Obtaining and Characterization of Nutraceuticals Based on Linoleic Acid Derivatives Obtained by Green Synthesis and Their Valorization in the Food Industry

Abstract

1. Introduction

2. Linoleic Acid: Structure, Properties, and Biological Significance

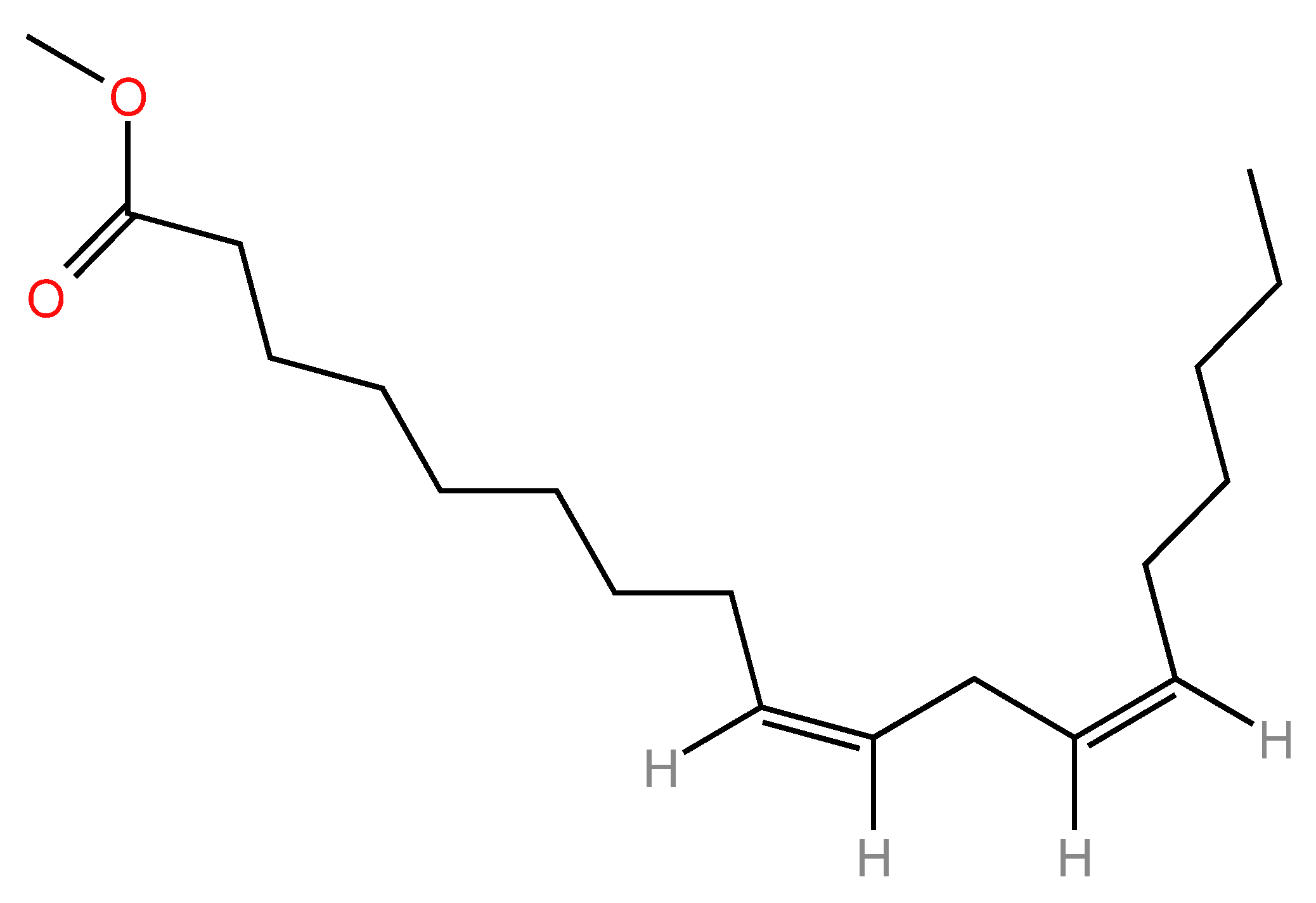

2.1. Chemical Structure and Physicochemical Properties

2.2. Biological Functions and Health Benefits

2.3. Dietary Sources and Importance in Human Nutrition

3. Green Synthesis of Linoleic Acid Derivatives

3.1. Principles of Green Chemistry in Synthesis

3.2. Eco-Friendly Catalysts, Solvents, and Processes

3.2.1. Eco-Friendly Catalysts in Green Synthesis of Linoleic Acid Derivatives

Enzyme-Based Catalysts (Biocatalysts)

Heterogeneous Catalysts

Organocatalysts

3.2.2. Green Solvents in Linoleic Acid Derivative Synthesis

3.2.3. Sustainable Processes in Linoleic Acid Derivative Synthesis

3.3. Enzymatic vs. Chemical Synthesis Approaches

3.3.1. Chemical Synthesis of Linoleic Acid Derivatives

Conjugated Linoleic Acid (CLA) Production

Epoxidation of Linoleic Acid

Esterification and Transesterification

3.3.2. Enzymatic Synthesis of Linoleic Acid Derivatives

Bioconversion to Conjugated Linoleic Acid (CLA)

Enzymatic Epoxidation and Hydroxylation

Lipase-Catalyzed Esterification and Transesterification

3.3.3. Comparative Analysis and Industrial Implications

3.4. Recent Advancements and Innovations in Green Synthesis

3.4.1. Catalytic Innovations in Green Synthesis

3.4.2. Solvent-Free and Alternative Solvent Systems

3.4.3. Sustainable Nanotechnology and Green Nanomaterials

3.4.4. Energy-Efficient Strategies in Green Synthesis

4. Functional Properties and Nutraceutical Potential

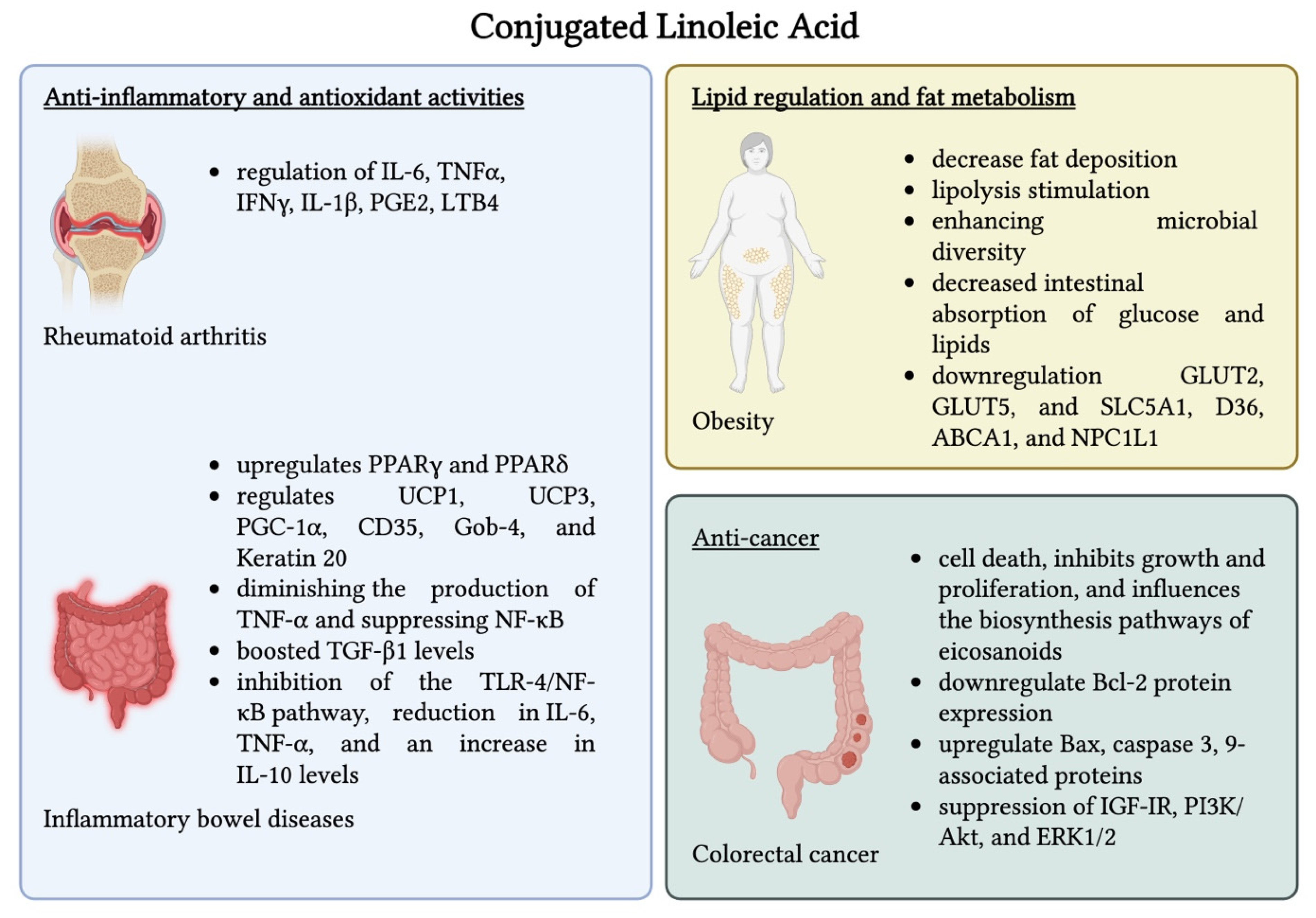

4.1. Conjugated Linoleic Acid (CLA)

Safety Considerations of CLA

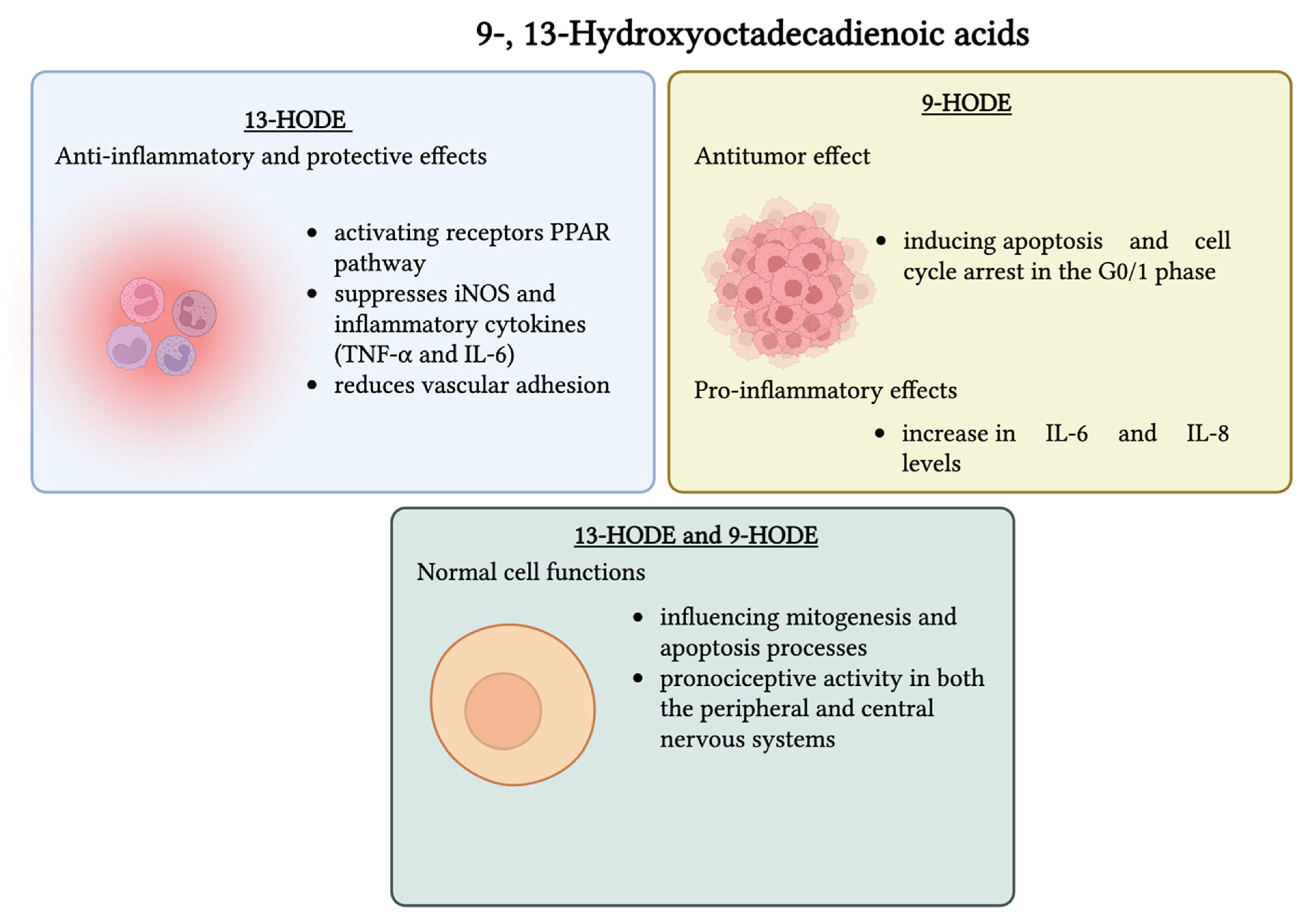

4.2. 9- and 13-Hydroxyoctadecadienoic Acids (9- and 13-HODEs)

