Abstract

As an emerging innovation paradigm in the digital economy era, digital innovation has become an important means for manufacturing firms to build supply chain resilience for sustainable development, but its intrinsic mechanism requires clarification. This research explores the impact of digital innovation (digital organizational innovation and digital product innovation) on supply chain resilience (supply chain readiness, supply chain responsiveness, and supply chain recovery) and sustainable performance via structural equation modeling involving data from 226 Chinese manufacturing firms. The results show that digital organizational innovation can promote digital product innovation. Digital organizational innovation and digital product innovation contribute to supply chain readiness, supply chain responsiveness, and supply chain recovery. Supply chain readiness, supply chain responsiveness, and supply chain recovery enhance sustainable performance. Finally, supply chain resilience mediates the relationship between digital innovation and sustainable performance. These findings reveal the role of digital innovation in improving sustainable performance through supply chain resilience and provide practical guidance for manufacturing companies to better conduct digital innovation to build supply chain resilience and thus realize sustainable development.

1. Introduction

As a core issue for national economic, social, and environmental development, coupled with the escalating challenges of resource scarcity, environmental pollution, and climate change, achieving sustainable development has increasingly become a priority for countries worldwide. For example, in 2021, China formulated the Action Plan for Carbon Peaking before 2030 to advance its green and low-carbon transition. The United States released the Federal Sustainable Development Plan in the same year, setting a target of net-zero emissions by 2050. In 2025, the European Union launched the Ecodesign Regulation for Sustainable Products to achieve its green and circular economy objectives. However, with traditional technological support, sustainable development faces numerous challenges, including the difficulty of addressing “opportunistic” governance stemming from information asymmetry and the challenge of realizing a “return on investment” due to high investment costs [1]. Against this backdrop, the rise and application of digital technologies have brought about unprecedented opportunities for achieving sustainable development [2]. For example, Sany Heavy Industry’s Changsha Plant No. 18 leverages digital technologies such as the industrial internet and blockchain to drive comprehensive transformation across product manufacturing, quality management, and environmental protection. This implementation has ultimately achieved sustainable operational outcomes, including a 123% increase in production capacity, a 98% improvement in personnel efficiency, a 29% reduction in unit manufacturing costs, and a carbon emission intensity below 0.015 tons per 10,000 yuan “https://www.sanygroup.com/news/11374.html (accessed on 12 May 2024)”. The Bosch Group’s Thailand factory has implemented a blockchain system to record more than 150 data points, including processing temperatures and quality inspection reports for automotive components, on the blockchain. This initiative has reduced the traceability time from three weeks to just 10 min, minimizing production delays caused by quality issues and thus lowering operating costs “https://mp.weixin.qq.com/s?__biz=Mzg2NTYyMjE0Mw==&mid=2247484399&idx=1&sn=ee044a2ee8b7259aa7685a2704a3a906 (accessed on 12 May 2024)”. From a corporate practice perspective, the application of digital technologies has a pronounced double-edged sword effect on sustainable development [3]. Some scholars have reported that digital technology and sustainable development exhibit an inverted U-shaped relationship [4,5,6]. Therefore, how to effectively leverage digital technologies to advance sustainable development has become a critical challenge that manufacturing enterprises urgently need to address.

As the concentrated embodiment of digital technology applications, digital innovation centers on the deep integration of digital technologies with physical components. It leverages digital technologies throughout the innovation process to drive transformative changes in products, services, processes, or business models [7]. For example, Haier’s Tianjin factory leveraged big data and artificial intelligence technologies to drive production process innovation. By establishing equipment power load models, it successfully achieved environmental benefits, including a 35% reduction in energy consumption and a 36% decrease in greenhouse gas emissions “https://www.haier.com/press-events/news/20230116_205211.shtml (accessed on 15 May 2024)”. The Foxconn industrial internet leverages artificial intelligence and IoT technologies to optimize material recycling, track real-time carbon footprints, and drive process innovation. This approach has reduced direct carbon emissions by 42% and indirect emissions by 24%, demonstrating the critical value of digital innovation in advancing sustainable development within the manufacturing sector “https://cn.weforum.org/press/2024/10/world-economic-forum-recognizes-leading-companies-transforming-global-manufacturing-with-ai-innovation-cn/ (accessed on 15 May 2024)”. Although the practices outlined above have demonstrated the immense potential of digital innovation, for many enterprises, it remains a multistage, complex process that requires precise strategies, long-term investment, and continuous optimization. Although some studies have begun to examine the positive impact of digital innovation on sustainable performance, research remains largely confined to exploring the direct relationship between the two, and it typically relies solely on metrics such as the number of digital patents or single-dimensional scales for measurement [8]. The lack of systematic deconstruction and in-depth analysis of the multidimensional implications of digital innovation make it difficult to fully reflect its actual impact on enterprises and value chains, thus hindering the clarification of its specific role in enhancing sustainable performance. On this basis, this paper proposes the first research question:

RQ1: How does digital innovation affect sustainable performance?

As the social division of labor continues to refine and supply chain networks grow increasingly complex, coupled with external shocks such as trade protectionism, geopolitical tensions, and natural disasters, maintaining stable supply chain operations amid disruptions has become a critical safeguard for manufacturing enterprises to achieve sustainable development. Supply chain resilience is defined as the capacity to respond to disruption risks, specifically the ability of a supply chain to rapidly recover to its initial state or an even more favorable state following a risk-induced disruption [9]. However, the current level of supply chain resilience among manufacturing firms still needs improvement, as classic strategies are increasingly inadequate for effectively addressing the growing frequency and severity of supply chain disruptions. Data from the supply chain analytics firm AutoForecast Solutions indicate that, despite a relative easing of semiconductor supply constraints in 2023 compared with the previous two years, the global automotive industry still cumulatively reduced production by approximately 220,000 vehicles as of 15 January 2023 because of chip shortages “https://www.ithome.com/0/668/348.htm (accessed on 20 May 2024)”. The supply chain consulting firm Resilinc noted that global supply chain disruptions increased by 38% in 2024 compared with the previous year, presenting new challenges for the global supply network “https://news.cctv.com/2025/03/16/ARTIPn3bpKI0vKuwAzpWYIXB250316.shtml (accessed on 20 May 2024)”. In the same year, a survey by McKinsey’s Global Supply Chain Leaders revealed that supply chain disruptions have become the new normal globally. However, when faced with such disruptions, companies rarely implement new countermeasures “https://news.cctv.com/2025/03/16/ARTIPn3bpKI0vKuwAzpWYIXB250316.shtml (accessed on 20 May 2024)”. As a result, how to help enterprises build supply chain resilience amid turbulence has become an urgent issue requiring attention. As an emerging innovation paradigm in the digital economy era, digital innovation can help enterprises enhance supply chain resilience [10], thus achieving sustainable development. Digital innovation, underpinned by technologies such as the Internet of Things (IoT) and big data, enables enterprises to capture supply–demand fluctuations and identify potential risk points in real time while dynamically allocating resources. This not only enhances supply chains’ resilience to disruptions but also reduces waste through precise resource matching, thus providing technological support for sustainable development. However, existing research has yet to sufficiently explore the underlying mechanisms and pathways through which digital innovation impacts sustainable development. In particular, an in-depth analysis of the role that supply chain resilience plays in the relationship between digital innovation and sustainable performance is lacking. Hence, this paper proposes the second research question:

RQ2: What is the role of supply chain resilience in the relationship between digital innovation and sustainable performance?

