Performance and Exergy Analyses of a Solar Assisted Heat Pump with Seasonal Heat Storage and Grey Water Heat Recovery Unit

Abstract

1. Introduction

2. Description of Analyzed Systems

2.1. Case Building

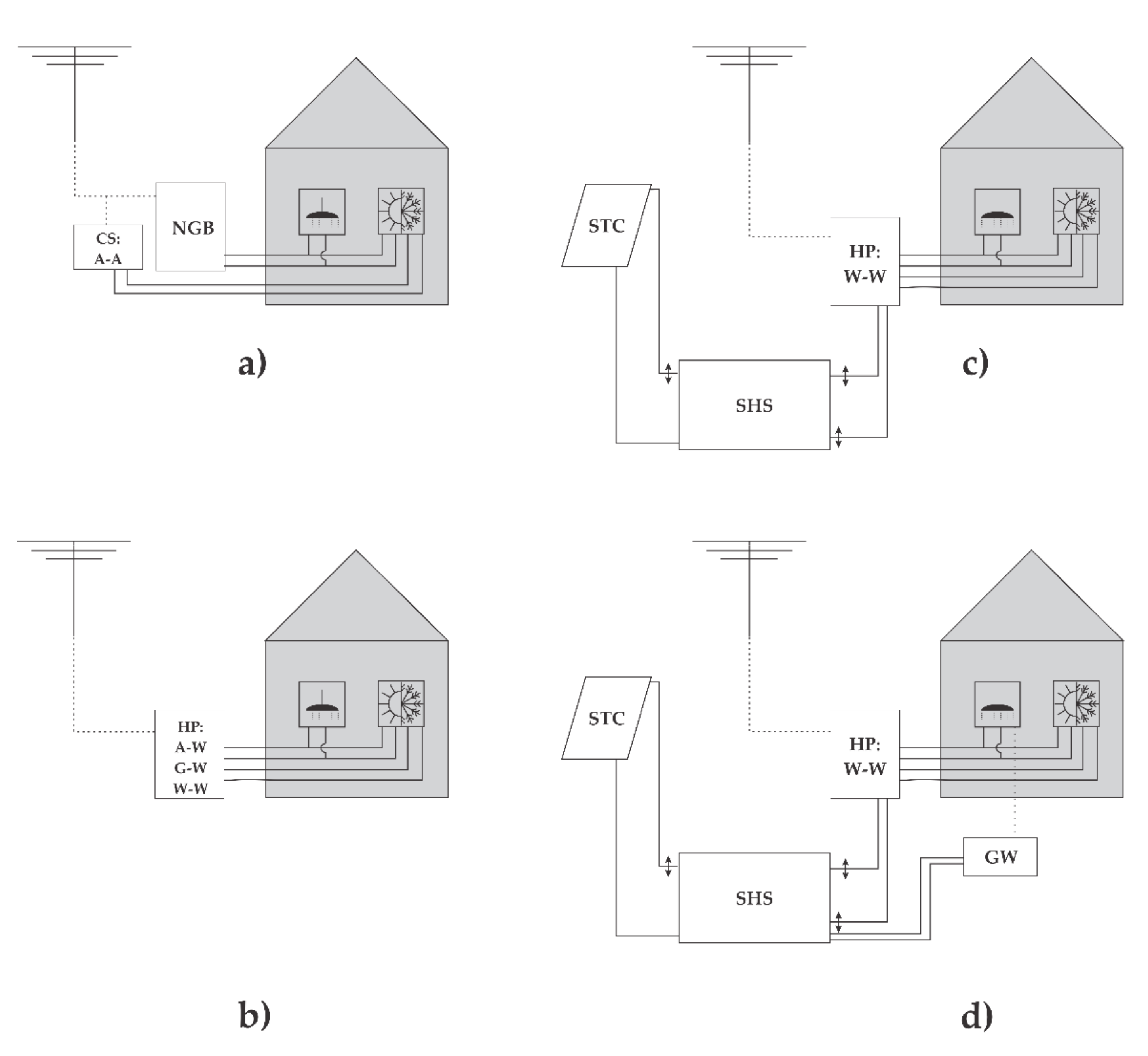

2.2. Description of Heating and Cooling Energy Production Systems

- GB: Building service systems based on a natural gas boiler for heating purposes and an auxiliary air–air vapor-compression cooling device for cooling purposes (Figure 3a).

- HP A–W, W–W, G–W: Building service systems based on air–water, water–water and ground–water heat pumps for heating and cooling purposes (Figure 3b).

- SHS(STC)–HP W–W: Building service systems based on a water–water heat pump for heating and cooling purposes, seasonal heat storage and solar thermal collectors (Figure 3c).

- SHS(STC + GW)–HP W–W: Building service systems based on a water–water heat pump for heating and cooling purposes, seasonal heat storage, solar thermal collectors and grey water recovery unit (Figure 3d).

