Uncertainty Quantification at the Microscale: A Data-Driven Multi-Scale Approach †

Abstract

1. Introduction

2. Methodology

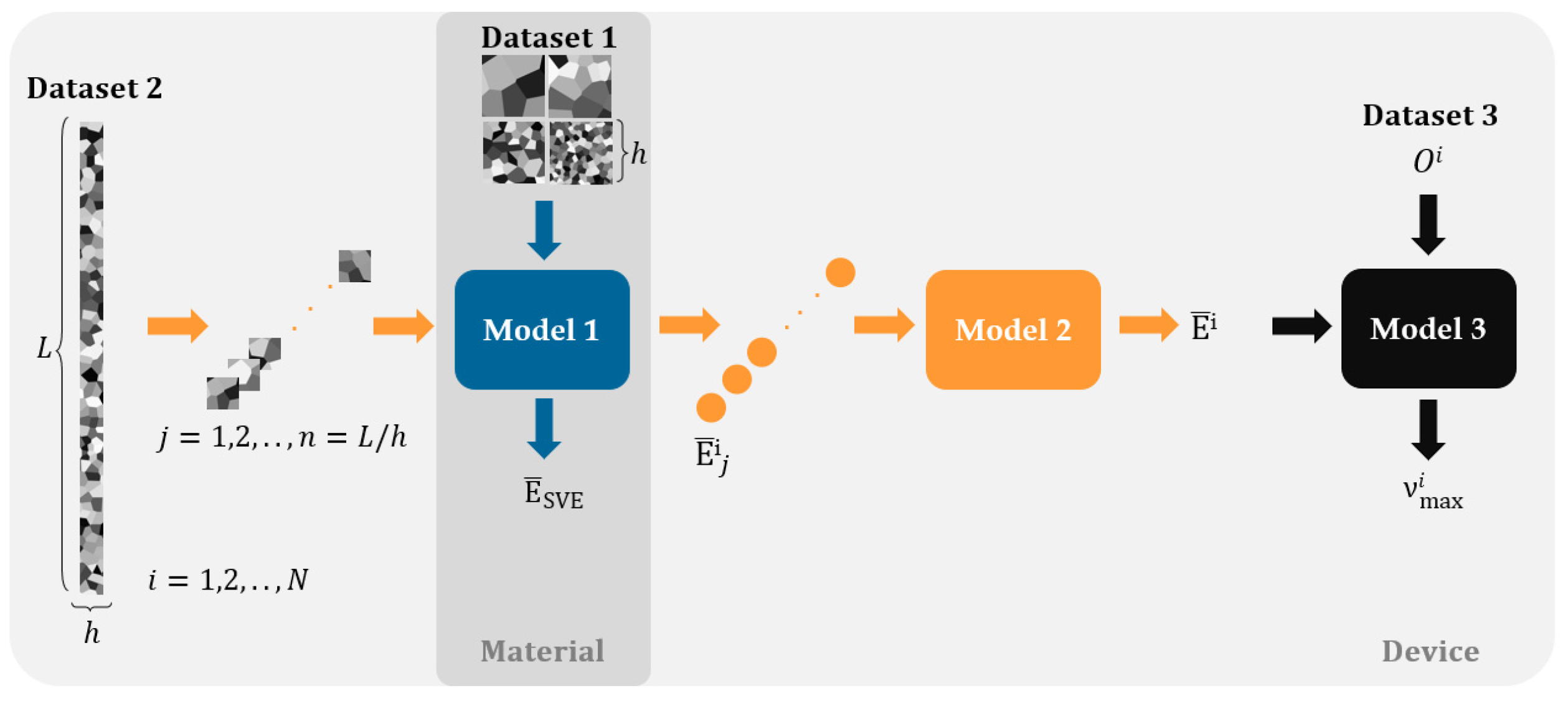

2.1. Data-Driven Multi-Scale Approach

2.2. Implementation Details

2.3. Input Data Generation

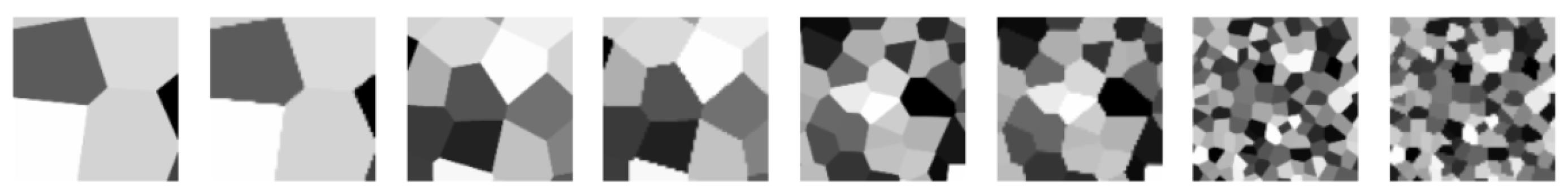

2.3.1. Dataset 1

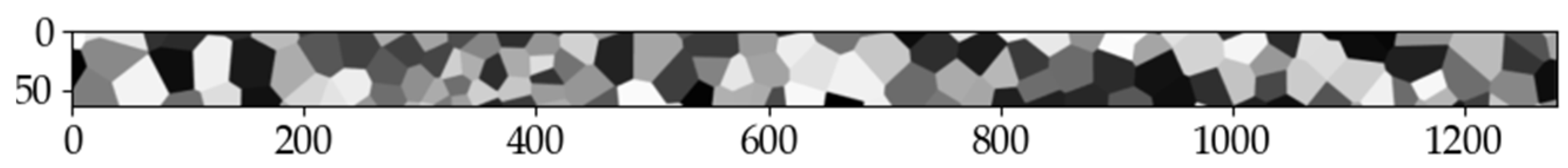

2.3.2. Dataset 2

2.3.3. Dataset 3

3. Results

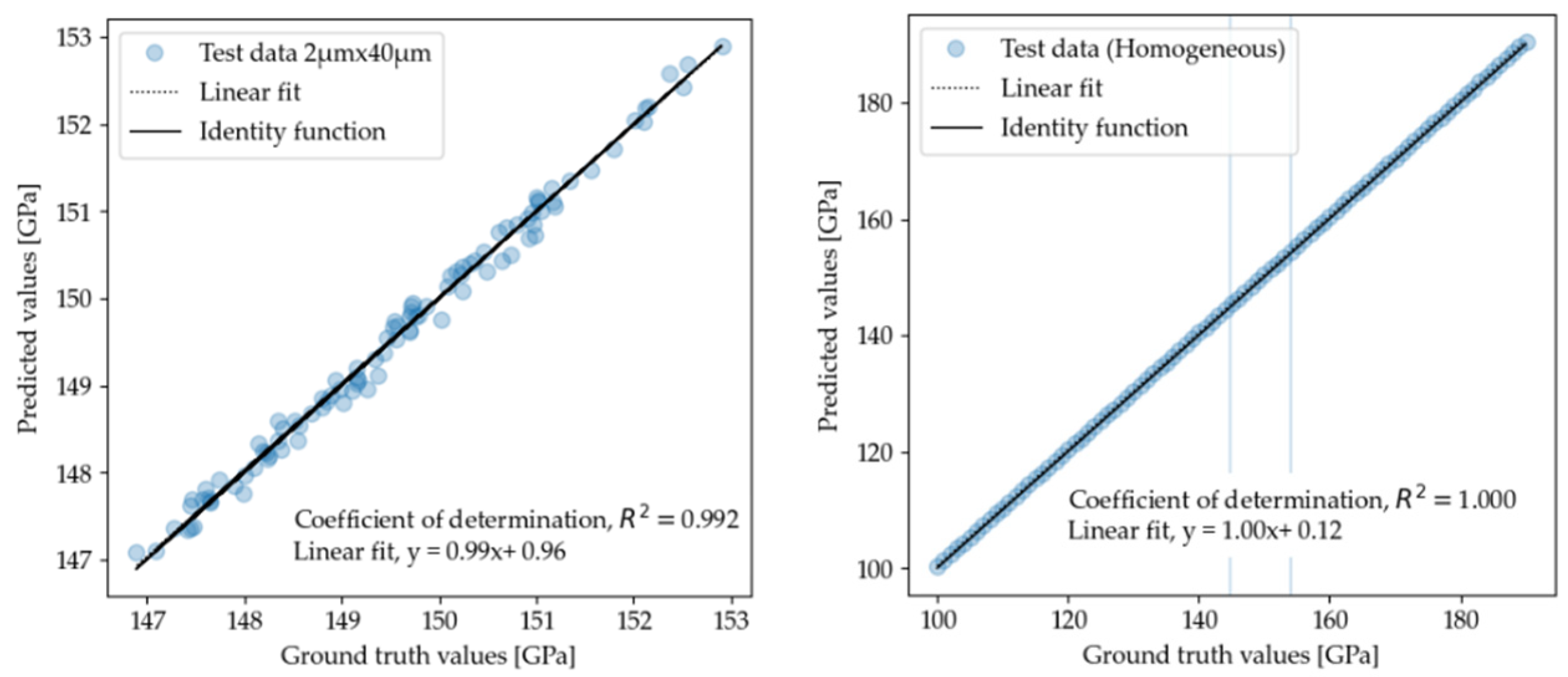

3.1. Homogenization of the Stochastic Volume Elements (SVE)

3.2. Homogenization of the Resonant Structure

3.3. Maximum Oscillation Amplitude of the Lorentz Force MEMS Magnetometer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mariani, S.; Ghisi, A.; Corigliano, A.; Martini, R.; Simoni, B. Two-scale simulation of drop-induced failure of polysilicon MEMS sensors. Sensors 2011, 11, 4972–4989. [Google Scholar] [CrossRef] [PubMed]

- Kalidindi, S.R. Materials, Data, and Informatics. In Hierarchical Materials Informatics; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–32. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Niezgoda, S.R.; Salem, A.A. Microstructure informatics using higher-order statistics and efficient data-mining protocols. JOM 2011, 63, 34–41. [Google Scholar] [CrossRef]

