Hybrid Membrane Distillation and Wet Scrubber for Simultaneous Recovery of Heat and Water from Flue Gas

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Set Up of Hybrid MD-Wet Scrubber

2.2. Membrane Characteristics

2.3. Scrubber Unit Installation

2.4. Membrane Distillation Cell Assembly

2.5. Fluxes and Recovery Determination

3. Results and Discussion

3.1. Hybrid System Operation Assessment

3.2. Performance of the Scrubber Unit

3.3. Performance of MD Unit

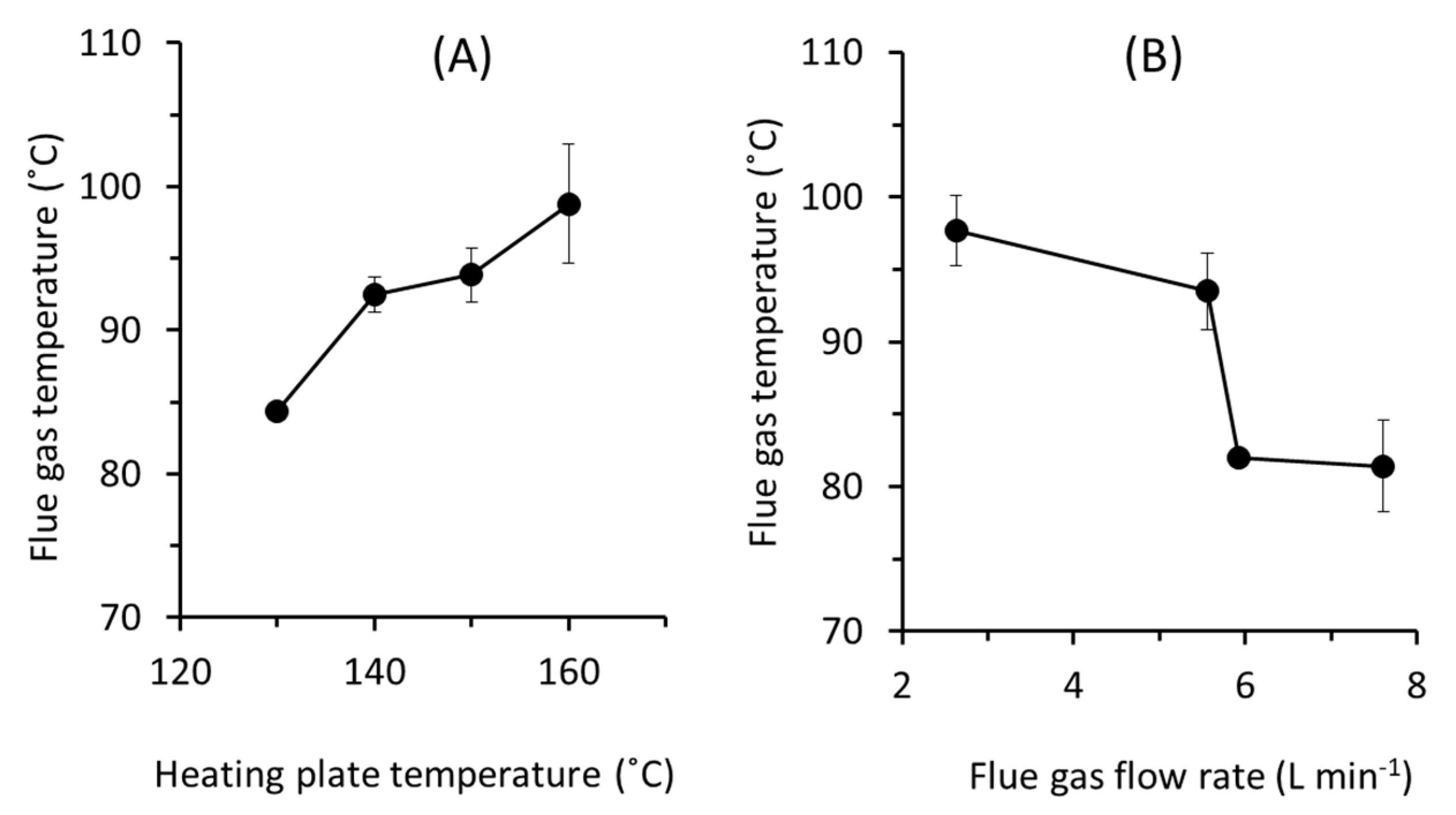

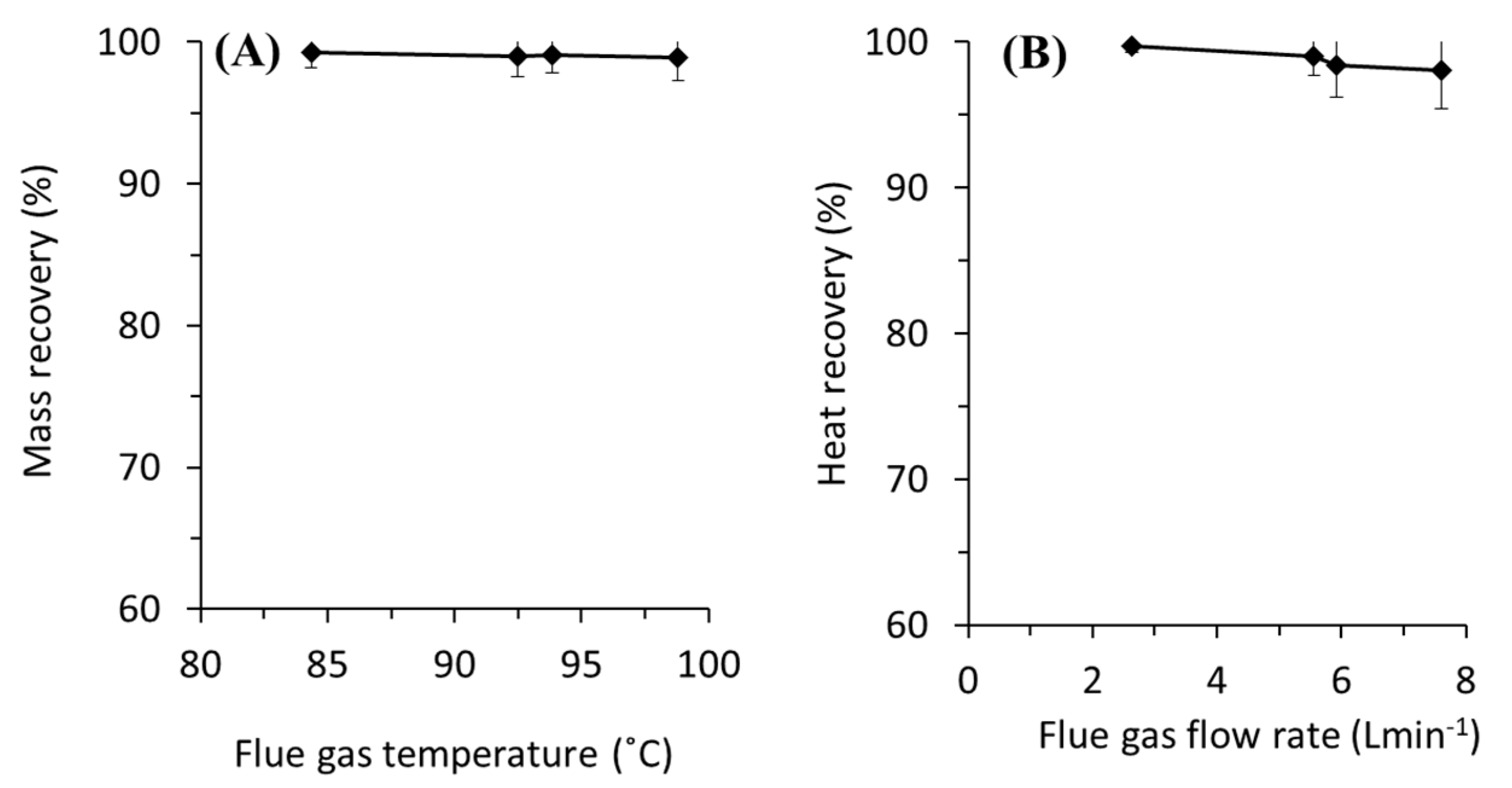

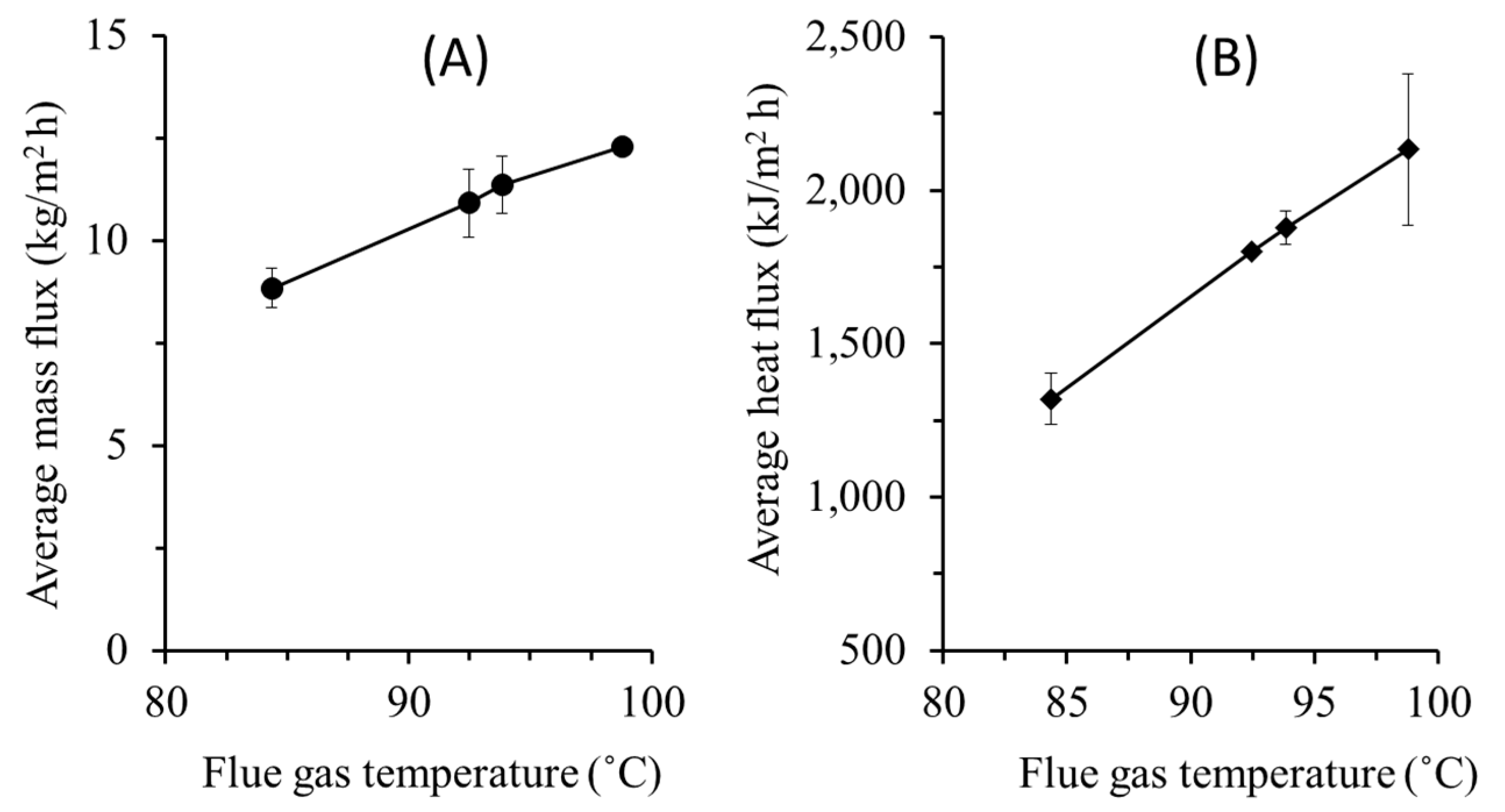

