1. Introduction

Regular designs are widely applied in agriculture, industry, and other fields. The selection of optimal regular designs for improving yield and shortening testing cycles has garnered attention in theoretical and practical fields. Several criteria have been established for the selection of optimal designs. The first criterion is the maximum resolution (MR) criterion introduced by Box and Hunter [

1], which selects designs with higher resolutions. The second one, proposed by Fries and Hunter [

2], is the minimum aberration (MA) criterion, which is based on the word-length pattern (WLP). The third criterion, based on the definition of clear effects, was proposed by Wu and Chen [

3], which selects designs with the maximum number of clear main effects and two-factor interactions (2fis) [

4]. More details of the above criteria can be found in Mukerjee and Wu [

5] and Wu and Hamada [

6]. Zhang and Wang [

7] proved the entropy optimality of orthogonal designs. The characterization of confounding information under these criteria varies, leading to the selection of different optimal designs.

To reveal the essence of the aforementioned criteria, Zhang et al. [

8] introduced an aliased effect-number pattern (AENP) for two-level designs. Based on AENP, a general minimum lower-order confounding (GMC) criterion is proposed to evaluate two-level regular designs. Zhang and Mukerjee [

9] studied the properties of

s-level GMC designs via complementary sets. Li et al. [

10] introduced the aliased component-number pattern (ACNP) and proposed a three-level GMC criterion. Li et al. [

11] proved that classification patterns for MR, MA, and CE can be represented by the ACNP. In this sense, the GMC criterion is more informative and elaborate than other criteria. Up to now, there have been many achievements for three-level GMC designs [

12,

13]. However, the classification patterns of all the above results are based on the component properties of designs. Unlike the two-level case, the interpretability of component confounding is limited in higher-level designs. It is not easy to distinguish between factor aliasing effectively. Furthermore, the number of components increases exponentially, significantly raising computational complexity. The nonlinear relationships between component effects may introduce unnecessary complexity in modeling [

6].

In a practical model, the aliasing between factors with three levels is often more critical to optimize experimental conditions (Jaynes et al. [

14], Suriyaamporn et al. [

15], and Nieweś [

16]). Guo et al. [

17] and Cheng et al. [

18] screened the optimal process conditions through three-level orthogonal designs and validated the selected results using the entropy weight method. So far, the study of higher-level factor aliasing remains unfulfilled for regular designs with three levels. It is difficult for the existing results to express the aliasing among factor effects. Motivated by the analysis above, we focus on studying three-level factor aliasing. From a factor-based perspective, the aliasing measure aims to reduce computational complexity, make the results easier to interpret, and enhance the practical value for modeling applications. Thus, the main contributions and innovations of our work focus on the following aspects:

(i) A factor aliasing pattern is first proposed to describe the aliasing information of three-level regular designs, and a new criterion is introduced based on the pattern. For the two-level design, the pattern is equivalent to the AENP. However, it differs from the ACNP of three-level designs because of the relationship between factor and component effects.

(ii) We analyze the relationship between the proposed and existing patterns to reveal the essential characteristics of various confounding and alias relations.

(iii) Based on the proposed criterion, we propose an aliasing algorithm of lower-order factors to choose optimal designs. Compared with other criteria, tables list all 27-, some 81-, and 243-run optimal designs.

The main structure of this paper is organized as follows.

Section 2 introduces a new measure for describing factor aliasing, known as the aliased factor-number pattern (AFNP) for three-level regular designs, along with a criterion for general minimizing lower-order aliasing based on factor effect (GMAF), which utilizes the AFNP. The relationship between the new criterion and the GMC, entropy, MA, and CE criteria is discussed in

Section 3.

Section 4 presents an aliasing algorithm of the GMAF criteria and a catalog of the optimal designs for all 27- and some 81- and 243-run designs of resolution IV or higher.

Section 5 provides an example to illustrate the application of the new criterion.

Section 6 offers a brief conclusion.

2. Some Basic Concepts

We first review some basic concepts of three-level designs. Let

n and

m be two positive integers with

. Define

and

. The numbers

correspond to

q independent columns. A

saturated design

is determined by the following recursive process:

where

for

and

. Here, the operation

is the element-wise addition modulo 3 over the Galois field of order 3, denoted as

. Thus,

A

design with

n factors

, each having three levels, is constructed by

q independent columns

and

m additional columns generated from the three-level saturated design

. We call

an

i-order factor interaction (

ifi) of the design, corresponding to

orthogonal factor-interaction components (fics). In particular,

is the main effect, and

means a 2fi.

