Mechanical Properties and Corrosion Resistance of NbTiAlSiZrNx High-Entropy Films Prepared by RF Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design and Fabrication of NbTiAlSiZrNx HEA Thin Films

2.1.1. Design of NbTiAlSiZrNx HEA Films

2.1.2. Preparing the NbTiAlSiZrNx HEA Film

2.2. Characterization of the NbTiAlSiZrNx HEA Thin Film Method

2.2.1. Assessment of Film Thickness

2.2.2. Assessment of the Film Surface

2.2.3. Assessment of Film Hardness

2.2.4. Thin Film Corrosion Resistance

2.2.5. Thin Film Crystal Structure Test

3. Results

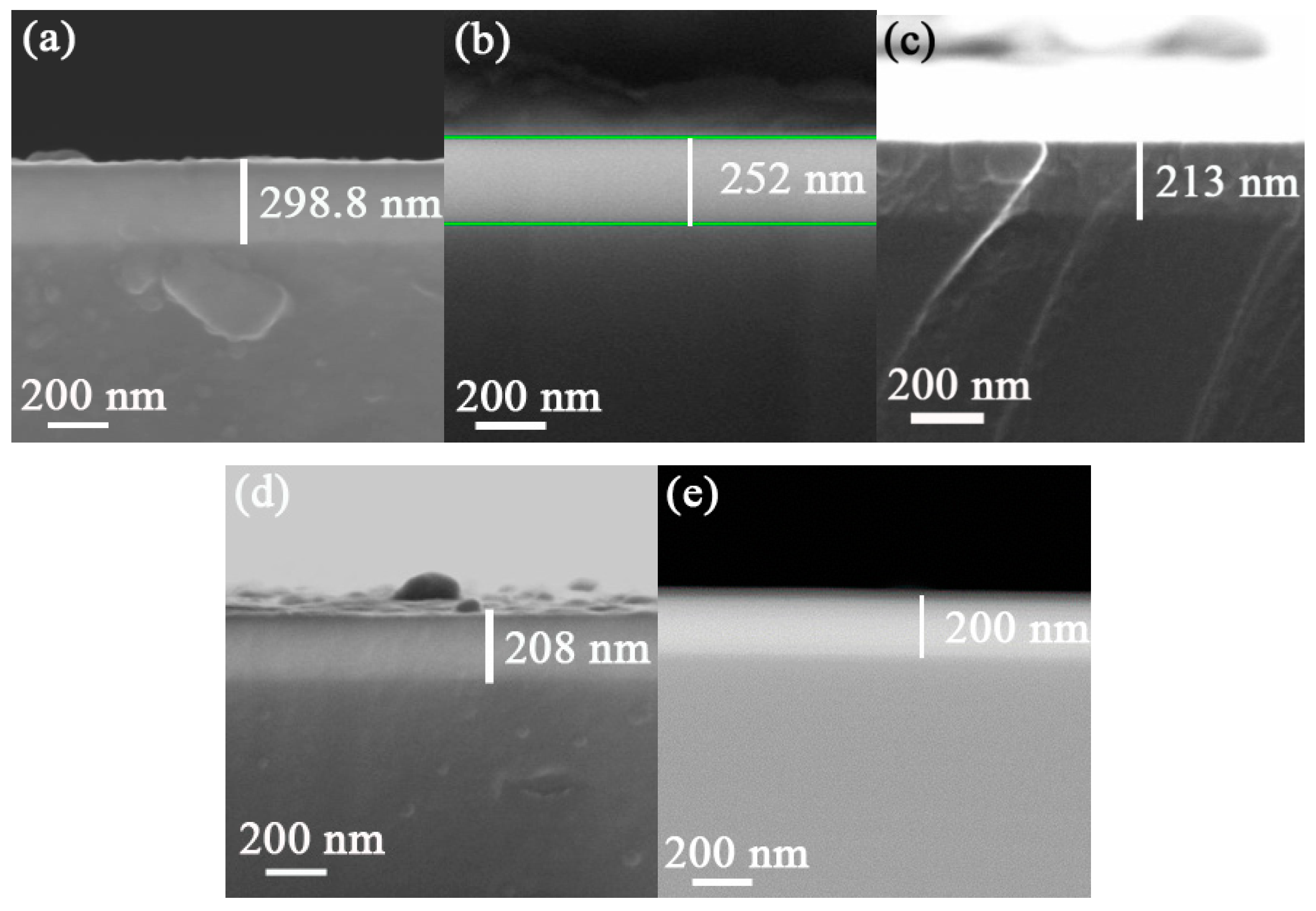