Safety Considerations of 9- and 13-HODEs

4.3. Epoxygenated Fatty Acids (EpFAs)

Safety Considerations of EpFAs

4.4. Oxo-Fatty Acids (Oxo-FAs)

Safety Considerations of Oxo-FAs

4.5. Linoleic Acid-Derived Esters

Safety Considerations of Linoleic Acid-Derived Esters

5. Valorization in the Food Industry

5.1. Incorporation in Functional Foods and Beverages

5.1.1. Technological Considerations for Incorporation

5.1.2. Dairy-Based Functional Products

5.1.3. Plant-Based Emulsified Systems

5.1.4. Functional Bakery and Snack Products

5.1.5. Functional Beverages: Aqueous and Carbonated Systems

5.1.6. Nutraceutical Powders and Meal Replacements

5.1.7. Integration into Personalized Nutrition Paradigms

5.2. Role as Food Preservatives and Stabilizers

5.2.1. Antioxidant Activity and Lipid Oxidation Inhibition

5.2.2. Antimicrobial Effects and Microbiological Preservation

5.2.3. Emulsifying and Physical Stabilization Properties

5.2.4. Synergistic Combinations with Other Natural Preservatives

5.2.5. Applications in Packaging and Edible Films

5.2.6. Regulatory and Sensory Considerations

5.3. Potential as Flavor Enhancers and Nutritional Fortifiers

5.3.1. Flavor Modulation Through Lipid-Derived Volatiles

5.3.2. Interaction with the Maillard Reaction and Thermal Flavor Chemistry

5.3.3. Nutritional Fortification: Enhancing Functional Lipid Profiles

6. Regulatory Status and Market Trends

6.1. Regulatory Frameworks Governing Linoleic Acid and Its Derivatives

6.1.1. United States—FDA and GRAS Status

6.1.2. European Union—EFSA and Novel Food Authorization

6.1.3. Asia–Pacific and Codex Alimentarius Considerations

6.1.4. Market Trends and Commercialization Strategies

6.1.5. Global Market Dynamics

6.1.6. Key Players and Technological Differentiators

7. Challenges, Limitations, and Future Prospects

7.1. Current Limitations in Synthesis, Characterization, and Application

7.1.1. Challenges in Green Synthesis Pathways

7.1.2. Analytical and Characterization Limitations

7.1.3. Formulation and Application Constraints

7.2. Scale-Up Challenges for Industrial Production

7.2.1. Process Engineering Constraints in Enzymatic Synthesis

7.2.2. Bottlenecks in Microbial Fermentation Processes

7.2.3. Challenges in Photocatalytic and Electrochemical Oxidation

7.2.4. Process Integration, Purification, and Formulation

7.3. Future Directions for Research and Development

7.3.1. Advanced Green Synthesis Pathways and Biotechnological Innovations

7.3.2. Integration of Green Chemistry with Smart Formulation Technologies

7.3.3. Expanding the Biological Understanding and Therapeutic Potential

7.3.4. Regulatory Science and Harmonization

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Santini, A.; Cammarata, S.M.; Capone, G.; Ianaro, A.; Tenore, G.C.; Pani, L.; Novellino, E. Nutraceuticals: Opening the Debate for a Regulatory Framework. Br. J. Clin. Pharmacol. 2018, 84, 659–672. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Maity, M.K.; Nazmi, A.S.; Ali, M. Anthocyanins: Pharmacology and Nutraceutical Importance. In Anthocyanins: Pharmacology and Nutraceutical Importance; Bentham Science Publishers Pvt. Ltd.: Sharjah, United Arab Emirates, 2024; pp. 92–107. [Google Scholar] [CrossRef]

- Cena, H.; Calder, P.C. Defining a Healthy Diet: Evidence for the Role of Contemporary Dietary Patterns in Health and Disease. Nutrients 2020, 12, 334. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Noncommunicable Diseases Country Profiles 2018; World Health Organization: Geneva, Switzerland, 2018; pp. 1–223. [Google Scholar]

- Przybyłowicz, K.E.; Danielewicz, A. Eating Habits and Disease Risk Factors. Nutrients 2022, 14, 3143. [Google Scholar] [CrossRef] [PubMed]

- Vij, S.; Kumar, R.; Singh, A.P.; Singh, A.P.; Sharma, P. Nutraceuticals: A Review. Int. J. Eng. Sci. Gen. Res. 2024, 8, 32–41. [Google Scholar] [CrossRef]

- Nasri, H.; Baradaran, A.; Shirzad, H.; Kopaei, M.R. New Concepts in Nutraceuticals as Alternative for Pharmaceuticals. Int. J. Prev. Med. 2014, 5, 1487–1499. [Google Scholar] [PubMed]

- Santini, A.; Tenore, G.C.; Novellino, E. Nutraceuticals: A Paradigm of Proactive Medicine. Eur. J. Pharm. Sci. 2017, 96, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Mercola, J.; D’Adamo, C.R. Linoleic Acid: A Narrative Review of the Effects of Increased Intake in the Standard American Diet and Associations with Chronic Disease. Nutrients 2023, 15, 3129. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.K.; Keum, Y.S. Omega-3 and Omega-6 Polyunsaturated Fatty Acids: Dietary Sources, Metabolism, and Significance—A Review. Life Sci. 2018, 203, 255–267. [Google Scholar] [CrossRef] [PubMed]

- Granato, D.; Zabetakis, I.; Koidis, A. Sustainability, Nutrition, and Scientific Advances of Functional Foods under the New EU and Global Legislation Initiatives. J. Funct. Foods 2023, 109, 105793. [Google Scholar] [CrossRef]

- Burns, J.L.; Nakamura, M.T.; Ma, D.W.L. Differentiating the Biological Effects of Linoleic Acid from Arachidonic Acid in Health and Disease. Prostaglandins Leukot. Essent. Fatty Acids 2018, 135, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Whelan, J.; Fritsche, K. Linoleic Acid. Adv. Nutr. 2013, 4, 311–312. [Google Scholar] [CrossRef] [PubMed]

- Gocen, T.; Haman Bayarı, S.; Haluk Guven, M. Linoleic Acid and Its Potassium and Sodium Salts: A Combined Experimental and Theoretical Study. J. Mol. Struct. 2017, 1150, 68–81. [Google Scholar] [CrossRef]

- Lalman, J.A.; Bagley, D.M. Anaerobic Degradation and Inhibitory Effects of Linoleic Acid. Water Res. 2000, 34, 4220–4228. [Google Scholar] [CrossRef]

- Mabrouk, A.F.; Dugan, L.R. Solubility of Linoleic Acid in Aqueous Solutions and Its Reaction with Water. J. Am. Oil Chem. Soc. 1961, 38, 9–13. [Google Scholar] [CrossRef]

- Khuwijitjaru, P.; Kimura, Y.; Matsuno, R.; Adachi, S. Solubility of Oleic and Linoleic Acids in Subcritical Water. Food Sci. Technol. Res. 2004, 10, 261–263. [Google Scholar] [CrossRef]

- Valgimigli, L. Lipid Peroxidation and Antioxidant Protection. Biomolecules 2023, 13, 1291. [Google Scholar] [CrossRef] [PubMed]

- Santos, R.S.; Franco, M.S.F.; Ravagnani, F.G.; Chaves-Filho, A.B.; Miyamoto, S.; Baptista, M.S.; Shchepinov, M.S.; Yoshinaga, M.Y. Intracellular Distribution of Bis-Allylic Deuterated Linoleic Acid into the Lipidome of Human Keratinocytes. Redox Biochem. Chem. 2023, 5–6, 100005. [Google Scholar] [CrossRef]

- Ramsden, C.E.; Hennebelle, M.; Schuster, S.; Keyes, G.S.; Johnson, C.D.; Kirpich, I.A.; Dahlen, J.E.; Horowitz, M.S.; Zamora, D.; Feldstein, A.E.; et al. Effects of Diets Enriched in Linoleic Acid and Its Peroxidation Products on Brain Fatty Acids, Oxylipins, and Aldehydes in Mice. Biochim. Biophys. Acta Mol. Cell Biol. Lipids 2018, 1863, 1206. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, E.S.; Julio, L.M.; Henning, C.; Diehl, B.W.K.; Tomás, M.C.; Ixtaina, V.Y. Effect of Natural Antioxidants on the Physicochemical Properties and Stability of Freeze-Dried Microencapsulated Chia Seed Oil. J. Sci. Food Agric. 2019, 99, 1682–1690. [Google Scholar] [CrossRef] [PubMed]

- Mori, T.A.; Hodgson, J.M. Fatty Acids: Health Effects of Omega-6 Polyunsaturated Fatty Acids. Encycl. Hum. Nutr. 2013, 2–4, 209–214. [Google Scholar] [CrossRef]

- Ikonen, E. Roles of Lipid Rafts in Membrane Transport. Curr. Opin. Cell Biol. 2001, 13, 470–477. [Google Scholar] [CrossRef] [PubMed]

- Robichaud, P.P.; Munganyiki, J.E.; Boilard, E.; Surette, M.E. Polyunsaturated Fatty Acid Elongation and Desaturation in Activated Human T-Cells: ELOVL5 Is the Key Elongase. J. Lipid Res. 2018, 59, 2383–2396. [Google Scholar] [CrossRef] [PubMed]

- Wallis, J.G.; Watts, J.L.; Browse, J. Polyunsaturated Fatty Acid Synthesis: What Will They Think of Next? Trends Biochem. Sci. 2002, 27, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Tański, W.; Świątoniowska-Lonc, N.; Tabin, M.; Jankowska-Polańska, B. The Relationship between Fatty Acids and the Development, Course and Treatment of Rheumatoid Arthritis. Nutrients 2022, 14, 1030. [Google Scholar] [CrossRef] [PubMed]

- Veselinovic, M.; Vasiljevic, D.; Vucic, V.; Arsic, A.; Petrovic, S.; Tomic-Lucic, A.; Savic, M.; Zivanovic, S.; Stojic, V.; Jakovljevic, V. Clinical Benefits of N-3 PUFA and ɤ-Linolenic Acid in Patients with Rheumatoid Arthritis. Nutrients 2017, 9, 325. [Google Scholar] [CrossRef] [PubMed]

- Brzeski, M.; Madhok, R.; Capell, H.A. Evening primrose oil in patients with rheumatoid arthritis and side-effects of non-steroidal anti-inflammatory drugs. Rheumatology 1991, 30, 370–372. [Google Scholar] [CrossRef] [PubMed]

- Johnson, G.H.; Fritsche, K. Effect of Dietary Linoleic Acid on Markers of Inflammation in Healthy Persons: A Systematic Review of Randomized Controlled Trials. J. Acad. Nutr. Diet. 2012, 112, 1029–1041.e15. [Google Scholar] [CrossRef] [PubMed]

- McMullen, R.L. The Benefits and Challenges of Treating Skin with Natural Oils. Int. J. Cosmet. Sci. 2024, 46, 553–565. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jia, Y.; He, H. The Role of Linoleic Acid in Skin and Hair Health: A Review. Int. J. Molec Sci. 2024, 26, 246. [Google Scholar] [CrossRef] [PubMed]

- Schild, J.; Kalvodová, A.; Zbytovská, J.; Farwick, M.; Pyko, C. The Role of Ceramides in Skin Barrier Function and the Importance of Their Correct Formulation for Skincare Applications. Int. J. Cosmet. Sci. 2024, 46, 526–543. [Google Scholar] [CrossRef] [PubMed]

- Alarcon-Gil, J.; Sierra-Magro, A.; Morales-Garcia, J.A.; Sanz-SanCristobal, M.; Alonso-Gil, S.; Cortes-Canteli, M.; Niso-Santano, M.; Martínez-Chacón, G.; Fuentes, J.M.; Santos, A.; et al. Neuroprotective and Anti-Inflammatory Effects of Linoleic Acid in Models of Parkinson’s Disease: The Implication of Lipid Droplets and Lipophagy. Cells 2022, 11, 2297. [Google Scholar] [CrossRef] [PubMed]

- Farvid, M.S.; Ding, M.; Pan, A.; Sun, Q.; Chiuve, S.E.; Steffen, L.M.; Willett, W.C.; Hu, F.B. Dietary Linoleic Acid and Risk of Coronary Heart Disease: A Systematic Review and Meta-Analysis of Prospective Cohort Studies. Circulation 2014, 130, 1568. [Google Scholar] [CrossRef] [PubMed]

- Forouhi, N.G.; Imamura, F.; Sharp, S.J.; Koulman, A.; Schulze, M.B.; Zheng, J.; Ye, Z.; Sluijs, I.; Guevara, M.; Huerta, J.M.; et al. Association of Plasma Phospholipid N-3 and n-6 Polyunsaturated Fatty Acids with Type 2 Diabetes: The EPIC-InterAct Case-Cohort Study. PLoS Med. 2016, 13. [Google Scholar] [CrossRef] [PubMed]

- Asp, M.L.; Collene, A.L.; Norris, L.E.; Cole, R.M.; Stout, M.B.; Tang, S.Y.; Hsu, J.C.; Belury, M.A. Time-Dependent Effects of Safflower Oil to Improve Glycemia, Inflammation and Blood Lipids in Obese, Post-Menopausal Women with Type 2 Diabetes: A Randomized, Double-Masked, Crossover Study. Clin. Nutr. 2011, 30, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Summers, L.K.M.; Fielding, B.A.; Bradshaw, H.A.; Ilic, V.; Beysen, C.; Clark, M.L.; Moore, N.R.; Frayn, K.N. Substituting Dietary Saturated Fat with Polyunsaturated Fat Changes Abdominal Fat Distribution and Improves Insulin Sensitivity. Diabetologia 2002, 45, 369–377. [Google Scholar] [CrossRef] [PubMed]

- Vessby, B.; Aro, A.; Skarfors, E.; Berglund, L.; Salminen, I.; Lithell, H. The Risk to Develop NIDDM Is Related to the Fatty Acid Composition of the Serum Cholesterol Esters. Diabetes 1994, 43, 1353–1357. [Google Scholar] [CrossRef] [PubMed]

- Risérus, U.; Willett, W.C.; Hu, F.B. Dietary Fats and Prevention of Type 2 Diabetes. Prog. Lipid Res. 2009, 48, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Henderson, G.; Crofts, C.; Schofield, G. Linoleic Acid and Diabetes Prevention. Lancet Diabetes Endocrinol. 2018, 6, 12–13. [Google Scholar] [CrossRef] [PubMed]

