1. Introduction

Rolling bearings are the most important parts of rotating machinery and are widely used in modern mechanized equipment [

1,

2]. The fault of rolling bearing components can cause serious damage to the running status of the machine and the production process. Therefore, it is important to explore a new fault diagnosis technique. However, in practical engineering, the collected bearing vibration signals contain various interference signals (e.g., white noise, harmonic interference), and have nonlinear and nonstationary properties, which makes it difficult to distinguish the bearing fault types and to identify them [

3]. Therefore, to improve the fault diagnosis accuracy of rolling bearings, this paper researched three aspects of signal denoising, fault feature extraction, and fault type identification of rolling bearings.

Common vibration signal denoising methods include empirical mode decomposition (EMD) [

4], discrete wavelet transform (DWT) [

5], singular-value decomposition (SVD) [

6,

7,

8], and so on. Abdelkader et al. [

9], based on EMD algorithm, proposed a method to determine the travel point based on the energy values of the IMF components of each order, and an improved wavelet threshold was used to denoise the selected IMF component-bearing vibration signals. Zhao et al. [

10] fused the EMD algorithm and selected and tested (ST) the algorithm to denoise the signal, solving the low accuracy in the low-speed operation of the bearing of the EMD denoising method based on the number of interrelationships and the kurtosis criterion. Gao et al. [

11] added the CEEMDAN algorithm to adaptive noise, further reducing the modal effect, yielding better convergence, and realizing the fault diagnosis of rolling bearings.

The hard and soft thresholding functions in wavelet thresholding denoising are widely used, but both functions have their shortcomings and can cause a certain degree of distortion when reconstructing the signal. Tajeddini et al. [

12] proposed a generic threshold function based on an unbiased risk estimation method to carry out wavelet-packet transform preprocessing of the vibration signal, followed by generic threshold denoising. Kumar et al. [

13] proposed an improved modified kurtosis-mixing threshold rule to denoise the vibration signal, which improved the signal-to-noise ratio. Yang et al. [

14] used a particle-swarm algorithm to perform adaptive optimal processing of the initial parameters of the wavelet threshold function, which solved the problem of the initial parameters being influenced by empirical values and overcame the defects such as signal noise removal not being complete enough or removing the useful information. Chegini et al. Ref. [

15] proposed a new method of bearing vibration signal denoising based on empirical wavelet transform (EWT) as well as the threshold function, which better overcame the defect of constant deviation of the traditional soft threshold function. However, the denoising performance of the wavelet threshold denoising method is closely related to the wavelet basis function and the threshold function, and is not adaptive. Although the CEEMDAN algorithm is adaptive, the definition of noise and useful signal is relatively vague, resulting in high distortion of the denoised signal. Shi et al. [

3] proposed a de-trending fluctuation analysis technique for the critical values of the noise component and the useful signal component. This method ensures the accuracy of signal correlation discrimination to a certain extent. Based on the CEEMDAN algorithm decomposition of the vibration signal, Chaabi et al. [

16] used wavelet analysis, principal component analysis, and order tracking analysis to perform multi-method denoising. In order to improve identification accuracy of rolling bearings with nonlinear and nonstationary vibration signals, Chen et al. [

17] proposed a novel fault diagnosis method based on wavelet thresholding denoising and CMEEMDAN with adaptive noise. To verify the denoising effectiveness of combined wavelet thresholding and CEEMDAN, Bie et al. [

18] added random Gaussian white noise to the bearing fault signal to simulate the actual noise disturbance of rolling bearings, and adopted the CEEMDAN-wavelet threshold function to the denoising method. The experimental results showed that the combined denoising method could effectively remove the interference of noise. Therefore, based on the application characteristics of each denoising method, this paper proposed a denoising method based on a CEEMDAN-DFA-improved wavelet threshold function. The method uses the CEEMDAN algorithm to decompose the vibration signal, performs detrended fluctuation analysis (DFA) on the obtained eigenmode function (IMF), calculates the scalar function value of each IMF component, selects the noise-dominated IMF component, and applies an improved wavelet threshold function to denoise it.

The current methods of fault feature extraction for rolling bearings are mainly time-domain analysis, frequency domain analysis, and time-frequency domain analysis; among them, the time-frequency domain analysis method is most commonly used. Zhen et al. [

19] decomposed the vibration signal using wavelet packets and selected a suitable bandwidth according to the Kurtosis spectrum correlation theory, and finally applied the envelope spectrum analysis to extract the eigenfrequencies. Han et al. [

20] used the Teager energy operator to enhance the signal after wavelet denoising and then extracted the bearing fault features by the CEEMD algorithm. Li et al. [

21] used exchange entropy (PE) for bearing fault feature extraction, but could not measure multi-scale signals. Multi-scale variational entropy (MPE) [

22,

23] was introduced into fault diagnosis by Yin et al. [

24]. Du et al. [

25] used MPE to extract fault features and combined them with a self-organizing fuzzy classifier based on the harmonic mean difference (HMDSOF) to classify the fault features. MPE can respond to the changes of vibration signals very well, but its parameters have a great influence on the calculation of entropy values. If the parameters are not selected properly, it will cause the arrangement entropy values of multiple signals of bearings to be mixed, and thus the type of bearing failure cannot be identified. In order to achieve complete separation of arrangement entropy values under different operating conditions of the bearings, this paper adopted quantum particle swarm optimization (QPSO) to optimize the initial parameters of MPE, and then selected the appropriate MPE entropy values to construct the rolling bearing fault feature vector.