2.2.1. Building Heating and Cooling Energy Distribution Systems

2.2.2. Building Ventilation System

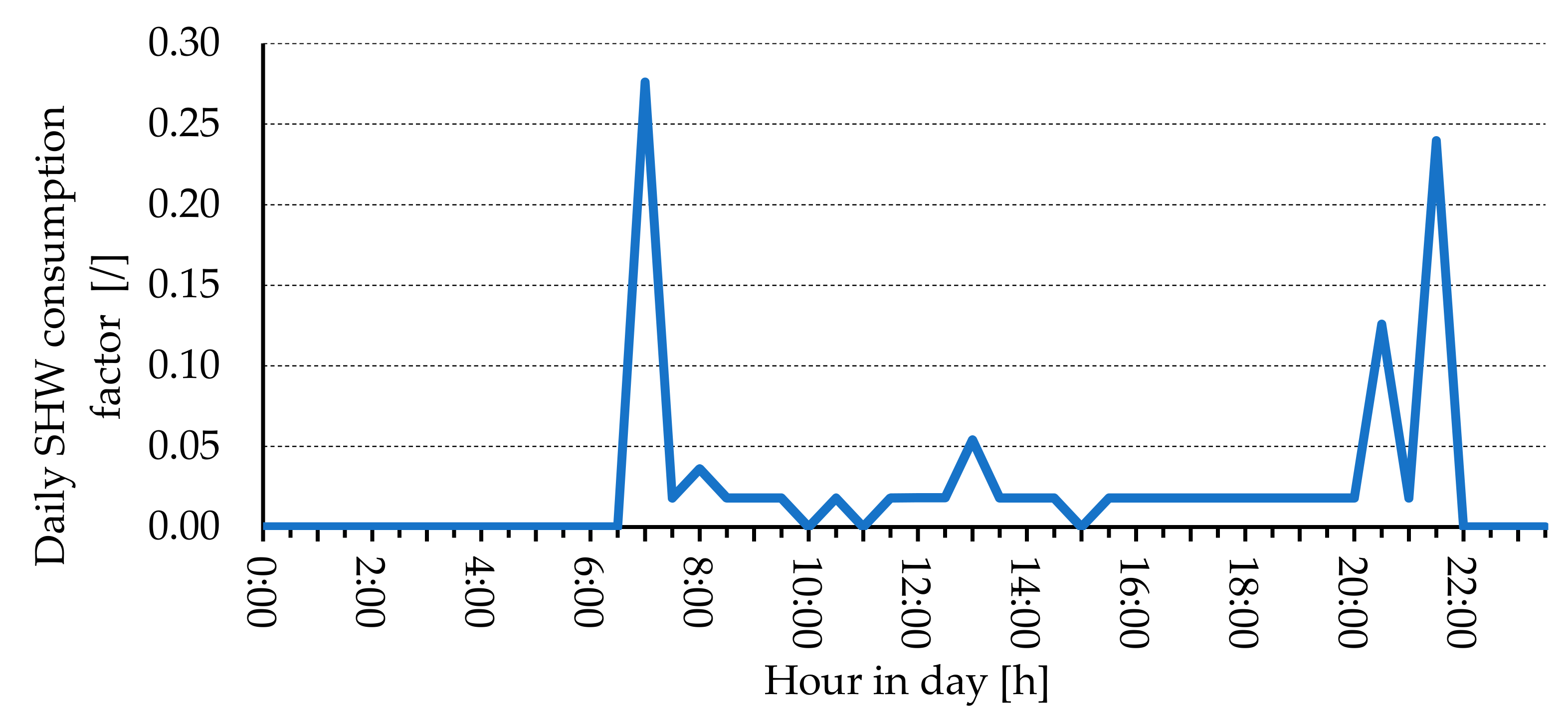

2.2.3. Sanitary Hot Water System

2.2.4. Solar Thermal Collector System

2.2.5. Seasonal Heat Storage

2.2.6. Grey Water Heat Recovery Unit

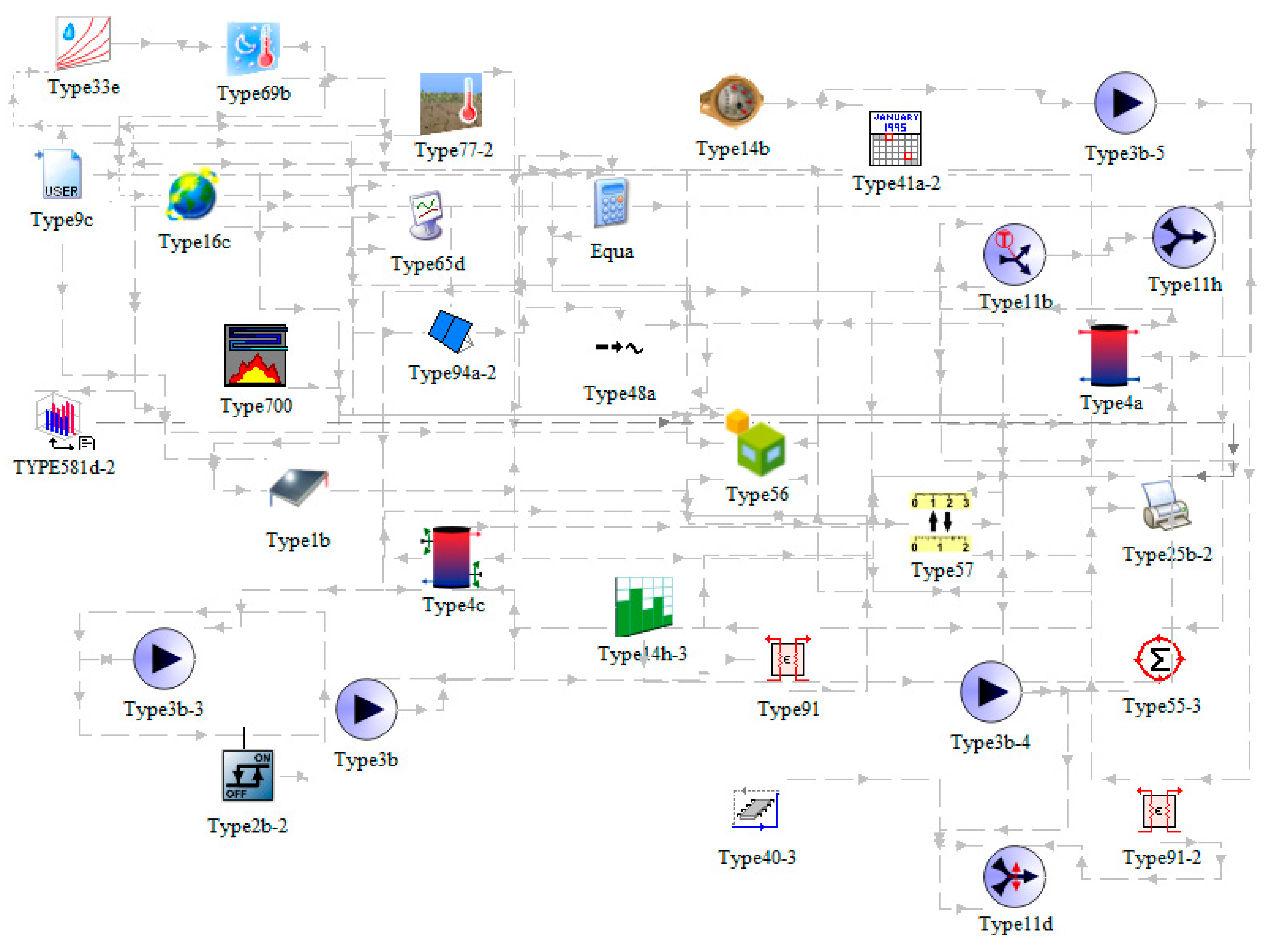

