Effect of Sodium Chloride Concentrations on Processing Characteristics and Quality of Mianpi Made Using Different Wheat Flour–Starch Levels

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

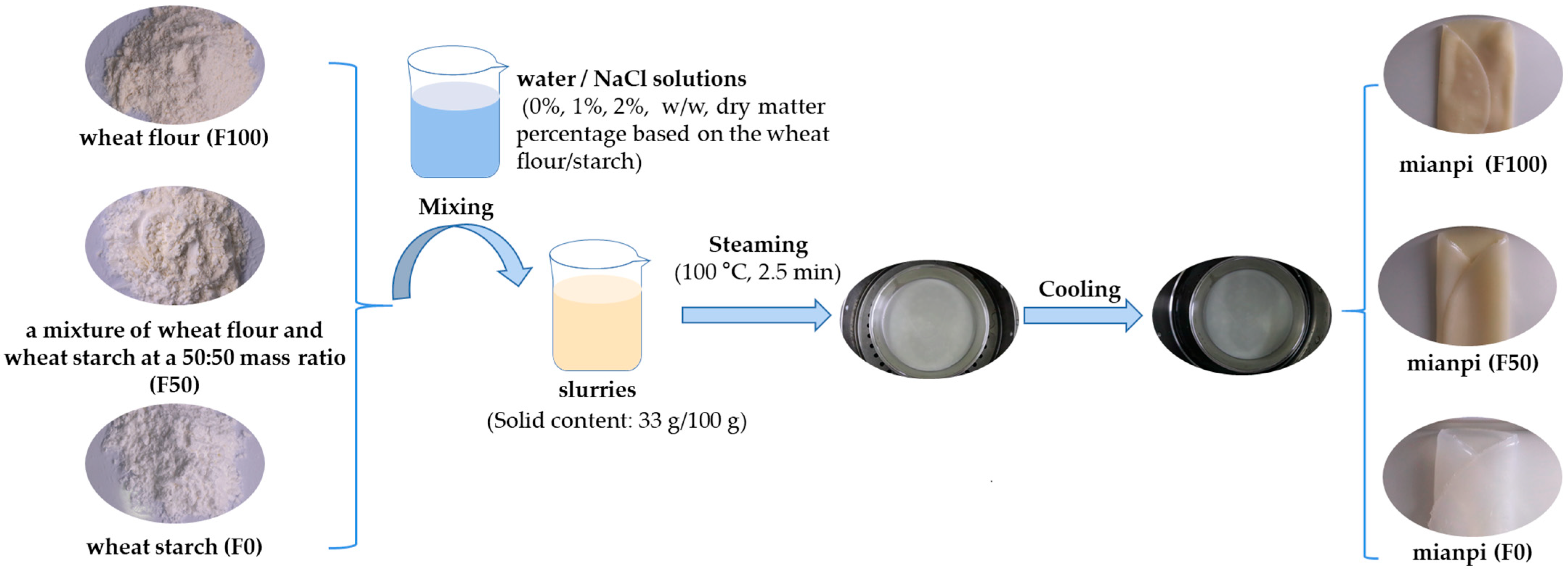

2.2. Preparation of Mianpi Slurries

2.3. Flow Behavior Analysis

2.4. Rapid Visco Analyzer (RVA)

2.5. Preparation of Mianpi

2.6. Color Measurement of Mianpi

