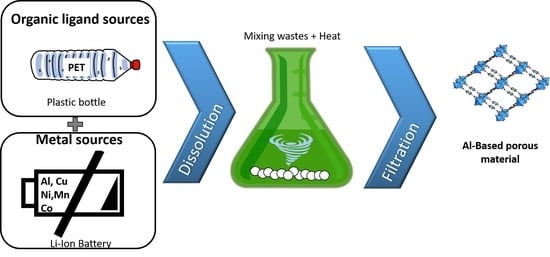

Combining Organic and Inorganic Wastes to Form Metal–Organic Frameworks

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Protocols

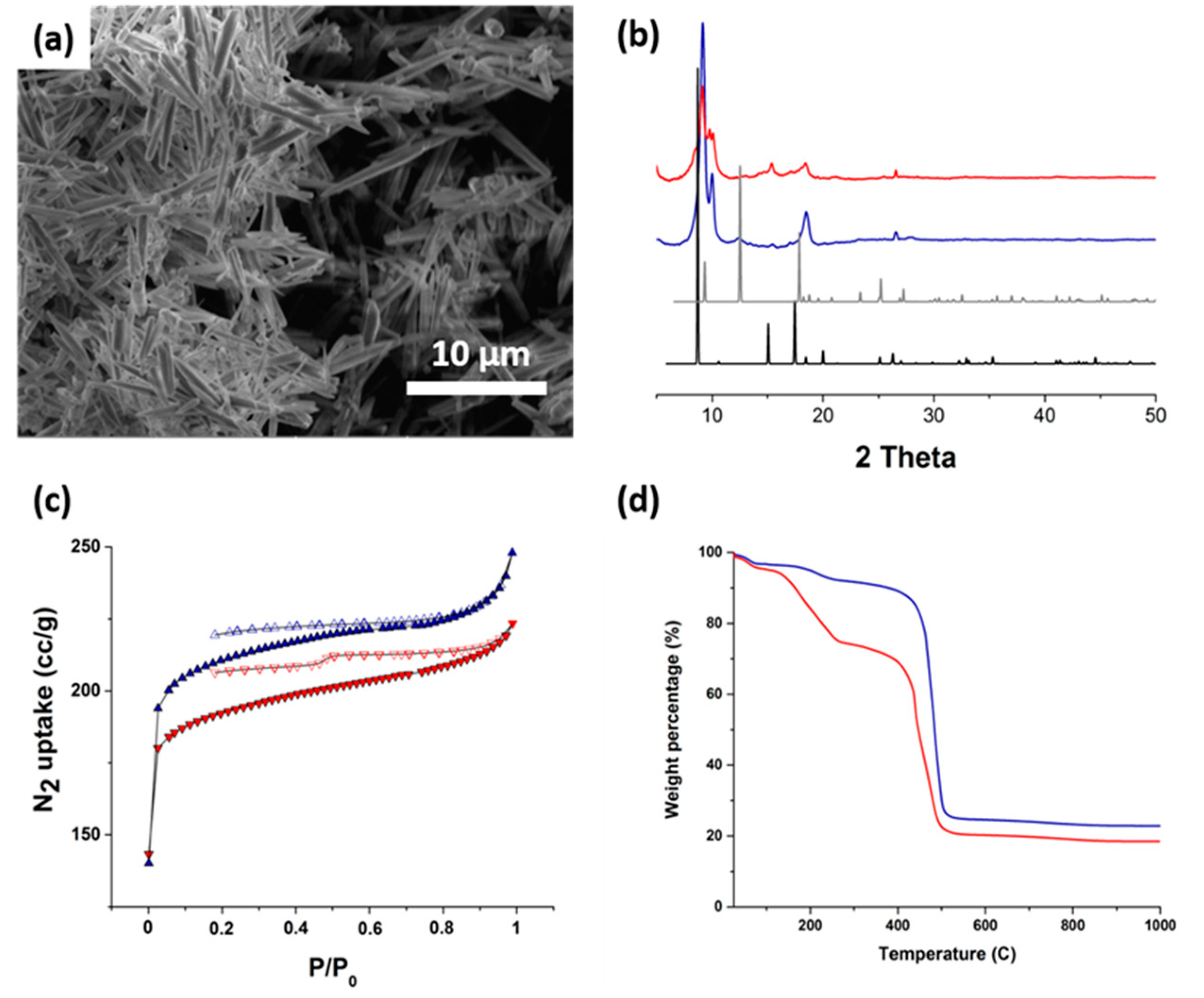

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Armand, M.; Tarascon, J.-M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Susai, F.A.; Sclar, H.; Shilina, Y.; Penki, T.R.; Raman, R.; Maddukuri, S.; Maiti, S.; Halalay, I.C.; Luski, S.; Markovsky, B.; et al. Horizons for Li-Ion Batteries Relevant to Electro-Mobility: High-Specific-Energy Cathodes and Chemically Active Separators. Adv. Mater. 2018, 30, 1801348. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Thomas, H.; Francis, R.W.; Lum, K.R.; Wang, J.; Liang, B. A review of processes and technologies for the recycling of lithium-ion secondary batteries. J. Power Sources 2008, 177, 512–527. [Google Scholar] [CrossRef]