- Warensjö, E.; Sundström, J.; Lind, L.; Vessby, B. Factor Analysis of Fatty Acids in Serum Lipids as a Measure of Dietary Fat Quality in Relation to the Metabolic Syndrome in Men. Am. J. Clin. Nutr. 2006, 84, 442–448. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.H.Y.; Marklund, M.; Imamura, F.; Tintle, N.; Ardisson Korat, A.V.; de Goede, J.; Zhou, X.; Yang, W.S.; de Oliveira Otto, M.C.; Kröger, J.; et al. Omega-6 Fatty Acid Biomarkers and Incident Type 2 Diabetes: Pooled Analysis of Individual-Level Data for 39,740 Adults from 20 Prospective Cohort Studies. Lancet Diabetes Endocrinol. 2017, 5, 965–974. [Google Scholar] [CrossRef] [PubMed]

- Taha, A.Y. Linoleic Acid–Good or Bad for the Brain? npj Sci. Food 2020, 4, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Fritsche, K.L. Linoleic Acid, Vegetable Oils & Inflammation. Mo. Med. 2014, 111, 41. [Google Scholar] [PubMed]

- Kris-Etherton, P.M.; Taylor, D.S.; Yu-Poth, S.; Huth, P.; Moriarty, K.; Fishell, V.; Hargrove, R.L.; Zhao, G.; Etherton, T.D. Polyunsaturated Fatty Acids in the Food Chain in the United States. Am. J. Clin. Nutr. 2000, 71, 179S–188S. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Zhang, J.; Li, F.; Zheng, J.; Xu, G. Effect of Oils in Feed on the Production Performance and Egg Quality of Laying Hens. Animals 2021, 11, 3482. [Google Scholar] [CrossRef] [PubMed]

- Hardman, W.E. Omega-3 Fatty Acids to Augment Cancer Therapy. J. Nutr. 2002, 132, 3508S–3512S. [Google Scholar] [CrossRef] [PubMed]

- Akkaya, M.R. Prediction of Fatty Acid Composition of Sunflower Seeds by Near-Infrared Reflectance Spectroscopy. J. Food Sci. Technol. 2018, 55, 2318. [Google Scholar] [CrossRef] [PubMed]

- Blasbalg, T.L.; Hibbeln, J.R.; Ramsden, C.E.; Majchrzak, S.F.; Rawlings, R.R. Changes in Consumption of Omega-3 and Omega-6 Fatty Acids in the United States during the 20th Century. Am. J. Clin. Nutr. 2011, 93, 950–962. [Google Scholar] [CrossRef] [PubMed]

- Siemionow, M.; Kulahci, Y.; Agaoglu, G. Diabetic Neuropathy: Pathogenesis and Treatment. Oxidative Stress. Neurodegener. Disord. 2007, 132, 543–579. [Google Scholar] [CrossRef]

- Kim, H.; Kim, H.; Lee, E.; Kim, Y.; Ha, E.H.; Chang, N. Association between Maternal Intake of N-6 to n-3 Fatty Acid Ratio during Pregnancy and Infant Neurodevelopment at 6 Months of Age: Results of the MOCEH Cohort Study. Nutr. J. 2017, 16, 23. [Google Scholar] [CrossRef] [PubMed]

- Steenweg-De Graaff, J.; Tiemeier, H.; Ghassabian, A.; Rijlaarsdam, J.; Jaddoe, V.W.V.; Verhulst, F.C.; Roza, S.J. Maternal Fatty Acid Status During Pregnancy and Child Autistic Traits: The Generation R Study. Am. J. Epidemiol. 2016, 183, 792–799. [Google Scholar] [CrossRef] [PubMed]

- Cannon, A.; Edwards, S.; Jacobs, M.; Moir, J.W.; Roy, M.A.; Tickner, J.A. An actionable definition and criteria for “sustainable chemistry” based on literature review and a global multisectoral stakeholder working group. RSC Sustain. 2023, 1, 2092–2106. [Google Scholar] [CrossRef]

- Olaniyan, O.F.; Ariwaodo, C.A.; Ibrahim, S.O.; Atolani, O.; Kambizi, L. Advances in Green Synthesis and Application of Nanoparticles from Crop Residues: A Comprehensive Review. Sci. Afr. 2025, 28, e02654. [Google Scholar] [CrossRef]

- Freund, R.; Lächelt, U.; Gruber, T.; Rühle, B.; Wuttke, S. Multifunctional Efficiency: Extending the Concept of Atom Economy to Functional Nanomaterials. ACS Nano 2018, 12, 2094–2105. [Google Scholar] [CrossRef] [PubMed]

- Martinengo, B.; Diamanti, E.; Uliassi, E.; Bolognesi, M.L. Harnessing the 12 Green Chemistry Principles for Sustainable Antiparasitic Drugs: Toward the One Health Approach. ACS Infect. Dis. 2024, 10, 1856–1870. [Google Scholar] [CrossRef] [PubMed]

- Pena-Pereira, F.; Kloskowski, A.; Namiesnik, J. ChemInform Abstract: Perspectives on the Replacement of Harmful Organic Solvents in Analytical Methodologies: A Framework Toward the Implementation of a Generation of Eco-Friendly Alternatives. ChemInform 2015, 46, 1–19. [Google Scholar] [CrossRef]

- Sahoo, T.; Panda, J.; Sahu, J.; Sarangi, D.; Sahoo, S.K.; Nanda, B.B.; Sahu, R. Green Solvent: Green Shadow on Chemical Synthesis. Curr. Org. Synth. 2020, 17, 426–439. [Google Scholar] [CrossRef] [PubMed]

- Fraguela-Meissimilly, H.; Bastías-Monte, J.M.; Vergara, C.; Ortiz-Viedma, J.; Lemus-Mondaca, R.; Flores, M.; Toledo-Merma, P.; Alcázar-Alay, S.; Gallón-Bedoya, M. New Trends in Supercritical Fluid Technology and Pressurized Liquids for the Extraction and Recovery of Bioactive Compounds from Agro-Industrial and Marine Food Waste. Molecules 2023, 28, 4421. [Google Scholar] [CrossRef] [PubMed]

- Adeeyo, A.O.; Oyetade, J.A.; Alabi, M.A.; Adeeyo, R.O.; Samie, A.; Makungo, R. Tuning Water Chemistry for the Recovery of Greener Products: Pragmatic and Sustainable Approaches. RSC Adv. 2023, 13, 6808–6826. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Jain, R.; Soni, P.; de los Santos-Villalobos, S.; Chattaraj, S.; Roy, D.; Mitra, D.; Gaur, A. Graphing the Green Route: Enzymatic Hydrolysis in Sustainable Decomposition. Curr. Res. Microb. Sci. 2024, 7, 100281. [Google Scholar] [CrossRef] [PubMed]

- Crisenza, G.E.M.; Melchiorre, P. Chemistry Glows Green with Photoredox Catalysis. Nat. Commun. 2020, 11, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Alazaiza, M.Y.D.; Bin Mokaizh, A.A.; Baarimah, A.O.; Al-Zghoul, T. From Agro-Waste to Bioactive Wealth: Analyzing Nutraceutical Extraction and Applications. Case Stud. Chem. Environ. Eng. 2025, 11, 101066. [Google Scholar] [CrossRef]

- Pal, P.; Singh, A.K.; Srivastava, R.K.; Rathore, S.S.; Sahoo, U.K.; Subudhi, S.; Sarangi, P.K.; Prus, P. Circular Bioeconomy in Action: Transforming Food Wastes into Renewable Food Resources. Foods 2024, 13, 3007. [Google Scholar] [CrossRef] [PubMed]

- Bommakanti, V.; Puthenparambil Ajikumar, A.; Sivi, C.M.; Prakash, G.; Mundanat, A.S.; Ahmad, F.; Haque, S.; Prieto, M.A.; Rana, S.S. An Overview of Herbal Nutraceuticals, Their Extraction, Formulation, Therapeutic Effects and Potential Toxicity. Separations 2023, 10, 177. [Google Scholar] [CrossRef]

- France, S.P.; Lewis, R.D.; Martinez, C.A. The Evolving Nature of Biocatalysis in Pharmaceutical Research and Development. JACS Au 2023, 3, 715–735. [Google Scholar] [CrossRef] [PubMed]

- Ravi, M. Spectroscopic Methods for Pollution Analysis—Course Development and Delivery Using the Integrated Course Design Framework. J. Chem. Educ. 2023, 100, 3516–3525. [Google Scholar] [CrossRef]

- Meher, A.K.; Zarouri, A. Green Analytical Chemistry—Recent Innovations. Analytica 2025, 6, 10. [Google Scholar] [CrossRef]

- Mishra, A.; Aghaee, M.; Tamer, I.M.; Budman, H. Spectroscopic Advances in Real Time Monitoring of Pharmaceutical Bioprocesses: A Review of Vibrational and Fluorescence Techniques. Spectrosc. J. 2025, 3, 12. [Google Scholar] [CrossRef]

- Singh, S. Analytical Control Strategies for Process Chemists. Org. Process Res. Dev. 2025, 29, 209–211. [Google Scholar] [CrossRef]

- Anastas, P.; Eghbali, N. Green Chemistry: Principles and Practice. Chem. Soc. Rev. 2009, 39, 301–312. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.Y.; Li, X.; Du, K.F.; Yao, S.; Song, H. Conjugated Linoleic Acid Production by Alkali Isomerization of Linoleic Acid from Idesia Polycarpa Maxim. Var. Vestita Diels Oil. Asian J. Chem. 2013, 25, 3744–3748. [Google Scholar] [CrossRef]

- Yang, B.; Gao, H.; Stanton, C.; Ross, R.P.; Zhang, H.; Chen, Y.Q.; Chen, H.; Chen, W. Bacterial Conjugated Linoleic Acid Production and Their Applications. Prog. Lipid Res. 2017, 68, 26–36. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.D. Green Chemistry in Daily Life. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 70–73. [Google Scholar] [CrossRef]

- Mitarlis, M.; Azizah, U.; Yonata, B. Alternative Lesson Design of Basic Chemistry Learning to Integrate Green Chemistry Principles as View of Scientific Character Values. Proc. Semin. Nas. Kim. Natl. Semin. Chem. 2018, 171, 159–163. [Google Scholar] [CrossRef]

- Huarong, W.; Surif, J. Global Trends and Influences in Green Chemistry Education: A Comprehensive Review of Contributions (2014–2024). Int. J. Acad. Res. Prog. Educ. Dev. 2024, 13, 2281–2291. [Google Scholar] [CrossRef] [PubMed]

- Reisenbauer, J.C.; Sicinski, K.M.; Arnold, F.H. Catalyzing the Future: Recent Advances in Chemical Synthesis Using Enzymes. Curr. Opin. Chem. Biol. 2024, 83, 102536. [Google Scholar] [CrossRef] [PubMed]

- Masci, D.; Castagnolo, D. CHAPTER 4: Biocatalysis, an Introduction. Exploiting Enzymes as Green Catalysts in the Synthesis of Chemicals and Drugs. In Sustainable Organic Synthesis: Tools and Strategies; Royal Society of Chemistry: London, UK, 2021; pp. 68–118. [Google Scholar] [CrossRef]

- Usman, M.; Cheng, S.; Boonyubol, S.; Cross, J.S. Evaluating Green Solvents for Bio-Oil Extraction: Advancements, Challenges, and Future Perspectives. Energies 2023, 16, 5852. [Google Scholar] [CrossRef]

- Kaya, S.I.; Cetinkaya, A.; Ozkan, S.A. Green Analytical Chemistry Approaches on Environmental Analysis. Trends Environ. Anal. Chem. 2022, 33, e00157. [Google Scholar] [CrossRef]

- Ahmad, S.; Jaiswal, R.; Yadav, R.; Verma, S. Recent Advances in Green Chemistry Approaches for Pharmaceutical Synthesis. Sustain. Chem. One World 2024, 4, 100029. [Google Scholar] [CrossRef]

- Kar, S.; Sanderson, H.; Roy, K.; Benfenati, E.; Leszczynski, J. Green Chemistry in the Synthesis of Pharmaceuticals. Chem. Rev. 2022, 122, 3637–3710. [Google Scholar] [CrossRef] [PubMed]

- Chafran, L.; Matias, A.E.; Silva, L.P. Green Catalysts in the Synthesis of Biopolymers and Biomaterials. ChemistrySelect 2022, 7, e202201276. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, H.; Shi, H.; Wang, F.; Li, X. Green Synthesis of Conjugated Linoleic Acids from Plant Oils Using a Novel Synergistic Catalytic System. J. Agric. Food Chem. 2017, 65, 5322–5329. [Google Scholar] [CrossRef] [PubMed]

- Benjamin, S.; Spener, F. Conjugated Linoleic Acids as Functional Food: An Insight into Their Health Benefits. Nutr Metab 2009, 6, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yu, B.; Wang, Z.; Hu, J.; Fu, M.; Wang, Y.; Liu, J.; Guo, Z.; Xu, X.; Ding, Y. Highly Selective Isomerization of Cottonseed Oil into Conjugated Linoleic Acid Catalyzed by Multiwalled Carbon Nanotube Supported Ruthenium. RSC Adv. 2019, 9, 20698–20705. [Google Scholar] [CrossRef] [PubMed]

- Aouf, C.; Durand, E.; Lecomte, J.; Figueroa-Espinoza, M.C.; Dubreucq, E.; Fulcrand, H.; Villeneuve, P. The Use of Lipases as Biocatalysts for the Epoxidation of Fatty Acids and Phenolic Compounds. Green Chem. 2014, 16, 1740–1754. [Google Scholar] [CrossRef]

- Ali, S.; Khan, S.A.; Hamayun, M.; Lee, I.J. The Recent Advances in the Utility of Microbial Lipases: A Review. Microorganisms 2023, 11, 510. [Google Scholar] [CrossRef] [PubMed]

- Pahl, A. Lipoxygenase. In xPharm: The Comprehensive Pharmacology Reference; Enna, S.J., Bylund, D.B., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 1–7. [Google Scholar] [CrossRef]

- Ahrari, F.; Mohammadi, M. Combined Cross-Linking of Rhizomucor Miehei Lipase and Candida Antarctica Lipase B for the Effective Enrichment of Omega-3 Fatty Acids in Fish Oil. Int. J. Biol. Macromol. 2024, 260, 129362. [Google Scholar] [CrossRef] [PubMed]

