Variational Principle of Least Psychomotor Action: Modelling Effects on Action from Disturbances in Psychomotor Work Involving Human, Cyborg, and Robot Workers

Abstract

1. Introduction

2. Heuristic Framework for Modelling Disturbances in Psychomotor Work

2.1. Rule-of-Thumb Heuristics

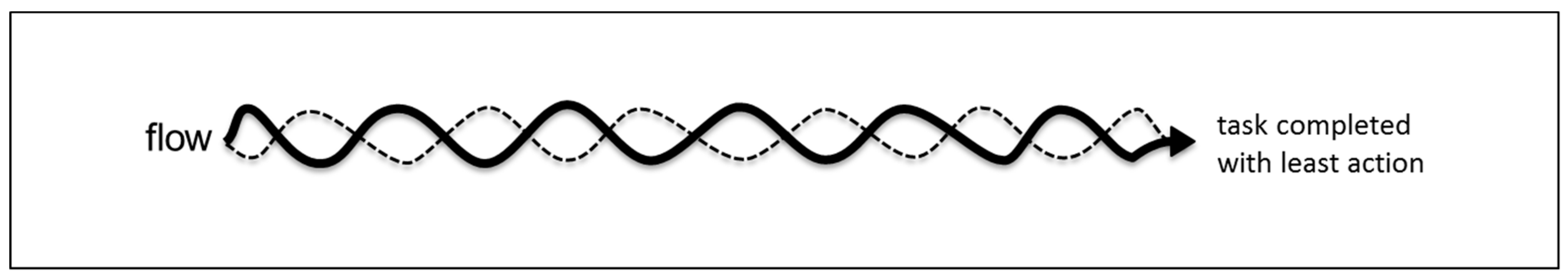

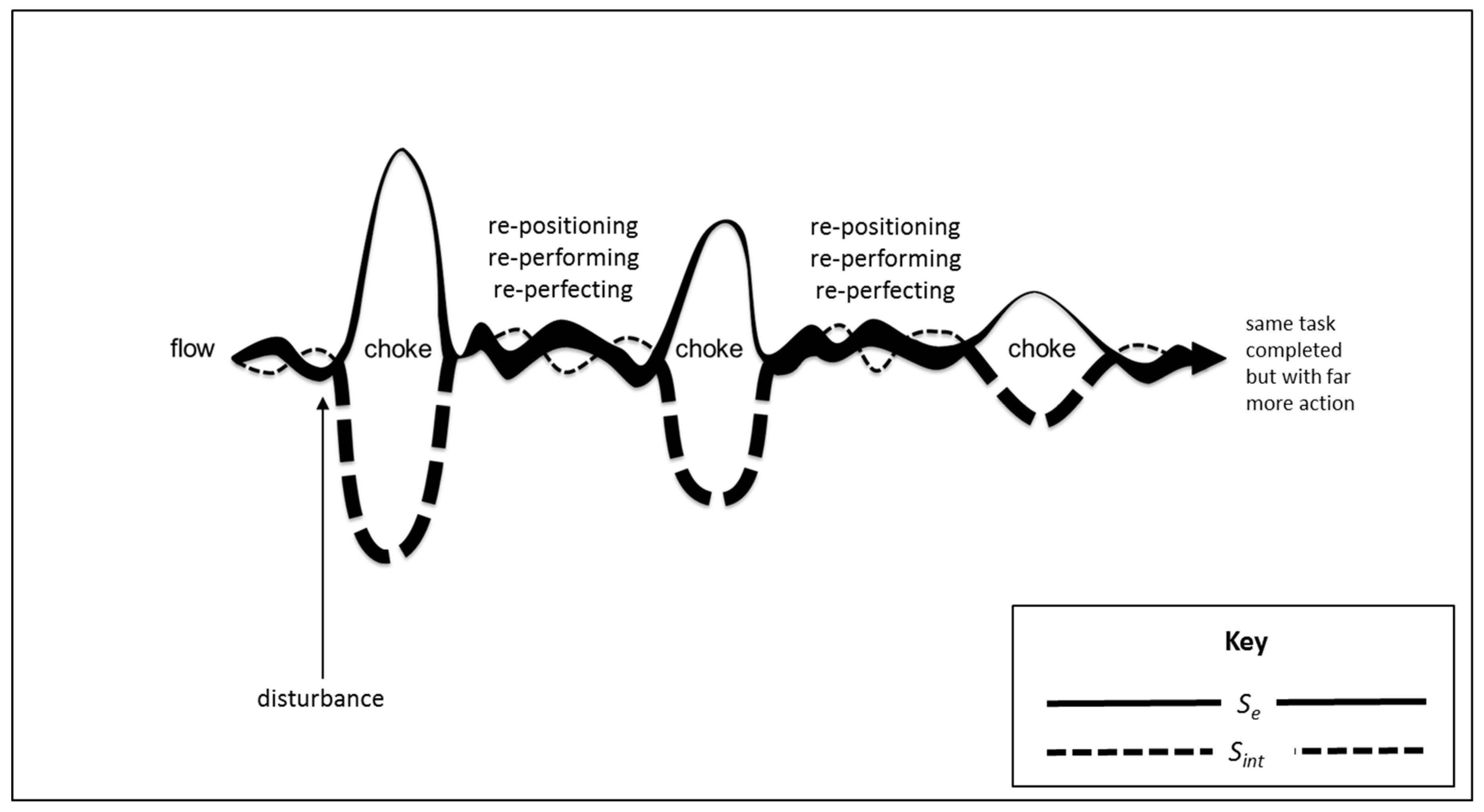

2.2. States in Psychomotor Work: Flow and Choke

2.3. Perturbation Theory and Disturbances in Psychomotor Work

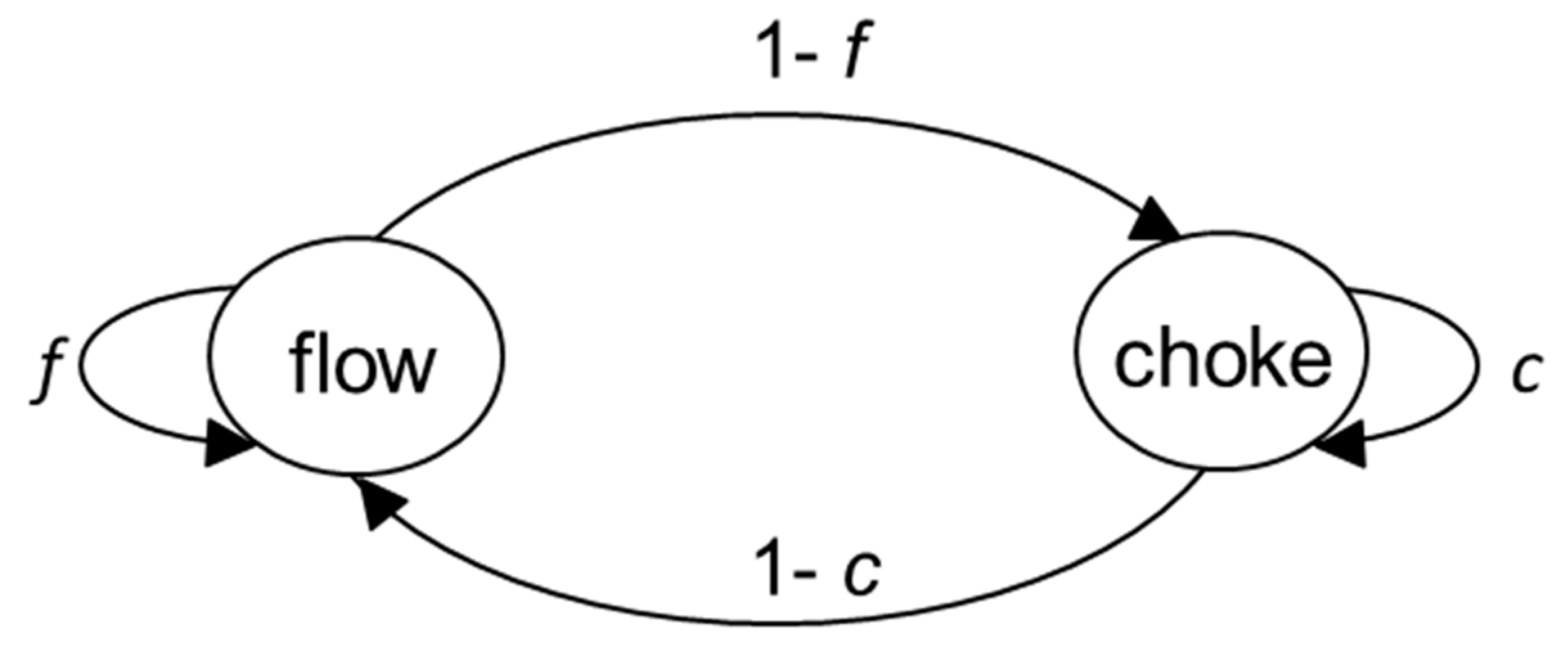

2.4. Two-State Markov Processes

3. Heuristic Modelling of Effects on Internal Action (Sint) from Disturbances

3.1. Formulae

3.2. Ratios

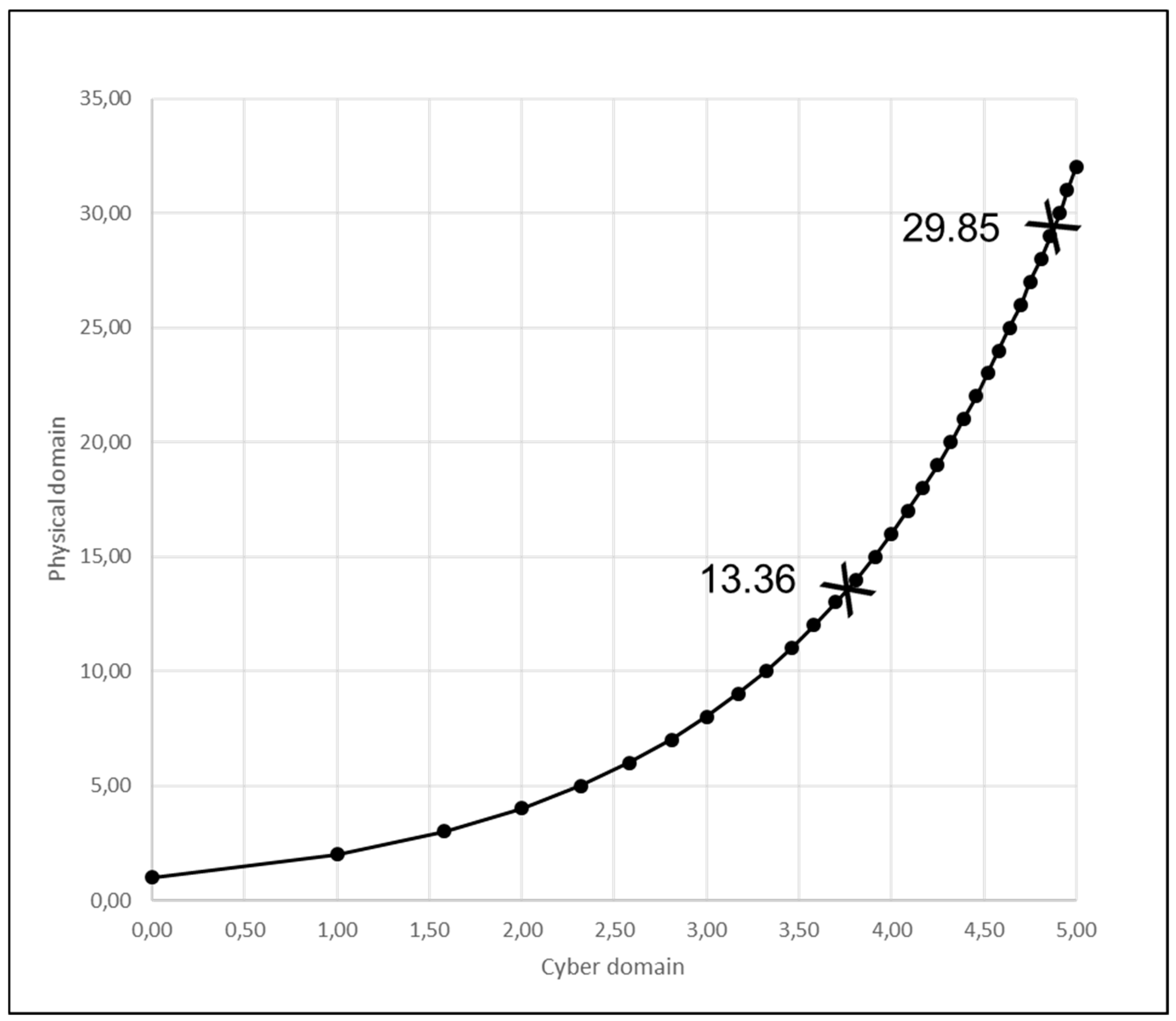

4. Heuristic Modelling of Effects on External Actions (Se) from Disturbances

4.1. Formulae

4.2. Ratios

5. Examples

6. Conclusions

6.1. Principal Contributions

6.2. Implications for Practice

6.3. Limitations and Directions for Further Research

Author Contributions

Funding

Conflicts of Interest

References

