignment in chalcogenide thin film solar cells from photoelectron spectroscopy. J. Phys. Condens. Matter 2015, 27, 134201. [Google Scholar] [CrossRef] [PubMed]

- Subedi, I.; Silverman, T.J.; Deceglie, M.; Podraza, N.J. Impact of infrared optical properties on crystalline Si and thin film CdTe solar cells. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 2771–2775. [Google Scholar]

| Parameter | Schott D263T | Borosilicate (Pyrex 7740) |

|---|---|---|

| Thickness/Width (mm) | 0.1 | 1.1 |

| Density, ρ | 2.51 | 2.23 |

| CTE | 7.2 ppm/K | 3.2 |

| Refractive index | 1.52 | 1.50 |

| Transmission (λ = 550 nm) | 92% | 92% |

| Abbe value | 55 | 64 |

| Extinction coefficient | 7.11 × 10−8 | 4.09 × 10−7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amin, N.; Karim, M.R.; ALOthman, Z.A. Optical Losses of Frontal Layers in Superstrate CdS/CdTe Solar Cells Using OPAL2. Coatings 2021, 11, 943. https://doi.org/10.3390/coatings11080943

Amin N, Karim MR, ALOthman ZA. Optical Losses of Frontal Layers in Superstrate CdS/CdTe Solar Cells Using OPAL2. Coatings. 2021; 11(8):943. https://doi.org/10.3390/coatings11080943

Chicago/Turabian StyleAmin, Nowshad, Mohammad Rezaul Karim, and Zeid Abdullah ALOthman. 2021. "Optical Losses of Frontal Layers in Superstrate CdS/CdTe Solar Cells Using OPAL2" Coatings 11, no. 8: 943. https://doi.org/10.3390/coatings11080943