The Behaviour of Contaflex Soft Contact Lens Material During Hydration

Abstract

1. Introduction

2. Results and Discussion

2.1. Results

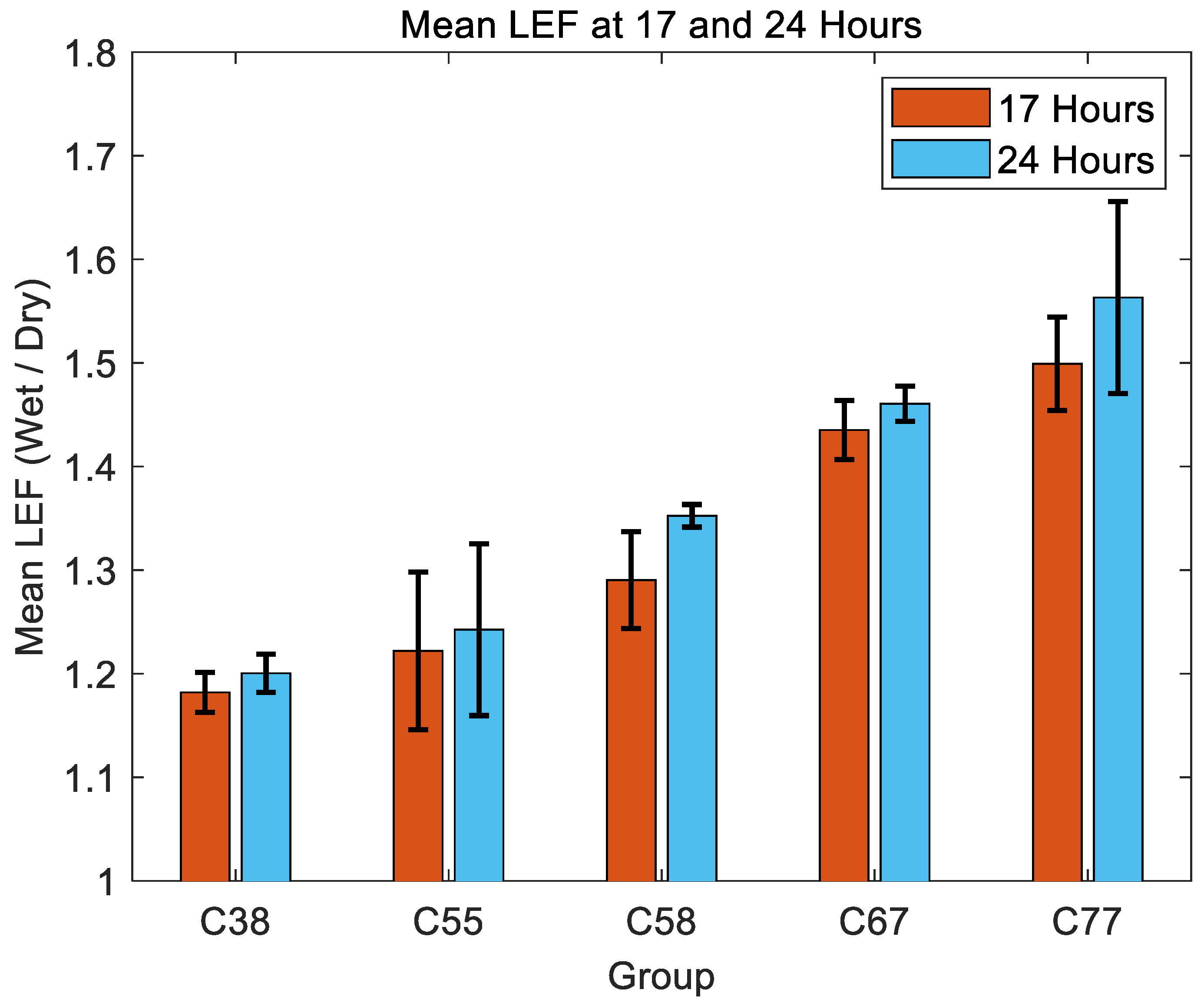

2.1.1. Linear Expansion Factor (LEF)

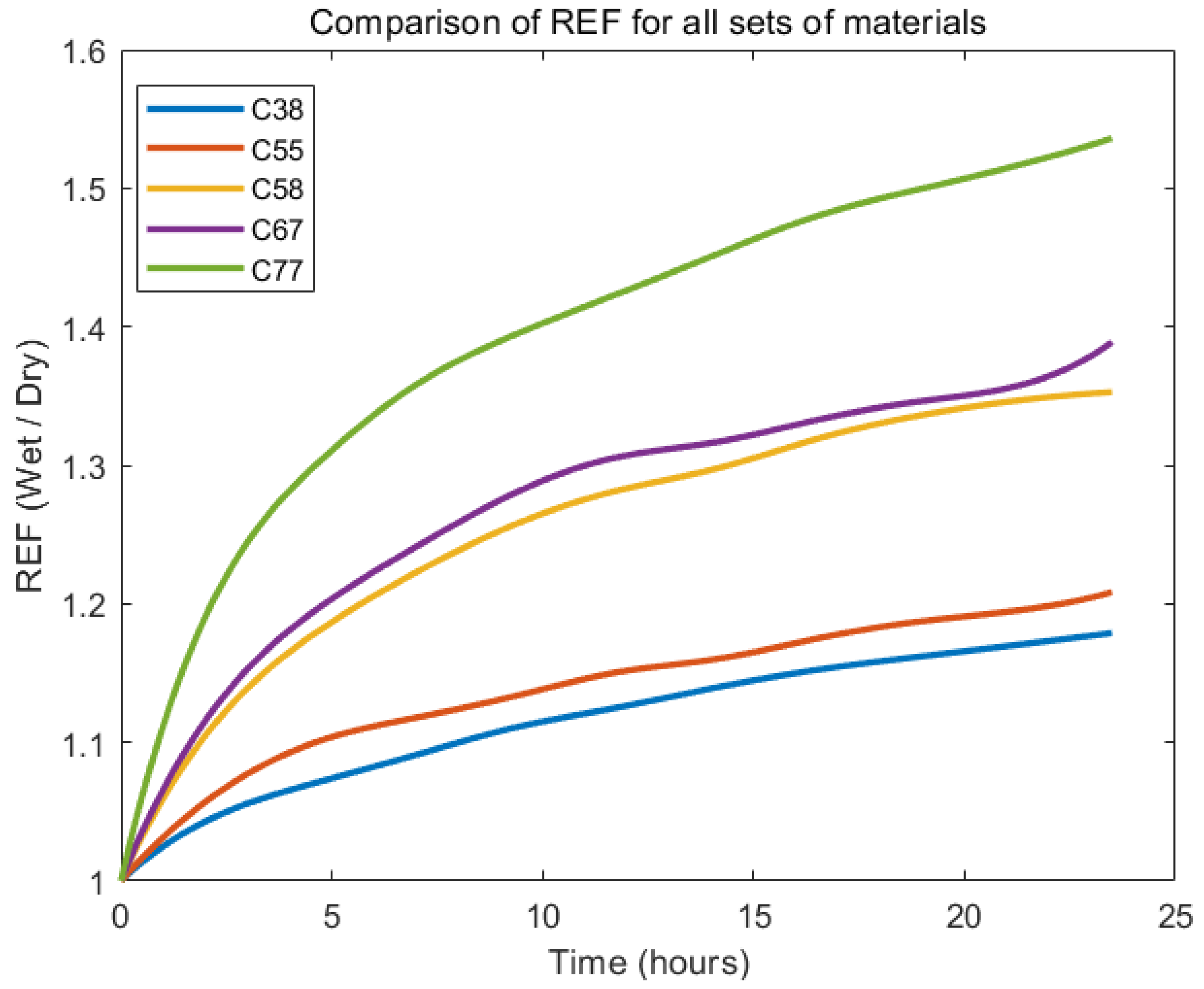

2.1.2. Radial Expansion Factor (REF)

2.1.3. Refractive Indices

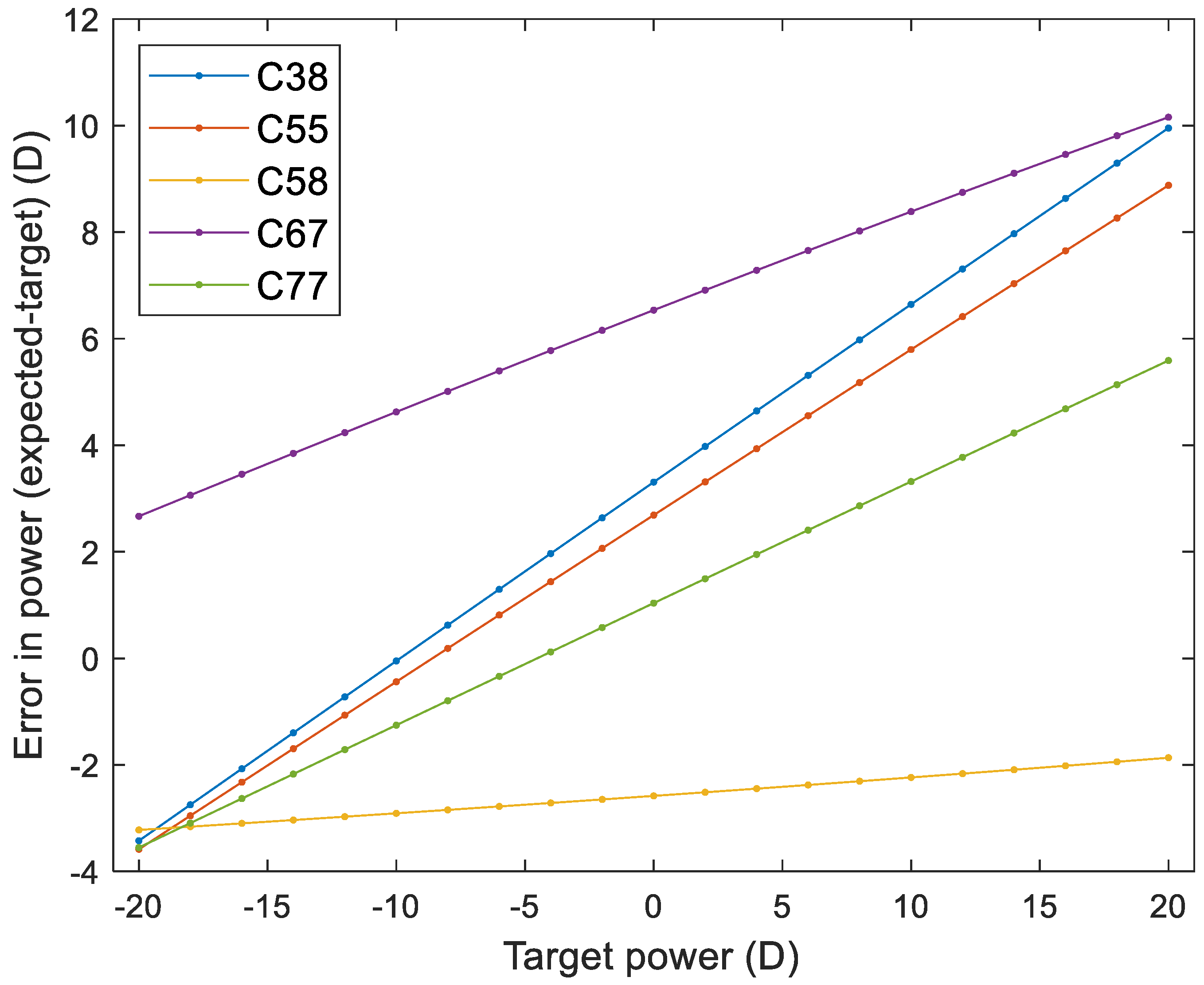

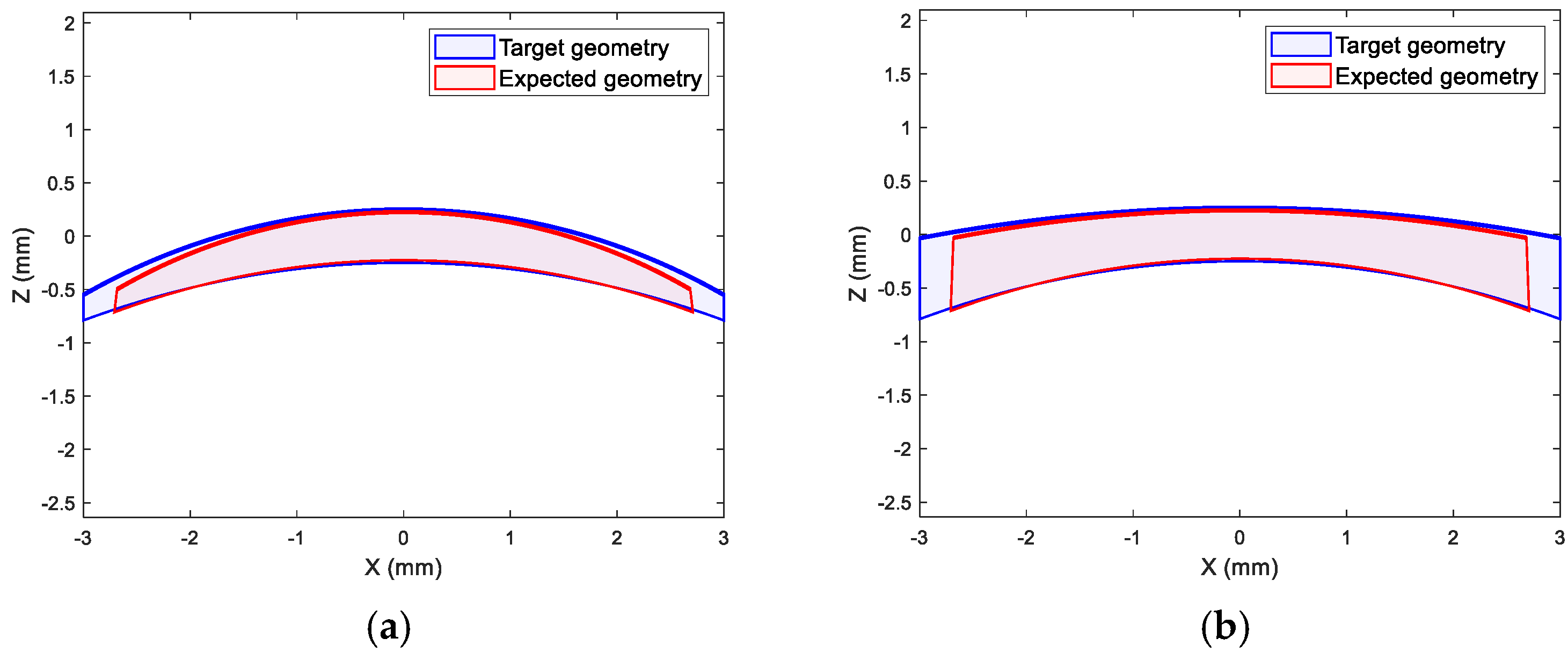

2.1.4. Soft Contact Lens Performance Simulation

2.1.5. Water-Content

2.1.6. Transparency Detection

2.2. Discussion

3. Conclusions

4. Materials and Methods

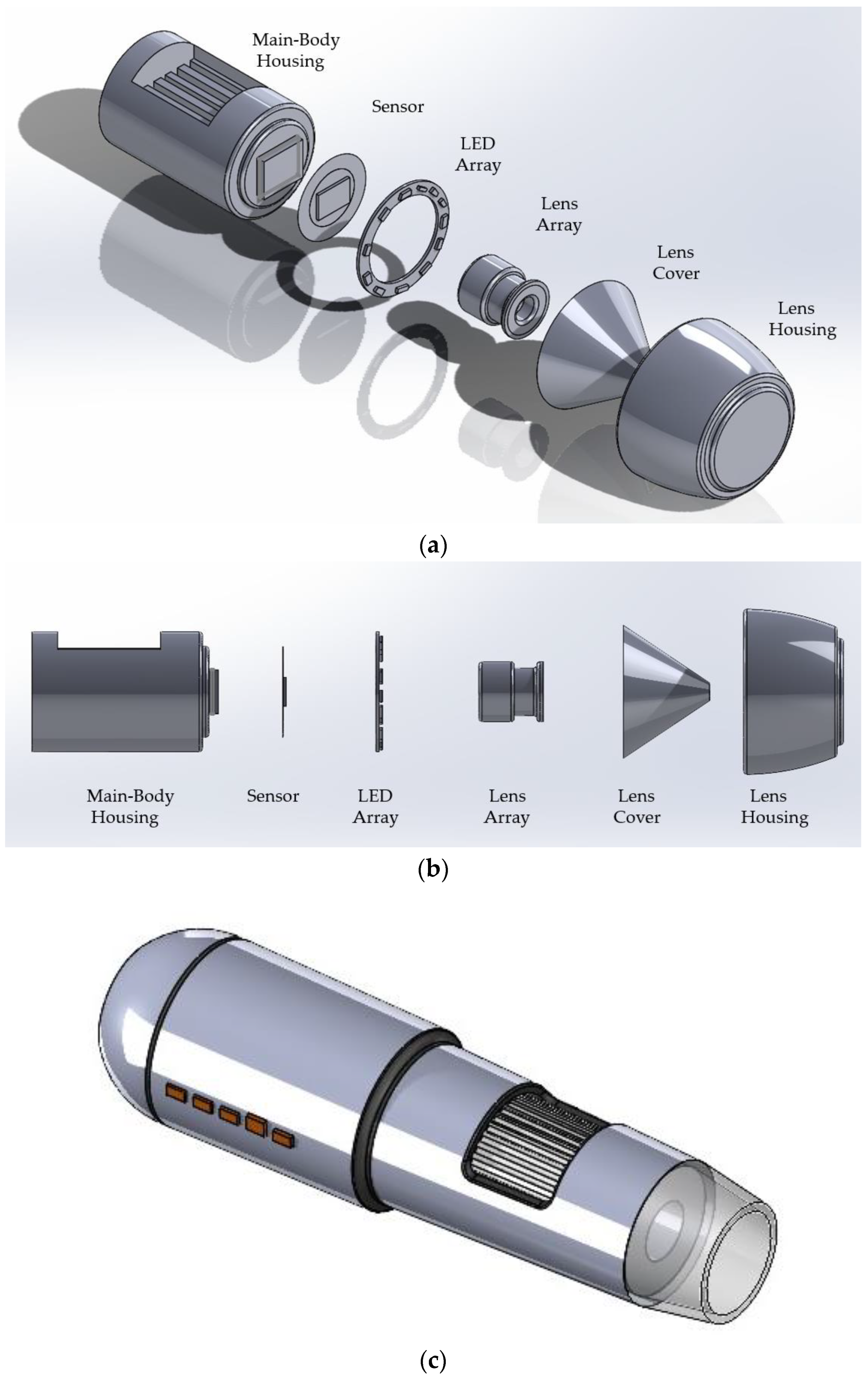

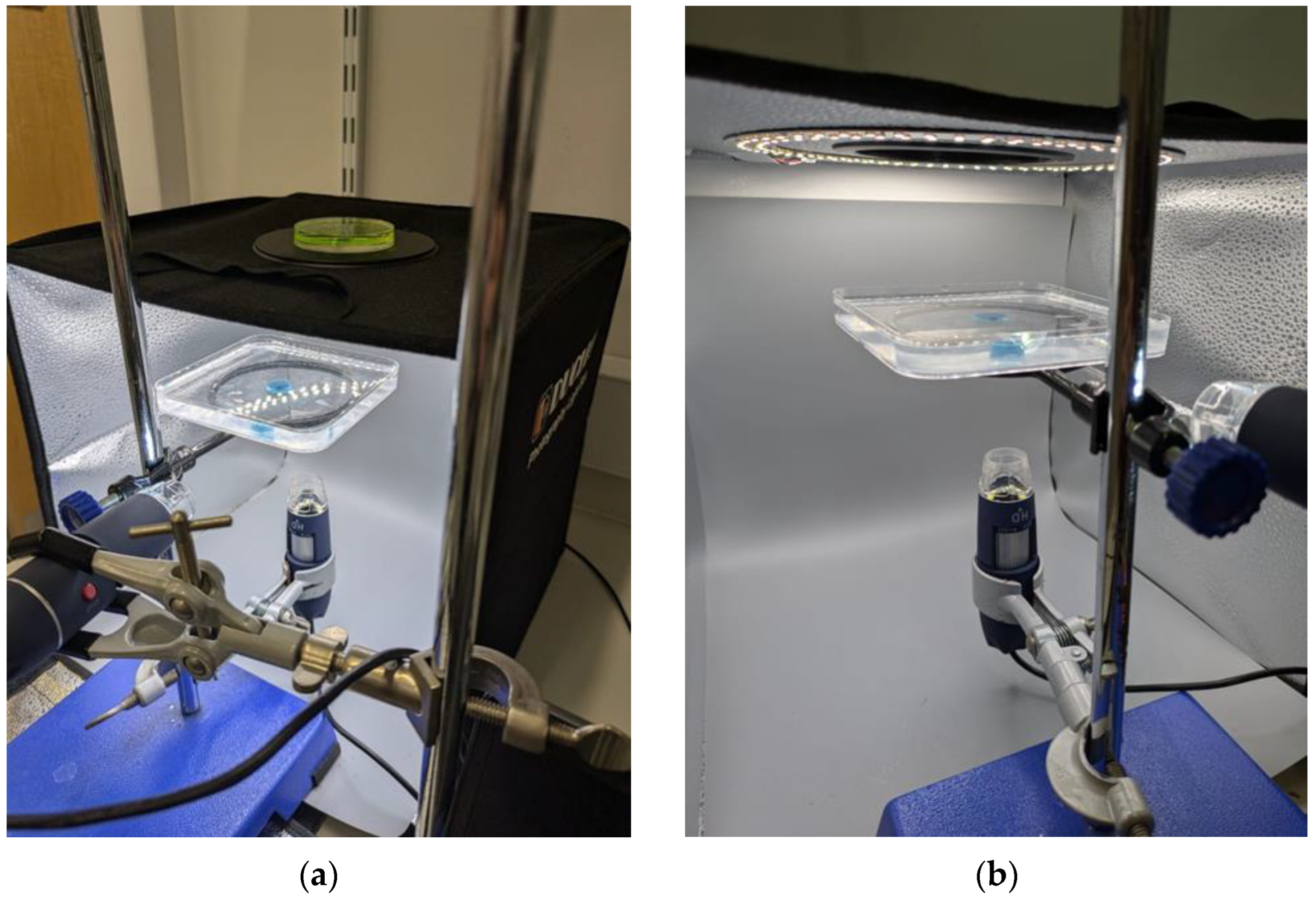

4.1. High-Resolution Digital Image Tracking System

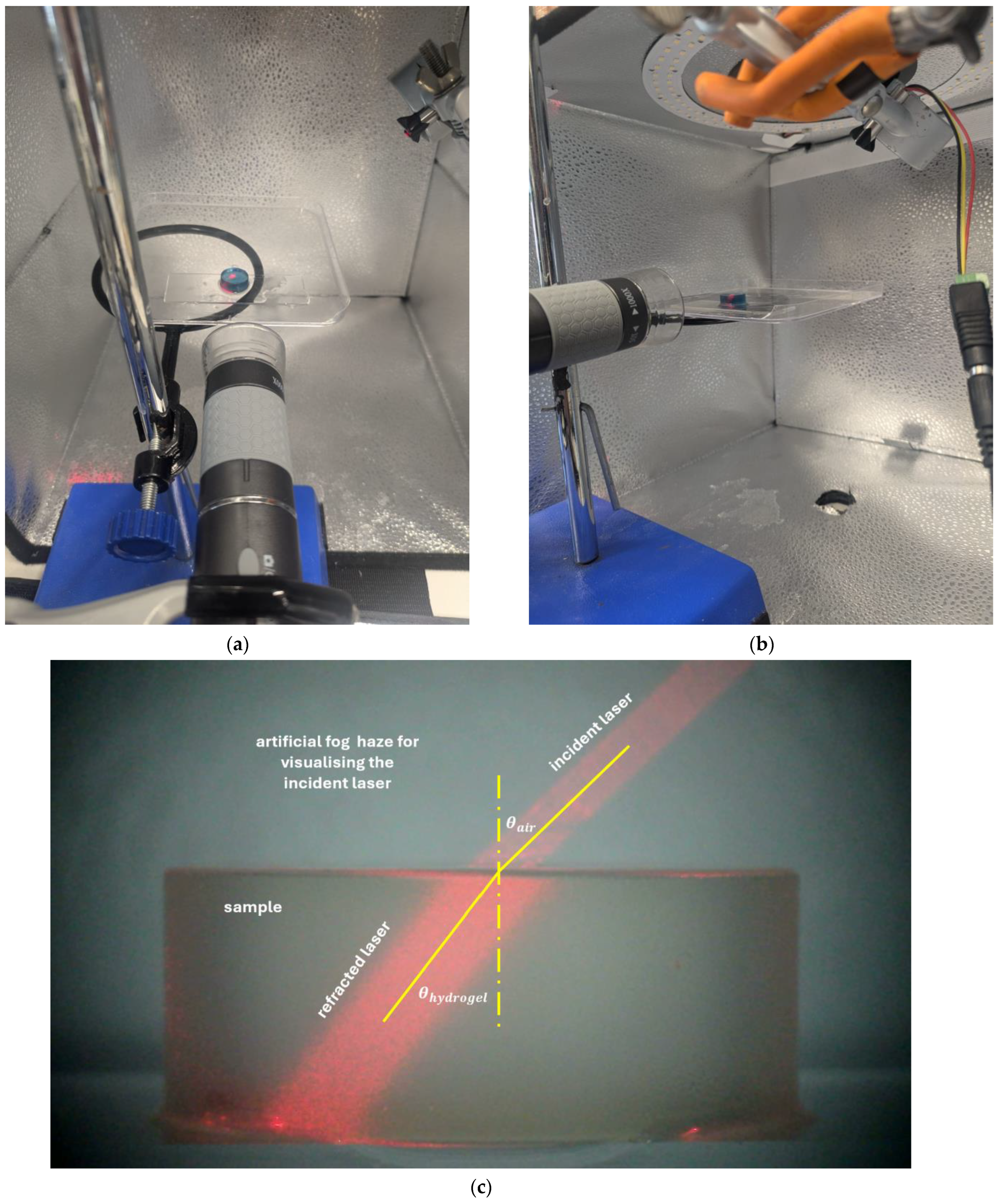

4.2. Transparency Measurement via Light Detection and Ranging System

