Enhanced Toughness of High-Entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C Ceramics with SiC Whiskers by High-Pressure and High-Temperature Sintering

Abstract

:1. Introduction

2. Experimental

2.1. Materials Processing

2.2. Materials Characterization

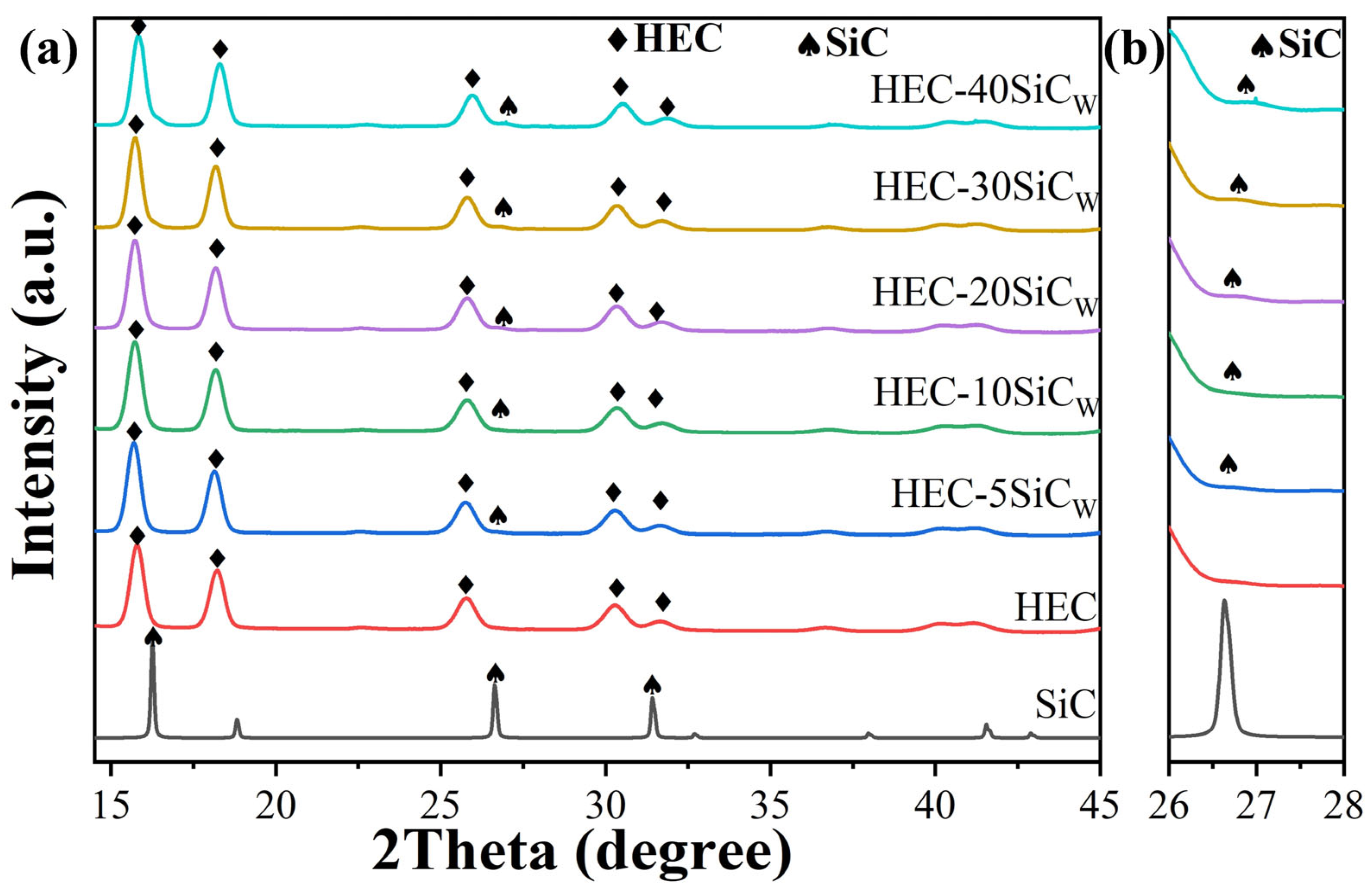

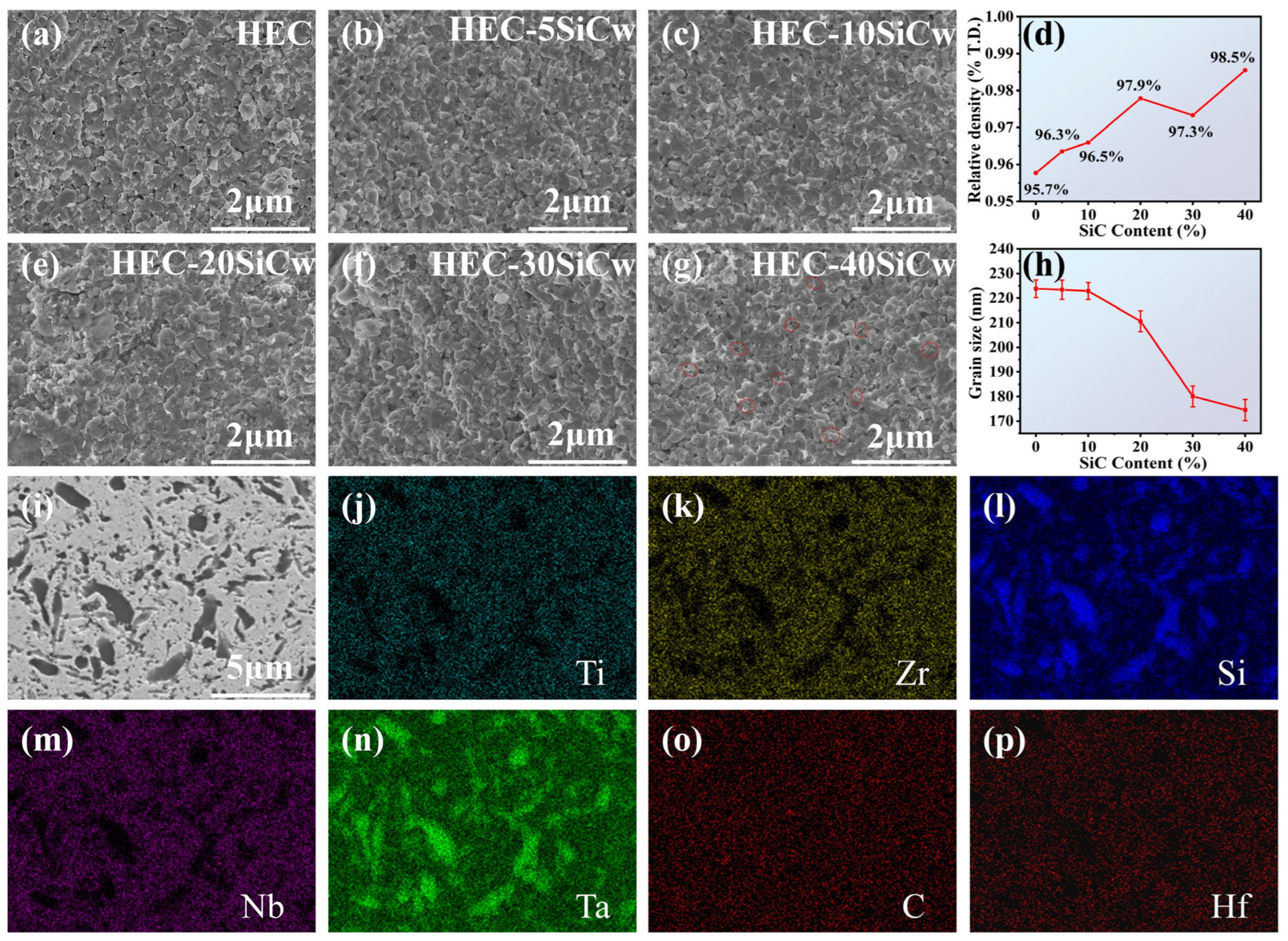

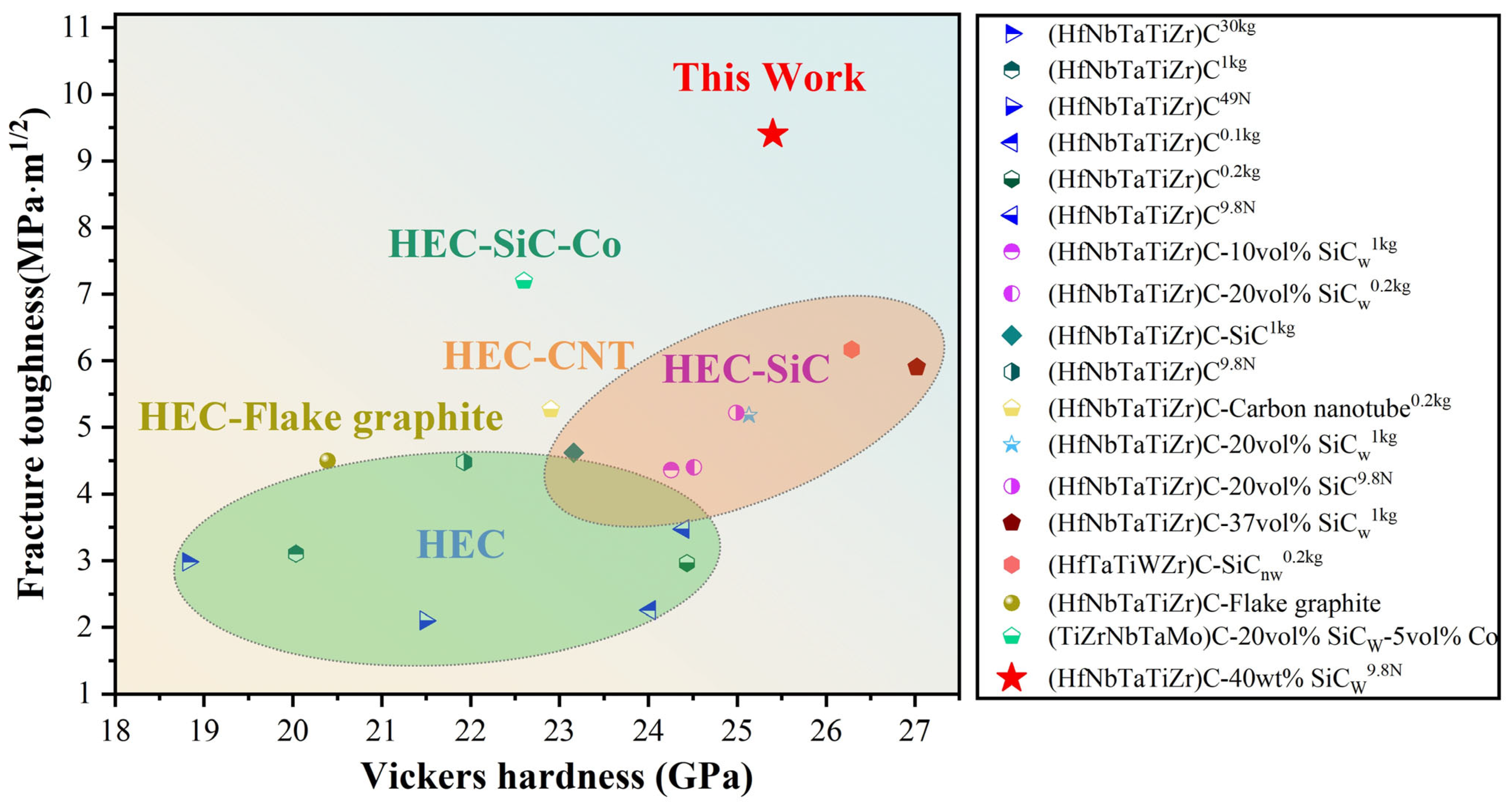

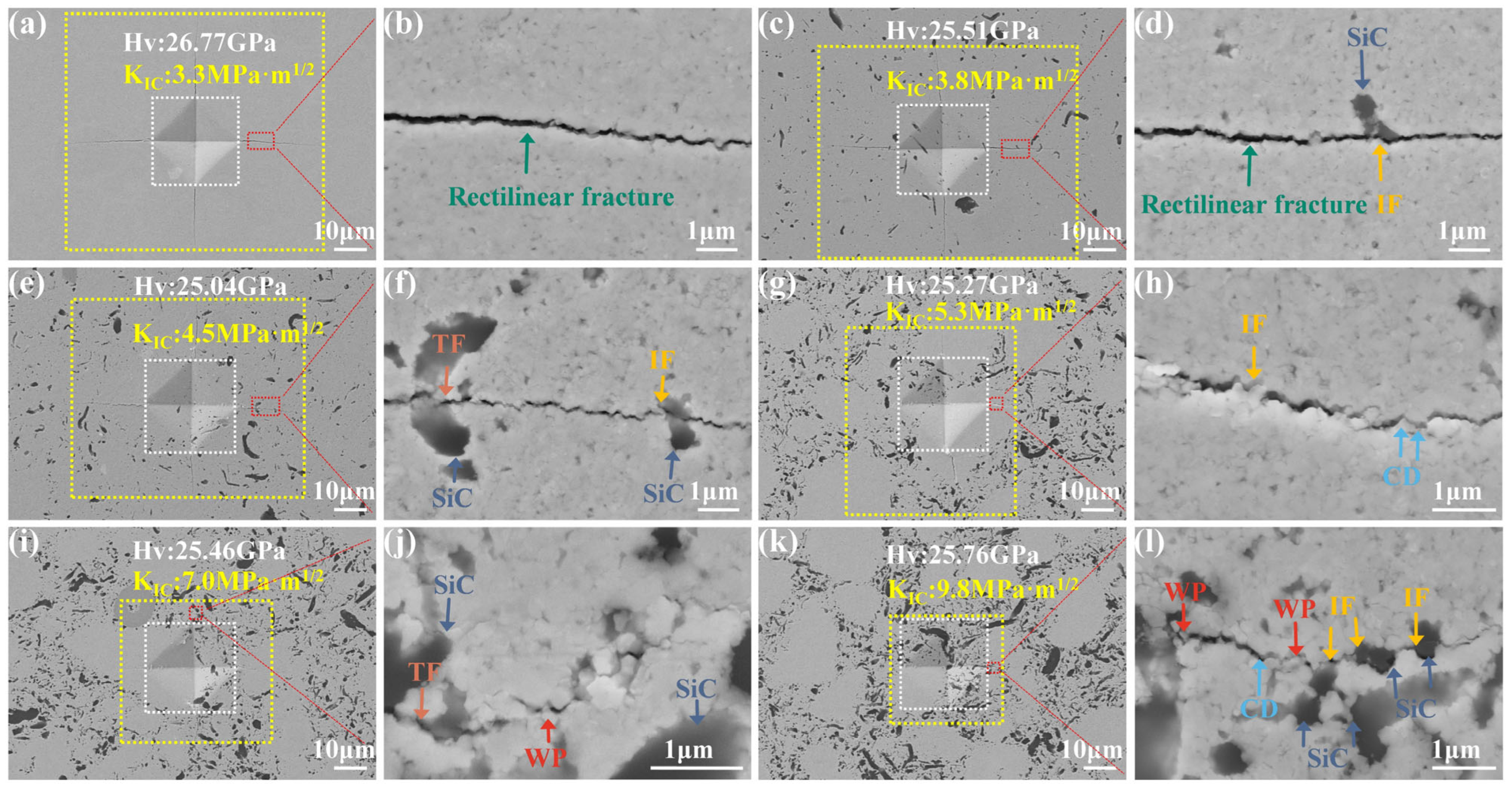

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Csanádi, T.; Zhang, H.; Dusza, J.; Reece, M.J.; Zhang, R. Enhanced Hardness in High-Entropy Carbides through Atomic Randomness. Adv. Theory Simul. 2020, 3, 2000111. [Google Scholar]

- Wang, K.; Chen, L.; Xu, C.; Zhang, W.; Liu, Z.; Wang, Y.; Ouyang, J.; Zhang, X.; Fu, Y.; Zhou, Y. Microstructure and Mechanical Properties of (TiZrNbTaMo)C High-Entropy Ceramic. J. Mater. Sci. Technol. 2020, 39, 99–105. [Google Scholar]

