Application of Novel Machine Learning Techniques for Predicting the Surface Chloride Concentration in Concrete Containing Waste Material

Abstract

:1. Introduction

2. Materials and Methods

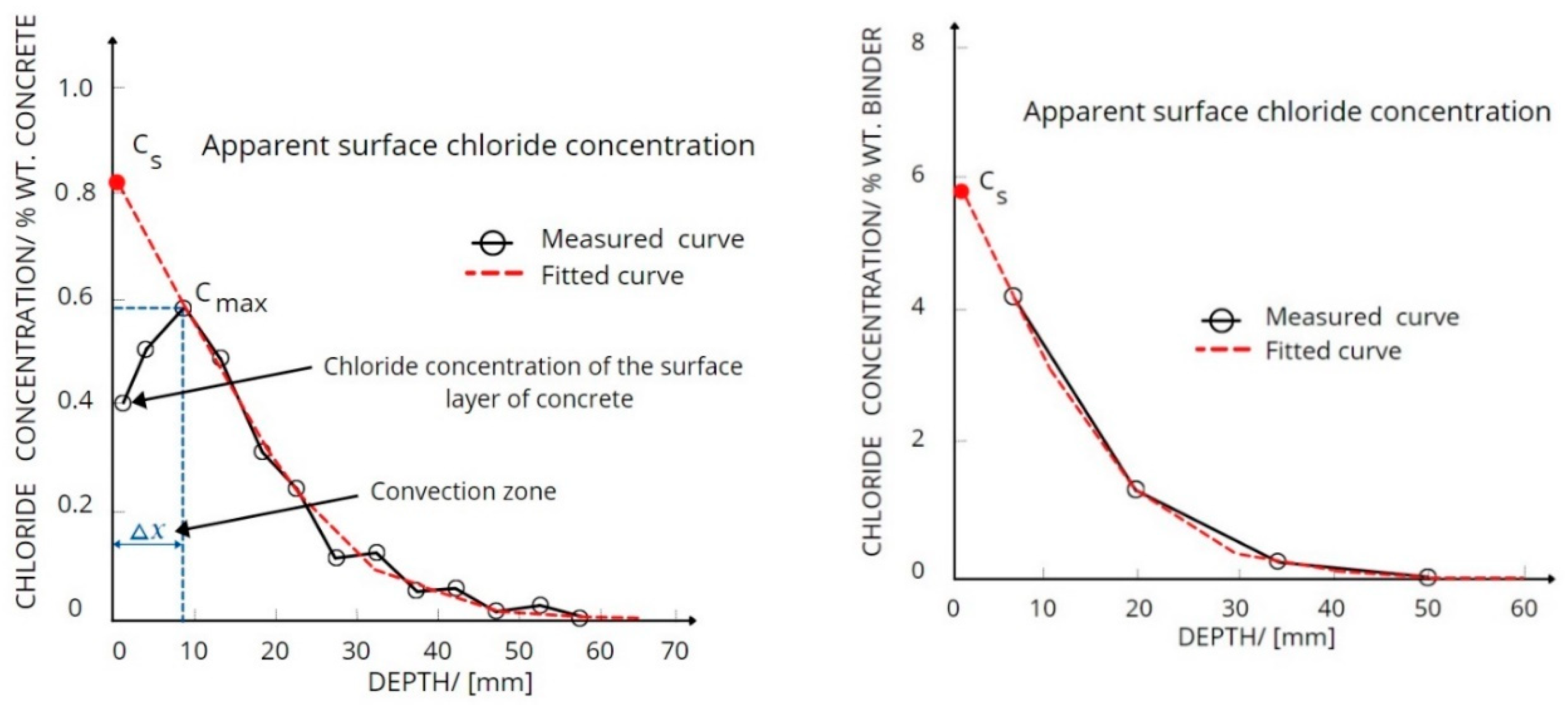

2.1. Apparent Surface Chloride Content

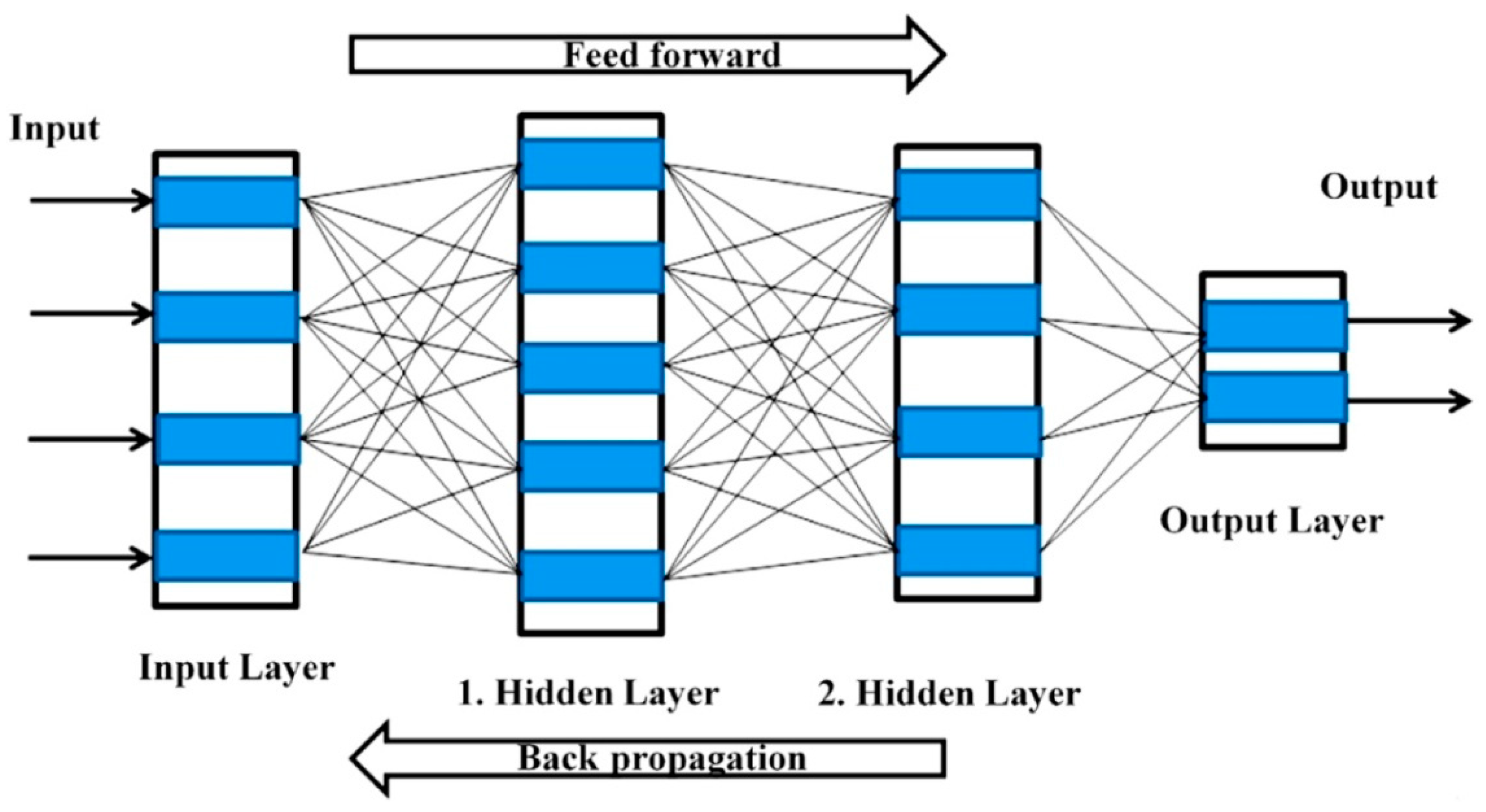

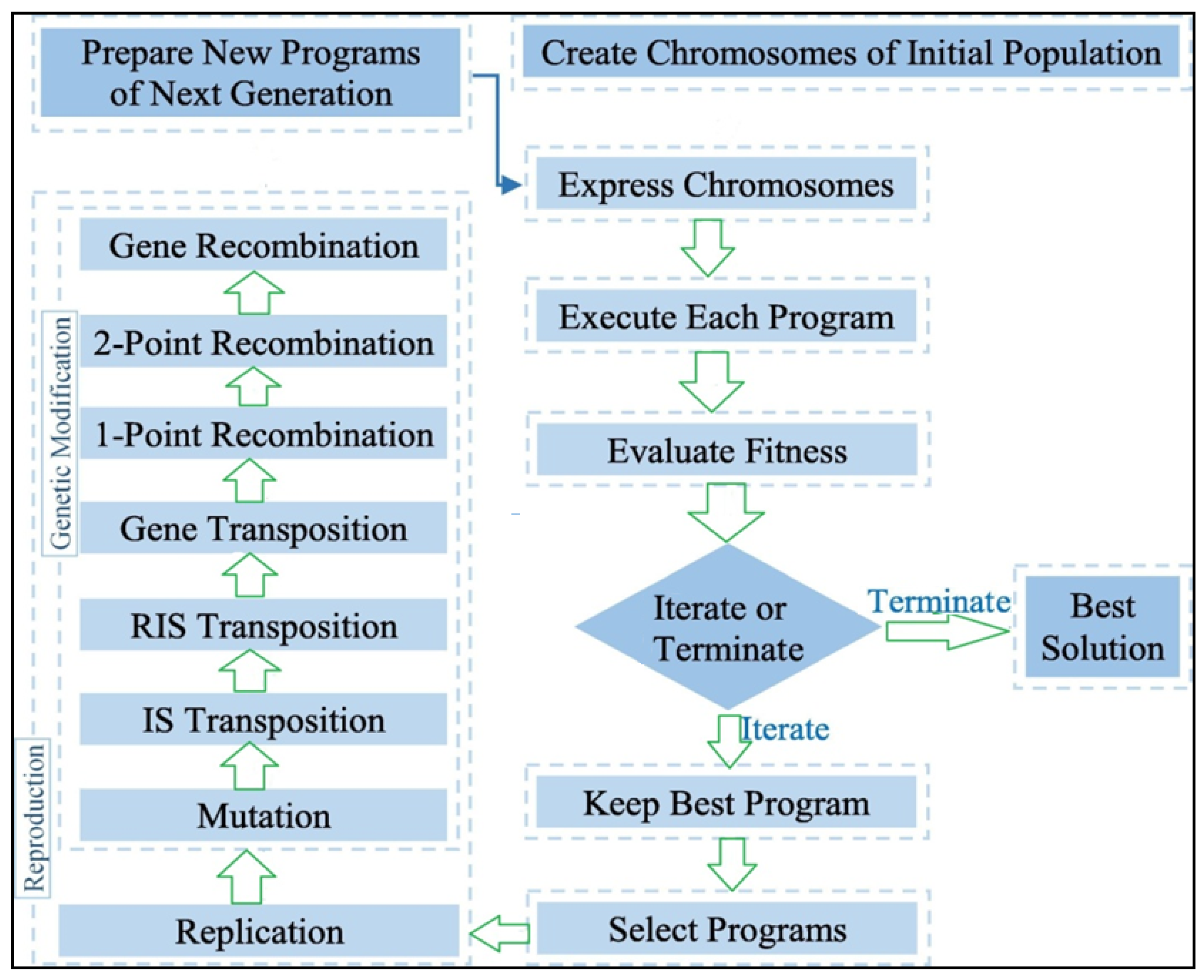

2.2. Machine Learning (ML) and Ensemble Learning (EL) Approaches

2.3. Description of the Obtained Data

2.4. Machine Learning Algorithms

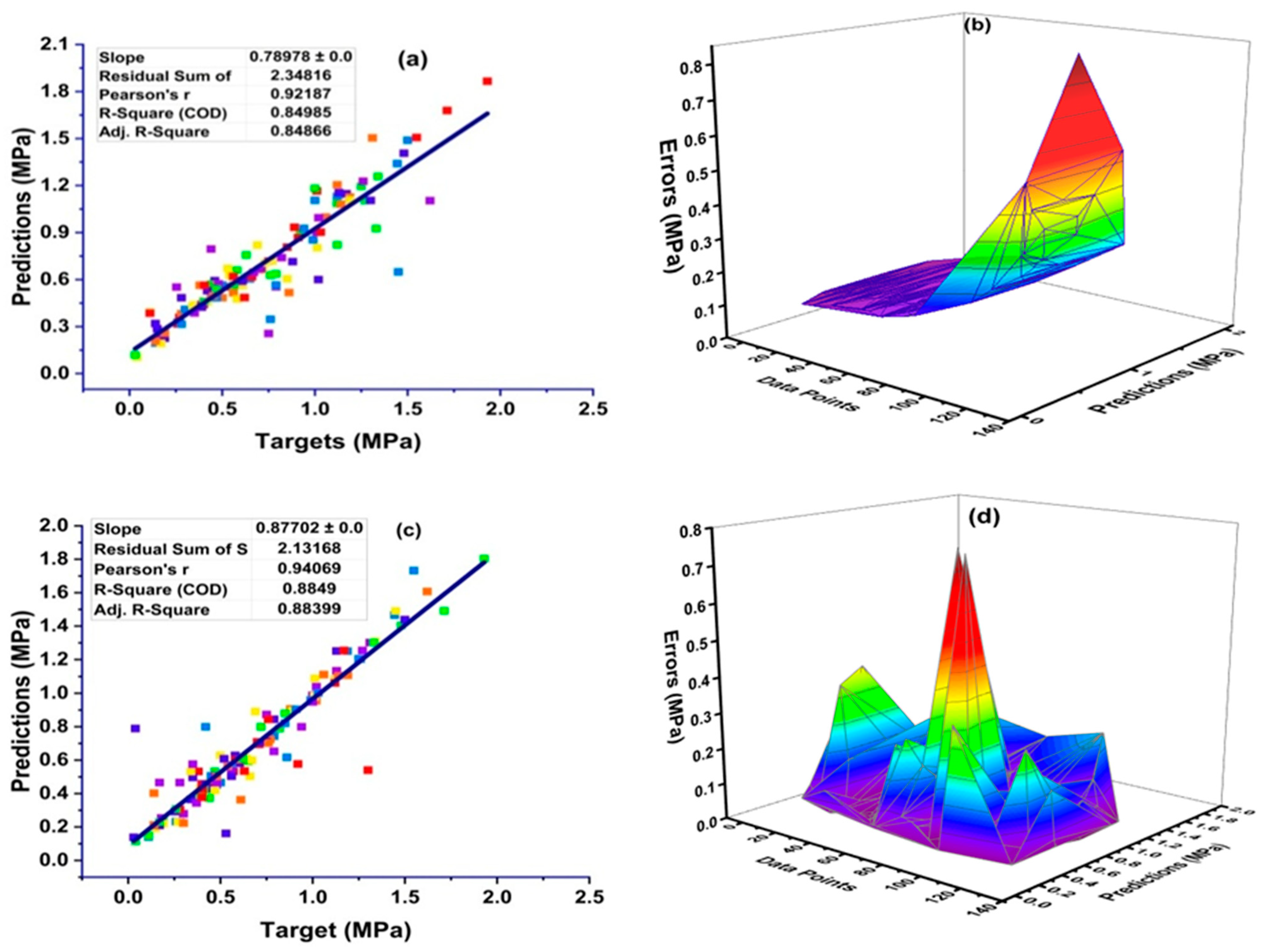

3. Results and Their Analyses

3.1. Statistical Analysis

3.2. K-Fold Cross Validation

- —experimental value;

- —predicted value;

- —mean experimental value;

- —mean predicted value obtained by the model;

- n—number of samples.

4. Discussion

5. Conclusions

- ●

- The GEP algorithm is very effective for predicting chloride surface concentrations and can be successfully used for this purpose. This was also proved by comparing it with other algorithms used in the literature.