- Grundstein, S.; Freitag, M.; Scholz-Reiter, B. A new method for autonomous control of complex job shops: Integrating order release, sequencing and capacity control to meet due dates. J. Manuf. Syst. 2017, 42, 11–28. [Google Scholar] [CrossRef]

- Lu, S.; Xu, C.; Zhong, R.Y.; Wang, L. A RFID-enabled positioning system in automated guided vehicle for smart factories. J. Manuf. Syst. 2017, 44, 179–190. [Google Scholar] [CrossRef]

- Kuenzel, R.; Teizer, J.; Mueller, M.; Blickle, A. SmartSite: Intelligent and autonomous environments, machinery, and processes to realize smart road construction projects. Autom. Constr. 2016, 71, 21–33. [Google Scholar] [CrossRef]

- Dadhich, S.; Bodin, U.; Andersson, U. Key challenges in automation of earth-moving machines. Autom. Constr. 2016, 68, 212–222. [Google Scholar] [CrossRef]

- Fox, S.; Kotelba, A.; Niskanen, I. Cognitive Factories: Modeling situated entropy in physical work carried out by humans and robots. Entropy 2018, 20, 659. [Google Scholar] [CrossRef]

- Fox, S.; Kotelba, A. Principle of Least Psychomotor Action: Modelling situated entropy in optimization of psychomotor work involving humans, cyborg and robot workers. Entropy 2018, 20, 836. [Google Scholar] [CrossRef]

- Carvalko, J. The Techno-human Shell: A Jump in the Evolutionary Gap; Sunbury Press: Mechanicsburg, PA, USA, 2012. [Google Scholar]

- Halacy, D.S. Cyborg: Evolution of the Superman; Harper and Row Publishers: New York, NY, USA, 1965. [Google Scholar]

- Haraway, D.A. Cyborg Manifesto: Science, Technology, and Socialist-Feminism in the Late Twentieth Century. In Simians, Cyborgs and Women: The Reinvention of Nature; Routledge: New York, NY, USA, 1991; pp. 150–182. [Google Scholar]

- Eveleth, R. Why did I implant a chip in my hand? My so-called cyborg life. Popular Science. 24 May 2016. Available online: https://www.popsci.com/my-boring-cyborg-implant (accessed on 28 May 2019).

- Popescu, A. This $425 DIY Implant Will Make You a Cyborg: Cyborg Nest manufactures DIY kits meant to bring transhumanism to the masses. Bloomberg. 16 February 2017. Available online: https://www.bloomberg.com/news/articles/2017-02-16/this-425-diy-implant-will-make-you-a-cyborg (accessed on 28 May 2019).