- Liu, P.; Peng, F.; Liu, F.; Wang, H.; Xu, C.; Wang, Q.; Zhou, X.; Yin, W.; Yin, S.; Li, Y.; et al. High-Pressure Preparation of Bulk Tungsten Material with near-Full Densification and High Fracture Toughness. Int. J. Refract. Met. Hard Mater. 2014, 42, 47–50. [Google Scholar]

- Peierls, R. The size of a dislocation. Proc. Phys. Soc. 1940, 52, 34–37. [Google Scholar]

- An, Z.; Mao, S.; Liu, Y.; Yang, L.; Vayyala, A.; Wei, X.; Liu, C.; Shi, C.; Jin, H.; Liu, C.; et al. Inherent and Multiple Strain Hardening Imparting Synergistic Ultrahigh Strength and Ductility in a Low Stacking Faulted Heterogeneous High-Entropy Alloy. Acta Mater. 2023, 243, 118516. [Google Scholar]

- Wang, X.; Tao, Q.; Han, Y.; Hu, Q.; Cheng, J.; Jia, H.; Zhu, P. TiB2 -Reinforced B4C Composites Produced by Reaction Sintering at High-Pressure and High Temperature. High Press. Res. 2020, 40, 245–256. [Google Scholar]

- Luo, S.-C.; Guo, W.-M.; Plucknett, K.; Lin, H.-T. Low-Temperature Densification of High-Entropy (Ti,Zr,Nb,Ta,Mo)C—Co Composites with High Hardness and High Toughness. J. Adv. Ceram. 2022, 11, 805–813. [Google Scholar]

- Tu, J.; Wang, X.; Dai, W.; Zhang, H.; Liu, B. Mechanical Properties and Microstructures of HPHT Sintered Polycrystalline Diamond Compacts Reinforced with SiC Whiskers. J. Mater. Res. Technol. 2023, 27, 153–167. [Google Scholar]

- Liu, Y.; Guo, W.-M.; Xu, L.; Sun, S.-K.; Lin, H.-T. Low-Temperature Sintered (Ti, Zr, Nb, Ta, Mo)C-Based Composites Toughened with Damage-Free SiCw. J. Eur. Ceram. Soc. 2023, 43, 1740–1745. [Google Scholar]

- Wang, J.; Wang, Z.; Wang, Y.; Ma, H.; Fang, S.; Chen, Q.; Wang, Y.; Wang, C.; Chen, L.; Jia, X. Effects of Pressure on the Phase Transformations and Mechanical Properties of 10 Mol% Mg-PSZ Sintered by HPHT. CrystEngComm 2022, 24, 886–892. [Google Scholar]

- Zhang, Y.; Zhu, Y.; Li, Z. Preparation and Characterization of Carbide Particle-Toughened Si–B System of High Thermostability Polycrystalline Diamond by HPHT Sintering. Materials 2023, 16, 3933. [Google Scholar] [CrossRef] [PubMed]

- Laurindo, Q.M.G.; Rosa, J.M.B.; Da Silva Guimarães, R.; Teixeira, S.R.; Lima, L.S.; Xing, Y.; Filgueira, M. Polycrystalline Diamond Obtained in the Diamond-Mo System with Enhanced Thermal Stability Sintered by HPHT. Int. J. Refract. Met. Hard Mater. 2024, 118, 106464. [Google Scholar]

- Zhang, B.; Sun, R.; Ying, P.; Li, P.; Li, Z.; Gao, Y.; Ma, M.; Liu, C. High-Pressure Sintering of Full-Dense B6O Ceramic with Excellent Hardness and Fracture Toughness. Int. J. Refract. Met. Hard Mater. 2023, 117, 106405. [Google Scholar]

- Jian, Q.; Jiang, Z.; Han, Y.; Zhu, Y.; Li, Z. Fabrication and Evaluation of Mechanical Properties of Polycrystalline Diamond Reinforced with Carbon-Nanotubes by HPHT Sintering. Ceram. Int. 2020, 46, 21527–21532. [Google Scholar]

- Zou, Q.; Wu, H.; Li, Y.; Wang, X.; Dai, L.; Luo, Y. Effects of Carbon Nanotubes and Sintering Parameters on Microstructure and Properties of PCD. Diam. Relat. Mater. 2022, 128, 109293. [Google Scholar]