2.7. Texture Profile Analysis (TPA)

2.8. Tensile Properties of Mianpi

2.9. Frequency Sweep Test of Mianpi

2.10. Raman Spectroscopic Analysis of Mianpi

2.11. Fourier Transform Infrared (FTIR) Spectroscopic Analysis of Mianpi

2.12. Statistical Analysis

3. Results and Discussion

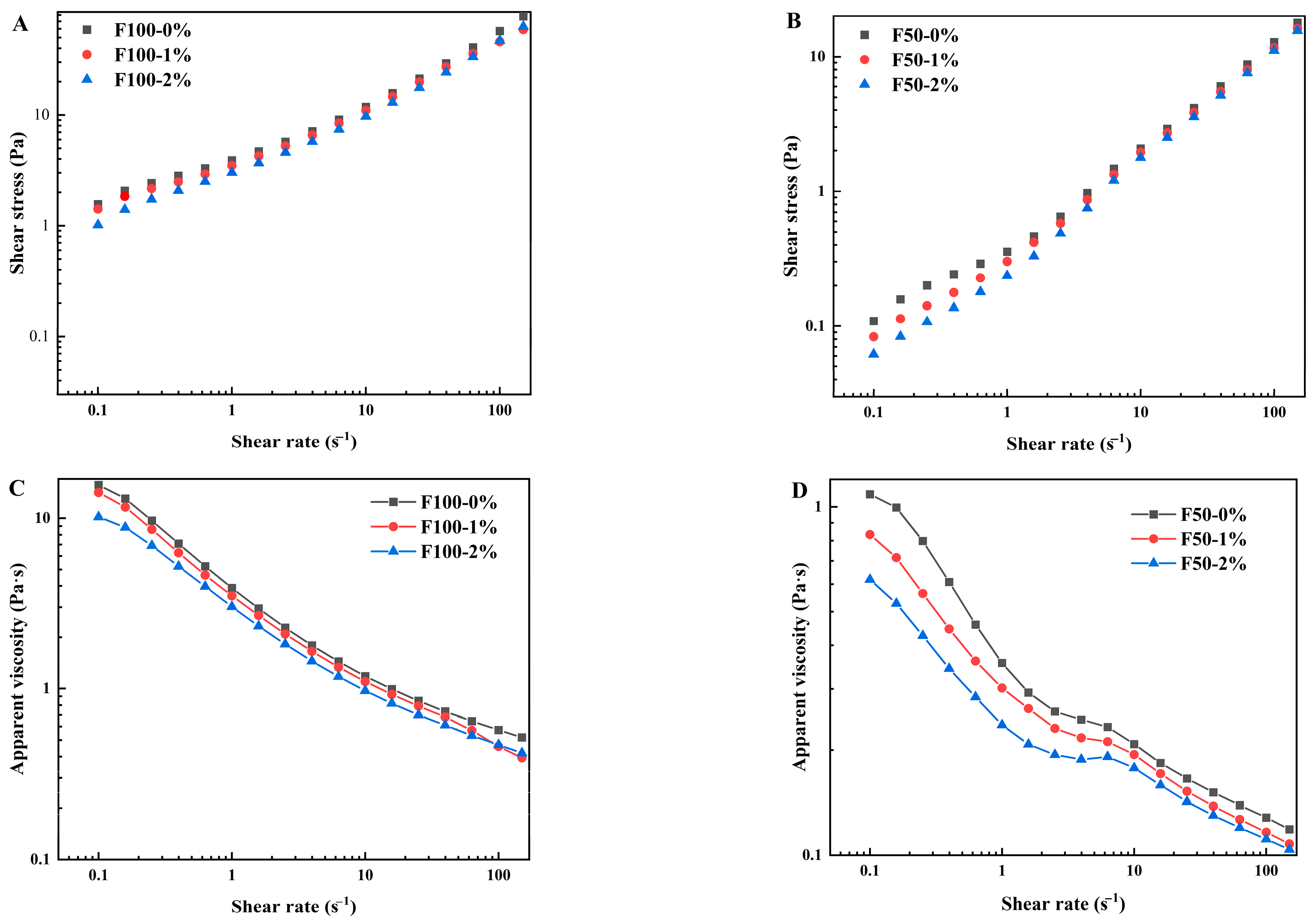

3.1. Effects of NaCl on Flow Properties of the Slurries