- Freitas, L.; Perez, V.H.; Santos, J.C.; De Castro, H.F. Enzymatic Synthesis of Glyceride Esters in Solvent-Free System: Influence of the Molar Ratio, Lipase Source and Functional Activating Agent of the Support. J. Braz. Chem. Soc. 2007, 18, 1360–1366. [Google Scholar] [CrossRef]

- Gardner, H.W. Soybean Lipoxygenase-1 Enzymically Forms Both (9S)- and (13S)-Hydroperoxides from Linoleic Acid by a PH-Dependent Mechanism. BBA 1989, 1001, 274–281. [Google Scholar] [CrossRef] [PubMed]

- Alsalem, M.; Wong, A.; Millns, P.; Arya, P.H.; Chan, M.S.L.; Bennett, A.; Barrett, D.A.; Chapman, V.; Kendall, D.A. The Contribution of the Endogenous TRPV1 Ligands 9-HODE and 13-HODE to Nociceptive Processing and Their Role in Peripheral Inflammatory Pain Mechanisms. Br. J. Pharmacol. 2013, 168, 1961–1974. [Google Scholar] [CrossRef] [PubMed]

- Iorizzo, M.; Di Martino, C.; Letizia, F.; Crawford, T.W.; Paventi, G. Production of Conjugated Linoleic Acid (CLA) by Lactiplantibacillus Plantarum: A Review with Emphasis on Fermented Foods. Foods 2024, 13, 975. [Google Scholar] [CrossRef] [PubMed]

- Elnar, A.G.; Jang, Y.; Kim, G.B. Heterologous Expression and Polyphasic Analysis of CLA-Converting Linoleic Acid Isomerase from Bifidobacterium Breve JKL2022. J. Agric. Food Chem. 2024, 73, 1425–1440. [Google Scholar] [CrossRef] [PubMed]

- Melchiorre, M.; Cucciolito, M.E.; Di Serio, M.; Ruffo, F.; Tarallo, O.; Trifuoggi, M.; Esposito, R. Homogeneous Catalysis and Heterogeneous Recycling: A Simple Zn(II) Catalyst for Green Fatty Acid Esterification. ACS Sustain. Chem. Eng. 2021, 9, 6001–6011. [Google Scholar] [CrossRef] [PubMed]

- Sudarsanam, P.; Zhong, R.; Van Den Bosch, S.; Coman, S.M.; Parvulescu, V.I.; Sels, B.F. Functionalised Heterogeneous Catalysts for Sustainable Biomass Valorisation. Chem. Soc. Rev. 2018, 47, 8349–8402. [Google Scholar] [CrossRef] [PubMed]

- McPherson, P.A.C.; Boyle, P.M.; Türemen, B.T. Mechanism for the Enhanced Peroxidation of Linoleic Acid by a Titanium Dioxide/Hypochlorite System. Biochem. Biophys. Res. Commun. 2013, 430, 78–83. [Google Scholar] [CrossRef] [PubMed]

- Luna, F.M.T.; Cecilia, J.A.; Saboya, R.M.A.; Barrera, D.; Sapag, K.; Rodríguez-Castellón, E.; Cavalcante, C.L. Natural and Modified Montmorillonite Clays as Catalysts for Synthesis of Biolubricants. Materials 2018, 11, 1764. [Google Scholar] [CrossRef] [PubMed]

- Vrbková, E.; Šímová, A.; Vyskočilová, E.; Lhotka, M.; Červený, L. Acid Treated Montmorillonite—Eco-Friendly Clay as Catalyst in Carvone Isomerization to Carvacrol. Reactions 2021, 2, 486–498. [Google Scholar] [CrossRef]

- Yamada, Y.M.A.; Baek, H.; Sato, T.; Nakao, A.; Uozumi, Y. Metallically Gradated Silicon Nanowire and Palladium Nanoparticle Composites as Robust Hydrogenation Catalysts. Commun. Chem. 2020, 3, 81. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Liang, S.; Zhang, T.; Zhang, M.; Fang, H.; Tian, J.; Liu, J.; Peng, Y.; Zheng, L.; Wang, B.; et al. Surface Modification of Gold Nanoparticle Impacts Distinct Lipid Metabolism. Molecules 2025, 30, 1727. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, G.R.; Sreekumar, K. Supported and Reusable Organocatalysts. In New and Future Developments in Catalysis: Hybrid Materials and Composites, Organocatalysis; Series Editor: Smith, J.; Volume Editor: Dalko, P.I.; Wiley-VCH: Weinheim, Germany, 2013; pp. 343–364. [Google Scholar] [CrossRef]

- Cao, J.; Qi, B.; Liu, J.; Shang, Y.; Liu, H.; Wang, W.; Lv, J.; Chen, Z.; Zhang, H.; Zhou, X. Deep Eutectic Solvent Choline Chloride·2CrCl3·6H2O: An Efficient Catalyst for Esterification of Formic and Acetic Acid at Room Temperature. RSC Adv. 2016, 6, 21612–21616. [Google Scholar] [CrossRef]

- Pinho, M.R.; Lima, A.S.; de Almeida Ribeiro Oliveira, G.; Liao, L.M.; Franceschi, E.; da Silva, R.; Cardozo-Filho, L. Choline Chloride- and Organic Acids-Based Deep Eutectic Solvents: Exploring Chemical and Thermophysical Properties. J. Chem. Eng. Data 2024, 69, 3403–3414. [Google Scholar] [CrossRef]

- Thorat, B.R.; Mali, S.N.; Wavhal, S.S.; Bhagat, D.S.; Borade, R.M.; Chapolikar, A.; Gandhi, A.; Shinde, P. L-Proline: A Versatile Organo-Catalyst in Organic Chemistry. Comb. Chem. High. Throughput Screen. 2022, 26, 1108–1140. [Google Scholar] [CrossRef] [PubMed]

- Melgosa, R.; Teresa Sanz, M.; Solaesa, Á.G.; De Paz, E.; Beltrán, S.; Lamas, D.L. Supercritical Carbon Dioxide as Solvent in the Lipase-Catalyzed Ethanolysis of Fish Oil: Kinetic Study. J. CO2 Util. 2017, 17, 170–179. [Google Scholar] [CrossRef]

- Singhania, V.; Cortes-Clerget, M.; Dussart-Gautheret, J.; Akkachairin, B.; Yu, J.; Akporji, N.; Gallou, F.; Lipshutz, B.H. Lipase-Catalyzed Esterification in Water Enabled by Nanomicelles. Applications to 1-Pot Multi-Step Sequences. Chem. Sci. 2022, 13, 1440–1445. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Fang, Y.; Yang, J.; Chen, H.; Yang, B.; Wang, Y. A Green and Efficient Two-Step Enzymatic Esterification-Hydrolysis Method for Enrichment of C9,T11-CLA Isomer Based on a Three-Liquid-Phase System. RSC Adv. 2023, 13, 26690–26699. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, R.S.B.; Ferreira, A.M.; Coutinho, J.A.P.; Eduardo, E.A. Stability of Cholinium Chloride-Based Deep Eutectic Solvents with Carboxylic Acids: A Study on Ester Formation. ACS Sustain. Chem. Eng. 2024, 12, 15893–15900. [Google Scholar] [CrossRef]

- Lee, J.; Marrocchi, A. Advances in Green Chemistry and Engineering. Sci. Rep. 2024, 14, 1–3. [Google Scholar] [CrossRef] [PubMed]

- Eynde, V.; Das, A.; Banik, B.K. Microwave-Assisted Enzymatic Reactions toward Medicinally Active Heterocycles. Drugs Drug Candid. 2024, 3, 638–653. [Google Scholar] [CrossRef]

- Silva-Ramírez, A.S.; Rocha-Uribe, A.; González-Chávez, M.M.; González, C. Synthesis of Conjugated Linoleic Acid by Microwave-Assisted Alkali Isomerization Using Propylene Glycol as Solvent. Eur. J. Lipid Sci. Technol. 2017, 119, 1600079. [Google Scholar] [CrossRef]

- Yasvanthrajan, N.; Sivakumar, P.; Muthukumar, K. Ultrasound Assisted Lipase Catalysed Transesterification Using Waste Cottonseed Oil. J. Taiwan Inst. Chem. Eng. 2025, 106076. [Google Scholar] [CrossRef]

- Hartman, R.L. Flow Chemistry Remains an Opportunity for Chemists and Chemical Engineers. Curr. Opin. Chem. Eng. 2020, 29, 42–50. [Google Scholar] [CrossRef]

- Kumari, S.; Raturi, S.; Kulshrestha, S.; Chauhan, K.; Dhingra, S.; András, K.; Thu, K.; Khargotra, R.; Singh, T. A Comprehensive Review on Various Techniques Used for Synthesizing Nanoparticles. J. Mater. Res. Technol. 2023, 27, 1739–1763. [Google Scholar] [CrossRef]

- Atanasov, A.G.; Waltenberger, B.; Pferschy-Wenzig, E.M.; Linder, T.; Wawrosch, C.; Uhrin, P.; Temml, V.; Wang, L.; Schwaiger, S.; Heiss, E.H.; et al. Discovery and Resupply of Pharmacologically Active Plant-Derived Natural Products: A Review. Biotechnol. Adv. 2015, 33, 1582–1614. [Google Scholar] [CrossRef] [PubMed]

- Banjara, R.A.; Kumar, A.; Aneshwari, R.K.; Satnami, M.L.; Sinha, S.K. A Comparative Analysis of Chemical vs Green Synthesis of Nanoparticles and Their Various Applications. Environ. Nanotechnol. Monit. Manag. 2024, 22, 100988. [Google Scholar] [CrossRef]

- Taylor, C.J.; Pomberger, A.; Felton, K.C.; Grainger, R.; Barecka, M.; Chamberlain, T.W.; Bourne, R.A.; Johnson, C.N.; Lapkin, A.A. A Brief Introduction to Chemical Reaction Optimization. Chem. Rev. 2023, 123, 3089–3126. [Google Scholar] [CrossRef] [PubMed]

- Vishwanath, R.; Negi, B. Conventional and Green Methods of Synthesis of Silver Nanoparticles and Their Antimicrobial Properties. Current Res. Green Sustain. Chem. 2021, 4, 100205. [Google Scholar] [CrossRef]

- Wu, S.; Snajdrova, R.; Moore, J.C.; Baldenius, K.; Bornscheuer, U.T. Biocatalysis: Enzymatic Synthesis for Industrial Applications. Angew. Chem. Int. Ed. 2021, 60, 88–119. [Google Scholar] [CrossRef] [PubMed]

- van Schie, M.M.C.H.; Spöring, J.D.; Bocola, M.; Domínguez de María, P.; Rother, D. Applied Biocatalysis beyond Just Buffers—From Aqueous to Unconventional Media. Options and Guidelines. Green Chem. 2021, 23, 3191–3206. [Google Scholar] [CrossRef] [PubMed]

- Reetz, M.T. What Are the Limitations of Enzymes in Synthetic Organic Chemistry? Chem. Rec. 2016, 16, 2449–2459. [Google Scholar] [CrossRef] [PubMed]

- Bernas, A.; Kumar, N.; Mäki-Arvela, P.; Kul’kova, N.V.; Holmbom, B.; Salmi, T.; Murzin, D.Y. Isomerization of Linoleic Acid over Supported Metal Catalysts. Appl. Catal. A Gen. 2003, 245, 257–275. [Google Scholar] [CrossRef]

- Asif, M. Green synthesis, green chemistry, and environmental sustainability. Green Chem. Technol. Lett. 2021, 7, 18–27. [Google Scholar] [CrossRef]

- Yang, T.-S.; Liu, T.-T. Optimization of production of conjugated linoleic acid from soybean oil. J. Agric. Food Chem. 2004, 52, 5079–5084. [Google Scholar] [CrossRef] [PubMed]

- Mäki-Arvela, P.; Kuusisto, J.; Sevilla, E.M.; Simakova, I.; Mikkola, J.P.; Myllyoja, J.; Salmi, T.; Murzin, D.Y. Catalytic Hydrogenation of Linoleic Acid to Stearic Acid over Different Pd- and Ru-Supported Catalysts. Appl. Catal. A Gen. 2008, 345, 201–212. [Google Scholar] [CrossRef]

- Mahadi, M.B.; Azmi, I.S.; Ahmad, M.A.; Rahim, N.H.; Jalil, M.J. Catalytic Epoxidation of Sunflower Oil Derived by Linoleic Acid via in Situ Peracid Mechanism. Biomass Convers. Biorefin 2024, 15, 9505–9512. [Google Scholar] [CrossRef]

- Lewandowski, G.; Musik, M.; Malarczyk-Matusiak, K.; Sałaciński, Ł.; Milchert, E. Epoxidation of Vegetable Oils, Unsaturated Fatty Acids and Fatty Acid Esters: A Review. Mini Rev. Org. Chem. 2020, 17, 412–422. [Google Scholar] [CrossRef]

- Varghese, N.K.; Mkrtchian, E.; Singh, A.; Savio, L.; Boccia, M.; Marzocchi, V.; Comite, A. NiFe on CeO2, TiO2, and ZrO2 Supports as Efficient Oxygen Evolution Reaction Catalysts in Alkaline Media. ACS Appl. Energy Mater. 2025, 8, 3087–3095. [Google Scholar] [CrossRef] [PubMed]

- Marchetti, J.M.; Errazu, A.F. Esterification of Free Fatty Acids Using Sulfuric Acid as Catalyst in the Presence of Triglycerides. Biomass Bioenergy 2008, 32, 892–895. [Google Scholar] [CrossRef]

- Murrieta, C.M.; Hess, B.W.; Rule, D.C. Comparison of Acidic and Alkaline Catalysts for Preparation of Fatty Acid Methyl Esters from Ovine Muscle with Emphasis on Conjugated Linoleic Acid. Meat Sci. 2003, 65, 523–529. [Google Scholar] [CrossRef] [PubMed]

- de Regil, R.; Sandoval, G. Biocatalysis for Biobased Chemicals. Biomolecules 2013, 3, 812–847. [Google Scholar] [CrossRef] [PubMed]