- ●

- The presented method does not depend on the zone in which it is used (except the atmospheric zone where the transport of chloride ions is more difficult to describe).

- ●

- The high performance of the GEP algorithm was also proved using k-fold validation.

- ●

- The dataset can be expanded with laboratory tests, field tests, or numerical analyses using different upsizing methods (e.g., Monte Carlo).

- ●

- There is still the possibility of expanding the dataset with the results of surface chloride concentrations obtained for elements located in the atmospheric zone.

- ●

- Due to the fact that there is no model in the literature that is 100% accurate, there is still the possibility of using a different, more accurate, algorithm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Notations | |

| ML | Machine learning |

| HPC | High performance concrete |

| GGBS | Ground granulated blast furnace slag |

| GEP | Genetic engineering programming |

| ANN | Artificial neural network |

| Dt | Decision tree |

| DL | Deep learning |

| DM | Deep machine |

| RF | Random forest |

| GB | Gradient boosting |

| FA | Fly ash |

| SF | Silica fume |

| POFA | Palm oil fuel ash |

| SCC | Self-compacting concrete |

| RHA | Rice husk ash |

| RKSA | Random kitchen sink algorithm |

| SVM | Support vector machine |

| ANFIS | Adaptive neuro fuzzy inference system |

| IREMSVM-FR | Intelligent rule-based enhanced multiclass support vector machine |

| RMS | Response surface method |

References

- Scott, R.H.; Chikermane, S.; Vidakovic, M.; McKinley, B.; Sun, T.; Banerji, P.; Grattan, K.T.V. Development of low cost packaged fibre optic sensors for use in reinforced concrete structures. Meas. J. Int. Meas. Confed. 2019, 135, 617–624. [Google Scholar] [CrossRef]

