Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites

Abstract

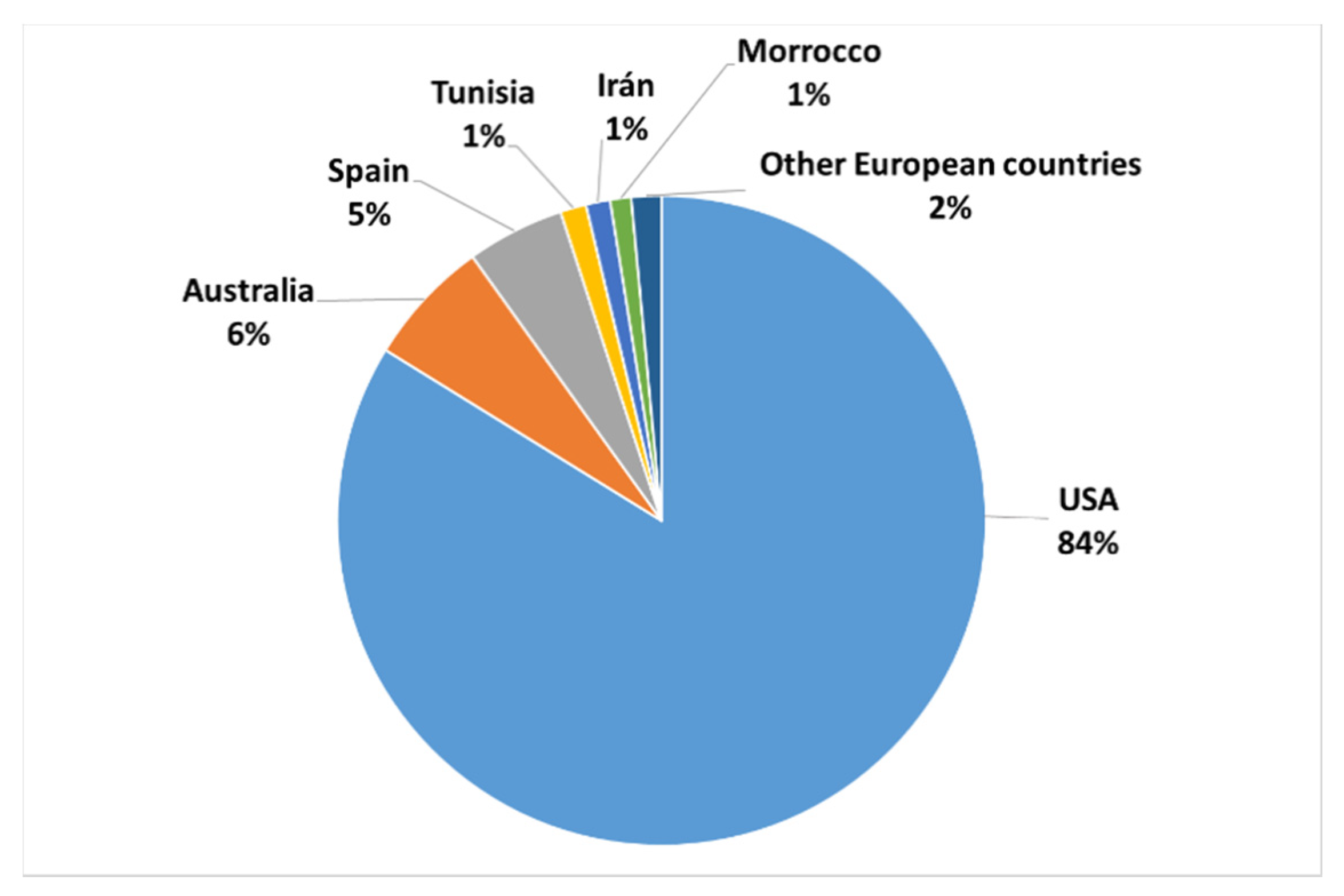

1. Introduction

2. Materials and Methods

2.1. Materials

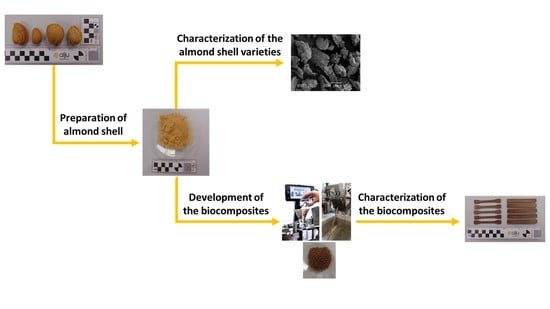

2.2. Experimental Procedure

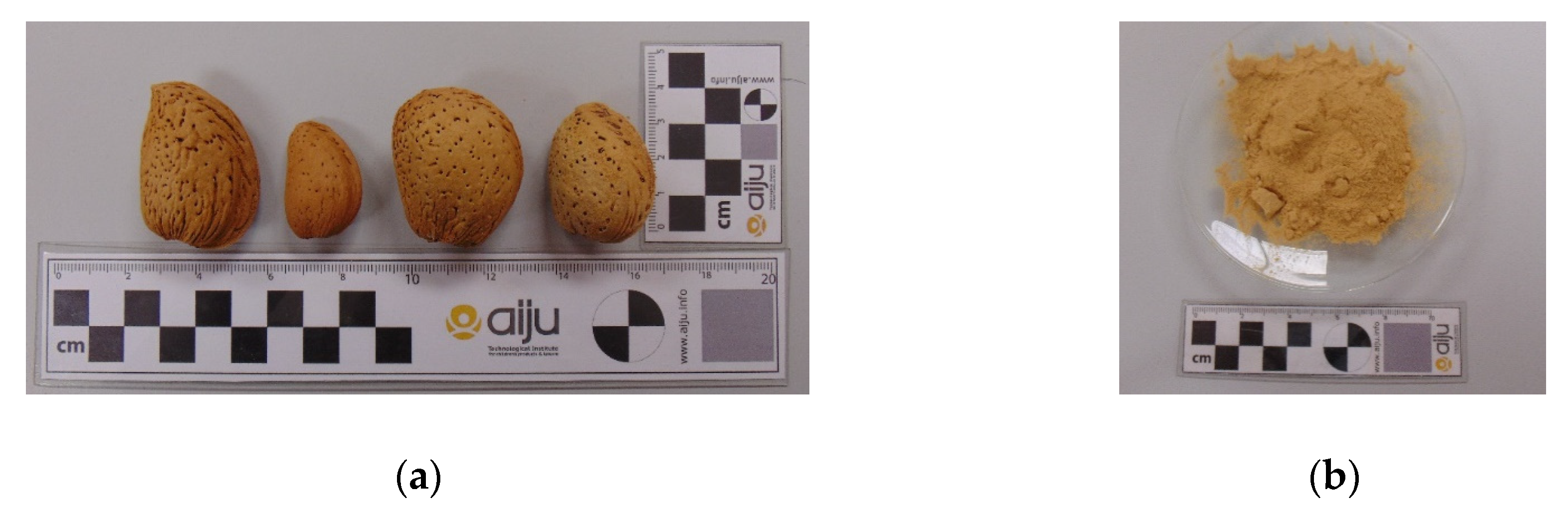

2.2.1. Milling of Almond Shell

2.2.2. Infrared Spectroscopy (FTIR)

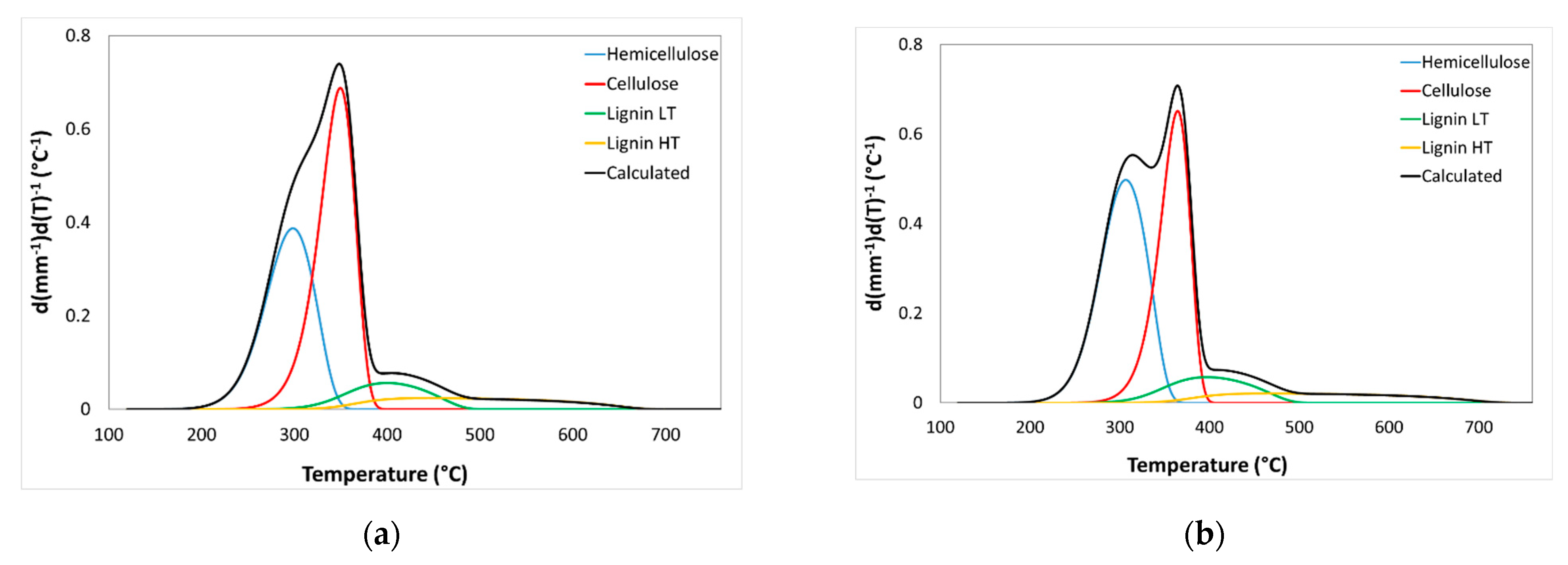

2.2.3. Thermogravimetric Analysis (TGA)

2.2.4. Differential Scanning Calorimetry

2.2.5. X-ray Diffraction

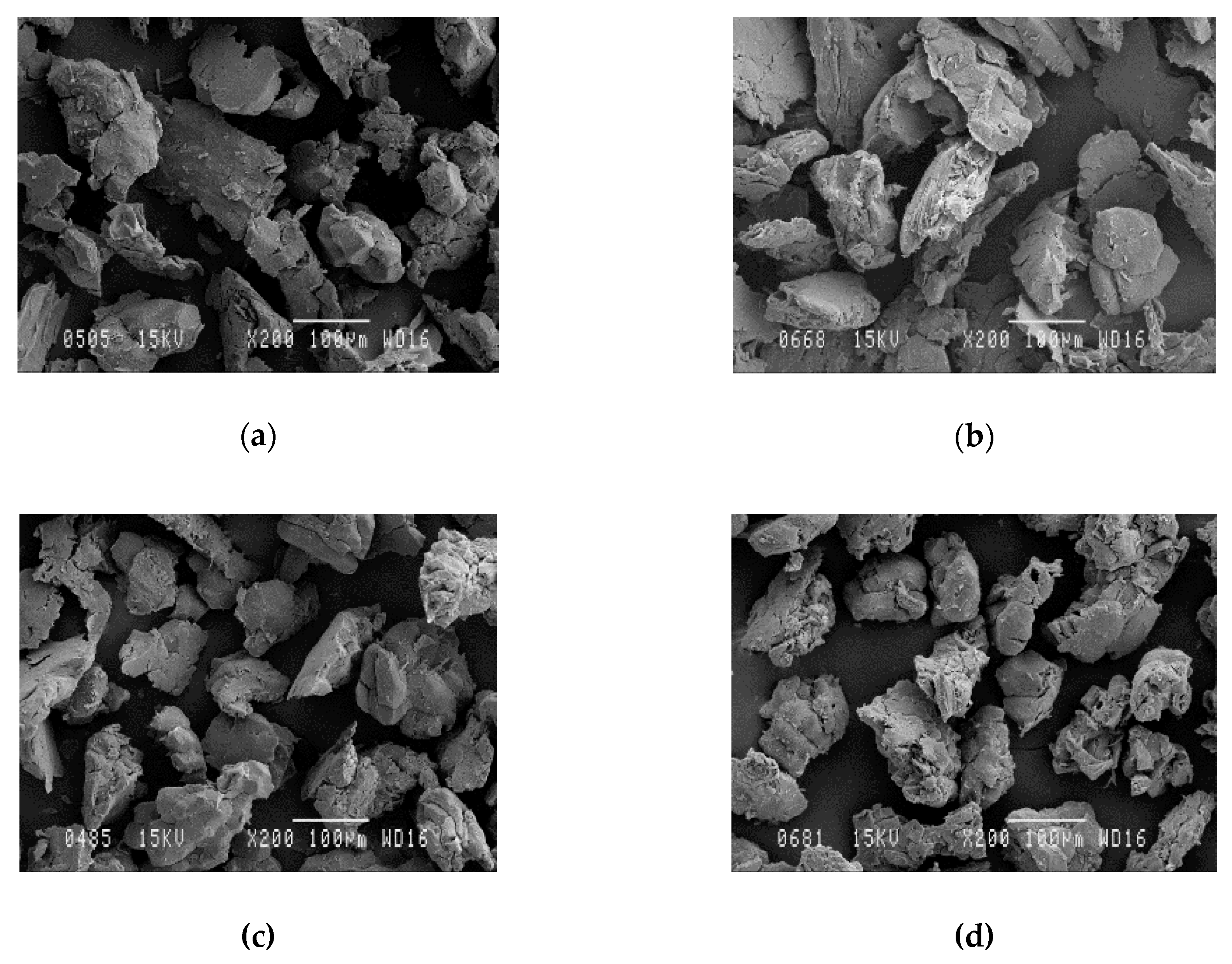

2.2.6. Scanning Electron Microscopy (SEM)

2.2.7. Preparation of Composites

2.2.8. Injection Moulding

2.2.9. Tensile Strength and Modulus

2.2.10. Impact Strength

2.2.11. Flexural

2.2.12. Shore D Hardness

3. Results and Discussion

3.1. Characterisation of Almond Shell Varieties

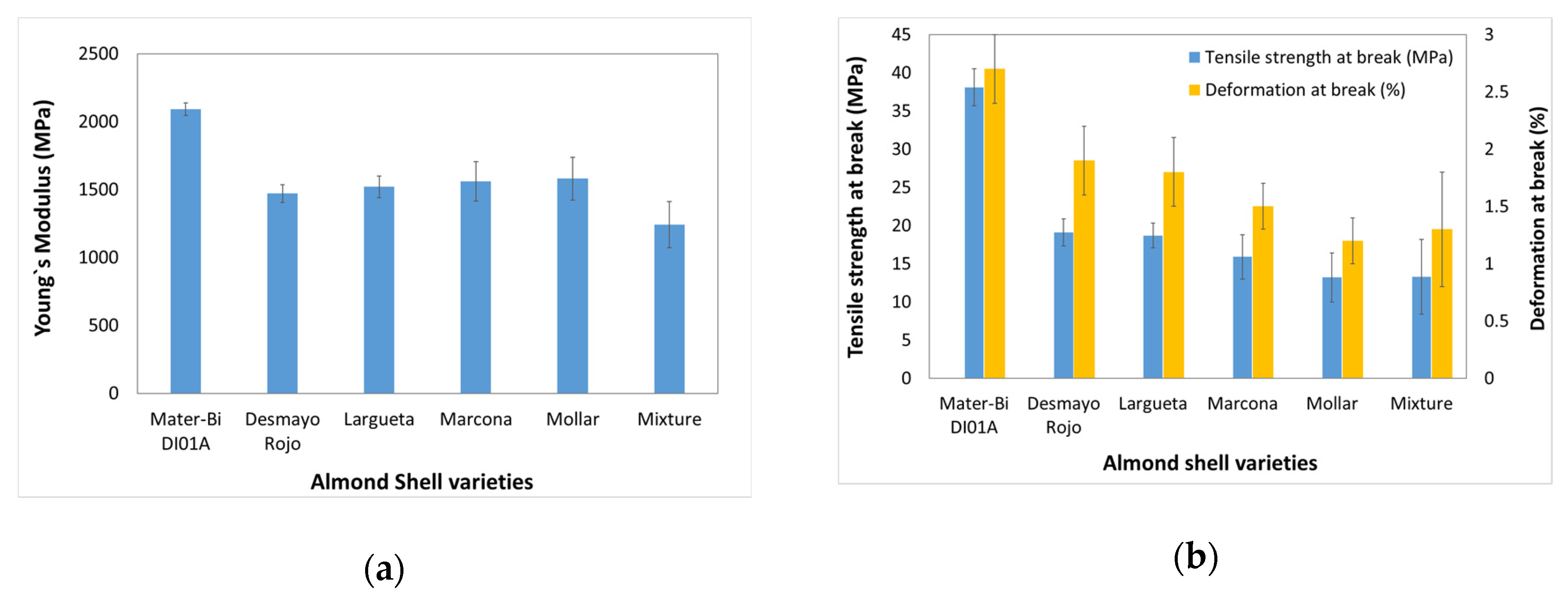

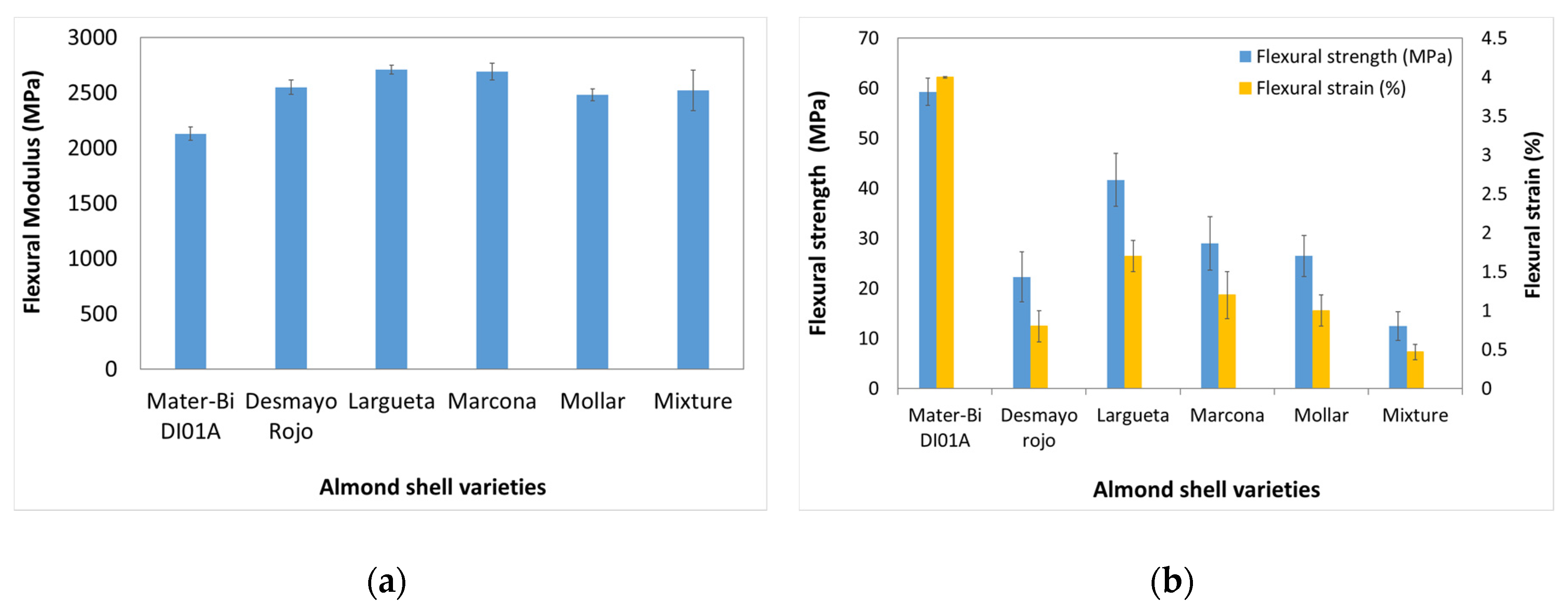

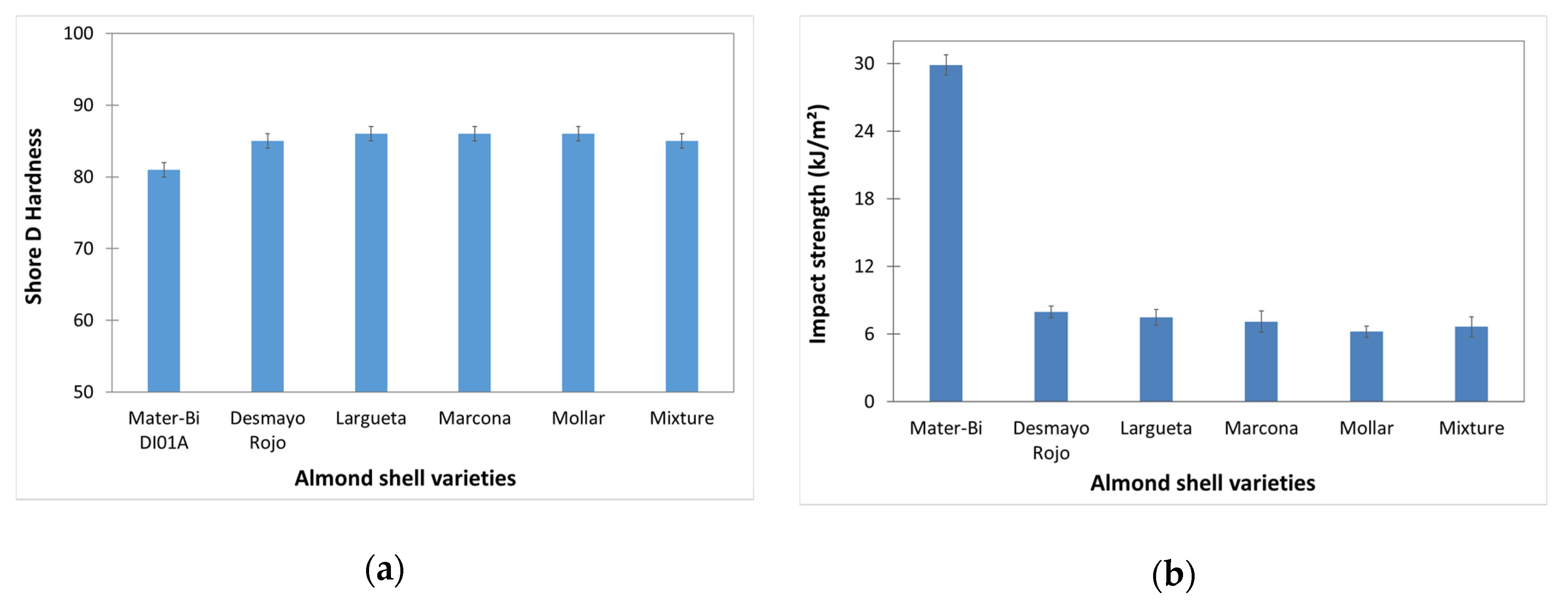

3.2. Development and Characterisation of the Biocomposites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Jawaid, M.; Paridah, M.T.; Saba, N. Introduction to Biomass and Its Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Agroinformacion.com. La producción mundial de almendra alcanzará las 1.29 millones de toneladas, un 2.34 % más. Available online: https://agroinformacion.com/la-produccion-mundial-de-almendra-alcanzara-las-129-millones-de-toneladas-un-234-mas/ (accessed on 15 May 2020).