3.3.1. Effect of Temperature

3.3.2. Effect of Flue Gas Flow Rate

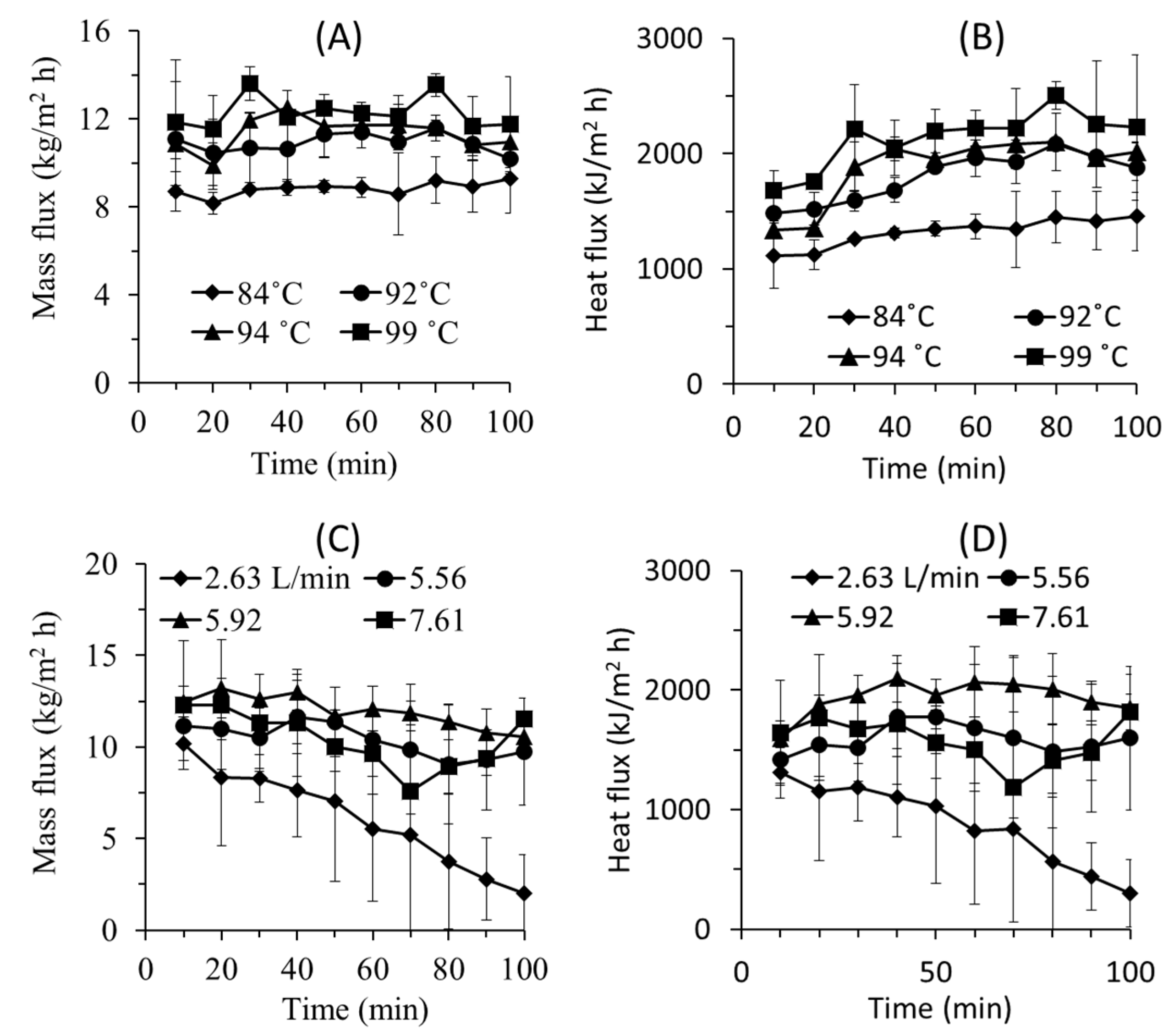

3.3.3. Water and Heat Flux Evolution

3.4. Practical Consideration

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Yusaf, T. Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. Energy 2014, 69, 427–445. [Google Scholar] [CrossRef]

- Ismail, M.S.; Moghavvemi, M.; Mahlia, T.M.I. Characterization of PV panel and global optimization of its model parameters using genetic algorithm. Energy Convers. Manag. 2013, 73, 10–25. [Google Scholar] [CrossRef]