4.3. Refractive Index

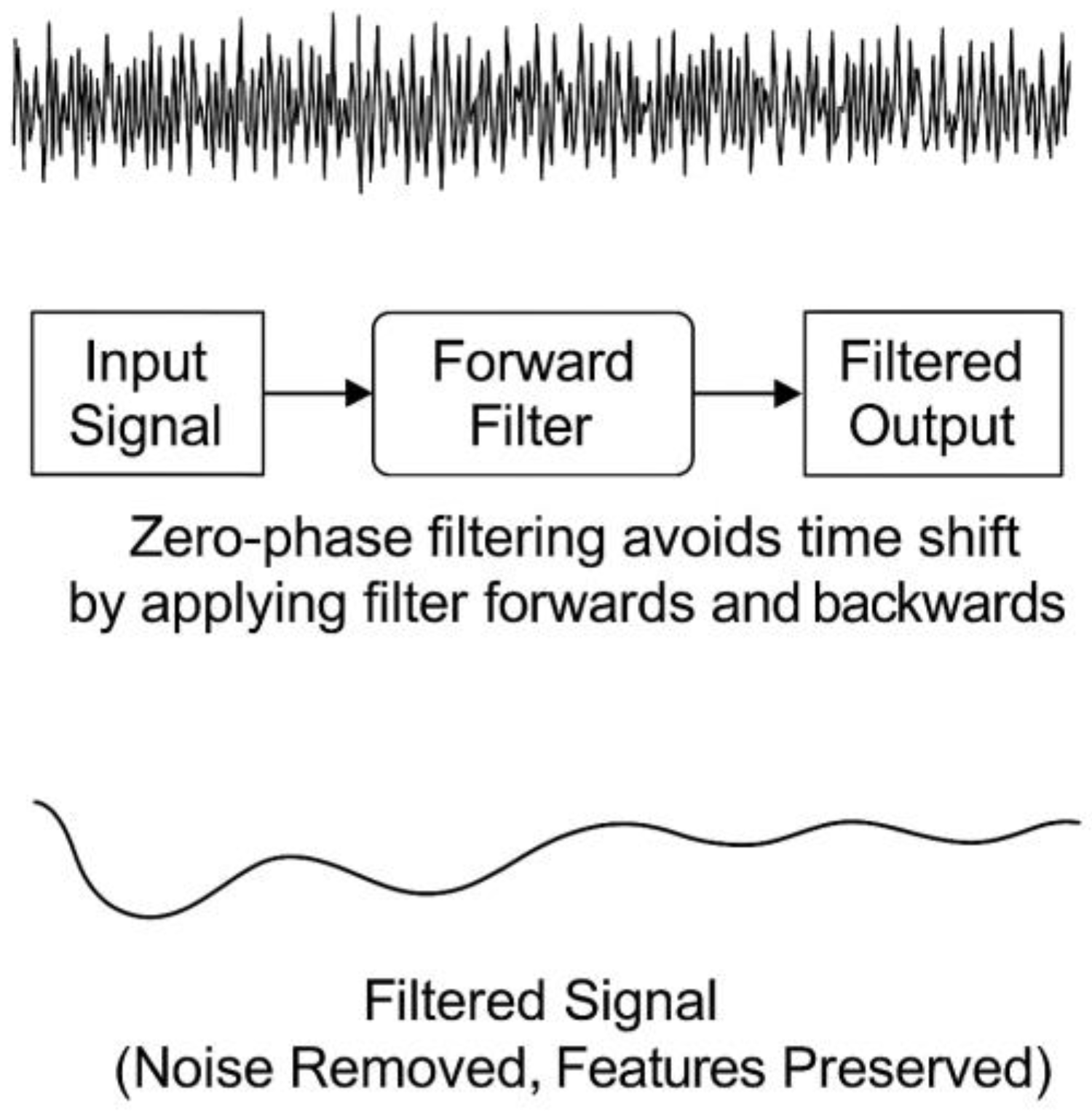

4.4. Statistical Analysis

4.5. Soft Contact Lens Geometry Simulation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CAD | Computer-aided design |

| CC | Contamac contaflex |

| CI | confidence intervals |

| HL | Hodges–Lehmann |

| ISO | International Organisation for Standardisation |

| LEF | Linear expansion factor |

| LiDAR | Light detection and ranging |

| OCT | Optical coherence tomography |

| PBS | Phosphate-buffered saline |

| pHEMA | Poly hydroxyethyl methacrylate |

| REF | Radial expansion factor |

Appendix A

| import cv2, os, time from datetime import datetime def capture_images_from_webcam(output_folder, interval): while True: try: if not os.path.exists(output_folder): os.makedirs(output_folder) cap = cv2.VideoCapture(0) if