- Li, X.; Liu, Y.; Hao, J.; Wang, W. Study of Almond Shell Characteristics. Materials 2018, 11, 1782. [Google Scholar] [CrossRef] [PubMed]

- Essabir, H.; Nekhlaoui, S.; Malha, M.; Bensalah, M.O.; Arrakhiz, F.Z.; Qaiss, A.; Bouhfid, R. Bio-Composites Based on Polypropylene Reinforced with Almond Shells Particles: Mechanical and Thermal Properties. Mater. Des. 2013, 51, 225–230. [Google Scholar] [CrossRef]

- Ledbetter, C.A. Shell Cracking Strength in Almond (Prunus Dulcis [Mill.] D.A. Webb.) and Its Implication in Uses as a Value-Added Product. Bioresour. Technol. 2008, 99, 5567–5573. [Google Scholar] [CrossRef]

- Jahanban, A.; Jamei, R.; Jahanban, R. The Importance of Almond (Prunus Amygdalus L.) and Its by-Products. Food Chem. 2010, 120, 349–360. [Google Scholar] [CrossRef]

- Ahmedna, M.; Marshall, W.E.; Husseiny, A.A.; Goktepe, I.; Rao, R.M. The Use of Nutshell Carbons in Drinking Water Filters for Removal of Chlorination By-Products. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2004, 1097, 1092–1097. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable Composites Based on Lignocellulosic Fibers-An Overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of Highly Sustainable Polylactide/Almond Shell Flour