- Ryl, J.; Wysocka, J.; Cieslik, M.; Gerengi, H.; Ossowski, T.; Krakowiak, S.; Niedzialkowski, P. Understanding the origin of high corrosion inhibition efficiency of bee products towards aluminium alloys in alkaline environments. Electrochim. Acta 2019, 304, 263–274. [Google Scholar] [CrossRef]

- Moreno, J.D.; Bonilla, M.; Adam, J.M.; Borrachero, M.V.; Soriano, L. Determining corrosion levels in the reinforcement rebars of buildings in coastal areas. A case study in the Mediterranean coastline. Constr. Build. Mater. 2015, 100, 11–21. [Google Scholar] [CrossRef]

- Zhang, P.; Cong, Y.; Vogel, M.; Liu, Z.; Müller, H.S.; Zhu, Y.; Zhao, T. Steel reinforcement corrosion in concrete under combined actions: The role of freeze-thaw cycles, chloride ingress, and surface impregnation. Constr. Build. Mater. 2017, 148, 113–121. [Google Scholar] [CrossRef]

- Balafas, I.; Burgoyne, C.J. Environmental effects on cover cracking due to corrosion. Cem. Concr. Res. 2010, 40, 1429–1440. [Google Scholar] [CrossRef]

- Ann, K.Y.; Ahn, J.H.; Ryou, J.S. The importance of chloride content at the concrete surface in assessing the time to corrosion of steel in concrete structures. Constr. Build. Mater. 2009, 23, 239–245. [Google Scholar] [CrossRef]

- Nikoo, M.; Sadowski, Ł.; Nikoo, M. Prediction of the Corrosion Current Density in Reinforced Concrete Using a Self-Organizing Feature Map. Coatings 2017, 7, 160. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, L. Non-destructive investigation of corrosion current density in steel reinforced concrete by artificial neural networks. Archiv. Civ. Mech. Eng. 2013, 13, 104–111. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Shah, S.H.A.; Rehman, S.U.; Hussain, I.; Iqbal, M. A step towards durable, ductile and sustainable concrete: Simultaneous incorporation of recycled aggregates, glass fiber and fly ash. Constr. Build. Mater. 2020, 251, 118980. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, Z.; Du, J.; Sui, L.; Xing, F. Bond behavior of FRP-to-concrete interface under sulfate attack: An experimental study and modeling of bond degradation. Constr. Build. Mater. 2015, 85, 9–21. [Google Scholar] [CrossRef]

- Akiyama, M.; Frangopol, D.M.; Suzuki, M. Integration of the effects of airborne chlorides into reliability-based durability design of reinforced concrete structures in a marine environment. Struct. Infrastruct. Eng. 2012, 8, 125–134. [Google Scholar] [CrossRef]

- Sadowski, L.; Nikoo, M. Corrosion current density prediction in reinforced concrete by imperialist competitive algorithm. Neural Comput. Appl. 2014, 25, 1627–1638. [Google Scholar] [CrossRef] [Green Version]

- Dai, J.G.; Akira, Y.; Wittmann, F.H.; Yokota, H.; Zhang, P. Water repellent surface impregnation for extension of service life of reinforced concrete structures in marine environments: The role of cracks. Cem. Concr. Compos. 2010, 32, 101–109. [Google Scholar] [CrossRef]

- Moradllo, M.K.; Shekarchi, M.; Hoseini, M. Time-dependent performance of concrete surface coatings in tidal zone of marine environment. Constr. Build. Mater. 2012, 30, 198–205. [Google Scholar] [CrossRef]

- Zuquan, J.; Xia, Z.; Tiejun, Z.; Jianqing, L. Chloride ions transportation behavior and binding capacity of concrete exposed to different marine corrosion zones. Constr. Build. Mater. 2018, 177, 170–183. [Google Scholar] [CrossRef]

- Liu, Q.-F.; Hu, Z.; Lu, X.-Y.; Yang, J.; Azim, I.; Sun, W. Prediction of Chloride Distribution for Offshore Concrete Based on Statistical Analysis. Materials 2020, 13, 174. [Google Scholar] [CrossRef] [Green Version]

- Bastidas-Arteaga, E.; Chateauneuf, A.; Sánchez-Silva, M.; Bressolette, P.; Schoefs, F. A comprehensive probabilistic model of chloride ingress in unsaturated concrete. Eng. Struct. 2011, 33, 720–730. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.B.; Zhou, W.H.; Sadowski, Ł.; Yin, Z.Y. Metaheuristic model for the interface shear strength between granular soil and structure considering surface morphology. Comput. Geotech. 2021, 135, 104141. [Google Scholar] [CrossRef]

- Cai, R.; Han, T.; Liao, W.; Huang, J.; Li, D.; Kumar, A.; Ma, H. Prediction of surface chloride concentration of marine concrete using ensemble machine learning. Cem. Concr. Res. 2020, 136, 106164. [Google Scholar] [CrossRef]

- Hoang, N.D.; Chen, C.T.; Liao, K.W. Prediction of chloride diffusion in cement mortar using Multi-Gene Genetic Programming and Multivariate Adaptive Regression Splines. Measurement 2017, 112, 141–149. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the compressive strength of silica fume concrete using hybrid artificial neural network with multi-objective grey wolves. J. Clean. Prod. 2018, 202, 54–64. [Google Scholar] [CrossRef]

- Getahun, M.A.; Shitote, S.M.; Gariy, Z.C.A. Artificial neural network based modelling approach for strength prediction of concrete incorporating agricultural and construction wastes. Constr. Build. Mater. 2018, 190, 517–525. [Google Scholar] [CrossRef]