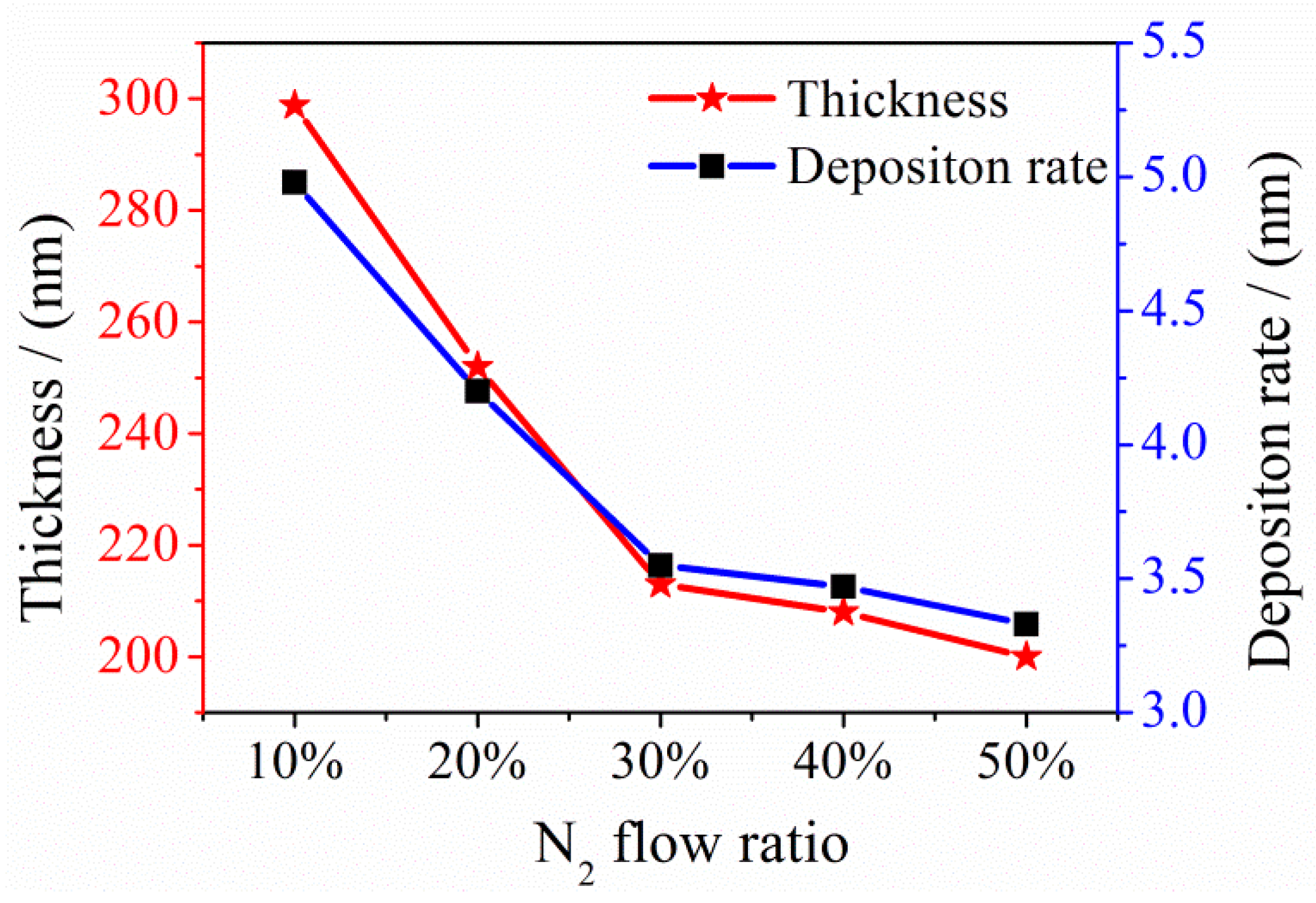

3.1. Assessment of Film Thickness

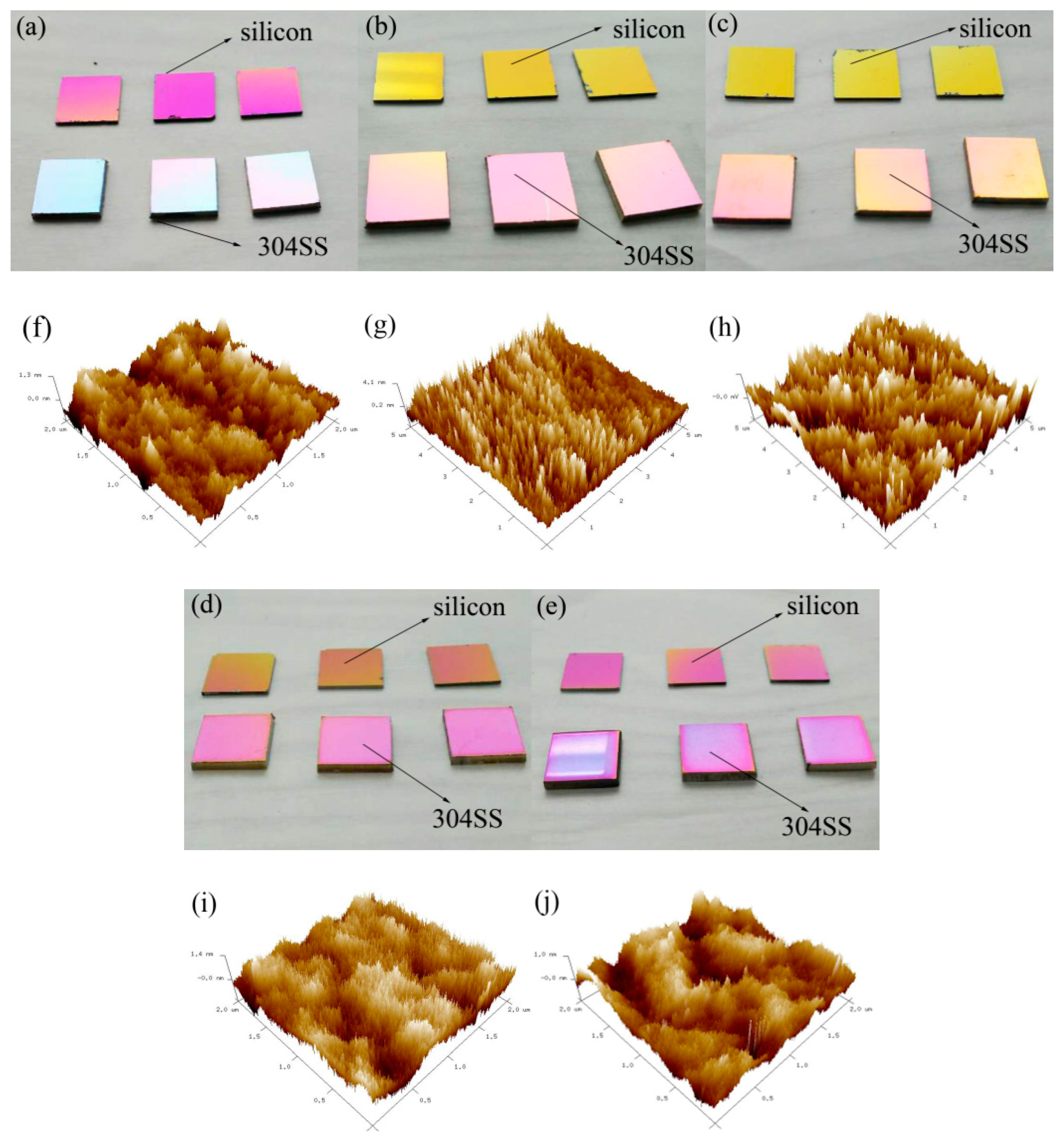

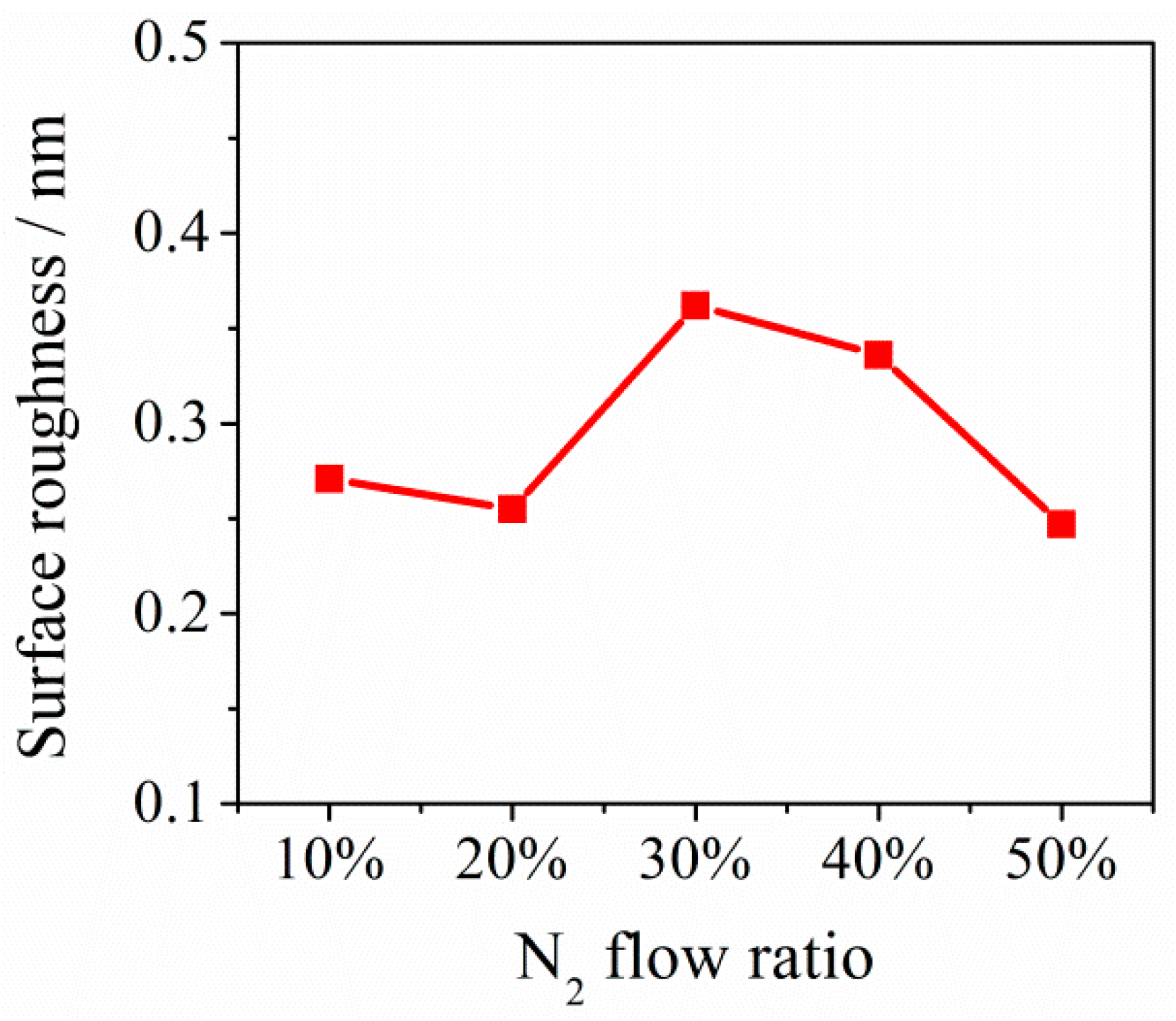

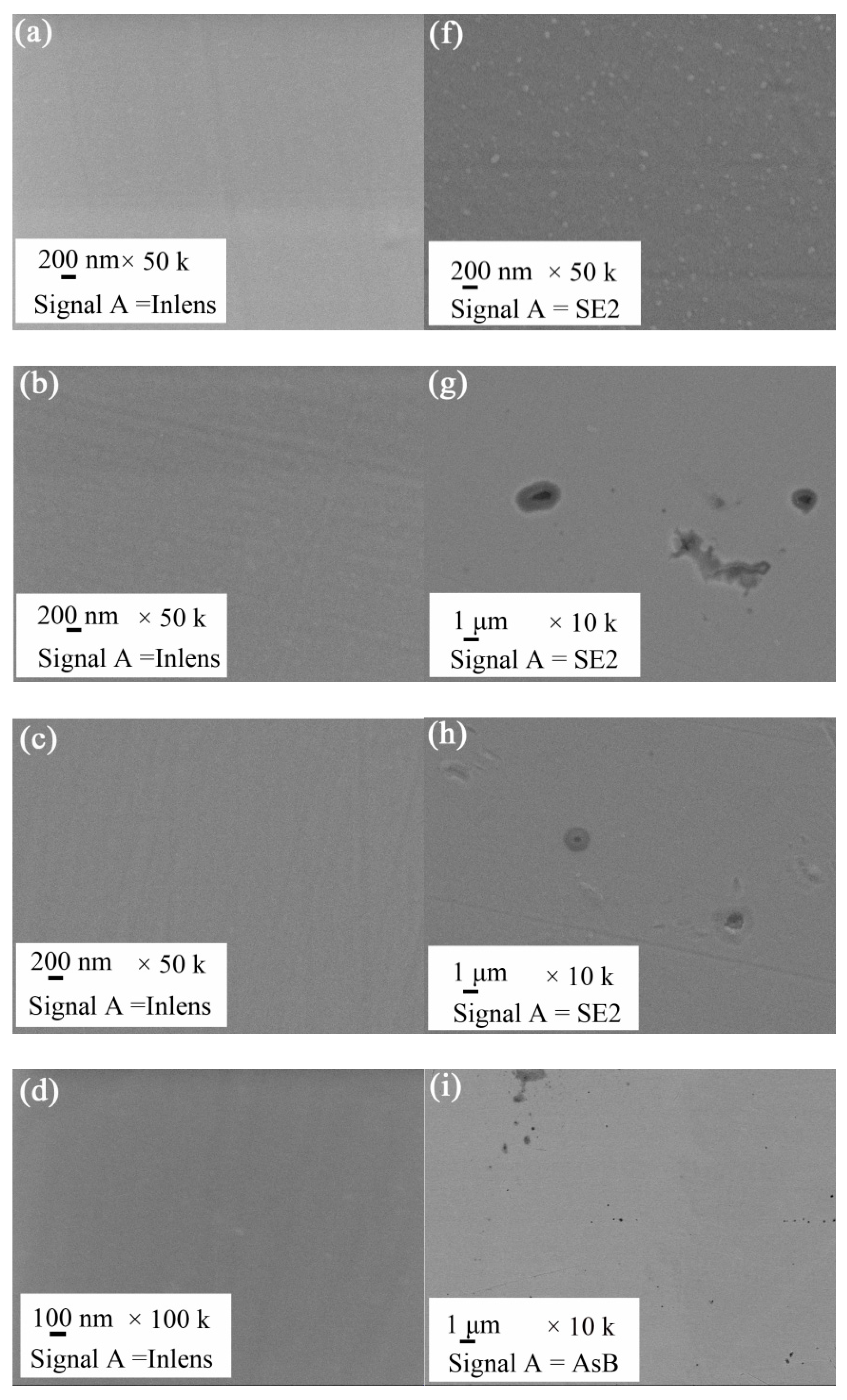

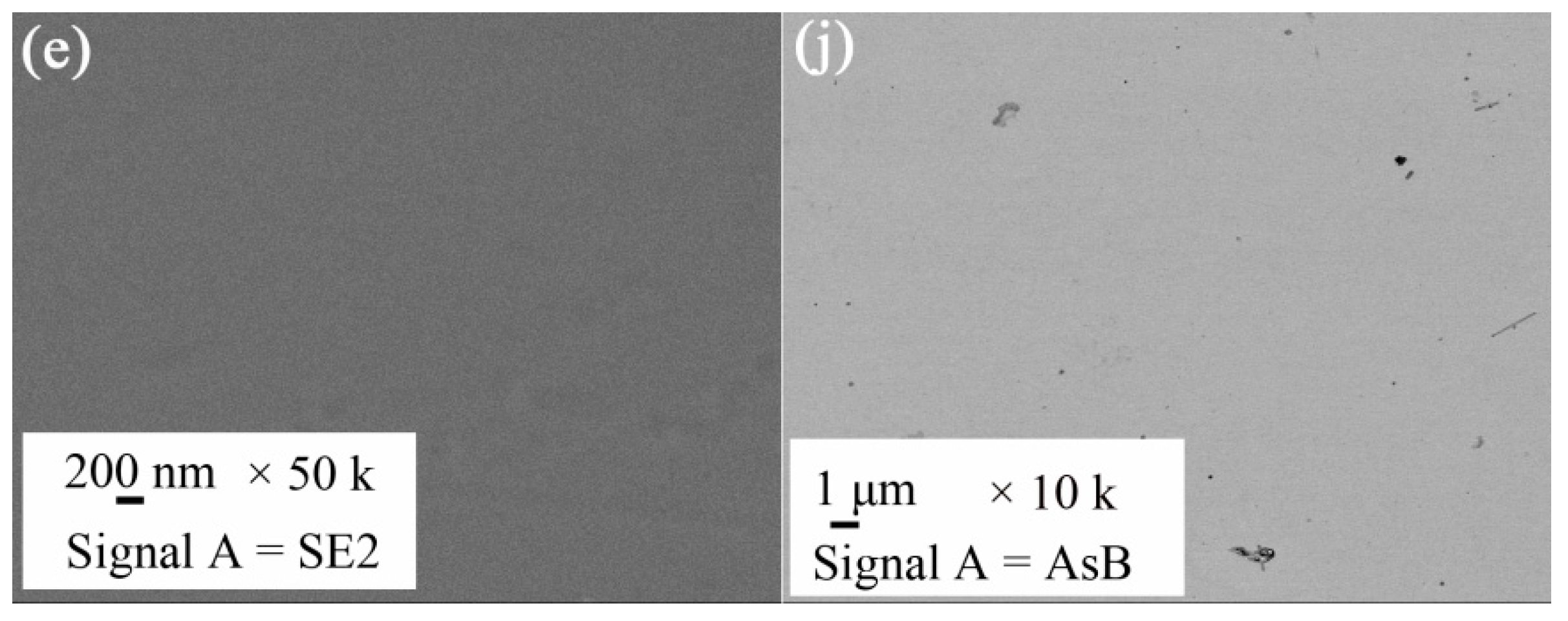

3.2. Assessment of the Film Surface

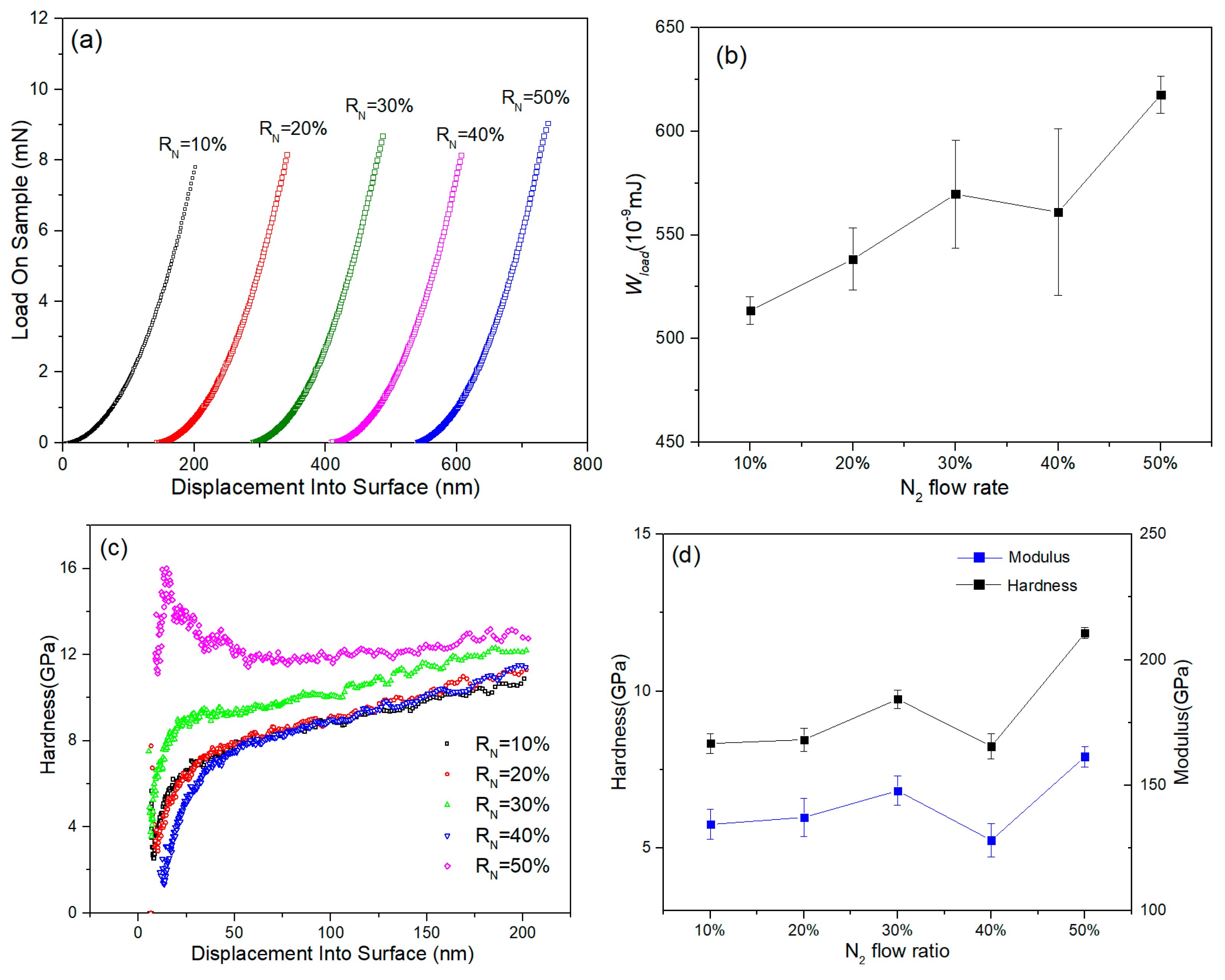

3.3. Assessment of Film Hardness

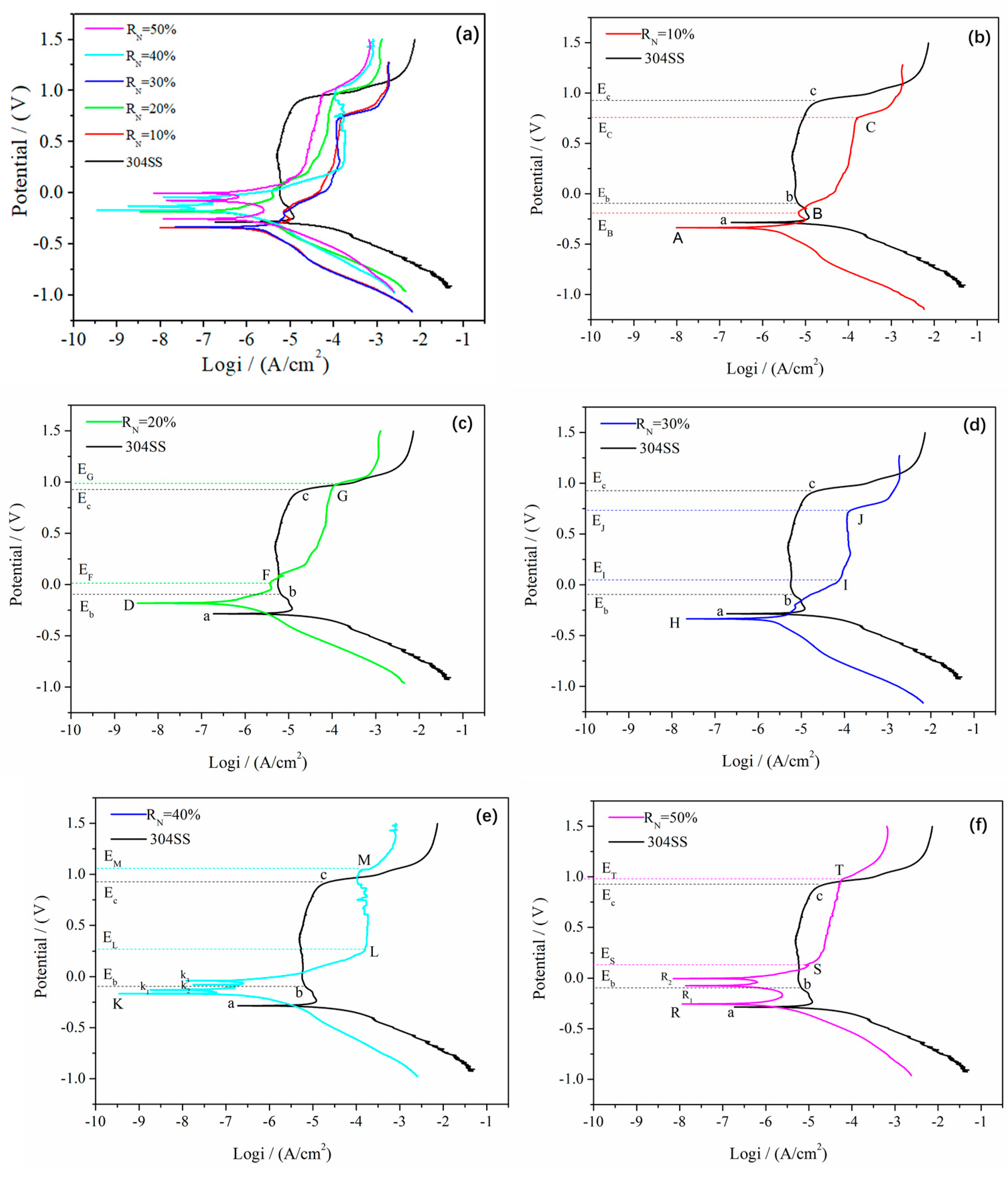

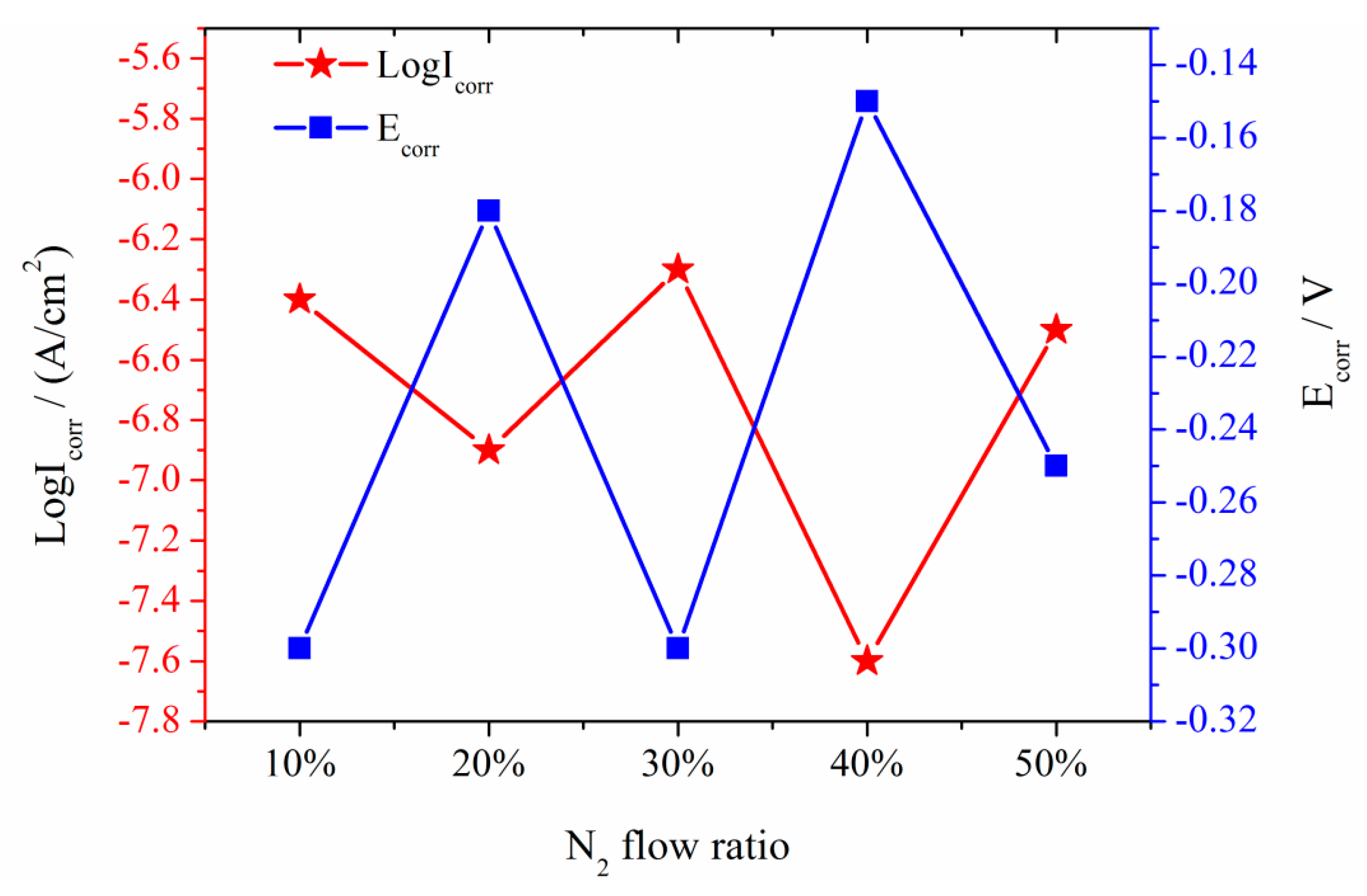

3.4. Thin Film Corrosion Resistance

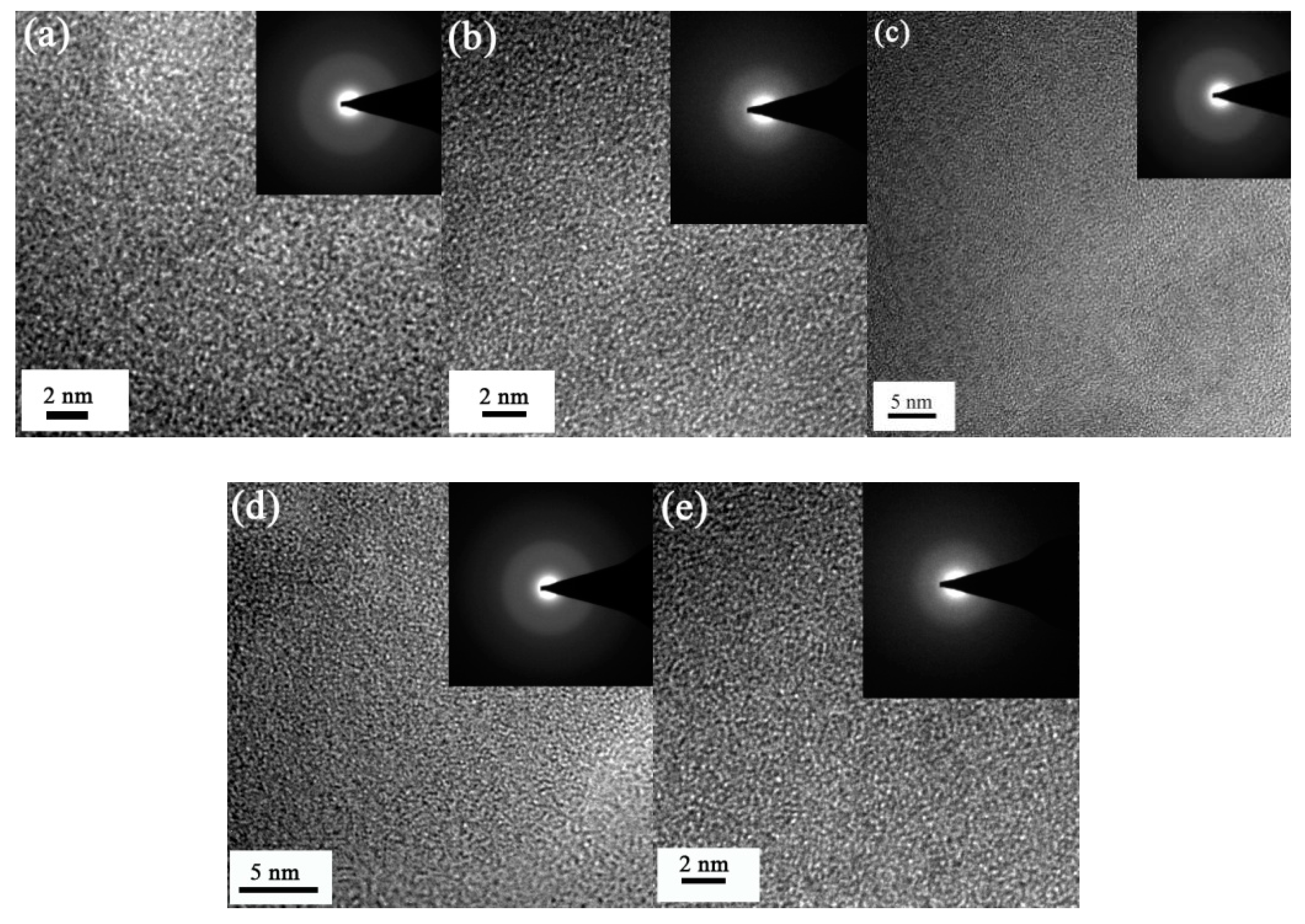

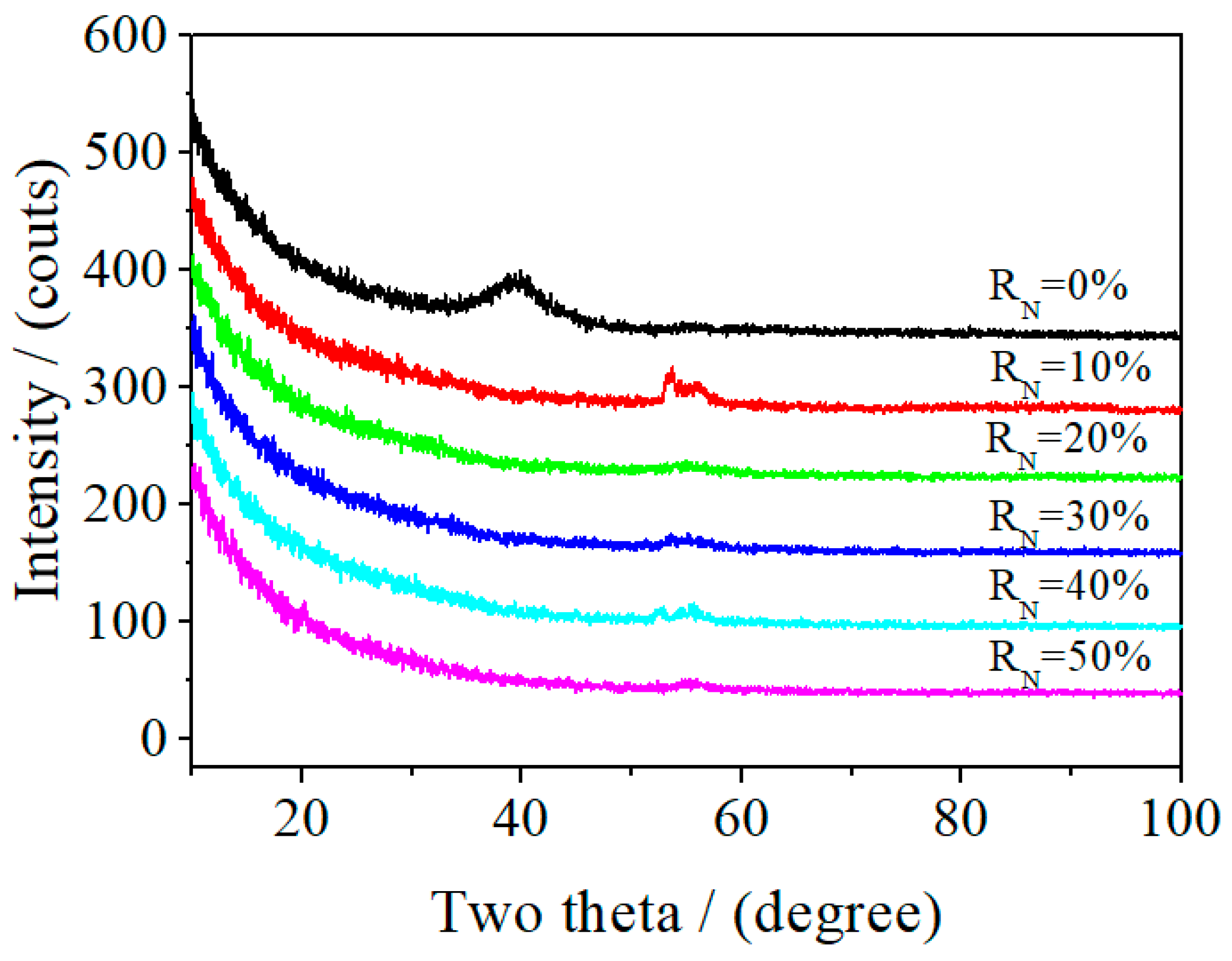