Common fault classification and identification methods include artificial neural networks (ANN) [

26], extreme learning machines (ELM) [

27,

28], and support vector machines (SVM) [

29,

30]. The ANN has made possible many achievements in the field of pattern identification, but its identification performance is strongly influenced by parameters and it is easy to fall into local minima during the optimization process. Although ELM runs fast, its generalization performance is poor. SVM has fewer adjustable parameters and runs stably. It can obtain higher diagnostic accuracy under the condition of fewer training samples [

24]. Therefore, this paper used a SVM for fault identification of rolling bearings. This paper also proposed a comprehensive rolling bearing fault feature extraction and identification method based on the combination of QPSO-MPE-SVM.

The main work and contributions of this paper are summarized as follows:

- (1)

A CEEMDAN-DFA-improved wavelet thresholding denoising method was proposed. The method uses the CEEMDAN algorithm to decompose the vibration signal, performs DFA on the obtained IMF, calculates the scalar function value of each IMF component, selects the noise-dominated IMF component, and applies an improved wavelet threshold function to denoise it.

- (2)

Combining QPSO-MPE-SVM into an effective fault diagnosis method can accurately extract fault features and improve the identification accuracy of bearing faults.

- (3)

Experimental cases were used to illustrate the effectiveness of the proposed method in bearing vibration signal denoising, fault feature extraction, and fault identification.

The rest of this paper is organized as follows. The CEEMDAN-DFA-improved wavelet thresholding denoising method is introduced, and its validity is verified in

Section 2. The QPSO-MPE-SVM fault feature extraction and diagnosis method is presented, and its validity is verified in

Section 3. The effectiveness of the proposed method is proven by experimental example in

Section 4. In addition, contrastive analysis among the different methods is conducted. Finally, some conclusions are summarized in

Section 5.

4. Fault Diagnosis of Rolling Bearing of Sine Roller Screen Based on Vibration Signal

The experimental platform is shown in

Figure 11. The experimental platform completes the tasks of installing sensors, driving bearings, applying radial loads and acquiring vibration signals. The test bearing was a grease-lubricated deep-groove ball bearing, and rolling bearing parameters as shown in

Table 4. The working limit temperature of the bearing is 400 °C. The rotational speed is 10–800 r/min, and the limit rotational speed is 2000 r/min. The speed can be continuously adjusted, and the error is less than ±1%. The applied radial load is 120 kg, the ultimate is 500 kg, the model number of the load sensor is MZLF-2, and the sensor sensitivity is 2.0 ± 0.01 mV/V. The model number of the acceleration sensor is KH-HZD-B-2-12, and the sensitivity is 20 ± 0.05 mV/mm/s. The model number of data acquisition cards is USB3200N (32 bit, 4 channels, 20 MHz); the vibration sensor (MIC-HZB-F-2-12) collected the vibration acceleration of the bearing in real-time, and transferred the vibration signal to the data-acquisition card. The signal was finally transferred to the computer for data processing. All the experimental data were within the allowable error range.

4.1. Rolling Bearing Feature Frequency Calculation

The rolling bearing speed is 500 r/min. The theoretical formula of the fault frequency is expressed as:

- (1)

Journal rotation frequency is expressed as:

- (2)

Inner-ring fault characteristic frequency is expressed as:

- (3)

Outer-ring fault characteristic frequency is expressed as:

- (4)

Rolling-body fault characteristic frequency is expressed as:

where

v is journal rotation speed.

The calculation results by the formulas are shown in

Table 5.

4.2. Rolling Bearing Fault Signal Denoising and Feature Extraction

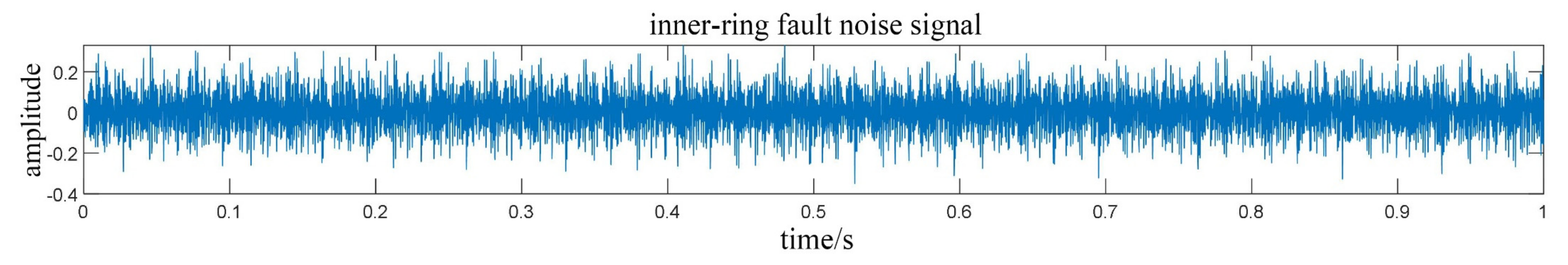

Taking the inner ring fault signal as an example, the original vibration signal and HHT envelope spectrum of the inner-ring fault are shown in