- Wang, X.; Wang, D.; Ma, S.; Dong, X.; Rong, K.; You, C.; Wang, F.; Li, H.; Li, D.; Tao, Q.; et al. Enhanced Toughness of Boron Carbide by Single-Wall Carbon Nanotube Bundles. Mater. Today Commun. 2023, 35, 105651. [Google Scholar]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar]

- Song, B.; Zhao, B.; Lu, Y.; Wei, S.; Fan, B.; Zhang, X.; Zhang, R. Investigation on the Growth Mechanism of SiC Whiskers during Microwave Synthesis. Phys. Chem. Chem. Phys. 2018, 20, 25799–25805. [Google Scholar]

- Luo, S.-C.; Guo, W.-M.; Zhou, Y.-Z.; Plucknett, K.; Lin, H.-T. Textured and Toughened High-Entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiCw Ceramics. J. Mater. Sci. Technol. 2021, 94, 99–103. [Google Scholar]

- Nisar, A.; Dolmetsch, T.; Paul, T.; Sakthivel, T.S.; Zhang, C.; Boesl, B.; Seal, S.; Agarwal, A. Unveiling Enhanced Oxidation Resistance and Mechanical Integrity of Multicomponent Ultra-high Temperature Carbides. J. Am. Ceram. Soc. 2022, 105, 2500–2516. [Google Scholar]

- Zhang, W.; Chen, L.; Xu, C.; Lu, W.; Wang, Y.; Ouyang, J.; Zhou, Y. Densification, Microstructure and Mechanical Properties of Multicomponent (TiZrHfNbTaMo)C Ceramic Prepared by Pressureless Sintering. J. Mater. Sci. Technol. 2021, 72, 23–28. [Google Scholar] [CrossRef]

- Kombamuthu, V.; Ünsal, H.; Chlup, Z.; Tatarková, M.; Kovalčíková, A.; Zhukova, I.; Hosseini, N.; Hičák, M.; Dlouhý, I.; Tatarko, P. Effect of SiC on Densification, Microstructure and Mechanical Properties of High Entropy Diboride (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2. J. Eur. Ceram. Soc. 2024, 44, 5358–5369. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, J.; Guo, Z.; Zhou, H.; Yang, T.; Yang, L.; Zhao, W. Preparation of High-Entropy (Zr0.25Hf0.25Ta0.25Ti0.25)C-Ni-Co Composite by Spark Plasma Sintering. Metall. Mater. Trans. A 2020, 51, 6706–6713. [Google Scholar]

- Wang, Z.; Li, Z.-T.; Zhao, S.-J.; Wu, Z.-G. High-Entropy Carbide Ceramics: A Perspective Review. Tungsten 2021, 3, 131–142. [Google Scholar]

- Wei, X.-F.; Liu, J.-X.; Bao, W.; Qin, Y.; Li, F.; Liang, Y.; Xu, F.; Zhang, G.-J. High-Entropy Carbide Ceramics with Refined Microstructure and Enhanced Thermal Conductivity by the Addition of Graphite. J. Eur. Ceram. Soc. 2021, 41, 4747–4754. [Google Scholar] [CrossRef]

- Sun, K.; Yang, Z.; Mu, R.; Niu, S.; Wang, Y.; Wang, D. Densification and Joining of a (HfTaZrNbTi)C High-Entropy Ceramic by Hot Pressing. J. Eur. Ceram. Soc. 2021, 41, 3196–3206. [Google Scholar] [CrossRef]

- Feng, L.; Chen, W.; Fahrenholtz, W.G.; Hilmas, G.E. Strength of Single-phase High-entropy Carbide Ceramics up to 2300 °C. J. Am. Ceram. Soc. 2021, 104, 419–427. [Google Scholar] [CrossRef]

- Lin, G.; Liu, J.; Qin, Y.; Zhang, G. Low-temperature Reactive Sintering of Carbon Vacant High-entropy Carbide Ceramics with In-situ Formed Silicon Carbide. J. Am. Ceram. Soc. 2022, 105, 2392–2398. [Google Scholar] [CrossRef]