3.5. Assessment of the Thin Film’s Crystal Structure

4. Discussion

4.1. Preparation of NbTiAlSiZrNx HEA Films Using N2 Magnetron Sputtering and Thin Film Forming Effect

4.2. Organizational Structure of the NbTiAlSiZrNx HEA Thin Film

4.3. Performance of the NbTiAlSiZrNx HEA Thin Film

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Braic, M.; Braic, V. Characteristics of (TiAlCrNbY)C films deposited by reactive magnetron sputtering. Surf. Coat. Technol. 2010, 204, 2010–2014. [Google Scholar] [CrossRef]

- Tsai, C.; Lai, S. Strong amorphization of high-entropy AlBCrSiTi nitrde film. Thin Solid Films 2012, 520, 2613–2618. [Google Scholar] [CrossRef]

- Xue, W.; Zhu, Q. Characterization of ceramic coatings fabricated on zirconium alloy by plasma electrolytic oxidation in silicate electrolyte. Mater. Chem. Phys. 2010, 120, 656–660. [Google Scholar] [CrossRef]

- Huang, M.; Wang, Y. Corrosion Resistance of Fe–Al/Al2O3 Duplex Coating on Pipeline Steel X80 in Simulated Oil and Gas Well Environment. Surf. Rev. Lett. 2015, 22, 1550045. [Google Scholar] [CrossRef]

- Xue, K.; Niu, L. XPS Analysis of Silicon Oxycarbide Formed on the Surface of Rf-sputter Deposited SiC Thin Films. Key Eng. Mater. 