A Comparison of the Resistance- and Capacitance-Based Sensing of Geopolymer and Cement Composites with Graphite Filler Under Compression

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Mixing Procedure

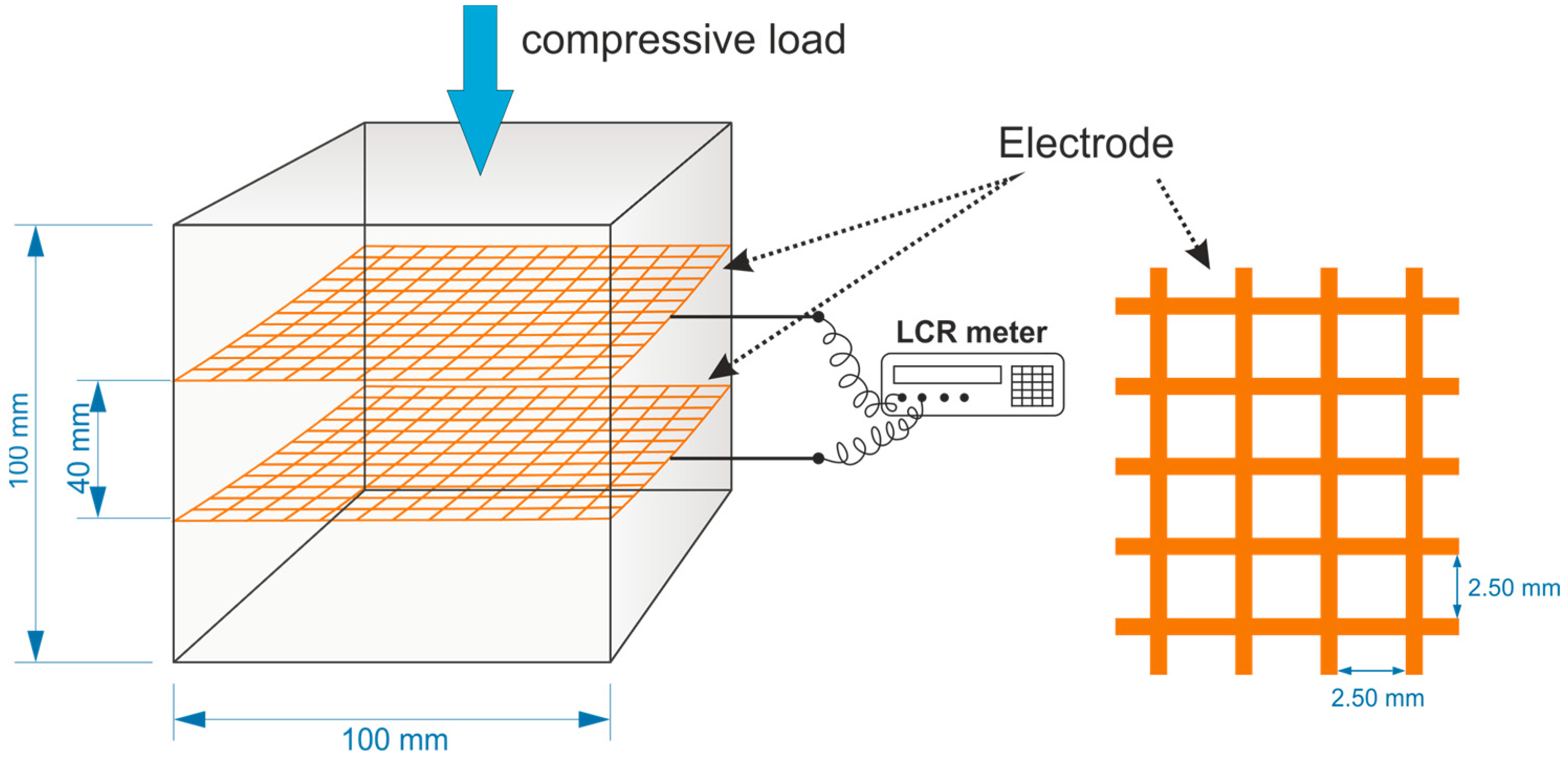

2.2. Testing Methods

3. Results

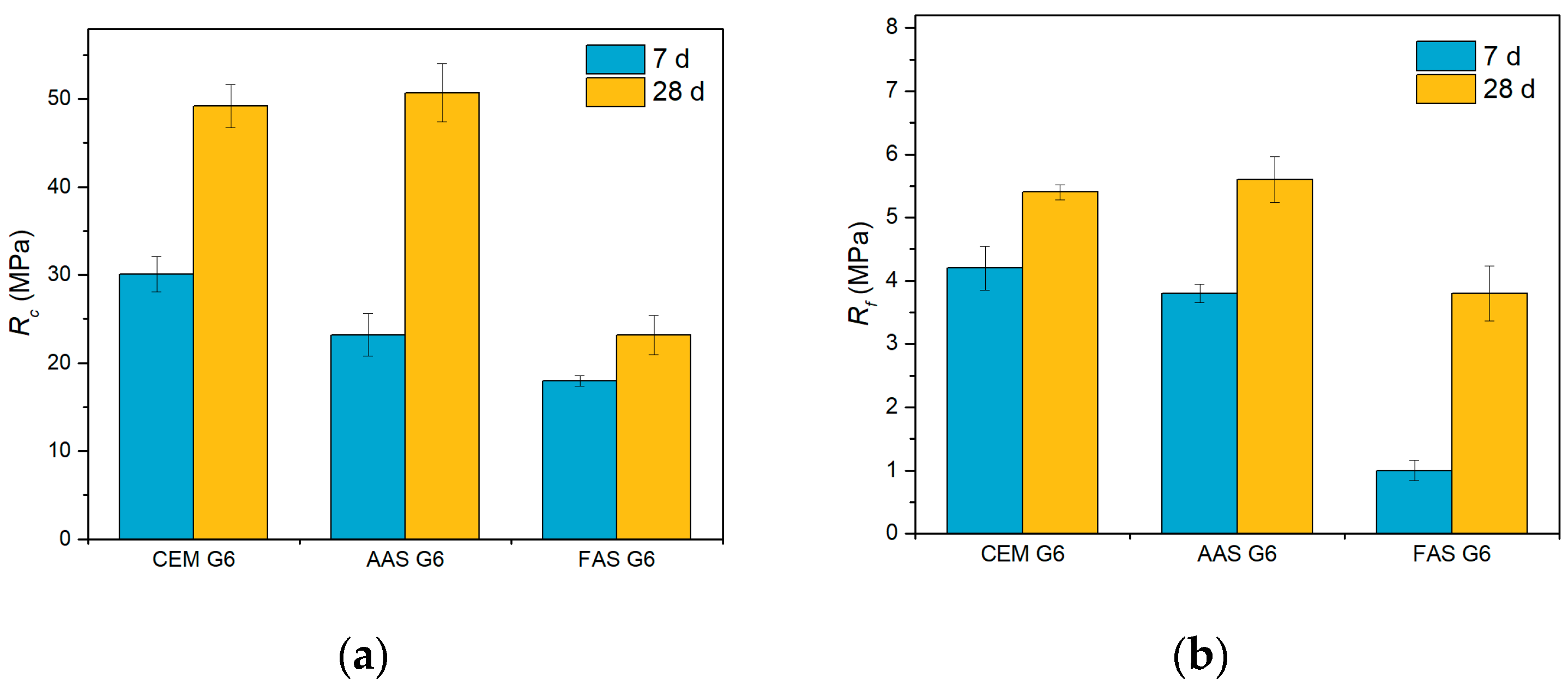

3.1. Mechanical Properties

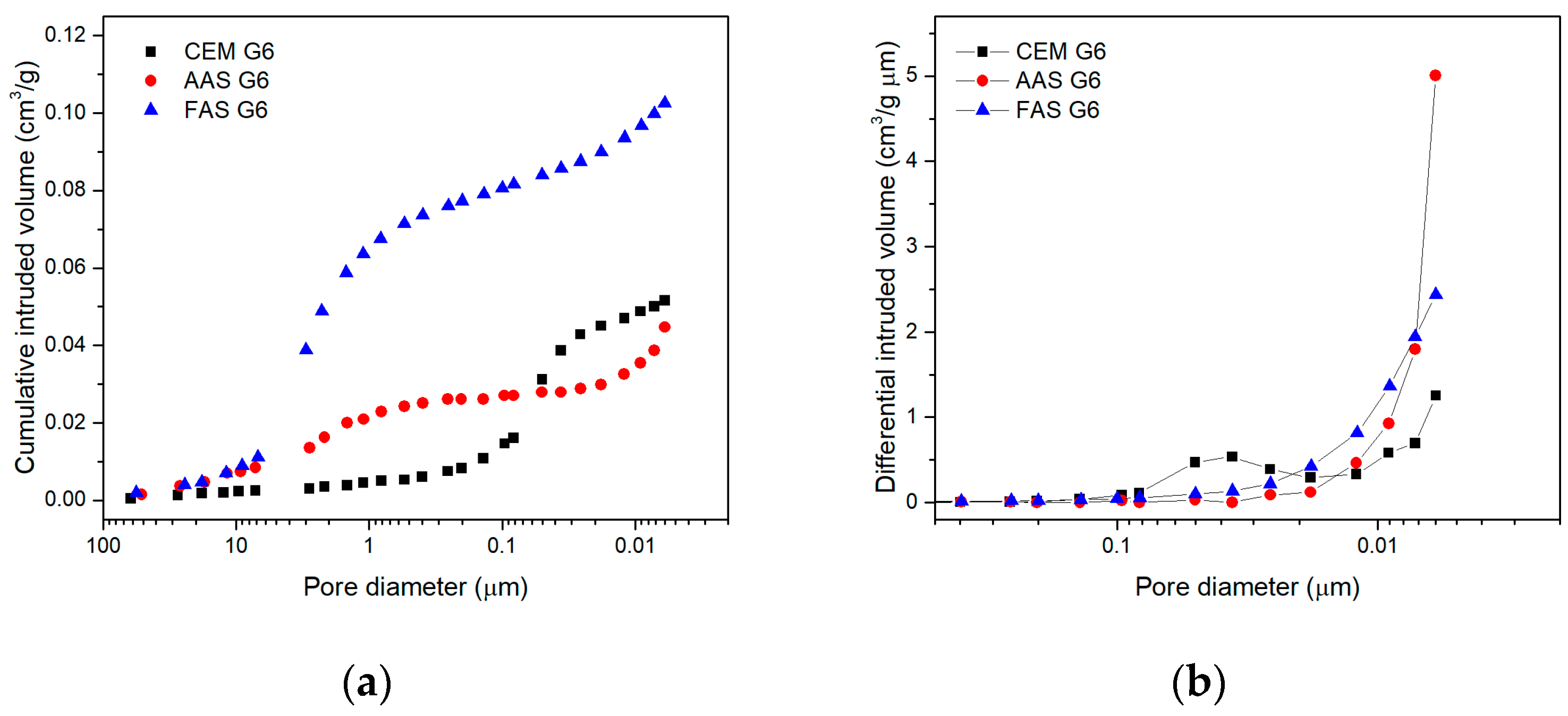

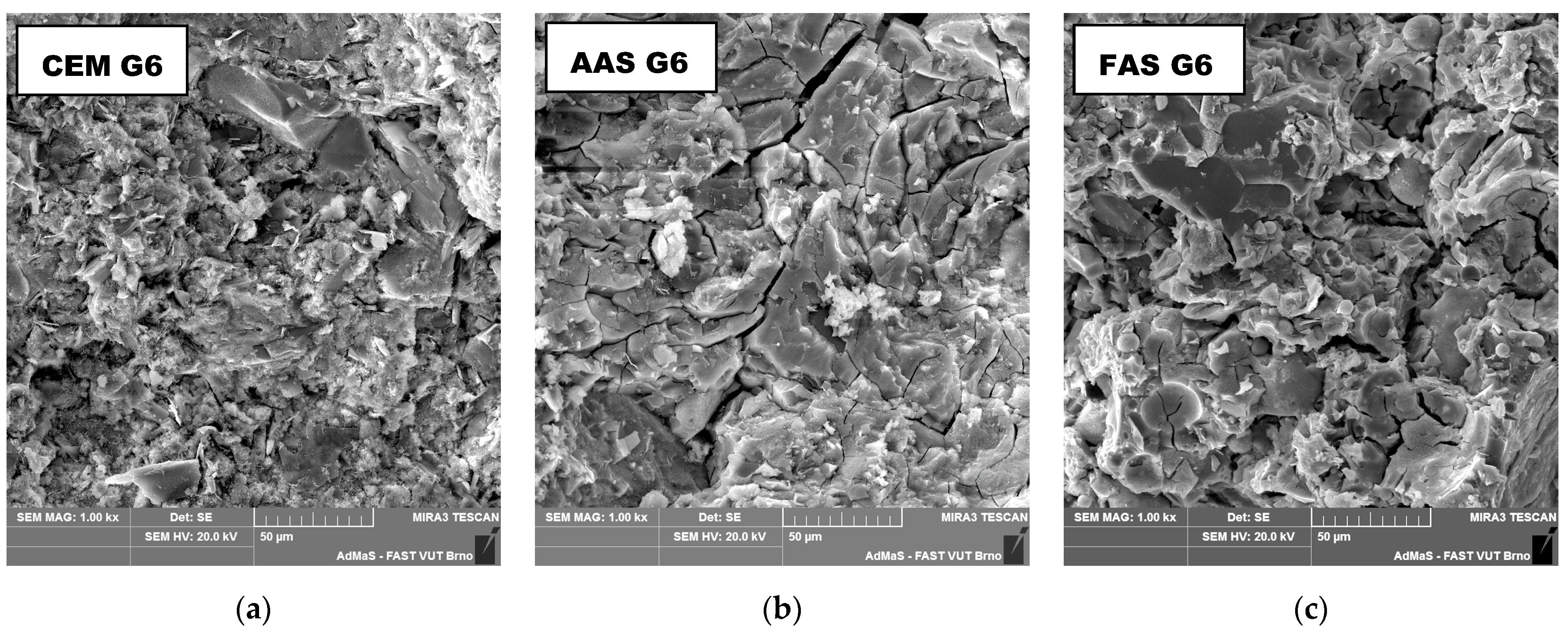

3.2. Mercury Intrusion Porosimetry

3.3. Self-Sensing Properties

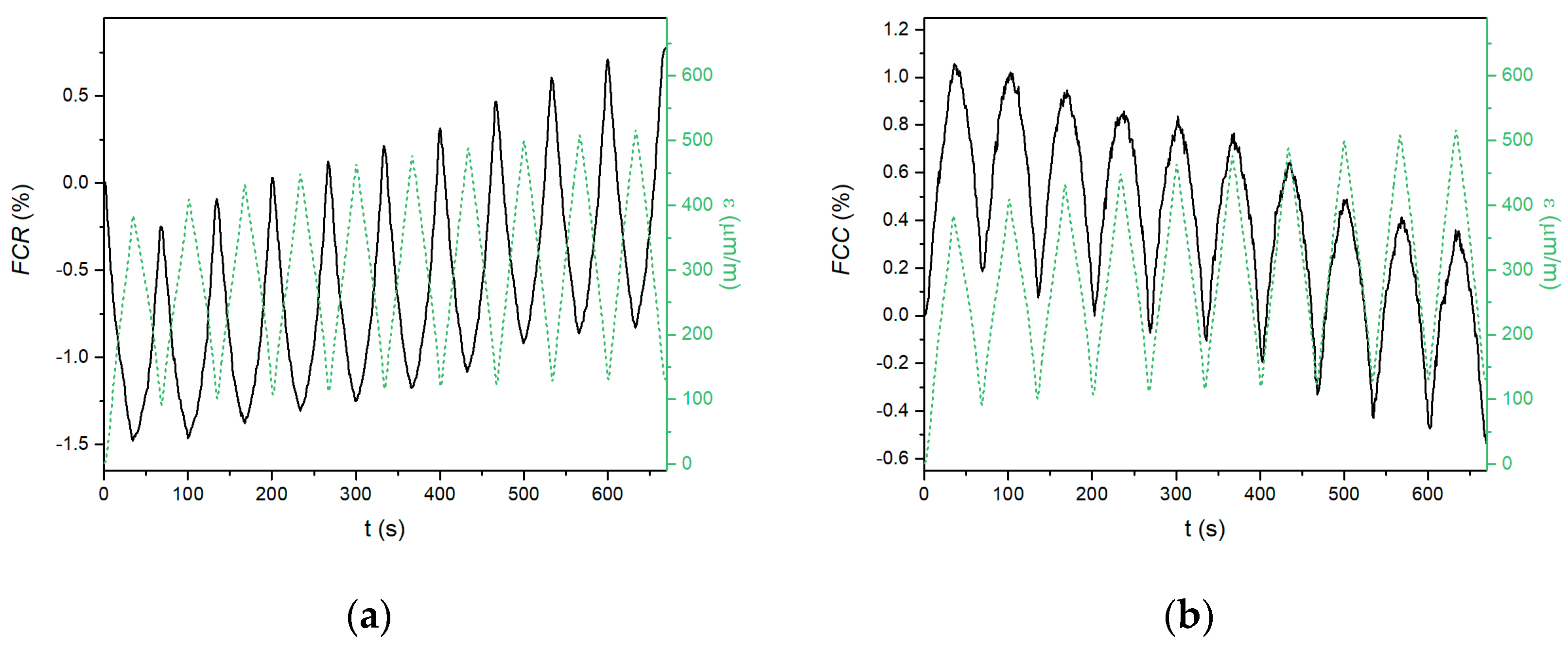

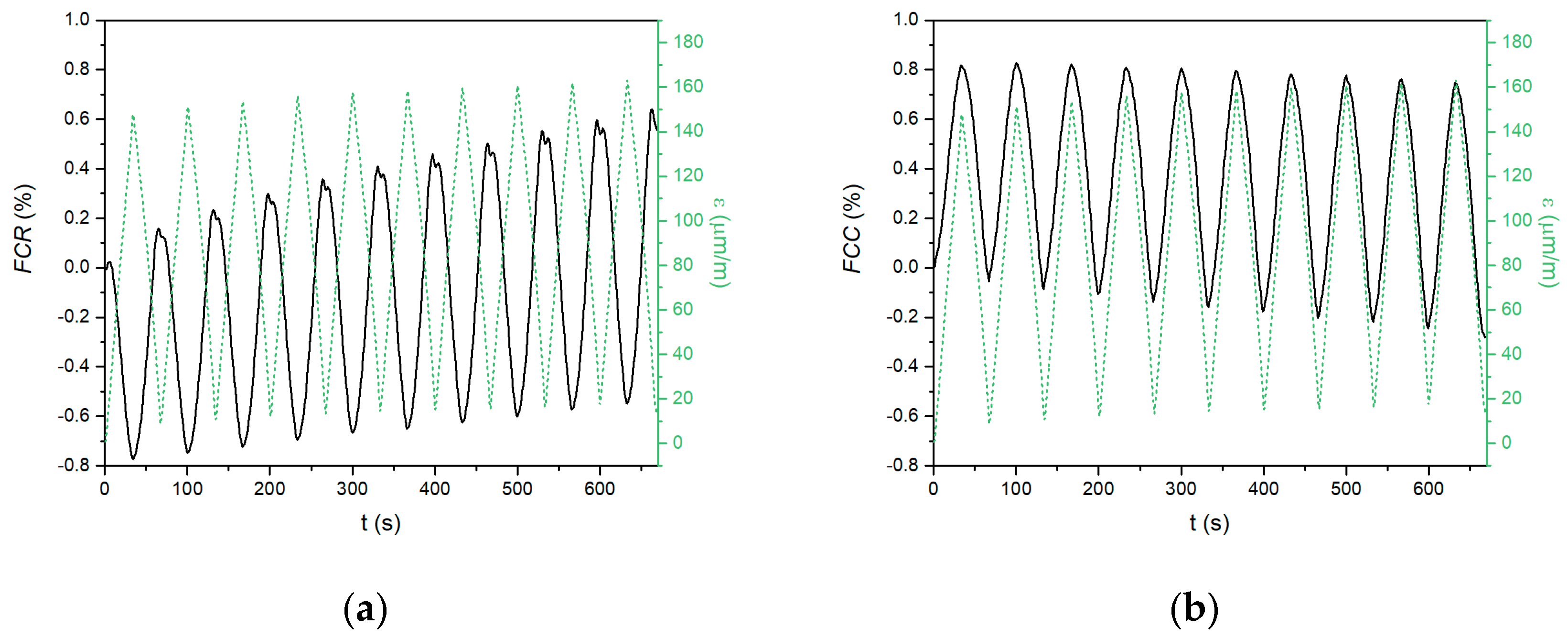

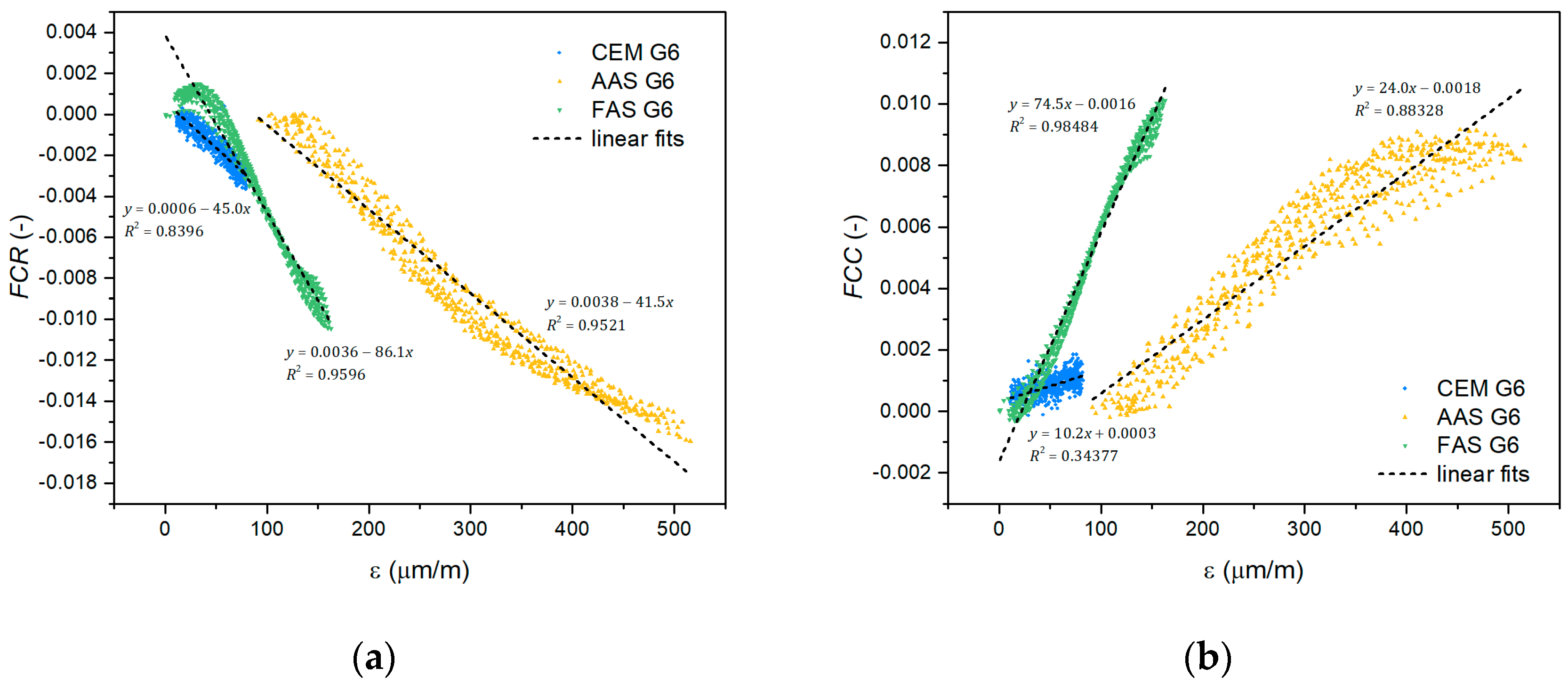

4. Discussion

5. Conclusions