not cap.isOpened(): time.sleep(interval) continue cap.set(cv2.CAP_PROP_FRAME_WIDTH, 3840) cap.set(cv2.CAP_PROP_FRAME_HEIGHT, 2160) width = int(cap.get(cv2.CAP_PROP_FRAME_WIDTH)) height = int(cap.get(cv2.CAP_PROP_FRAME_HEIGHT)) img_counter = 0 while True: ret, frame = cap.read() if not ret: raise Exception(“Capture failed.”) timestamp = datetime.now().strftime(“%Y-%m-%d %H:%M:%S.%f”)[:-3] font = cv2.FONT_HERSHEY_SIMPLEX scale, colour, thick = 2, (0, 255, 255), 3 sz, _ = cv2.getTextSize(timestamp, font, scale, thick) pos = (width - sz[0] - 10, height - 10) cv2.putText(frame, timestamp, pos, font, scale, colour, thick, cv2.LINE_AA) img_path = os.path.join(output_folder, f”image_{img_counter:04d}.png”) cv2.imwrite(img_path, frame) img_counter += 1 cv2.imshow(‘Webcam’, frame) t0 = time.time() while time.time() - t0 < interval: if cv2.waitKey(1) & 0xFF == ord(‘q’): cap.release() cv2.destroyAllWindows() return except Exception: time.sleep(interval) # Parameters output_folder = r” interval = 60 capture_images_from_webcam(output_folder, interval) |

Appendix B

| import cv2 import os def create_timelapse(input_folder, output_file, fps): # Verify if the input folder exists if not os.path.exists(input_folder): print(f”Error: The directory {input_folder} does not exist.”) return # Get list of image files in the folder images = [img for img in os.listdir(input_folder) if img.endswith(“.jpg”) or img.endswith(“.png”)] if not images: print(f“Error: No image files found in the directory {input_folder}.”) return images.sort() # Sort the images by filename # Read the first image to get the frame size first_image_path = os.path.join(input_folder, images[15]) frame = cv2.imread(first_image_path) if frame is None: print(f“Error: Unable to read the first image file {first_image_path}.”) return height, width, layers = frame.shape # Initialise the video writer fourcc = cv2.VideoWriter_fourcc(*’XVID’) video = cv2.VideoWriter(output_file, fourcc, fps, (width, height)) # Add each image to the video for image in images: image_path = os.path.join(input_folder, image) frame = cv2.imread(image_path) if frame is None: print(f“Warning: Unable to read the image file {image_path}. Skipping.”) continue video.write(frame) # Release the video writer video.release() print(f“Timelapse video saved as {output_file}”) # Parameters input_folder = r” # Replace with your folder path output_file =” # Output video file name fps = 30 # Frames per second # Print the input folder path to verify it print(f“Using input folder: {input_folder}”) # Create the timelapse video create_timelapse(input_folder, output_file, fps) |

References

- Yoon, J.; Cai, S.; Suo, Z.; Hayward, R.C. Poroelastic swelling kinetics of thin hydrogel layers: Comparison of theory and experiment. Soft Matter 2010, 6, 6004–6012. [Google Scholar] [CrossRef]

- Fornasiero, F.; Ung, M.; Radke, C.; Prausnitz, J. Glass-transition temperatures for soft-contact-lens materials. Dependence on water content. Polymer 2005, 46, 4845–4852. [Google Scholar] [CrossRef]

- Weinmüller, C.; Langel, C.; Fornasiero, F.; Radke, C.J.; Prausnitz, J.M. Sorption kinetics and equilibrium uptake for water vapor in soft-contact-lens hydrogels. J. Biomed. Mater. Res. A 2006, 77, 230–241. [Google Scholar] [CrossRef]