2007, 353–358, 1871–1874. [Google Scholar] [CrossRef]

- Mondal, A.K.; Kumar, S. Effect of laser surface treatment on corrosion and wear resistance of ACM720 Mg alloy. Surf. Coat. Technol. 2008, 202, 3187–3198. [Google Scholar] [CrossRef]

- Hsueh, H.; Shen, W. Effect of nitrogen content and substrate bias on mechanical and corrosion properties of (Al Cr Si Ti Zr)100-xNx high-entropy films. Surf. Coat. Technol. 2012, 206, 4106–4112. [Google Scholar] [CrossRef]

- Li, Z. Study on the Design and Preparation of a New Type of Reflective Film with Wide Band Width Angle. Ph.D. Thesis, University of Chinese Academy of Sciences, Beijing, China, 2016. [Google Scholar]

- Bertolino, V.; Cavallaro, G. Halloysite nanotubes sandwiched between chitosan layers: Novel bionanocomposites with multilayer structures. New J. Chem. 2018, 42, 8384–8390. [Google Scholar] [CrossRef]

- Cicco, D.; Asaee, Z. Use of Nanoparticles for Enhancing the Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints-A Review. Nanomaterials 2017, 7, 360. [Google Scholar] [CrossRef]

- Duan, H.; Sun, J. Research progress of coating materials and sputtering targets. In Proceedings of the 2015 Annual Meeting of the Society of Vacuum Society of Guangdong Province, Zhanjiang, China, 26–28 November 2015. [Google Scholar]

- Shen, W.; Tsai, M. Effects of substrate bias on the structure and mechanical properties of (Al1.5CrNb0.5Si0.5Ti)Nx coatings. Thin Solid Films 2012, 520, 6183–6188. [Google Scholar] [CrossRef]

- Zhang, Y. Amorphous and High-Entropy Alloys; Science Press: Beijing, China, 2010. [Google Scholar]

- Murty, B.S.; Yeh, J. High-Entropy Alloys; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 25–35. [Google Scholar]