- Alkali-activated composites (AAS G6 and FAS G6) show better electrical response to applied compressive load than cement-based composite. On the one hand, this is caused by a lower initial electrical resistance, and on the other hand, it is associated with a less stiff structure and higher compressive strain.

- All the composites showed an increase in baseline resistance and a decrease in baseline capacitance during cyclic loading, which can be attributed to permanent changes in the microstructure. Alkali-activated composites appeared more prone to permanent microstructural damage even at low compressive stress, likely due to the closing of pre-existing microcracks. The analysis of permanent changes in the electrical properties can be used to detect microstructural changes that are not reflected in other parameters, for example, compressive strain.

- The values of the gauge factors showed that the resistance-based self-sensing ability was generally better than that of capacitance-based sensing for all the composites tested. The fly ash/slag geopolymer composite (FAS G6) demonstrated the highest sensitivity for both resistance-based and capacitance-based sensing, with gauge factor values approximately twice as high as those of the other composites, which was attributed to its higher ionic conductivity from soluble alkalis.

- Overall, the study demonstrated that alkali-activated composites with graphite filler have promising self-sensing capabilities based on both resistance and capacitance measurements, which could be advantageous for smart structure applications, despite some compromise in the mechanical properties. The cement-based composite showed very poor sensitivity for capacitance-based sensing; in this regard, capacitance-based sensing is not suitable for ordinary Portland cement concrete when a sandwich configuration of electrodes is applied. The considerable variability in the initial capacitance among different materials requires further investigation of the conditions (temperature and moisture) that have a significant effect on the electrical parameters and the assessment of their influence on the self-sensing sensitivity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Bontea, D.-M.; Chung, D.D.L.; Lee, G.C. Damage in carbon fiber-reinforced concrete, monitored by electrical resistance measurement. Cem. Concr. Res. 2000, 30, 651–659. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Damage in carbon fiber-reinforced concrete, monitored by both electrical resistance measurement and acoustic emission analysis. Constr. Build. Mater. 2008, 22, 2196–2201. [Google Scholar] [CrossRef]

- Song, F.; Chen, Q.; Zheng, Q. Multifunctional ultra-high performance fibre-reinforced concrete with integrated self-sensing and repair capabilities towards in-situ structure monitoring. Compos. Struct. 2023, 321, 117240. [Google Scholar] [CrossRef]

- Wang, X.; Ding, S.; Ni, Y.-Q.; Zhang, L.; Dong, S.; Han, B. Intrinsic self-sensing concrete to energize infrastructure intelligence and resilience: A review. J. Infrastruct. Intell. Resil. 2024, 3, 100094. [Google Scholar] [CrossRef]