- Ismail, M.S.; Moghavvemi, M.; Mahlia, T.M.I. Techno-economic analysis of an optimized photovoltaic and diesel generator hybrid power system for remote houses in a tropical climate. Energy Convers. Manag. 2013, 69, 163–173. [Google Scholar] [CrossRef]

- Kusumo, F.; Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Siswantoro, J.; Mahlia, T.M.I. Optimization of transesterification process for Ceiba pentandra oil: A comparative study between kernel-based extreme learning machine and artificial neural networks. Energy 2017, 134, 24–34. [Google Scholar] [CrossRef]

- Kusumo, F.; Silitonga, A.S.; Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I. A comparative study of ultrasound and infrared transesterification of Sterculia foetida oil for biodiesel production. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1339–1346. [Google Scholar] [CrossRef]

- Ong, H.C.; Milano, J.; Silitonga, A.S.; Hassan, M.H.; Shamsuddin, A.H.; Wang, C.-T.; Indra Mahlia, T.M.; Siswantoro, J.; Kusumo, F.; Sutrisno, J. Biodiesel production from Calophyllum inophyllum-Ceiba pentandra oil mixture: Optimization and characterization. J. Clean. Prod. 2019, 219, 183–198. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Shamsuddin, A.H.; Mahlia, T.M.I.; Milano, J.; Kusumo, F.; Siswantoro, J.; Dharma, S.; Sebayang, A.H.; Masjuki, H.H.; Ong, H.C. Biodiesel synthesis from Ceiba pentandra oil by microwave irradiation-assisted transesterification: ELM modeling and optimization. Renew. Energy 2020, 146, 1278–1291. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Mahlia, T.M.I.; Kusumo, F.; Dharma, S.; Sebayang, A.H.; Sembiring, R.W.; Shamsuddin, A.H. Intensification of Reutealis trisperma biodiesel production using infrared radiation: Simulation, optimisation and validation. Renew. Energy 2019, 133, 520–527. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Mahlia, T.M.I.; Ong, H.C.; Riayatsyah, T.M.I.; Kusumo, F.; Ibrahim, H.; Dharma, S.; Gumilang, D. A comparative study of biodiesel production methods for Reutealis trisperma biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 2006–2014. [Google Scholar] [CrossRef]

- Warsinger, D.; Mistry, K.; Nayar, K.; Chung, H.; Lienhard, J. Entropy Generation of Desalination Powered by Variable Temperature Waste Heat. Entropy 2015, 17, 7530–7566. [Google Scholar] [CrossRef]

- Jouhara, H.; Olabi, A.G. Editorial: Industrial waste heat recovery. Energy 2018, 160, 1–2. [Google Scholar] [CrossRef]

- Yang, B.; Jiang, Y.; Fu, L.; Zhang, S. Conjugate heat and mass transfer study of a new open-cycle absorption heat pump applied to total heat recovery of flue gas. Appl. Therm. Eng. 2018, 138, 888–899. [Google Scholar] [CrossRef]

- Xu, G.; Xu, C.; Yang, Y.; Fang, Y.; Li, Y.; Song, X. A novel flue gas waste heat recovery system for coal-fired ultra-supercritical power plants. Appl. Therm. Eng. 2014, 67, 240–249. [Google Scholar] [CrossRef]

- Semkov, K.; Mooney, E.; Connolly, M.; Adley, C. Efficiency improvement through waste heat reduction. Appl. Therm. Eng. 2014, 70, 716–722. [Google Scholar] [CrossRef]

- Xu, G.; Huang, S.; Yang, Y.; Wu, Y.; Zhang, K.; Xu, C. Techno-economic analysis and optimization of the heat recovery of utility boiler flue gas. Appl. Energy 2013, 112, 907–917. [Google Scholar] [CrossRef]

- Sun, E.; Hu, H.; Li, H.; Liu, C.; Xu, J. How to Construct a Combined S-CO2 Cycle for Coal Fired Power Plant? Entropy 2018, 21, 19. [Google Scholar] [CrossRef]

- Mistry, K.; Lienhard, J. An Economics-Based Second Law Efficiency. Entropy 2013, 15, 2736–2765. [Google Scholar] [CrossRef]