Figure 12 and

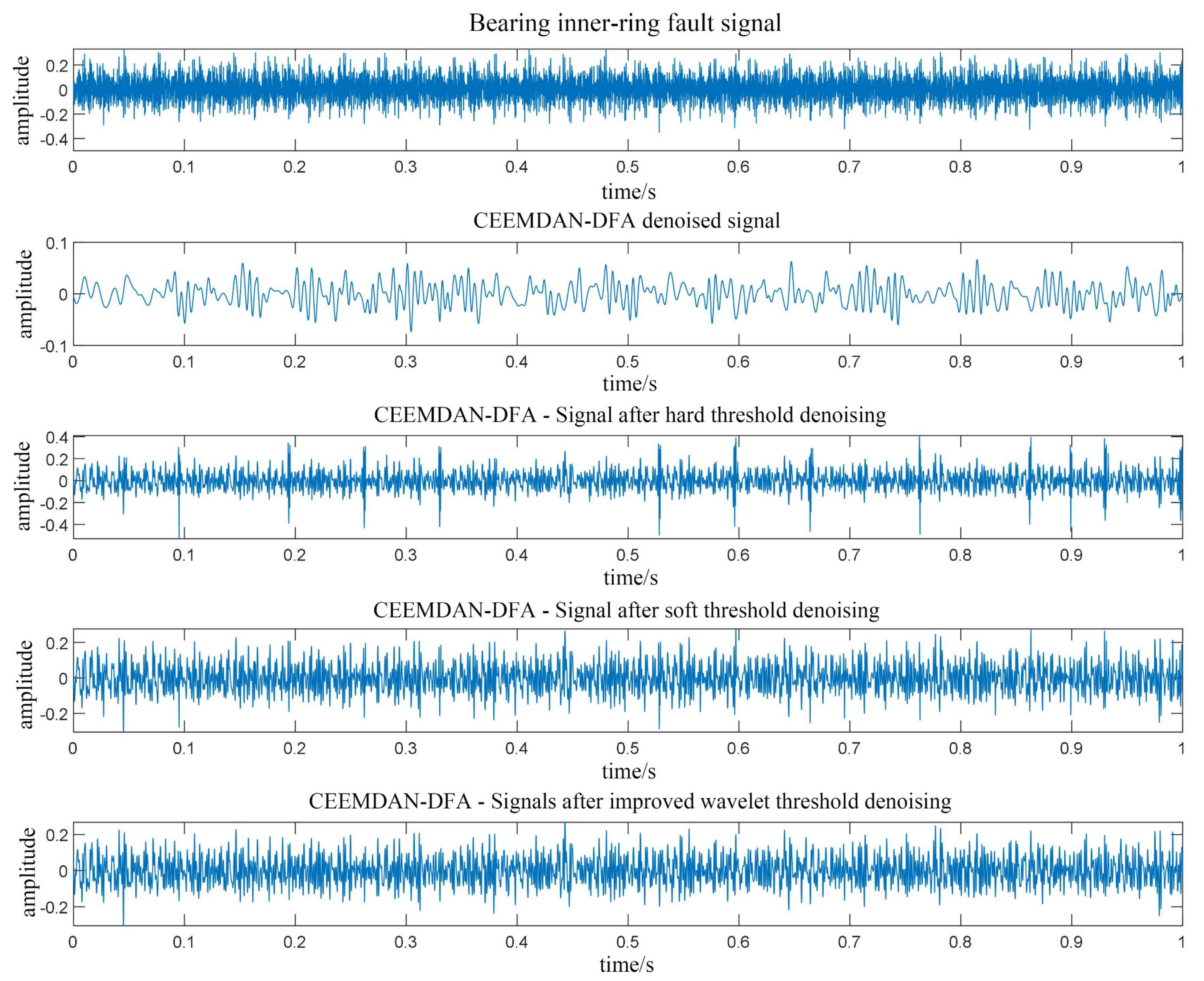

Figure 13, respectively. It was denoised using CEEMDAN-DFA-improved wavelet thresholding.

The IMFs were generated by the CEEMDAN decomposition, and the value of the scaling function

of the IMFs was calculated.

values of the first eighth-order IMFs are shown in

Table 6.

According to the DFA, correlation can be judged that the first fourth-order IMFs were dominated by noise, so the first four-order IMFs need to be denoised. The time-domain signal of the inner-ring fault after denoising is shown in

Figure 14. The denoised signal and the remaining IMFs were reconstructed, and the reconstructed signal is the fault signal of the bearing inner ring.