- Ling, H.; Qian, C.; Kang, W.; Liang, C.; Chen, H. Combination of Support Vector Machine and K-Fold cross validation to predict compressive strength of concrete in marine environment. Constr. Build. Mater. 2019, 206, 355–363. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Deo, R.C.; Hilal, A.; Abd, A.M.; Bueno, L.C.; Salcedo-Sanz, S.; Nehdi, M.L. Predicting compressive strength of lightweight foamed concrete using extreme learning machine model. Adv. Eng. Softw. 2018, 115, 112–125. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Sistonen, E. Machine learning for durability and service-life assessment of reinforced concrete structures: Recent advances and future directions. Autom. Constr. 2017, 77, 1–14. [Google Scholar] [CrossRef]

- Yokoyama, S.; Matsumoto, T. Development of an Automatic Detector of Cracks in Concrete Using Machine Learning. Procedia Eng. 2017, 1250–1255. [Google Scholar] [CrossRef]

- Chaabene, W.B.; Flah, M.; Nehdi, M.L. Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 2020, 260. [Google Scholar] [CrossRef]

- Farooq, F.; Ahmed, W.; Akbar, A.; Aslam, F.; Alyousef, R. Predictive modelling for sustainable high-performance concrete from industrial wastes: A comparison and optimization of models using ensemble learners. J. Clean. Prod. 2021, 126032. [Google Scholar] [CrossRef]

- Balf, F.R.; Kordkheili, H.M.; Kordkheili, A.M. A New Method for Predicting the Ingredients of Self-Compacting Concrete (SCC) Including Fly Ash (FA) Using Data Envelopment Analysis (DEA). Arab. J. Sci. Eng. 2020, 1–22. [Google Scholar] [CrossRef]

- Bušić, R.; Benšić, M.; Miličević, I.; Strukar, K. Prediction models for the mechanical properties of self-compacting concrete with recycled rubber and silica fume. Materials 2020, 13, 1821. [Google Scholar] [CrossRef] [Green Version]

- Azimi-Pour, M.; Eskandari-Naddaf, H.; Pakzad, A. Linear and non-linear SVM prediction for fresh properties and compressive strength of high volume fly ash self-compacting concrete. Constr. Build. Mater. 2020, 230, 117021. [Google Scholar] [CrossRef]

- Saha, P.; Debnath, P.; Thomas, P. Prediction of fresh and hardened properties of self-compacting concrete using support vector regression approach. Neural Comput. Appl. 2020, 32, 7995–8010. [Google Scholar] [CrossRef]

- Al-Mughanam, T.; Aldhyani, T.H.H.; Alsubari, B.; Al-Yaari, M. Modeling of compressive strength of sustainable self-compacting concrete incorporating treated palm oil fuel ash using artificial neural network. Sustainability 2020, 12, 9322. [Google Scholar] [CrossRef]

- Javed, M.F.; Farooq, F.; Memon, S.A.; Akbar, A.; Khan, M.A.; Aslam, F.; Alyousef, R.; Alabduljabbar, H.; Rehman, S.K.U. New prediction model for the ultimate axial capacity of concrete-filled steel tubes: An evolutionary approach. Crystals 2020, 10, 741. [Google Scholar] [CrossRef]

- Aslam, F.; Farooq, F.; Amin, M.N.; Khan, K.; Waheed, A.; Akbar, A.; Javed, M.F.; Alyousef, R.; Alabdulijabbar, H. Applications of Gene Expression Programming for Estimating Compressive Strength of High-Strength Concrete. Adv. Civ. Eng. 2020. [Google Scholar] [CrossRef]

- Farooq, F.; Amin, M.N.; Khan, K.; Sadiq, M.R.; Javed, M.F.; Aslam, F.; Alyousef, R. A comparative study of random forest and genetic engineering programming for the prediction of compressive strength of high strength concrete (HSC). Appl. Sci. 2020, 10, 7330. [Google Scholar] [CrossRef]

- Asteris, P.G.; Kolovos, K.G. Self-compacting concrete strength prediction using surrogate models. Neural Comput. Appl. 2019, 31, 409–424. [Google Scholar] [CrossRef]

- Selvaraj, S.; Sivaraman, S. Prediction model for optimized self-compacting concrete with fly ash using response surface method based on fuzzy classification. Neural Comput. Appl. 2019, 31, 1365–1373. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, G.; Huang, Y.; Sun, J.; Aslani, F.; Nener, B. Modelling uniaxial compressive strength of lightweight self-compacting concrete using random forest regression. Constr. Build. Mater. 2019, 210, 713–719. [Google Scholar] [CrossRef]

- Kaveh, A.; Bakhshpoori, T.; Hamze-Ziabari, S.M. M5’ and mars based prediction models for properties of selfcompacting concrete containing fly ash. Period. Polytech. Civ. Eng. 2018, 62, 281–294. [Google Scholar] [CrossRef] [Green Version]

- Sathyan, D.; Anand, K.B.; Prakash, A.J.; Premjith, B. Modeling the Fresh and Hardened Stage Properties of Self-Compacting Concrete using Random Kitchen Sink Algorithm. Int. J. Concr. Struct. Mater. 2018, 12, 1–10. [Google Scholar] [CrossRef]

- Vakhshouri, B.; Nejadi, S. Prediction of compressive strength of self-compacting concrete by ANFIS models. Neurocomputing 2018, 280, 13–22. [Google Scholar] [CrossRef]

- Douma, O.B.; Boukhatem, B.; Ghrici, M.; Tagnit-Hamou, A. Prediction of properties of self-compacting concrete containing fly ash using artificial neural network. Neural Comput. Appl. 2017, 28, 707–718. [Google Scholar] [CrossRef]