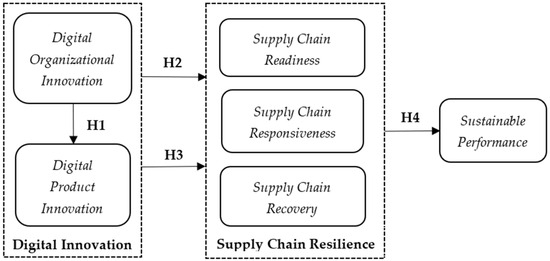

This study constructs a “digital innovation → supply chain resilience → sustainable performance” conceptual model. Using questionnaire data from 226 Chinese manufacturing enterprises, this study conducts empirical testing through structural equation modeling. The main contributions of this study include the following: First, it subdivides digital innovation into digital organizational innovation and digital product innovation. By constructing the influence pathways between the two, it delves into the intrinsic effects of digital innovation, aiming to help enterprises prioritize their digital innovation activities. Second, by integrating the phased characteristics of enterprises’ responses to supply chain disruptions, supply chain resilience is conceptualized as a composite of multiple capabilities, including supply chain preparedness, supply chain responsiveness, and supply chain recovery. This approach expands the analytical framework commonly employed in sustainable performance research, which often treats supply chain resilience as a single-dimensional capability. Third, this study examines the specific role of supply chain resilience in the process through which digital innovation impacts sustainable performance, providing robust evidence for enterprises to implement digital innovation and build supply chain resilience. Moreover, this study provides evidence from Chinese manufacturing firms leveraging digital innovation and supply chain resilience to achieve sustainable development.

2. Literature Review and Research Hypotheses

2.1. Literature Review

Digital innovation is first defined as the generation of new products through new combinations of digital technologies and physical components [11]. This definition is then gradually expanded to include the use of digital technologies in the innovation process [12]. Although expressed differently, scholars generally agree that digital innovation has three core elements: digital technology, the innovation process, and innovation output [13]—and classify it into digital product innovation, digital service innovation, digital process innovation, digital organizational innovation, and digital business model innovation [14]. In terms of antecedents, organizational resources and capabilities [15] contribute to digital innovation. The results indicate that digital innovation, which is the key to establishing sustainable competitive advantages for firms in the digital environment, can improve firm performance, including environmental, social, and governance (ESG) performance [16]; and firm competitiveness [17]. In accordance with Nambisan [12], this study defines digital innovation as the process by which organizations drive innovation through digital technologies to reshape their products, processes, or business models, including two dimensions—digital organizational innovation and digital product innovation—with digital organizational innovation focusing on the use of digital technologies to reconfigure organizational structures and governance models and digital product innovation emphasizing the use of digital technologies to develop new products or iterative innovations to existing products.

Supply chain resilience is the capability of a supply chain to react quickly to external shocks, quickly identify potential threats, and quickly return to its pre-disruption state of operation or to a new desired state [18]. Studies have shown that resources such as social capital [19], organizational resources [20], supply chain alertness [21], supply chain flexibility [22], and other capabilities, as well as technologies such as artificial intelligence [23], big data analytics [24], and blockchain [25], can significantly increase supply chain resilience. In addition, supply chain resilience is crucial not only for supply chains to withstand the impact of disruptive events but also for building the core competitiveness of the supply chain, which can help companies improve their operational performance [19], supply chain performance [26], and so forth. In accordance with Qader et al. [27], this study defines supply chain resilience as the ability of a supply chain to prepare for unforeseen events and to react, recover and reach or exceed its original level of operations quickly after an external shock. Additionally, this study divides supply chain resilience into three aspects—supply chain readiness, supply chain responsiveness and supply chain recovery. Supply chain readiness is the ability of a firm to fully understand the operational state of its supply chain and prepare accordingly before a supply chain disruption occurs [28]. Supply chain responsiveness is the ability of a firm to correctly respond to risks in a timely manner when a supply chain disruption occurs [29]. Finally, supply chain recovery is the ability of a firm to rapidly reach its original or better operational state [30].

Sustainable performance is rooted in the concept of sustainable development and aims to measure the level of sustainability in a quantifiable manner. Elkington [30] introduced the concept of the triple bottom line, which relates to economic, social, and environmental performance. He argued that companies should measure their performance from a multidimensional perspective to achieve a balance of economic, social, and environmental benefits [31]. Since then, the concept of the triple bottom line has gained widespread recognition among scholars and has been applied to measure sustainable performance. Most existing research on sustainable performance focuses on the microlevel of enterprises, emphasizing its influencing factors. Existing research indicates that corporate resources such as green innovation [32], and digital supply chain networks [33], as well as corporate capabilities such as supply chain collaboration [34], supply chain resilience [35], and supply chain integration [36], can all significantly enhance sustainable performance. The impact of digital technology applications on sustainable performance is a current focus of research among scholars. Research has demonstrated that the application of digital technologies such as artificial intelligence [37], blockchain [38], and big data analytics [39] contributes to enhancing sustainable performance. In line with Gelhard & von Delft [40], this study defines sustainable performance as a performance metric that integrates human well-being and ecological constraints while addressing stakeholder needs to establish a competitive advantage.

2.2. Relationships Within Digital Innovation

Existing research has confirmed that organizational innovation is a crucial prerequisite for product innovation [41]. Digital technology applications bring changes in organizational culture, organizational structure, and organizational governance that can drive digital product innovation. First, the application of digital technologies can help enterprises develop a digital innovation-oriented organizational culture [42], which in turn encourages employees to actively experiment with new technologies and methods, promotes departmental collaboration and knowledge sharing, and ultimately facilitates the development of product innovation activities [43,44]. Second, enterprises can leverage digital technologies for flat and borderless organizations [45] and build collaborative networks across departments and even supply chains to gain valuable insights into emerging technologies, market trends, and user preferences, thus improving the efficiency, success, and effectiveness of product innovation [46,47]. Finally, digital changes in organizational governance can help companies analyze R&D needs, technology bottlenecks, manufacturing processes and the fit of existing resources in real time; accurately identify problems in the supply chain operations process; and flexibly deploy human, technological, and production resources to eliminate the non-value-adding aspects of the process to continue promoting the digital innovation of products [48]. In summary, we hypothesize the following:

H1.

Digital organizational innovation positively affects digital product innovation.

2.3. Impact of Digital Innovation on Supply Chain Resilience

2.3.1. Impact of Digital Organizational Innovation on Supply Chain Resilience

First, digital organizational innovation can help enterprises prepare for supply chain disruptions. On the one hand, the application of blockchain, big data and other digital technologies helps enterprises closely monitor the operational status of the supply chain, perceive changes in the internal and external environments of the supply chain in a timely manner, and then fully prepare for supply chain disruption [49]. On the other hand, with the support of digital technologies, enterprises are able to accurately identify key internal and external risk factors to plan for risks in advance [50], thus enhancing their risk tolerance and readiness. For example, Gunasekaran et al. [51]. argue that firms using digital technology can identify disruption risks in advance, which in turn leads to a more sophisticated risk response and can thus mitigate the impact of risk disturbances faster and at a lower cost.

Second, digital organizational innovation can help enterprises respond quickly to supply chain disruptions. With the help of digital technology, enterprises can better coordinate all supply chain members to achieve information sharing, process synergy and resource integration to quickly adjust the supply chain structure and organizational relationships to achieve a rapid response to supply chain disruptions [52]. In addition, the use of digital technologies by firms allows them to reconfigure existing resources in response to changing environmental demands [53] and to respond proactively to supply chain disruptions through supply chain collaboration [54], initiating risk response plans [55], switching to alternate suppliers [56] and taking other measures to respond proactively to supply chain disruptions.

Finally, digital organizational innovation can help companies recover quickly or even reach a better state of operations. First, the deployment of digital technologies helps enterprises achieve a data-driven approach to supply chain management, increasing the value of their outputs while restoring supply chain operations by accurately analyzing market demand and optimizing production processes [57]. Second, to help enterprises recover quickly from disruptions, digital technologies can improve the efficiency of interfirm communication; effectively enhance the level of trust among supply chain members; and enable the sharing of information, knowledge and other resources [58]. Additionally, the application of digital technologies can enhance firms’ learning capabilities [59], helping them better learn experiential knowledge from disruptions and ultimately recover and optimize supply chain operations. In summary, the following hypotheses are proposed:

H2a.

Digital organizational innovation positively affects supply chain readiness.

H2b.

Digital organizational innovation positively affects supply chain responsiveness.

H2c.

Digital organizational innovation positively affects supply chain recovery.