Composites by Reactive Extrusion with Maleinized Linseed Oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Quiles-Carrillo, L.; Montanes, N.; Balart, R.; Torres-Giner, S.; Garcia-Garcia, D. Effect of Different Compatibilizers on Injection-Molded Green Composite Pieces Based on Polylactide Filled with Almond Shell Flour. Compos. Part B Eng. 2018, 76–85. [Google Scholar] [CrossRef]

- Bouhfid, R.; Hilali, E.; Laaziz, S.A.; Rodrigue, D.; Raji, M.; el kacem Qaiss, A.; Essabir, H. Bio-Composites Based on Polylactic Acid and Argan Nut Shell: Production and Properties. Int. J. Biol. Macromol. 2017, 104, 30–42. [Google Scholar] [CrossRef]

- Chin, D.D.V.S.; Yahya, M.N.B.; Che Din, N.B.; Ong, P. Acoustic Properties of Biodegradable Composite Micro-Perforated Panel (BC-MPP) Made from Kenaf Fibre and Polylactic Acid (PLA). Appl. Acoust. 2018, 138, 179–187. [Google Scholar] [CrossRef]

- Pan, P.; Zhu, B.; Kai, W.; Serizawa, S.; Iji, M.; Inoue, Y. Crystallization Behavior and Mechanical Properties of Bio-Based Green Composites Based on Poly(L-Lactide) and Kenaf Fiber. J. Appl. Polym. Sci. 2007, 105, 1511–1520. [Google Scholar] [CrossRef]

- Ogbomo, S.M.; Chapman, K.; Webber, C.; Bledsoe, R.; D’Souza, N.A. Benefits of Low Kenaf Loading in Biobased Composites of Poly(l-Lactide) and Kenaf Fiber. J. Appl. Polym. Sci. 2009, 112, 1294–1301. [Google Scholar] [CrossRef]

