Partitioned Stator Switched Flux Machine: Novel Winding Configurations

Abstract

1. Introduction

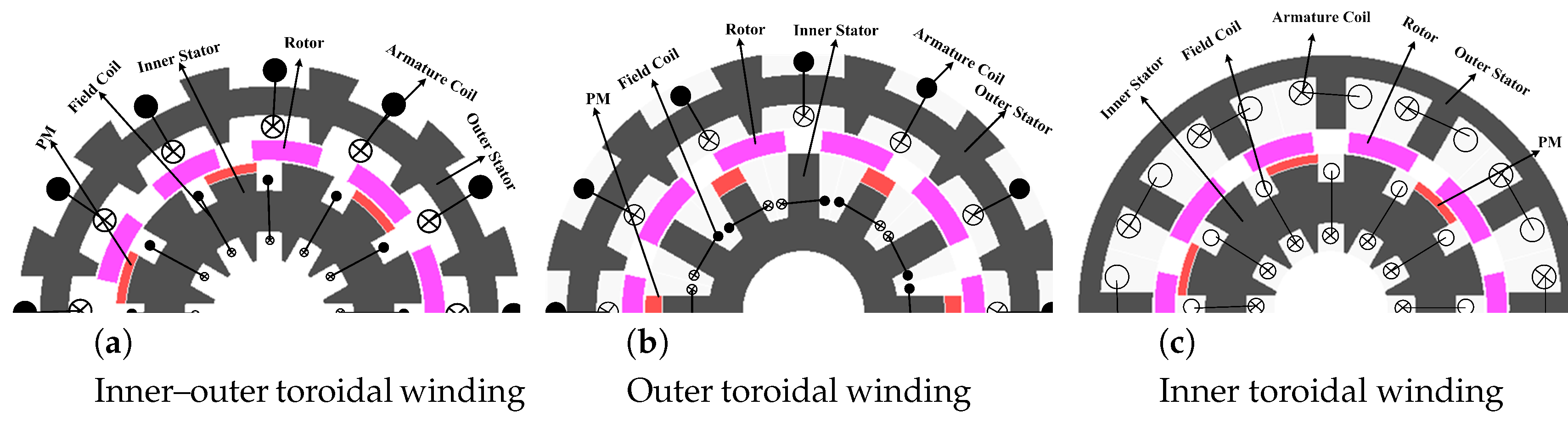

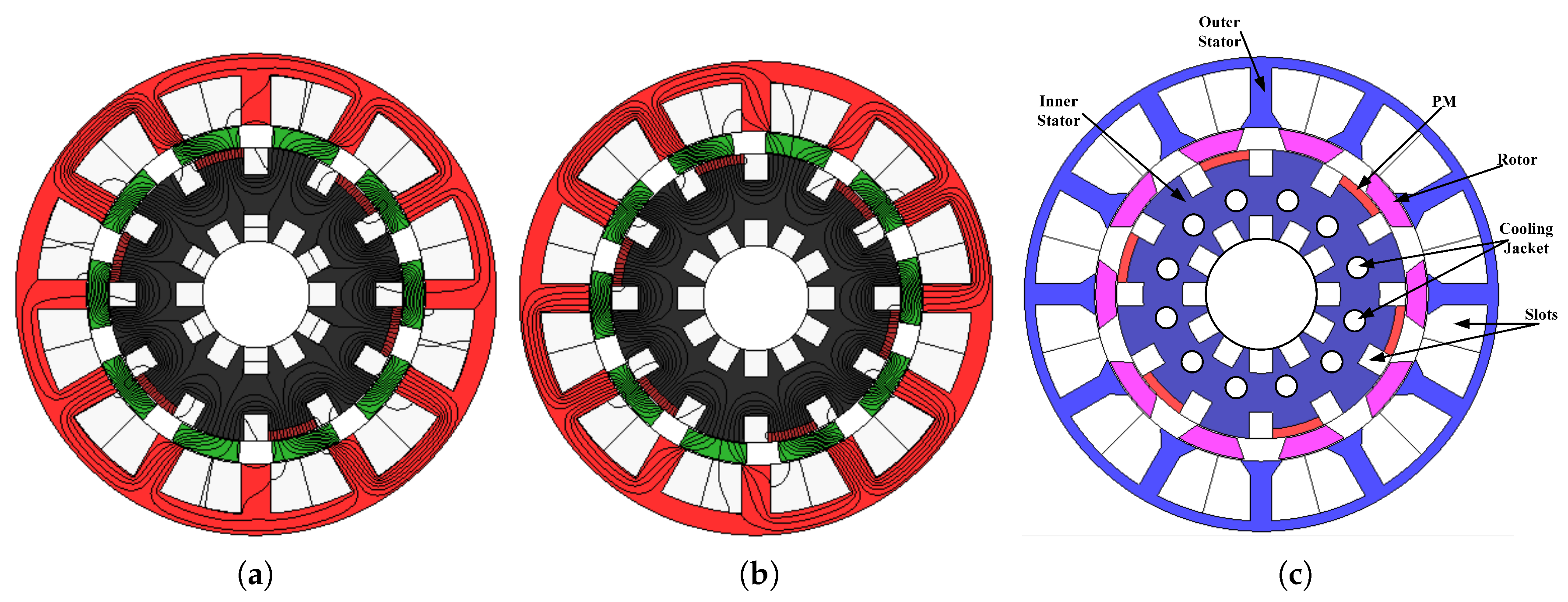

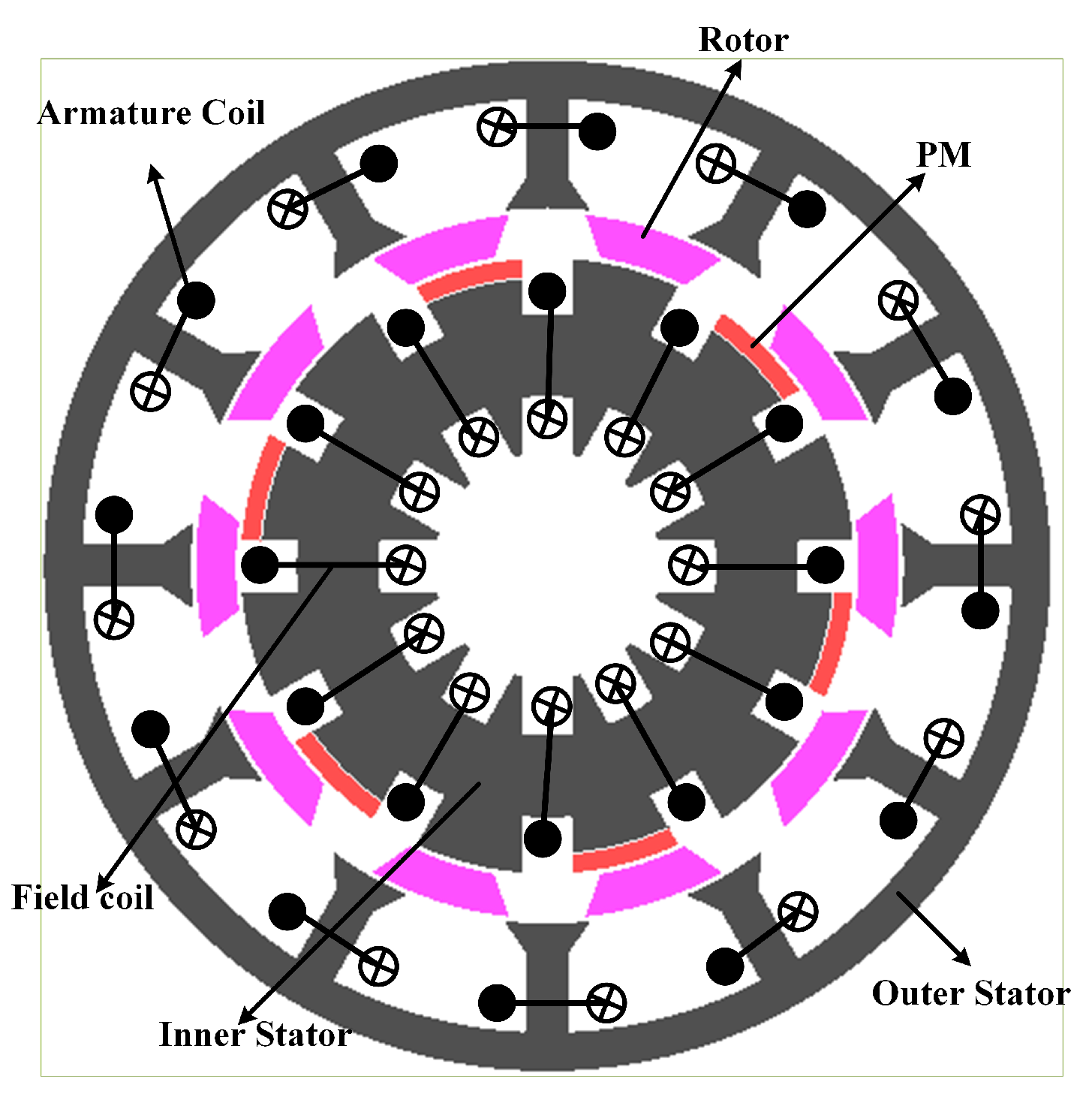

2. Design of Different Winding Configurations

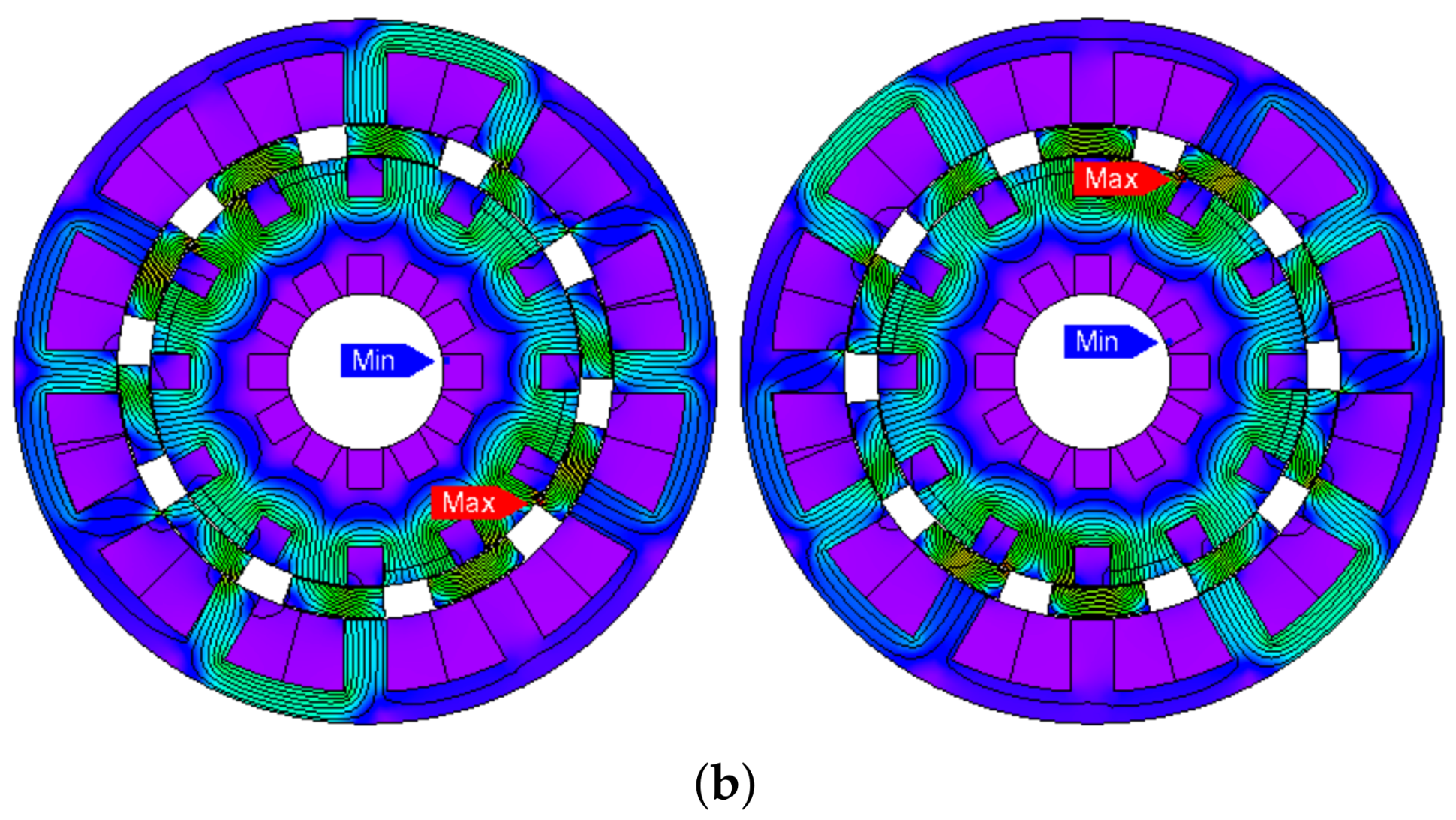

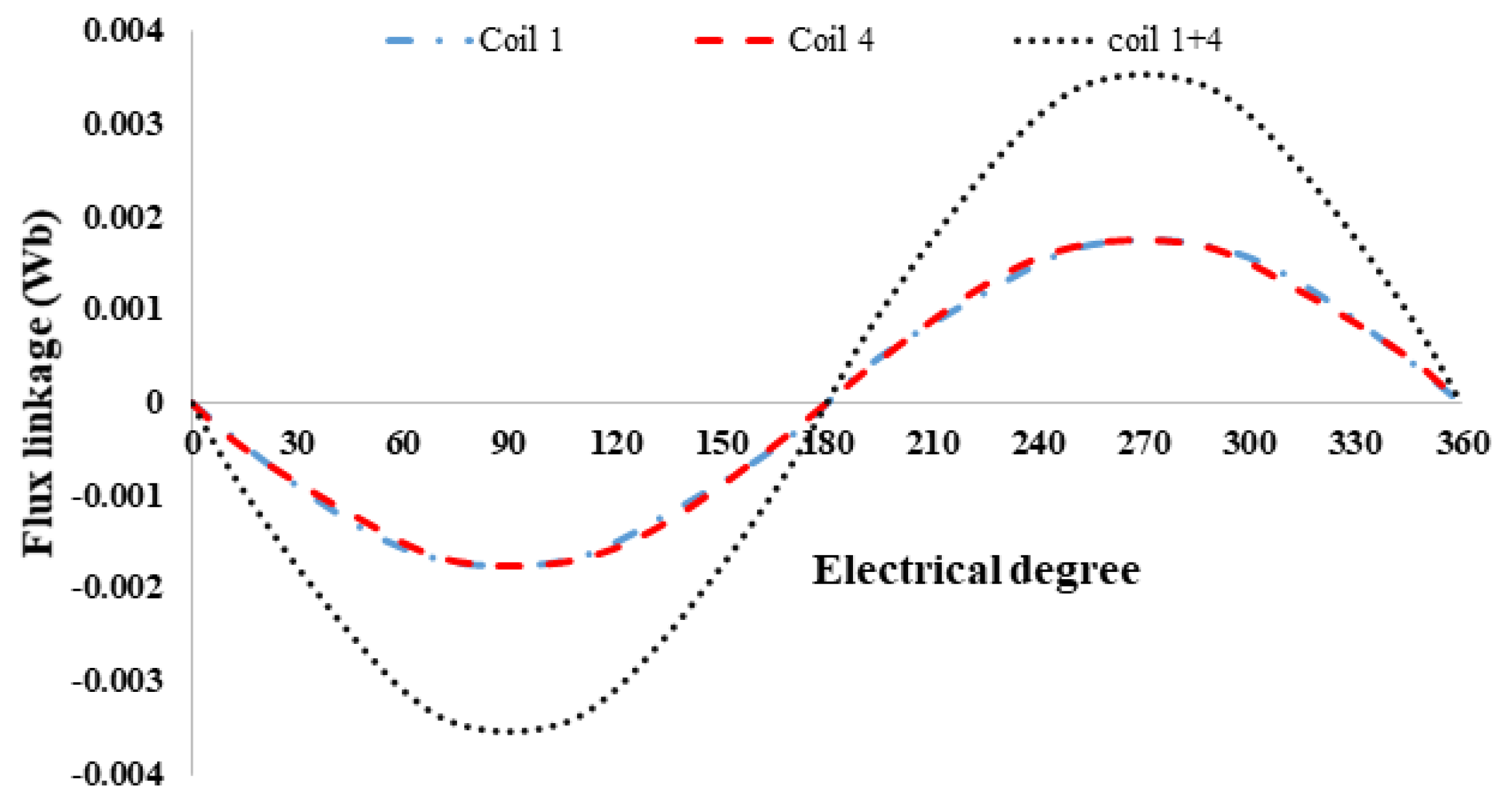