- Beckerle, P.; Christ, O.; Schürmann, T.; Vogt, J.; von Stryk, O.; Rinderknecht, S. A human-machine-centered design method for (powered) lower limb prosthetics. Robot. Auton. Syst. 2017, 95, 1–12. [Google Scholar] [CrossRef]

- Yan, T.; Cempini, M.; Oddo, C.M.; Vitiello, N. Review of assistive strategies in powered lower-limb orthoses and exoskeletons. Robot. Auton. Syst. 2015, 64, 120–136. [Google Scholar] [CrossRef]

- Pfeifer, R.; Bongard, J. How the Body Shapes the Way We Think: A New View of Intelligence; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Dant, T. The pragmatics of material interaction. J. Consum. Cult. 2008, 8, 11–33. [Google Scholar] [CrossRef]

- Brown, J.S.; Collins, A.; Duguid, P. Situated cognition and the culture of learning. Educ. Res. 1989, 18, 32–42. [Google Scholar] [CrossRef]

- Chandler, P.; Sweller, J. Cognitive load theory and the format of instruction. Cognit. Instr. 1991, 8, 293–332. [Google Scholar] [CrossRef]

- Gerritsen, J.; Patten, B.C. System theory formulation of ecological disturbance. Ecol. Model. 1985, 29, 383–397. [Google Scholar] [CrossRef]

- Lee, J.H.; Yu, Z. Worst-case formulations of model predictive control for systems with bounded parameters. Automatica 1997, 33, 763–781. [Google Scholar] [CrossRef]

- Stone, J.V. Information Theory: A Tutorial Introduction; Sebtel Press: Sheffield, UK, 2015. [Google Scholar]

- Valavanis, K.P. The entropy based approach to modeling and evaluating autonomy and intelligence of robotic systems. J. Intell. Robot. Syst. 2018, 91, 7–22. [Google Scholar] [CrossRef]

- Brusoni, S.; Prencipe, A. Making design rules: A multi-domain perspective. Organ. Sci. 2006, 17, 179–189. [Google Scholar] [CrossRef]

- Gregory, R.W.; Muntermann, J. Heuristic theorizing: Proactively generating design theories. Inform. Syst. Res. 2014, 25, 639–653. [Google Scholar] [CrossRef]

- Glynn, I. Elegance in Science: The Beauty of Simplicity; Oxford University Press: Oxford, UK, 2010. [Google Scholar]

- Todd, P.M. Heuristics for decision and choice. In International Encyclopedia of the Social and Behavioral Sciences; Elsevier: New York, NY, USA, 2001; pp. 6676–6679. [Google Scholar]

- Everitt, B.S.; Skrondal, A. Cambridge Dictionary of Statistics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Hutchinson, J.M.; Gigerenzer, G. Simple heuristics and rules of thumb: Where psychologists and behavioural biologists might meet. Behav. Process. 2005, 69, 97–124. [Google Scholar] [CrossRef]

- Jacobs, K.; Lund, A.P. Feedback control of nonlinear quantum systems: A rule of thumb. Phys. Rev. Lett. 2007, 99, 020501. [Google Scholar] [CrossRef]

- Mon-Williams, M.; Tresilian, J.R. A simple rule of thumb for elegant prehension. Curr. Biol. 2001, 11, 1058–1061. [Google Scholar] [CrossRef]

- Poulin, P.A. Paradigm Shift in Pharmacokinetic–Pharmacodynamic (PKPD) Modeling: Rule of Thumb for Estimating Free Drug Level in Tissue Compared with Plasma to Guide Drug Design. J. Pharm. Sci. 2015, 104, 2359–2368. [Google Scholar] [CrossRef]

- Gibson, N.; Whittaker, J. Rules of thumb. J. Manag. Eng. 1996, 12, 34–39. [Google Scholar] [CrossRef]

- Smith, R.; Mobley, R.K. Rules of Thumb for Maintenance and Reliability Engineers; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Woods, D.R. Rules of Thumb in Engineering Practice; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Fournier, J.F.; Bouix-Peter, C.; Duvert, D.; Luzy, A.P.; Ouvry, G. Intrinsic Property Forecast Index (iPFI) as a Rule of Thumb for Medicinal Chemists to Remove a Phototoxicity Liability. J. Med. Chem. 2018, 61, 3231–3236. [Google Scholar] [CrossRef] [PubMed]

- Wambier, C.G.; King, B.A. Rule of thumb: A simple tool to estimate 1% scalp surface area. J. Am. Acad. Dermatol. 2019. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.T.; Morris, Z.N.; Nnonyelu, C.J. Rules-of-thumb to design a uniform spherical array for direction finding—Its Cramér–Rao bounds’ nonlinear dependence on the number of sensors. J. Acoust. Soc. Am. 2019, 145, 714–723. [Google Scholar] [CrossRef] [PubMed]

- Aickelin, U.; Clark, A. Heuristic optimisation. J. Oper. Res. Soc. 2011, 62, 251–252. [Google Scholar] [CrossRef]

- Malmborg, C.J. Rule of thumb heuristics for configuring storage racks in automated storage and retrieval systems design. Int. J. Prod. Res. 2001, 39, 511–527. [Google Scholar] [CrossRef]

- McAllister, E.W. Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering Problems; Gulf Professional Publishing, Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Miller, J.L.; Friedman, E.J. Photonics Rules of Thumb; McGraw-Hill Professional Publishing: New York, NY, USA, 2003. [Google Scholar]

- Bingham, C.B.; Eisenhardt, K.M. Rational heuristics: The ‘simple rules’ that strategists learn from process experience. Strateg. Manag. J. 2011, 32, 1437–1464. [Google Scholar] [CrossRef]

- Chittenden, F.; Derregia, M. Uncertainty, irreversibility and the use of ‘rules of thumb’ in capital budgeting. Br. Account. Rev. 2015, 47, 225–236. [Google Scholar] [CrossRef]

- Ekman, A.; Torne, A.; Stromberg, D. A robot control formalism based on an information quality concept. In Conference on Intelligent Robotics in Field, Factory, Service and Space; NASA Johnson Space Center: Houston, TX, USA, 1994; Volume 2, pp. 580–590. [Google Scholar]

- Aarts, H.; Dijksterhuis, A. Habits as knowledge structures: Automaticity in goal-directed behavior. J. Personal. Soc. Psychol. 2000, 78, 53–63. [Google Scholar] [CrossRef]

- National Gallery of Art. Veiled Bust (“The Veiled Nun”). Available online: https://www.nga.gov/collection/art-object-page.176446.html (accessed on 28 May 2019).