- da Silva Moura, A.; Demori, R.; Leão, R.M.; Crescente Frankenberg, C.L.; Campomanes Santana, R.M. The Influence of the Coconut Fiber Treated as Reinforcement in PHB (Polyhydroxybutyrate) Composites. Mater. Today Commun. 2019, 18, 191–198. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Garkhail, S.K.; Peijs, T. Biodegradable Composites Based on Flax/Polyhydroxybutyrate and Its Copolymer with Hydroxyvalerate. Ind. Crops Prod. 2010, 31, 34–42. [Google Scholar] [CrossRef]

- Chen, F.; Qian, J.; Huang, J.; Zhang, J.; Wolcott, M.P.; Zhu, Y.; Jiang, L. Study of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV)/Bamboo Pulp Fiber Composites: Effects of Nucleation Agent and Compatibilizer. J. Polym. Environ. 2008, 16, 83–93. [Google Scholar] [CrossRef]

- Buzarovska, A.; Bogoeva-Gaceva, G.; Grozdanov, A.; Avella, M.; Gentile, G.; Errico, M. Crystallization Behavior of Poly(Hydroxybytyrate-Co-Valerate) in Model and Bulk PHBV/Kenaf Fiber Composites. J. Mater. Sci. 2007, 42, 6501–6509. [Google Scholar] [CrossRef]

- Rosa, M.F.; Chiou, B.S.; Medeiros, E.S.; Wood, D.F.; Williams, T.G.; Mattoso, L.H.C.; Orts, W.J.; Imam, S.H. Effect of Fiber Treatments on Tensile and Thermal Properties of Starch/Ethylene Vinyl Alcohol Copolymers/Coir Biocomposites. Bioresour. Technol. 2009, 100, 5196–5202. [Google Scholar] [CrossRef]