3. Operation Principle and Machine Topology

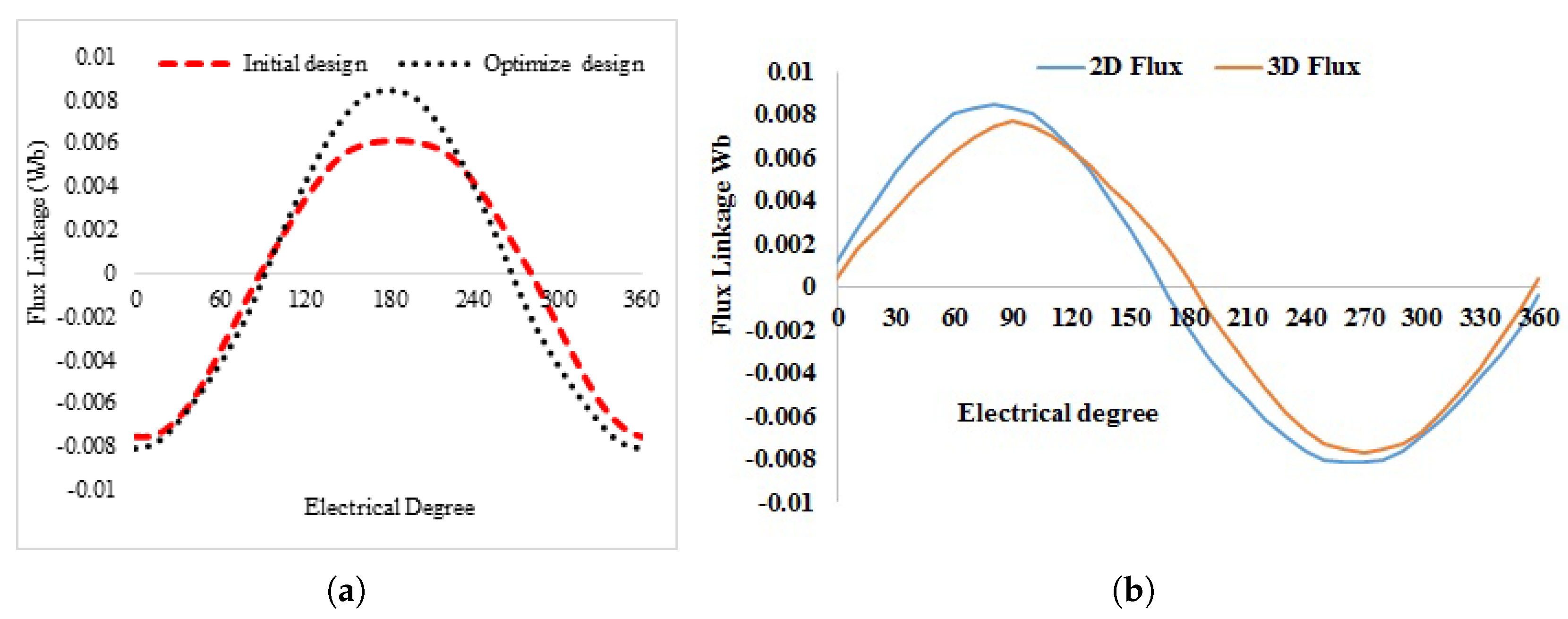

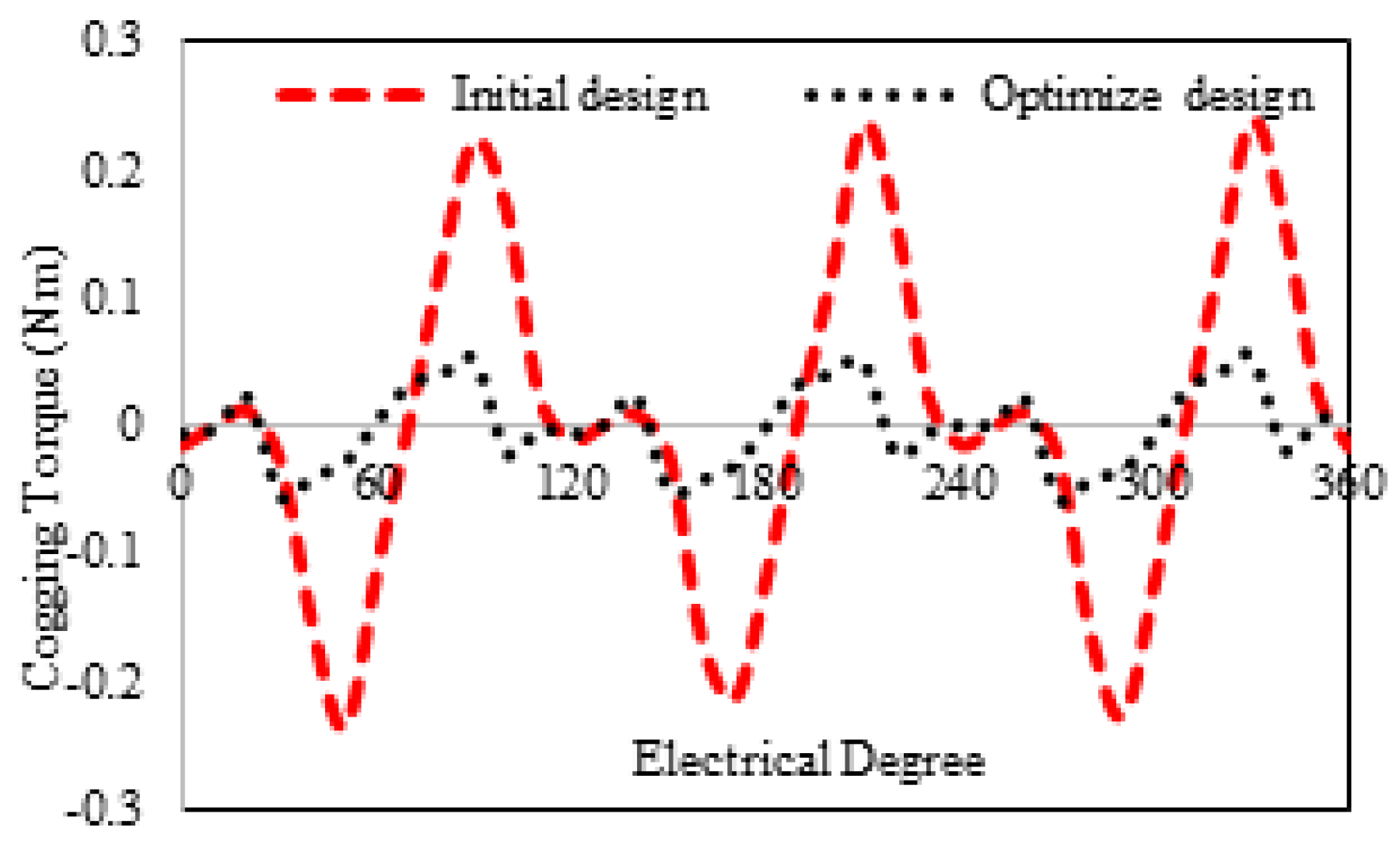

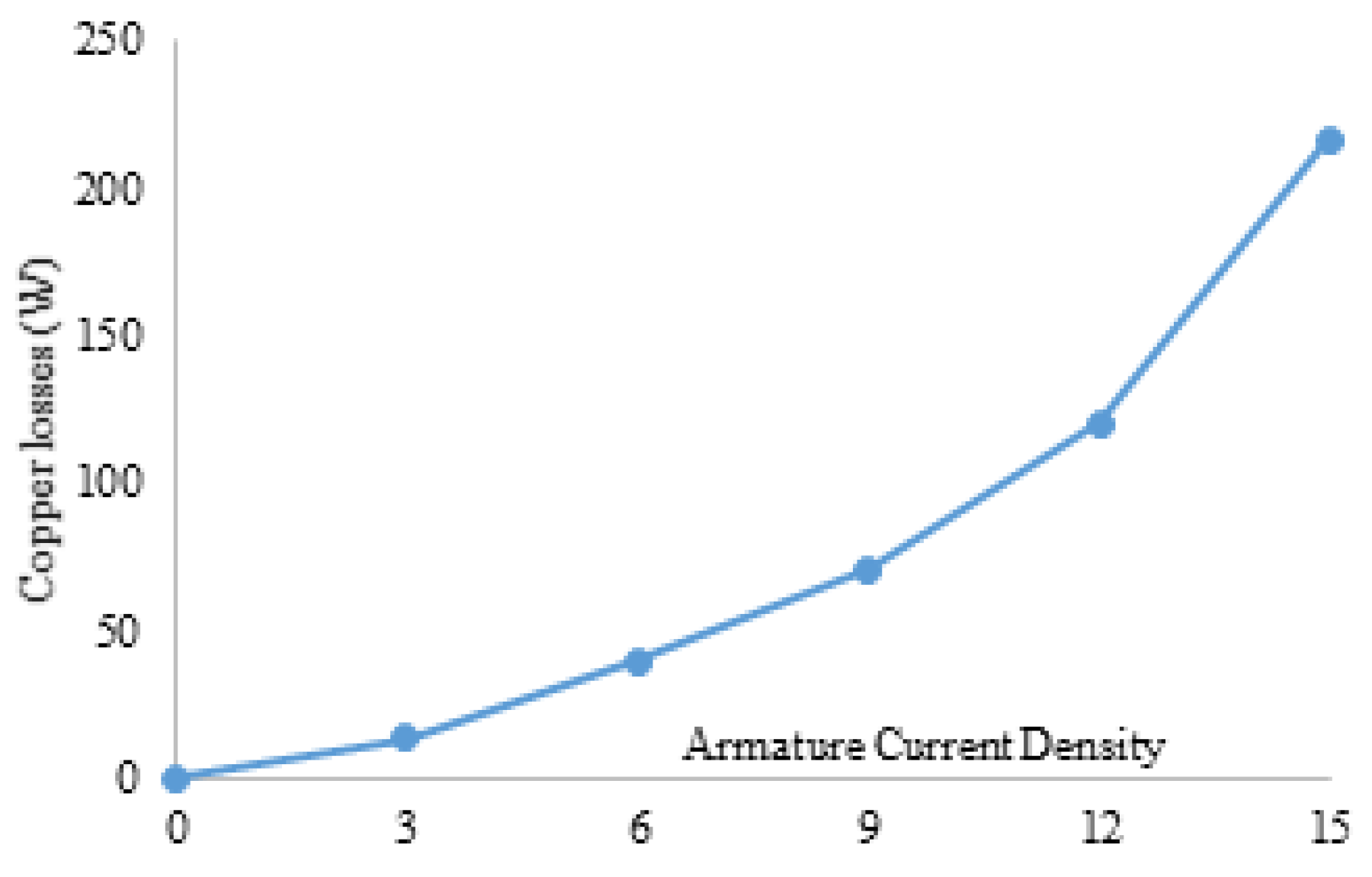

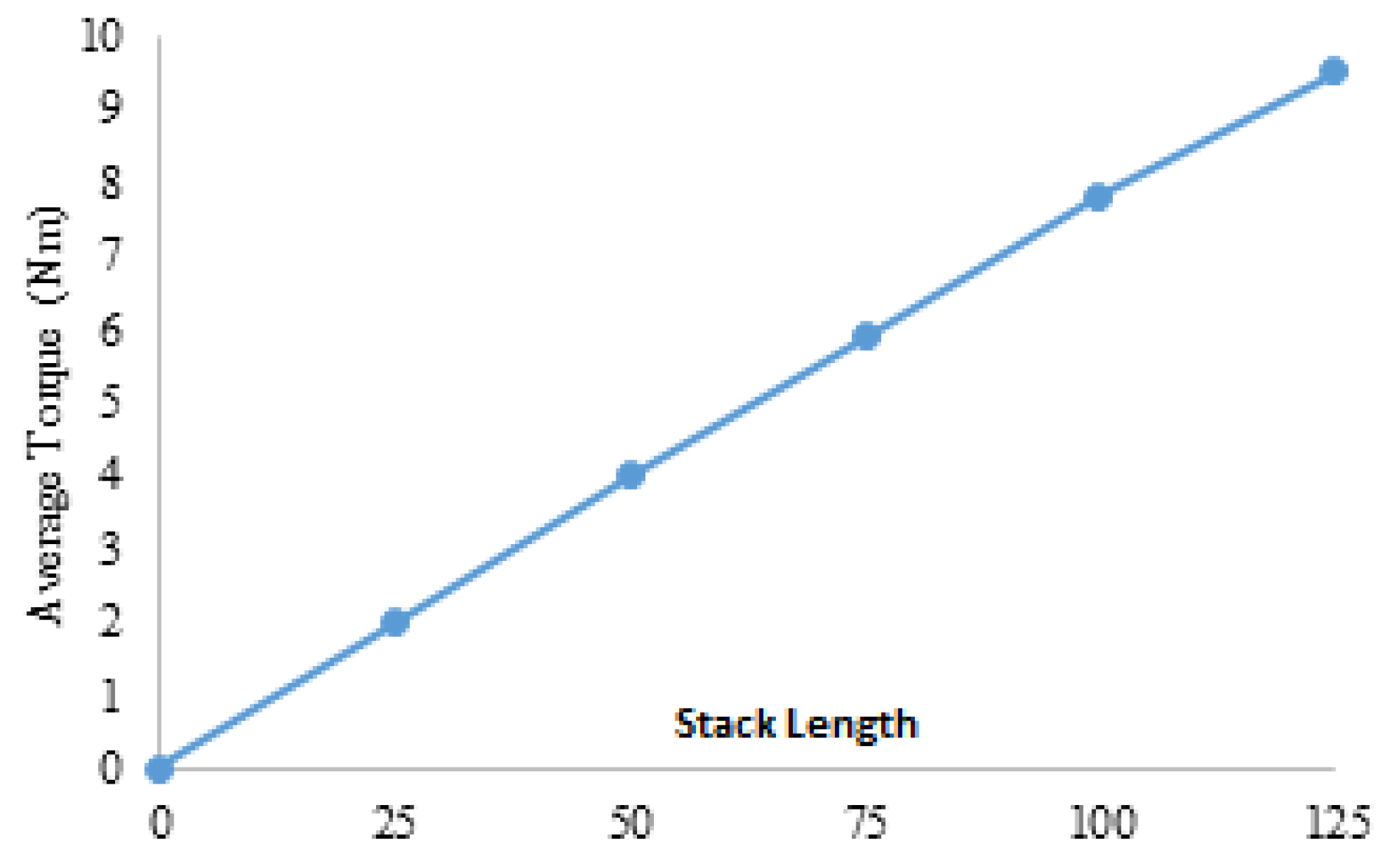

4. Electromagnetic Performance

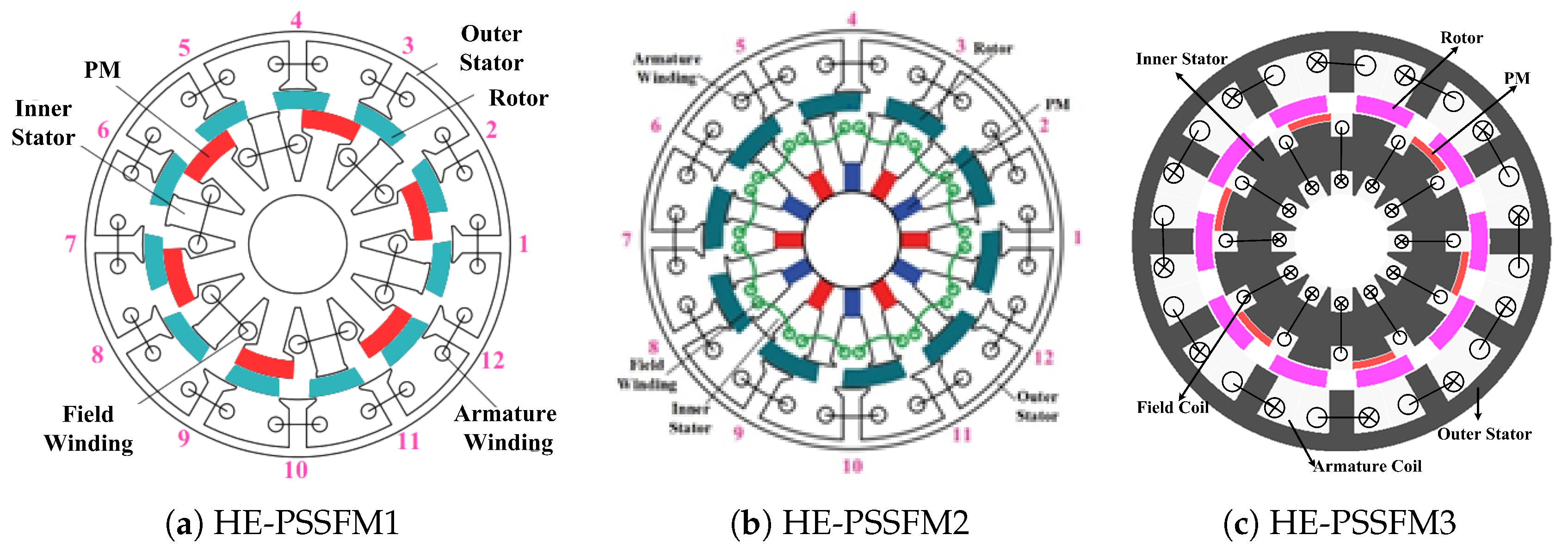

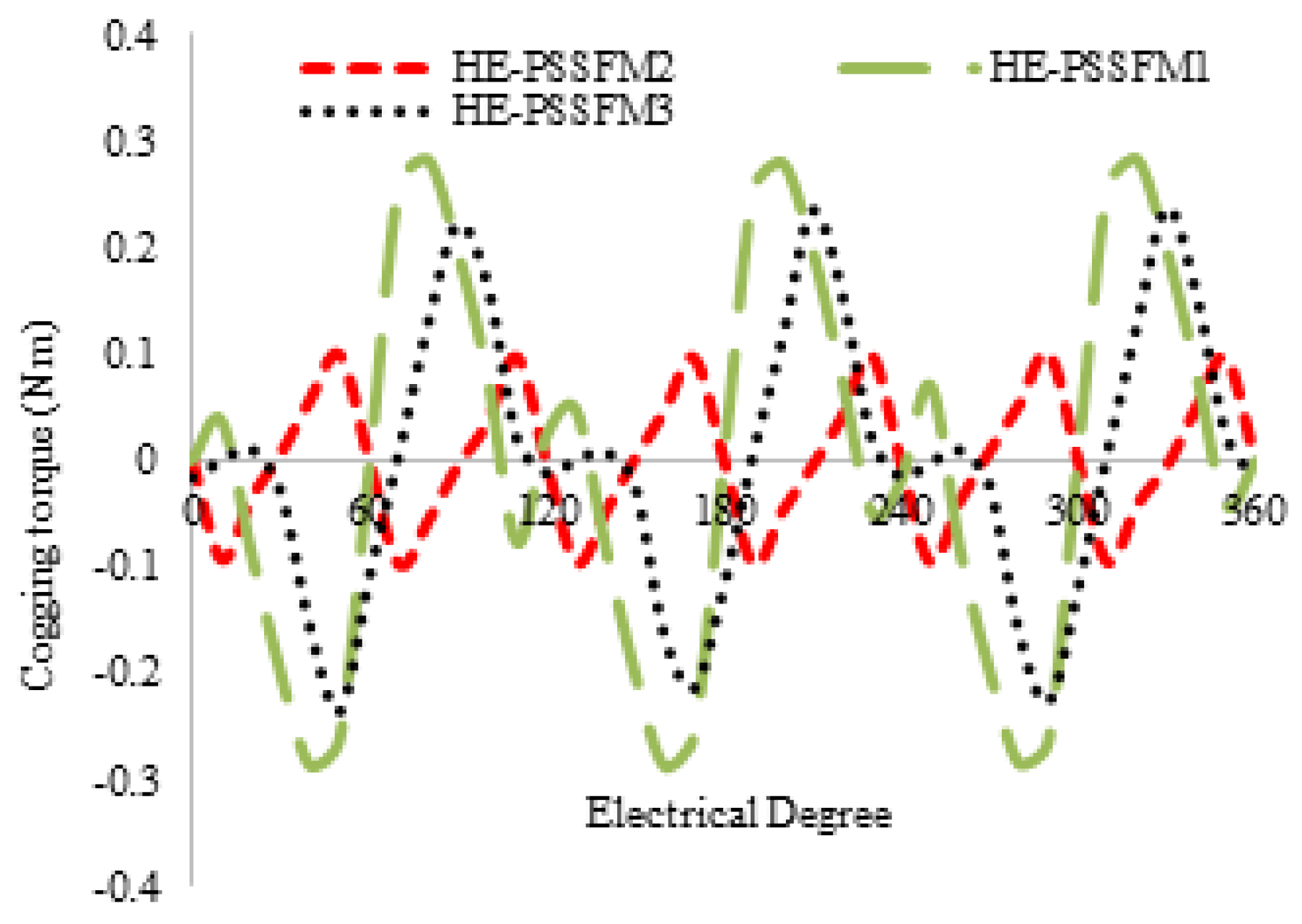

4.1. Cogging Torque