Consider a design with the defining relation . Suppose that third- and higher-order interactions are negligible. By multiplying both sides of by main effect and 2fic, we have and It is evident that no main effects are aliased with other main effects or 2fics, and six 2fics are confounded with one other 2fic. Suppose any component of a factor effect is confounded with a component of another factor. In that case, the factor is aliased with the corresponding factor, and the symbol “≈” denotes that two factors are aliased. Thus, 2fis are aliased with one other two-factor interaction, denoted by In this example, the confounding relationship between component and factor effects is one-to-one. However, this is a special case. In most three-level designs, the confounding relationships between the two are not necessarily one-to-one. For example, consider another design with the defining relation . We have , , , and . Thus, 2fis , and . Note that in the aliasing relationship denoted by ≈, transitivity does not hold. Using the aforementioned aliasing relationships as an example, is aliased with three 2fis: , , , and one main effect 5. However, it cannot be inferred that the 2fi is aliased with , , or the main effect 5.

Next, we introduce a new classification pattern to describe the aliasing relationships among various factor effects in three-level designs. In the orthogonal component system, a jfi consists of mutually orthogonal jfics. Thus, an ifi is aliased with at most one component of a jfi, while the remaining ifics are not aliased with this jfi. Denote . An ifi is aliased with at most jfis. For and , let be the number of ifis aliased with k jfis. The set is used to measure the aliasing degrees between various factor effects of any three-level designs. The larger k is, the more severe the aliasing in the set. Given the fixed value , are arranged according to the aliasing severity, and denote for .

Based on the effect hierarchy principle, we introduce a factorial effect hierarchy principle (FEHP): (i) A lower-order factor effect is likely more important than a higher-order one, and (ii) factor effects of the same order are equally important. For any

and

, the sorting rules are based on the FEHP: (i) If

, then

is ranked before

. (ii) If

and

, then

is ranked before

. (iii) If

and

,

, then

is ranked before

. Note that the 0th-order effect is the grand mean. For

, we have

and

, where

is the number of

ifics aliased with the grand mean. We use

to denote

s successive zero components; the tail part is cut hereafter if it has a tail with successive zero components. Since

is determined from the preceding

,

is ignored in the ranking process. According to the above ranking rules, we obtain a new sequence as follows:

called the aliased factor-number pattern (AFNP) of a three-level design. For the abovementioned

design, we have

(2,3;7,3;0,0,6,4). Based on the definition of factor aliasing, the relationship

holds. Thus, in analyzing the aliasing between main effects and 2fis, only

needs to be considered.

One of the main objectives of experimental design is to estimate as many factor effects as possible, particularly lower-order factor effects, such as main effects and 2fis. Therefore, a good design should minimize aliasing among lower-order factor effects and sequentially maximize the elements in #A. Based on the AFNP, we propose a new optimal criterion as follows.

Definition 1. Let be the l-th component of # and # be the AFNPs of designs . Suppose that # is the first element such that # and # are different. If , then has less general lower-order aliasing based on factor effect (GLOAF) than . A design D is said to have general minimum lower-order aliasing based on factor effects (GMLOAF, or GMAF for short) if no other design has less GLOAF than D, and such a design is a GMAF design.

Example 1. Consider three designs . Table 1 shows the elements of their AFNPs. Thus, the optimal ordering of the designs under the GMAF criterion is , whereas the ordering changes to under the GMC criterion. This indicates that the ranking results of designs vary significantly under different optimal criteria. The designs selected based on the GMAF criterion minimize aliasing among lower-order factor effects. Unlike the GMC criterion, which evaluates confounding at the components of a factor, GMAF considers the factor as a whole, thereby reducing computational complexity and improving the efficiency of identifying optimal factor combinations. Under the assumption that all three-order or higher-order effects are negligible, we only analyze two elements

and

of the AFNP. Let

be a set of all possible pairwise combinations of elements in

, with its explicit structure:

For instance,

Note that the number of elements in

is given by

, and the number of elements in

is

. Let

denote the factor structure of

D. In a three-level design

D, the number of 2fis aliased with

is defined as:

where

represents the corresponding two-factor interaction. Thus, the following expressions of

and

are derived by

for

.