- Nasrollahzadeh, A.; Mollaei Tavani, S.; Arjeh, E.; Jafari, S.M. Production of Conjugated Linoleic Acid by Lactic Acid Bacteria; Important Factors and Optimum Conditions. Food Chem. X 2023, 20, 100942. [Google Scholar] [CrossRef] [PubMed]

- Piazza, G.J.; Nuñez, A.; Foglia, T.A. Epoxidation of Fatty Acids, Fatty Methyl Esters, and Alkenes by Immobilized Oat Seed Peroxygenase. J. Mol. Catal. B Enzym. 2003, 21, 143–151. [Google Scholar] [CrossRef]

- Municoy, M.; González-Benjumea, A.; Carro, J.; Aranda, C.; Linde, D.; Renau-Mínguez, C.; Ullrich, R.; Hofrichter, M.; Guallar, V.; Gutiérrez, A.; et al. Fatty-Acid Oxygenation by Fungal Peroxygenases: From Computational Simulations to Preparative Regio: From Stereoselective Epoxidation. ACS Catal. 2020, 10, 13584–13595. [Google Scholar] [CrossRef]

- Kirk, O.; Christensen, M.W. Lipases from Candida Antarctica: Unique Biocatalysts from a Unique Origin. Org. Process Res. Dev. 2002, 6, 446–451. [Google Scholar] [CrossRef]

- Ortega-Requena, S.; Montiel, C.; Máximo, F.; Gómez, M.; Murcia, M.D.; Bastida, J. Esters in the Food and Cosmetic Industries: An Overview of the Reactors Used in Their Biocatalytic Synthesis. Materials 2024, 17, 268. [Google Scholar] [CrossRef] [PubMed]

- Kurul, F.; Doruk, B.; Topkaya, S.N. Principles of Green Chemistry: Building a Sustainable Future. Discov. Chem. 2025, 2, 68. [Google Scholar] [CrossRef]

- Hu, N.J.; Li, S.Y.; Liu, Y.C. Recent Advances in Biocatalysis and Metabolic Engineering. Catalysts 2021, 11, 1052. [Google Scholar] [CrossRef]

- Dror, A.; Shemesh, E.; Dayan, N.; Fishman, A. Protein Engineering by Random Mutagenesis and Structure-Guided Consensus of Geobacillus Stearothermophilus Lipase T6 for Enhanced Stability in Methanol. Appl. Environ. Microbiol. 2014, 80, 1515–1527. [Google Scholar] [CrossRef] [PubMed]

- Guan, A.; Hou, Y.; Yang, R.; Qin, J. Enzyme Engineering for Functional Lipids Synthesis: Recent Advance and Perspective. Bioresour. Bioprocess. 2024, 11, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Davis, H.J.; Ward, T.R. Artificial Metalloenzymes: Challenges and Opportunities. ACS Cent. Sci. 2019, 5, 1120–1136. [Google Scholar] [CrossRef] [PubMed]

- Muñoz Robles, V.; Ortega-Carrasco, E.; Alonso-Cotchico, L.; Rodriguez-Guerra, J.; Lledós, A.; Maréchal, J.D. Toward the Computational Design of Artificial Metalloenzymes: From Protein-Ligand Docking to Multiscale Approaches. ACS Catal. 2015, 5, 2469–2480. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, S.; Dong, M.; Fan, W. CO2 Hydrogenation on Metal-Organic Frameworks-Based Catalysts: A Mini Review. Front. Chem. 2022, 10, 956223. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.G.; Bigdeli, F.; Panjehpour, A.; Larimi, A.; Morsali, A.; Dhakshinamoorthy, A.; Garcia, H. Metal Organic Framework Composites for Reduction of CO2. Coord. Chem. Rev. 2023, 493, 215257. [Google Scholar] [CrossRef]

- Kushnarenko, A.; Zabelina, A.; Guselnikova, O.; Miliutina, E.; Vokatá, B.; Zabelin, D.; Burtsev, V.; Valiev, R.; Kolska, Z.; Paidar, M.; et al. Merging Gold Plasmonic Nanoparticles and L-Proline inside a MOF for Plasmon-Induced Visible Light Chiral Organocatalysis at Low Temperature. Nanoscale 2024, 16, 5313–5322. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Huang, S.; Huang, X.; Ma, D. Enhanced Photocatalysis of Metal/Covalent Organic Frameworks by Plasmonic Nanoparticles and Homo/Hetero-Junctions. Mater. Horiz. 2024, 11, 1611–1637. [Google Scholar] [CrossRef] [PubMed]

- Di Gioia, M.L.; Duarte, A.R.C.; Gawande, M.B. Editorial: Advances in the Development and Application of Deep Eutectic Solvents. Front. Chem. 2023, 11, 1258718. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Hu, X.; Zhang, D.; Zhang, Y.; Xu, H.; Sun, Y.; Gu, X.; Luo, J.; Gao, B. Environmental Applications and Toxicity of Ionic Liquids. J. Environ. Chem. Eng. 2024, 12, 114638. [Google Scholar] [CrossRef]

- Wagle, D.V.; Zhao, H.; Baker, G.A. Deep Eutectic Solvents: Sustainable Media for Nanoscale and Functional Materials. Acc. Chem. Res. 2014, 47, 2299–2308. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Xu, W.; Pan, Y.; Wang, F.; Hu, X.; Lu, Y.; Jiang, M. Deep Eutectic-like Solvents: Promising Green Media for Biomass Treatment and Preparation of Nanomaterials. Bioresources 2022, 17, 5485–5509. [Google Scholar] [CrossRef]

- Sugiarto, S.; Aloka Weerasinghe, U.; Kinyanjui Muiruri, J.; Yu Qing Chai, A.; Chee Chuan Yeo, J.; Wang, G.; Zhu, Q.; Jun Loh, X.; Li, Z.; Kai, D. Nanomaterial Synthesis in Deep Eutectic Solvents. Chem. Eng. J. 2024, 499, 156177. [Google Scholar] [CrossRef]

- Isambert, N.; Del Mar Sanchez Duque, M.; Plaquevent, J.C.; Génisson, Y.; Rodriguez, J.; Constantieux, T. Multicomponent Reactions and Ionic Liquids: A Perfect Synergy for Eco-Compatible Heterocyclic Synthesis. Chem. Soc. Rev. 2011, 40, 1347–1357. [Google Scholar] [CrossRef] [PubMed]

- Shirini, F.; Rad-Moghadam, K.; Akbari-Dadamahaleh, S. Application of Ionic Liquids in Multicomponent Reactions. In Green Solvents II: Properties and Applications of Ionic Liquids; Mohammad, A., Inamuddin, D., Eds.; Springer: Dordrecht, The Netherlands, 2012; pp. 289–334. [Google Scholar] [CrossRef]

- Li, H.; Bhadury, P.S.; Song, B.; Yang, S. Immobilized Functional Ionic Liquids: Efficient, Green, and Reusable Catalysts. RSC Adv. 2012, 2, 12525–12551. [Google Scholar] [CrossRef]

- Do, J.L.; Friščić, T. Mechanochemistry: A Force of Synthesis. ACS Cent. Sci. 2017, 3, 13–19. [Google Scholar] [CrossRef] [PubMed]

- Achar, T.K.; Bose, A.; Mal, P. Mechanochemical Synthesis of Small Organic Molecules. Beilstein J. Org. Chem. 2017, 13, 1907–1931. [Google Scholar] [CrossRef] [PubMed]

- Reynes, J.F.; Leon, F.; García, F. Mechanochemistry for Organic and Inorganic Synthesis. ACS Org. Inorg. Au 2024. [Google Scholar] [CrossRef] [PubMed]

- Kubota, K.; Ito, H. Mechanochemical Cross-Coupling Reactions. Trends Chem. 2020, 2, 1066–1081. [Google Scholar] [CrossRef]

- Krusenbaum, A.; Grätz, S.; Tigineh, G.T.; Borchardt, L.; Kim, J.G. The Mechanochemical Synthesis of Polymers. Chem. Soc. Rev. 2022, 51, 2873–2905. [Google Scholar] [CrossRef] [PubMed]

- Kuppusamy, P.; Yusoff, M.M.; Maniam, G.P.; Govindan, N. Biosynthesis of Metallic Nanoparticles Using Plant Derivatives and Their New Avenues in Pharmacological Applications—An Updated Report. Saudi Pharm. J. 2016, 24, 473–484. [Google Scholar] [CrossRef] [PubMed]

- Sorbiun, M.; Shayegan Mehr, E.; Ramazani, A.; Mashhadi Malekzadeh, A. Biosynthesis of Metallic Nanoparticles Using Plant Extracts and Evaluation of Their Antibacterial Properties. Nanochem Res. 2018, 3, 1–16. [Google Scholar] [CrossRef]

- Padilla-Cruz, A.L.; Garza-Cervantes, J.A.; Vasto-Anzaldo, X.G.; García-Rivas, G.; León-Buitimea, A.; Morones-Ramírez, J.R. Synthesis and Design of Ag–Fe Bimetallic Nanoparticles as Antimicrobial Synergistic Combination Therapies against Clinically Relevant Pathogens. Sci. Rep. 2021, 11, 5351. [Google Scholar] [CrossRef] [PubMed]

- Gwada, C.A.; Ndivhuwo, P.S.; Matshetshe, K.; Aradi, E.; Mdluli, P.; Moloto, N.; Otieno, F.; Airo, M. Phytochemical-Assisted Synthesis, Optimization, and Characterization of Silver Nanoparticles for Antimicrobial Activity. RSC Adv. 2025, 15, 14170–14181. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Srinivas, S.P.; Kumawat, M.; Daima, H.K. Ligand-Based Surface Engineering of Nanomaterials: Trends, Challenges, and Biomedical Perspectives. OpenNano 2024, 15, 100194. [Google Scholar] [CrossRef]

- Macuvele, D.L.P.; Riella, H.G.; Padoin, N.; Soares, C. Eco-Friendly and Green Synthesis of Carbon Nanostructures. In Handbook of Functionalized Carbon Nanostructures; Barhoum, A., Deshmukh, K., Eds.; Springer: Cham, Switzerland, 2024; pp. 789–821. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Svetlichnyi, V.A.; Mintcheva, N.; Pawelski, D.; Plonska-Brzezinska, M.E. Microwave-Assisted Synthesis as a Promising Tool for the Preparation of Materials Containing Defective Carbon Nanostructures: Implications on Properties and Applications. Materials 2023, 16, 6549. [Google Scholar] [CrossRef] [PubMed]

- Sani, M.N.H.; Amin, M.; Siddique, A.B.; Nasif, S.O.; Ghaley, B.B.; Ge, L.; Wang, F.; Yong, J.W.H. Waste-Derived Nanobiochar: A New Avenue towards Sustainable Agriculture, Environment, and Circular Bioeconomy. Sci. Total Environ. 2023, 905, 166881. [Google Scholar] [CrossRef] [PubMed]

- Laishram, D.; Kim, S.B.; Lee, S.Y.; Park, S.J. Advancements in Biochar as a Sustainable Adsorbent for Water Pollution Mitigation. Adv. Sci. 2025, 12, 2410383. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Zhang, Y.; Zhou, Y.; Nie, Y.; Ban, L.; Wu, D.; Yang, S.; Zhang, H.; Li, C.; Zhang, K. Photocatalytic and Electrochemical Synthesis of Biofuel via Efficient Valorization of Biomass. Adv. Energy Mater. 2025, 15, 2406098. [Google Scholar] [CrossRef]

- Akhade, S.A.; Singh, N.; Gutierrez, O.Y.; Lopez-Ruiz, J.; Wang, H.; Holladay, J.D.; Liu, Y.; Karkamkar, A.; Weber, R.S.; Padmaperuma, A.B.; et al. Electrocatalytic Hydrogenation of Biomass-Derived Organics: A Review. Chem. Rev. 2020, 120, 11370–11419. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Liu, Y.; Lei, A. Electrochemical Oxidative Cross-Coupling with Hydrogen Evolution: A Green and Sustainable Way for Bond Formation. Chem 2018, 4, 27–45. [Google Scholar] [CrossRef]

- Adhikari, A.; Bhakta, S.; Ghosh, T. Microwave-Assisted Synthesis of Bioactive Heterocycles: An Overview. Tetrahedron 2022, 126, 133085. [Google Scholar] [CrossRef]

- Javahershenas, R.; Makarem, A.; Klika, K.D. Recent Advances in Microwave-Assisted Multicomponent Synthesis of Spiro Heterocycles. RSC Adv. 2024, 14, 5547–5565. [Google Scholar] [CrossRef] [PubMed]

- Patil, N.G.; Hermans, A.I.G.; Benaskar, F.; Meuldijk, J.A.; Hulshof, L.; Hessel, V.; Schouten, J.C.; Rebrov, E.V. Energy Efficient and Controlled Flow Processing under Microwave Heating by Using a Millireactor–Heat Exchanger. AIChE J. 2012, 58, 3144–3155. [Google Scholar] [CrossRef]

- Benítez, M.; Rodríguez-Carrillo, C.; Sánchez-Artero, S.; El Haskouri, J.; Amorós, P.; Ros-Lis, J.V. Scaled-up Microwave-Assisted Batch and Flow Synthesis and Life Cycle Assessment of a Silica Mesoporous Material: UVM-7. Green Chem. 2024, 26, 785–793. [Google Scholar] [CrossRef]

- Viladomiu, M.; Hontecillas, R.; Bassaganya-Riera, J. Modulation of Inflammation and Immunity by Dietary Conjugated Linoleic Acid. Eur. J. Pharmacol. 2016, 785, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Kelley, N.S.; Hubbard, N.E.; Erickson, K.L. Conjugated Linoleic Acid Isomers and Cancer. J. Nutr. 2007, 137, 2599–2607. [Google Scholar] [CrossRef] [PubMed]

- Sugano, M.; Tsujita, A.; Yamasaki, M.; Noguchi, M.; Yamada, K. Conjugated Linoleic Acid Modulates Tissue Levels of Chemical Mediators and Immunoglobulins in Rats. Lipids 1998, 33, 521–527. [Google Scholar] [CrossRef] [PubMed]