2.3. Description of the Simulation Framework

3. Exergy Efficiency Calculations

4. Results and Discussion

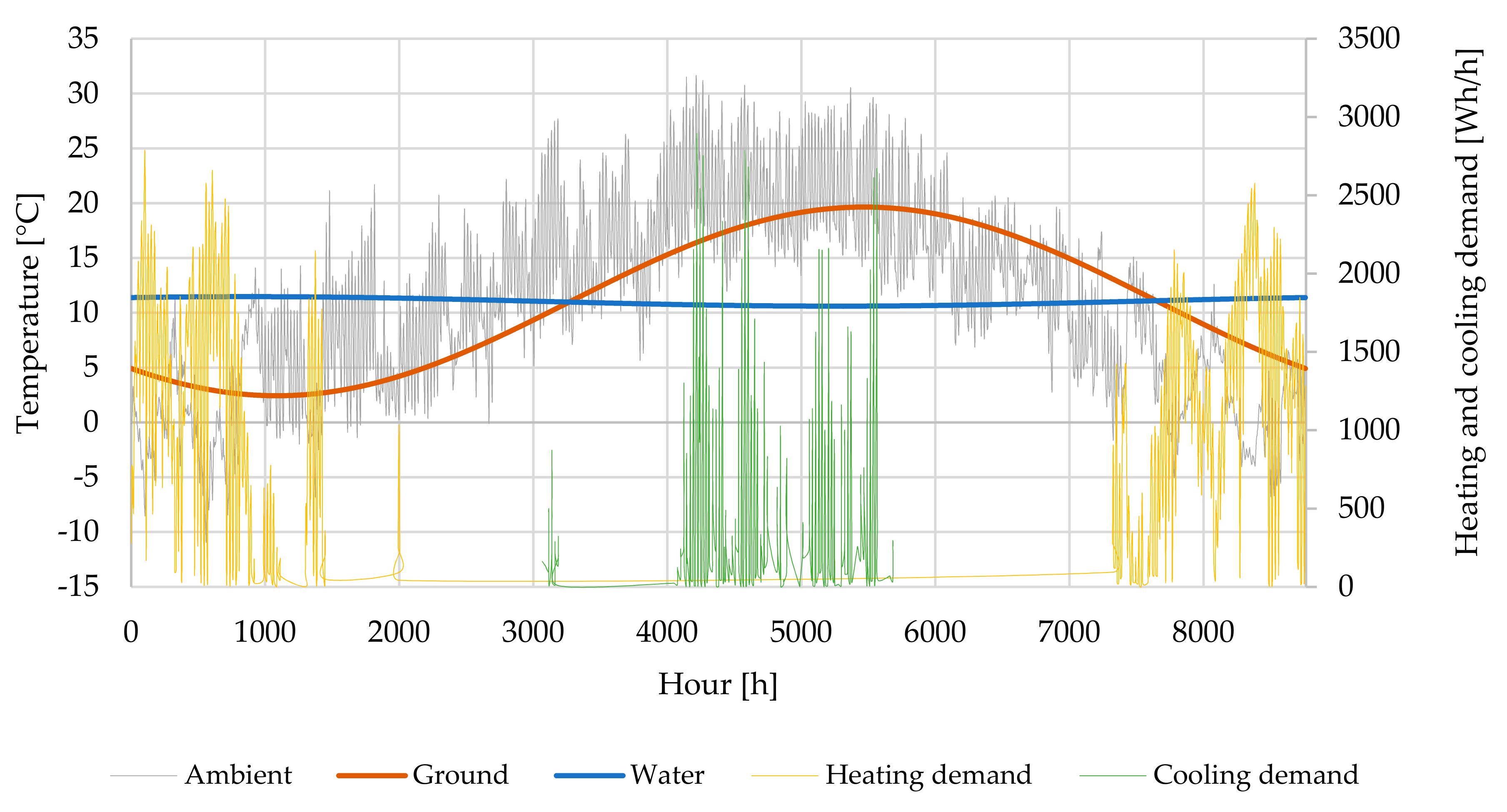

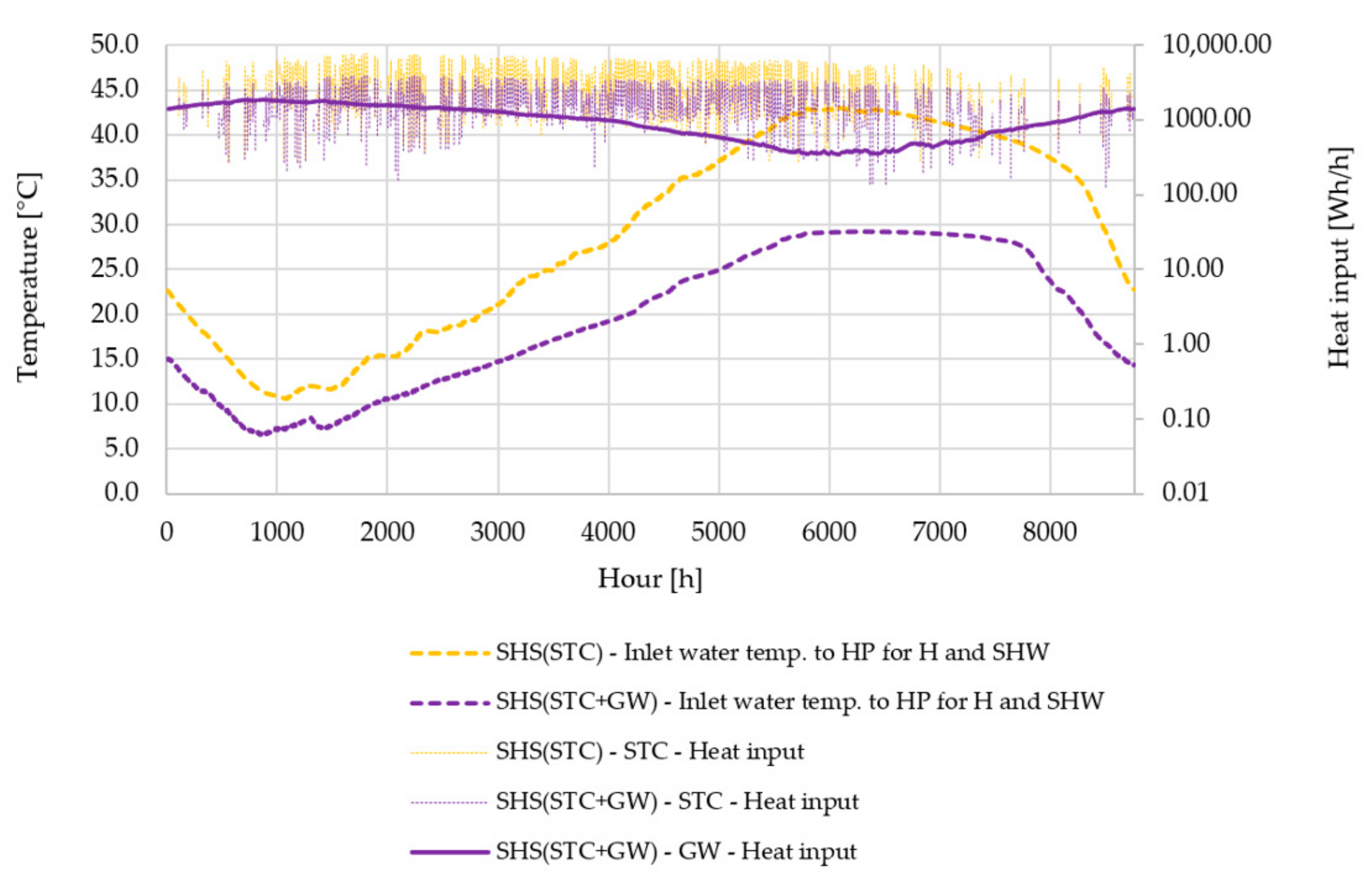

4.1. Performance Analysis of Building Simulation

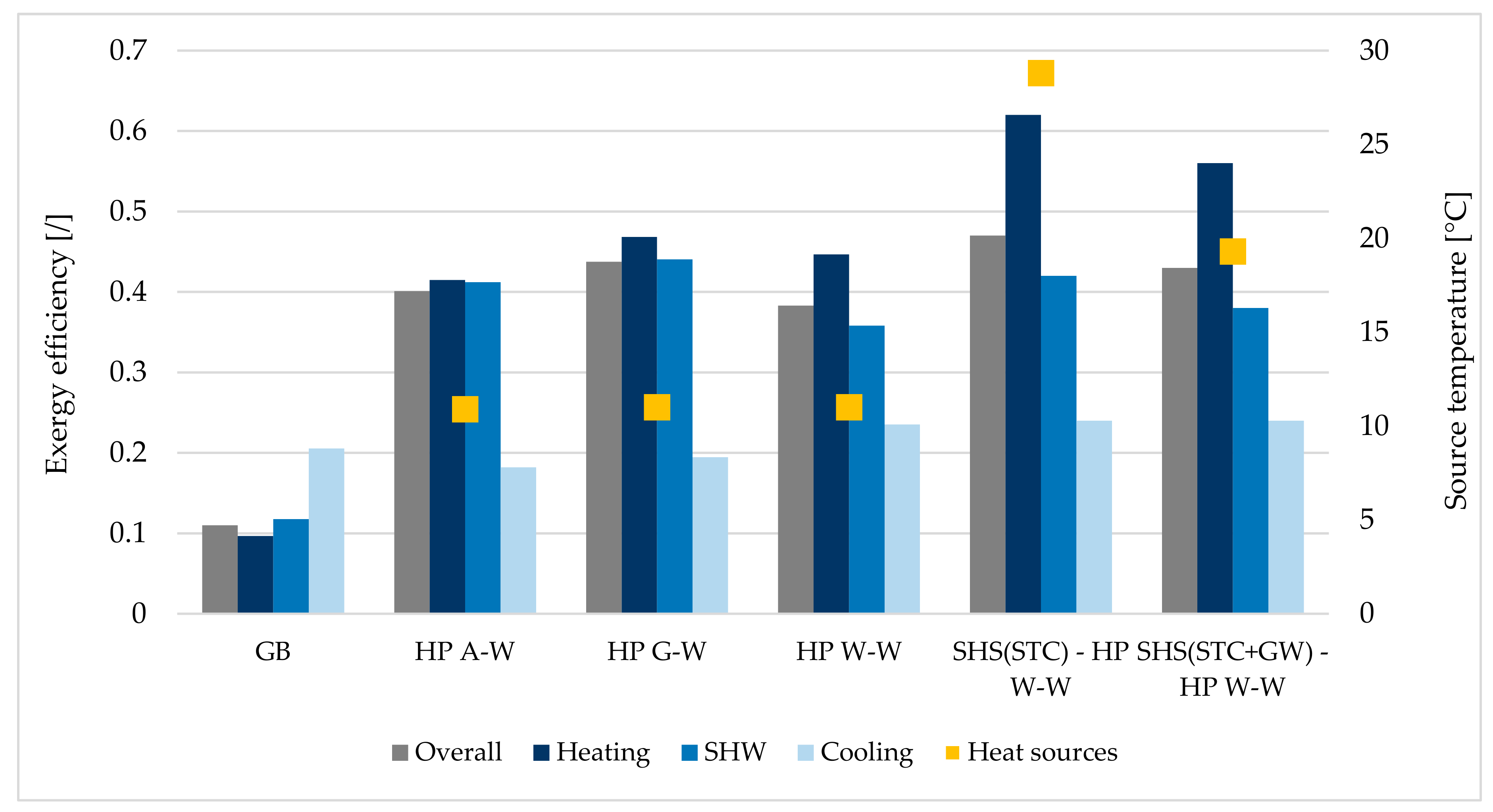

4.2. Exergy Efficiency—Annualy Averaged