- Yaman, M.A.; Abd Elaty, M.; Taman, M. Predicting the ingredients of self compacting concrete using artificial neural network. Alex. Eng. J. 2017, 56, 523–532. [Google Scholar] [CrossRef]

- Asteris, P.G.; Kolovos, K.G.; Douvika, M.G.; Roinos, K. Prediction of self-compacting concrete strength using artificial neural networks. Eur. J. Environ. Civ. Eng. 2016, 20, s102–s122. [Google Scholar] [CrossRef]

- Siddique, R.; Aggarwal, P.; Aggarwal, Y. Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks. Adv. Eng. Softw. 2011, 42, 780–786. [Google Scholar] [CrossRef]

- Prasad, B.K.R.; Eskandari, H.; Reddy, B.V.V. Prediction of compressive strength of SCC and HPC with high volume fly ash using ANN. Constr. Build. Mater. 2009, 23, 117–128. [Google Scholar] [CrossRef]

- Chalee, W.; Jaturapitakkul, C.; Chindaprasirt, P. Predicting the chloride penetration of fly ash concrete in seawater. Mar. Struct. 2009, 22, 341–353. [Google Scholar] [CrossRef]

- Costa, A.; Appleton, J. Chloride penetration into concrete in marine environment-Part I: Main parameters affecting chloride penetration. Mater. Struct. Constr. 1999, 32, 252–259. [Google Scholar] [CrossRef]

- Huan, X.U.E.; Zuquan, J.I.N.; Xiaojie, W. Chloride ion penetration into concrete exposed to marine environment for a long period. Ocean Eng. 2015, 33, 60–65. [Google Scholar]

- Moradllo, M.K.; Sadati, S.; Shekarchi, M. Quantifying maximum phenomenon in chloride ion profiles and its influence on service-life prediction of concrete structures exposed to seawater tidal zone-A field oriented study. Constr. Build. Mater. 2018, 180, 109–116. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, L.; Wang, Y.; Li, Q.; Xiao, Z. Prediction model of long-term chloride diffusion into plain concrete considering the effect of the heterogeneity of materials exposed to marine tidal zone. Constr. Build. Mater. 2018, 159, 297–315. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Zhang, Y.; Huang, J.; Zhuang, H.X.; Zhang, J.Z. Time dependence and similarity analysis of peak value of chloride concentration of concrete under the simulated chloride environment. Constr. Build. Mater. 2018, 181, 609–617. [Google Scholar] [CrossRef]

- Safehian, M.; Ramezanianpour, A.A. Assessment of service life models for determination of chloride penetration into silica fume concrete in the severe marine environmental condition. Constr. Build. Mater. 2013, 48, 287–294. [Google Scholar] [CrossRef]

- Nanukuttan, S.V.; Basheer, L.; McCarter, W.J.; Robinson, D.J.; Basheer, P.M. Muhammed Basheer, Full-scale marine exposure tests on treated and untreated concretes-initial 7-year results. ACI Mater. J. 2008, 105, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Markeset, G.; Skjølsvold, O. Time Dependent Chloride Diffusion Coefficient-Field Studies of Concrete Exposed to Marine Environment in Norway. In Proceedings of the 2nd International Symposium on Service Life Design for Infrastructure, Delft, The Netherlands, 4–6 October 2010; pp. 83–90. [Google Scholar]

- Safehian, M.; Ramezanianpour, A.A. Prediction of RC structure service life from field long term chloride diffusion. Comput. Concr. 2015, 15, 589–606. [Google Scholar] [CrossRef]

- Song, H.W.; Lee, C.H.; Ann, K.Y. Factors influencing chloride transport in concrete structures exposed to marine environments. Cem. Concr. Compos. 2008, 30, 113–121. [Google Scholar] [CrossRef]

- Pack, S.W.; Jung, M.S.; Song, H.W.; Kim, S.H.; Ann, K.Y. Prediction of time dependent chloride transport in concrete structures exposed to a marine environment. Cem. Concr. Res. 2010, 40, 302–312. [Google Scholar] [CrossRef]

- Ghods, P.; Chini, M.; Alizadeh, R.; Hoseini, M. The Effect of Different Exposure Conditions on the Chloride Diffusion into Concrete in the Persian Gulf Region. In Proceedings of the 3th ConMAT; University of British Columbia: Vancouver, BC, Canada, 2005. [Google Scholar]

- Farahani, A.; Taghaddos, H.; Shekarchi, M. Prediction of long-term chloride diffusion in silica fume concrete in a marine environment. Cem. Concr. Compos. 2015, 59, 10–17. [Google Scholar] [CrossRef]

- Gao, Y.H.; Zhang, J.Z.; Zhang, S.; Zhang, Y.R. Probability distribution of convection zone depth of chloride in concrete in a marine tidal environment. Constr. Build. Mater. 2017, 140, 485–495. [Google Scholar] [CrossRef]

- Pang, L.; Li, Q. Service life prediction of RC structures in marine environment using long term chloride ingress data: Comparison between exposure trials and real structure surveys. Constr. Build. Mater. 2016, 113, 979–987. [Google Scholar] [CrossRef]

- Valipour, M.; Pargar, F.; Shekarchi, M.; Khani, S.; Moradian, M. In situ study of chloride ingress in concretes containing natural zeolite, metakaolin and silica fume exposed to various exposure conditions in a harsh marine environment. Constr. Build. Mater. 2013, 46, 63–70. [Google Scholar] [CrossRef]

- Alizadeh, R.; Ghods, P.; Chini, M.; Hoseini, M.; Ghalibafian, M.; Shekarchi, M. Effect of Curing Conditions on the Service Life Design of RC Structures in the Persian Gulf Region. J. Mater. Civ. Eng. 2008, 20, 2–8. [Google Scholar] [CrossRef]

- Tang, L. Chloride Ingress in Concrete Exposed to Marine Environment—Field Data up to 10 Years Exposure; Swedish National Testing and Research Institute: Borås, Sweden, 2003; ISBN 91-7848-948-2. [Google Scholar]