- Feng, X.; Tang, G. Chemical state and phase structure of (TaNbTiW)N films prepared by combinatined magnetron sputtering and PBII. Appl. Surf. Sci. 2013, 280, 388–393. [Google Scholar] [CrossRef]

- Michael, C.G. Progress in High Entropy Alloys. JOM 2014, 66, 1964–1965. [Google Scholar] [CrossRef]

- Feng, W.; Qi, Y. Effects of Short-Range Order on the Magnetic and Mechanical Properties of FeCoNi(AlSi)x High Entropy Alloys. Metals 2017, 7, 482. [Google Scholar] [CrossRef]

- Zhai, S.; Wang, W. Effect of Co and Gd Additions on Microstructures and Properties of FeSiBAlNi High Entropy Alloys. Entropy 2018, 20, 487. [Google Scholar] [CrossRef]

- Liu, X.; Yin, H. Microstructure, Mechanical and Tribological Properties of Oxide Dispersion Strengthened High-Entropy Alloys. Materials 2017, 10, 1312. [Google Scholar] [CrossRef]

- Klimova, M.; Stepanov, N. Microstructure and Mechanical Properties Evolution of the Al, C-Containing CoCrFeNiMn-Type High-Entropy Alloy during Cold Rolling. Materials 2018, 11, 53. [Google Scholar] [CrossRef]

- Cicala, G.; Giordano, D.; Tosto, C.; Filippone, G.; Recca, A.; Blanco, I. Polylactide (PLA) Filaments a Biobased Solution for Additive Manufacturing: Correlating Rheology and Thermomechanical Properties with Printing Quality. Materials 2018, 11, 1191. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C. Microstructure and Propeties of Aluminum-Containing Refractory High-Entropy Alloys. JOM 2014, 66, 2030–2042. [Google Scholar] [CrossRef]

- Sheng, W.; Yang, X. Nano-Crystallization of High-Entropy Amorphous NbTiAlSiWxNy Films Prepared by Magnetron Sputtering. Entropy 2016, 18, 226. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, J. Stable nanocrystalline NbMoTaW high-entropy alloy thin films with excellent mechanical and electrical propeies. Mater. Lett. 2018, 210, 24–27. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, C. Synthesis of Laser High Entropy Alloying Coating on The Surface of Single-element Fe Base Alloy. Acta Metall. Sin. 2014, 50, 555–560. [Google Scholar] [CrossRef]

- Li, P.; Chen, J. Research progress of high-entropy alloy coating. Mater. Prot. 2015, 48, 44–46. [Google Scholar] [CrossRef]

- Braeckman, B.R.; Boydens, F. High entropy alloy thin films deposited by magnetron sputtering of powder targets. Thin Solid Films 2015, 580, 71–76. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H. Advances in ion plating technology. Vacuum 2014, 51, 1–8. [Google Scholar] [CrossRef]

- Huang, P.; Yeh, J. Effects of nitrogen content on structure and mechanical properties of multi-element. Surf. Coat. Technol. 2009, 203, 1891–1896. [Google Scholar] [CrossRef]

- Chang, S.; Lin, S. Microstructures and mechanical properties of multi-component (AlCrTiZr)NxCy nanocomposite coatings. Thin Solid Films 2011, 519, 4865–4869. [Google Scholar] [CrossRef]

- Liu, X. Study on AlxFeCrCoNiCu High-Entropy Alloy Coating for Corrosion Protection of Steel Matrix. Ph.D. Thesis, Institute of technology Dalian, Dalian, China, 2014; pp. 81–100. [Google Scholar]

- Sheng, W.; Yang, X. Amorphous phase stability of NbTiAlSiNX high-entropy films. Rare Metal. 2018, 32, 682–689. [Google Scholar] [CrossRef]

- Xing, Q.; Xia, S. Mechanical properties and thermal stability of (NbTiAlSiZr)Nx high-entropy ceramic films at high temperatures. J. Mater. Res. 2018, 33, 3347–3354. [Google Scholar] [CrossRef]

- Xing, Q.; Ma, J. High-Throughput Screening Solar-Thermal Conversion Films in a Pseudobinary (Cr, Fe, V)-(Ta, W) System. ACS Comb. Sci. 2018, 20, 602–610. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, X. Effects of Nitrogen Content on the Structure and Mechanical Properties of (Al0.5CrFeNiTi0.25)Nx High-Entropy Films by Reactive Sputtering. Entropy 2018, 20, 624. [Google Scholar] [CrossRef]

- Gao, L.; Liao, W. Microstructure, Mechanical and Corrosion Behaviors of CoCrFeNiAl0.3 High Entropy Alloy (HEA) Films. Coatings 2017, 7, 156. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, Y. Size effects on the mechanical properties of nanocrystalline NbMoTaW refractory high entropy alloy thin films. Int. J. Plast. 2017, 95, 264–277. [Google Scholar] [CrossRef]

| Element | Nb | Ti | Al | Si | Zr |

|---|---|---|---|---|---|

| ri | 1.48 | 1.45 | 1.43 | 1.34 | 1.60 |

| Element | Nb | Ti | Al | Si | Zr |

|---|---|---|---|---|---|

| Nominal content/at. % | 20 | 20 | 20 | 20 | 20 |

| Actual content/at. % | 20.56 | 19.52 | 21.00 | 19.38 | 19.54 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Q.; Wang, H.; Chen, M.; Chen, Z.; Li, R.; Jin, P.; Zhang, Y. Mechanical Properties and Corrosion Resistance of NbTiAlSiZrNx High-Entropy Films Prepared by RF Magnetron Sputtering. Entropy 2019, 21, 396. https://doi.org/10.3390/e21040396

Xing Q, Wang H, Chen M, Chen Z, Li R, Jin P, Zhang Y. Mechanical Properties and Corrosion Resistance of NbTiAlSiZrNx High-Entropy Films Prepared by RF Magnetron Sputtering. Entropy. 2019; 21(4):396. https://doi.org/10.3390/e21040396

Chicago/Turabian StyleXing, Qiuwei, Haijiang Wang, Mingbiao Chen, Zhaoyun Chen, Rongbin Li, Peipeng Jin, and Yong Zhang. 2019. "Mechanical Properties and Corrosion Resistance of NbTiAlSiZrNx High-Entropy Films Prepared by RF Magnetron Sputtering" Entropy 21, no. 4: 396. https://doi.org/10.3390/e21040396

APA StyleXing, Q., Wang, H., Chen, M., Chen, Z., Li, R., Jin, P., & Zhang, Y. (2019). Mechanical Properties and Corrosion Resistance of NbTiAlSiZrNx High-Entropy Films Prepared by RF Magnetron Sputtering. Entropy, 21(4), 396. https://doi.org/10.3390/e21040396