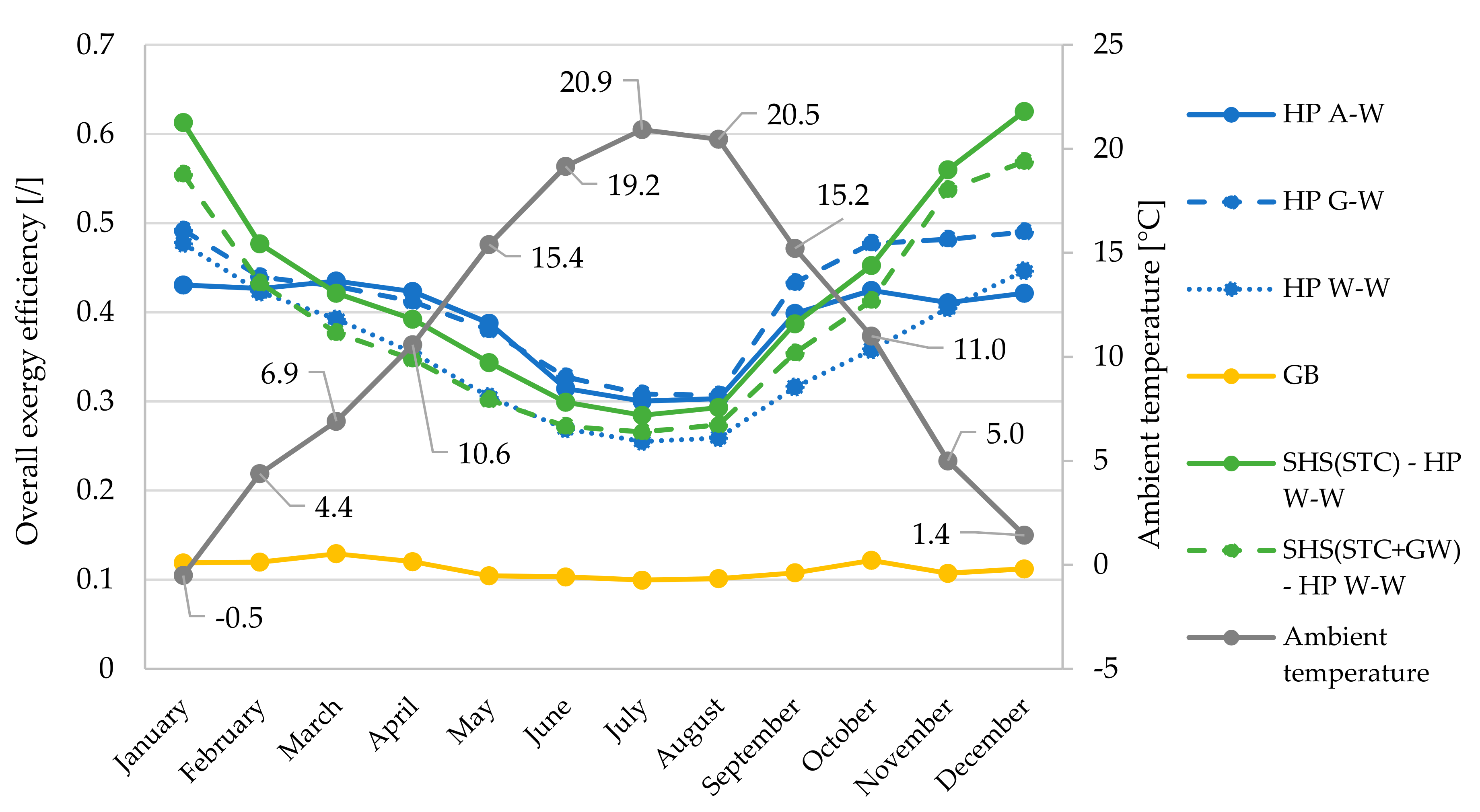

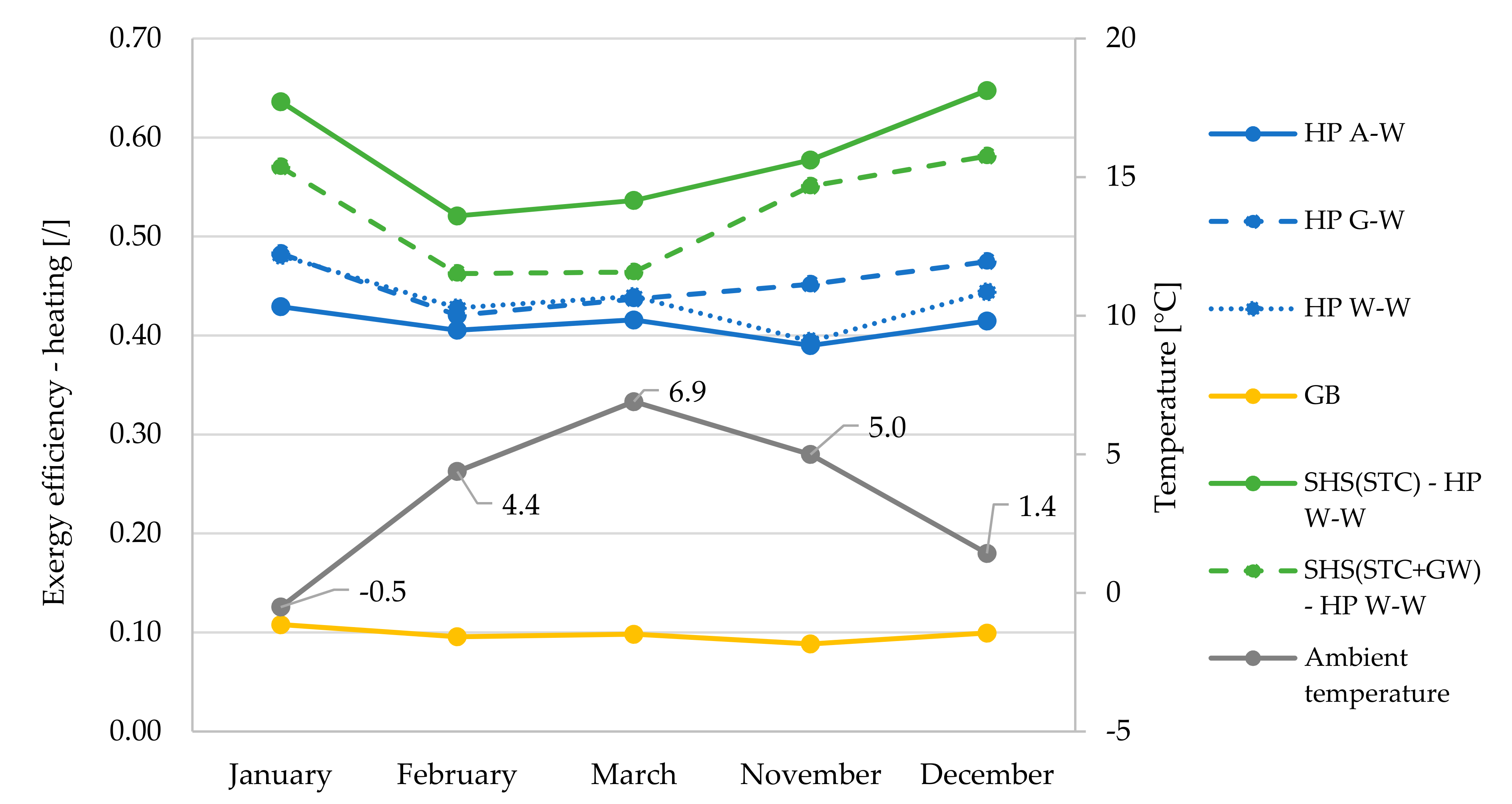

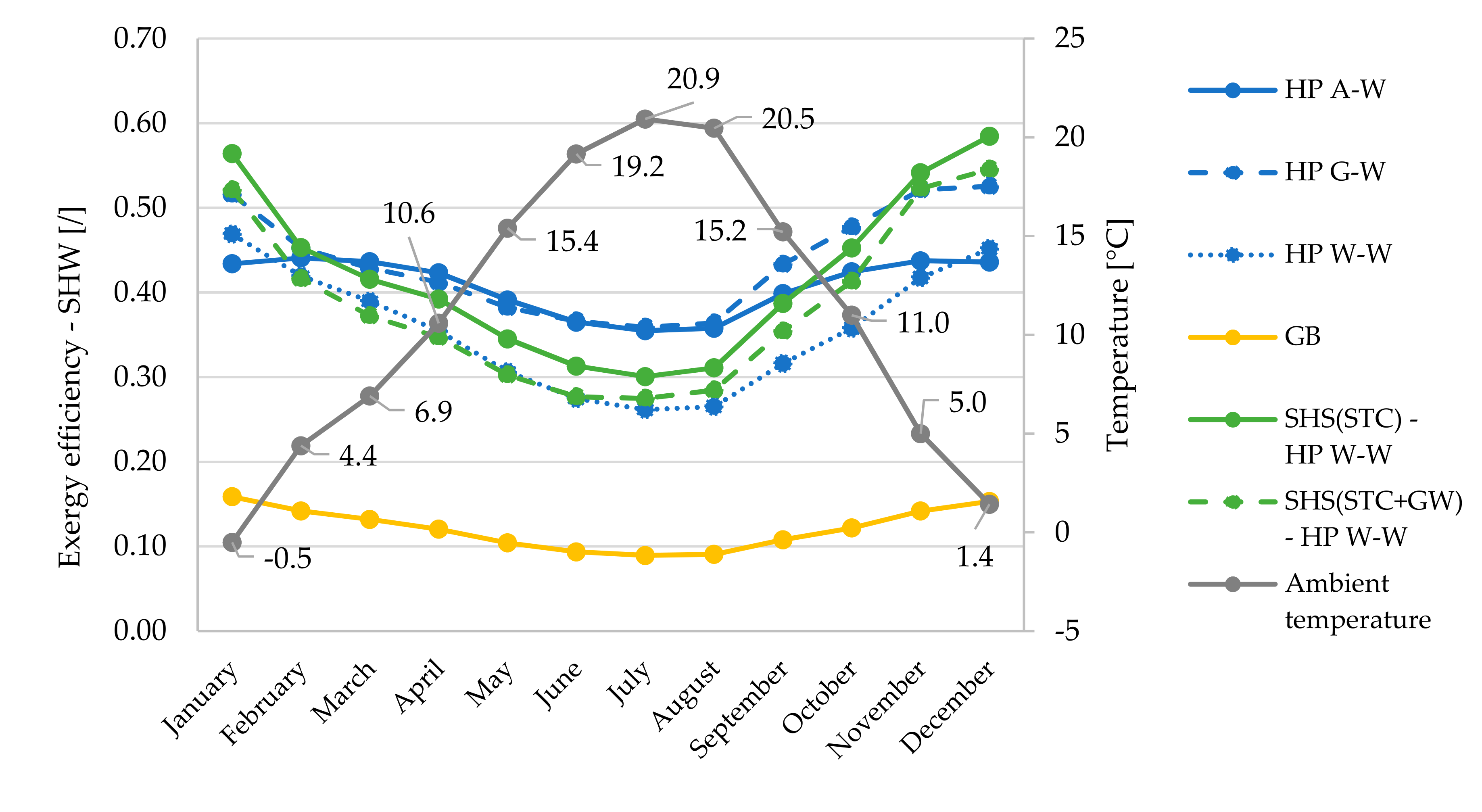

4.3. Exergy Efficiency—Monthly Averaged

5. Conclusions

- The system based on the NG boiler for space heating and SHW production purposes has up to 36% percentage points lower overall annual exergy efficiency compared to the most efficient system (0.11 vs. 0.47—SHS (STC)–HP W–W). This shows an enormous waste of exergy when NG is burned for heating purposes only. From the point of view of overall energy (and exergy) efficiency, it would be much more sensible to promote systems such as combined heat and power plant (electrical energy + heat production). The other possible systems that are far more energy efficient are based on natural gas-driven heat pumps and hybrid heat pumps. In the latter case, natural gas can be used as a heat source, while, in the former case, burning natural gas represents chemical energy that can be converted into mechanical work in the compressor.