2.3.2. Impact of Digital Product Innovation on Supply Chain Resilience

First, digital product innovation contributes to supply chain readiness. On the one hand, digital technology can strengthen the ability of enterprises to collect and analyze user feedback, thus helping them continuously optimize existing products to extend their lifecycle [60,61]. This situation not only helps enterprises adapt effectively to market fluctuations but also reduces the likelihood of supply chain disruptions by identifying and correcting weaknesses in supply chain processes ahead of time in the innovation process [46]. On the other hand, by utilizing digital technologies to develop new products, enterprises can not only expand their revenue streams but also create a diversified product strategy that reduces their dependence on existing products [58], which in turn effectively diversifies potential supply chain risks and reduces supply chain vulnerability. In addition, the utilization of digital sharing platforms can help enterprises effectively integrate internal and external resources and information from the supply chain, strengthen their close collaboration with supply chain members, and thus collaborate to realize product innovation [62]. Scholten & Schilder [54] argued that the aforementioned synergies are themselves among the key elements in strengthening the supply chain’s readiness to risk.

Second, digital product innovation contributes to supply chain responsiveness. Digital technologies such as digital twins, artificial intelligence, and big data can help quickly assess the feasibility of different product innovation solutions and then quickly adjust production to respond to changes in the market and demand in a timely manner, thus reducing the scope and duration of supply chain disruptions [63]. Moreover, the use of Industry 4.0 technologies such as the IoT and blockchain by enterprises can improve the transparency and traceability of the entire supply chain process, helping enterprises monitor the operational process in real time to optimize resource allocation and thus improve the agility and flexibility of the supply chain [27]. In addition, the utilization of digital technologies can alleviate the information asymmetry of supply chain members, thus increasing the degree of trust among supply chain partners [64]. Such effective collaboration that maintains mutual trust has been recognized as an important factor for coping with supply chain disruptions.

Finally, digital product innovation contributes to supply chain recovery. In the product conceptualization stage, enterprises are able to exploit the openness of digital technology to enable different subjects to collaboratively participate in product design, thus realizing product innovation and value added to recover operations more effectively [65]. In the product development stage, the support of technologies such as digital twins can help enterprises reduce the trial-and-error cost of product innovation [66] and thus flexibly adjust their product production strategies. In the product production phase, the application of digital technologies such as the IoT and blockchain can help enterprises achieve transparent monitoring of the production chain [67]. Previous studies have also concluded that digital technologies can help companies reshape their product value creation paths while restoring operations by building digital channels, redefining value propositions, and improving resource utilization [68]. In summary, the following hypotheses are proposed:

H3a.

Digital product innovation positively affects supply chain readiness.

H3b.

Digital product innovation positively affects supply chain responsiveness.

H3c.

Digital product innovation positively affects supply chain recovery.

2.4. Impact of Supply Chain Resilience on Sustainable Performance

Supply chain resilience can help enterprises prepare for unforeseen events and react quickly to, recover from, or exceed their original level of operations after an external shock [69], which in turn leads to better sustainable performance [35].

First, being prepared means that the supply chain has a high level of visibility, is prepared with appropriate redundant resources, and has advanced warnings of risks [70,71]. Improved supply chain visibility helps enterprises obtain timely and accurate operational information to better respond to market fluctuations, reduce supply chain disruption, and bring about sustainable competitive advantages to the supply chain [72]. Additionally, the preparation of redundant resources, such as extra inventory, capacity, and labor can help firms reduce the supply chain disruptions, response costs, and resource waste [73] and thus achieve stable supply chain operations. Early warnings of risk can help enterprises detect market demand fluctuations and potential operational risks in advance and then reduce the possibility of supply chain disruptions by formulating reasonable contingency plans, thus realizing sustainable development.

Second, being responsive means that the supply chain can make appropriate risk management decisions, has a high degree of agility and is able to implement supply chain collaboration [74]. For example, Sun et al. [75] showed that effective risk management decisions can strengthen enterprises’ ability to respond flexibly to supply chain disruptions, which in turn can help them improve their financial performance. Moreover, increased supply chain agility can help enterprises quickly allocate internal resources in unpredictable environments to continuously improve the quality of products and services to better respond to market demand and enhance sustainable performance [61,76]. In addition, Sudusinghe & Seuring [77] asserted that collaboration with supply chain partners can help enterprises strengthen internal controls in the supply chain, thus effectively responding to supply chain disruptions and ensuring sustainable performance improvement.

Finally, rapid recovery means that supply chains are able to flexibly allocate resources, implement contingency plans, and reinforce organizational learning [78,79]. On the one hand, the rapid reconfiguration of existing resources enables enterprises to accelerate the development of high-quality products that meet the needs of society and the environment, opening new paths to sustainable value growth while restoring supply chain operations [80]. On the other hand, the implementation of contingency plans can help enterprises reduce the economic losses caused by supply chain disruptions so that they can quickly resume operations to meet customer demand and improve their economic efficiency [81]. In addition, as important support for supply chain recovery, organizational learning helps enterprises not only learn from supply chain disruptions to improve their operations [82] but also incorporate sustainability concepts into their organizational cultures and practices to achieve sustainable development [83]. Thus, we propose the following:

H4a.

Supply chain readiness positively affects sustainable performance.

H4b.

Supply chain responsiveness positively affects sustainable performance.

H4c.

Supply chain recovery positively affects sustainable performance.

The conceptual model of this study is shown in Figure 1.

Figure 1.

Conceptual model.

3. Research Methods

3.1. Sample Selection and Data Collection

This study focuses on Chinese manufacturing firms, and methodologically, it uses a questionnaire survey to obtain data. Owing to the characteristics of regional economic development in China, Guangdong, Shanghai, Tianjin, and Chongqing were selected as sampling regions [84]. The specific reasons these regions were chosen are as follows: Guangdong, which is located in the Pearl River Delta Economic Zone in southern China, is a global advanced manufacturing base with highly developed emerging manufacturing industries such as electronic information, new energy vehicles and biomedicine; Shanghai, which is located in the Yangtze River Delta Economic Zone on China’s eastern coast, is a global science and innovation center and high-end manufacturing hub, with particular prominence in industries such as integrated circuits, biomedicine, and intelligent equipment; Tianjin, which is located in the Beijing—Tianjin–Hebei urban agglomeration in northern China, is China’s high-end equipment manufacturing base, with significant advantages in high-end manufacturing industries such as aerospace, petrochemicals and heavy machinery; and Chongqing, which is located in the Chengdu—Chongqing urban agglomeration in western China, is a manufacturing hub in China’s inland region with extremely advanced traditional manufacturing industries such as automobiles, cell phones and computer equipment. These four regions cover both the coastal and inland areas of China, reflecting the differences in the regional economic and industrial development of the four major city clusters in China, as well as the status quo of the synergistic development of traditional and emerging industries. Therefore, the four regions can reflect the actual development of China’s manufacturing industry to a certain extent. In addition, because smaller firms may not be able to carry out relatively well-developed supply chain activities, this survey sets the total number of employees of target firms to more than 100 people [85]. Moreover, to ensure that the data can truly reflect the actual situation of the enterprise’s operations, the respondents are limited to top managers, such as the chairperson, general manager and CEO, as well as middle managers, such as department managers, project managers and workshop supervisors.

The questionnaire used in this study was developed through the following steps: First, based on established items from the literature, three graduate students specializing in logistics engineering and management were invited to construct an initial questionnaire using the back-translation method, ensuring the accuracy and consistency of the wording. We then consulted two professors specializing in logistics and supply chain management to confirm the validity, logical consistency, and cultural applicability of the measurement items. Finally, we pilot tested the questionnaire. Ten mid- to senior-level corporate managers were invited to complete a trial questionnaire. Based on their feedback, the measurement items were further revised to ensure that all the questions were unambiguous and easy to understand, ultimately forming the official version of the survey questionnaire.

In total, 414 questionnaires were distributed. Those with completion time anomalies, answer repetition rate anomalies, extreme value anomalies, etc., were excluded, and finally, 226 valid questionnaires were recovered, for an effective response rate of 54.59%. This sample size meets Jackson’s [86] recommendation of no fewer than 200 cases, and the ratio of the sample size to measurement parameters (approximately 9) also satisfies Bentler & Chih-Ping’s [87] recommendation of greater than 5. Therefore, the sample size of this study is sufficient to support structural equation modeling analysis of the existing conceptual model. As shown in Table 1 and Table 2, the sample enterprises are evenly distributed across the four regions, with the electronics and electrical appliance industry and private enterprises accounting for the largest share. More than 70% of the enterprises have more than 500 employees, and approximately 90% of the enterprises have been in business for more than 10 years. Moreover, approximately 90% of the respondents had been employed in middle and senior positions for more than 3 years, which ensures the authenticity and accuracy of the data to a large extent.