- Oropallo, W.; Piegl, L.A. Ten challenges in 3D printing. Eng. Comput. 2016, 32, 135–148. [Google Scholar] [CrossRef]

- Clark, A. Supersizing the Mind: Embodiment, Action, and Cognitive Extension; Oxford University Press: Oxford, UK, 2011. [Google Scholar]

- Spencer, D.C. Habit(us), body techniques and body callusing: An ethnography of mixed martial arts. Body Soc. 2009, 15, 119–143. [Google Scholar] [CrossRef]

- Gotts, S.J.; Chow, C.C.; Martin, A. Repetition priming and repetition suppression: A case for enhanced efficiency through neural synchronization. Cogn. Neurosci. 2012, 3, 227–259. [Google Scholar] [CrossRef] [PubMed]

- Carey, J.R.; Bhatt, E.; Nagpal, A. Neuroplasticity promoted by task complexity. Exerc. Sport Sci. Rev. 2005, 33, 24–31. [Google Scholar]

- Fitts, P.M.; Posner, M.I. Human Performance; Brooks: Belmont, CA, USA, 1967. [Google Scholar]

- Ullén, F.; Hambrick, D.Z.; Mosing, M.A. Rethinking expertise: A multifactorial gene–environment interaction model of expert performance. Psychol. Bull. 2016, 142, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Perencevich, K.C.; Seidel, R.J.; Kett, A.L. From Principles of Learning to Strategies for Instruction: Empirically Based Ingredients to Guide Instructional Development; Springer: Berlin, Germany, 2006. [Google Scholar]

- Grosz, E. Habit today: Ravaisson, Bergson, Deleuze and us. Body Soc. 2013, 19, 217–239. [Google Scholar] [CrossRef]

- Adler, J.D. Stages of skill acquisition: A guide for teachers. Mot. Skills Theory Pract. 1981, 5, 75–80. [Google Scholar]

- Hauser, T. The Black Lights: Inside the World of Professional Boxing; University of Arkansas Press: Fayetteville, NC, USA, 2000. [Google Scholar]

- Pannekoek, A. The discovery of Neptune. Centaurus 1953, 3, 126–137. [Google Scholar] [CrossRef]

- Bender, C.M.; Orszag, S.A. Advanced Mathematical Methods for Scientists and Engineers I: Asymptotic Methods and Perturbation Theory; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Rizzolatti, G.; Fadiga, L.; Gallese, V.; Fogassi, L. Premotor cortex and the recognition of motor actions. Cogn. Brain Res. 1996, 3, 131–141. [Google Scholar] [CrossRef]

- Dindo, H.; Nivel, E.; La Tona, G.; Chella, A.; Thórisson, K.R. An architecture for observational learning and decision making based on internal models. Biol. Inspired Cogn. Archit. 2013, 5, 52–63. [Google Scholar] [CrossRef]

- Jordan, M.; Rumelhart, D. Forward models: Supervised learning with a distal teacher. Cogn. Sci. 1992, 16, 307–354. [Google Scholar] [CrossRef]

- Wolpert, D.M.; Diedrichsen, J.; Flanagan, J.R. Principles of sensorimotor learning. Nat. Rev. Neurosci. 2011, 12, 739. [Google Scholar] [CrossRef] [PubMed]

- Xu, P. Measurement-based perturbation theory and differential equation parameter estimation with applications to satellite gravimetry. Commun. Nonlinear Sci. Numer. Simul. 2018, 59, 515–543. [Google Scholar] [CrossRef]

- Schwartz, D.L.; Bransford, J.; Sears, D. Efficiency and innovation in transfer. In Transfer of Learning from a Modern Multidisciplinary Perspective; Mestre, J., Ed.; Information Age Publishing: Greenwich, CT, USA, 2005. [Google Scholar]

- Shadmehr, R.; Mussa-Ivaldi, F. Adaptive representation of dynamics during learning of a motor task. J. Neurosci. 1994, 14, 3208–3224. [Google Scholar] [CrossRef] [PubMed]

- Wolpert, D.M.; Kawato, M. Multiple paired forward and inverse models for motor control. Neural Netw. 1998, 11, 1317–1329. [Google Scholar] [CrossRef]

- Fox, S.; Jokinen, T.; Lindfors, N.; Ylen, J.-P. Formulation of robust strategies for project manufacturing business. Int. J. Manag. Proj. Bus. 2009, 2, 217–237. [Google Scholar] [CrossRef]

- Weilenmann, M.; Kraemer, L.; Faist, P.; Renner, R. Axiomatic relation between thermodynamic and information-theoretic entropies. Phys. Rev. Lett. 2016, 117, 260601. [Google Scholar] [CrossRef] [PubMed]

- Monostori, L.; Kádár, B.; Bauernhans, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Akanmu, A.; Anumba, C.J. Cyber-physical systems integration of building information models and the physical construction. Eng. Constr. Archit. Manag. 2015, 22, 516–535. [Google Scholar] [CrossRef]

- Cover, T.M.; Thomas, J.A. Elements of Information Theory; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- Lanczos, C. The Variational Principles of Mechanics, 4th ed.; Dover Publications: New York, NY, USA, 2012. [Google Scholar]