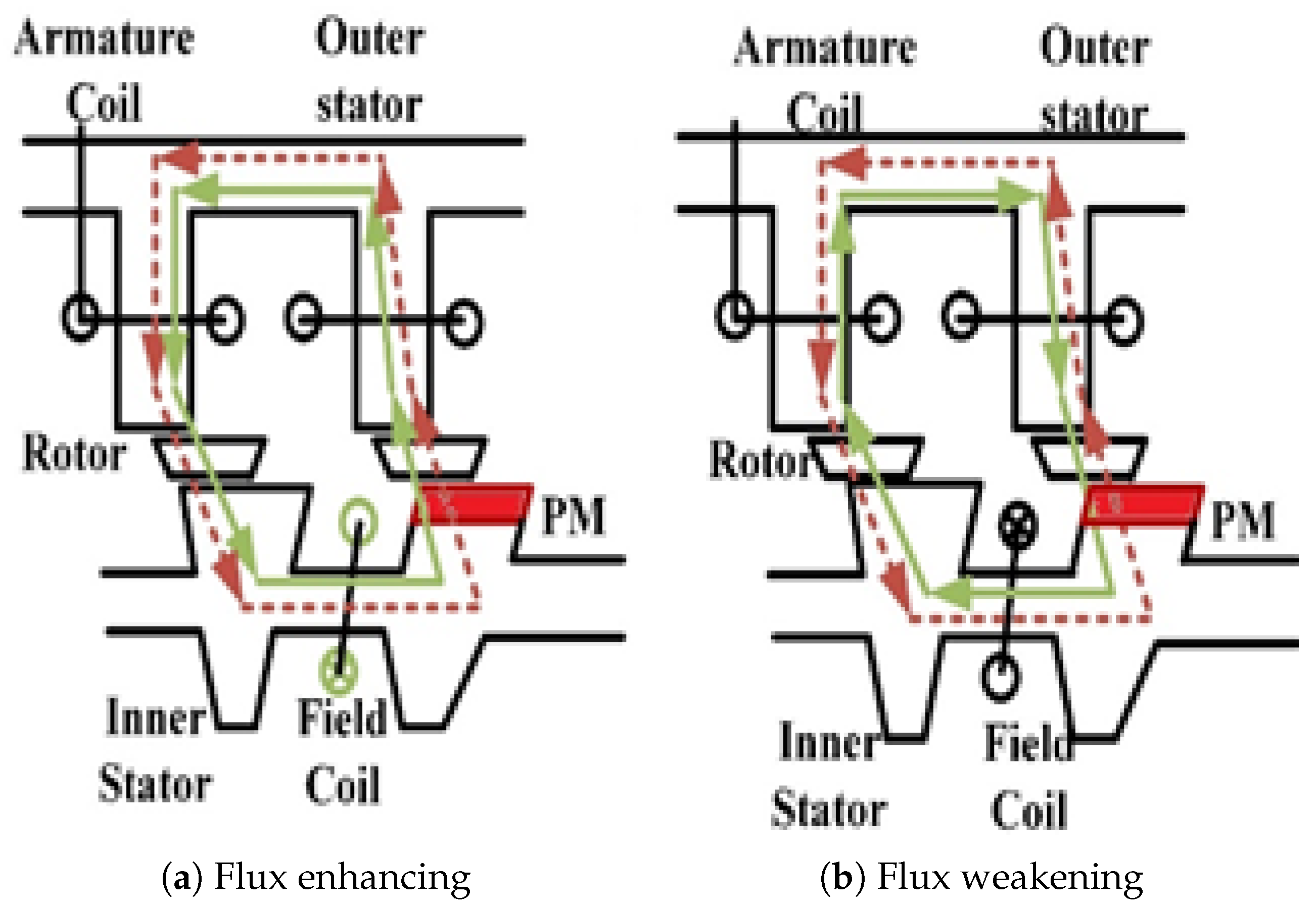

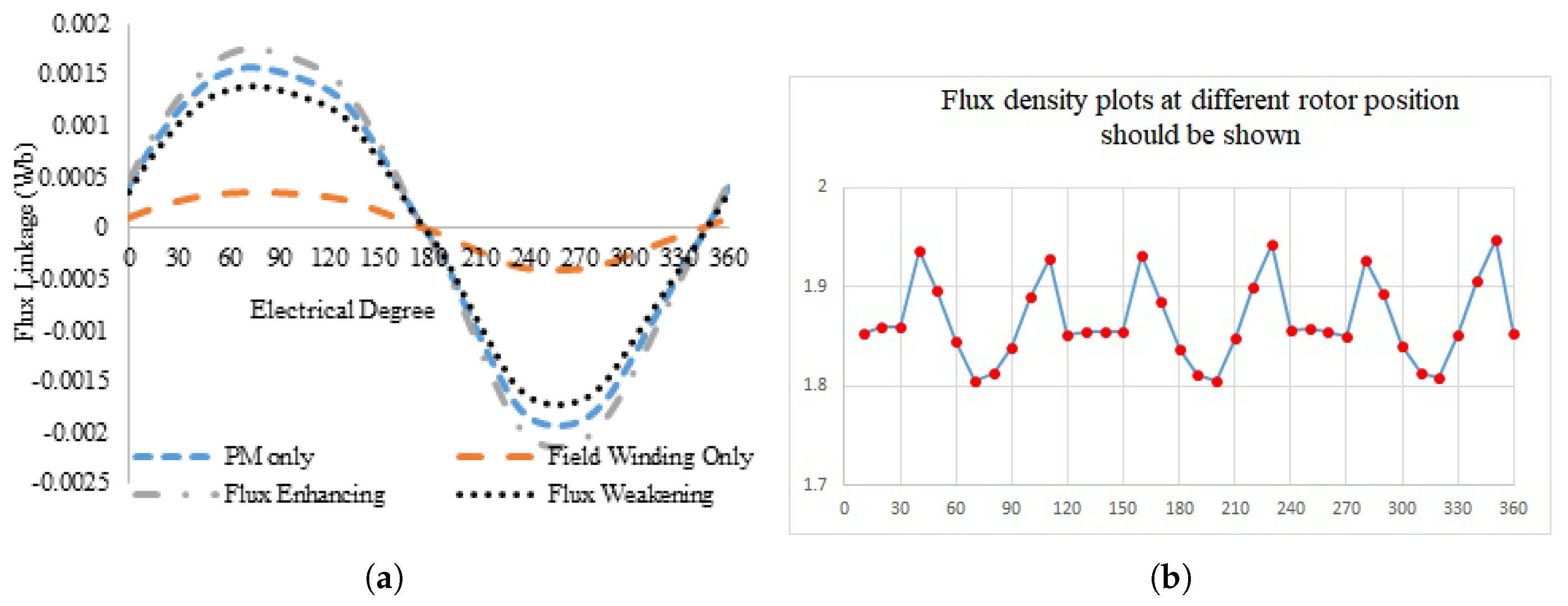

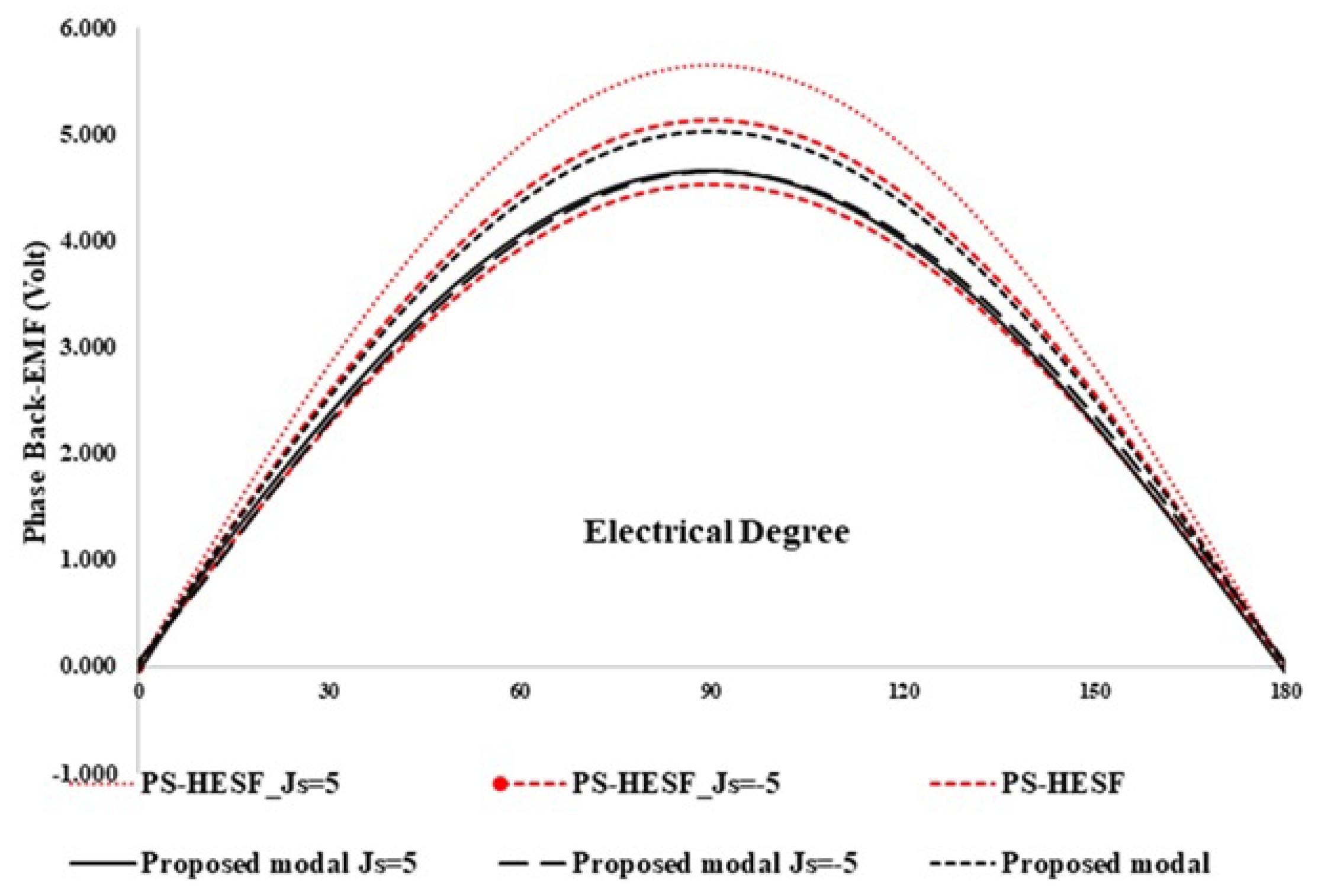

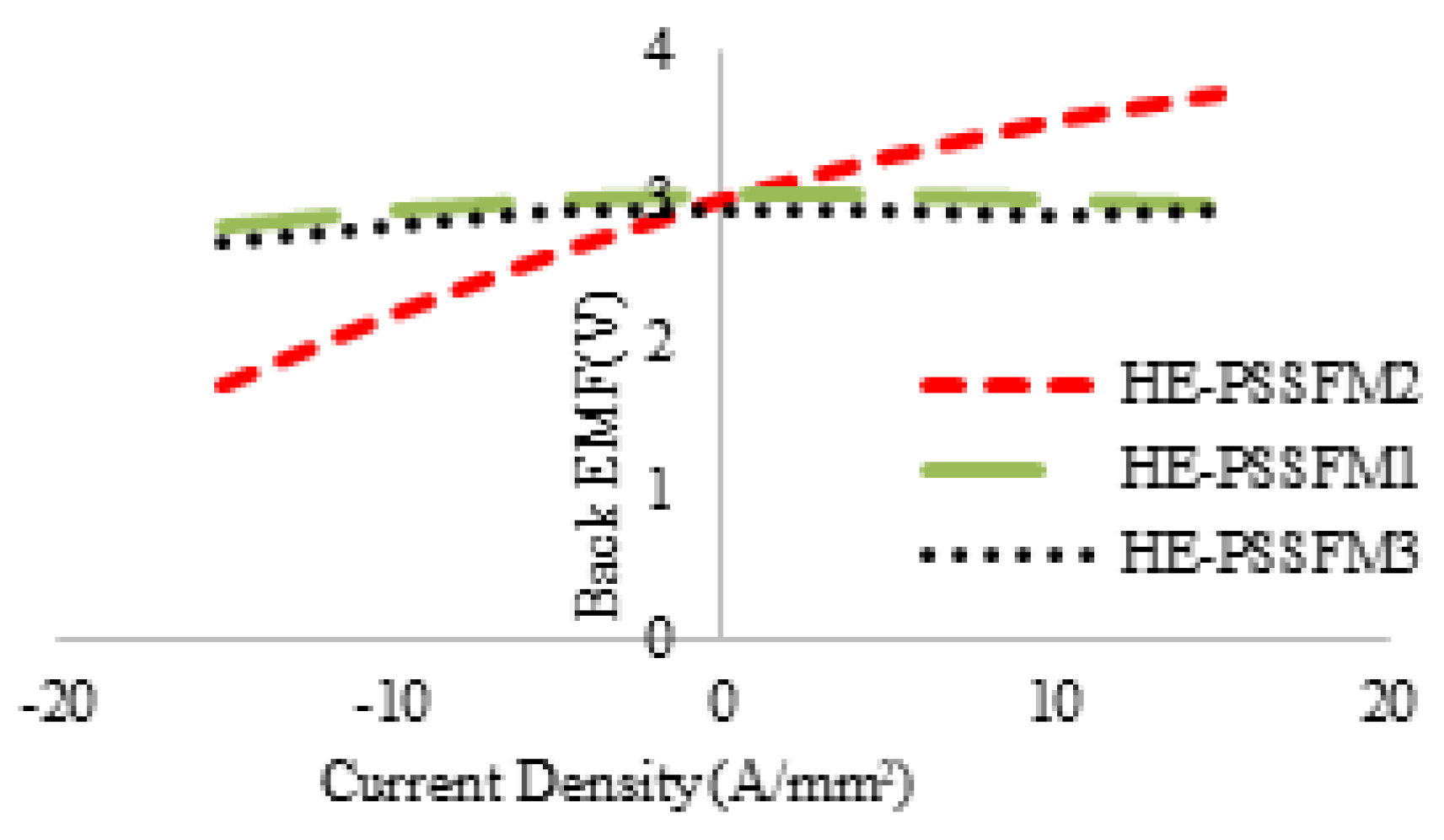

4.2. Flux Regulation

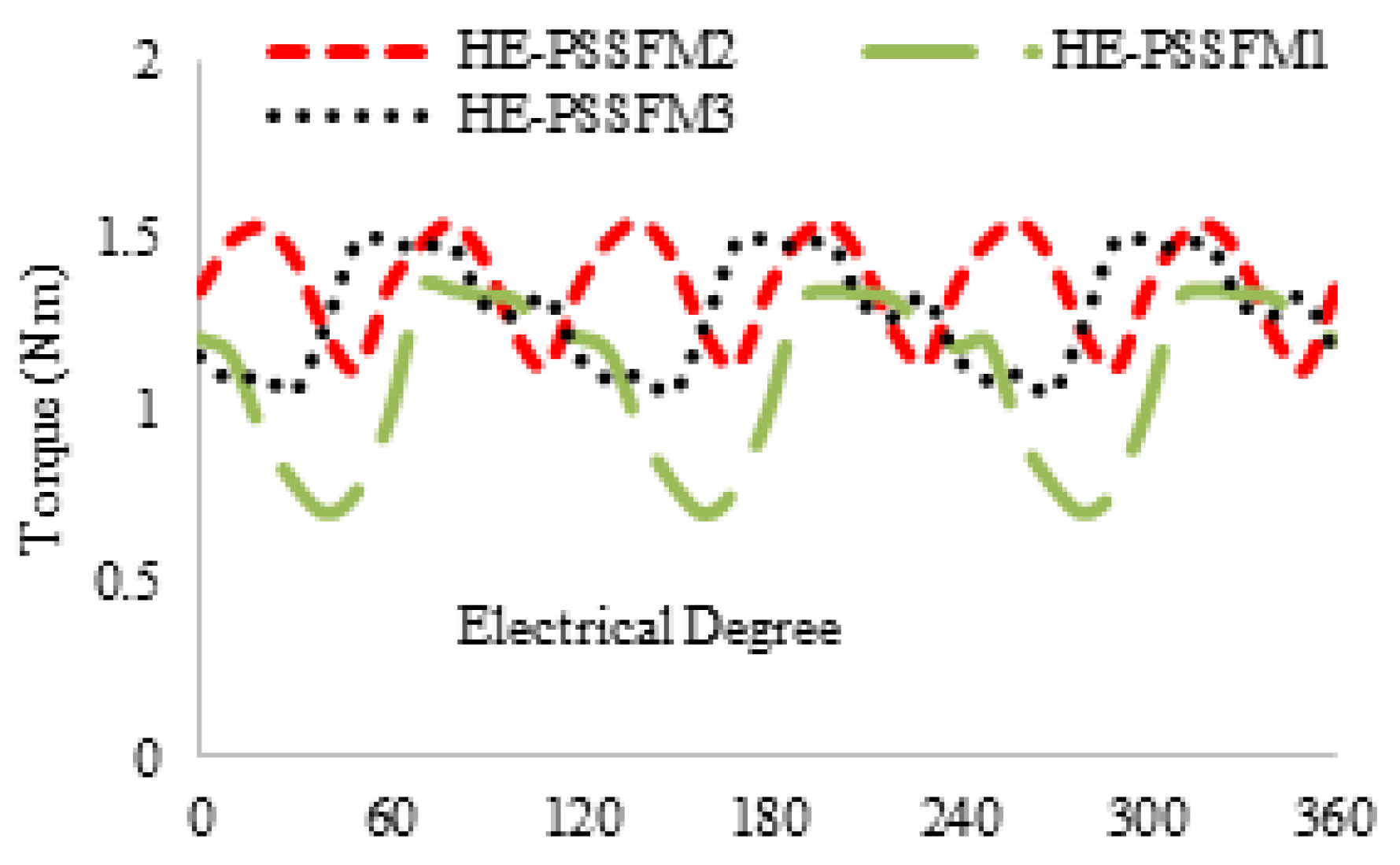

4.3. Torque

5. Optimization Procedure

5.1. Analytical Design Procedure of Power Splitting Ratio for Torque Maximization

5.2. Optimal Electric Loading