Table 1.

Characteristics of the sample companies.

Table 2.

Respondent characteristics.

3.2. Variable Measurement

In this study, the scientific procedure for scale design was strictly followed, and the measurement items for all variables were adapted from the literature. With the exception of the firm’s basic information, all items were measured via a 5-point Likert scale, with 1 indicating “strongly disagree”, 2 indicating “disagree”, 3 indicating “generally”, 4 indicating “agree”, and 5 indicating “strongly agree”. The scale is detailed in the Appendix A.

Digital innovation(DI). In accordance with Ali & Park [88], digital organizational innovation (DOI) and digital product innovation (DPI) were measured via four and five items, respectively, where the respondents were asked to evaluate the use of digital technologies in their organizations to adjust the departmental division of labor or manage day-to-day affairs and to improve existing products or develop new products.

Supply chain resilience(SCR). In accordance with Yu et al. [81], supply chain resilience can be categorized into three dimensions, i.e., supply chain readiness (SCRd), supply chain responsiveness (SCRp), and supply chain recovery (SCRc), which were measured via four items for each dimension. Among them, SCRd focuses on evaluating the performance of enterprises in material preparation and the formulation of contingency plans; SCRp focuses on evaluating the performance of enterprises in making correct decisions and taking appropriate measures in the event of supply chain disruptions; and SCRc focuses on evaluating the performance of enterprises in allocating resources and recovering quickly in the event of supply chain disruptions.

Sustainable performance (SP). In accordance with Gelhard & von Delft [40], SP is measured using five items. The respondents were asked to evaluate the performance of their firms in terms of their responsiveness to sustainability needs and the speed of developing sustainable products.

Control variables. In this study, firm age, firm size, and the region are taken as control variables. On the one hand, firms that have been in operation longer and are larger typically have more redundant resources and are more likely than other firms to have better sustainable performance. On the other hand, firms in different regions may differ in terms of resource allocation efficiency, environmental regulatory intensity, and stakeholder pressure, which in turn affects sustainable performance.

Firm age is treated as a continuous variable, where 1 represents less than 10 years, 2 represents 10–19 years, 3 represents 20–29 years, and 4 represents 30 years or more. Similarly, firm size is set as a continuous variable, where 1 represents 100–299 employees, 2 represents 301–499 employees, 3 represents 500–999 employees, and 4 represents 1000 or more employees. Region measured by three dummy variables (i.e., Tianjin, Guangzhou and Chongqing). Specifically, Tianjin equals 1 if the manufacturing firm is located in Tianjin and 0 otherwise; Guangzhou equals 1 if the manufacturing firm is located in Guangzhou and 0 otherwise; and Chongqing equals 1 if the manufacturing firm is located in Chongqing and 0 otherwise.

3.3. Nonresponse Bias and Common Method Bias

Prior to distributing the questionnaire, this study initially screened target manufacturing firms by referencing sources such as the China Manufacturing Enterprise Directory and the China Manufacturing Yellow Pages. Initial interest was gauged through online channels, including telephone and email, and questionnaires were ultimately distributed to firms that were willing to participate in the survey. To increase the response rate, this study followed Frohlich’s [89] methodology by reminding the respondents to complete the survey via phone calls and emails. According to Armstrong & Overton [90], the earliest 20% and the latest 20% of returned questionnaires were grouped based on response timing. An independent samples t-test was applied to compare the number of employees, annual sales revenue, and other fundamental corporate characteristics between these two groups. The findings show no significant nonresponse bias.

Since all the data used in this study originate from evaluations by middle and top managers, common method bias may be present. Therefore, this study followed the recommendations in Podsakoff et al. [91] to minimize the impact of common method bias through both procedural controls and statistical testing. In terms of procedural control, this study employed appropriate preemptive measures during the questionnaire design and collection phase to mitigate common method bias. In questionnaire design, this study followed a rigorous questionnaire design process, with multiple rounds of refinement and optimization of questionnaire items and wording to ensure that the item statements were easy to understand and unambiguous, thus guaranteeing the project’s accuracy and feasibility. Additionally, prior to this survey, the respondents were assured that the questionnaire would be completed entirely anonymously and that the data collected would be intended solely for academic research purposes and would be kept strictly confidential. The respondents were requested to answer honestly to minimize interference from other factors. In questionnaire distribution, following the approach of Chang et al. [92], this study employed a two-stage questionnaire survey to collect the data. In the first phase, data on sample firm characteristics, respondent characteristics, DOI, DPI, and SP were collected. In the second phase, only supply chain resilience related data were collected to reduce common method bias. In terms of statistical testing, this study employed confirmatory factor analysis (CFA) to examine whether common method bias was present. As shown in Table 3, first, CFA was conducted on the Harman single-factor model, and all fit indices were unacceptable. Second, a six-factor model was constructed, and all fit indices were acceptable, indicating that this model is strongly robust. Finally, a method factor was added to the six-factor model to form a seven-factor model. Although the model fit indices were acceptable, no significant improvement was observed compared with the six-factor model. Therefore, the 6-factor model is the most reasonable, and there is no obvious common method bias in this study.

Table 3.

Fit indices of the measurement model.

3.4. Reliability and Validity

As shown in Table 4, the Cronbach’s alpha (α) coefficients and composite reliability (CR) values of all the variables are greater than 0.8 (0.802~0.857), indicating that the scale has good reliability. First, the questionnaire items were revised by referring to the mature scales in the literature, which can better ensure their content validity. Second, the factor loadings of each variable passed the significance test (p < 0.001), and all loadings exceeded the criterion of acceptability of 0.5 (0.657~0.769). In addition, as shown in Table 4 and Table 5, the average variance extracted (AVE) of each variable exceeded the recommended threshold of 0.5 (0.504~0.546) and was higher than its correlation coefficients with the other variables, indicating that the scale had good convergent and discriminant validity. Finally, the square root of the AVE for each variable was greater than its correlation coefficient with the other variables, indicating that the variables had good discriminant validity. In summary, the measurement model has good reliability and validity.

Table 4.

Results of reliability and validity analysis.

Table 5.

Means, standard deviations and correlation coefficients.

3.5. Hypothesis Testing

The hypotheses were verified by structural equation modeling via AMOS 28.0. The fit indices are χ2/df = 1.909, GFI = 0.818, IFI = 0.872, TLI = 0.857, CFI = 0.870, RMSEA = 0.064, and SRMR = 0.069, indicating that the model is acceptable.

As shown in Figure 2, digital organizational innovation has a facilitating effect on digital product innovation (b = 0.647, p < 0.001), and H1 is supported. Digital organizational innovation has positive effects on supply chain readiness (b = 0.357, p < 0.001), supply chain responsiveness (b = 0.271, p < 0.01), and supply chain recovery (b = 0.450, p < 0.001), thus supporting H2a, H2b, and H2c, respectively. Digital product innovation has the same facilitating effects on supply chain readiness (b = 0.478, p < 0.001), supply chain responsiveness (b = 0.577, p < 0.001), and supply chain recovery (b = 0.463, p < 0.001), supporting H3a, H3b, and H3c, respectively. Supply chain readiness (b = 0.249, p < 0.01), supply chain responsiveness (b = 0.261, p < 0.01), and supply chain recovery (b = 0.364, p < 0.001) significantly enhance sustainable performance, and H4a, H4b, and H4c are supported, respectively. In addition, neither firm size nor region has a significant effect on sustainable performance, while the number of years the firm has been in business has a positive effect on sustainable performance (b = 0.104, p < 0.05).

Figure 2.

Structural equation modeling results. Note: *** indicates p < 0.001, ** indicates p < 0.01, * indicates p < 0.05, and n.s. indicates p > 0.05.