- Grylewicz, A.; Spychaj, T.; Zdanowicz, M. Thermoplastic Starch/Wood Biocomposites Processed with Deep Eutectic Solvents. Compos. Part A Appl. Sci. Manuf. 2019, 121, 517–524. [Google Scholar] [CrossRef]

- Fazeli, M.; Keley, M.; Biazar, E. Preparation and Characterization of Starch-Based Composite Films Reinforced by Cellulose Nanofibers. Int. J. Biol. Macromol. 2018, 116, 272–280. [Google Scholar] [CrossRef]

- Liu, D.; Zhong, T.; Chang, P.R.; Li, K.; Wu, Q. Starch Composites Reinforced by Bamboo Cellulosic Crystals. Bioresour. Technol. 2010, 101, 2529–2536. [Google Scholar] [CrossRef] [PubMed]

- Moriana, R.; Vilaplana, F.; Karlsson, S.; Ribes-greus, A. Composites: Part A Improved Thermo-Mechanical Properties by the Addition of Natural Fibres in Starch-Based Sustainable Biocomposites. Compos. Part A 2011, 42, 30–40. [Google Scholar] [CrossRef]

- Liminana, P.; Balart, R.; Montanes, N. Development and Characterization of Environmentally Friendly Composites from Poly (Butylene Succinate) (PBS) and Almond Shell Fl Our with Di Ff Erent Compatibilizers. Compos. Part B 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Qu, W. Mechanical Properties of Poly(Butylene Succinate) (PBS) Biocomposites Reinforced with Surface Modified Jute Fibre. Compos. Part A Appl. Sci. Manuf. 2009, 40, 669–674. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Nakatani, H.; Kobayashi, S.; Song, J.I. Mechanical and Thermal Properties and Water Absorption of Jute Fiber Reinforced Poly(Butylene Succinate) Biodegradable Composites. Adv. Compos. Mater. 2012, 21, 241–258. [Google Scholar] [CrossRef]

- Bao, L.; Chen, Y.; Zhou, W.; Wu, Y.; Huang, Y. Bamboo Fibers @ Poly(Ethylene Glycol)-Reinforced Poly(Butylene Succinate) Biocomposites. J. Appl. Polym. Sci. 2011, 122, 2456–2466. [Google Scholar] [CrossRef]

- Dash, B.N.; Nakamura, M.; Sahoo, S.; Kotaki, M.; Nakai, A.; Hamada, H. Mechanical Properties of Hemp Reinforced Poly(Butylene Succinate) Biocomposites. J. Biobased Mater. Bioenergy 2008, 2, 273–281. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.E.; Beaugrand, J. Development of Sustainable Biodegradable Lignocellulosic Hemp Fiber/Polycaprolactone Biocomposites for Light Weight Applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. Composites: Part A A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of Particle Size, Particle/Matrix Interface Adhesion and Particle Loading on Mechanical Properties of Particulate-Polymer Composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Mohamed, W.Z.W.; Baharum, A.; Ahmad, I.; Abdullah, I.; Zakaria, N.E. Effects of Fiber Size and Fiber Content on Mechanical and Physical Properties of Mengkuang Reinforced Thermoplastic Natural Rubber Composites. BioResources 2018, 13, 2945–2959. [Google Scholar] [CrossRef]

- Tawakkal, I.S.M.A.; Cran, M.J.; Bigger, S.W. Effect of Kenaf Fibre Loading and Thymol Concentration on the Mechanical and Thermal Properties of PLA/Kenaf/Thymol Composites. Ind. Crops Prod. 2014, 61, 74–83. [Google Scholar] [CrossRef]

- Moriana, R.; Vilaplana, F.; Karlsson, S.; Ribes, A. Correlation of Chemical, Structural and Thermal Properties of Natural Fibres for Their Sustainable Exploitation. Carbohydr. Polym. 2014, 112, 422–431. [Google Scholar] [CrossRef]

- Araújo, M.A.; Cunha, A.M.; Mota, M. Enzymatic Degradation of Starch-Based Thermoplastic Compounds Used in Protheses: Identification of the Degradation Products in Solution. Biomaterials 2004, 25, 2687–2693. [Google Scholar] [CrossRef]

- Zhang, J.F.; Sun, X. Mechanical Properties of Poly(Lactic Acid)/Starch Composites Compatibilized by Maleic Anhydride. Biomacromolecules 2004, 5, 1446–1451. [Google Scholar] [CrossRef]

- Aldas, M.; Rayón, E.; López-Martínez, J.; Arrieta, M.P. A Deeper Microscopic Study of the Interaction between Gum Rosin Derivatives and a Mater-Bi Type Bioplastic. Polymers 2020, 12, 226. [Google Scholar] [CrossRef]

- Lopez, J.P.; Vilaseca, F.; Barberà, L.; Bayer, R.J.; Pèlach, M.A.; Mutjé, P. Processing and Properties of Biodegradable Composites Based on Mater-Bi ® and Hemp Core Fibres. Resour. Conserv. Recycl. 2012, 59, 38–42. [Google Scholar] [CrossRef]

- Haque, M.; Alvarez, V.; Paci, M.; Pracella, M. Composites: Part A Processing, Compatibilization and Properties of Ternary Composites of Mater-Bi with Polyolefins and Hemp Fibres. Compos. Part A 2011, 42, 2060–2069. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Curvelo, A.A.S.; Teixeira, E.M.; Mendes, F.M.; Carvalho, A.J.F.; Felissia, F.E.; Area, M.C. Composite Materials of Thermoplastic Starch and Fibers from the Ethanol-Water Fractionation of Bagasse. Ind. Crops Prod. 2011, 33, 739–746. [Google Scholar] [CrossRef]

- Di Franco, C.R.; Cyras, V.P.; Busalmen, J.P.; Ruseckaite, R.A.; Vázquez, A. Degradation of Polycaprolactone/Starch Blends and Composites with Sisal Fibre. Polym. Degrad. Stab. 2004, 86, 95–103. [Google Scholar] [CrossRef]

- Campos, A.; Marconcini, J.M.; Martins-Franchetti, S.M.; Mattoso, L.H.C. The Influence of UV-C Irradiation on the Properties of Thermoplastic Starch and Polycaprolactone Biocomposite with Sisal Bleached Fibers. Polym. Degrad. Stab. 2012, 97, 1948–1955. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Biocomposites from Wheat Straw Nanofibers: Morphology, Thermal and Mechanical Properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Elfehri, K.; Carrot, C.; Jaziri, M. Composites: Part A Biocomposites of Alfa Fibers Dispersed in the Mater-Bi Ò Type Bioplastic: Morphology, Mechanical and Thermal Properties. Compos. Part A 2015, 78, 371–379. [Google Scholar] [CrossRef]

- Blasco, C.; Varela, F.J.; Ibáñez, A. Consumer Attitudes and Bioplastic for Eco-Babies & Bio-Parenting. Bioplastic Mag. 2019, 22–24. [Google Scholar]

- Frutas y hortalizas. Available online: https://www.frutas-hortalizas.com/Fruits/Types-varieties-Almond.html (accessed on 1 September 2020).