- Aryaeian, N.; Djalali, M.; Shahram, F.; Djazayery, A.; Eshragian, M.R. Effect of Conjugated Linoleic Acid, Vitamin E, Alone or Combined on Immunity and Inflammatory Parameters in Adults with Active Rheumatoid Arthritis: A Randomized Controlled Trial. Int. J. Prev. Med. 2014, 5, 1567. [Google Scholar] [PubMed]

- Lin, G.; Wang, H.; Dai, J.; Li, X.; Guan, M.; Gao, S.; Ding, Q.; Wang, H.; Fang, H. Conjugated Linoleic Acid Prevents Age-Induced Bone Loss in Mice by Regulating Both Osteoblastogenesis and Adipogenesis. Biochem. Biophys. Res. Commun. 2017, 490, 813–820. [Google Scholar] [CrossRef] [PubMed]

- Abdulrahman, S.J.; Abdulhadi, M.A.; Turki Jalil, A.; Falah, D.; Merza, M.S.; Almulla, A.F.; Ali, A.; Ali, R.T. Conjugated Linoleic Acid and Glucosamine Supplements May Prevent Bone Loss in Aging by Regulating the RANKL/RANK/OPG Pathway. Mol. Biol. Rep. 2023, 50, 10579–10588. [Google Scholar] [CrossRef] [PubMed]

- Shan, Z.; Zhao, Y.; Qiu, Z.; Angxiu, S.; Gu, Y.; Luo, J.; Bi, H.; Luo, W.; Xiong, R.; Ma, S.; et al. Conjugated Linoleic Acid Prompts Bone Formation in Ovariectomized Osteoporotic Rats and Weakens Osteoclast Formation after Treatment with Ultraviolet B. Ann. Transl. Med. 2021, 9, 503. [Google Scholar] [CrossRef] [PubMed]

- Chaplin, A.; Palou, A.; Serra, F. Body Fat Loss Induced by Calcium in Co-Supplementation with Conjugated Linoleic Acid Is Associated with Increased Expression of Bone Formation Genes in Adult Mice. J. Nutr. Biochem. 2015, 26, 1540–1546. [Google Scholar] [CrossRef] [PubMed]

- DeGuire, J.R.; Mak, I.L.; Lavery, P.; Agellon, S.; Wykes, L.J.; Weiler, H.A. Orchidectomy-Induced Alterations in Volumetric Bone Density, Cortical Porosity and Strength of Femur Are Attenuated by Dietary Conjugated Linoleic Acid in Aged Guinea Pigs. Bone 2015, 73, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Kim, Y.J.; Park, Y. Conjugated Linoleic Acid and Postmenopausal Women’s Health. J. Food Sci. 2015, 80, R1137–R1143. [Google Scholar] [CrossRef] [PubMed]

- Huebner, S.M.; Olson, J.M.; Campbell, J.P.; Bishop, J.W.; Crump, P.M.; Cook, M.E. Low Dietary C9t11-Conjugated Linoleic Acid Intake from Dairy Fat or Supplements Reduces Inflammation in Collagen-Induced Arthritis. Lipids 2016, 51, 807–819. [Google Scholar] [CrossRef] [PubMed]

- Olson, J.M.; Haas, A.W.; Lor, J.; McKee, H.S.; Cook, M.E. A Comparison of the Anti-Inflammatory Effects of Cis-9, Trans-11 Conjugated Linoleic Acid to Celecoxib in the Collagen-Induced Arthritis Model. Lipids 2017, 52, 151–159. [Google Scholar] [CrossRef] [PubMed]

- Muhlenbeck, J.A.; Olson, J.M.; Hughes, A.B.; Cook, M.E. Conjugated Linoleic Acid Isomers Trans-10, Cis-12 and Cis-9, Trans-11 Prevent Collagen-Induced Arthritis in a Direct Comparison. Lipids 2018, 53, 689–698. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Wang, S.; Li, J. Treatment of Inflammatory Bowel Disease: A Comprehensive Review. Front. Med. 2021, 8, 765474. [Google Scholar] [CrossRef] [PubMed]

- Bassaganya-Riera, J.; Reynolds, K.; Martino-Catt, S.; Cui, Y.; Hennighausen, L.; Gonzalez, F.; Rohrer, J.; Benninghoff, A.U.; Hontecillas, R. Activation of PPAR γ and δ by Conjugated Linoleic Acid Mediates Protection from Experimental Inflammatory Bowel Disease. Gastroenterology 2004, 127, 777–791. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.K.; Sheppard, D.; Chapman, H.A. TGF-Β1 Signaling and Tissue Fibrosis. Cold Spring Harb. Perspect. Biol. 2018, 10, a022293. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Chen, H.; Ding, J.; Stanton, C.; Ross, R.P.; Zhao, J.; Zhang, H.; Yang, B.; Chen, W. Bifidobacterium Longum Ameliorates Dextran Sulfate Sodium-Induced Colitis by Producing Conjugated Linoleic Acid, Protecting Intestinal Mechanical Barrier, Restoring Unbalanced Gut Microbiota, and Regulating the Toll-Like Receptor-4/Nuclear Factor-ΚB Signaling Pathway. J. Agric. Food Chem. 2021, 69, 14593–14608. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Chen, H.; Gao, H.; Wang, J.; Stanton, C.; Ross, R.P.; Zhang, H.; Chen, W. Bifidobacterium Breve CCFM683 Could Ameliorate DSS-Induced Colitis in Mice Primarily via Conjugated Linoleic Acid Production and Gut Microbiota Modulation. J. Funct. Foods 2018, 49, 61–72. [Google Scholar] [CrossRef]

- Bassaganya-Riera, J.; Hontecillas, R.; Horne, W.T.; Sandridge, M.; Herfarth, H.H.; Bloomfeld, R.; Isaacs, K.L. Conjugated Linoleic Acid Modulates Immune Responses in Patients with Mild to Moderately Active Crohn’s Disease. Clin. Nutr. 2012, 31, 721–727. [Google Scholar] [CrossRef] [PubMed]

- Badawy, S.; Liu, Y.; Guo, M.; Liu, Z.; Xie, C.; Marawan, M.A.; Ares, I.; Lopez-Torres, B.; Martínez, M.; Maximiliano, J.E.; et al. Conjugated Linoleic Acid (CLA) as a Functional Food: Is It Beneficial or Not? Food Res. Int. 2023, 172, 113158. [Google Scholar] [CrossRef] [PubMed]

- Azain, M.J. Role of Fatty Acids in Adipocyte Growth and Development. J. Anim. Sci. 2004, 82, 916–924. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, A.; Rahman, M.M.; Sun, D.; Lawrence, R.; Mejia, W.; McCarter, R.; O’Shea, M.; Fernandes, G. The Combination of Dietary Conjugated Linoleic Acid and Treadmill Exercise Lowers Gain in Body Fat Mass and Enhances Lean Body Mass in High Fat–Fed Male Balb/C Mice. J. Nutr. 2005, 135, 1124–1130. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Hou, X.; Li, L.; Tang, Y.; Zheng, M.; Zeng, W.; Lei, X.L. Improving Obesity and Lipid Metabolism Using Conjugated Linoleic Acid. Vet. Med. Sci. 2022, 8, 2538–2544. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Fu, X.; Lin, D.; Li, T.; Zhang, N.; Huo, Y.; Zhu, P.; Guo, F.; Huang, F. Conjugated Linoleic Acid Alleviates Glycolipid Metabolic Disorders by Modulating Intestinal Microbiota and Short-Chain Fatty Acids in Obese Rats. Food Funct. 2023, 14, 1685–1698. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; He, Y.; Wang, K.; Miao, J.; Zheng, Z. Metagenomics Approach to the Intestinal Microbiome Structure and Function in High Fat Diet-Induced Obesity in Mice Fed with Conjugated Linoleic Acid (CLA). Food Funct. 2020, 11, 9729–9739. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Qu, C.; Zhao, H.; Wang, P.; Zheng, Z.; Miao, J. Conjugated Linoleic Acid from Suaeda Salsa Improves the Intestinal Health in T2DM Mice by Regulating Colonic Barrier Function, Intestinal Glycolipid Transporters and Intestinal Flora. Food Biosci. 2024, 58, 103805. [Google Scholar] [CrossRef]

- Mądry, E.; Malesza, I.J.; Subramaniapillai, M.; Czochralska-Duszyńska, A.; Walkowiak, M.; Miśkiewicz-Chotnicka, A.; Walkowiak, J.; Lisowska, A. Body Fat Changes and Liver Safety in Obese and Overweight Women Supplemented with Conjugated Linoleic Acid: A 12-Week Randomised, Double-Blind, Placebo-Controlled Trial. Nutrients 2020, 12, 1811. [Google Scholar] [CrossRef] [PubMed]

- Dai, Z.B.; Ren, X.L.; Xue, Y.L.; Tian, Y.; He, B.B.; Xu, C.L.; Yang, B. Association of Dietary Intake and Biomarker of α-Linolenic Acid with Incident Colorectal Cancer: A Dose-Response Meta-Analysis of Prospective Cohort Studies. Front. Nutr. 2022, 9, 948604. [Google Scholar] [CrossRef] [PubMed]

- Palombo, J.D.; Ganguly, A.; Bistrian, B.R.; Menard, M.P. The Antiproliferative Effects of Biologically Active Isomers of Conjugated Linoleic Acid on Human Colorectal and Prostatic Cancer Cells. Cancer Lett. 2002, 177, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Park, H.S.; Cho, H.Y.; Ha, Y.L.; Park, J.H.Y. Dietary Conjugated Linoleic Acid Increases the MRNA Ratio of Bax/Bcl-2 in the Colonic Mucosa of Rats. J. Nutr. Biochem. 2004, 15, 229–235. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.L.; Futakuchi, M.; Ogawa, K.; Iwata, T.; Kasai, M.; Tokudome, S.; Hirose, M.; Shirai, T. Dose Response Study of Conjugated Fatty Acid Derived from Safflower Oil on Mammary and Colon Carcinogenesis Pretreated with 7,12-Dimethylbenz[a]Anthracene (DMBA) and 1,2-Dimethylhydrazine (DMH) in Female Sprague–Dawley Rats. Cancer Lett. 2003, 196, 161–168. [Google Scholar] [CrossRef] [PubMed]

- Bozzo, F.; Bocca, C.; Colombatto, S.; Miglietta, A. Antiproliferative Effect of Conjugated Linoleic Acid in Caco-2 Cells: Involvement of PPARγ and APC/β-Catenin Pathways. Chem. Biol. Interact. 2007, 169, 110–121. [Google Scholar] [CrossRef] [PubMed]

- Bocca, C.; Bozzo, F.; Gabriel, L.; Miglietta, A. Conjugated Linoleic Acid Inhibits Caco-2 Cell Growth via ERK-MAPK Signaling Pathway. J. Nutr. Biochem. 2007, 18, 424–432. [Google Scholar] [CrossRef] [PubMed]

- Miller, A.; Stanton, C.; Devery, R. Cis-9, Trans-11- and Trans-10, Cis-12-Conjugated Linoleic Acid Isomers Induce Apoptosis in Cultured SW480 Cells. Anticancer. Res. 2002, 22, 3879–3887. [Google Scholar] [PubMed]

- Kim, K.H.; Park, H.S. Dietary Supplementation of Conjugated Linoleic Acid Reduces Colon Tumor Incidence in DMH-Treated Rats by Increasing Apoptosis with Modulation of Biomarkers. Nutrition 2003, 19, 772–777. [Google Scholar] [CrossRef] [PubMed]

- Lampen, A.; Leifheit, M.; Voss, J.; Nau, H. Molecular and Cellular Effects of Cis-9, Trans-11-Conjugated Linoleic Acid in Enterocytes: Effects on Proliferation, Differentiation, and Gene Expression. BBA 2005, 1735, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.J.; Kang, I.J.; Cho, H.J.; Kim, W.K.; Ha, Y.L.; Park, J.H.Y. Conjugated Linoleic Acid Downregulates Insulin-Like Growth Factor-I Receptor Levels in HT-29 Human Colon Cancer Cells. J. Nutr. 2003, 133, 2675–2681. [Google Scholar] [CrossRef] [PubMed]

- Mandir, N.; Goodlad, R.A. Conjugated Linoleic Acids Differentially Alter Polyp Number and Diameter in the Apcmin/+ Mouse Model of Intestinal Cancer. Cell Prolif. 2008, 41, 279–291. [Google Scholar] [CrossRef] [PubMed]

- Faramarzi, E.; Mohammadzadeh, M.; Sanaie, S.; Andersen, V.; Mahdavi, R. Effects of Conjugated Linoleic Acid Supplementation on Serum Leptin Levels, Oxidative Stress Factors and Tumor Marker in Rectal Cancer Patients Undergoing Preopeatrive Chemoradiotherapy. Med. J. Nutrition Metab. 2021, 14, 245–253. [Google Scholar] [CrossRef]

- Mahdavi, R.; Moahmmadzaeh, M.; Sanaie-Oskouei, S.; Faramarzi, E. The Effects of Conjugated Linoleic Acid on Serum Fatty Acids Composition and Lipid Profile in Patients with Rectal Cancer Undergoing Chemoradiotherapy. J. Isfahan Med. School 2021, 38, 996–1003. [Google Scholar] [CrossRef]

- U.S. Food and Drug Administration (FDA). GRAS Notice Inventory—GRN No. 000218. Available online: https://www.fda.gov/food/generally-recognized-safe-gras/gras-notice-inventory (accessed on 16 June 2025).