- The system based on SHS in combination with STC (SHS (STC)–HP W–W) was identified as one of the most efficient systems in terms of overall exergy efficiency. The main factor contributing to higher efficiency values is higher water temperatures within SHS, as this is the heat source for the HP W–W. Compared to ambient air, ground and ground water, the annual average water temperature within the SHS was significantly higher (10.9 vs. 11.0 vs. 11.0 vs. 28.8 K).

- Special attention should be paid to auxiliary pumps in real systems, as electrical energy is pure exergy and represents direct exergy losses (entropy generation). For example, HP A–W does not require an auxiliary water pump, unlike HP W–W and HP G–W (with a rated electrical power of 350 W and 50 W respectively) and systems with SHS(STC) and SHS(STC + GW)-rated electrical outputs of 50 W and 50 + 50 W, respectively. Therefore, the STC and GW based systems have achieved an overall energy efficiency of 0.43, which is directly comparable to the efficiency of the system with a HP G–W (0.44) and is close to the system based on HP A–W (0.40). However, the system based on SHS(STC+GW) represents an enormous energy saving by using the waste heat from grey water, as described in more detail in the Addendum.

6. Addendum

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A–W | Air—water heat pump |

| ACH | Air-change rate |

| COP | Coefficient of performance |

| G–W | Ground—water heat pump |

| GW | Grey water unit |

| HP | Heat pump |

| NG | Natural gas |

| PV/T | Photovoltaic/thermal |

| RES | Renewable energy sources |

| SCW | Sanitary cold water |

| SHS | Seasonal heat storage |

| SHW | Sanitary hot water |

| SPF | Seasonal performance factor |

| STC | Solar thermal collectors |

| W–W | Water—water heat pump |

Nomenclature

| e | Specific exergy (J/kg) |

| E | Exergy (J) |

| H | Calorific value (J/kg) |

| Q | Heat (J) |

| T | Temperature (K) |

| Greek Letters | |

| η | Efficiency (/) |

| Subscripts | |

| a | Ambient |

| c | Cooling |

| CH4 | Methane |

| ex | Exergy |

| h | Heating |

| in | Input |

| ov | Overall |

| s | Superior |

| shw | Sanitary hot-water |

References

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: An EU Strategy on Heating and Cooling. Available online: https://ec.europa.eu/transparency/regdoc/rep/1/2016/EN/1-2016-51-EN-F1-1.PDF (accessed on 19 October 2020).

- Kazanci, O.B.; Shukuya, M.; Olesen, B.W. Exergy performance of different space heating systems: A theoretical study. Build. Environ. 2016, 99, 119–129. [Google Scholar] [CrossRef]

- Razmara, M.; Maasoumy, M.; Shahbakhti, M.; Robinett, R.D. Optimal exergy control of building HVAC system. Appl. Energy 2015, 156, 555–565. [Google Scholar] [CrossRef]

- Sutherland, K. Wastewater filtration: A future for grey water recycling. Filtr. Sep. 2008, 45, 18–21. [Google Scholar] [CrossRef]

- Dannemand, M.; Perers, B.; Furbo, S. Performance of a demonstration solar PVT assisted heat pump system with cold buffer storage and domestic hot water storage tanks. Energy Build. 2019, 188, 46–57. [Google Scholar] [CrossRef]

- Hengel, F.; Heschl, C.; Inschlag, F.; Klanatsky, P. System efficiency of pvt collector-driven heat pumps. Int. J. Thermofluids 2020, 5, 100034. [Google Scholar] [CrossRef]

- Dong, X.; Tian, Q.; Li, Z. Energy and exergy analysis of solar integrated air source heat pump for radiant floor heating without water. Energy Build. 2017, 142, 128–138. [Google Scholar] [CrossRef]

- Akbulut, U.; Utlu, Z.; Kincay, O. Exergy, exergoenvironmental and exergoeconomic evaluation of a heat pump-integrated wall heating system. Energy 2016, 107, 502–522. [Google Scholar] [CrossRef]

- Suleman, F.; Dincer, I.; Agelin-Chaab, M. Energy and exergy analyses of an integrated solar heat pump system. Appl. Therm. Eng. 2014, 73, 559–566. [Google Scholar] [CrossRef]

- Naranjo-Mendoza, C.; Oyinlola, M.A.; Wright, A.J.; Greenough, R.M. Experimental study of a domestic solar-assisted ground source heat pump with seasonal underground thermal energy storage through shallow boreholes. Appl. Therm. Eng. 2019, 162, 114218. [Google Scholar] [CrossRef]

- Ezzat, M.F.; Dincer, I. Energy and exergy analyses of a new geothermal–solar energy based system. Sol. Energy 2016, 134, 95–106. [Google Scholar] [CrossRef]

- Wong, L.T.; Mui, K.W.; Guan, Y. Shower water heat recovery in high-rise residential buildings of Hong Kong. Appl. Energy 2010, 87, 703–709. [Google Scholar] [CrossRef]

- Ni, L.; Lau, S.K.; Li, H.; Zhang, T.; Stansbury, J.S.; Shi, J.; Neal, J. Feasibility study of a localized residential grey water energy-recovery system. Appl. Therm. Eng. 2012, 39, 53–62. [Google Scholar] [CrossRef]

- McNabola, A.; Shields, K. Efficient drain water heat recovery in horizontal domestic shower drains. Energy Build. 2013, 59, 44–49. [Google Scholar] [CrossRef]

- Sun, X.; Wu, J.; Wang, R. Exergy analysis and comparison of multi-functional heat pump and conventional heat pump systems. Energy Convers. Manag. 2013, 73, 51–56. [Google Scholar] [CrossRef]