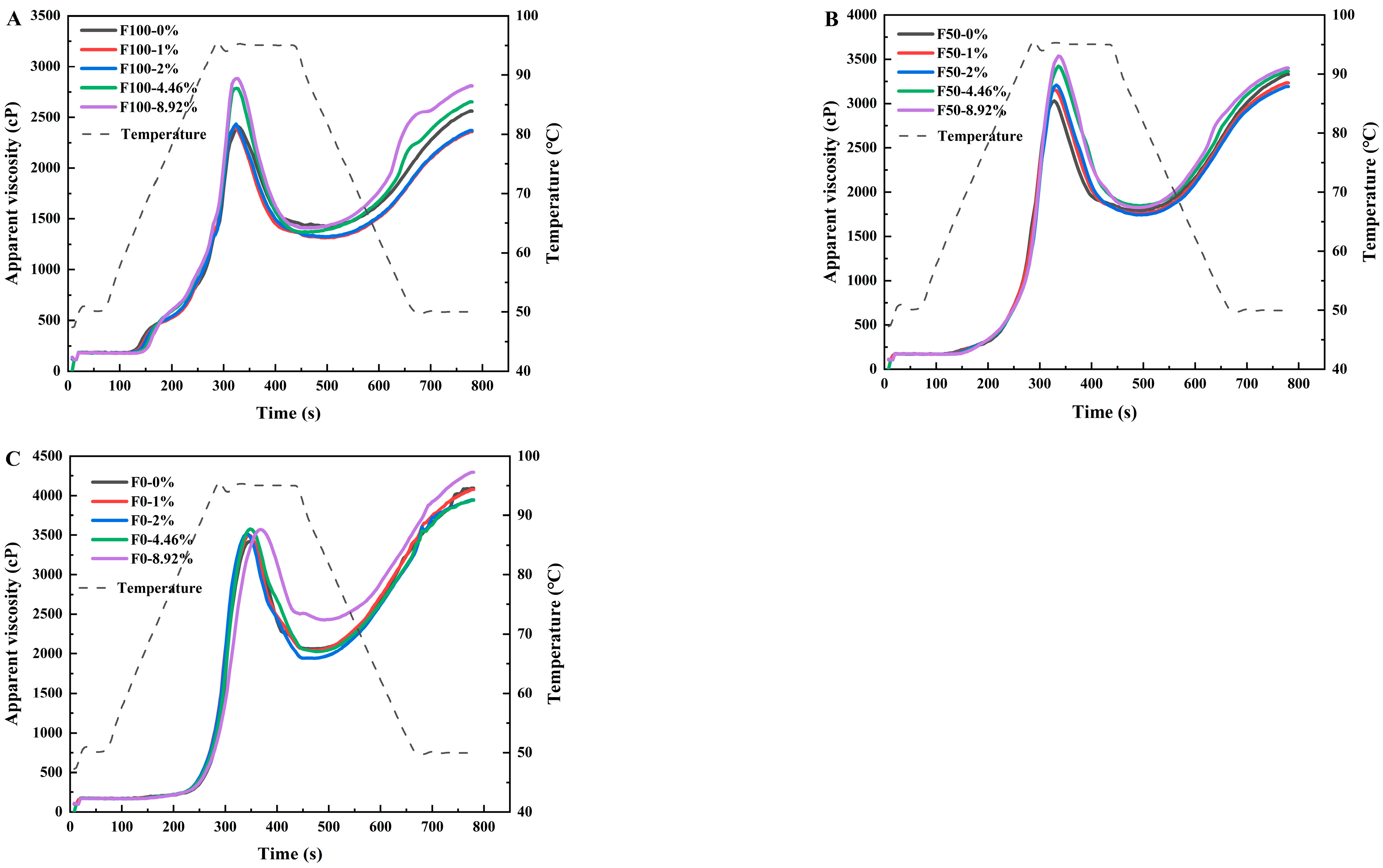

3.2. Effects of NaCl on Pasting Properties of the Slurries

3.3. Effects of NaCl on Qualities of Mianpi

3.3.1. Color

3.3.2. Textural Properties

3.3.3. Tensile Properties

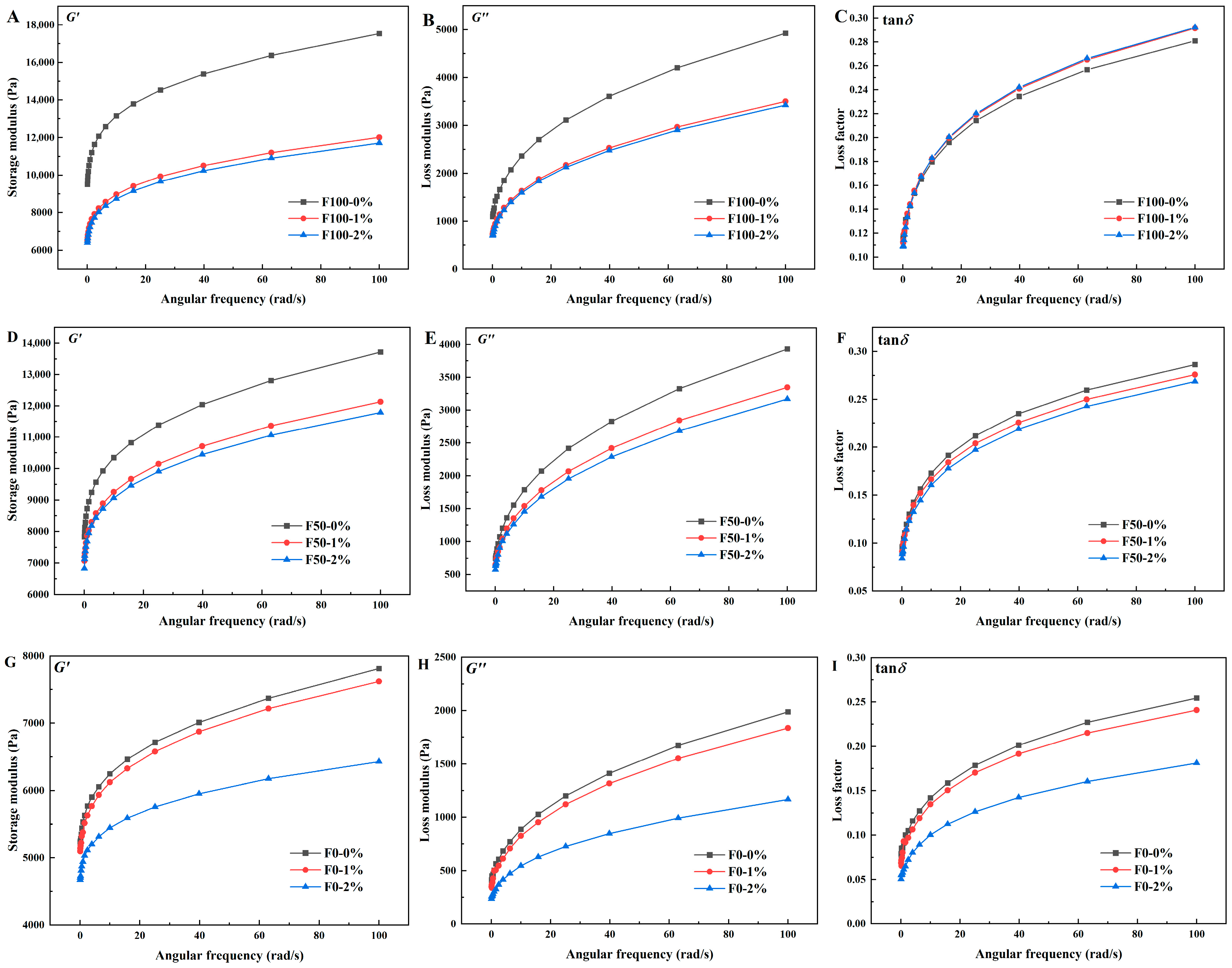

3.4. Effects of NaCl on Viscoelastic Properties of Mianpi

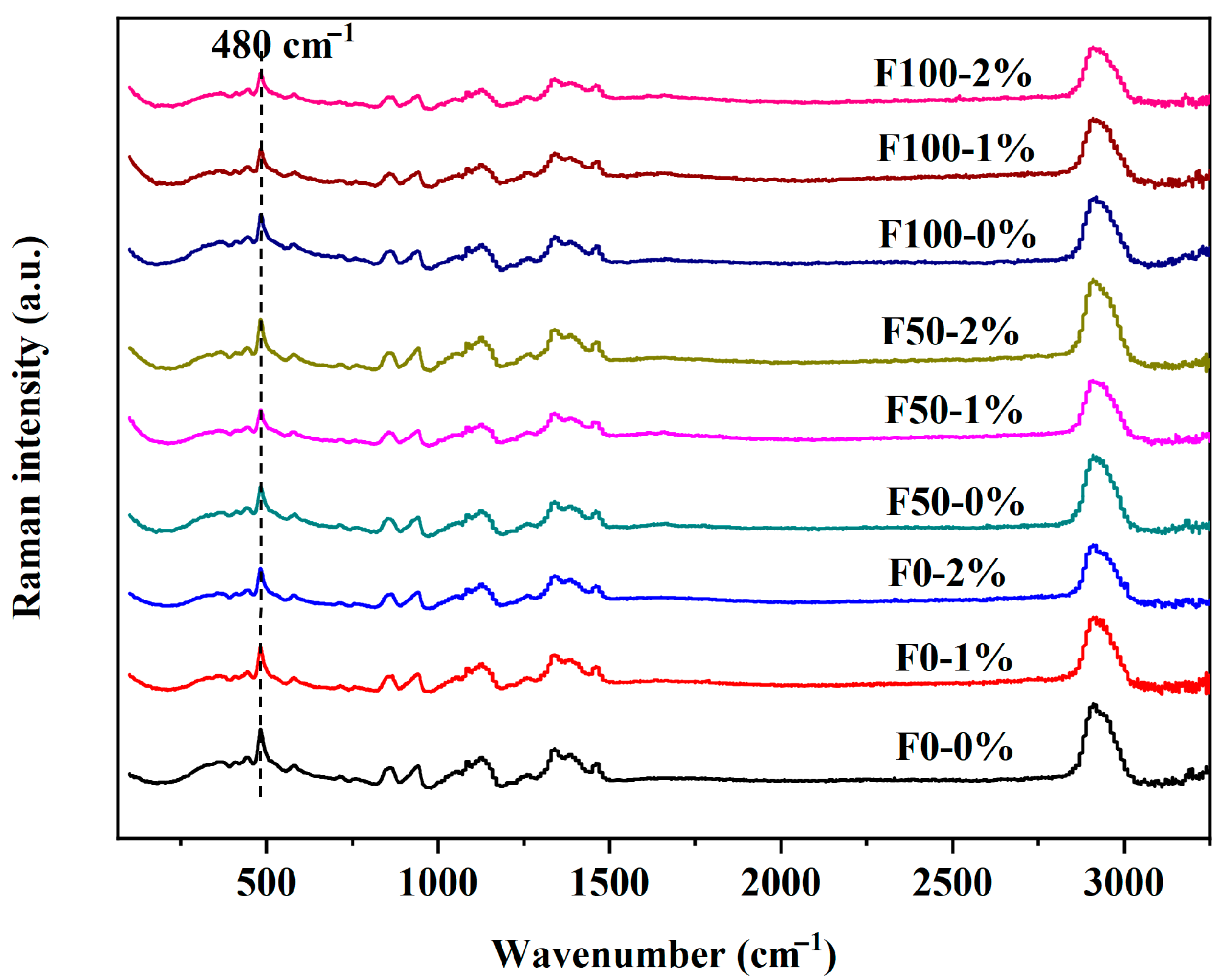

3.5. Effects of NaCl on Structural Characteristics of Starch Components in Mianpi