- Scientific Opinion on the Safety of “Conjugated Linoleic Acid (CLA)-Rich Oil” (Clarinol®) as a Novel Food Ingredient. EFSA J. 2010, 8. [CrossRef]

- Chen, Y.; Xiao, J.; Zhu, X.; Fan, X.; Peng, M.; Mu, Y.; Wang, C.; Xia, L.; Zhou, M. Exploiting Conjugated Linoleic Acid for Health: A Recent Update. Food Funct. 2025, 16, 147–167. [Google Scholar] [CrossRef] [PubMed]

- Cooper, M.H.; Miller, J.R.; Mitchell, P.L.; Currie, D.L.; McLeod, R.S. Conjugated Linoleic Acid Isomers Have No Effect on Atherosclerosis and Adverse Effects on Lipoprotein and Liver Lipid Metabolism in ApoE−/− Mice Fed a High-Cholesterol Diet. Atherosclerosis 2008, 200, 294–302. [Google Scholar] [CrossRef] [PubMed]

- Europe PMC. Available online: https://europepmc.org/article/med/17024956 (accessed on 13 April 2025).

- Whigham, L.D.; O’Shea, M.; Mohede, I.C.M.; Walaski, H.P.; Atkinson, R.L. Safety Profile of Conjugated Linoleic Acid in a 12-Month Trial in Obese Humans. Food Chem. Toxicol. 2004, 42, 1701–1709. [Google Scholar] [CrossRef] [PubMed]

- Derakhshande-Rishehri, S.M.; Mansourian, M.; Kelishadi, R.; Heidari-Beni, M. Association of Foods Enriched in Conjugated Linoleic Acid (CLA) and CLA Supplements with Lipid Profile in Human Studies: A Systematic Review and Meta-Analysis. Public Health Nutr. 2015, 18, 2041–2054. [Google Scholar] [CrossRef] [PubMed]

- Basak, S.; Duttaroy, A.K. Conjugated Linoleic Acid and Its Beneficial Effects in Obesity, Cardiovascular Disease, and Cancer. Nutrients 2020, 12, 1913. [Google Scholar] [CrossRef] [PubMed]

- Lehnen, T.E.; da Silva, M.R.; Camacho, A.; Marcadenti, A.; Lehnen, A.M. A Review on Effects of Conjugated Linoleic Fatty Acid (CLA) upon Body Composition and Energetic Metabolism. J. Int. Soc. Sports Nutr. 2015, 12, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Benjamin, S.; Prakasan, P.; Sreedharan, S.; Wright, A.D.G.; Spener, F. Pros and Cons of CLA Consumption: An Insight from Clinical Evidences. Nutr. Metab. 2015, 12, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Gaullier, J.M.; Halse, J.; Høye, K.; Kristiansen, K.; Fagertun, H.; Vik, H.; Gudmundsen, O. Supplementation with Conjugated Linoleic Acid for 24 Months Is Well Tolerated by and Reduces Body Fat Mass in Healthy, Overweight Humans. J. Nutr. 2005, 135, 778–784. [Google Scholar] [CrossRef] [PubMed]

- Blankson, H.; Stakkestad, J.A.; Fagertun, H.; Thom, E.; Wadstein, J.; Gudmundsen, O. Conjugated Linoleic Acid Reduces Body Fat Mass in Overweight and Obese Humans. J. Nutr. 2000, 130, 2943–2948. [Google Scholar] [CrossRef] [PubMed]

- Gaullier, J.M.; Halse, J.; Høivik, H.O.; Syvertsen, C.; Nurminiemi, M.; Hassfeld, C.; Einerhand, A.; O’Shea, M.; Gudmundsen, O. Six Months Supplementation with Conjugated Linoleic Acid Induces Regional-Specific Fat Mass Decreases in Overweight and Obese. Br. J. Nutr. 2007, 97, 550–560. [Google Scholar] [CrossRef] [PubMed]

- Steck, H.; Christophersen, A.; Blankson, H.; Stakkestad, J.A.; Fagertun, H.; Thom, E.; Wadstein, J.; Gudmundsen, O. Safety of Conjugated Linoleic Acid (CLA) in Overweight or Obese Human Volunteers. Nutrients 2025, 102, 455–462. [Google Scholar]

- Osthues, T.; Sisignano, M. Oxidized Lipids in Persistent Pain States. Front. Pharmacol. 2019, 10, 473908. [Google Scholar] [CrossRef] [PubMed]

- Vangaveti, V.N.; Jansen, H.; Kennedy, R.L.; Malabu, U.H. Hydroxyoctadecadienoic Acids: Oxidised Derivatives of Linoleic Acid and Their Role in Inflammation Associated with Metabolic Syndrome and Cancer. Eur. J. Pharmacol. 2016, 785, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Vangaveti, V.; Baune, B.T.; Kennedy, R.L. Hydroxyoctadecadienoic Acids: Novel Regulators of Macrophage Differentiation and Atherogenesis. Ther. Adv. Endocrinol. Metab. 2010, 1, 51. [Google Scholar] [CrossRef] [PubMed]

- Tsuchida, K.; Sakiyama, N. 9-Hydroxyoctadecadienoic Acid Plays a Crucial Role in Human Skin Photoaging. Biochem. Biophys. Res. Commun. 2023, 679, 75–81. [Google Scholar] [CrossRef] [PubMed]

- Ramsden, C.E.; Domenichiello, A.F.; Yuan, Z.X.; Sapio, M.R.; Keyes, G.S.; Mishra, S.K.; Gross, J.R.; Majchrzak-Hong, S.; Zamora, D.; Horowitz, M.S.; et al. A Systems Approach for Discovering Linoleic Acid Derivatives That Potentially Mediate Pain and Itch. Sci. Signal 2017, 10, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Hohmann, S.W.; Angioni, C.; Tunaru, S.; Lee, S.; Woolf, C.J.; Offermanns, S.; Geisslinger, G.; Scholich, K.; Sisignano, M. The G2A Receptor (GPR132) Contributes to Oxaliplatin-Induced Mechanical Pain Hypersensitivity. Sci. Rep. 2017, 7, 446. [Google Scholar] [CrossRef] [PubMed]

- Wedel, S.; Osthues, T.; Zimmer, B.; Angioni, C.; Geisslinger, G.; Sisignano, M. Oxidized Linoleic Acid Metabolites Maintain Mechanical and Thermal Hypersensitivity during Sub-Chronic Inflammatory Pain. Biochem. Pharmacol. 2022, 198, 114953. [Google Scholar] [CrossRef] [PubMed]

- Pauls, S.D.; Rodway, L.A.; Winter, T.; Taylor, C.G.; Zahradka, P.; Aukema, H.M. Anti-Inflammatory Effects of α-Linolenic Acid in M1-like Macrophages Are Associated with Enhanced Production of Oxylipins from α-Linolenic and Linoleic Acid. J. Nutr. Biochem. 2018, 57, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Obinata, H.; Hattori, T.; Nakane, S.; Tatei, K.; Izumi, T. Identification of 9-Hydroxyoctadecadienoic Acid and Other Oxidized Free Fatty Acids as Ligands of the G Protein-Coupled Receptor G2A. J. Biol. Chem. 2005, 280, 40676–40683. [Google Scholar] [CrossRef] [PubMed]

- McReynolds, C.; Morisseau, C.; Wagner, K.; Hammock, B. Epoxy Fatty Acids Are Promising Targets for Treatment of Pain, Cardiovascular Disease and Other Indications Characterized by Mitochondrial Dysfunction, Endoplasmic Stress and Inflammation. Adv. Exp. Med. Biol. 2020, 1274, 71–99. [Google Scholar] [PubMed]

- Zhang, G.; Kodani, S.; Hammock, B.D. Stabilized Epoxygenated Fatty Acids Regulate Inflammation, Pain, Angiogenesis and Cancer. Prog. Lipid Res. 2013, 53, 108. [Google Scholar] [CrossRef] [PubMed]

- Bystrom, J.; Wray, J.A.; Sugden, M.C.; Holness, M.J.; Swales, K.E.; Warner, T.D.; Edin, M.L.; Zeldin, D.C.; Gilroy, D.W.; Bishop-Bailey, D. Endogenous Epoxygenases Are Modulators of Monocyte/Macrophage Activity. PLoS ONE 2011, 6, e26591. [Google Scholar] [CrossRef] [PubMed]

- Edin, M.L.; Zeldin, D.C. Regulation of Cardiovascular Biology by Microsomal Epoxide Hydrolase. Toxicol. Res. 2021, 37, 285–292. [Google Scholar] [CrossRef] [PubMed]

- Node, K.; Huo, Y.; Ruan, X.; Yang, B.; Spiecker, M.; Ley, K.; Zeldin, D.C.; Liao, J.K. Anti-Inflammatory Properties of Cytochrome P450 Epoxygenase-Derived Eicosanoids. Science 1999, 285, 1276–1279. [Google Scholar] [CrossRef] [PubMed]

- Richter, F.C.; Friedrich, M.; Kampschulte, N.; Piletic, K.; Alsaleh, G.; Zummach, R.; Hecker, J.; Pohin, M.; Ilott, N.; Guschina, I.; et al. Adipocyte Autophagy Limits Gut Inflammation by Controlling Oxylipin and IL-10. EMBO J. 2023, 42, e112202. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Liao, J.; Li, H.; Dong, H.; Bai, H.; Yang, A.; Hammock, B.D.; Yang, G.Y. Reduction of Inflammatory Bowel Disease-Induced Tumor Development in IL-10 Knockout Mice with Soluble Epoxide Hydrolase Gene Deficiency. Mol. Carcinog. 2013, 52, 726–738. [Google Scholar] [CrossRef] [PubMed]

- Berg, D.J.; Zhang, J.; Weinstock, J.V.; Ismail, H.F.; Earle, K.A.; Alila, H.; Pamukcu, R.; Moore, S.; Lynch, R.G. Rapid Development of Colitis in NSAID-Treated IL-10–Deficient Mice. Gastroenterology 2002, 123, 1527–1542. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Panigrahy, D.; Mahakian, L.M.; Yang, J.; Liu, J.Y.; Lee, K.S.S.; Wettersten, H.I.; Ulu, A.; Hu, X.; Tam, S.; et al. Epoxy Metabolites of Docosahexaenoic Acid (DHA) Inhibit Angiogenesis, Tumor Growth, and Metastasis. Proc. Natl. Acad. Sci. USA 2013, 110, 6530–6535. [Google Scholar] [CrossRef] [PubMed]

- Goswami, S.K.; Wan, D.; Yang, J.; Trindade Da Silva, C.A.; Morisseau, C.; Kodani, S.D.; Yang, G.Y.; Inceoglu, B.; Hammock, B.D. Anti-Ulcer Efficacy of Soluble Epoxide Hydrolase Inhibitor TPPU on Diclofenac-Induced Intestinal Ulcers. J. Pharmacol. Exp. Ther. 2016, 357, 529–536. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Whitcomb, R.; MacIntyre, E.; Do Tran, V.; Zung, N.; Sabry, J.; Patel, D.V.; Anandan, S.K.; Gless, R.; Webb, H.K. Pharmacokinetics and Pharmacodynamics of AR9281, an Inhibitor of Soluble Epoxide Hydrolase, in Single- and Multiple-Dose Studies in Healthy Human Subjects. J. Clin. Pharm. 2012, 52, 319–328. [Google Scholar] [CrossRef] [PubMed]

- Lazaar, A.L.; Yang, L.; Boardley, R.L.; Goyal, N.S.; Robertson, J.; Baldwin, S.J.; Newby, D.E.; Wilkinson, I.B.; Tal-Singer, R.; Mayer, R.J.; et al. Pharmacokinetics, Pharmacodynamics and Adverse Event Profile of GSK2256294, a Novel Soluble Epoxide Hydrolase Inhibitor. Br. J. Clin. Pharmacol. 2016, 81, 971. [Google Scholar] [CrossRef] [PubMed]

- Bays, H.E.; Hallén, J.; Vige, R.; Fraser, D.; Zhou, R.; Hustvedt, S.O.; Orloff, D.G.; Kastelein, J.J.P. Icosabutate for the Treatment of Very High Triglycerides: A Placebo-Controlled, Randomized, Double-Blind, 12-Week Clinical Trial. J. Clin. Lipidol. 2016, 10, 181–191.e2. [Google Scholar] [CrossRef] [PubMed]

- Bhatt, D.L.; Steg, P.G.; Miller, M.; Brinton, E.A.; Jacobson, T.A.; Ketchum, S.B.; Doyle, R.T.; Juliano, R.A.; Jiao, L.; Granowitz, C.; et al. Cardiovascular Risk Reduction with Icosapent Ethyl for Hypertriglyceridemia. N. Engl. J. Med. 2019, 380, 11–22. [Google Scholar] [CrossRef] [PubMed]

- FDA Approves Use of Drug to Reduce Risk of Cardiovascular Events in Certain Adult Patient Groups|FDA. Available online: https://www.fda.gov/news-events/press-announcements/fda-approves-first-treatment-reduce-risk-serious-heart-problems-specifically-adults-obesity-or (accessed on 21 April 2025).