- Alsalman, A.; Assi, L.N.; Kareem, R.S.; Carter, K.; Ziehl, P. Energy and CO2 emission assessments of alkali-activated concrete and Ordinary Portland Cement concrete: A comparative analysis of different grades of concrete. Clean. Environ. Syst. 2021, 3, 100047. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J.; Xia, J. Compressive Strength and Chloride Resistance of Slag/Metakaolin-Based Ultra-High-Performance Geopolymer Concrete. Materials 2023, 16, 181. [Google Scholar] [CrossRef] [PubMed]

- Tennakoon, C.; Shayan, A.; Sanjayan, J.G.; Xu, A. Chloride ingress and steel corrosion in geopolymer concrete based on long term tests. Mater. Des. 2017, 116, 287–299. [Google Scholar] [CrossRef]

- Amorim Júnior, N.S.; Andrade Neto, J.S.; Santana, H.A.; Cilla, M.S.; Ribeiro, D.V. Durability and service life analysis of metakaolin-based geopolymer concretes with respect to chloride penetration using chloride migration test and corrosion potential. Constr. Build. Mater. 2021, 287, 122970. [Google Scholar] [CrossRef]

- Khan, H.A.; Castel, A.; Khan, M.S.H. Corrosion investigation of fly ash based geopolymer mortar in natural sewer environment and sulphuric acid solution. Corros. Sci. 2020, 168, 108586. [Google Scholar] [CrossRef]

- Sata, V.; Sathonsaowaphak, A.; Chindaprasirt, P. Resistance of lignite bottom ash geopolymer mortar to sulfate and sulfuric acid attack. Cem. Concr. Compos. 2012, 34, 700–708. [Google Scholar] [CrossRef]

- Bakharev, T. Durability of geopolymer materials in sodium and magnesium sulfate solutions. Cem. Concr. Res. 2005, 35, 1233–1246. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.B. Sulfate attack on alkali-activated slag concrete. Cem. Concr. Res. 2002, 32, 211–216. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Yonggen, W. Freeze–thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Özdal, M.; Karakoç, M.B.; Özcan, A. Investigation of the properties of two different slag-based geopolymer concretes exposed to freeze–thaw cycles. Struct. Concr. 2021, 22, E332–E340. [Google Scholar] [CrossRef]

- Zhao, R.; Yuan, Y.; Cheng, Z.; Wen, T.; Li, J.; Li, F.; Ma, Z.J. Freeze-thaw resistance of Class F fly ash-based geopolymer concrete. Constr. Build. Mater. 2019, 222, 474–483. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Debbarma, S.; Rashid, R.S.M. Fire resistance of geopolymer concrete: A critical review. Constr. Build. Mater. 2022, 324, 126722. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, Q.; Zhou, Q.; Li, X.; Xiang, Z. Experimental Study on Fire Resistance of Geopolymer High-Performance Concrete Prefabricated Stairs. Buildings 2024, 14, 3783. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W.; Luo, W. Thermal Behavior of Portland Cement and Fly Ash–Metakaolin-Based Geopolymer Cement Pastes. Arab. J. Sci. Eng. 2015, 40, 2261–2269. [Google Scholar] [CrossRef]

- Gökçe, H.S. Durability of slag-based alkali-activated materials: A critical review. J. Aust. Ceram. Soc. 2024, 60, 885–903. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Liang, T.; Ruan, S.; Wang, W.; Lin, J.; Liu, Y.; Yan, D. EIS investigation on electrical properties of metakaolin-based geopolymer. Constr. Build. Mater. 2024, 437, 136851. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Comparison of electrical and self-sensing properties of Portland cement and alkali-activated slag mortars. Cem. Concr. Res. 2019, 118, 84–91. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Tian, Z.; Li, Y.; Zheng, J.; Wang, S. A state-of-the-art on self-sensing concrete: Materials, fabrication and properties. Compos. Part B Eng. 2019, 177, 107437. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self sensing carbon nanotube (CNT) and nanofiber (CNF) cementitious composites for real time damage assessment in smart structures. Cem. Concr. Comp. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Al-Dahawi, A.; Sarwary, M.H.; Öztürk, O.; Yıldırım, G.; Akın, A.; Şahmaran, M.; Lachemi, M. Electrical percolation threshold of cementitious composites possessing self-sensing functionality incorporating different carbon-based materials. Smart Mater. Struct. 2016, 25, 105005. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Zi, G.; Lee, S.-J. Effects of carbon nanomaterial type and amount on self-sensing capacity of cement paste. Measurement 2019, 134, 750–761. [Google Scholar] [CrossRef]

- Thomoglou, A.K.; Falara, M.G.; Voutetaki, M.E.; Fantidis, J.G.; Tayeh, B.A.; Chalioris, C.E. Electromechanical properties of multi-reinforced self-sensing cement-based mortar with MWCNTs, CFs, and PPs. Constr. Build. Mater. 2023, 400, 132566. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, J.; Qiang, S.; Lu, H.; Li, J. Effect of carbon fibers and graphite particles on mechanical properties and electrical conductivity of cement composite. J. Build. Eng. 2024, 94, 110036. [Google Scholar] [CrossRef]

- Chen, P.-W.; Chung, D.D.L. Concrete as a new strain/stress sensor. Compos. Part B Eng. 1996, 27, 11–23. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Carbon fiber-reinforced cement as a thermistor. Cem. Concr. Res. 1999, 29, 961–965. [Google Scholar] [CrossRef]