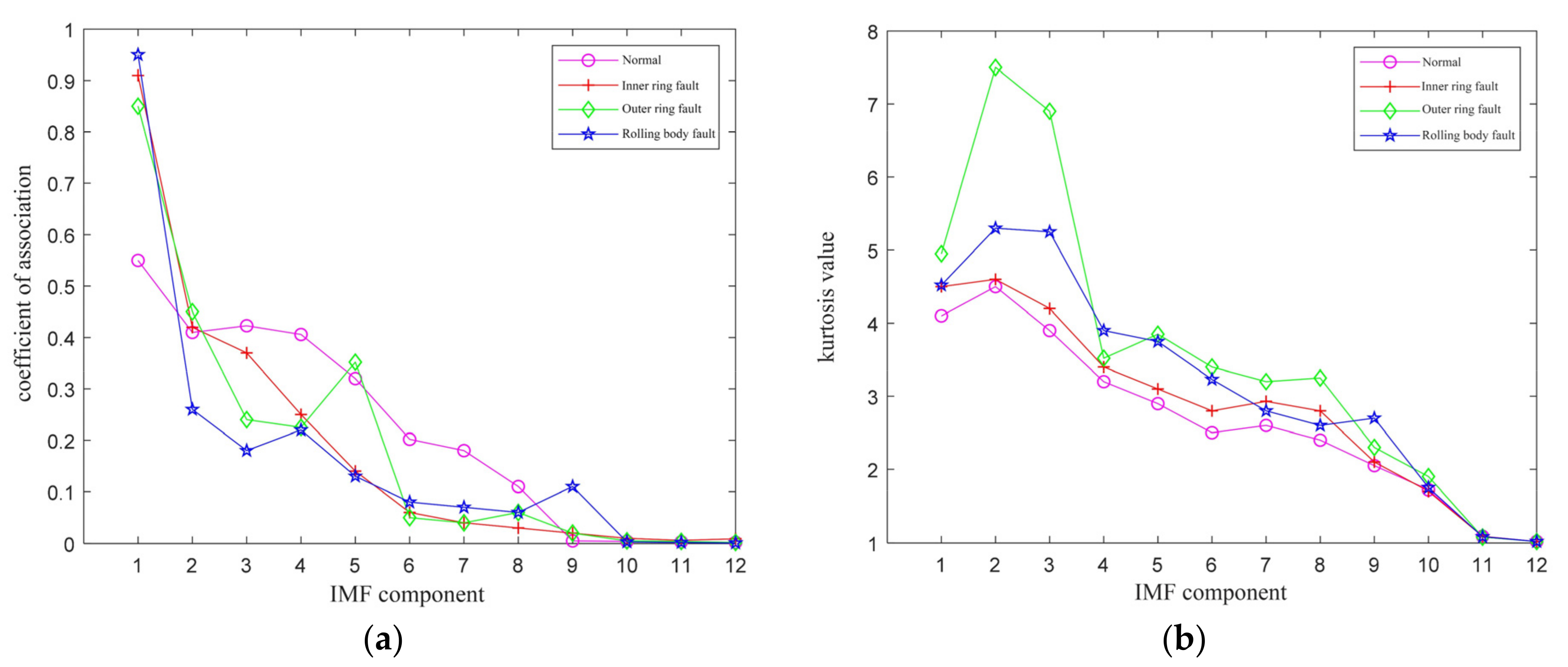

The denoised signal was again decomposed by the CEEMDAN, and the correlation coefficients and Kurtosis values of each IMF were calculated. The calculation results are shown in

Table 7.