Example 2. Consider a design , with its factor structure . The confounding relationships between main effects and 2fics are given as follows: We first calculate the values of

for

by the definition of

. For

, we have:

Thus,

. For all other

k,

. Then,

. For

, we have:

Hence,

, and

. For all other

k,

. Therefore,

.

3. Relationship with the Existing Criteria

3.1. Relationship with GMC Criterion

We review the GMC criterion proposed by Li et al. [

10] for selecting optimal three-level designs. For

, let

be the number of

ith-order effects confounded with

k jth-order effects. Denote

for

and

. We call the simplified sequence

the ACNP of the design. A design that sequentially maximizes

# is called a GMC design. Following Li et al. [

10], for a

design

D,

is the number of 2fics in

D, confounded with

, and defined as follows:

Further,

and

are expressed as:

Since every main effect only corresponds to a component, it follows that:

That is to say,

always holds. More generally,

for any

.

Based on the GMAF criterion, we analyze the relationship between the AFNP and the ACNP. If an

is aliased with

k , let

represent the degree of confounding between the

t-th component of the

and

, where

. It holds that

. In the case of 2fis, each 2fi generates two components. Thus, for a

design, the value of

represents the number of

that are aliased with

2fis, and is defined as

with

. The terms

and

indicate the degrees to which the two 2fics of a given 2fi are confounded with other 2fics, and their sum reflects the overall degree of aliasing of the 2fi. Consequently, for each component, we have:

In the case that and are aliased, if the within contain only one that is confounded with , the component confounding and factor aliasing can be considered to have a one-to-one relationship. In this specific scenario, the AFNP and the ACNP are equivalent, that is, . Next, we will analyze the relationship between the lower-order AFNP and ACNP in general cases.

Theorem 1. For a regular design with resolution III, the following results hold.

- (a)

For , we have

- (b)

If for , then - (c)

If for , then

Proof. (a) According to the definition of factor aliasing, if a 2fi is not aliased with other 2fis, its components are also not confounded with any other 2fics. However, a 2fi may have one component confounded with other 2fics while the other remains unconfounded. This scenario leads to the inequality .

To quantify this phenomenon, we use

to represent the number of 2fics within 2fis that are aliased with other 2fis but, at the same time, are not themselves confounded with any other 2fics. For such 2fis, there exists exactly one 2fic that is not confounded with any other 2fics. Without loss of generality, assume that the first 2fic of such a 2fi is unconfounded with other 2fics, i.e., let

. Under this assumption, the number of 2fics satisfying the above description can be expressed as:

(b) In the case of 2fis aliased with k other 2fis, if one of the two 2fic components of the 2fi is confounded with k other 2fics while the other 2fic is not confounded with any other 2fics, then .

If a 2fi is aliased with other 2fis to a degree strictly greater than

k, two particular 2fics involving this 2fi can be identified. One of these 2fics is confounded with exactly

k other 2fics, while the other, although also confounded with this 2fic, has a confounding degree with other 2fics that is not equal to

k. The number of such 2fics is expressed as:

On the other hand, if both 2fics of the 2fi are confounded with

k other 2fics, the difference value of

reflects the number of 2fics within 2fis whose aliasing degree is

. These 2fics are also confounded with

k other 2fics. The number of 2fics satisfying this condition can be expressed as:

Therefore, when

, the corresponding difference equals the total number of 2fics within 2fis aliased with more than

k other 2fis, where the degree of confounding with 2fics is

k. This total number can be expressed as:

In this scenario, at least one 2fic must be confounded with

k other 2fics. Thus,

.

(c) When , the aliasing degree k can be achieved in multiple ways. If a has only one confounded with k other , while the remaining is not confounded with any other , then the aliasing degree k is entirely determined by this single component. In this scenario, the factor aliasing and component confounding correspond individually.

When at least two components determine the aliasing degree

k, the difference value of

represents a situation that, among the 2fis aliased with

k other 2fis, the degree

k is jointly determined by exactly two 2fics. The number of 2fis fitting this description can be expressed as:

Note that the aliasing degree

k can only be determined by a single component when

. Therefore, the situation

can only occur when

. □

We provide an example to illustrate Theorem 1.

Example 3. Consider a design . Based on the AFNP and ACNP, its lower-order aliasing indices are and . The specific confounding patterns of the 2fics are as follows: According to Theorem 1, . Thus, there are 10 2fis with two components, one of which is confounded with the other 2fics, and the other is not. These 2fis are . From , it can be concluded that among the 2fis aliased with at least one other 2fi, two of their components, 26 and , are each confounded with one other 2fic. Finally, from , it follows that there exists a 2fi aliased with two other 2fis, and its aliasing degree is determined by two components. The 2fi satisfying this case is .