- Bledzki, A.K.; Letman-Sakiewicz, M.; Murr, M. Influence of Static and Cyclic Climate Condition on Bending Properties of Wood Plastic Composites (WPC). Express Polym. Lett. 2010, 4, 364–372. [Google Scholar] [CrossRef]

- Marcovich, N.E.; Reboredo, M.M.; Aranguren, M.I. Dependence of the Mechanical Properties of Woodflour-Polymer Composites on the Moisture Content. J. Appl. Polym. Sci. 1998, 68, 2069–2076. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of Water Absorption on the Mechanical Properties of Hemp Fibre Reinforced Unsaturated Polyester Composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Muñoz-Guillena, M.; Linares-Solano, A.; Salinas-Martinez de Lecea, C. Determination of Calorific Values of Coals by Differential Thermal Analysis. Fuel 1992, 71, 579–583. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and Characterization of Natural Cellulose Fibers/Thermoset Polymer Composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, Z.; Dai, M.; Fang, S.; Liao, Y.; Yu, Z.; Ma, X. Co-Pyrolysis Kinetics of Sewage Sludge and Bagasse Using Multiple Normal Distributed Activation Energy Model (M-DAEM). Bioresour. Technol. 2018, 259, 173–180. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A Comprehensive Review on the Pyrolysis of Lignocellulosic Biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Di Blasi, C. Modeling Chemical and Physical Processes of Wood and Biomass Pyrolysis. Prog. Energy Combust. Sci. 2008, 34, 47–90. [Google Scholar] [CrossRef]

- Antunes, F.J.A.; Figueiredo, J.L. 99/03241 Pyrolysis Kinetics of Lignocellosic Materials—Three Independent Reactions Model. Fuel Energy Abstr. 1999, 40, 340. [Google Scholar] [CrossRef]

- Pirayesh, H.; Khazaeian, A. Using Almond (Prunus Amygdalus L.) Shell as a Bio-Waste Resource in Wood Based Composite. Compos. Part B Eng. 2012, 43, 1475–1479. [Google Scholar] [CrossRef]

- Martínez-García, A.; Ibáñez-García, A.; León-Cabezas, M.A.; Sánchez-Reche, A. Study of the Influence of the Almond Variety in the Properties of Injected Parts with Biodegradable Almond Shell Based Masterbatches. Waste Biomass Valorization 2015, 6, 363–370. [Google Scholar] [CrossRef]

- Matrix, P.B.S.; Liminana, P.; Quiles-carrillo, L.; Boronat, T.; Balart, R. The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly (Butylene Succinate Linseed Oil (MLO). Materials 2018, 11, 2179. [Google Scholar] [CrossRef]

| Natural Fibre | Cellulose (%) | Hemicellulose (%) | Lignin (%) |

|---|---|---|---|

| Bagasse | 55.2 | 16.8 | 25.3 |

| Bamboo | 26–43 | 30 | 21–31 |

| Flax | 71 | 18.6–20.6 | 2.2 |

| Kenaf | 72 | 20.3 | 9 |

| Jute | 61–71 | 14–20 | 12–13 |

| Hemp | 68 | 15 | 10 |

| Ramie | 68.6–76.2 | 13–16 | 0.6–0.7 |

| Abaca | 56–63 | 20–25 | 7–9 |

| Sisal | 65 | 12 | 9.9 |

| Coir | 81 | -- | 12.7 |

| Pinapple | 81 | -- | 12.7 |

| Wheat straw | 38–45 | 15–31 | 12–20 |

| Rice husk | 35–45 | 19–25 | 20 |

| Rice straw | 41–57 | 33 | 8–10 |

| Characteristics | TEST | Values |

|---|---|---|

| Min. processing temperature (°C) | Novamont test | 170 |

| Max. processing temperature (°C) | Novamont test | 260 |

| Melting temperature (°C) | ASTM-D3418 | 160 |

| Melt viscosity (Pa·s) (T = 190 °C, γ = 1000 s−1) | ASTM-D3835 | 140 |

| Tensile strength at break (MPa) | ASTM-D638 | 20 |

| Max. tensile strength (MPa) | ASTM-D638 | 48 |

| Elongation at break (%) | ASTM-D638 | 22 |

| Elongation at max strength | ASTM-D638 | 2.5 |

| Young modulus (MPa) | ASTM-D638 | 2700 |

| Parameters | Injection Moulding Conditions |

|---|---|

| Injection temperature (°C) | 40–180–190–200–200 |

| Mould temperature (°C) | 30 |

| Injection speed (mm/s) | 70 |

| Injection pressure (max)(bar) | 165 |

| Back pressure (bar) | 83 |

| Cooling time (s) | 35 |

| Injection temperature (°C) | 40–180–190–200–200 |

| Mould temperature (°C) | 30 |

| Injection speed (mm/s) | 70 |

| Wavenumber (cm−1) | Functional Group | Vibration Type | Cause |

|---|---|---|---|

| 3300–3500 | ─OH | stretching vibration | cellulose, hemicellulose |

| 2900–2935 | ─CH | stretching vibration | - |

| 1640–1735 | C=O | stretching vibration | lignin, hemicellulose |

| 1580–1605 | benzene ring | stretching vibration | lignin |

| 1455–1465 | ─CH3O | stretching vibration | lignin |

| 1320–1430 | ─CH | bending vibration | - |

| 1221–1230 | C─C C─O | stretching vibration | lignin |

| 1025–1035 | C─O | stretching vibration | cellulose, hemicellulose and lignin |

| 885–895 | R2C=CH2 | bending vibration | - |

| 810–833 | benzene ring | disubstituted benzene | - |

| Almond Shell Variety | Moisture (%) | Volatile Matter (%) | Fixed Carbon (%) | Ash (%) |

|---|---|---|---|---|

| Desmayo Rojo | 6.2 | 73.9 | 18.9 | 1.0 |

| Largueta | 5.8 | 75.1 | 17.1 | 2.0 |

| Marcona | 5.2 | 73.1 | 17.7 | 4.0 |

| Mollar | 6.3 | 73.7 | 19.1 | 0.9 |

| Mixture | 7.4 | 64.5 | 19.4 | 8.7 |

| Almond Shell Variety | Component | Ea (kJ·mol−1) | K0 (s−1) | α (kJ∙mol−1) | α Ea−1 (%) | Tm (°C) | Weight Loss (%) | Amount (%) |