- McAlorum, J.; Perry, M.; Vlachakis, C.; Biondi, L.; Lavoie, B. Robotic spray coating of self-sensing metakaolin geopolymer for concrete monitoring. Autom. Constr. 2021, 121, 103415. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P. Effect of water saturation on the electrical properties of cement and alkali-activated slag composites with graphite conductive admixture. Constr. Build. Mater. 2022, 361, 11. [Google Scholar] [CrossRef]

- Biondi, L.; Perry, M.; McAlorum, J.; Vlachakis, C.; Hamilton, A. Geopolymer-based moisture sensors for reinforced concrete health monitoring. Sens. Actuators B Chem. 2020, 309, 127775. [Google Scholar] [CrossRef]

- Chung, D.D.L. Damage detection using self-sensing concepts. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 509–520. [Google Scholar] [CrossRef]

- Mizerova, C.; Kusák, I.; Topolár, L.; Schmid, P.; Rovnaník, P. Self-Sensing Properties of Fly Ash Geopolymer Doped with Carbon Black under Compression. Materials 2021, 14, 4350. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Ma, E.; Chung, D.D.L.; Anderson, W.A. Self-monitoring in carbon fiber reinforced mortar by reactance measurement. Cem. Concr. Res. 1997, 27, 845–852. [Google Scholar] [CrossRef]

- Ozturk, M. Capacitance-based compression self-sensing effectiveness of cement paste with curing time. Mag. Concr. Res. 2023, 75, 965–972. [Google Scholar] [CrossRef]

- Mwelango, M.; Zhu, T.; Wen, K.; Zhang, Z.; Yuan, X.; Li, W.; Yin, X. Coplanar capacitive sensors and their applications in non-destructive evaluation: A review. Nondestruct. Test. Eval. 2023, 38, 861–905. [Google Scholar] [CrossRef]

- Ozturk, M.; Chung, D.D.L. Piezopermittivity of cement mortar with various water contents and its application to capacitance-based structural self-sensing of stress. Sens. Actuators A Phys. 2024, 369, 115206. [Google Scholar] [CrossRef]

- Ozturk, M.; Xi, X. Enhancing Capacitive Self-sensing Ability of Cement Mortar by Designing Electrode Configuration. J. Electron. Mater. 2025, 54, 1731–1738. [Google Scholar] [CrossRef]

- Chung, D.D.L.; Wang, Y. Capacitance-based stress self-sensing in cement paste without requiring any admixture. Cem. Concr. Comp. 2018, 94, 255–263. [Google Scholar] [CrossRef]

- Xi, X.; Ozturk, M.; Chung, D.D.L. DC electric polarization of cured cement paste being unexpectedly hindered by free water. J. Am. Ceram. Soc. 2022, 105, 1074–1082. [Google Scholar] [CrossRef]

- Hou, Y.-Y.; Sun, M.-Q.; Chen, J.-Z. Electrical resistance and capacitance responses of smart ultra-high performance concrete with compressive strain by DC and AC measurements. Constr. Build. Mater. 2022, 327, 127007. [Google Scholar] [CrossRef]

- Roshan, M.J.; Correia, A.G.; Fangueiro, R.; Mendes, P.M. Self-sensing cementitious composites for structural health monitoring: Recent advances and challenges and future prospects. Meas. Sci. Technol. 2024, 36, 012006. [Google Scholar] [CrossRef]

- Di Mare, M.; Ouellet-Plamondon, C.M. Greener, smarter, stronger: Self-sensing construction materials from one-part alkali-activated materials. Mater. Lett. 2023, 349, 134830. [Google Scholar] [CrossRef]

- Bi, S.; Liu, M.; Shen, J.; Hu, X.M.; Zhang, L. Ultrahigh Self-Sensing Performance of Geopolymer Nanocomposites via Unique Interface Engineering. ACS Appl. Mater. Interfaces 2017, 9, 12851–12858. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Coffetti, D.; Crotti, E.; Coppola, L.; Meoni, A.; Ubertini, F. Self-Sensing Properties of Green Alkali-Activated Binders with Carbon-Based Nanoinclusions. Sustainability 2020, 12, 9916. [Google Scholar] [CrossRef]

- Deng, L.; Ma, Y.; Hu, J.; Yin, S.; Ouyang, X.; Fu, J.; Liu, A.; Zhang, Z. Preparation and piezoresistive properties of carbon fiber-reinforced alkali-activated fly ash/slag mortar. Constr. Build. Mater. 2019, 222, 738–749. [Google Scholar] [CrossRef]

- Vlachakis, C.; Wang, X.; Al-Tabbaa, A. Investigation of the compressive self-sensing response of filler-free metakaolin geopolymer binders and coatings. Constr. Build. Mater. 2023, 392, 131682. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, W.; Hu, J.; Fu, J.; Zhang, Z.; Wang, H. Optimization on the piezoresistivity of alkali-activated fly ash/slag mortar by using conductive aggregates and carbon fibers. Cem. Concr. Comp. 2020, 114, 103735. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Electrical and Self-Sensing Properties of Alkali-Activated Slag Composite with Graphite Filler. Materials 2019, 12, 1616. [Google Scholar] [CrossRef] [PubMed]

- Luo, T.; Wang, Q.; Fang, Z. Effect of graphite on the self-sensing properties of cement and alkali-activated fly ash/slag based composite cementitious materials. J. Build. Eng. 2023, 77, 107493. [Google Scholar] [CrossRef]

- Lu, M.; Xie, H.; Wang, H.; Ma, Y. Self-sensing properties of steel fiber reinforced-alkali-activated fly ash/slag mortar. Constr. Build. Mater. 2025, 458, 139580. [Google Scholar] [CrossRef]

- Ma, Y.; Li, F.; Xie, H.; Liu, W.; Ouyang, X.; Fu, J.; Wang, H. Self-sensing properties of alkali-activated materials prepared with different precursors. Constr. Build. Mater. 2023, 409, 134201. [Google Scholar] [CrossRef]

- EN 196-1:2016 E; Methods of Testing Cement. Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016.