- Maldonado-Codina, C.; Efron, N. An Investigation of the Discrete and Continuum Models of Water Behavior in Hydrogel Contact Lenses. Eye Contact Lens Sci. Clin. Pract. 2005, 31, 270–278. [Google Scholar] [CrossRef]

- Díaz-Marín, C.D.; Zhang, L.; Lu, Z.; Alshrah, M.; Grossman, J.C.; Wang, E.N. Kinetics of Sorption in Hygroscopic Hydrogels. Nano Lett. 2022, 22, 1100–1107. [Google Scholar] [CrossRef]

- Efron, N.; Brennan, N.A.; O’Brien, K.A.; Murphy, P.J. Surface hydration of hydrogel contact lenses. Clin. Exp. Optom. 1986, 69, 219–222. [Google Scholar] [CrossRef]

- Pescosolido, N.; Casciani, L. Identification by means of low-field nuclear magnetic resonance of the chemical-physical characteristics of multidose artificial tear solutions in interaction with hydrogel model contact lenses. J. Ocul. Pharmacol. Ther. Off. J. Assoc. Ocul. Pharmacol. Ther. 2007, 23, 551–558. [Google Scholar] [CrossRef]

- Gulsen, D.; Chauhan, A. Effect of water content on transparency, swelling, lidocaine diffusion in p-HEMA gels. J. Membr. Sci. 2006, 269, 35–48. [Google Scholar] [CrossRef]

- González-Méijome, J.M.; Lira, M.; López-Alemany, A.; Almeida, J.B.; Parafita, M.A.; Refojo, M.F. Refractive index and equilibrium water content of conventional and silicone hydrogel contact lenses. Ophthalmic. Physiol. Opt. 2006, 26, 57–64. [Google Scholar] [CrossRef]

- Mlyniuk, P.; Stachura, J.; Jiménez, A.; Grulkowski, I.; Kaluzny, B. Changes of the curvature of modern daily disposable soft contact lenses during wear. Contact Lens Anterior Eye 2019, 42, e8. [Google Scholar] [CrossRef]

- Jones, L.; May, C.; Nazar, L.; Simpson, T. In vitro evaluation of the dehydration characteristics of silicone hydrogel and conventional hydrogel contact lens materials. Contact Lens Anterior Eye 2002, 25, 147–156. [Google Scholar] [CrossRef]

- DeDonato, L.M. Changes in the Hydration of Hydrogel Contact Lenses with Wear. Optom. Vis. Sci. 1982, 59, 213–214. [Google Scholar] [CrossRef]

- Shi, X.; Cantu-Crouch, D.; Sharma, V.S.; Pruitt, J.C.; Yao, G.; Fukazawa, K.; Wu, J.Y.; Ishihara, K. Surface characterisation of a silicone hydrogel contact lens having bioinspired 2-methacryloyloxyethyl phosphorylcholine polymer layer in hydrated state. Colloids Surf. B Biointerfaces 2020, 199, 111539. [Google Scholar]

- Chwalik-Pilszyk, G.; Wiśniewska, A. Influence of Selected Ophthalmic Fluids on the Wettability and Hydration of Hydrogel and Silicone Hydrogel Contact Lenses—In Vitro Study. Materials 2022, 15, 930. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, S.; Cui, Q.; Ni, J.-H.; Wang, X.; Cheng, X.; Alem, H.; Tebon, P.J.; Xu, C.; Guo, C.; et al. Microengineered poly(HEMA) hydrogels for wearable contact lens biosensing. Lab A Chip 2020, 20, 4205–4214. [Google Scholar] [CrossRef]

- Moore, J.; Lopes, B.T.; Eliasy, A.; Geraghty, B.; Wu, R.; White, L.; Elsheikh, A.; Abass, A. Simulation of the Effect of Material Properties on Soft Contact Lens On-Eye Power. Bioengineering 2019, 6, 94. [Google Scholar] [CrossRef]

- Musgrave, C.S.A.; Fang, F. Contact Lens Materials: A Materials Science Perspective. Materials 2019, 12, 261. [Google Scholar] [CrossRef]

- Lira, M.; Lourenço, C.; Silva, M.; Botelho, G. Physicochemical stability of contact lenses materials for biomedical applications. J. Optom. 2020, 13, 120–127. [Google Scholar] [CrossRef]

- Abass, A.; Stuart, S.; Lopes, B.T.; Zhou, D.; Geraghty, B.; Wu, R.; Jones, S.; Flux, I.; Stortelder, R.; Snepvangers, A.; et al. Simulated optical performance of soft contact lenses on the eye. PLoS ONE 2019, 14, e0216484. [Google Scholar] [CrossRef]

- Doll, T.; Moore, J.; Shihab, A.H.; Lopes, B.T.; Eliasy, A.; Maklad, O.; Wu, R.; White, L.; Jones, S.; Elsheikh, A.; et al. Which feature influences on-eye power change of soft toric contact lenses: Design or corneal shape? PLoS ONE 2020, 15, e0242243. [Google Scholar] [CrossRef]

- Wu, L.-Y.; Lin, W.-P.; Wu, R.; White, L.; Abass, A. FEA-Based Stress–Strain Barometers as Forecasters for Corneal Refractive Power Change in Orthokeratology. Bioengineering 2024, 11, 166. [Google Scholar] [CrossRef]

- Allgaier, M.; Cooper, M.G.; Carlson, A.E.; Cooley, S.W.; Ryan, J.C.; Smith, B.J. Direct measurement of optical properties of glacier ice using a photon-counting diffuse LiDAR. J. Glaciol. 2022, 68, 1210–1220. [Google Scholar] [CrossRef]

- Chen, B.; Shi, P.; Wang, Y.; Xu, Y.; Ma, H.; Wang, R.; Zheng, C.; Chu, P. Determining Surface Shape of Translucent Objects with the Combination of Laser-Beam-Based Structured Light and Polarization Technique. Sensors 2021, 21, 6587. [Google Scholar] [CrossRef]