3.6. Indirect Effect Test

The PROCESS plug-in for SPSS 27.0 (bootstrapping = 5000) is used to test the indirect effect of digital innovation on sustainable performance. As shown in Table 6, digital product innovation indirectly improves sustainable performance through supply chain readiness (b = 0.117, [0.047, 0.245]), supply chain responsiveness (b = 0.138, [0.016, 0.311]), and supply chain recovery (b = 0.161, [0.060, 0.287]). Similarly, digital organizational innovation indirectly enhances sustainable performance through supply chain readiness (b = 0.201, [0.080, 0.385]), supply chain responsiveness (b = 0.215, [0.104, 0.343]), and supply chain recovery (b = 0.280, [0.157, 0.425]). In addition, digital organizational innovation can indirectly affect supply chain readiness (b = 0.194, [0.057, 0.368]), supply chain responsiveness (b = 0.234, [0.095, 0.440]), and supply chain recovery (b = 0.189, [0.072, 0.343]) through digital product innovation.

Table 6.

Results of the indirect effect test.

4. Discussion

4.1. Theoretical Contributions

First, we find that digital innovation helps build supply chain resilience. Existing studies have focused mainly on the effects of a specific digital technology [25,93] or the digital technology-related patents [48], which lacks an in-depth analysis of the individual effects of different digital innovations. Thus, revealing the complex relationship between digital innovation and supply chain resilience is difficult. This study divides digital innovation into digital organizational innovation and digital product innovation, follows the dynamic relationship from the “process” to the “result” of digital innovation [94], and constructs the “digital organizational innovation–digital product innovation” mechanism, which effectively responds to the call for research on explaining the process path of digital innovation and identifying the key links [95], thus deepening understandings of the impacts of digital innovation. As the two key aspects of digital innovation, digital organizational innovation is an important prerequisite and foundation for the implementation of digital product innovation, and the two are important motivators for improving supply chain resilience, which further clarifies the positive effects of digital innovation on supply chain readiness, supply chain responsiveness, and supply chain recovery. The conclusions of this study further support and expand upon Wang et al.’s [96] view that digital innovation promotes supply chain resilience. In addition, digital organizational innovation contributes most prominently to supply chain recovery, whereas digital product innovation contributes most significantly to supply chain responsiveness. The reason for this finding might be that digital organizational innovation involves the adjustment of the internal organizational structure and the optimization of governance models within enterprises, enabling them to quickly reorganize resources and adjust processes after experiencing disruptions, thus significantly enhancing the efficiency of supply chain recovery. Digital product innovation usually involves adding new attributes and functions to products through digital technologies, with a greater focus on market-oriented and explicit product functions. This finding helps enterprises capture user demands and market signals more quickly and make targeted adjustments, thus responding rapidly to constantly changing market demands, which directly enhances the supply chain’s response. In summary, this study enriches the research on the antecedents of supply chain resilience while expanding the understanding of digital innovation outcomes.

Second, we find that supply chain resilience enhances sustainable performance. Most existing studies have viewed supply chain resilience as a single-dimensional capability [35,97,98], neglecting its essential characteristics as a combination of multiple capabilities. Moreover, some scholars have argued that supply chain resilience, with its emphasis on “redundancy”, and sustainable development, with its emphasis on “savings”, may be partially at odds with each other [99]. This research explores the multidimensional connotation of supply chain resilience in the context of the stage-by-stage characterization of firms’ response to supply chain disruptions, and it explores whether and how supply chain resilience is a key enabler of sustainable performance before (supply chain readiness), during (supply chain responsiveness), and after (supply chain restoration) disruptive events. The results are consistent with those of Ben et al. [97], Junaid et al. [98], and Li [35], further verifying the promoting effect of supply chain resilience on sustainable performance. More importantly, unlike the aforementioned research, which regards supply chain resilience as an overall capability, this study reveals its differentiated impacts along different dimensions. The results show that supply chain recovery contributes most significantly to sustainable performance, followed by supply chain responsiveness, whereas supply chain readiness has a weaker effect. The reason for this finding is that supply chain recovery is directly related to the speed and efficiency of restoring normal operations after a disruption, which directly determines whether the enterprise can realize sustainable development; thus, the promoting role is most prominent. Supply chain responsiveness emphasizes rapid response, which can mitigate shocks from risk to some extent, but has a slightly weaker effect on sustainable performance than recovery does. Conversely, supply chain readiness aims to prevent risks in advance, and its effects are often difficult to show directly before the realization of risks and have limited short-term impacts on sustainable performance; thus, its role is relatively small.

Third, we find that supply chain resilience is an important mediator through which digital innovation affects sustainable performance. While studies have recognized the potentially positive impact that digital innovation on sustainable performance, the studies mainly focus on the direct impact of digital innovation on sustainable performance, and the pathways between the two urgently need to be deconstructed [100]. There is limited empirical evidence on how digital innovation affects sustainable performance. To that end, this study employs the “behavior—capability—outcome” research paradigm to thoroughly examine the mediating role of supply chain resilience in the relationship between digital innovation and sustainable performance. In doing so, it expands upon the research of Zhang et al. [101], who focused solely on the direct impact of digital innovation on sustainable performance.

Furthermore, unlike the study of Tariq et al. [8], who focused on the IT industry, this research focuses on the manufacturing sector. It reveals that the positive impact of digital innovation on sustainable performance is equally present in manufacturing, thus broadening the applicability of the findings and deepening our understanding of the relationship between digital innovation and sustainable performance. Meanwhile, studies by Ben et al. [97] on small and medium-sized service enterprises in the UK and France and Junaid et al. [98] on Pakistani healthcare enterprises indicate that supply chain resilience promotes sustainable performance in different contexts. In this study, Chinese manufacturing enterprises are used as a sample, and supply chain resilience is subdivided into three capabilities: readiness, responsiveness, and recovery. It verifies the multidimensional contribution of supply chain resilience to sustainable performance. Doing so not only broadens the applicability of the aforementioned conclusions across different national and industry contexts but also deepens our understanding of how supply chain resilience enhances sustainable performance.

4.2. Managerial Implications

First, digital technologies for digital innovation activities should be actively embraced. (1) Digital innovation should be promoted in enterprises. Enterprises can achieve digital organizational innovation in a variety of ways. For instance, by learning from the practices of enterprises such as Huawei and Xiaomi, digital technology should be incorporated into the employee behavior and quality assessment system, and a corresponding reward mechanism should be established to encourage employees’ enthusiasm for learning emerging digital technologies and their initiative in exploring applications, thus enhancing their digital literacy. Moreover, drawing on Haier’s experience, a cross-departmental collaboration platform should be established to enable information sharing and to stimulate digital innovation thinking among employees. At the same time, by fostering a culture that encourages innovation and embraces change, enterprises can leverage internal communication platforms to regularly organize activities such as sharing best practices and discussing cutting-edge topics. This will empower employees to confidently experiment with digital tools and methodologies while actively pursuing innovative initiatives. (2) Digital technology should be utilized to drive product innovation. On the one hand, enterprises should pay attention to market trends in a timely manner and rationally deploy human, material and financial resources to develop smart products that integrate digital technologies such as the IoT and artificial intelligence. On the other hand, enterprises should use digital technologies such as digital twins to simulate and optimize their production process to improve productivity and product quality. Additionally, enterprises can draw on the practical experience of enterprises such as Gree and Anta to actively leverage big data analytics for customer purchasing behavior and market trends. By deeply mining data value and accurately forecasting market demand, they can achieve data-driven organizational innovation and product optimization. (3) Digital innovation should be leveraged to improve supply chain resilience. Enterprises should integrate digital innovations into their operational strategies, adopt data-driven decision-making mechanisms, and use digital technologies such as artificial intelligence and big data analytics to optimize operations and demand forecasting, thus reducing the risk of supply chain disruptions. In addition, they can utilize digital platforms to promote collaboration with supply chain partners and enhance supply chain synergy while dynamically adjusting operational plans through information sharing and real-time data analysis to respond to and quickly recover from supply chain disruptions in a timely manner.