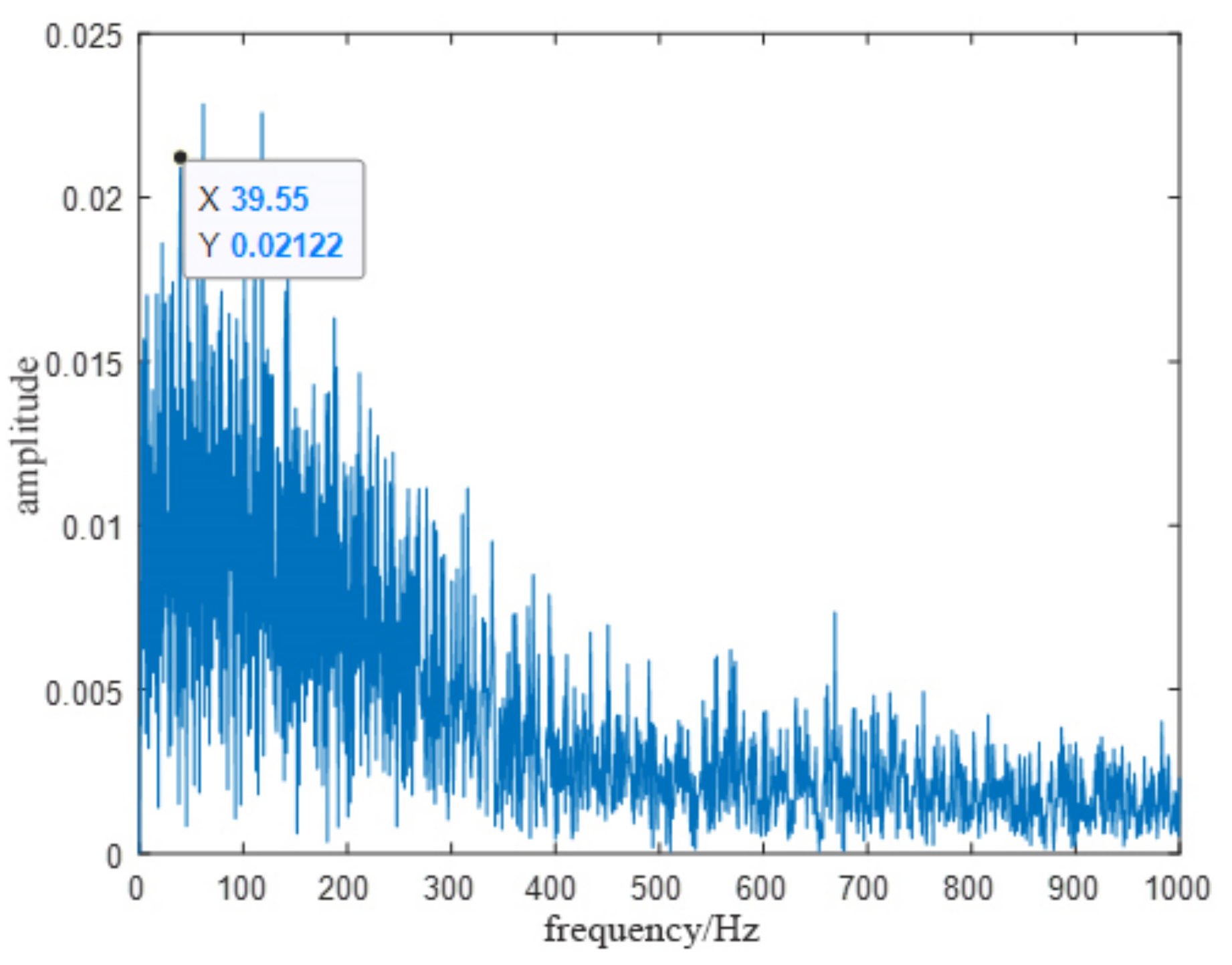

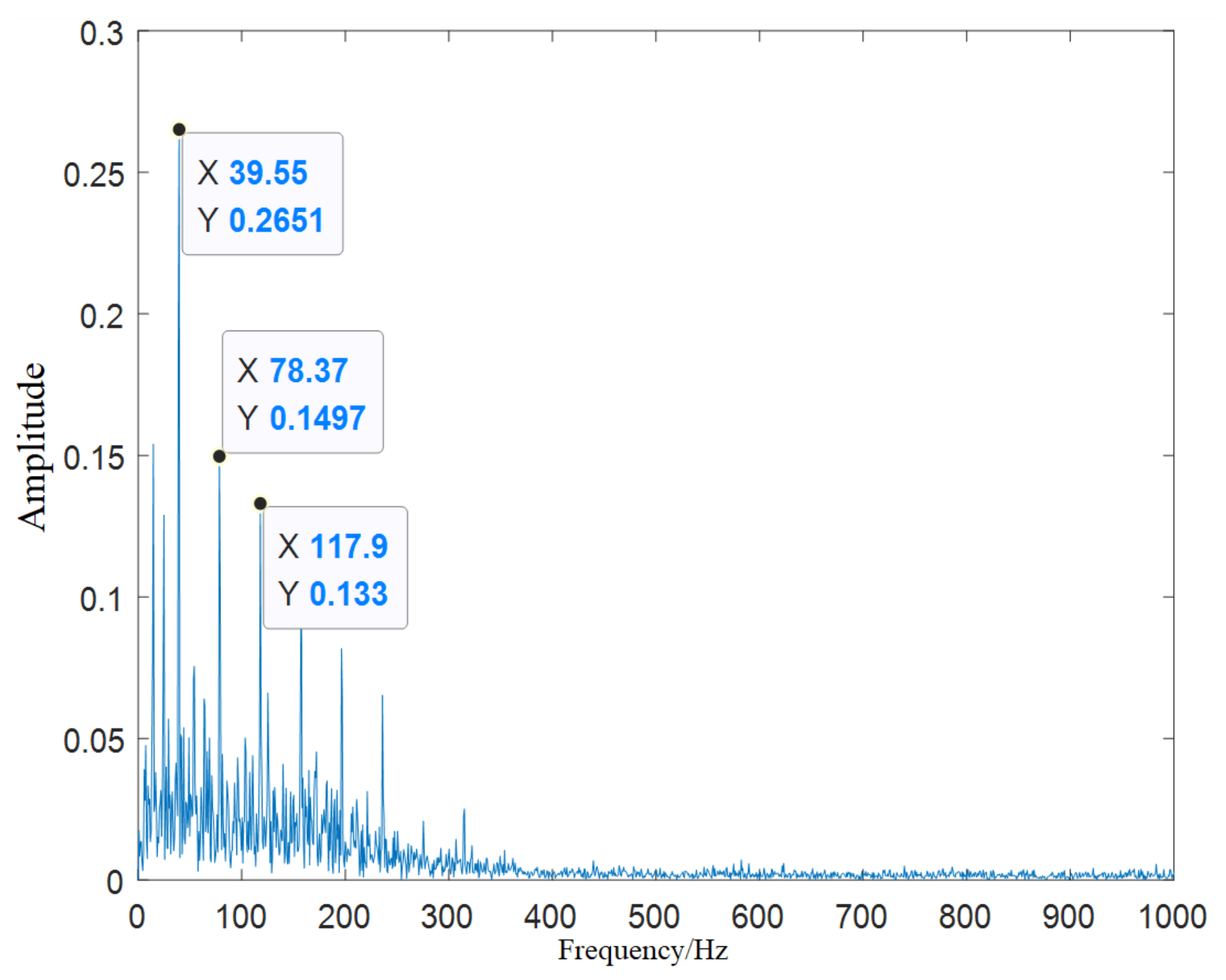

From

Table 7, it can be found that the correlation coefficients of the first fifth-order IMF components were greater than 0.1, and the Kurtosis values were greater than three. Therefore, the first fifth-order IMF component signal was reconstructed, and the HHT envelope spectrum of the reconstructed signal was analyzed. The analysis result is shown in

Figure 15. It can be seen that the characteristic frequency of the inner-ring fault signal was 39.55 Hz, which is close to the theoretically calculated value (40.143 Hz).