- Tunsu, C.; Petranikova, M.; Gergorić, M.; Ekberg, C.; Retegan, T. Reclaiming rare earth elements from end-of-life products: A review of the perspectives for urban mining using hydrometallurgical unit operations. Hydrometallurgy 2015, 156, 239–258. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Boil. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Shi, H.; Adams, C.D.; Ma, Y. Assessment of metal contaminations leaching out from recycling plastic bottles upon treatments. Environ. Sci. Pollut. Res. 2010, 17, 1323–1330. [Google Scholar] [CrossRef] [PubMed]

- Kirchon, A.; Feng, L.; Drake, H.F.; Joseph, E.A.; Zhou, H.-C. From fundamentals to applications: A toolbox for robust and multifunctional MOF materials. Chem. Soc. Rev. 2018, 47, 8611–8638. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The Chemistry and Applications of Metal-Organic Frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Wang, S.; Chen, Y.; Serre, C. Direct synthesis of robust hcp UiO-66(Zr) MOF using poly(ethylene terephthalate) waste as ligand source. Microporous Mesoporous Mater. 2019, 290, 109674. [Google Scholar] [CrossRef]

- Dyosiba, X.; Ren, J.; Musyoka, N.M.; Langmi, H.W.; Mathe, M.K.; Onyango, M.S. Feasibility of Varied Polyethylene Terephthalate Wastes as a Linker Source in Metal–Organic Framework UiO-66 (Zr) Synthesis. Ind. Eng. Chem. Res. 2019, 58, 17010–17016. [Google Scholar] [CrossRef]

- Doan, V.D.; Do, T.L.; Ho, T.M.T.; Le, V.T.; Nguyen, H.T. Utilization of waste plastic pet bottles to prepare copper-1,4-benzenedicarboxylate metal-organic framework for methylene blue removal. Sep. Sci. Technol. 2020, 55, 444–455. [Google Scholar] [CrossRef]

- Roy, P.K.; Ramanan, A.; Rajagopal, C. Post consumer PET waste as potential feedstock for metal organic frameworks. Mater. Lett. 2013, 106, 390–392. [Google Scholar] [CrossRef]

- Lo, S.-H.; Raja, D.S.; Chen, C.-W.; Kang, Y.-H.; Chen, J.-J.; Lin, C.-H. Waste polyethylene terephthalate (PET) materials as sustainable precursors for the synthesis of nanoporous MOFs, MIL-47, MIL-53(Cr, Al, Ga) and MIL-101(Cr). Dalton Trans. 2016, 45, 9565–9573. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Dyosiba, X.; Musyoka, N.M.; Langmi, H.W.; North, B.C.; Mathe, M.; Onyango, M.S. Green synthesis of chromium-based metal-organic framework (Cr-MOF) from waste polyethylene terephthalate (PET) bottles for hydrogen storage applications. Int. J. Hydrogen Energy 2016, 41, 18141–18146. [Google Scholar] [CrossRef]

- Deleu, W.P.R.; Stassen, I.; Jonckheere, D.; Ameloot, R.; De Vos, D.E. Waste PET (bottles) as a resource or substrate for MOF synthesis. J. Mater. Chem. A 2016, 4, 9519–9525. [Google Scholar] [CrossRef]

- Perez, E.; Andre, M.-L.; Amador, R.N.; Hyvrard, F.; Borrini, J.; Carboni, M.; Meyer, D. Recovery of metals from simulant spent lithium-ion battery as organophosphonate coordination polymers in aqueous media. J. Hazard. Mater. 2016, 317, 617–621. [Google Scholar] [CrossRef] [PubMed]

- Perez, E.; Amador, R.N.; Carboni, M.; Meyer, D. In-situ precipitation of Metal–Organic Frameworks from a simulant battery waste solution. Mater. Lett. 2016, 167, 188–191. [Google Scholar] [CrossRef]

- Cognet, M.; Condomines, J.; Cambedouzou, J.; Madhavi, S.; Carboni, M.; Meyer, D. An original recycling method for Li-ion batteries through large scale production of Metal Organic Frameworks. J. Hazard. Mater. 2020, 385, 121603. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lagae-Capelle, E.; Cognet, M.; Madhavi, S.; Carboni, M.; Meyer, D. Combining Organic and Inorganic Wastes to Form Metal–Organic Frameworks. Materials 2020, 13, 441. https://doi.org/10.3390/ma13020441

Lagae-Capelle E, Cognet M, Madhavi S, Carboni M, Meyer D. Combining Organic and Inorganic Wastes to Form Metal–Organic Frameworks. Materials. 2020; 13(2):441. https://doi.org/10.3390/ma13020441

Chicago/Turabian StyleLagae-Capelle, Eléonore, Marine Cognet, Srinivasan Madhavi, Michaël Carboni, and Daniel Meyer. 2020. "Combining Organic and Inorganic Wastes to Form Metal–Organic Frameworks" Materials 13, no. 2: 441. https://doi.org/10.3390/ma13020441

APA StyleLagae-Capelle, E., Cognet, M., Madhavi, S., Carboni, M., & Meyer, D. (2020). Combining Organic and Inorganic Wastes to Form Metal–Organic Frameworks. Materials, 13(2), 441. https://doi.org/10.3390/ma13020441