The definitions of the GMAF and GMC criteria clearly show that the GMAF criterion imposes stricter requirements for optimal designs than the GMC criterion. The GMAF criterion focuses on the overall aliasing of factor effects rather than the factor effect components.

3.2. Relationship with Entropy

To adapt to the entropy formulation, in a

design, denote the factors as

, where

represent independent factors (i.e., independent columns), and the remaining

are generator factors (i.e., additional columns). We employ entropy to measure factor uncertainty. Let

denote all possible combinations of factor values, and

represent the estimated probability of occurrence for a particular combination

[

17,

18]. The entropy of the design matrix is defined as

In fractional factorial designs, to assess the degree of aliasing among factors, we focus on the conditional entropy of generators with respect to other factors, such as

. Lower conditional entropy indicates stronger dependence of the factor on other generators, implying more severe aliasing. Specifically, if a factor is a function of other generators, its conditional entropy equals zero, indicating aliasing. Conversely, higher conditional entropy suggests that the factor retains uncertainty given other factors, indicating less aliasing.

Example 4. Consider two designs: and , where is the only generated factor. In design D, the conditional entropy , indicating that is fully determined by and , and thus entirely confounded with them. In contrast, for , although , it holds that , meaning that retains some uncertainty given only and . This implies that design has a lower degree of aliasing compared to D.

Therefore, for a fixed number of factors n and generators m with the same number of levels, we can compare the conditional entropies associated with generators across designs to evaluate the confounding severity. Specifically, under the same conditions, a larger conditional entropy indicates lower confounding among factors and higher resolution. Consequently, the designs selected based on the conditional entropy criterion yield the same results as those obtained under the MR criterion. However, the conditional entropy criterion exhibits an inherent limitation; it cannot differentiate among multiple designs with same resolution. Based on Definition 1, we can directly obtain the following theorem.

Theorem 2. A GMAF design must have maximum resolution among all designs, and exhibit the minimum factor aliasing among all designs with the same conditional entropy.

According to this theorem, the GMAF criterion overcomes the inherent limitations of the conditional entropy criterion. GMAF designs not only satisfy the maximum resolution criterion, but also minimize factor aliasing among all designs with the same conditional entropy. This provides a more precise discrimination for comparing designs with the same conditional entropy.

3.3. Relationship with MA Criterion

For a design, the set of all possible products of the m words generates a defining contrast subgroup G. Let () denote the number of words of length i in G. The vector is called the WLP. A design sequentially minimizing the vector W is considered an MA design. To study the relationship between the GMAF and MA criteria, we investigate the relationship between the WLP and the AFNP as the cores of MA and GMAF criteria, respectively.

Theorem 3. For a regular design with a resolution , we have: Proof. If

, it is known from Zhang and Mukerjee [

9] that:

Since

, then by keeping

on the right-hand side, we have:

Dividing both sides by

i yields:

By rearranging this equation, the value of

can be expressed as a weighted sum of

,

, and

. Moreover, since the resolution

, the main effects are not aliased with other main effects, and the following equivalence holds:

In particular, it follows that

when

. □

Through calculations, the relationship between the three-level WLP and AFNP is derived as follows:

For example, a

design

have

. Hence,

.

Note that a design includes k from the same in its independent defining relation, which necessarily results in when . Based on the WLP, the designs with different WLPs may have different AFNPs. Minimizing the WLP sequentially is equivalent to maximizing or sequentially. However, the different AFNPs may have the same WLP.

Example 5. Consider the two designs: The AFNPs of designs and are different. In particular, they first differ at and . However, they share the same .

Consequently, the AFNP is a more refined pattern than the WLP since the WLP is only related to the elements

of the AFNP. Consider two design:

where

represent factors 10, 11, and 12, respectively. Under the MA criterion, the design

D is better than

. However, according to the GMAF criterion, the design

is optimal. Since the MA criterion uses only part of the information in the AFNP, the optimal design under the MA criterion is not as good as that obtained by the GMAF criterion.

3.4. Relationship with CE Criterion

For a three-lever design, a main effect or 2fi is called clear if it is not aliased with other main effects or 2fis. We study the relationship between the CE and GMAF criteria by calculating the number of clear effects using the AFNP. Let , , and be the number of clear main effects, clear 2fis, and clear 2fics, respectively.