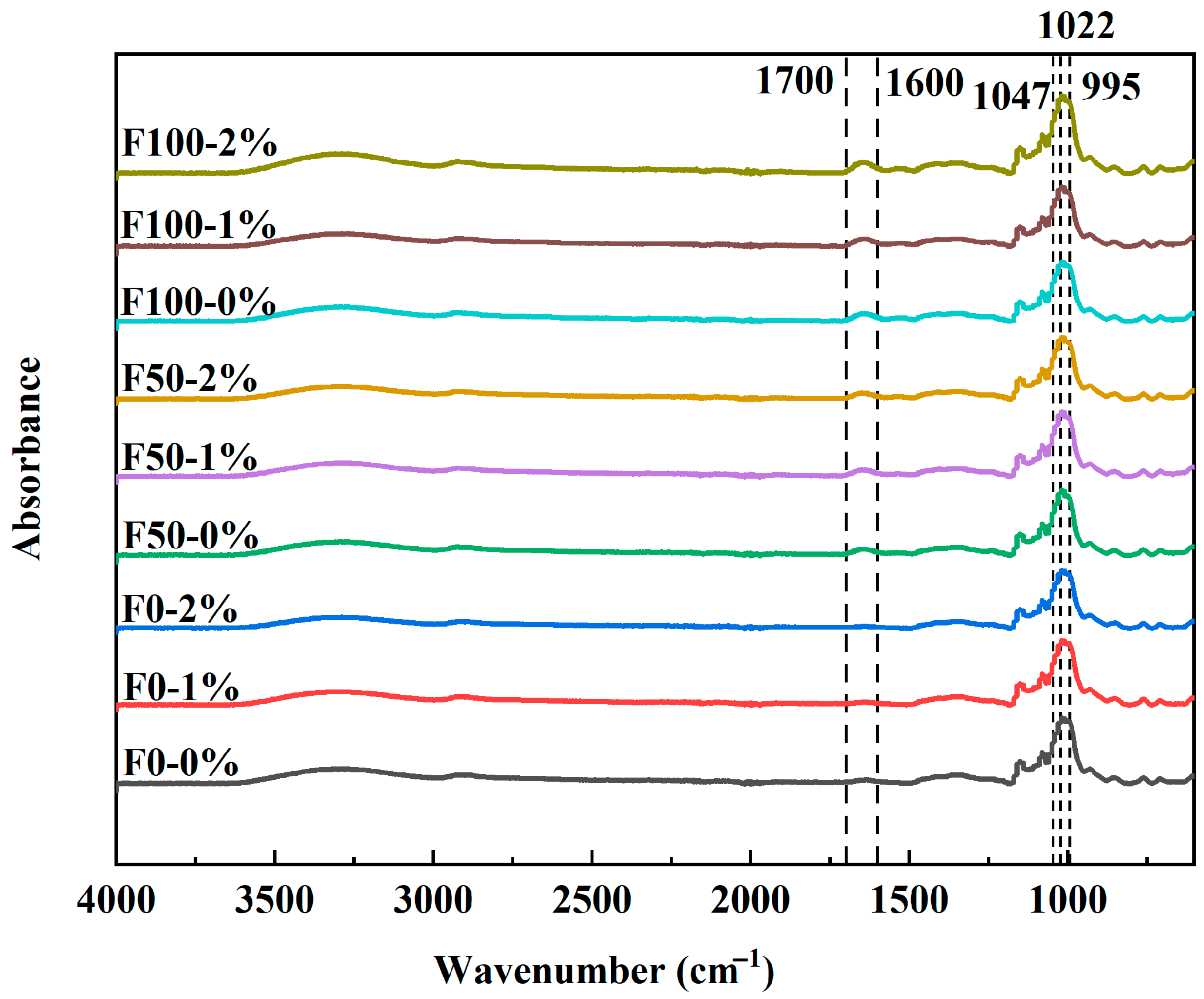

3.6. Effects of NaCl on Structural Characteristics of Proteins in Mianpi

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Albarracín, W.; Sánchez, I.C.; Grau, R.; Barat, J.M. Salt in food processing; usage and reduction: A review. Int. J. Food Sci. Technol. 2011, 46, 1329–1336. [Google Scholar] [CrossRef]