- Van Brunt, B. The Calculus of Variations; Springer-Verlag: New York, NY, USA, 2004. [Google Scholar]

- Byrne, M.D.; Hossain, M.M. Production planning: An improved hybrid approach. Int. J. Prod. Econ. 2005, 93, 225–229. [Google Scholar] [CrossRef]

- Hwang, G.; Lee, J.; Park, J.; Chang, T.W. Developing performance measurement system for Internet of Things and smart factory environment. Int. J. Prod. Res. 2017, 55, 2590–2602. [Google Scholar] [CrossRef]

- Wirojanagud, P.; Gel, E.S.; Fowler, J.W.; Cardy, R. Modelling inherent worker differences for workforce planning. Int. J. Prod. Res. 2007, 45, 525–553. [Google Scholar] [CrossRef]

- Fowler, J.W.; Wirojanagud, P.; Gel, E.S. Heuristics for workforce planning with worker differences. Eur. J. Oper. Res. 2008, 190, 724–740. [Google Scholar] [CrossRef]

- Techawiboonwong, A.; Yenradee, P.; Das, S.K. A master scheduling model with skilled and unskilled temporary workers. Int. J. Prod. Econ. 2006, 103, 798–809. [Google Scholar] [CrossRef]

- Muthusamy, V.; Abdul Rasid, S.Z. Formulating the right labor mix for a Malaysian food manufacturer. Glob. Bus. Organ. Excell. 2018, 38, 41–46. [Google Scholar] [CrossRef]

- Friston, K.J. The free-energy principle: A unified brain theory? Nat. Rev. Neurosci. 2010, 11, 127–138. [Google Scholar] [CrossRef] [PubMed]

- Friston, K.J.; Stephan, K.E. Free-energy and the brain. Synthese 2007, 159, 417–458. [Google Scholar] [CrossRef] [PubMed]

- Shannon, C.E. A mathematical theory of communication, part I. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Makkuva, A.V.; Wu, Y. Equivalence of additive-combinatorial linear inequalities for Shannon entropy and differential entropy. IEEE Trans. Inform. Theory 2018, 64, 3579–3589. [Google Scholar] [CrossRef]

- Nielsen, F.; Nock, R. MaxEnt upper bounds for the differential entropy of univariate continuous distributions. IEEE Signal Process. Lett. 2017, 24, 402–406. [Google Scholar] [CrossRef]

- Bérut, A.; Arakelyan, A.; Petrosyan, A.; Ciliberto, S.; Dillenschneider, R.; Lutz, E. Experimental verification of Landauer’s principle linking information and thermodynamics. Nature 2012, 483, 187. [Google Scholar] [CrossRef]

- Sengupta, B.; Stemmler, M.B. Power consumption during neuronal computation. Proc. IEEE 2014, 102, 738–750. [Google Scholar] [CrossRef]

- Niven, J.E. Neuronal energy consumption: Biophysics, efficiency and evolution. Curr. Opin. Neurobiol. 2016, 41, 129–135. [Google Scholar] [CrossRef] [PubMed]

- Mrazek, V.; Sarwar, S.S.; Sekanina, L.; Vasicek, Z.; Roy, K. Design of power-efficient approximate multipliers for approximate artificial neural networks. In Proceedings of the IEEE/ACM International Conference on Computer-Aided Design, Austin, TX, USA, 7–10 November 2016; pp. 1–7. [Google Scholar]

- Shafique, M.; Hafiz, R.; Javed, M.U.; Abbas, S.; Sekanina, L.; Vasicek, Z.; Mrazek, V. Adaptive and energy-efficient architectures for machine learning: Challenges, opportunities, and research roadmap. In Proceedings of the IEEE Computer Society Annual Symposium on VLSI, Bochum, Germany, 3–5 July 2017; pp. 627–632. [Google Scholar]

- Liqun, L. The brain achieves its computational power through a massive parallel architecture. In Think Tank: Forty Scientists Explore the Biological Roots of Human Experience; Linden, D.J., Ed.; Yale University Press: New Haven, CT, USA, 2018. [Google Scholar]

- Kim, S.; Nussbaum, M.A.; Esfahani, M.I.M.; Alemi, M.M.; Jia, B.; Rashedi, E. Assessing the influence of a passive, upper extremity exoskeletal vest for tasks requiring arm elevation: Part II—“Unexpected” effects on shoulder motion, balance, and spine loading. Appl. Ergon. 2018, 70, 323–330. [Google Scholar] [CrossRef] [PubMed]

- Feynman, R.P.; Leighton, R.B.; Sands, M. The Feynman Lectures on Physics: Mainly Electromagnetism and Matter; Addison-Wesley Publishing: Reading, MA, USA, 1964. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.A. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Klötzer, C.; Weißenborn, J.; Pflaum, A. The evolution of cyber-physical systems as a driving force behind digital transformation. In Proceedings of the IEEE 19th Conference on Business Informatics (CBI), Thessaloniki, Greece, 24–26 July 2017; Volume 2, pp. 5–14. [Google Scholar]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards industrial digitalization based on an Industry 4.0 maturity model for manufacturing enterprises. Procedia CIRP 2019, 79, 409–414. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Wang, L.; Mohammed, A.; Wang, X.V.; Schmidt, B. Energy-efficient robot applications towards sustainable manufacturing. Int. J. Comput. Integr. Manuf. 2018, 31, 692–700. [Google Scholar] [CrossRef]

- Karvouniari, A.; Michalos, G.; Dimitropoulos, N.; Makris, S. An approach for exoskeleton integration in manufacturing lines using Virtual Reality techniques. Procedia CIRP 2018, 78, 103–108. [Google Scholar] [CrossRef]

- Gonzalez, C. Manufacturing workers become more than human with exoskeletons. Machine Design. 7 December 2017. Available online: https://www.machinedesign.com/motion-control/manufacturing-workers-become-more-human-exoskeletons (accessed on 28 May 2019).