Theorem 4. For any three-level design with resolution III or higher, we have: Proof. For three-level designs with resolution or higher, any main effect is not aliased with other main effects. The is just the number of main effects that are aliased with neither any main effect nor any 2fi, that is, .

Consider a 2fi , with its two 2fics and not confounded with any other 2fics. Suppose or is confounded with a main effect. In a defining word of length 3, if or is confounded with a main effect, the defining word must include both factors A and B. This would inevitably lead to or being confounded with other 2fics, contradicting the initial assumption. Therefore, if the two components of a 2fi are not confounded with any other 2fics, then the 2fi is clear. Based on the definition of , it represents the number of 2fis that are not aliased with any other 2fis. Thus, . □

Therefore, in the factor aliasing of three-level designs, the CE criterion selects designs that sequentially maximize

and

. According to the definitions of clear 2fis and clear 2fics, the difference value between

and

represents the number of 2fics within 2fis aliased with other 2fis but not with any other 2fics. Specifically, this relationship can be expressed as:

The inequality

implies that, in general, the number of clear 2fics is greater than or equal to the number of clear 2fis. This follows from the fact that a 2fi is considered clear only if both of its 2fics are clear. Therefore, the criterion for a clear 2fi is inherently more stringent than that for individual components. From a design perspective, the stricter requirement for clarity in factor effects better aligns with the practical need to accurately identify significant factor effects in experimental settings.

The following results are obtained based on Theorems 1 and 3 in Ai and Zhang [

19].

Theorem 5. (i) If , a design with sequentially maximizing and is an optimal design under CE criterion.

(ii) If there exists an optimal design with resolution IV under the CE criterion, then the GMAF design must be the best one among all optimal designs under the CE criterion, where the meaning of ’best’ is under the comparison in Definition 1 of the GMAF criterion.

However, the CE criterion cannot distinguish designs with the same number of clear main effects and 2fis, while the GMAF criterion can. The following example illustrates this point.

Example 6. Consider the type of designs. According to Xu [20], there are 19 non-isomorphic designs. Under the CE criterion, the optimal designs are and . Both designs have 7 clear main effects and no clear 2fis. However, , and . Under the GMAF criterion, the design D is better than the design . It can be concluded that the optimal design under the GMAF criterion represents the best-performing design among all optimal designs under the CE criterion. 4. Aliasing Algorithm of Lower-Order Factors

Factor aliasing patterns are crucial in selecting optimal designs, especially in aliasing lower-order factors. This section mainly introduces some algorithms to calculate the lower-order factor aliasing. The algorithm is based on defined contrast subgroups. It includes the following three steps: (i) generate a design matrix from a saturated design, (ii) construct the defining contrast subgroup matrix, and (iii) calculate the low-order factor aliasing values of the design. The specific implementation code is available in the

Supplementary Materials.

4.1. Generate Design Matrix

Let be the design matrix of a design D. The matrix is generated from the corresponding saturated design , which each component is expressed as , where and are not all zero. Proportional components are considered equivalent. A vector can be denoted as , with the convention that is omitted for . For example, in , 12 corresponds to the vector , while in , it is represented as . In the following, we present an algorithm for generating the design matrix.

Example 7. Consider a design with index set . The design matrix is constructed by extracting columns 1, 2, 5, 8, and 4 from the saturated design matrix . Using Algorithm 1, we obtain: The saturated matrix has 13 columns, each of which can be represented as a component. The first and second columns of are independent components. Using addition modulo 3 over , the interaction of the first and second columns produces two components, 12 and , represented by the third and fourth columns of , respectively. According to the design column index set , the 1st, 2nd, 5th, 8th, and 4th columns are selected from to form the design matrix .

| Algorithm 1: Generate design matrix |

![Entropy 27 00680 i001]() |

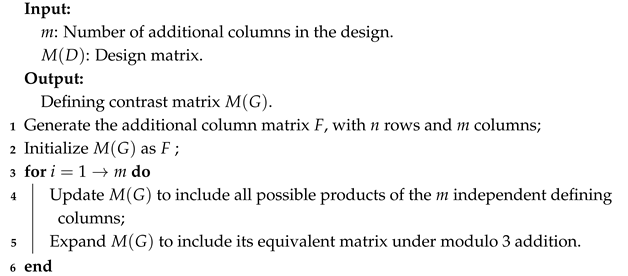

4.2. Construct Defining Contrast Matrix

Through Algorithm 1, we can obtain the additional column matrix F from the design matrix . Next, we calculate the defining contrast matrix under modulo 3 addition in Algorithm 2.

| Algorithm 2: Construct defining contrast matrix |

![Entropy 27 00680 i002]() |

In Example 7, the two columns of

F represent

and

. Subsequently, we construct a defining contrast matrix

under modulo 3 addition, which contains eight elements, including the modulo 3 equivalent components for each element.