- Sun, X.; Koksel, F.; Scanlon, M.G.; Nickerson, M.T.; Arntfield, S.D. Effects of water, salt, and mixing on the rheological properties of bread dough at large and small deformations: A review. Cereal Chem. 2022, 99, 709–723. [Google Scholar] [CrossRef]

- Avramenko, N.A.; Tyler, R.T.; Scanlon, M.G.; Hucl, P.; Nickerson, M.T. The chemistry of bread making: The role of salt to ensure optimal functionality of its constituents. Food Rev. Int. 2018, 34, 204–225. [Google Scholar] [CrossRef]

- Silow, C.; Axel, C.; Zannini, E.; Arendt, E.K. Current status of salt reduction in bread and bakery products—A review. J. Cereal Sci. 2016, 72, 135–145. [Google Scholar] [CrossRef]

- Belz, M.C.E.; Axel, C.; Beauchamp, J.; Zannini, E.; Arendt, E.K.; Czerny, M. Sodium chloride and its influence on the aroma profile of yeasted bread. Foods 2017, 6, 66. [Google Scholar] [CrossRef] [PubMed]

- Carcea, M.; Narducci, V.; Turfani, V.; Mellara, F. A comprehensive study on the influence of sodium chloride on the technological quality parameters of soft wheat dough. Foods 2020, 9, 952. [Google Scholar] [CrossRef]

- Fan, H.; Fu, F.; Chen, Y.; Liu, M.; Ai, Z.; Bian, K. Effect of NaCl on rheological properties of dough and noodle quality. J. Cereal Sci. 2020, 93, 102936. [Google Scholar] [CrossRef]

- Wang, J.-R.; Guo, X.-N.; Xing, J.-J.; Zhu, K.-X. Revealing the effect mechanism of NaCl on the rheological properties of dough of Chinese traditional hand-stretched dried noodles. Food Chem. 2020, 320, 126606. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, C.; Li, L.; Li, J.; Wang, J.; Fan, X.; Zheng, X. Structural characteristics and paste properties of wheat starch in natural fermentation during traditional Chinese Mianpi processing. Int. J. Biol. Macromol. 2024, 262, 129993. [Google Scholar] [CrossRef]

- Shang, J.; Liu, C.; Li, L.; Hong, J.; Liu, M.; Liu, Z.; Zhao, B.; Zheng, X. Effect of salt and alkali on the viscoelastic behavior of noodle dough sheet with different wheat starch granule sizes. Food Res. Int. 2024, 197, 115185. [Google Scholar] [CrossRef] [PubMed]

- Li, E.; Lv, J.; Huo, D.; Jia, B.; Li, C. Importance of amylose chain-length distribution in determining starch gelatinization and retrogradation property of wheat flour in the presence of different salts. Carbohydr. Polym. 2023, 308, 120648. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Li, G.; Corke, H.; Zhu, F. Physicochemical properties of starch in sodium chloride solutions and sucrose solutions: Importance of starch structure. Food Chem. 2023, 421, 136141. [Google Scholar] [CrossRef]

- Nicol, T.W.J.; Isobe, N.; Clark, J.H.; Matubayasi, N.; Shimizu, S. The mechanism of salt effects on starch gelatinization from a statistical thermodynamic perspective. Food Hydrocoll. 2019, 87, 593–601. [Google Scholar] [CrossRef]

- Chen, Z.; Li, X.; Tong, Z.; Huang, J.; Pu, H.; Zhong, H. The effects of NaCl on starch molecular conformation. Starch-Stärke 2023, 75, 5–6. [Google Scholar]

- Hedayati, S.; Shahidi, F.; Majzoobi, M.; Koocheki, A.; Farahnaky, A. Structural, rheological, pasting and textural properties of granular cold water swelling maize starch: Effect of NaCl and CaCl2. Carbohydr. Polym. 2020, 242, 116406. [Google Scholar] [CrossRef]

- Zheng, L.; Ren, A.; Liu, R.; Xing, Y.; Yu, X.; Jiang, H. Effect of sodium chloride solution on quality of 3D-printed samples molded using wheat starch gel. Food Hydrocoll. 2022, 123, 107197. [Google Scholar] [CrossRef]

- GB/T 24853-2010; General Pasting Method for Wheat or Rye Flour or Starch—Using the Rapid Visco Analyzer. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China (SAC): Beijing, China, 2010.

- Xiao, X.; Yang, L.; Xu, Z.; Huang, P.; Shu, C.; Song, S.; Zhang, Y.; Pei, H. Research on rice starch gel preparation and crosslink network structure–rheological property based on direct-writing 3D printing. Heliyon 2024, 10, e24057. [Google Scholar] [CrossRef]

- Chen, G.; Ehmke, L.; Sharma, C.; Miller, R.; Faa, P.; Smith, G.; Li, Y. Physicochemical properties and gluten structures of hard wheat flour doughs as affected by salt. Food Chem. 2019, 275, 569–576. [Google Scholar] [CrossRef]