Second, supply chain resilience should be built through multiple channels to achieve sustainable development. Such resilience should be guaranteed in many ways. (1) Drawing on the digital transformation experience of manufacturing enterprises such as Gree, enterprises should leverage technologies such as cloud computing, the IoT, and big data to identify vulnerabilities in supply chain management and eliminate potential risks. At the same time, supply chain risk early warning systems should be established to detect possible disruptions in advance, providing companies with time to prepare. (2) Multilevel response capabilities should be developed. For example, the adoption of the diversified supplier management strategy employed by BYD and Toyota can ensure that enterprises are able to swiftly identify alternative suppliers during supply chain disruptions, enabling timely responses to such disruptions and shortening production recovery cycles. In addition, enterprises can work closely with suppliers, customers, and other supply chain members to share demand and inventory information, thereby achieving efficient resource allocation and rapid response. (3) Diversified recovery measures should be implemented. On the one hand, such implementation strengthens the comprehensive quality of employees and improves their execution and cohesion while encouraging them to continuously try new technologies and modes to help operational responses. On the other hand, such implementation simplifies supply chain management and optimizes the supply chain layout. Moreover, digital tools should be adopted to achieve resource integration and information sharing, and management efficiency should be improved.

4.3. Limitations and Future Research Directions

There are some limitations in this paper, which provide directions for future research. First, all the samples in this study are limited to Chinese manufacturing firms, which can be further expanded to other countries or industries in the future to increase the generalizability of the findings. Moreover, the data used in this study are cross-sectional data obtained through a questionnaire survey. A longitudinal study can be attempted in the future by combining secondary data with panel data to explore the dynamic causal relationships among digital innovation, supply chain resilience and sustainable performance. Second, the path through which digital innovation affects sustainable performance is not unique; this study verifies only the mediating mechanism of supply chain resilience, and in the future, the role of variables such as lean production, agile response, and green practices could be further explored from the perspectives of the resource-based view and institutional theory to enrich the intrinsic mechanism through which digital innovation affects sustainable performance. Third, the impact of digital innovation on supply chain resilience and sustainable performance may be affected by contextual factors, and contextual factors such as the level of regional digitization, digital readiness, and government regulation can be further incorporated in the future to more comprehensively examine the boundary conditions under which digital innovation affects supply chain resilience and sustainable performance.

Author Contributions

Conceptualization, Y.L. (Yuhan Liu) and Y.Y.; methodology, Y.L. (Yuhan Liu), Y.Y. and M.Z.; validation, Y.Y., M.Z. and Y.W.; formal analysis, Y.L. (Yuhan Liu); investigation, Y.L. (Yuhan Liu); resources, Y.Y. and Y.L. (Yanqiu Liu); data curation, Y.L. (Yuhan Liu); writing—original draft preparation, Y.L. (Yuhan Liu); writing—review and editing, Y.Y., M.Z. and Y.W.; supervision, Y.Y., M.Z. and Y.W.; project administration, Y.Y. and Y.L. (Yanqiu Liu); and funding acquisition, Y.Y. and Y.L. (Yanqiu Liu). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the General Project of National Social Science Fund of China (#24BGL241), Major Humanities and Social Sciences Research Projects in Zhejiang Higher Education Institutions (#2023GH072), Inner Mongolia Natural Science Foundation (#2023LHMS07004; #2024QN07018), and Key Research Institute of Humanities and Social Sciences at Universities of Inner Mongolia Autonomous Region - Open Project of Inner Mongolia Modern Logistics and Supply Chain Management Research Center (#KFSM-GDSK0203).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to express their gratitude for the support from the Key Research Center of Philosophy and Social Sciences in Zhejiang Province—Research Center for Modern Port Service Industry and Creative Culture, as well as the New Key Specialized Think Tank of Ningbo Municipality—Ningbo Digital-Intelligence Supply Chain Innovation Research Institute.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| DOI | Digital organizational innovation |

| DPI | Digital product innovation |

| SCRd | Supply chain readiness |

| SCRp | Supply chain responsiveness |

| SCRc | Supply chain recover |

| SP | Sustainable performance |

Appendix A

Table A1.

Measurements and sources.

Table A1.

Measurements and sources.

| Variable | Item | Source |

|---|---|---|

| Digital Organizational Innovation | DOI1 Our company adjusts the division of departmental functions according to the needs of digital technology application. | [88] |

| DOI2 Our company’s department heads utilize digital means to manage daily operations. | ||

| DOI3 Our company incorporates digital skills as one of the assessment criteria when recruiting new employees. | ||

| DOI4 Our company employs digital systems for performance management and assessment. | ||

| Digital Product Innovation | DPI1 Our company’s new products developed through digital technologies have generated substantial profits. | [88] |

| DPI2 Compared to competitors, our company leverages digital technologies to achieve faster new product launches. | ||

| DPI3 Compared to competitors, our company has a stronger capability in leveraging digital technologies for new product development. | ||

| DPI4 Our company employs digital technologies to implement enhancements and upgrades to existing products. | ||

| DPI5 Our company leverages digital technologies to shorten the time to market for new products. | ||

| Supply Chain Readiness | SCRd1 Our company has redundant resources in place prior to potential disruptions. | [70,79] |

| SCRd2 Our company can identify potential risks or unexpected events in advance. | ||

| SCRd3 Our company is able to recognize supply chain disruptions quickly | ||

| SCRd4 Our company is able to provide an early warning of supply chain disruptions. | ||

| Supply Chain Responsiveness | SCRp1 Our company is able to make the appropriate risk management decisions at the time of disruptions. | [70,79,81] |

| SCRp2 Our company is able to provide a quick response to supply chain disruptions. | ||

| SCRp3 Our company can undertake adequate responses to a crisis. | ||

| SCRp4 Our company’s supply chain can sustain its essential structure and function at the time of disruptions. | ||

| Supply Chain Recovery | SCRc1 Our company’s supply chain is able to quickly resume normal operations after disruptions. | [70,79] |

| SCRc2 Our company’s supply chain is able to recover quickly after disruptions by reconfiguring resources. | ||

| SCRc3 Our company can quickly deploy a crisis response team to restore supply chain operations. | ||

| SCRc4 Our company is able to recover quickly from supply chain disruptions. | ||

| Sustainable Performance | SP1 Our company was the first to offer environmentally friendly products/services in the market. | [40] |

| SP2 Our company develops new products and services that contribute to social and environmental sustainability. | ||

| SP3 Our company improves existing products and services to meet social and environmental sustainability requirements. | ||

| SP4 Our company’s reputation in terms of sustainability is superior to that of our competitors. | ||

| SP5 Compared to our competitors, our company has better responded to societal and ethical demands. |

References

- Xu, M.; Tse, Y.K.; Geng, R.; Liu, Z.; Potter, A. Greenwashing and market value of firms: An empirical study. Int. J. Prod. Econ. 2025, 284, 109606. [Google Scholar] [CrossRef]

- Santos, A.D.M.; Sant Anna, Â.M.O. Industry 4.0 technologies for sustainability within small and medium enterprises: A systematic literature review and future directions. J. Clean. Prod. 2024, 467, 143023. [Google Scholar] [CrossRef]

- Ahmadi-Gh, Z.; Bello-Pintado, A. Towards sustainable manufacturing: How does digitalization and development affect sustainability barriers? J. Clean. Prod. 2024, 476, 143792. [Google Scholar] [CrossRef]

- Gebauer, H.; Fleisch, E.; Lamprecht, C.; Wortmann, F. Growth paths for overcoming the digitalization paradox. Bus. Horiz. 2020, 63, 313–323. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Q.; Xiong, N.; Liu, C. Digital transformation and environmentally sustainable innovation: Based on machine learning and text analysis methods. J. Environ. Manag. 2025, 393, 127090. [Google Scholar] [CrossRef] [PubMed]

- Li, L. Digital transformation and sustainable performance: The moderating role of market turbulence. Ind. Mark. Manag. 2022, 104, 28–37. [Google Scholar] [CrossRef]

- Fichman, R.G.; Dos Santos, B.L.; Zheng, Z. Digital innovation as a fundamental and powerful concept in the information systems curriculum. Mis Q. 2014, 38, 315–329. [Google Scholar] [CrossRef]

- Tariq, A.; Sumbal, M.S.U.K.; Dabic, M.; Raziq, M.M.; Torkkeli, M. Interlinking networking capabilities, knowledge worker productivity, and digital innovation: A critical nexus for sustainable performance in small and medium enterprises. J. Knowl. Manag. 2024, 28, 179–198. [Google Scholar] [CrossRef]

- Ozdemir, D.; Sharma, M.; Dhir, A.; Daim, T. Supply chain resilience during the COVID-19 pandemic. Technol. Soc. 2022, 68, 101847. [Google Scholar] [CrossRef]