- Macedonio, F.; Brunetti, A.; Barbieri, G.; Drioli, E. Membrane condenser configurations for water recovery from waste gases. Sep. Purif. Technol. 2017, 181, 60–68. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Syaheed, H.; Abas, A.E.P.; Kusumo, F.; Shamsuddin, A.H.; Ong, H.C.; Bilad, M.R. Organic Rankine Cycle (ORC) System Applications for Solar Energy: Recent Technological Advances. Energies 2019, 12, 2930. [Google Scholar] [CrossRef]

- Zhao, S.; Yan, S.; Wang, D.K.; Wei, Y.; Qi, H.; Wu, T.; Feron, P.H.M. Simultaneous heat and water recovery from flue gas by membrane condensation: Experimental investigation. Appl. Therm. Eng. 2017, 113, 843–850. [Google Scholar] [CrossRef]

- Ye, B.; Wang, Z.; Yan, X.; Chen, G. Performance analysis of a variable-stage open absorption heat pump combined with a membrane absorber. Energy Convers. Manag. 2019, 184, 290–300. [Google Scholar] [CrossRef]

- Yan, S.; Cui, Q.; Tu, T.; Xu, L.; He, Q.; Feron, P.H.M.; Zhao, S. Membrane heat exchanger for novel heat recovery in carbon capture. J. Membr. Sci. 2019, 577, 60–68. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Macedonio, F.; Cersosimo, M.; Brunetti, A.; Barbieri, G.; Drioli, E. Water recovery from humidified waste gas streams: Quality control using membrane condenser technology. Chem. Eng. Process. Process Intensif. 2014, 86, 196–203. [Google Scholar] [CrossRef]

- Brunetti, A.; Macedonio, F.; Barbieri, G.; Drioli, E. Membrane condenser as emerging technology for water recovery and gas pre-treatment: Current status and perspectives. BMC Chem. Eng. 2019, 1, 19. [Google Scholar] [CrossRef]

- Wei, M.; Zhao, X.; Fu, L.; Zhang, S. Performance study and application of new coal-fired boiler flue gas heat recovery system. Appl. Energy 2017, 188, 121–129. [Google Scholar] [CrossRef]

- Yang, B.; Chen, H. Heat and water recovery from flue gas: Application of micro-porous ceramic membrane tube bundles in gas-fired power plant. Chem. Eng. Process. Process Intensif. 2019, 137, 116–127. [Google Scholar] [CrossRef]

- Pangarkar, B.; Deshmukh, S.; Sapkal, V.S.; Sapkal, R.S. Review of membrane distillation process for water purification. Desalin. Water Treat. 2014, 57, 2959–2981. [Google Scholar] [CrossRef]

- Macedonio, F.; Brunetti, A.; Barbieri, G.; Drioli, E. Membrane Condenser as a New Technology for Water Recovery from Humidified “Waste” Gaseous Streams. Ind. Eng. Chem. Res. 2013, 52, 1160–1167. [Google Scholar] [CrossRef]

- Wang, T.; Yue, M.; Qi, H.; Feron, P.H.M.; Zhao, S. Transport membrane condenser for water and heat recovery from gaseous streams: Performance evaluation. J. Membr. Sci. 2015, 484, 10–17. [Google Scholar] [CrossRef]

- Yue, M.; Zhao, S.; Feron, P.H.M.; Qi, H. Multichannel Tubular Ceramic Membrane for Water and Heat Recovery from Waste Gas Streams. Ind. Eng. Chem. Res. 2016, 55, 2615–2622. [Google Scholar] [CrossRef]

- Aouini, I.; Ledoux, A.; Estel, L.; Mary, S. Pilot Plant Studies for CO2 Capture from Waste Incinerator Flue Gas Using MEA Based Solvent. Oil Gas Sci. Technol. Rev. dIFP Energies Nouv. 2014, 69, 1091–1104. [Google Scholar] [CrossRef]

- Curcio, E.; Drioli, E. Membrane Distillation and Related Operations—A Review. Sep. Purif. Rev. 2005, 34, 35–86. [Google Scholar] [CrossRef]