- Lu, K.; Liu, J.-X.; Wei, X.-F.; Bao, W.; Wu, Y.; Li, F.; Xu, F.; Zhang, G.-J. Microstructures and Mechanical Properties of High-Entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C Ceramics with the Addition of SiC Secondary Phase. J. Eur. Ceram. Soc. 2020, 40, 1839–1847. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Chen, Y.; Wang, L.; Yun, X.; Huang, Z. Toughening in Low-Dimensional Nanomaterials High-Entropy Ceramic Nanocomposite. Compos. Part B Eng. 2022, 231, 109586. [Google Scholar]

- Cao, Z.; Sun, J.; Meng, L.; Zhang, K.; Zhao, J.; Huang, Z.; Yun, X. Progress in Densification and Toughening of High Entropy Carbide Ceramics. J. Mater. Sci. Technol. 2023, 161, 10–43. [Google Scholar]

- Zhao, X.; Shao, G.; Feng, L.; Wang, H.; Fan, B.; Lu, H.; Xu, H.; Chen, D.; Zhang, R. ZrB2 -SiCw Ceramic Composites Synthesized by in Situ Reaction and Spark Plasma Sintering. Int. J. Appl. Ceram. Technol. 2017, 14, 845–850. [Google Scholar]

- Yan, T.; Luo, M.; Chen, J.; Zhu, H.; Chai, J.; Niu, L.; Chen, B.; Zhu, Y.; Shen, T. Microstructure and Mechanical Properties of High Entropy (MoTaTiVW)C5 Ceramics Toughened with Silicon Carbide Whisker. Ceram. Int. 2024, 50, 15840–15847. [Google Scholar]

- Rumiantseva, Y.Y.; Bushlya, V.N.; Turkevich, V.Z. The Influence of SiC and Al2O3 Whiskers on the Properties of Whisker-Reinforced cBN-Based Composites. J. Superhard Mater. 2019, 41, 377–387. [Google Scholar]

- Zhu, T.; Guo, W.; Zhang, J.; Sang, S.; Li, Y.; Xie, Z.; Liang, X.; Wang, H.; Han, Y. Synergistic Toughening Effect of SiC Whiskers and Particles in ZrO2–Al2O3–SiC Ceramics. Ceram. Int. 2023, 49, 36337–36343. [Google Scholar]

- Li, Z.; Guo, R.; Li, L.; Zheng, R.; Ma, C. Microstructure and Fracture Toughness of SiAlCN Ceramics Toughened by SiCw or GNPs. Ceram. Int. 2023, 49, 29709–29718. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Yang, Z.; Lian, M.; Ma, S.; Li, W.; Wei, X.; Zhao, X.; Pan, Y.; She, Y.; Dang, L.; et al. Enhanced Toughness of High-Entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C Ceramics with SiC Whiskers by High-Pressure and High-Temperature Sintering. Materials 2025, 18, 1655. https://doi.org/10.3390/ma18071655

Li H, Yang Z, Lian M, Ma S, Li W, Wei X, Zhao X, Pan Y, She Y, Dang L, et al. Enhanced Toughness of High-Entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C Ceramics with SiC Whiskers by High-Pressure and High-Temperature Sintering. Materials. 2025; 18(7):1655. https://doi.org/10.3390/ma18071655

Chicago/Turabian StyleLi, Hao, Zhenxing Yang, Min Lian, Shuailing Ma, Wei Li, Xinmiao Wei, Xingbin Zhao, Yilong Pan, Yunfeng She, Lingyan Dang, and et al. 2025. "Enhanced Toughness of High-Entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C Ceramics with SiC Whiskers by High-Pressure and High-Temperature Sintering" Materials 18, no. 7: 1655. https://doi.org/10.3390/ma18071655

APA StyleLi, H., Yang, Z., Lian, M., Ma, S., Li, W., Wei, X., Zhao, X., Pan, Y., She, Y., Dang, L., Yuan, B., & Cui, T. (2025). Enhanced Toughness of High-Entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C Ceramics with SiC Whiskers by High-Pressure and High-Temperature Sintering. Materials, 18(7), 1655. https://doi.org/10.3390/ma18071655