- Lindvall, A. Chloride ingress data from field and laboratory exposure-Influence of salinity and temperature. Cem. Concr. Compos. 2007, 29, 88–93. [Google Scholar] [CrossRef]

- Dousti, A.; Rashetnia, R.; Ahmadi, B.; Shekarchi, M. Influence of exposure temperature on chloride diffusion in concretes incorporating silica fume or natural zeolite. Constr. Build. Mater. 2013, 49, 393–399. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Roke, D.A. Assessment of artificial neural network and genetic programming as predictive tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Jahangir, H.; Eidgahee, D.R. A new and robust hybrid artificial bee colony algorithm-ANN model for FRP-concrete bond strength evaluation. Compos. Struct. 2021, 257, 113160. [Google Scholar] [CrossRef]

- Asteris, P.G.; Skentou, A.D.; Bardhan, A.; Samui, P.; Pilakoutas, K. Predicting concrete compressive strength using hybrid ensembling of surrogate machine learning models. Cem. Concr. Res. 2021, 145, 106449. [Google Scholar] [CrossRef]

- Ju, X.; Wu, L.; Lin, C.; Yang, X.; Yang, C. Prediction of chloride concentration with elevation in concrete exposed to cyclic drying-wetting conditions in marine environments. Constr. Build. Mater. 2021, 278, 122370. [Google Scholar] [CrossRef]

- Oluwaseun Azeez, M.; Abd El Fattah, A. Service Life Modeling of Concrete with SCMs Using Effective Diffusion Coefficient and a New Binding Model. Crystals 2020, 10, 967. [Google Scholar] [CrossRef]

- Hadzima-Nyarko, M.; Nyarko, E.K.; Ademović, N.; Miličević, I.; Kalman Šipoš, T. Modelling the Influence of Waste Rubber on Compressive Strength of Concrete by Artificial Neural Networks. Materials 2019, 12, 561. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Lp. | Algorithm Name | Notation | Dataset | Prediction Properties | Year | Waste Material Used | References |

|---|---|---|---|---|---|---|---|

| 1. | Individual with ensemble modeling | ANN, bagging and boosting | 1030 | Compressive strength | 2021 | FA | [28] |

| 2. | Data envelopment analysis | DEA | 114 | Compressive strength Slump test L-box test V-funnel test | 2021 | FA | [29] |

| 3. | Multivariate | MV | 21 | Compressive strength | 2020 | Crumb rubber with SF | [30] |

| 4. | Support vector machine | SVM | - | Compressive strength | 2020 | FA | [31] |

| 5. | Support vector machine | SVM | 115 | Slump test L-box test V-funnel test Compressive strength | 2020 | FA | [32] |

| 6. | Adaptive neuro fuzzy inference system | ANFIS with ANN | 7 | Compressive strength | 2020 | POFA | [33] |

| 7. | Gene expression programming | GEP | 277 | Axial capacity | 2020 | - | [34] |

| 8. | Gene expression programming | GEP | 357 | Compressive strength | 2020 | - | [35] |

| 9. | Random forest and gene expression programming | RF and GEP | 357 | Compressive strength | 2020 | - | [36] |

| 10. | Artificial neural network | ANN | 205 | Compressive strength | 2019 | FA GGBFS SF RHA | [37] |

| 11. | Intelligent rule-based enhanced multiclass support vector machine and fuzzy rules | IREMSVM-FR with RSM | 114 | Compressive strength | 2019 | FA | [38] |

| 12. | Random forest | RF | 131 | Compressive strength | 2019 | FA GGBFS FA | [39] |

| 13. | Multivariate adaptive regression spline | M5 MARS | 114 | Compressive strength Slump test L-box test V-funnel test | 2018 | FA | [40] |

| 14. | Random kitchen sink algorithm | RKSA | 40 | V-funnel test J-ring test Slump test Compressive strength | 2018 | FA | [41] |

| 15. | Adaptive neuro fuzzy inference system | ANFIS | 55 | Compressive strength | 2018 | - | [42] |

| 16. | Artificial neural network | ANN | 114 | Compressive strength | 2017 | FA | [43] |

| 17. | Artificial neural network | ANN | 69 | Compressive strength | 2017 | FA | [44] |

| 18. | Artificial neural network | ANN | 169 | Compressive strength | 2016 | FA GGBFS FA RHA | [45] |

| 19. | Artificial neural network | ANN | 80 | Compressive strength | 2011 | FA | [46] |

| 20. | Artificial neural network | ANN | 300 | Compressive strength | 2009 | FA | [47] |

| Parameters | Abbreviation | Units | Minimum | Maximum |

|---|---|---|---|---|

| Cement | C | kg/m3 | 110 | 519 |

| Fly ash | FA | kg/m3 | 0 | 239 |

| Ground furnace slag | GFS | kg/m3 | 0 | 292.5 |

| Silica fume | SF | kg/m3 | 0 | 50 |

| Super plasticizer | SP | kg/m3 | 0 | 10.2 |

| Water | W | kg/m3 | 38.5 | 311 |

| Fine aggregate | FA | kg/m3 | 552 | 1232 |

| Coarse aggregate | CA | kg/m3 | 410 | 1305 |

| Water/binder | W/C | - | 0.3 | 0.75 |

| Exposure time | T | years | 0.08 | 48.65 |

| Annual mean temperature | AMT | °C | 7 | 50 |

| Chloride concentration in seawater | CCS | kg/m3 | 13 | 27.37 |

| Surface chloride concentration | SCC | kg/m3 | 0.023 | 1.945 |

| Parameters Descriptionr | C | FA | GFS | SF | SP | W | FA | CA | W/C | T | AMT | CCS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | 370.70 | 33.97 | 11.41 | 5.41 | 1.47 | 187.54 | 765.77 | 993.81 | 0.46 | 4.24 | 17.78 | 18.99 |