|---|---|---|---|---|---|---|---|---|

| Desmayo Rojo | Hemicellulose | 132 | 4.2·109 | 4.2 | 3.2 | 299 | 25.9 | 36 |

| Cellulose | 169 | 1.2·1012 | 0.0 | 0.0 | 351 | 33.8 | 40 | |

| Lignin LT | 170 | 1.4·1010 | 14.6 | 8.6 | 401 | 6.0 | 24 | |

| Lignin HT | 240 | 3.2·1011 | 60.0 | 25.0 | 445 | 5.8 | ||

| Largueta | Hemicellulose | 155 | 2.9·1011 | 6.6 | 4.2 | 308 | 33.0 | 44 |

| Cellulose | 202 | 3.6·1014 | 0.0 | 0.0 | 366 | 28.2 | 32 | |

| Lignin LT | 173 | 1.6·1010 | 17.9 | 10.3 | 398 | 6.7 | 24 | |

| Lignin HT | 242 | 8.8·1010 | 63.8 | 26.4 | 466 | 5.7 | ||

| Marcona | Hemicellulose | 140 | 1.9·1010 | 4.6 | 3.3 | 302 | 28.9 | 40 |

| Cellulose | 185 | 2.3·1013 | 0.0 | 0.0 | 356 | 30.7 | 36 | |

| Lignin LT | 170 | 1.5·1010 | 13.7 | 8.1 | 401 | 5.8 | 24 | |

| Lignin HT | 242 | 1.6·1011 | 64.8 | 26.8 | 450 | 6.3 | ||

| Mollar | Hemicellulose | 140 | 1.3·1010 | 7.3 | 5.2 | 302 | 28.6 | 40 |

| Cellulose | 185 | 2.2·1013 | 0.0 | 0.0 | 355 | 28.6 | 35 | |

| Lignin LT | 171 | 1.4·1010 | 14.6 | 8.6 | 402 | 6.2 | 25 | |

| Lignin HT | 240 | 3.2·1011 | 60.0 | 25.0 | 445 | 5.8 | ||

| Mixture | Hemicellulose | 127 | 1.2·109 | 9.1 | 7.1 | 287 | 22.6 | 37 |

| Cellulose | 173 | 4.9·1012 | 0.0 | 0.0 | 342 | 19.6 | 27 | |

| Lignin LT | 178 | 3.1·1010 | 22.0 | 22.0 | 389 | 8.7 | 36 | |

| Lignin HT | 240 | 3.2·1011 | 65.0 | 65.0 | 428 | 6.7 |

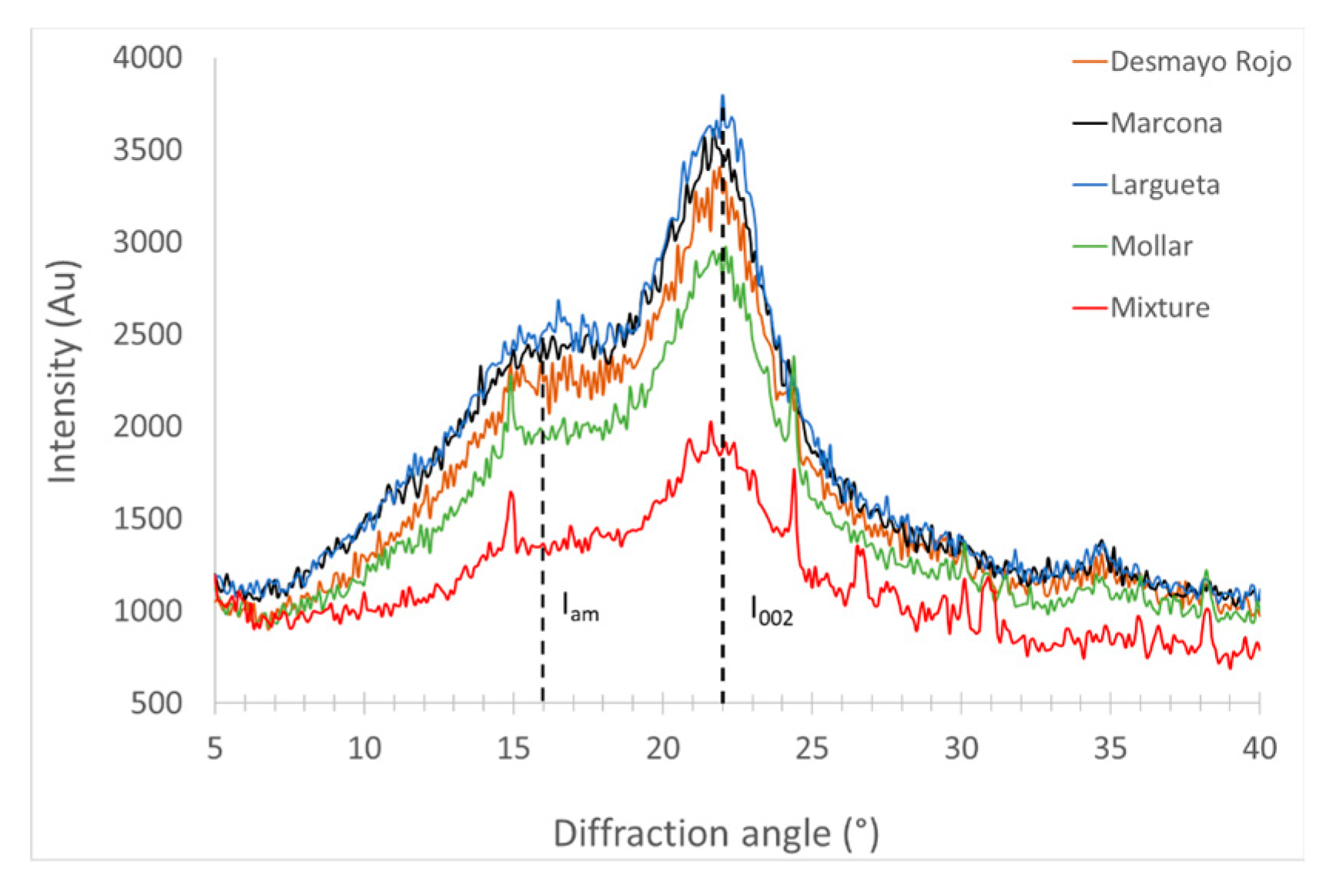

| Almond Shell Variety | CrI (%) |

|---|---|

| Desmayo Rojo | 31.3 |

| Largueta | 33.8 |

| Marcona | 29.7 |

| Mollar | 30.2 |

| Mixture | 25.1 |

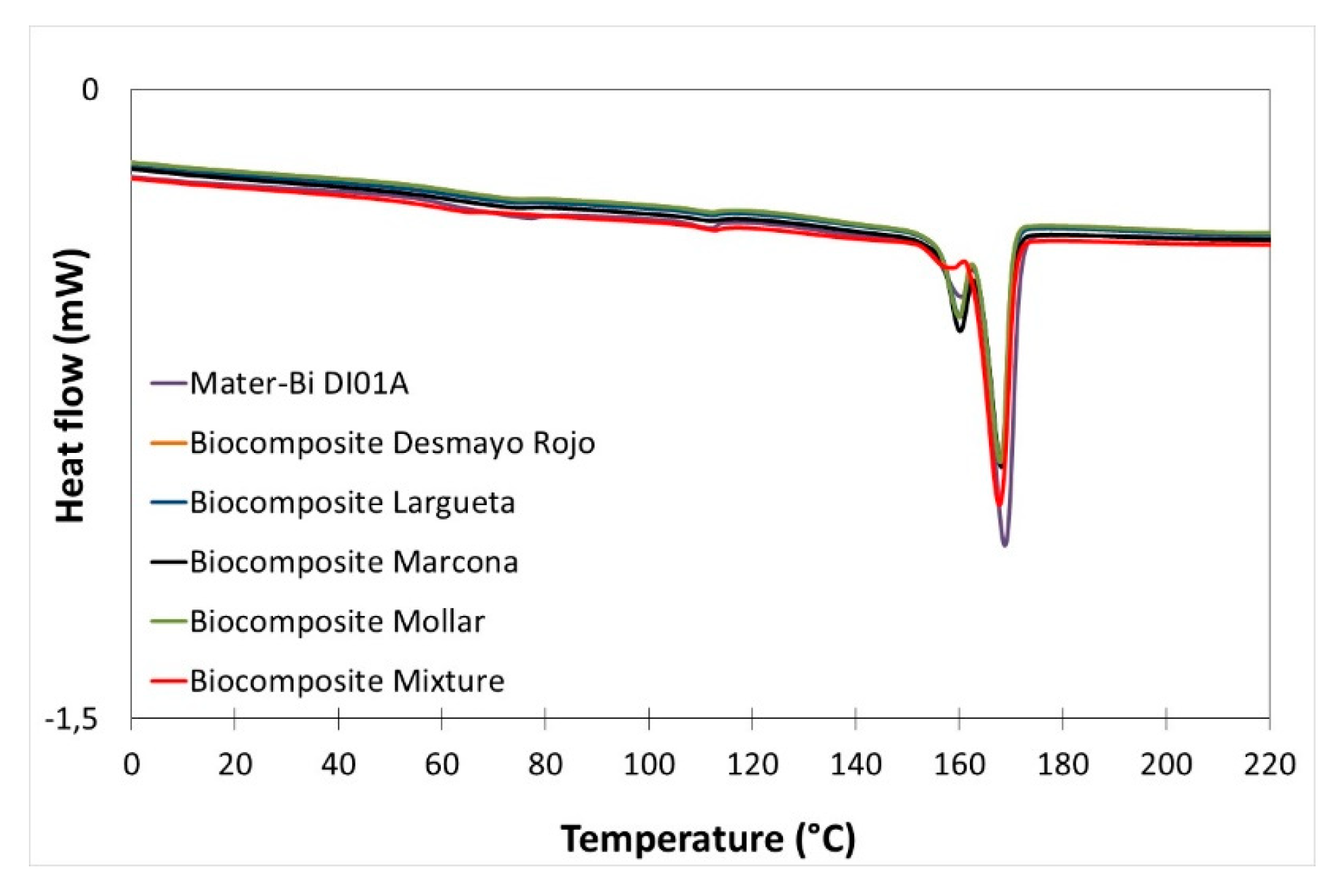

| Materials | Melt Enthalphy (J·g−1) | Melt Peak Temperature (°C) |

|---|---|---|