5.3. Genetic Algorithm

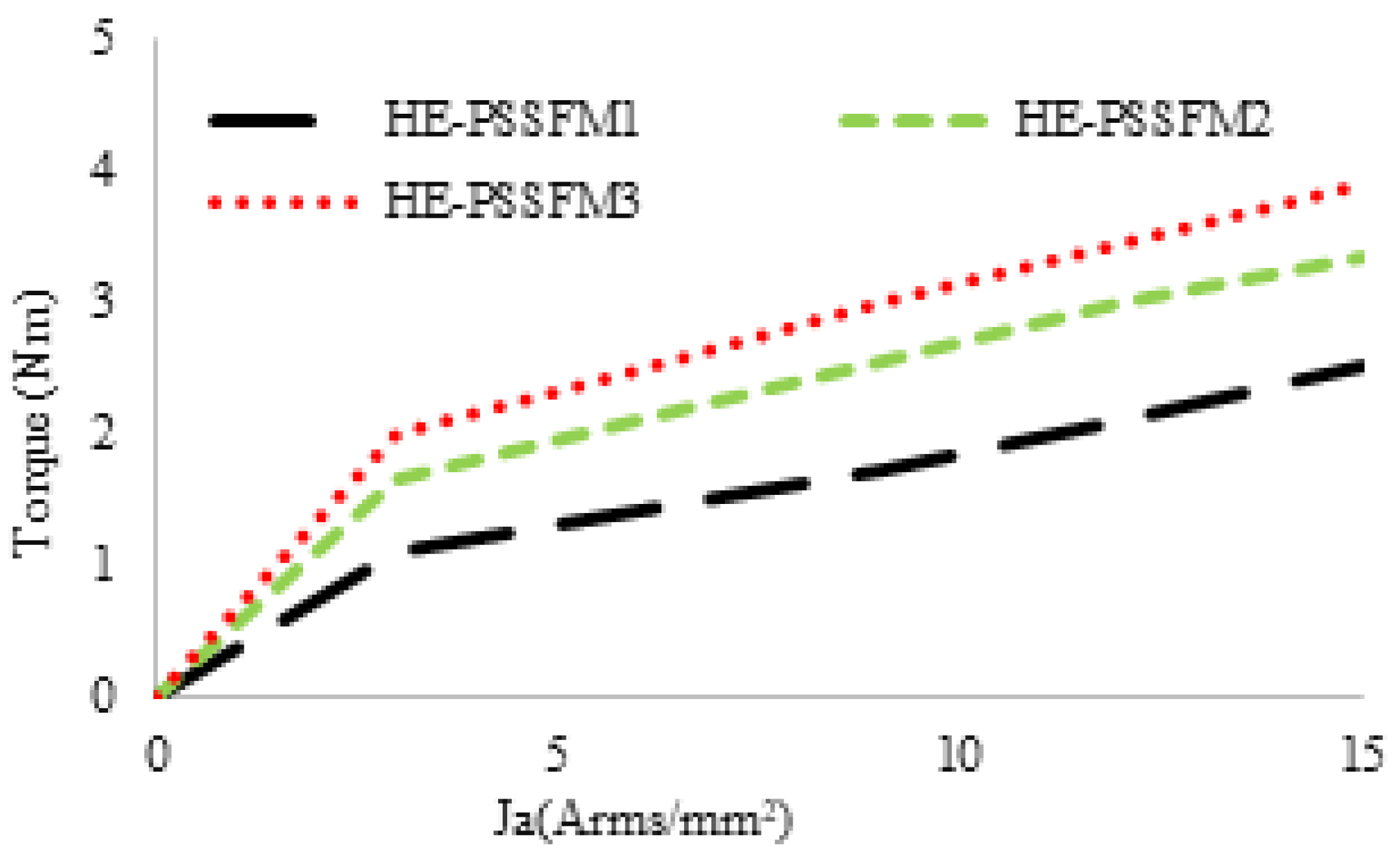

6. Torque Comparison with HE-PSSFM1 and HE-PSSFM2 Machine

7. Stress Analysis

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kahourzade, S.; Mahmoudi, A.; Soong, W.L.; Ertugrul, N.; Pellegrino, G. Estimation of PM Machine Efficiency Maps From Limited Data. IEEE Trans. Ind. Appl. 2020, 56, 2612–2621. [Google Scholar] [CrossRef]

- Ding, H.; Liu, M.; Sarlioglu, B. Design of Conical Rotor Flux-Switching Permanent Magnet Machine with Improved Flux-Weakening Capability for Traction Applications. In Proceedings of the 2019 International Aegean Conference on Electrical Machines and Power Electronics (ACEMP) & 2019 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Istanbul, Turkey, 27–29 August 2019; pp. 172–177. [Google Scholar]

- Khan, F.; Ullah, W.; Sulaiman, E. Sub-Domain Modelling and Multi-Variable Optimization of Partitioned PM Consequent Pole Flux Switching Machines. IET Electr. Power Appl. 2020, 14, 1360–1369. [Google Scholar] [CrossRef]

- Venkataramanujam, V.; Larochelle, P.M. Design and development of planar reconfigurable motion generators. Mech. Based Des. Struct. Mach. 2016, 44, 426–439. [Google Scholar] [CrossRef]

- Hua, H.; Hua, W.; Zhao, G.; Cheng, M. Torque Production Mechanism of Switched Reluctance Machines with Air-gap Field Modulation Principle. IEEE Trans. Energy Convers. 2020. [Google Scholar] [CrossRef]