- Cui, P.; Wan, Y.; Shao, X.; Ling, X.; Zhao, L.; Gong, Y.; Zhu, C. Study on Shrinkage in Alkali-Activated Slag–Fly Ash Cementitious Materials. Materials 2023, 16, 3958. [Google Scholar] [CrossRef] [PubMed]

- Puertas, F.; Martínez-Ramírez, S.; Alonso, S.; Vázquez, T. Alkali-activated fly ash/slag cements: Strength behaviour and hydration products. Cem. Concr. Res. 2000, 30, 1625–1632. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Ou, J. Electrical characteristics and pressure-sensitive response measurements of carboxyl MWNT/cement composites. Cem. Concr. Comp. 2012, 34, 794–800. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, X. Positive and negative pressure sensitivities of carbon fiber-reinforcedcement-matrix composites and their mechanism. Acta Mater. Compos. Sin. 2005, 22, 40–46. [Google Scholar]

- Chung, D.D.L. Self-sensing concrete: From resistance-based sensing to capacitance-based sensing. Int. J. Smart Nano Mater. 2021, 12, 1–19. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Effect of water content on the piezoresistivity of MWNT/cement composites. J. Mater. Sci. 2010, 45, 3714–3719. [Google Scholar] [CrossRef]

- Saxena, S.C.; Tayal, G.M. Capacitive Moisture Meter. IEEE Trans. Ind. Electron. Control. Instrum. 1981, IECI-28, 37–39. [Google Scholar] [CrossRef]

- Hudec, P.; MacInnis, C.; Moukwa, M. The capacitance effect method of measuring moisture and salt content of concrete. Cem. Concr. Res. 1986, 16, 481–490. [Google Scholar] [CrossRef]

- Kucharczyková, B.; Nápravník, P.; Kocáb, D.; Lisztwan, D.; Rovnaník, P.; Hajzler, J.; Bílek, V. Comprehensive study of moist curing duration and activator type on mechanical properties, shrinkage, and cracking of alkali-activated slag. Constr. Build. Mater. 2024, 416, 135199. [Google Scholar] [CrossRef]

- Wei, Y.; Dou, H.; He, T.; Song, K.; Zhang, Q. Investigation of shrinkage mechanism of alkali-activated slag. Case Stud. Constr. Mater. 2024, 21, e03493. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | MnO | TiO2 | SO3 | Others |

|---|---|---|---|---|---|---|---|---|---|

| Slag (%) | 41.64 | 7.81 | 0.35 | 36.25 | 8.06 | 0.59 | 0.46 | 1.21 | 3.63 |

| Fly ash (%) | 51.67 | 23.31 | 7.08 | 4.45 | 0.36 | 1.14 | 1.00 | 0.01 | 10.98 |

| Cement (%) | 20.98 | 5.47 | 3.84 | 59.67 | 1.31 | 0.10 | 0.26 | 2.51 | 5.86 |

| Mixture | AAS G6 | FAS G6 | CEM G6 |

|---|---|---|---|

| Slag (g) | 1000 | 500 | - |

| Fly ash (g) | - | 500 | - |

| Cement (g) | - | - | 1000 |

| Britesil (g) | 200 | 400 | - |

| Sand (g) | 3000 | 3000 | 3000 |

| Graphite (g) | 60 | 60 | 60 |

| Triton X-100 (mL) | 30 | 30 | 30 |

| Lukosan S (mL) | 22 | 22 | 22 |

| Water (mL) | 415 | 404 | 400 |

| Mixture | CEM G6 | AAS G6 | FAS G6 |

|---|---|---|---|

| Initial resistance (Ω) | 9.81 × 105 | 9.60 × 104 | 180 |

| GFR | 45.0 ± 0.4 | 41.5 ± 0.7 | 86.1 ± 1.3 |

| Initial capacitance (nF) | 0.13 | 0.74 | 218 |

| GFc | 10.2 ± 0.3 | 24.0 ± 0.9 | 74.5 ± 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rovnaník, P.; Kusák, I.; Schmid, P.; Bayer, P. A Comparison of the Resistance- and Capacitance-Based Sensing of Geopolymer and Cement Composites with Graphite Filler Under Compression. Materials 2025, 18, 750. https://doi.org/10.3390/ma18040750

Rovnaník P, Kusák I, Schmid P, Bayer P. A Comparison of the Resistance- and Capacitance-Based Sensing of Geopolymer and Cement Composites with Graphite Filler Under Compression. Materials. 2025; 18(4):750. https://doi.org/10.3390/ma18040750

Chicago/Turabian StyleRovnaník, Pavel, Ivo Kusák, Pavel Schmid, and Patrik Bayer. 2025. "A Comparison of the Resistance- and Capacitance-Based Sensing of Geopolymer and Cement Composites with Graphite Filler Under Compression" Materials 18, no. 4: 750. https://doi.org/10.3390/ma18040750

APA StyleRovnaník, P., Kusák, I., Schmid, P., & Bayer, P. (2025). A Comparison of the Resistance- and Capacitance-Based Sensing of Geopolymer and Cement Composites with Graphite Filler Under Compression. Materials, 18(4), 750. https://doi.org/10.3390/ma18040750