| As-received Mater-Bi DI01A | 28.01 | 168.84 |

| Biocomposite Mater-Bi DI01A/Desmayo Rojo | 21.12 | 167.91 |

| Biocomposite Mater-Bi DI01A/Largueta | 21.31 | 168.02 |

| Biocomposite Mater-Bi DI01A/Marcona | 22.04 | 168.11 |

| Biocomposite Mater-Bi DI01A/Mollar | 21.41 | 167.95 |

| Biocomposite Mater-Bi DI01A/Mixture | 22.03 | 167.70 |

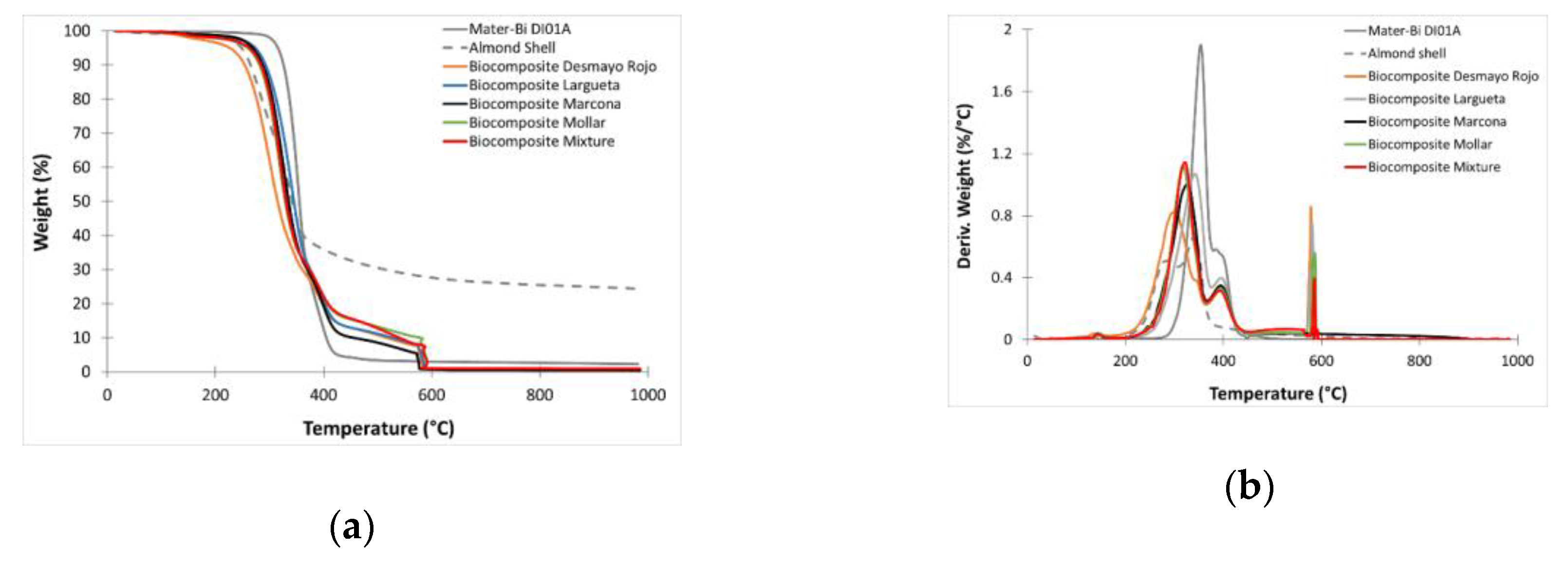

| Materials | TONSET (°C) | TMAX (°C) | Residual Weight (%) |

|---|---|---|---|

| As-received Mater-Bi DI01A | 325.98 | 353.58 | 2.33 |

| Almond shell | 254.67 | 351.06 | 22.81 |

| Biocomposite Mater-Bi DI01A/Desmayo Rojo | 256.76 | 304.46 | 0.63 |

| Biocomposite Mater-Bi DI01A/Largueta | 293.91 | 341.46 | 0.65 |

| Biocomposite Mater-Bi DI01A/Marcona | 281.00 | 325.27 | 0.74 |

| Biocomposite Mater-Bi DI01A/Mollar | 282.60 | 318.28 | 0.83 |

| Biocomposite Mater-Bi DI01A/Mixture | 286.19 | 319.09 | 0.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibáñez García, A.; Martínez García, A.; Ferrándiz Bou, S. Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites. Polymers 2020, 12, 2049. https://doi.org/10.3390/polym12092049

Ibáñez García A, Martínez García A, Ferrándiz Bou S. Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites. Polymers. 2020; 12(9):2049. https://doi.org/10.3390/polym12092049

Chicago/Turabian StyleIbáñez García, Ana, Asunción Martínez García, and Santiago Ferrándiz Bou. 2020. "Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites" Polymers 12, no. 9: 2049. https://doi.org/10.3390/polym12092049

APA StyleIbáñez García, A., Martínez García, A., & Ferrándiz Bou, S. (2020). Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites. Polymers, 12(9), 2049. https://doi.org/10.3390/polym12092049