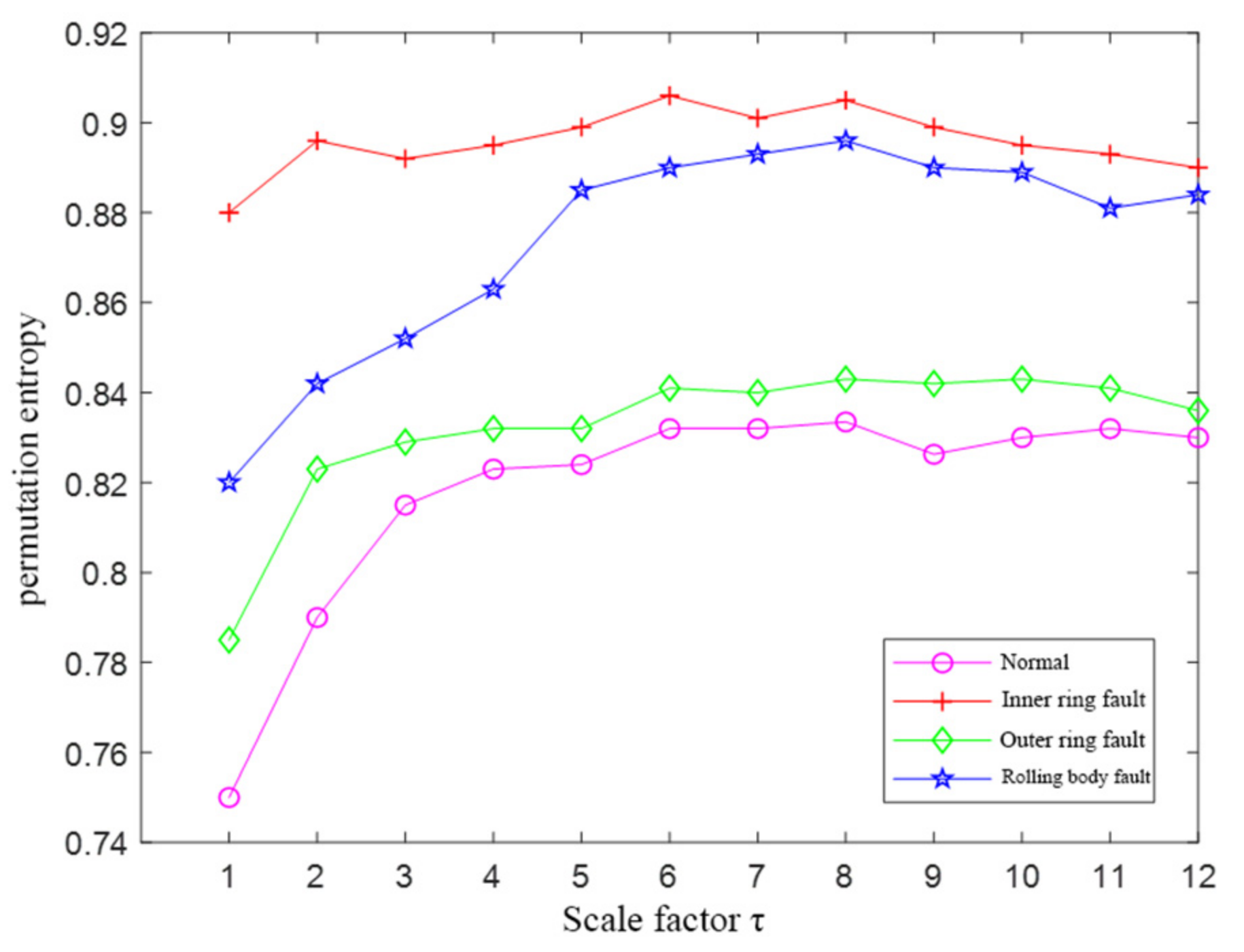

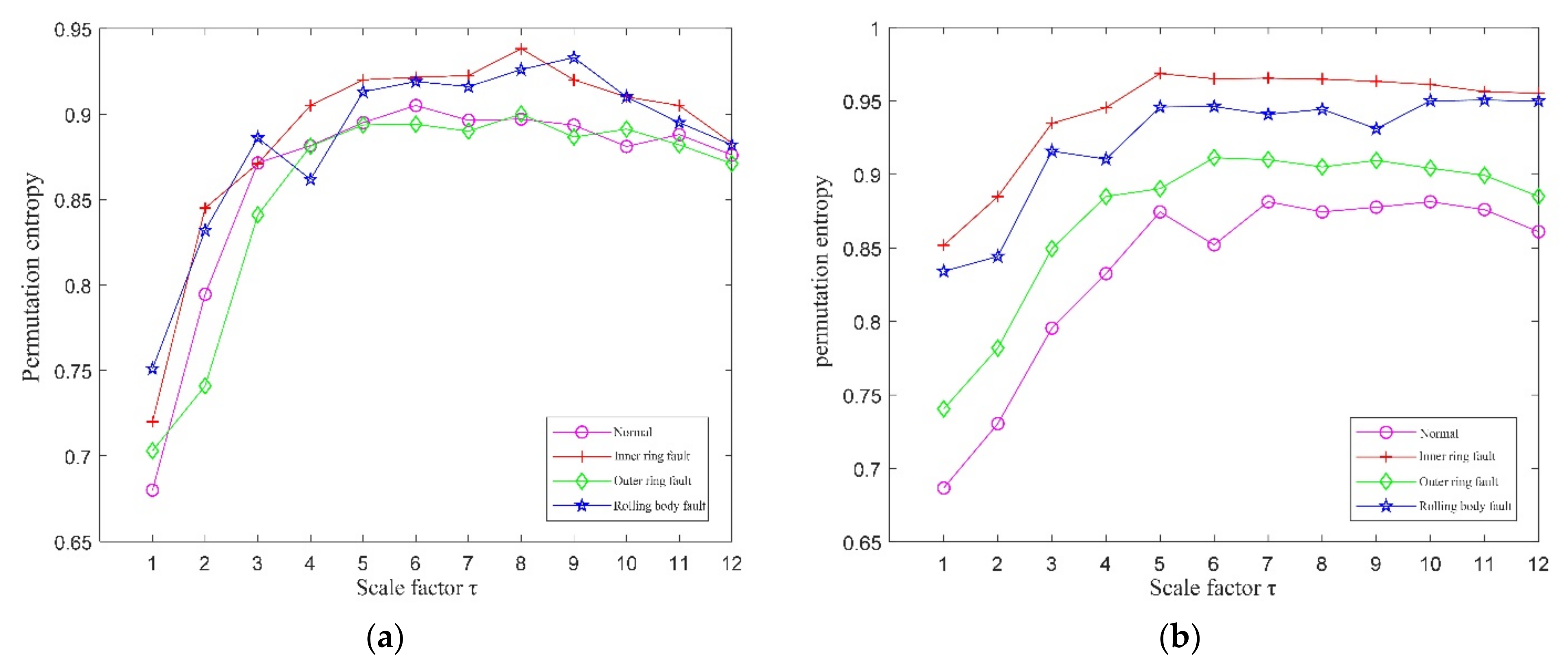

The initial parameters of the MPE of the four running signals were all set as

= 1024,

,

,

. The MPE values were calculated using the initial parameters, and the results are shown in

Figure 16a. It can be seen that the MPE values of four signals had small differences and overlapped each other, which is not conducive to the construction of the fault feature set.

The initial parameters were optimized using the QPSO, and the results are shown in

Table 8.

The MPE values of the four running signals were calculated using the optimized parameters, and the results are shown in

Figure 16b. It can be seen that the MPE values of the four signals achieved separation without overlap, which is suitable for constructing fault feature sets for fault-type identification. The MPE values with scale factors (5, 6, 7, 8, 9, and 10) were selected to construct the fault feature vectors.