- Ding, Y.; Li, J.; Song, Y.; Sahut, J. How does the cross-border M&A network affect digital innovation? Empirical evidence from Chinese listed companies. Res. Int. Bus. Financ. 2024, 70, 102382. [Google Scholar]

- Yoo, Y.; Henfridsson, O.; Lyytinen, K. Research Commentary-The New Organizing Logic of Digital Innovation: An Agenda for Information Systems Research. Inf. Syst. Res. 2010, 21, 724–735. [Google Scholar] [CrossRef]

- Nambisan, S. Digital Entrepreneurship: Toward a Digital Technology Perspective of Entrepreneurship. Entrep. Theory Pract. 2017, 41, 1029–1055. [Google Scholar] [CrossRef]

- Fang, X.; Liu, M. How does the digital transformation drive digital technology innovation of enterprises? Evidence from enterprise’s digital patents. Technol. Forecast. Soc. Chang. 2024, 204, 123428. [Google Scholar] [CrossRef]

- Uršič, D.; čater, T. Digital innovation in management and business: A comprehensive review, multi-level framework, and future research agenda. J. Bus. Res. 2025, 197, 115475. [Google Scholar] [CrossRef]

- Abrell, T.; Pihlajamaa, M.; Kanto, L.; Vom Brocke, J.; Uebernickel, F. The role of users and customers in digital innovation: Insights from B2B manufacturing firms. Inf. Manag. 2016, 53, 324–335. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, P. Substantive digital innovation or symbolic digital innovation: Which type of digital innovation is more conducive to corporate ESG performance? Int. Rev. Econ. Financ. 2024, 93, 1212–1228. [Google Scholar] [CrossRef]

- Xie, Y.; Wu, D. How does competition policy affect enterprise digitization? Dual perspectives of digital commitment and digital innovation. J. Bus. Res. 2024, 178, 114651. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Gölgeci, I.; Kuivalainen, O. Does social capital matter for supply chain resilience? The role of absorptive capacity and marketing-supply chain management alignment. Ind. Mark. Manag. 2020, 84, 63–74. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Fosso Wamba, S.; Chiappetta Jabbour, C.J.; Machado, M.C. Supply chain resilience in the UK during the coronavirus pandemic: A resource orchestration perspective. Int. J. Prod. Econ. 2022, 245, 108405. [Google Scholar] [CrossRef]

- Nikookar, E.; Yanadori, Y. Preparing supply chain for the next disruption beyond COVID-19: Managerial antecedents of supply chain resilience. Int. J. Oper. Prod. Manag. 2022, 42, 59–90. [Google Scholar] [CrossRef]

- Dey, P.K.; Chowdhury, S.; Abadie, A.; Vann Yaroson, E.; Sarkar, S. Artificial intelligence-driven supply chain resilience in Vietnamese manufacturing small- and medium-sized enterprises. Int. J. Prod. Res. 2024, 62, 5417–5456. [Google Scholar] [CrossRef]

- Lee, V.H.; Foo, P.; Cham, T.; Hew, T.; Tan, G.W.; Ooi, K. Big data analytics capability in building supply chain resilience: The moderating effect of innovation-focused complementary assets. Ind. Manag. Data. Systems. 2024, 124, 1203–1233. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, W.; Feng, T.; Xi, M. Blockchain technology adoption and supply chain resilience: Exploring the role of transformational supply chain leadership. Supply Chain Manag. 2024, 29, 371–387. [Google Scholar] [CrossRef]

- Alvarenga, M.Z.; de Oliveira, M.P.V.; Oliveira, T. Let’s talk about bad experiences instead of forgetting them: An empirical study on the importance of memory for supply chain disruption management. Int. J. Prod. Econ. 2023, 261, 108872. [Google Scholar] [CrossRef]

- Qader, G.; Junaid, M.; Abbas, Q.; Mubarik, M.S. Industry 4.0 enables supply chain resilience and supply chain performance. Technol. Forecast. Soc. Chang. 2022, 185, 122026. [Google Scholar] [CrossRef]

- Parast, M.M. Toward a contingency perspective of organizational and supply chain resilience. Int. J. Prod. Econ. 2022, 250, 108667. [Google Scholar] [CrossRef]

- Hussain, G.; Nazir, M.S.; Rashid, M.A.; Sattar, M.A. From supply chain resilience to supply chain disruption orientation: The moderating role of supply chain complexity. J. Enterp. Inf. Manag. 2023, 36, 70–90. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M. Supply chain resilience: Conceptualization and scale development using dynamic capability theory. Int. J. Prod. Econ. 2017, 188, 185–204. [Google Scholar] [CrossRef]

- Elkington, J. Accounting for the Triple Bottom Line. Meas. Bus. Excell. 1998, 2, 18–22. [Google Scholar] [CrossRef]

- Javed, H.; Du, J.; Farooq Islam, M. Unpacking organizational capabilities and green Innovation for sustainable Performance: The role of environmental regulations in manufacturing industry. J. Clean. Prod. 2025, 507, 145453. [Google Scholar] [CrossRef]

- Sharma, M.; Kumar, A.; Luthra, S.; Joshi, S.; Upadhyay, A. The impact of environmental dynamism on low-carbon practices and digital supply chain networks to enhance sustainable performance: An empirical analysis. Bus. Strateg. Environ. 2022, 31, 1776–1788. [Google Scholar] [CrossRef]

- Billah, M.M.; Alam, S.S.; Masukujjaman, M.; Ali, M.H.; Makhbul, Z.K.M.; Salleh, M.F.M. Effects of Internet of Things, supply chain collaboration and ethical sensitivity on sustainable performance: Moderating effect of supply chain dynamism. J. Enterp. Inf. Manag. 2023, 36, 1270–1295. [Google Scholar] [CrossRef]

- Li, K.; Bashiri, M.; Lim, M.K.; Akpobi, T. How to improve supply chain sustainable performance by resilience practices through dynamic capability view: Evidence from Chinese construction. Resour. Conserv. Recy. 2025, 212, 107965. [Google Scholar] [CrossRef]

- Lin, J.; Fan, Y. Seeking sustainable performance through organizational resilience: Examining the role of supply chain integration and digital technology usage. Technol. Forecast. Soc. Chang. 2024, 198, 123026. [Google Scholar] [CrossRef]

- Khan, A.N. Artificial intelligence and sustainable performance: Role of organisational agility and environmental dynamism. Technol. Anal. Strateg. Manag. 2025, 37, 568–583. [Google Scholar] [CrossRef]

- Li, L.; Hou, Y.; Chen, L.; Liu, Y.; Trindade, M.A.M. Unlocking sustainable performance with blockchain technology: Insights from organizational learning theory. Int. J. Prod. Econ. 2025, 283, 109555. [Google Scholar] [CrossRef]

- Ertz, M.; Latrous, I.; Dakhlaoui, A.; Sun, S. The impact of Big Data Analytics on firm sustainable performance. Corp. Soc. Responsib. Environ. Manag. 2025, 32, 1261–1278. [Google Scholar] [CrossRef]

- Gelhard, C.; von Delft, S. The role of organizational capabilities in achieving superior sustainability performance. J. Bus. Res. 2016, 69, 4632–4642. [Google Scholar] [CrossRef]

- Lee, S.; Jung, S. Does organizational innovation facilitate product innovation? Evidence from Korean Manufacturing Firms. Eurasian Bus. Rev. 2024, 14, 551–585. [Google Scholar] [CrossRef]

- Melanie Pfaff, Y.; Judith Wohlleber, A.; Münch, C.; Küffner, C.; Hartmann, E. How digital transformation impacts organizational culture—A multi-hierarchical perspective on the manufacturing sector. Comput. Ind. Eng. 2023, 183, 109432. [Google Scholar] [CrossRef]

- Guy, J. Digital technology, digital culture and the metric/nonmetric distinction. Technol. Forecast. Soc. Chang. 2019, 145, 55–61. [Google Scholar] [CrossRef]

- Martínez-Caro, E.; Cegarra-Navarro, J.G.; Alfonso-Ruiz, F.J. Digital technologies and firm performance: The role of digital organisational culture. Technol. Forecast. Soc. Chang. 2020, 154, 119962. [Google Scholar] [CrossRef]