- Bilad, M.R.; Guillen-Burrieza, E.; Mavukkandy, M.O.; Al Marzooqi, F.A.; Arafat, H.A. Shrinkage, defect and membrane distillation performance of composite PVDF membranes. Desalination 2015, 376, 62–72. [Google Scholar] [CrossRef]

- Mat Nawi, N.I.; Bilad, M.R.; Zolkhiflee, N.; Nordin, N.A.H.; Lau, W.J.; Narkkun, T.; Faungnawakij, K.; Arahman, N.; Mahlia, T.M.I. Development of A Novel Corrugated Polyvinylidene difluoride Membrane via Improved Imprinting Technique for Membrane Distillation. Polymers 2019, 11, 865. [Google Scholar] [CrossRef]

- Nawi, N.I.M.; Bilad, M.R.; Nordin, N.A.H.M.; Mavukkandy, M.O.; Putra, Z.A.; Wirzal, M.D.H.; Jaafar, J.; Khan, A.L. Exploiting the Interplay between Liquid-Liquid Demixing and Crystallization of the PVDF Membrane for Membrane Distillation. Int. J. Polym. Sci. 2018, 2018, 1525014. [Google Scholar] [CrossRef]

- Kharraz, J.A.; Bilad, M.R.; Arafat, H.A. Flux stabilization in membrane distillation desalination of seawater and brine using corrugated PVDF membranes. J. Membr. Sci. 2015, 495, 404–414. [Google Scholar] [CrossRef]

- Guillen-Burrieza, E.; Mavukkandy, M.O.; Bilad, M.R.; Arafat, H.A. Understanding wetting phenomena in membrane distillation and how operational parameters can affect it. J. Membr. Sci. 2016, 515, 163–174. [Google Scholar] [CrossRef]

- AlMarzooqi, F.A.; Bilad, M.R.; Arafat, H.A. Development of PVDF membranes for membrane distillation via vapour induced crystallisation. Eur. Polym. J. 2016, 77, 164–173. [Google Scholar] [CrossRef]

| Physicochemical Information | Value |

|---|---|

| Pore Size (µm) | 0.22 |

| Air flow rate (L min−1 cm2) | 3 |

| Bubble Point (psi) | 14.8–20.9 |

| Porosity (%) | 70 |

| Filter Surface | Plain |

| Thickness (µm) | 175 |

| Cutting dimension (cm2) | 8.5 × 4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Yusoff, M.H.; Nyunt, E.K.; Bilad, M.R.; Arahman, N.; Mulyati, S.; Rizal, S.; Nordin, N.A.H.; Leam, J.J.; Khan, A.L.; Jaafar, J. Hybrid Membrane Distillation and Wet Scrubber for Simultaneous Recovery of Heat and Water from Flue Gas. Entropy 2020, 22, 178. https://doi.org/10.3390/e22020178

Mohd Yusoff MH, Nyunt EK, Bilad MR, Arahman N, Mulyati S, Rizal S, Nordin NAH, Leam JJ, Khan AL, Jaafar J. Hybrid Membrane Distillation and Wet Scrubber for Simultaneous Recovery of Heat and Water from Flue Gas. Entropy. 2020; 22(2):178. https://doi.org/10.3390/e22020178

Chicago/Turabian StyleMohd Yusoff, Mohd Hizami, Ein K. Nyunt, Muhammad Roil Bilad, Nasrul Arahman, Sri Mulyati, Samsul Rizal, Nik Abdul Hadi Nordin, Jia Jia Leam, Asim Laeeq Khan, and Juhana Jaafar. 2020. "Hybrid Membrane Distillation and Wet Scrubber for Simultaneous Recovery of Heat and Water from Flue Gas" Entropy 22, no. 2: 178. https://doi.org/10.3390/e22020178

APA StyleMohd Yusoff, M. H., Nyunt, E. K., Bilad, M. R., Arahman, N., Mulyati, S., Rizal, S., Nordin, N. A. H., Leam, J. J., Khan, A. L., & Jaafar, J. (2020). Hybrid Membrane Distillation and Wet Scrubber for Simultaneous Recovery of Heat and Water from Flue Gas. Entropy, 22(2), 178. https://doi.org/10.3390/e22020178