- Fu, H.D.; Pei, G.; Ji, J.; Long, H.; Zhang, T.; Chow, T.T. Experimental study of a photovoltaic solar-assisted heat-pump/heat-pipe system. Appl. Therm. Eng. 2012, 40, 343–350. [Google Scholar] [CrossRef]

- Ammar, A.A.; Sopian, K.; Alghoul, M.A.; Elhub, B.; Elbreki, A.M. Performance study on photovoltaic/thermal solar-assisted heat pump system. J. Therm. Anal. Calorim. 2019, 136, 79–87. [Google Scholar] [CrossRef]

- Caliskan, H.; Hepbasli, A.; Dincer, I. Exergy Analysis and Sustainability Assessment of a Solar-Ground Based Heat Pump With Thermal Energy Storage. J. Sol. Energy Eng. 2011, 133. [Google Scholar] [CrossRef]

- Abusoglu, A.; Sedeeq, M.S. Comparative exergoenvironmental analysis and assessment of various residential heating systems. Energy Build. 2013, 62, 268–277. [Google Scholar] [CrossRef]

- Yildiz, A.; Güngör, A. Energy and exergy analyses of space heating in buildings. Appl. Energy 2009, 86, 1939–1948. [Google Scholar] [CrossRef]

- Zmeureanu, R.; Yu Wu, X. Energy and exergy performance of residential heating systems with separate mechanical ventilation. Energy 2007, 32, 187–195. [Google Scholar] [CrossRef]

- EEN 18599. 2007: Energy Efficiency of Buildings—Calculation of the Energy Needs, Delivered Energy and Primary Energy for Heating, Cooling, Ventilation, Domestic Hot Water and Lighting; German Institute for Standardisation: Berlin, Germany, 2007. [Google Scholar]

- Heat Pump. Available online: https://kronoterm.com/en/ (accessed on 19 October 2020).

- SAP 2016 Seasonal Efficiency Values for Boilers (All Fuels), Building Research Establishment Ltd. (BRE). Available online: www.ncmpcdb.org.uk/sap (accessed on 19 October 2020).

- CEN—CR 1752 Ventilation for Buildings—Design Criteria for the Indoor Environment. Available online: https://standards.iteh.ai/catalog/standards/cen/b1ab2055-b8b7-442f-8d15-06719bf38a69/cr-1752-1998 (accessed on 23 December 2020).

- Hidria_kolektorji.pdf. Available online: http://www.lagoja.si/pdf/Hidria_kolektorji.pdf (accessed on 23 December 2020).

- Niewitecka, K. Possibilities of heat energy recovery from greywater systems. E3S Web Conf. 2018, 30, 03003. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and Sustainable Development; Elsevier Science: Newnes, Australia, 2012; ISBN 9780080970899. [Google Scholar]

- Rant, Z. Eksergija goriv. Strojniški Vestn. J. Mech. Eng. 2017, 5, 23–40. [Google Scholar]

| Dimension | Value |

|---|---|

| U—outside wall | 0.142 W/m2K |

| U—roof | 0.155 W/m2K |

| U—inner wall | 0.426 W/m2K |

| U—floor to ground | 0.211 W/m2K |

| U—glazing | 1.4 W/m2K |

| g of glazing | 0.62 |

| Infiltration as air exchange per hour | 0.2 h−1 |

| Heat gains | 5 W/m2 |

| Heating set point | 20 °C |

| Cooling set point | 25 °C |

| Type of Heat/Cold Generator | Characteristic of Generator |

|---|---|

| Air—water heat pump [23] | , at A2/W35 |

| , at A35/W7 | |

| Ground (brine)—water heat pump [23] | , at B0/W35 |

| , at B10/W7 | |

| Water—water heat pump [23] | , at W10/W35 |

| , at W10/W7 | |

| Natural gas boiler [24] | |

| Auxiliary air—air vapor-compression cooling system [22] | at A35/W7 |

| Characteristic | Value |

|---|---|

| Type | Flat plat collector |

| Length × Width (mm) | 2170 × 1170 |

| Intercept efficiency | 0.79 |

| Efficiency slope (W/m2K) | 4.03 |

| Efficiency curvature (W/m2K2) | 0.0107 |

| Component | TRNSYS Type |

|---|---|

| Building | TYPE 56 |

| Solar collector | TYPE 1 |

| Seasonal and SHW storage tank | TYPE 4 |

| Weather and data reader | TYPE 9 |

| Pump, fan | TYPE 3 |

| Heat pump—modelled by multi-dimensional data interpolation | TYPE 581 |

| Natural gas boiler | TYPE 700 |

| ON/OFF Differential controller | TYPE 2 |

| Solar radiation processor | TYPE 16 |

| Soil temperature profile | TYPE77 |

| Heat exchanger, recuperator | TYPE 91 |

| Daily, annual occupation | TYPE 14 |

| Ventilation system control | TYPE 40 |

| Equation editor | EQUA |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poredoš, P.; Vidrih, B.; Poredoš, A. Performance and Exergy Analyses of a Solar Assisted Heat Pump with Seasonal Heat Storage and Grey Water Heat Recovery Unit. Entropy 2021, 23, 47. https://doi.org/10.3390/e23010047

Poredoš P, Vidrih B, Poredoš A. Performance and Exergy Analyses of a Solar Assisted Heat Pump with Seasonal Heat Storage and Grey Water Heat Recovery Unit. Entropy. 2021; 23(1):47. https://doi.org/10.3390/e23010047

Chicago/Turabian StylePoredoš, Primož, Boris Vidrih, and Alojz Poredoš. 2021. "Performance and Exergy Analyses of a Solar Assisted Heat Pump with Seasonal Heat Storage and Grey Water Heat Recovery Unit" Entropy 23, no. 1: 47. https://doi.org/10.3390/e23010047

APA StylePoredoš, P., Vidrih, B., & Poredoš, A. (2021). Performance and Exergy Analyses of a Solar Assisted Heat Pump with Seasonal Heat Storage and Grey Water Heat Recovery Unit. Entropy, 23(1), 47. https://doi.org/10.3390/e23010047