- Henneberger, G.; HADJI, M.J.; Ciorba, R. Design and test of permanent magnet synchronous motor with auxiliary excitation winding for electric vehicle application. In Proceedings of the European Power Electronics Chapter Symposium, Lausanne, Switzerland, 19–20 October 1994. [Google Scholar]

- Fodorean, D.; Djerdir, A.; Viorel, I.A.; Miraoui, A. A double excited synchronous machine for direct drive application—Design and prototype tests. IEEE Trans. Energy Convers. 2007, 22, 656–665. [Google Scholar] [CrossRef]

- Laldin, O.; Sudhoff, S.D.; Pekarek, S. Analysis and design of hybrid machines for DC generation. IEEE Trans. Energy Convers. 2015, 30, 1192–1199. [Google Scholar] [CrossRef]

- Di Barba, P.; Bonislawski, M.; Palka, R.; Paplicki, P.; Wardach, M. Design of hybrid excited synchronous machine for electrical vehicles. IEEE Trans. Magn. 2015, 51, 1–6. [Google Scholar] [CrossRef]

- Amara, Y.; Vido, L.; Gabsi, M.; Hoang, E.; Ahmed, A.H.B.; Lecrivain, M. Hybrid excitation synchronous machines: Energy-efficient solution for vehicles propulsion. IEEE Trans. Veh. Technol. 2008, 58, 2137–2149. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, Y.; Yang, S.; Bo, Z. Principle of operation and feature investigation of a new topology of hybrid excitation synchronous machine. IEEE Trans. Magn. 2008, 44, 2174–2180. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, S.; Dai, J.; Yan, Y. Investigation of hybrid excitation synchronous machines with axial auxiliary air-gaps and non-uniform air-gaps. IEEE Trans. Ind. Appl. 2013, 50, 1729–1737. [Google Scholar] [CrossRef]

- Khan, F.; Sulaiman, E.; Ahmad, M.Z. A novel wound field flux switching machine with salient pole rotor and nonoverlapping windings. Turk. J. Electr. Eng. Comput. Sci. 2017, 25, 950–964. [Google Scholar] [CrossRef]

- Khan, F.; Sulaiman, E. Design optimization and efficiency analysis of 12slot-10pole wound field flux switching machine. In Proceedings of the 2015 IEEE International Magnetics Conference (INTERMAG), Beijing, China, 11–15 May 2015; p. 1. [Google Scholar]

- Shah, F.M.; Maqsood, S.; Shah, Z.M.; Muhammad, F.; Kim, S. Multilevel LVDC Distribution System with Voltage Unbalancing and Disturbance Rejection Control Topology. IEEE Access 2020, 8, 133787–133801. [Google Scholar] [CrossRef]

- Tong, M.; Cheng, M.; Hua, W.; Ding, S. A Single-Phase On-Board Two-Stage Integrated Battery Charger for EVs Based on a Five-Phase Hybrid-Excitation Flux-Switching Machine. IEEE Trans. Veh. Technol. 2020, 69, 3793–3804. [Google Scholar] [CrossRef]

- Ur Rahman, L.; Khan, F.; Khan, M.A.; Ahmad, N.; Khan, H.A.; Shahzad, M.; Ali, S.; Ali, H. Modular Rotor Single Phase Field Excited Flux Switching Machine with Non-Overlapped Windings. Energies 2019, 12, 1576. [Google Scholar] [CrossRef]

- Owen, R.L.; Zhu, Z.; Jewell, G.W. Hybrid-excited flux-switching permanent-magnet machines with iron flux bridges. IEEE Trans. Magn. 2010, 46, 1726–1729. [Google Scholar] [CrossRef]

- Hua, H.; Zhu, Z.; Zhan, H. Novel consequent-pole hybrid excited machine with separated excitation stator. IEEE Trans. Ind. Electron. 2016, 63, 4718–4728. [Google Scholar] [CrossRef]

- Hua, H.; Zhu, Z. Novel partitioned stator hybrid excited switched flux machines. IEEE Trans. Energy Convers. 2017, 32, 495–504. [Google Scholar] [CrossRef]

- Khan, F.; Sulaiman, E.; Ahmad, M.Z. Review of switched flux wound-field machines technology. IETE Tech. Rev. 2017, 34, 343–352. [Google Scholar] [CrossRef]

- Eger, T.; Bol, T.; Thanu, A.; Daróczy, L.; Janiga, G.; Schroth, R.; Thévenin, D. Application of Entropy Generation to Improve Heat Transfer of Heat Sinks in Electric Machines. Entropy 2017, 19, 255. [Google Scholar] [CrossRef]

- Farrell, R.E.; Kongthon, J. The square root rule—A case study of a scaling factor for machines with dynamic similitude. Mech. Based Des. Struct. Mach. 2019, 1–18. [Google Scholar] [CrossRef]

| Characteristic | Unit | Different Winding Configuration | ||

|---|---|---|---|---|

| Inner Toroidal | Outer Toroidal | Inner and Outer Toroidal | ||

| Cogging torque | mNm | 438.5 | 683.4 | 484.1 |

| Flux linkage | mWb | 12.4 | 5.1 | 4.3 |

| Average torque | mNm | 1287.25 | 560 | 250 |

| Parameter | HE-PSSFM3 | HE-PSSFM2 | HE-PSSFM1 |

|---|---|---|---|

| Stator slot number | 12 | 12 | 12 |

| PM height (mm) | 1.67 | 5.6 | 5.6 |

| Slot package factor | 0.5 | 0.5 | 0.5 |

| PM thickness (mm) | 10 | 3 | 3 |

| PM volume (mm) | 2500 | 5000 | 2500 |

| Rotor pole-pair number | 10 | 10 | 10 |

| Inner radius of outer stator (mm) | 31.95 | 31.95 | 31.95 |

| Rotor inner pole arc | 24 | 24 | 24 |

| Inner stator inner radius (mm) | 10.4 | 10.4 | 10.4 |

| Rotor thickness (mm) | 3.5 | 3.5 | 3.5 |

| Rated speed (rpm) | 400 | 400 | 400 |

| Inner stator outer radius (mm) | 27.45 | 27.45 | 27.45 |

| Air-gap length (mm) | 0.5 | 0.5 | 0.5 |

| Active axial length (mm) | 25 | 25 | 25 |

| Inner stator yoke radius | 7.5 | 16.5 | 16.5 |

| Outer radius stator (mm) | 45 | 45 | 45 |

| HE-PSSFM3 | HE-PSSFM1 | HE-PSSFM2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Field Winding | Unit | 0 | Js = −5 | Js = 5 | 0 | Js = 5 | Js= −5 | 0 | Js = 5 | Js= −5 |

| Tavg | Nm | 1.29 | 1.25 | 1.34 | 1.0 | 1.12 | 0.87 | 1.08 | 1.28 | 1.0012 |

| Parameter | Unit | Initial Design | Optimize Design |

|---|---|---|---|

| Stator slot number | Not exist | 12 | 12 |

| PM height | mm | 1.67 | 1.67 |

| Slot package factor | Not exist | 0.5 | 0.5 |

| PM thickness | Mm | 10 | 10 |

| PM volume | mm | 2500 | 2500 |

| Stator yoke radius | mm | 43 | 41 |

| Active axial length | mm | 25 | 25 |

| Rotor inner pole arc | deg. | 24 | 16.5 |

| Rated speed | r/min | 400 | 400 |

| Rotor outer pole arc | deg. | 25 | 24 |

| Rotor radial thickness | mm | 3.5 | 3.5 |

| Inner stator outer radius | mm | 27.45 | 27.45 |

| Inner stator inner radius | mm | 10.4 | 10.4 |

| Rotor pole-pair number | Not exist | 10 | 10 |

| Outer Stator inner radius | mm | 31.95 | 31.95 |

| Air-gap length | mm | 0.5 | 0.5 |

| Stator outer radius | mm | 45 | 45 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irfan, M.; Rehman, N.U.; Khan, F.; Muhammad, F.; Alwadie, A.S.; Glowacz, A. Partitioned Stator Switched Flux Machine: Novel Winding Configurations. Entropy 2020, 22, 920. https://doi.org/10.3390/e22090920

Irfan M, Rehman NU, Khan F, Muhammad F, Alwadie AS, Glowacz A. Partitioned Stator Switched Flux Machine: Novel Winding Configurations. Entropy. 2020; 22(9):920. https://doi.org/10.3390/e22090920

Chicago/Turabian StyleIrfan, Muhammad, Naveed Ur Rehman, Faisal Khan, Fazal Muhammad, Abdullah S. Alwadie, and Adam Glowacz. 2020. "Partitioned Stator Switched Flux Machine: Novel Winding Configurations" Entropy 22, no. 9: 920. https://doi.org/10.3390/e22090920

APA StyleIrfan, M., Rehman, N. U., Khan, F., Muhammad, F., Alwadie, A. S., & Glowacz, A. (2020). Partitioned Stator Switched Flux Machine: Novel Winding Configurations. Entropy, 22(9), 920. https://doi.org/10.3390/e22090920