4.3. Calculate the Lower-Order Factor Aliasing

Based on the FEHP, lower-order factor effects are more important than high-order ones. An algorithm is used to calculate and for any design D. These results are instrumental in identifying GMAF designs. The detailed steps of the algorithm are outlined below.

Algorithm 3 provides a method for calculating lower-order factor aliasing based on the defining contrast matrix

. For Example 7, we first generate the corresponding 2fic matrix

as follows:

The elements in the

are written as follows:

| Algorithm 3: Calculate and |

![Entropy 27 00680 i003]() |

Subsequently, each and is combined with the columns of under addition modulo 3 over to perform the Kronecker product. The result is , indicating that two main effects are not aliased with any 2fi, and the remaining three main effects are each aliased with one other 2fi. Among the 10 2fis, six are aliased with two other 2fis, and the remaining four are aliased with three other 2fis, represented as .

4.4. A Catalog of Three-Level Designs with Lower-Order AFNP

Based on the aforementioned aliasing algorithm, the lower-order AFNP of all the 27-, 81-run designs with factor numbers

, and 243-run designs with resolution IV or higher are listed in

Table 2,

Table 3 and

Table 4. For a design

, denoted as

, we only list the additional columns (abbreviated as add. columns), where

i indicates the ranking of the design under the GMAF criterion. Here, the

design is always the GMAF design. The first column of the table represents the selected design, and the second column represents the positions in the Yates order. The table also includes

(

,

,

,

),

,

,

, and the two primary components

and

of the AFNP, along with the two primary components

and

of the ACNP. The designs are ranked under the GMC and MA criteria at the end.

Table 2 presents all 27-run designs. The results show that each GMAF design is also a GMC and MA design, with equal rankings under both GMAF and GMC criteria. This indicates that the GMAF designs with 27 runs retain the advantageous properties of both GMC designs and MA designs. Moreover, the rankings of designs 5-2.2 and 5-2.3 under the GMC and MA criteria are 2, 3, and 3, 2, respectively. Similarly, for designs 6-3.3 and 6-3.4, the rankings under the GMC and MA criteria are 3, 4, and 4, 3, respectively. The rankings of the remaining 23 designs are consistent under the GMAF, GMC, and MA criteria.

For 81-run designs, there can be up to 40 columns.

Table 3 lists the WLP, the number of clear main effects and clear 2fis, the AFNP, and the ACNP of some 81-run designs. As Xu [

20] noted, any 27-run design can be considered a degenerate 81-run design. The number of non-isomorphic designs for

is equal to the number of non-isomorphic designs for

. Thus, only 81-run designs with

are listed. It can be observed that the GMAF designs for the 81-run are not necessarily GMC or MA designs. The results are summarized as follows. In the 81-run designs, among the optimal designs selected under the GMAF criterion: (i) Only designs 7-3.1 and 8-4.1 are not optimal under the GMC criterion, while the remaining designs are optimal under both the GMAF and GMC criteria. (ii) Only designs 12-8.1, 13-9.1, 14-10.1, 15-11.1, and 16-12.1 are not optimal under the MA criterion, while the remaining designs are optimal under both the GMAF and MA criteria.

For 243-run designs, there can be a maximum of 121 columns.

Table 4 lists some 243-run designs. Following Xu [

20], each 243-run design with a resolution of at least IV has a maximum of 20 columns. We only list 243-run designs with

. It can be observed that in the 243-run designs, when the number of independent columns is fewer than 7, designs 6-1.1, 7-2.1, 8-3.1, 9-4.1, 10-5.1, and 11-6.1 are optimal under the GMAF, GMC, and MA criteria. However, when the number of independent columns exceeds 7, designs 13-8.1, 14-9.1, 15-10.1, 16-11.1, 17-12.1, 18-13.1, 19-14.1, and 20-15.1 are optimal only under the GMAF criterion.