- Liu, X.; Luan, H.; Yu, J.; Wang, S.; Wang, S.; Copeland, L. A method for characterizing short-range molecular order in amorphous starch. Carbohydr. Polym. 2020, 242, 116405. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Ren, X.; An, Y.; Song, X.; Zhao, Y.; Wen, Y.; Zhang, W. Changes in physicochemical characteristics of wheat flour and quality of fresh wet noodles induced by microwave treatment. Grain Oil Sci. Technol. 2024, 7, 177–185. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, F.; Liu, J.; Zhou, Y.; Lei, L.; Zhao, G. Rheological nature and dropping performance of sweet potato starch dough as influenced by the binder pastes. Food Hydrocoll. 2018, 85, 39–50. [Google Scholar] [CrossRef]

- Mioduszewski, Ł.; Cieplak, M. Viscoelastic properties of wheat gluten in a molecular dynamics study. PLoS Comput. Biol. 2021, 17, e1008840. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, H.; Chen, R.; Chen, J.; Liu, X.; Luo, S.; Chen, T. Effects of creeping fig seed polysaccharide on pasting, rheological, textural properties and in vitro digestibility of potato starch. Food Hydrocoll. 2021, 118, 106810. [Google Scholar] [CrossRef]

- Saleh, M. Wheat batter physical properties as influenced by starch/flour types and egg contents. J. Food Meas. Charact. 2018, 12, 800–807. [Google Scholar] [CrossRef]

- Xue, J.; Ngadi, M. Rheological properties of batter systems formulated using different flour combinations. J. Food Eng. 2006, 77, 334–341. [Google Scholar] [CrossRef]

- Li, M.; Sun, Q.-J.; Han, C.-W.; Chen, H.-H.; Tang, W.-T. Comparative study of the quality characteristics of fresh noodles with regular salt and alkali and the underlying mechanisms. Food Chem. 2018, 246, 335–342. [Google Scholar] [CrossRef]

- Li, D.; Fayet, C.; Homer, S. The effect of sodium chloride on gluten network formation and dough rheology in wheat flour. J. Cereal Sci. 2020, 95, 103057. [Google Scholar]

- Tan, H.-L.; Tan, T.-C.; Easa, A.M. The use of selected hydrocolloids and salt substitutes on structural integrity, texture, sensory properties, and shelf life of fresh no salt wheat noodles. Food Hydrocoll. 2020, 108, 105996. [Google Scholar] [CrossRef]

- Guo, J.; Lian, X.; Kang, H.; Gao, K.; Li, L. Effects of glutenin in wheat gluten on retrogradation of wheat starch. Eur. Food Res. Technol. 2016, 242, 1485–1494. [Google Scholar] [CrossRef]

- Bai, J.; Dong, M.; Li, J.; Tian, L.; Xiong, D.; Jia, J.; Yang, L.; Liu, X.; Duan, X. Effects of egg white on physicochemical and functional characteristics of steamed cold noodles (a wheat starch gel food). LWT-Food Sci. Technol. 2022, 169, 114057. [Google Scholar] [CrossRef]

- Torres, M.D.; Raymundo, A.; Sousa, I. Influence of Na+, K+ and Ca2+ on mechanical and structural properties of gels from chestnut and rice flours. Carbohydr. Polym. 2014, 102, 30–37. [Google Scholar] [CrossRef] [PubMed]

- Sangpring, Y.; Fukuoka, M.; Ratanasumawong, S. The effect of sodium chloride on microstructure, water migration, and texture of rice noodle. LWT-Food Sci. Technol. 2015, 64, 1107–1113. [Google Scholar]

- Tao, H.; Lu, F.; Zhu, X.-F.; Xu, G.-X.; Xie, H.-Q.; Xu, X.-M.; Wang, H.-L. Removing surface proteins promote the retrogradation of wheat starch. Food Hydrocoll. 2021, 113, 106437. [Google Scholar] [CrossRef]

- Li, W.; Zhang, K.; Qin, Y.; Li, M.; Li, H.; Guo, M.; Xu, T.; Sun, Q.; Ji, N.; Xie, F. Effects of sodium chloride on the textural attributes, rheological properties, microstructure, and 3D printing performance of rice starch-curdlan composite gel. Food Chem. 2025, 465, 141986. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Tian, Y.; Ma, R. Assessment of order of helical structures of retrograded starch by Raman spectroscopy. Food Hydrocoll. 2023, 134, 108064. [Google Scholar] [CrossRef]

- Bilal, M.; Zhang, Y.; Li, D.; Xie, C.; Yang, R.; Gu, Z.; Jiang, D.; Wang, P. Optimizing techno-functionality of germinated whole wheat flour steamed bread via glucose oxidase (Gox) and pentosanase (Pn) enzyme innovation. Grain Oil Sci. Technol. 2023, 6, 219–226. [Google Scholar] [CrossRef]

- Ma, R.; Tian, Y.; Chen, L.; Cai, C.; Jin, Z. Effects of cooling rate on retrograded nucleation of different rice starch-aromatic molecule complexes. Food Chem. 2019, 294, 179–186. [Google Scholar] [CrossRef]

- Fevzioglu, M.; Ozturk, O.K.; Hamaker, B.R.; Campanella, O.H. Quantitative approach to study secondary structure of proteins by FT-IR spectroscopy, using a model wheat gluten system. Int. J. Biol. Macromol. 2020, 164, 2753–2760. [Google Scholar] [CrossRef]

- Zhan, J.; Ma, S.; Wang, X.-X.; Li, L.; Zheng, X.-L. Effect of baked wheat germ on gluten protein network in steamed bread dough. Int. J. Food Sci. Technol. 2019, 54, 2839–2846. [Google Scholar] [CrossRef]