4.3. Rolling Bearing Failure Identification and Control Experiment

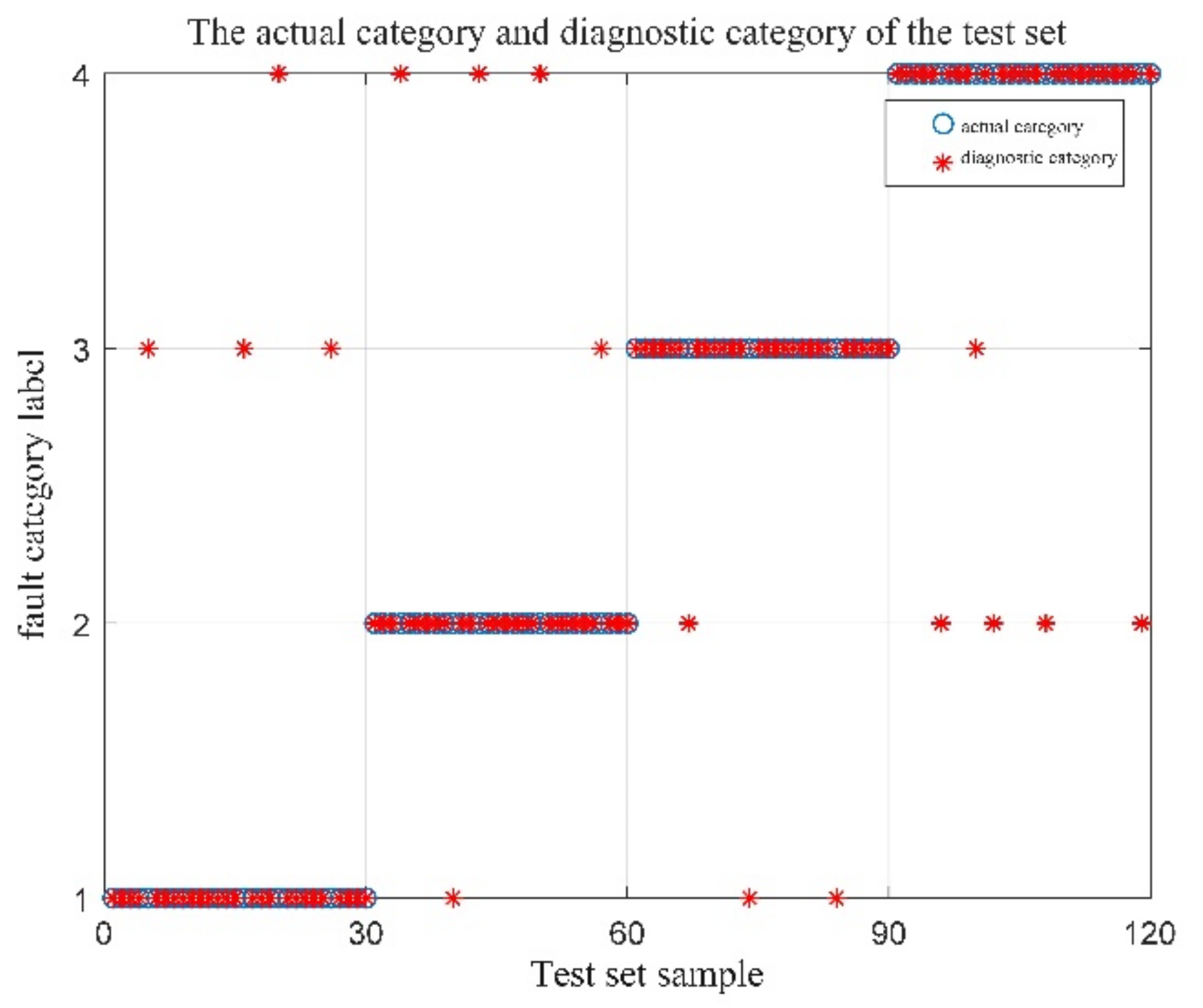

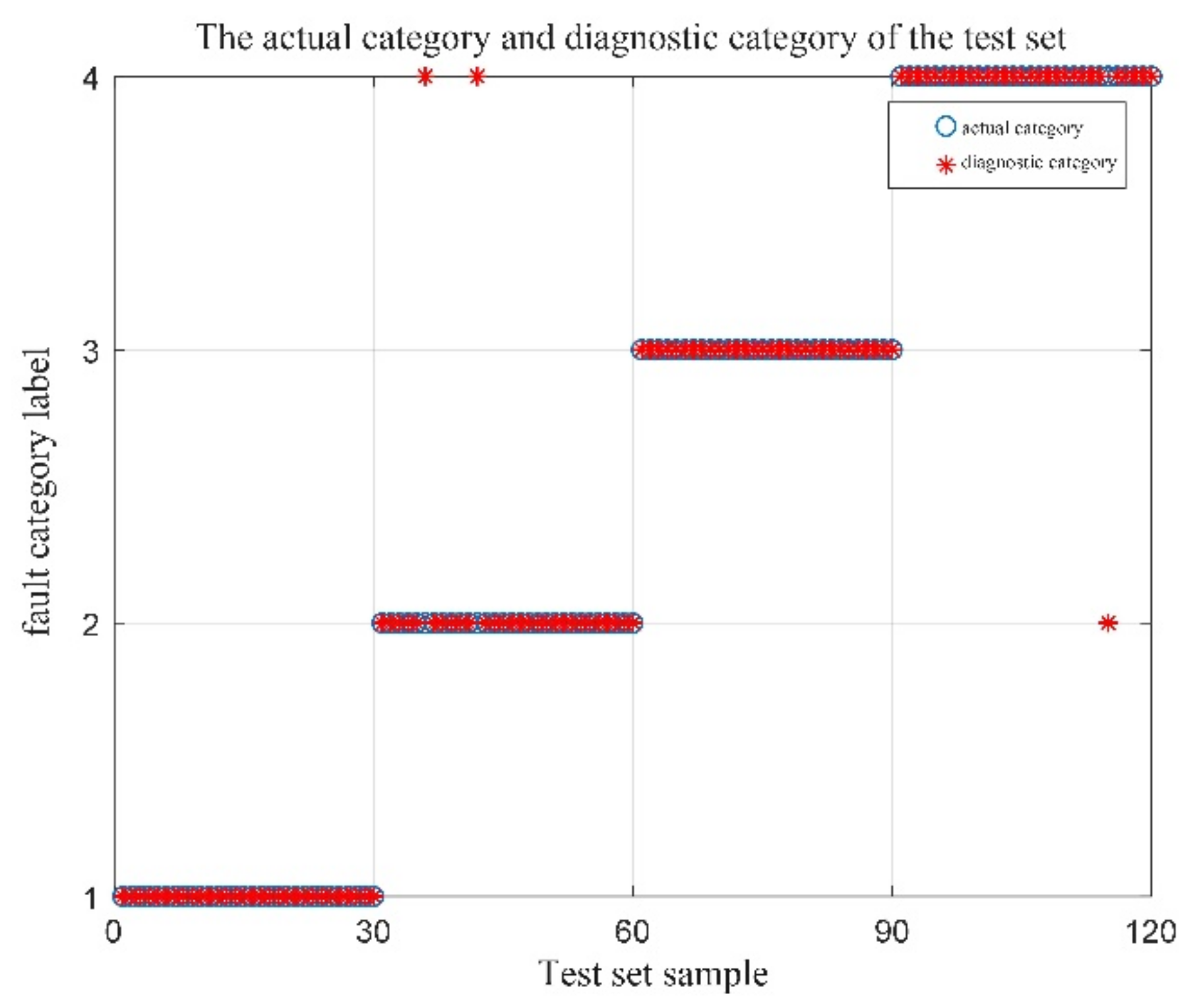

A total of 160 sets of vibration experimental data were selected from 40 sets of four running signals, of which 100 sets were used as training samples and the remaining 60 sets were used as test samples. Comparing the four test sets, the recognition results are shown in

Figure 17. The fault identification result of the original signal by MPE-SVM is shown in

Figure 17a. The fault identification result of QPSO-MPE-SVM to the original signal is shown in

Figure 17b. The results of MPE-SVM fault identification on the denoised (CEEMDAN-DFA-improved wavelet threshold function) signal are shown in

Figure 17c. The results of QPSO-MPE-SVM fault identification on the denoised (CEEMDAN-DFA-improved wavelet threshold function) signal are shown in

Figure 17d.

The following conclusions can be drawn from the analysis of

Figure 17.

When using the MPE-SVM method for fault identification on the original signal without denoising, there were 23 false identifications, and the identification accuracy was only 61.67%. When using the QPSO-MPE-SVM method for fault identification on the original signal without denoising, there were 17 false identifications, and the identification accuracy was 71.67%, which shows that the noise in the collected vibration signal had a large interference to the bearing fault diagnosis.

When using the MPE-SVM method for fault identification on the denoised signal, the number of false identifications was reduced to 10, and the identification accuracy increased to 83.33%. When using the QPSO-MPE-SVM method for fault identification on the denoised signal, the number of false identifications was only three and the fault identification accuracy was 95%.

By applying the comprehensive diagnosis method proposed in this paper to the experimental platform of rolling bearings, the fault diagnosis of the actual measured fault signal of the inner ring of the bearing was achieved. The de-noising process and fault feature extraction were completed, and the fault feature set was constructed to achieve fault identification. The experimental results showed that the fault identification accuracy could be 95%. The method was verified, by several experiments, to not only have high accuracy and reliability, but also not be limited to inner-ring fault diagnosis, also being applicable to vibration signals with non-smooth and non-linear characteristics (such as outer-ring fault signals). Therefore, the method has good practical application value.