5. A Real Example

This section provides a seatbelt experiment to illustrate the effectiveness of the AFNP and the GMAF criterion [

6]. In the study, we mainly investigate the aliasing properties of four factors on the pull strength of truck seat belts. The four factors are hydraulic pressure of crimping (1), die flat middle setting (2), length of crimp (3), and anchor lot (4), with each factor at three levels.

Since three-level regular designs are run size economy, we try to select an optimal

design under the GMAF and other criteria. For

designs, there are only two non-isomorphic

designs

and

, determined by the defining relations

and

, respectively. The set

is the factor structure of

. By calculation, we obtain the confounded relations between the main effects and 2fics of the design

as follows:

For

, we have:

From (

2), it yields that

. Similarly,

when

. For

, we have

. Thus,

. We observe that

is the first element, which makes

#A (

D1) ≠

#A (

D2). Thus, the design

is a GMAF design.

Under the GMC criterion, we need to calculate

and

. Based on the relationship of the AFNP and ACNP, we have

. That is to say,

, and

. According to Theorem 1, we have

For any other

k,

. Hence, we have

. Similarly, for the design

, we have

. Then, the design

is also a GMC design.

To compare the WLP and the number of clear factors between the two designs, it can be derived from Theorem 3 that:

According to Theorem 4, we have

,

,

, and

.

Consider the two designs described above: design , where factor is determined by and , and design , where factor is determined by , , and . In both designs, the individual entropies of the first three factors are approximately bits (corresponding to the case where, among three levels, one level appears once and another appears twice), indicating a relatively balanced level distribution. We examine the conditional entropy of factor to reveal its aliasing relationships with other factors. In design , since , its conditional entropy satisfies . This means that once and are given, the value of is completely determined with no remaining uncertainty, indicating that is confounded with and . In design , where , we have . However, the key difference is that . This indicates that when only and are known, retains some uncertainty. Therefore, , demonstrating that design has less aliasing compared to design , which aligns with the difference in design resolution.

The entropy analysis confirms the validity of the selected designs. Moreover, design is better than design under the MA, CE, GMC, and GMAF criteria. Thus, design should be selected for the experiment, with factors A–D assigned to its four columns. The WLP, along with and , is the core of the MA and CE criteria, and all are functions of the AFNP, which offers more comprehensive information on factor aliasing compared to the WLP and . Additionally, the GMAF criterion retains the advantages of GMC, MA, and CE criteria while measuring aliasing from the factors’ perspective, thereby reducing computational complexity. This indicates that the GMAF criterion is practical and applicable for optimizing and selecting experimental designs.

6. Conclusions

This paper introduces the AFNP, which mainly uses three-level regular designs, and proposes the GMAF criterion. The AFNP’s main advantage embodies several aspects. First, the classification pattern contains all aliasing information between various factors of any three-level design. Based on the FEHP, assuming higher-order interactions can be ignored, is defined to represent the number of 2fis aliased with in a design D. For different values of within the set D or , is used to represent both and , which facilitates the establishment of relationships between the GMAF criterion and other criteria. For instance, Theorem 1 demonstrates the quantitative relationship between and , establishing the connection between the GMAF and GMC criteria. Theorem 2 shows that the GMAF criterion overcomes the limitation of the conditional entropy criterion in evaluating designs with the same conditional entropy. Theorems 3 and 4 separately explore the relationships of the GMAF criterion with the MA and CE criteria. The MA criterion utilizes information from , whereas the CE criterion relies solely on . The GMAF criterion provides a more precise method for selecting designs. It overcomes the limitation of the MA criterion, which becomes inapplicable when the WLPs are identical. It outperforms the CE criterion by distinguishing optimal designs when the and parameters are equal. The results show that the core of other criteria is the specific functions of the AFNP. Then, an algorithm based on the definition of contrast subgroups is proposed to calculate lower-order factor aliasing, enabling the search for GMAF designs. The tables show catalogs of all 27-run designs, selected 81-run designs, and 243-run designs with resolutions higher than IV under the GMAF criterion. Finally, using the seatbelt experiment as an example, it is demonstrated that the GMAF criterion is practical and effective in its application.

This paper only focuses on the AFNP and GMAF criteria of three-level designs. The criterion can be extended to higher-level regular, blocked, and mixed-level designs. Additionally, how to construct a GMAF design needs to be further investigated, which is more complex than the topics discussed here and remains an open problem.