- Gao, L.; Huang, R. Digital transformation and green total factor productivity in the semiconductor industry: The role of supply chain integration and economic policy uncertainty. Int. J. Prod. Econ. 2024, 274, 109313. [Google Scholar] [CrossRef]

- Alyasein, O.I.Y.; Ojha, D.; Sadeghi, K. Supply chain digitalization, innovation capability, and organizational agility: The moderating role of institutionalization and supply chain integration. Ind. Mark. Manag. 2025, 125, 215–225. [Google Scholar] [CrossRef]

- Nasiri, M.; Ukko, J.; Saunila, M.; Rantala, T. Managing the digital supply chain: The role of smart technologies. Technovation 2020, 96–97, 102121. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, J.; Mei, L.; Shen, R. Digital innovation and performance of manufacturing firms: An affordance perspective. Technovation 2023, 119, 102458. [Google Scholar] [CrossRef]

- Schmidt, C.G.; Wagner, S.M. Blockchain and supply chain relations: A transaction cost theory perspective. J. Purch. Supply Manag. 2019, 25, 100552. [Google Scholar] [CrossRef]

- Feng, X.; Yu, R. How does digital transformation affect corporate risk-taking? Evidence from China. Int. Rev. Econ. Financ. 2025, 97, 103614. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Wamba, S.F.; Childe, S.J.; Hazen, B.; Akter, S. Big data and predictive analytics for supply chain and organizational performance. J. Bus. Res. 2017, 70, 308–317. [Google Scholar] [CrossRef]

- Han, H.; Trimi, S. Towards a data science platform for improving SME collaboration through Industry 4.0 technologies. Technol. Forecast. Soc. Chang. 2022, 174, 121242. [Google Scholar] [CrossRef]

- Cheng, C.; Wang, L.; Xie, H.; Yan, L. Mapping digital innovation: A bibliometric analysis and systematic literature review. Technol. Forecast. Soc. Chang. 2023, 194, 122706. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain Manag. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Habibi, F.; Chakrabortty, R.K.; Abbasi, A. Evaluating supply chain network resilience considering disruption propagation. Comput. Ind. Eng. 2023, 183, 109531. [Google Scholar] [CrossRef]

- Rice, J.B.; Caniato, F. Building a Secure and Resilient Supply Chain. Supply Chain Manag. Rev. 2003, 5, 22–30. [Google Scholar]

- Li, L.; Tong, Y.; Wei, L.; Yang, S. Digital technology-enabled dynamic capabilities and their impacts on firm performance: Evidence from the COVID-19 pandemic. Inf. Manag. 2022, 59, 103689. [Google Scholar] [CrossRef]

- Bilbao-Ubillos, J.; Camino-Beldarrain, V.; Intxaurburu-Clemente, G.; Velasco-Balmaseda, E. Industry 4.0, servitization, and reshoring: A systematic literature review. Eur. Res. Manag. Bus. Econ. 2024, 30, 100234. [Google Scholar] [CrossRef]

- Boeker, W.; Howard, M.D.; Basu, S.; Sahaym, A. Interpersonal relationships, digital technologies, and innovation in entrepreneurial ventures. J. Bus. Res. 2021, 125, 495–507. [Google Scholar] [CrossRef]

- Lu, Q.; Zhou, Y.; Luan, Z.; Song, H. The effect of SMEs’ ambidextrous innovations on supply chain financing performance: Balancing effect and moderating effect. Int. J. Oper. Prod. Manag. 2024, 44, 424–461. [Google Scholar] [CrossRef]

- Dong, Y.; Xia, Y.; Qi, X. Technology yields spoils: The impact of digitalization on innovation value appropriation. Technol. Forecast. Soc. Chang. 2025, 213, 124012. [Google Scholar] [CrossRef]

- Brady, T.; Davies, A.; Gann, D.M. Creating value by delivering integrated solutions. Int. J. Proj. Manag. 2005, 23, 360–365. [Google Scholar] [CrossRef]

- Jiang, W.; Wang, X. Enterprise digital transformation empowers supply Chain stability. Financ. Res. Lett. 2024, 66, 105693. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar] [CrossRef]

- Meng, T.; Li, Q.; He, C.; Dong, Z. Research on the configuration path of manufacturing enterprises’ digital servitization transformation. Int. Rev. Econ. Financ. 2025, 98, 103952. [Google Scholar] [CrossRef]

- Bhandal, R.; Meriton, R.; Kavanagh, R.E.; Brown, A. The application of digital twin technology in operations and supply chain management: A bibliometric review. Supply Chain Manag. 2022, 27, 182–206. [Google Scholar] [CrossRef]

- Birkel, H.S.; Hartmann, E. Internet of Things—The future of managing supply chain risks. Supply Chain Manag. 2020, 25, 535–548. [Google Scholar] [CrossRef]

- Birkel, H.; Hohenstein, N.; Hähner, S. How have digital technologies facilitated supply chain resilience in the COVID-19 pandemic? An exploratory case study. Comput. Ind. Eng. 2023, 183, 109538. [Google Scholar] [CrossRef]

- Papanagnou, C.; Seiler, A.; Spanaki, K.; Papadopoulos, T.; Bourlakis, M. Data-driven digital transformation for emergency situations: The case of the UK retail sector. Int. J. Prod. Econ. 2022, 250, 108628. [Google Scholar] [CrossRef]

- Gruchmann, T.; Stadtfeld, G.M.; Thürer, M.; Ivanov, D. Supply chain resilience as a system quality: Survey-based evidence from multiple industries. Int. J. Phys. Distrib. Logist. Manag. 2024, 54, 92–117. [Google Scholar] [CrossRef]

- Sadeghi, K.; Azadegan, A.; Ojha, D. A path to build supply chain cyber-resilience through absorptive capacity and visibility: Two empirical studies. Ind. Mark. Manag. 2023, 111, 202–215. [Google Scholar] [CrossRef]

- Qi, R.; Ma, G.; Liu, C.; Zhang, Q.; Wang, Q. Enterprise digital transformation and supply chain resilience. Financ. Res. Lett. 2024, 66, 105564. [Google Scholar] [CrossRef]

- El Baz, J.; Ruel, S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef]

- Wu, Q.; Zhu, J.; Cheng, Y. The effect of cross-organizational governance on supply chain resilience: A mediating and moderating model. J. Purch. Supply Manag. 2023, 29, 100817. [Google Scholar] [CrossRef]

- Sun, K.; Ooi, K.; Wei-Han Tan, G.; Lee, V. Small and medium-sized enterprises’ path to sustainable supply chains: Exploring the role of supply chain finance and risk management. Supply Chain Manag. 2024, 30, 1–18. [Google Scholar] [CrossRef]

- Roh, J.; Hong, P.; Min, H. Implementation of a responsive supply chain strategy in global complexity: The case of manufacturing firms. Int. J. Prod. Econ. 2014, 147, 198–210. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. Int. J. Prod. Econ. 2022, 245, 108402. [Google Scholar] [CrossRef]

- Tummala, R.; Schoenherr, T. Assessing and managing risks using the Supply Chain Risk Management Process (SCRMP). Supply Chain Manag. 2011, 16, 474–483. [Google Scholar] [CrossRef]

- Zhao, N.; Hong, J.; Lau, K.H. Impact of supply chain digitalization on supply chain resilience and performance: A multi-mediation model. Int. J. Prod. Econ. 2023, 259, 108817. [Google Scholar] [CrossRef]

- Li, G.; Xue, J.; Li, N.; Ivanov, D. Blockchain-supported business model design, supply chain resilience, and firm performance. Transp. Res. Part E Logist. Transp. Rev. 2022, 163, 102773. [Google Scholar] [CrossRef]

- Yu, W.; Jacobs, M.A.; Chavez, R.; Yang, J. Dynamism, disruption orientation, and resilience in the supply chain and the impacts on financial performance: A dynamic capabilities perspective. Int. J. Prod. Econ. 2019, 218, 352–362. [Google Scholar] [CrossRef]

- Do, H.; Budhwar, P.; Shipton, H.; Nguyen, H.; Nguyen, B. Building organizational resilience, innovation through resource-based management initiatives, organizational learning and environmental dynamism. J. Bus. Res. 2022, 141, 808–821. [Google Scholar] [CrossRef]