- Garcia, R.R.; Bittencourt, A.C.; Villani, E. Relevant factors for the energy consumption of industrial robots. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 464. [Google Scholar] [CrossRef]

- Wilson, A.D.; Schultz, J.A.; Ansari, A.R.; Murphey, T.D. Dynamic task execution using active parameter identification with the BAXTER research robot. IEEE Trans. Autom. Sci. Eng. 2017, 14, 391–397. [Google Scholar] [CrossRef]

- Fryar, C.D.; Kruszan-Moran, D.; Gu, Q.; Ogden, C.L. Mean body weight, weight, waist circumference, and body mass index among adults: United States, 1999–2000 through 2015–2016. Nat. Health Stat. Rep. 2018, 122, 1–15. [Google Scholar]

- O’Keefe, J.H.; Vogel, R.; Lavie, C.J.; Cordain, L. Exercise like a hunter-gatherer: A prescription for organic physical fitness. Prog. Cardiovasc. Dis. 2011, 53, 471–479. [Google Scholar] [CrossRef] [PubMed]

- Wallden, M.; Sisson, M. Modern disintegration and primal connectivity. J. Bodyw. Mov. Ther. 2019, 23, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Baltrusch, S.J.; van Dieën, J.H.; van Bennekom, C.A.M.; Houdijk, H. The effect of a passive trunk exoskeleton on functional performance in healthy individuals. Appl. Ergon. 2018, 72, 94–106. [Google Scholar] [CrossRef] [PubMed]

- Theurel, J.; Desbrosses, K.; Roux, T.; Savescu, A. Physiological consequences of using an upper limb exoskeleton during manual handling tasks. Appl. Ergon. 2018, 67, 211–217. [Google Scholar] [CrossRef]

- Hodson, H. Robotic suit gives shipyard workers super strength. New Scientist. 30 July 2014. Available online: https://institutions.newscientist.com/article/mg22329803-900-robotic-suit-gives-shipyard-workers-super-strength/ (accessed on 28 May 2019).

- Wilson, D.; Davenport, J.H.; England, M.; Bradford, R. Piano Mover’s Problem reformulated. In Proceedings of the 15th IEEE International Symposium on Symbolic and Numeric Algorithms for Scientific Computing (SYNASC), Timișoara, Romania, 23–26 September 2013; pp. 53–60. [Google Scholar]

- Johnson, M.; Kirchain, R. Quantifying the effects of parts consolidation and development costs on material selection decisions: A process-based costing approach. Int. J. Prod. Econ. 2009, 119, 174–186. [Google Scholar] [CrossRef]

- Stacey, K.; Nicolaou, A. Stitched up by robots. Financial Times. 18 July 2017. Available online: https://www.ft.com/content/9f146ab6-621c-11e7-91a7-502f7ee26895 (accessed on 24 May 2019).

- Fox, S. Leapfrog skills: Combining vertical and horizontal multi-skills to overcome skills trade-offs that limit prosperity growth. Tech. Soc. 2016, 47, 129–139. [Google Scholar] [CrossRef]

- Chen, Y.; Dubé, C.M.; Rice, C.J.; Baram, T.Z. Rapid loss of dendritic spines after stress involves derangement of spine dynamics by corticotropin-releasing hormone. J. Neurosci. 2008, 28, 2903–2911. [Google Scholar] [CrossRef]

- Grollman, D.H.; Jenkins, O.C. Sparse incremental learning for interactive robot control policy estimation. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 3315–3320. [Google Scholar]

- Teicholz, P. Labor-productivity declines in the construction industry: Causes and remedies (another look). AECbytes 2013. View Point#67, 14 March. Available online: http://www.aecbytes.com/viewpoint/2013/issue_67.html (accessed on 28 May 2019).

- Fox, S.; Ehlen, P.; Purver, M. Enabling distributed communication of manual skills. Int. J. Manag. Proj. Bus. 2011, 4, 49–63. [Google Scholar] [CrossRef]

- Von Neumann, J. Method in the physical sciences. In The Neumann Compendium, World Series in 20th Century Mathematics; Bródy, F., Vámos, T., Eds.; World Scientific Publishing Co.: Singapore, 1955; Volume 1, p. 628. [Google Scholar]

- Gibbs, S. Mercedes-Benz swaps robots for people on its assembly lines. The Guardian; London, UK, 26 February 2006. Available online: https://www.theguardian.com/technology/2016/feb/26/mercedes-benz-robots-people-assembly-lines (accessed on 28 May 2019).

- Gibbs, S. Elon Musk drafts in humans after robots slow down Tesla Model 3 production. The Guardian; London, UK, 16 April 2018. Available online: https://www.theguardian.com/technology/2018/apr/16/elon-musk-humans-robots-slow-down-tesla-model-3-production (accessed on 28 May 2019).