- Savchenko, T.; Degtyaryov, E.; Radzyukevich, Y.; Buryak, V. Therapeutic Potential of Plant Oxylipins. Int. J. Molec Sci. 2022, 23, 14627. [Google Scholar] [CrossRef] [PubMed]

- Furumoto, H.; Nanthirudjanar, T.; Kume, T.; Izumi, Y.; Park, S.B.; Kitamura, N.; Kishino, S.; Ogawa, J.; Hirata, T.; Sugawara, T. 10-Oxo-Trans-11-Octadecenoic Acid Generated from Linoleic Acid by a Gut Lactic Acid Bacterium Lactobacillus Plantarum Is Cytoprotective against Oxidative Stress. Toxicol. Appl. Pharmacol. 2016, 296, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Goto, T.; Kim, Y.-I.; Furuzono, T.; Takahashi, N.; Yamakuni, K.; Yang, H.E.; Li, Y.; Ohue, R.; Nomura, W.; Sugawara, T.; et al. 10-Oxo-12(Z)-Octadecenoic Acid, a Linoleic Acid Metabolite Produced by Gut Lactic Acid Bacteria, Potently Activates PPARγ and Stimulates Adipogenesis. Biochem. Biophys. Res. Commun. 2015, 459, 597–603. [Google Scholar] [CrossRef] [PubMed]

- Yasuda, M.; Nishizawa, T.; Ohigashi, H.; Tanaka, T.; Hou, D.X.; Colburn, N.H.; Murakami, A. Linoleic Acid Metabolite Suppresses Skin Inflammation and Tumor Promotion in Mice: Possible Roles of Programmed Cell Death 4 Induction. Carcinogenesis 2009, 30, 1209–1216. [Google Scholar] [CrossRef] [PubMed]

- Altmann, R.; Hausmann, M.; Spöttl, T.; Gruber, M.; Bull, A.W.; Menzel, K.; Vogl, D.; Herfarth, H.; Schölmerich, J.; Falk, W.; et al. 13-Oxo-ODE Is an Endogenous Ligand for PPARγ in Human Colonic Epithelial Cells. Biochem. Pharmacol. 2007, 74, 612–622. [Google Scholar] [CrossRef] [PubMed]

- Batsika, C.S.; Mantzourani, C.; Gkikas, D.; Kokotou, M.G.; Mountanea, O.G.; Kokotos, C.G.; Politis, P.K.; Kokotos, G. Saturated Oxo Fatty Acids (SOFAs): A Previously Unrecognized Class of Endogenous Bioactive Lipids Exhibiting a Cell Growth Inhibitory Activity. J. Med. Chem. 2021, 64, 5654–5666. [Google Scholar] [CrossRef] [PubMed]

- Mogi, K.; Koya, Y.; Yoshihara, M.; Sugiyama, M.; Miki, R.; Miyamoto, E.; Fujimoto, H.; Kitami, K.; Iyoshi, S.; Tano, S.; et al. 9-Oxo-ODAs Suppresses the Proliferation of Human Cervical Cancer Cells through the Inhibition of CDKs and HPV Oncoproteins. Sci. Rep. 2023, 13, 19208. [Google Scholar] [CrossRef] [PubMed]

- Zartmann, A.; Galano, J.M.; Hammann, S. Analysis of Glycerol Bound ω-Oxo-Fatty Acids as ω-Dioxane-FAME-Derivatives. Food Chem. 2025, 463, 141223. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-I.; Hirai, S.; Takahashi, H.; Goto, T.; Ohyane, C.; Tsugane, T.; Konishi, C.; Fujii, T.; Inai, S.; Iijima, Y.; et al. 9-Oxo-10(E),12(E)-Octadecadienoic Acid Derived from Tomato Is a Potent PPAR α Agonist to Decrease Triglyceride Accumulation in Mouse Primary Hepatocytes. Mol. Nutr. Food Res. 2011, 55, 585–593. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-I.; Hirai, S.; Goto, T.; Ohyane, C.; Takahashi, H.; Tsugane, T.; Konishi, C.; Fujii, T.; Inai, S.; Iijima, Y.; et al. Potent PPARα Activator Derived from Tomato Juice, 13-Oxo-9,11-Octadecadienoic Acid, Decreases Plasma and Hepatic Triglyceride in Obese Diabetic Mice. PLoS ONE 2012, 7, e31317. [Google Scholar] [CrossRef] [PubMed]

- Santoro, N.; Caprio, S.; Giannini, C.; Kim, G.; Kursawe, R.; Pierpont, B.; Shaw, M.M.; Feldstein, A.E. Oxidized Fatty Acids: A Potential Pathogenic Link Between Fatty Liver and Type 2 Diabetes in Obese Adolescents? Antioxid. Redox Signal 2014, 20, 383. [Google Scholar] [CrossRef] [PubMed]

- Mohri, S.; Takahashi, H.; Sakai, M.; Takahashi, S.; Waki, N.; Aizawa, K.; Suganuma, H.; Ara, T.; Matsumura, Y.; Shibata, D.; et al. Wide-Range Screening of Anti-Inflammatory Compounds in Tomato Using LC-MS and Elucidating the Mechanism of Their Functions. PLoS ONE 2018, 13, e0191203. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Kim, Y.I.; Hirai, S.; Goto, T.; Ohyane, C.; Tsugane, T.; Konishi, C.; Fujii, T.; Inai, S.; Iijima, Y.; et al. Comparative and Stability Analyses of 9- and 13-Oxo-Octadecadienoic Acids in Various Species of Tomato. Biosci. Biotechnol. Biochem. 2011, 75, 1621–1624. [Google Scholar] [CrossRef] [PubMed]

- Sofyana, N.T.; Zheng, J.; Manabe, Y.; Yamamoto, Y.; Kishino, S.; Ogawa, J.; Sugawara, T. Gut Microbial Fatty Acid Metabolites (KetoA and KetoC) Affect the Progression of Nonalcoholic Steatohepatitis and Reverse Cholesterol Transport Metabolism in Mouse Model. Lipids 2020, 55, 151–162. [Google Scholar] [CrossRef] [PubMed]

- Kuda, O.; Brezinova, M.; Rombaldova, M.; Slavikova, B.; Posta, M.; Beier, P.; Janovska, P.; Veleba, J.; Kopecky, J.; Kudova, E.; et al. Docosahexaenoic Acid–Derived Fatty Acid Esters of Hydroxy Fatty Acids (FAHFAs) With Anti-Inflammatory Properties. Diabetes 2016, 65, 2580–2590. [Google Scholar] [CrossRef] [PubMed]

- Paluchova, V.; Vik, A.; Cajka, T.; Brezinova, M.; Brejchova, K.; Bugajev, V.; Draberova, L.; Draber, P.; Buresova, J.; Kroupova, P.; et al. Triacylglycerol-Rich Oils of Marine Origin Are Optimal Nutrients for Induction of Polyunsaturated Docosahexaenoic Acid Ester of Hydroxy Linoleic Acid (13-DHAHLA) with Anti-Inflammatory Properties in Mice. Mol. Nutr. Food Res. 2020, 64, 1901238. [Google Scholar] [CrossRef] [PubMed]

- Giannetti, M.P.; Akin, C.; Hufdhi, R.; Hamilton, M.J.; Weller, E.; van Anrooij, B.; Lyons, J.J.; Hornick, J.L.; Pinkus, G.; Castells, M.; et al. Patients with Mast Cell Activation Symptoms and Elevated Baseline Serum Tryptase Level Have Unique Bone Marrow Morphology. J. Allergy Clin. Immunol. 2021, 147, 1497–1501.e1. [Google Scholar] [CrossRef] [PubMed]

- Kolar, M.J.; Konduri, S.; Chang, T.; Wang, H.; McNerlin, C.; Ohlsson, L.; Härröd, M.; Siegel, D.; Saghatelian, A. Linoleic Acid Esters of Hydroxy Linoleic Acids Are Anti-Inflammatory Lipids Found in Plants and Mammals. J. Biol. Chem. 2019, 294, 10698. [Google Scholar] [CrossRef] [PubMed]

- Worthmann, A.; Ridder, J.; Piel, S.Y.L.; Evangelakos, I.; Musfeldt, M.; Voß, H.; O’Farrell, M.; Fischer, A.W.; Adak, S.; Sundd, M.; et al. Fatty Acid Synthesis Suppresses Dietary Polyunsaturated Fatty Acid Use. Nat. Commun. 2024, 15, 45. [Google Scholar] [CrossRef] [PubMed]

- Green, C.J.; Pramfalk, C.; Charlton, C.A.; Gunn, P.J.; Cornfield, T.; Pavlides, M.; Karpe, F.; Hodson, L. Hepatic de Novo Lipogenesis Is Suppressed and Fat Oxidation Is Increased by Omega-3 Fatty Acids at the Expense of Glucose Metabolism. BMJ Open Diabetes Res. Care 2020, 8, e000871. [Google Scholar] [CrossRef] [PubMed]

- Sandri, E.C.; Camêra, M.; Sandri, E.M.; Harvatine, K.J.; De Oliveira, D.E. Peroxisome Proliferator-Activated Receptor Gamma (PPARγ) Agonist Fails to Overcome Trans-10, Cis-12 Conjugated Linoleic Acid (CLA) Inhibition of Milk Fat in Dairy Sheep. Animal 2018, 12, 1405–1412. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Wang, Z.; Riethoven, J.J.; Xia, Y.; Miner, J.; Fromm, M. Conjugated Linoleic Acid Activates AMP-Activated Protein Kinase and Reduces Adiposity More Effectively When Used with Metformin in Mice. J. Nutr. 2009, 139, 2244–2251. [Google Scholar] [CrossRef] [PubMed]

- Brezinova, M.; Kuda, O.; Hansikova, J.; Rombaldova, M.; Balas, L.; Bardova, K.; Durand, T.; Rossmeisl, M.; Cerna, M.; Stranak, Z.; et al. Levels of Palmitic Acid Ester of Hydroxystearic Acid (PAHSA) Are Reduced in the Breast Milk of Obese Mothers. Biochim. Biophys. Acta Mol. Cell Biol. Lipids 2018, 1863, 126–131. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.K.; Boruah, T.; Ghosh, P.; Ikram, A.; Rana, S.S.; Shanker, M.A.; Bachetti, A.; Jha, A.K.; Naik, B.; Kumar, V.; et al. Green Chemistry Revolutionizing Sustainability in the Food Industry: A Comprehensive Review and Call to Action. Sustain. Chem. Pharm. 2024, 42, 101774. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, Y.; Kim, Y.J.; Park, Y. Conjugated Linoleic Acid: Potential Health Benefits as a Functional Food Ingredient. Annu. Rev. Food Sci. Technol. 2016, 7, 221–244. [Google Scholar] [CrossRef] [PubMed]

- Boukid, F.; Folloni, S.; Sforza, S.; Vittadini, E.; Prandi, B. Current Trends in Ancient Grains-Based Foodstuffs: Insights into Nutritional Aspects and Technological Applications. Compr. Rev. Food Sci. Food Saf. 2018, 17, 123–136. [Google Scholar] [CrossRef] [PubMed]

- Koba, K.; Yanagita, T. Health Benefits of Conjugated Linoleic Acid (CLA). Obes. Res. Clin. Pract. 2014, 8, e525–e532. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; Park, G.B.; Kang, C.B.; Park, S.D.; Jung, M.Y.; Kim, J.O.; Ha, Y.L. Improvement of Oxidative Stability of Conjugated Linoleic Acid (CLA) by Microencapsulation in Cyolodextrins. J. Agric. Food Chem. 2000, 48, 3922–3929. [Google Scholar] [CrossRef] [PubMed]

- Ha, H.K.; Woo, D.B.; Lee, M.R.; Lee, W.J. Development of Hydrophobically Modified Casein Derivative-Based Delivery System for Docosahexaenoic Acids by an Acid-Induced Gelation. Food Sci. Anim. Resour. 2023, 43, 220–231. [Google Scholar] [CrossRef] [PubMed]

- Veverka, M.; Dubaj, T.; Jorík, V.; Veverková, E.; Šimon, P. Stabilization of Conjugated Linoleic Acid via Complexation with Arabinogalactan and β-Glucan. Eur. J. Lipid Sci. Technol. 2017, 119, 1600258. [Google Scholar] [CrossRef]

- Munin, A.; Edwards-Lévy, F. Encapsulation of Natural Polyphenolic Compounds; a Review. Pharmaceutics 2011, 3, 793–829. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J.; Decker, E.A.; Weiss, J. Emulsion-Based Delivery Systems for Lipophilic Bioactive Components. J. Food Sci. 2007, 72, R109–R124. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.X.; Yang, J.; Hu, M.; Lu, W.; Zhong, K.; Wang, Y.; Yang, G.; Loor, J.J.; Han, L. Milk Fat Globule Membrane Proteins Are Involved in Controlling the Size of Milk Fat Globules during Conjugated Linoleic Acid–Induced Milk Fat Depression. J. Dairy Sci. 2022, 105, 9179–9190. [Google Scholar] [CrossRef] [PubMed]

- El-Loly, M.M. Composition, properties and nutritional aspects of milk fat globule membrane—A review. Pol. J. Food Nutr. Sci. 2011, 61, 7–32. [Google Scholar] [CrossRef]

- Zhang, B.; Zheng, L.; Liang, S.; Lu, Y.; Zheng, J.; Zhang, G.; Li, W.; Jiang, H. Encapsulation of Capsaicin in Whey Protein and OSA-Modified Starch Using Spray-Drying: Physicochemical Properties and Its Stability. Foods 2022, 11, 612. [Google Scholar] [CrossRef] [PubMed]

- Lehtinen, P.; Laakso, S. Inhibition of Linoleic Acid Oxidation by Interaction with a Protein-Rich Oat Fraction. J. Agric. Food Chem. 2000, 48, 5654–5657. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Ye, A.; Lin, Q.; Han, J.; Singh, H. Gastric Digestion of Milk Protein Ingredients: Study Using an in Vitro Dynamic Model. J. Dairy Sci. 2018, 101, 6842–6852. [Google Scholar] [CrossRef] [PubMed]

- van Eijnatten, E.J.M.; Roelofs, J.J.M.; Camps, G.; Huppertz, T.; Lambers, T.T.; Smeets, P.A.M. Gastric Coagulation and Postprandial Amino Acid Absorption of Milk Is Affected by Mineral Composition: A Randomized Crossover Trial. Food Funct. 2024, 15, 3098–3107. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Development of Next-Generation Nutritionally Fortified Plant-Based Milk Substitutes: Structural Design Principles. Foods 2020, 9, 421. [Google Scholar] [CrossRef] [PubMed]

- Campbell, W.; Drake, M.A.; Larick, D.K. The Impact of Fortification with Conjugated Linoleic Acid (CLA) on the Quality of Fluid Milk. J. Dairy Sci. 2003, 86, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Lim, H.S.; Baik, M.Y. Emulsifiers for the Plant-Based Milk Alternatives: A Review. Food Sci. Biotechnol. 2025, 34. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.; Wang, Y.; He, Y.; Wei, P.; Li, C.; Xiong, X. Pickering Emulsions Stabilized by Conjugated Zein-Soybean Polysaccharides Nanoparticles: Fabrication, Characterization and Functional Performance. Polymers 2023, 15, 4474. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Huang, H.; Chen, H.; Lin, J.; Wang, Q. Food-Grade Nanoemulsions: Preparation, Stability and Application in Encapsulation of Bioactive Compounds. Molecules 2019, 24, 4242. [Google Scholar] [CrossRef] [PubMed]