- Gupta, A.; Cecen, A.; Goyal, S.; Singh, A.K.; Kalidindi, S.R. Structure-property linkages for non-metallic inclusions/steel composite system using a data science approach. Acta Mater 2015, 91, 239–254. [Google Scholar] [CrossRef]

- Çeçen, A.; Fast, T.; Kumbur, E.C.; Kalidindi, S.R. A data-driven approach to establishing microstructure-property relationships in porous transport layers of polymer electrolyte fuel cells. J. Power Sources 2014, 245, 144–153. [Google Scholar] [CrossRef]

- Bock, F.E.; Aydin, R.C.; Cyron, C.J.; Huber, N.; Kalidindi, S.R.; Klusemann, B. A Review of the Application of Machine Learning and Data Mining Approaches in Continuum Materials Mechanics. Front. Mater. 2019, 6, 110. [Google Scholar] [CrossRef]

- Cecen, A.; Dai, H.; Yabansu, Y.C.; Klidindi, S.R.; Song, L. Material structure-property linkages using three-dimensional convolutional neural networks. Acta Mater 2018, 146, 76–84. [Google Scholar] [CrossRef]

- Ganapathi, A.S. Prediction of two-phase composite microstructure properties through deep learning of reduced dimensional structure-response data. Comp. Part B Eng. 2021, 225, 109–282. [Google Scholar] [CrossRef]

- Quesada-Molina, J.P.; Mariani, S. A two-scale multi-physics deep learning model for smart MEMS sensors. J. Mater. Sci. Chem. Eng. 2021, 9, 41–52. [Google Scholar] [CrossRef]

- Quesada-Molina, J.P.; Mariani, S. Two-Scale Deep Learning Model for Polysilicon MEMS Sensors. Comput. Sci. Math. Forum 2022, 2, 12. [Google Scholar] [CrossRef]

- Quesada-Molina, J.P.; Mariani, S. Hybrid Model-Based and Data-Driven Solution for Uncertainty Quantification at the Microscale. Micro Nanosyst. 2022, 14, 281–286. [Google Scholar] [CrossRef]

- Quesada-Molina, J.P.; Mariani, S. Deep Learning-based Multiscale Modelling of Polysilicon MEMS. Proceedings of 2022 23rd International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), St. Julian, Malta, 24–27 April 2022. [Google Scholar] [CrossRef]

- Mariani, S.; Martini, R.; Ghisi, A.; Corigliano, A.; Beghi, M. Overall elastic properties of polysilicon films: A statistical investigation of the effects of polycrystal morphology. Int. J. Mult. Comp. Eng. 2011, 9, 327–346. [Google Scholar] [CrossRef]

- Bagherinia, M.; Bruggi, M.; Corigliano, A.; Mariani, S.; Lasalandra, E. Geometry Optimization of a Lorentz Force, Resonating MEMS Magnetometer. Microelectron. Reliab. 2014, 54, 1192–1199. [Google Scholar] [CrossRef]

- Bagherinia, S.M. Mariani. Stochastic effects on the dynamics of the resonant structure of a Lorentz force MEMS magnetometer. Actuators 2019, 8, 36. [Google Scholar] [CrossRef]

- Mirzazadeh, R.; Mariani, S. Uncertainty Quantification of Microstructure-Governed Properties of Polysilicon MEMS. Micromachines 2017, 8, 248. [Google Scholar] [CrossRef] [PubMed]

- Mirzazadeh, R.; Eftekhar Azam, S.; Mariani, S. Mechanical Characterization of Polysilicon MEMS: A Hybrid TMCMC/PODKriging Approach. Sensors 2018, 18, 1243. [Google Scholar] [CrossRef] [PubMed]

- O’Malley, T.; Bursztein, E.; Long, J.; Chollet, F.; Jin, H.; Invernizzi, L. Keras Tuner. 2019. Available online: https://github.com/keras-team/keras-tuner (accessed on 20 September 2022).

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the Young’s Modulus of Silicon? J. Micro. Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quesada-Molina, J.P.; Mariani, S. Uncertainty Quantification at the Microscale: A Data-Driven Multi-Scale Approach. Eng. Proc. 2022, 27, 38. https://doi.org/10.3390/ecsa-9-13351

Quesada-Molina JP, Mariani S. Uncertainty Quantification at the Microscale: A Data-Driven Multi-Scale Approach. Engineering Proceedings. 2022; 27(1):38. https://doi.org/10.3390/ecsa-9-13351

Chicago/Turabian StyleQuesada-Molina, José Pablo, and Stefano Mariani. 2022. "Uncertainty Quantification at the Microscale: A Data-Driven Multi-Scale Approach" Engineering Proceedings 27, no. 1: 38. https://doi.org/10.3390/ecsa-9-13351

APA StyleQuesada-Molina, J. P., & Mariani, S. (2022). Uncertainty Quantification at the Microscale: A Data-Driven Multi-Scale Approach. Engineering Proceedings, 27(1), 38. https://doi.org/10.3390/ecsa-9-13351