- Abelson, M.B.; Udell, I.J.; Weston, J.H. Normal human tear pH by direct measurement. Arch Ophthalmol. 1981, 99, 301. [Google Scholar] [CrossRef]

- Oppenheim, A.V.; Schafer, R.W. Discrete-Time Signal Processing; Pearson: London, UK, 2010. [Google Scholar]

- Smith, S.W. The Scientist and Engineer’s Guide to Digital Signal Processing; California Technical Pub.: San Diego, CA, USA, 1997. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Gardner, C.S.; Papen, G. 22—Optical Communications. In Reference Data for Engineers, 9th ed.; Middleton, W.M., Van Valkenburg, M.E., Eds.; Newnes: Woburn, MA, USA, 2002; pp. 22-21–22-28. [Google Scholar]

- Fagerland, M.W. t-tests, non-parametric tests, and large studies—A paradox of statistical practice? BMC Med. Res. Methodol. 2012, 12, 78. [Google Scholar] [CrossRef]

- Rousseeuw, P.J.; Verboven, S. Robust estimation in very small samples. Comput. Stat. Data Anal. 2002, 40, 741–758. [Google Scholar] [CrossRef]

- Lin, W.-P.; Wu, L.-Y.; Li, W.-K.; Lin, W.-R.; Wu, R.; White, L.; Abass, R.; Alanazi, R.; Towler, J.; Davies, J.; et al. Can AI Predict the Magnitude and Direction of Ortho-K Contact Lens Decentration to Limit Induced HOAs and Astigmatism? J. Clin. Med. 2024, 13, 5420. [Google Scholar] [CrossRef]

| Contaflex Material Group Based on Their Nominal Water-Content | LEF (17 h) | LEF (24 h) | REF (17 h) | REF (24 h) | Manufacturer Swell Factor |

|---|---|---|---|---|---|

| Mean ± Std | Mean ± Std | Mean ± Std | Mean ± Std | ||

| C38 | 1.182 ± 0.019 | 1.201 ± 0.019 | 1.154 ± 0.010 | 1.179 ± 0.011 | 1.20 |

| C55 | 1.206 ± 0.067 | 1.218 ± 0.070 | 1.180 ± 0.067 | 1.209 ± 0.080 | 1.35 |

| C58 | 1.290 ± 0.047 | 1.353 ± 0.011 | 1.325 ± 0.039 | 1.353 ± 0.042 | 1.36 |

| C67 | 1.428 ± 0.027 | 1.452 ± 0.017 | 1.337 ± 0.052 | 1.389 ± 0.055 | 1.47 |

| C77 | 1.499 ± 0.045 | 1.563 ± 0.093 | 1.485 ± 0.053 | 1.536 ± 0.052 | 1.66 |

| Group | LEF HL Median | LEF 95% CI Lower | LEF 95% CI Upper |

|---|---|---|---|

| C38 | −995.94 | −1002.42 | −982.56 |

| C55 | −1044.28 | −1044.39 | −978.44 |

| C58 | −1038.75 | −1117.89 | −1037.15 |

| C67 | −1179.62 | −1250.74 | −1179.62 |

| C77 | −1216.7 | −1223.16 | −1216.7 |

| Group | REF HL Median | REF 95% CI Lower | REF 95% CI Upper |

|---|---|---|---|

| C38 | −956.76 | −967.9 | −955.66 |

| C55 | −962.64 | −1060.4 | −952.55 |

| C58 | −1072.23 | −1173.68 | −1072.23 |

| C67 | −1060.4 | −1132.43 | −1060.4 |

| C77 | −1181.54 | −1277.85 | −1181.54 |

| n (17 h) | n (24 h) | Manufacturer Published Value | |

|---|---|---|---|

| Group | Mean ± Std | Mean ± Std | |

| C38 | 1.552 ± 0.063 | 1.526 ± 0.097 | 1.44 |

| C55 | 1.461 ± 0.043 | 1.418 ± 0.427 | 1.41 |

| C58 | 1.417 ± 0.036 | 1.354 ± 0.409 | 1.4 |

| C67 | 1.399 ± 0.028 | 1.388 ± 0.439 | 1.39 |

| C77 | 1.414 ± 0.070 | 1.372 ± 0.458 | 1.38 |

| Sample Group | Lab Measured Water-Content (%) | Manufacturer Published Nominal Water-Content (%) |

|---|---|---|

| C38 | 26.5 ± 12.8 | 38 |

| C55 | 33.1 ± 15.6 | 55 |

| C58 | 52.2 ± 5.3 | 58 |

| C67 | 60.7 ± 2.4 | 67 |

| C77 | 63.7 ± 13.4 | 77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Towler, J.; Zaplachinski, M.; Montiel, R.; Murari, N.; Deng, C.; Lego, R.; Fathy, A.; Abass, A. The Behaviour of Contaflex Soft Contact Lens Material During Hydration. Gels 2025, 11, 376. https://doi.org/10.3390/gels11050376

Towler J, Zaplachinski M, Montiel R, Murari N, Deng C, Lego R, Fathy A, Abass A. The Behaviour of Contaflex Soft Contact Lens Material During Hydration. Gels. 2025; 11(5):376. https://doi.org/10.3390/gels11050376

Chicago/Turabian StyleTowler, Joseph, Markus Zaplachinski, Roberto Montiel, Nikhil Murari, Christine Deng, Rimmo Lego, Arwa Fathy, and Ahmed Abass. 2025. "The Behaviour of Contaflex Soft Contact Lens Material During Hydration" Gels 11, no. 5: 376. https://doi.org/10.3390/gels11050376

APA StyleTowler, J., Zaplachinski, M., Montiel, R., Murari, N., Deng, C., Lego, R., Fathy, A., & Abass, A. (2025). The Behaviour of Contaflex Soft Contact Lens Material During Hydration. Gels, 11(5), 376. https://doi.org/10.3390/gels11050376