5. Conclusions

This paper proposed a CEEMDAN-DFA-improved wavelet threshold denoising method and QPSO-MPE-SVM fault feature extraction and identification method, the purpose being to realize the fault diagnosis of the rolling-bearing vibration signal.

The denoising process with the CEEMDAN-DFA-improved wavelet threshold method is as follows: Firstly, the vibration signal is decomposed into IMF by CEEMDAN, and the DFA is performed on the IMF components. Then, the scaling function of each IMF component is calculated to select the noise-dominated IMF component. Finally, the improved wavelet threshold function is applied to denoise the noise-dominated IMFs. The de-noised IMFs and the remaining other IMFs are merged to get reconfigured signals. The validation results showed that compared with traditional denoising methods, the CEEMDAN-DFA-improved wavelet threshold function method proposed in this paper could better remove noise, effectively reduce the signal distortion, and maintain the original characteristics of the signal.

The fault feature extraction and identification with the QPSO-MPE-SVM method are as follows: Firstly, the reconfigured signal is decomposed again by CEEMDAN, and the correlation coefficients and Kurtosis values of each order IMF component are calculated; the IMF components with larger values about correlation coefficients and Kurtosis are selected for signal reconstruction, and the HHT envelope spectrum analysis is performed on the reconstructed signal to extract the fault characteristic frequencies. Then, the initial parameters of MPE are optimized with QPSO, the MPE value is calculated for the reconstructed signal, and the appropriate MPE value is selected to construct the rolling-bearing fault feature vectors. Finally, the fault feature vectors are inputted to the trained SVM for rolling-bearing fault type identification. The validation results showed that the MPE parameters were optimized by the QPSO, which makes the MPE values of the four signals achieve separation without overlap, which is more suitable for constructing fault feature sets for fault type identification.

The algorithms proposed in the paper were all validated by building an experimental platform of rolling bearings. The experimental results showed that the fault identification accuracy of rolling bearings could reach 95%; it not only has high accuracy and reliability, but also can be applicable to vibration signals with non-smooth and non-linear characteristics, having good practical application value.