- Duclos, R. The psychology of investment behavior: (De)biasing financial decision-making one graph at a time. J. Consum. Psychol. 2015, 25, 317–325. [Google Scholar] [CrossRef]

- Bhandari, G.; Hassanein, K.; Deaves, R. Debiasing investors with decision support systems: An experimental investigation. Decis. Support Syst. 2008, 46, 399–410. [Google Scholar] [CrossRef]

| Theory | Variables | Sources of Disturbances Examples | |

|---|---|---|---|

| Embodied cognition [14] | Worker types | Human | Fatigue errors |

| Cyborg | Body/exoskeleton alignment errors | ||

| Robot | Sensor errors | ||

| Work pragmatics [15] | Work characteristics | Setting | Weather conditions |

| Composition | Natural materials | ||

| Uncertainty | Inconsistent interfaces | ||

| Situated cognition [16] | Worker-work interactions | Positioning actions | Slipping on ground dampened by rainfall |

| Performing actions | Misalignments when working natural material | ||

| Perfecting actions | Sensing errors of unique component interfaces | ||

| Cognitive load [17] | Embodied cognitive load | Extraneous | “Surprise” of unexpected sensory input |

| Intrinsic | Processing of misalignment information | ||

| Germane | Active inference to match inputs with schema | ||

| Known Solutions | Level | Example |

|---|---|---|

| Psychomotor work skills schema | Reforming products interfaces | Interface between reception desk and wall |

| Reassembling products | Reception desk | |

| Refitting sub-assemblies | Desk top | |

| Remaking parts | Desk drawer | |

| Reshaping materials | Wood | |

| Psychomotor general ability templates | Fine: dorsiflexion | Increasing palm–inner-arm angle to place part |

| Fine: palmar flexion | Decreasing palm–inner-arm angle to hold part | |

| Gross: medial/lateral rotation | Rotating arm closer or away from body for task | |

| Gross: abduction/adduction | Raising and lowering arms to reach work | |

| Gross: flexion/extension | Walking, standing, sitting to do work |

| Complexity | Disturbance | Complexity Following Disturbance | ||||

|---|---|---|---|---|---|---|

| X | 4/6, 1/6, 1/6 | 1.25 | work piece damaged due to sensory error | X* | 1/3, 1/3, 1/3 | 1.58 |

| Y | 1/10, 1/10, 6/10, 1/10, 1/10 | 1.77 | Y* | 1/5, 1/5, 1/5, 1/5, 1/5 | 2.32 | |

| Z | 4/5, 1/5 | 0.72 | Z* | 1/2, 1/2 | 1.00 | |

| 1.25 + 1.77 + 0.72 | 3.74 | 1.58 + 2.32 + 1.00 | 4.90 | |||

| f | 0.9 | c | 0.9 | |||

| 0.5 | 0.5 | |||||

| 1.87 | 2.45 | |||||

| = 1.87 + 2.45 − 0.5 0.5 = 5.32 | ||||||

| Worker Type | Positioning | Repositioning Following Disturbance | ||||

|---|---|---|---|---|---|---|

| Complexity | Cyber | Physical | Complexity | Cyber | Physical | |

| Human | 1/6, 4/6, 1/6 | 1.25 | 2.38 | 1/8, 3/8, 1/8, 2/8, 1/8 | 2.16 | 4.47 |

| Cyborg | 1/6, 4/6, 1/6 | 1.25 | 2.38 | 1/10, 1/10, 3/10, 2/10, 2/10, 1/10 | 2.45 | 5.46 |

| Robot | 1/6, 4/6, 1/6 | 1.25 | 2.38 | 1/12, 1/12, 1/12, 3/12, 2/12, 1/12, 2/12, 1/12 | 2.85 | 7.21 |

| Worker Type | Performing | Re-performing Following Disturbance | ||||

|---|---|---|---|---|---|---|

| Complexity | Cyber | Physical | Complexity | Cyber | Physical | |

| Human | 1/5, 3/5, 1/5 | 1.37 | 2.58 | 1/8, 1/8, 2/8, 1/8, 2/8, 1/8 | 2.75 | 6.73 |

| Cyborg | n/a | n/a | ||||

| Robot | 1.75/2, 0.25/2 | 0.54 | 1.45 | 1/2, ½ | 1.00 | 2.00 |

| Worker Type | Perfecting (none in Flow State) | Re-perfecting Following Disturbance | ||||

|---|---|---|---|---|---|---|

| Complexity | Cyber | Physical | Complexity | Cyber | Physical | |

| Human | n/a | n/a | n/a | 1/25, 1/25, 1/25, 1/25, 1/25, 2/25, 4/25, 4/25, 3/25, 3/25, 1/25, 1/25, 1/25, 1/25 | 3.54 | 11.67 |

| Cyborg | n/a | n/a | n/a | 1/2, 1/4, 1/4 | 1.5 | 2.86 |

| Robot | n/a | n/a | n/a | n/a | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fox, S.; Kotelba, A. Variational Principle of Least Psychomotor Action: Modelling Effects on Action from Disturbances in Psychomotor Work Involving Human, Cyborg, and Robot Workers. Entropy 2019, 21, 543. https://doi.org/10.3390/e21060543

Fox S, Kotelba A. Variational Principle of Least Psychomotor Action: Modelling Effects on Action from Disturbances in Psychomotor Work Involving Human, Cyborg, and Robot Workers. Entropy. 2019; 21(6):543. https://doi.org/10.3390/e21060543

Chicago/Turabian StyleFox, Stephen, and Adrian Kotelba. 2019. "Variational Principle of Least Psychomotor Action: Modelling Effects on Action from Disturbances in Psychomotor Work Involving Human, Cyborg, and Robot Workers" Entropy 21, no. 6: 543. https://doi.org/10.3390/e21060543

APA StyleFox, S., & Kotelba, A. (2019). Variational Principle of Least Psychomotor Action: Modelling Effects on Action from Disturbances in Psychomotor Work Involving Human, Cyborg, and Robot Workers. Entropy, 21(6), 543. https://doi.org/10.3390/e21060543