| Standard Error | 2.98 | 2.36 | 1.79 | 0.51 | 0.08 | 1.74 | 4.60 | 5.35 | 0.00 | 0.25 | 0.37 | 0.11 |

| Median | 375.00 | 0.00 | 0.00 | 0.00 | 1.00 | 180.00 | 800.00 | 1020.00 | 0.45 | 2.67 | 16.80 | 19.00 |

| Mode | 340.00 | 0.00 | 0.00 | 0.00 | 1.00 | 180.00 | 800.00 | 1020.00 | 0.45 | 5.00 | 7.00 | 19.00 |

| Standard Deviation | 75.61 | 59.88 | 45.45 | 12.85 | 1.99 | 44.08 | 116.46 | 135.43 | 0.08 | 6.28 | 9.38 | 2.79 |

| Sample Variance | 5716.21 | 3585.21 | 2066.15 | 165.02 | 3.95 | 1943.32 | 13,563.76 | 18,342.52 | 0.01 | 39.46 | 88.06 | 7.81 |

| Kurtosis | 0.60 | 3.46 | 15.48 | 4.11 | 4.67 | 2.80 | 4.74 | 7.56 | 1.04 | 24.71 | −0.85 | 0.72 |

| Skewness | −0.65 | 1.99 | 4.03 | 2.29 | 2.09 | 0.82 | 1.46 | −1.85 | 0.96 | 4.45 | 0.42 | 0.52 |

| Range | 409.00 | 239.00 | 292.50 | 50.00 | 10.20 | 272.50 | 680.00 | 895.00 | 0.45 | 48.57 | 43.00 | 14.37 |

| Minimum | 110.00 | 0.00 | 0.00 | 0.00 | 0.00 | 38.50 | 552.00 | 410.00 | 0.30 | 0.08 | 7.00 | 13.00 |

| Maximum | 519.00 | 239.00 | 292.50 | 50.00 | 10.20 | 311.00 | 1232.00 | 1305.00 | 0.75 | 48.65 | 50.00 | 27.37 |

| Sum | 237,992.50 | 21,809.50 | 7324.00 | 3475.00 | 942.56 | 120,398.80 | 491,625.00 | 638,027.00 | 292.43 | 2720.83 | 11,417.40 | 12,190.73 |

| Count | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 | 642.00 |

| K-Fold | GEP | ANN | DT | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | MAE | MSE | RMSE | R2 | MAE | MSE | RMSE | R2 | MAE | MSE | RMSE | |

| 1 | 0.78 | 7.66 | 5.67 | 2.38 | 0.89 | 8.98 | 4.67 | 2.16 | 0.91 | 10.56 | 7.58 | 2.75 |

| 2 | 0.86 | 6.55 | 6.38 | 2.53 | 0.74 | 7.29 | 5.98 | 2.45 | 0.86 | 7.28 | 9.39 | 3.06 |

| 3 | 0.89 | 6.65 | 4.89 | 2.21 | 0.87 | 7.98 | 8.98 | 3.00 | 0.72 | 7.25 | 6.93 | 2.63 |

| 4 | 0.92 | 9.79 | 3.89 | 1.97 | 0.88 | 9.10 | 6.25 | 2.50 | 0.93 | 7.84 | 6.77 | 2.60 |

| 5 | 0.73 | 5.38 | 6.89 | 2.62 | 0.62 | 5.98 | 5.47 | 2.34 | 0.68 | 9.18 | 6.21 | 2.49 |

| 6 | 0.65 | 5.73 | 7.26 | 2.69 | 0.71 | 8.40 | 6.87 | 2.62 | 0.75 | 6.84 | 5.39 | 2.32 |

| 7 | 0.74 | 6.21 | 6.98 | 2.64 | 0.65 | 8.32 | 4.22 | 2.05 | 0.84 | 9.10 | 6.16 | 2.48 |

| 8 | 0.94 | 5.11 | 7.24 | 2.69 | 0.78 | 6.98 | 5.18 | 2.28 | 0.93 | 6.84 | 5.89 | 2.43 |

| 9 | 0.69 | 9.36 | 5.55 | 2.36 | 0.75 | 5.78 | 9.37 | 3.06 | 0.69 | 5.77 | 7.21 | 2.69 |

| 10 | 0.75 | 7.89 | 6.43 | 2.54 | 0.82 | 6.74 | 8.96 | 2.99 | 0.90 | 5.98 | 6.98 | 2.64 |

| Machine Learning Methods | MAE (MPa) | MSE (MPa) | RMSE (MPa) |

|---|---|---|---|

| Gene Expression Program | 4.36 | 28.51 | 5.33 |

| Artificial Neural Network | 4.48 | 31.86 | 5.64 |

| Decision Tree | 4.55 | 36.73 | 6.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Śliwa-Wieczorek, K.; Czarnecki, S. Application of Novel Machine Learning Techniques for Predicting the Surface Chloride Concentration in Concrete Containing Waste Material. Materials 2021, 14, 2297. https://doi.org/10.3390/ma14092297

Ahmad A, Farooq F, Ostrowski KA, Śliwa-Wieczorek K, Czarnecki S. Application of Novel Machine Learning Techniques for Predicting the Surface Chloride Concentration in Concrete Containing Waste Material. Materials. 2021; 14(9):2297. https://doi.org/10.3390/ma14092297

Chicago/Turabian StyleAhmad, Ayaz, Furqan Farooq, Krzysztof Adam Ostrowski, Klaudia Śliwa-Wieczorek, and Slawomir Czarnecki. 2021. "Application of Novel Machine Learning Techniques for Predicting the Surface Chloride Concentration in Concrete Containing Waste Material" Materials 14, no. 9: 2297. https://doi.org/10.3390/ma14092297