- Gui, J.; Lu, Q. Effects of anions on water distribution, protein secondary structure and microstructure of noodles. J. Chin. Inst. Food Sci. Technol. 2021, 21, 159–165. [Google Scholar]

| Samples | K (Pa·sⁿ) | n | R2 |

|---|---|---|---|

| F50-0% | 0.29 ± 0.03 d | 0.82 ± 0.01 a | 1 |

| F50-1% | 0.28 ± 0.01 d | 0.80 ± 0.00 a | 1 |

| F50-2% | 0.27 ± 0.02 d | 0.82 ± 0.01 a | 1 |

| F100-0% | 2.27 ± 0.09 b | 0.70 ± 0.00 b | 0.997 |

| F100-1% | 2.96 ± 0.11 a | 0.60 ± 0.01 c | 0.999 |

| F100-2% | 2.00 ± 0.11 c | 0.69 ± 0.01 b | 0.998 |

| Samples | NaCl Content (% w/w) | TTPV (min) | PV (cP) | TV (cP) | BD (cP) | FV (cP) | SB (cP) |

|---|---|---|---|---|---|---|---|

| F100 | 0 | 5.40 ± 0.09 e | 2388 ± 30 f | 1412 ± 20 f | 976 ± 10 g | 2547 ± 21 h | 1135 ± 1 g |

| 1 | 5.40 ± 0.00 e | 2349 ± 68 f | 1321 ± 10 f | 1028 ± 78 g | 2351 ± 11 i | 1030 ± 21 h | |

| 2 | 5.40 ± 0.00 e | 2426 ± 8 f | 1321 ± 3 f | 1105 ± 6 fg | 2377 ± 11 i | 1056 ± 14 gh | |

| 4.46 | 5.43 ± 0.05 e | 2744 ± 60 e | 1382 ± 17 f | 1362 ± 77 de | 2636 ± 23 h | 1254 ± 40 f | |

| 8.92 | 5.47 ± 0.09 e | 2852 ± 42 de | 1393 ± 25 f | 1459 ± 16 bcd | 2763 ± 65 g | 1370 ± 40 e | |

| F50 | 0 | 5.43 ± 0.05 e | 2991 ± 55 d | 1768 ± 30 e | 1223 ± 25 ef | 3300 ± 42 ef | 1532 ± 12 d |

| 1 | 5.50 ± 0.05 de | 3141 ± 23 c | 1750 ± 8 e | 1391 ± 15 cd | 3217 ± 24 f | 1467 ± 16 e | |

| 2 | 5.53 ± 0.00 de | 3230 ± 30 c | 1751 ± 11 e | 1479 ± 19 bcd | 3216 ± 34 f | 1465 ± 23 e | |

| 4.46 | 5.63 ± 0.05 cde | 3458 ± 49 ab | 1847 ± 2 e | 1612 ± 47 ab | 3374 ± 15 de | 1527 ± 13 d | |

| 8.92 | 5.63 ± 0.05 cde | 3490 ± 67 ab | 1843 ± 24 e | 1647 ± 91 a | 3424 ± 32 d | 1581 ± 8 c | |

| F0 | 0 | 5.80 ± 0.00 bc | 3418 ± 6 b | 2061 ± 6 cd | 1357 ± 0 de | 4072 ± 31 b | 2011 ± 25 a |

| 1 | 5.87 ± 0.19 bc | 3526 ± 42 ab | 2111 ± 93 c | 1415 ± 52 cd | 4107 ± 43 b | 1996 ± 50 a | |

| 2 | 5.73 ± 0.00 cd | 3513 ± 3 ab | 1965 ± 32 d | 1549 ± 29 abc | 3968 ± 30 c | 2004 ± 2 a | |

| 4.46 | 5.97 ± 0.05 ab | 3566 ± 53 ab | 2214 ± 49 b | 1352 ± 4 de | 4152 ± 11 b | 1938 ± 60 b | |

| 8.92 | 6.13 ± 0.00 a | 3618 ± 68 a | 2427 ± 0 a | 1191 ± 68 f | 4312 ± 25 a | 1885 ± 25 b |

| Samples | NaCl Content (% w/w) | L* | a* | b* | ΔE |

|---|---|---|---|---|---|

| F100 | 0 | 58.13 ± 1.17 ab | −1.90 ± 0.22 d | 3.38 ± 0.40 a | NA |

| 1 | 59.24 ± 0.42 a | −1.94 ± 0.09 d | 1.74 ± 0.17 b | 2.02 ± 0.15 | |

| 2 | 58.26 ± 0.59 a | −2.03 ± 0.19 d | 1.54 ± 0.18 b | 1.95 ± 0.16 | |

| F50 | 0 | 56.89 ± 0.76 bc | −1.75 ± 0.11 cd | −1.65 ± 0.23 c | NA |

| 1 | 56.26 ± 0.67 c | −1.53 ± 0.16 c | −2.28 ± 0.36 cd | 1.09 ± 0.51 | |

| 2 | 54.97 ± 0.41 d | −1.55 ± 0.14 c | −2.51 ± 0.39 d | 2.14 ± 0.49 | |

| F0 | 0 | 53.17 ± 0.69 e | 1.11 ± 0.14 ab | −2.01 ± 0.32 cd | NA |

| 1 | 51.35 ± 1.13 f | 0.84 ± 0.26 b | −2.08 ± 0.43 cd | 2.89 ± 0.57 | |

| 2 | 51.08 ± 0.50 f | 1.27 ± 0.23 a | −2.28 ± 0.73 cd | 3.30 ± 0.25 |

| Samples | NaCl Content (% w/w) | Hardness (g) | Adhesiveness (g·s) | Springiness (-) | Chewiness (mJ) |

|---|---|---|---|---|---|

| F100 | 0 | 5707.70 ± 341.43 b | −235.74 ± 21.08 c | 0.908 ± 0.013 a | 3743.26 ± 170.28 a |

| 1 | 5713.03 ± 194.41 b | −256.40 ± 36.65 c | 0.921 ± 0.034 a | 3740.06 ± 169.10 a | |

| 2 | 5279.06 ± 253.82 cd | −241.68 ± 28.37 c | 0.905 ± 0.006 a | 3525.74 ± 157.79 ab | |

| F50 | 0 | 4709.56 ± 193.74 e | −220.65 ± 34.32 c | 0.917 ± 0.021 a | 3139.95 ± 325.46 b |

| 1 | 5014.91 ± 252.63 d | −271.52 ± 7.80 d | 0.868 ± 0.036 b | 3279.42 ± 241.09 b | |

| 2 | 5351.41 ± 107.72 cd | −344.52 ± 21.32 e | 0.895 ± 0.024 a | 3692.62 ± 174.44 ab | |

| F0 | 0 | 6392.36 ± 471.53 a | −91.04 ± 23.62 b | 0.677 ± 0.085 d | 3537.98 ± 391.21 ab |

| 1 | 5721.05 ± 207.45 b | −66.51 ± 5.81 a | 0.762 ± 0.053 c | 3431.04 ± 272.58 ab | |

| 2 | 4736.76 ± 378.25 e | −48.04 ± 9.32 a | 0.600 ± 0.031 d | 2038.85 ± 166.68 c |

| Samples | NaCl Content (% w/w) | Tensile Force (g) | Extension (mm) |

|---|---|---|---|

| F100 | 0 | 91.49 ± 6.53 c | −11.78 ± 0.52 b |

| 1 | 100.53 ± 6.39 ab | −12.39 ± 0.34 b | |

| 2 | 101.64 ± 6.50 ab | −13.04 ± 0.25 b | |

| F50 | 0 | 96.95 ± 7.71 bc | −11.90 ± 0.50 b |

| 1 | 118.17 ± 9.98 a | −12.13 ± 0.58 b | |

| 2 | 120.06 ± 8.63 a | −12.49 ± 0.46 b | |

| F0 | 0 | 102.54 ± 16.76 ab | −7.97 ± 1.25 a |

| 1 | 98.57 ± 9.22 bc | −8.01 ± 0.73 a | |

| 2 | 101.87 ± 5.37 ab | −8.63 ± 0.42 a |

| Samples | NaCl Content (% w/w) | FWHM | R1047/1022 | R1022/995 |

|---|---|---|---|---|

| F100 | 0 | 19.54 ± 0.51 a | 0.585 ± 0.002 e | 0.842 ± 0.008 abc |

| 1 | 19.51 ± 0.02 a | 0.559 ± 0.009 f | 0.873 ± 0.016 ab | |

| 2 | 19.44 ± 0.22 a | 0.558 ± 0.002 f | 0.888 ± 0.071 ab | |

| F50 | 0 | 19.48 ± 0.82 a | 0.659 ± 0.008 c | 0.899 ± 0.018 a |

| 1 | 19.18 ± 0.13 a | 0.679 ± 0.004 b | 0.892 ± 0.002 ab | |

| 2 | 18.77 ± 0.62 a | 0.681 ± 0.008 ab | 0.886 ± 0.006 ab | |

| F0 | 0 | 19.23 ± 0.00 a | 0.693 ± 0.002 a | 0.760 ± 0.005 d |

| 1 | 19.44 ± 1.03 a | 0.603 ± 0.012 d | 0.773 ± 0.014 cd | |

| 2 | 18.70 ± 0.78 a | 0.584 ± 0.006 e | 0.811 ± 0.002 bcd |

| Samples | NaCl Content (% w/w) | β-Sheet | Random Coil | α-Helix | β-Turn |

|---|---|---|---|---|---|

| F100 | 0 | 40.95 ± 0.44 a | 21.94 ± 0.56 a | 18.63 ± 0.66 a | 18.48 ± 0.59 a |

| 1 | 39.32 ± 0.32 a | 21.04 ± 0.08 a | 19.06 ± 0.09 a | 20.57 ± 0.49 a | |

| 2 | 39.23 ± 1.38 a | 20.99 ± 1.50 a | 19.36 ± 0.93 a | 20.42 ± 1.53 a | |

| F50 | 0 | 38.92 ± 0.56 a | 21.77 ± 0.76 a | 19.08 ± 0.54 a | 20.24 ± 0.91 a |

| 1 | 39.01 ± 0.87 a | 21.79 ± 2.27 a | 18.17 ± 0.74 a | 21.02 ± 1.95 a | |

| 2 | 38.41 ± 0.04 a | 22.62 ± 0.14 a | 18.82 ± 0.57 a | 20.15 ± 0.70 a | |

| F0 | 0 | NA | NA | NA | NA |

| 1 | NA | NA | NA | NA | |

| 2 | NA | NA | NA | NA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Tang, L.; Li, S.; Liu, P.; Chen, T.; Ye, F. Effect of Sodium Chloride Concentrations on Processing Characteristics and Quality of Mianpi Made Using Different Wheat Flour–Starch Levels. Foods 2025, 14, 3127. https://doi.org/10.3390/foods14173127

Lu Y, Tang L, Li S, Liu P, Chen T, Ye F. Effect of Sodium Chloride Concentrations on Processing Characteristics and Quality of Mianpi Made Using Different Wheat Flour–Starch Levels. Foods. 2025; 14(17):3127. https://doi.org/10.3390/foods14173127

Chicago/Turabian StyleLu, Yang, Luo Tang, Shuying Li, Peiling Liu, Ting Chen, and Fayin Ye. 2025. "Effect of Sodium Chloride Concentrations on Processing Characteristics and Quality of Mianpi Made Using Different Wheat Flour–Starch Levels" Foods 14, no. 17: 3127. https://doi.org/10.3390/foods14173127

APA StyleLu, Y., Tang, L., Li, S., Liu, P., Chen, T., & Ye, F. (2025). Effect of Sodium Chloride Concentrations on Processing Characteristics and Quality of Mianpi Made Using Different Wheat Flour–Starch Levels. Foods, 14(17), 3127. https://doi.org/10.3390/foods14173127