Construction of a Frequency Compliant Unit Commitment Framework Using an Ensemble Learning Technique

Abstract

:1. Introduction

- (1)

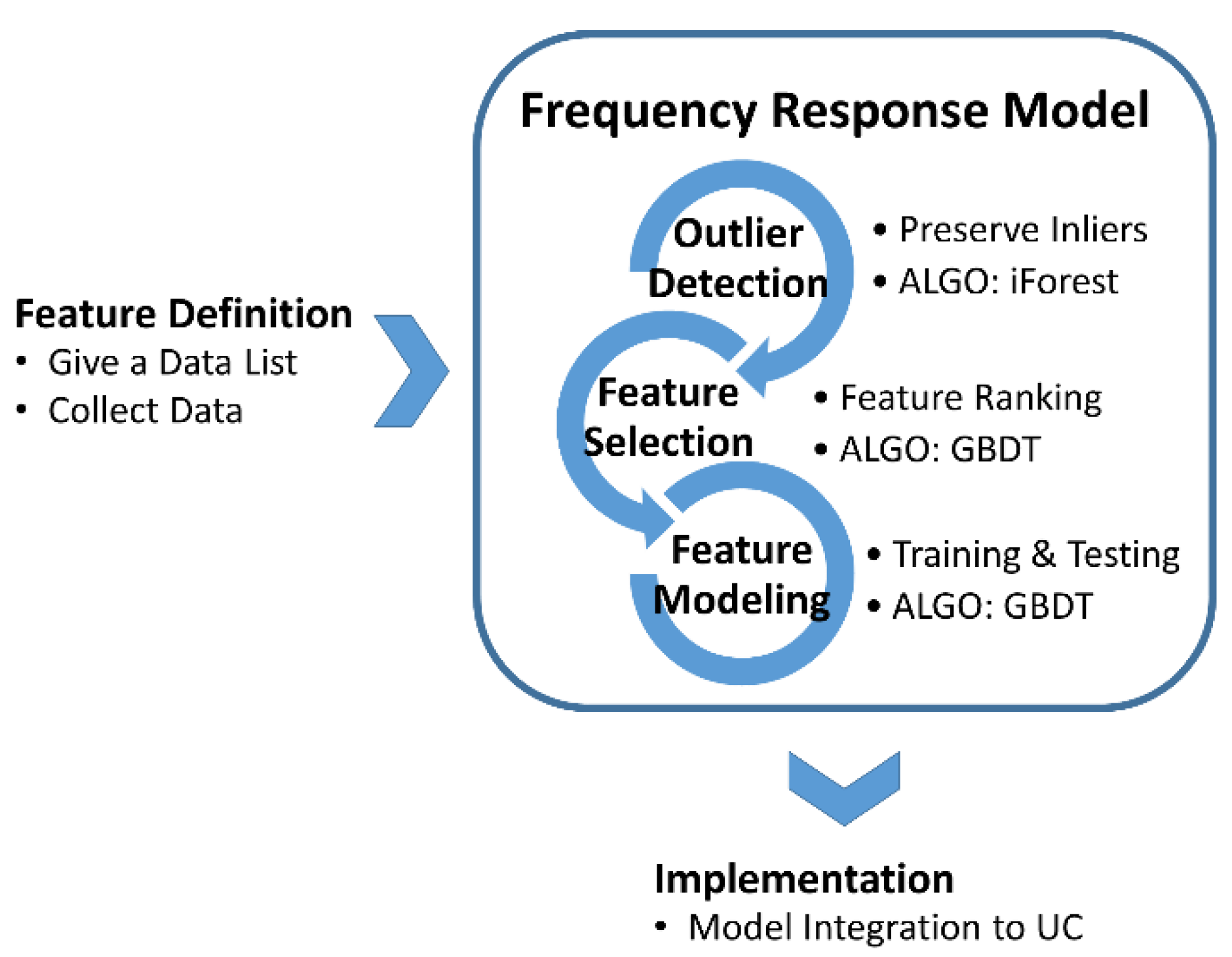

- This study commences by employing an ensemble machine learning technique to formulate a robust FRM. For the formulation process, the ensemble learning technique can not only deal with data refinement, such as outlier detection and feature selection, but also feature modeling based on the operation’s domain knowledge.

- (2)

- The FRM model that is formulated by the ensemble learning technique is able to conform to the frequency response of the actual system from time to time by automatically tuning the hyperparameters within the model.

- (3)

- The well-trained FRM model is further integrated with a UC program to determine the unit scheduling result. Testing results show that the proposed solution not only ensures the compliance of the unit dispatch schedule to the NERC’s CPS1 standard, but also further minimizes the system operating cost compared to that of the real dispatch history.

- (4)

- Comparative results from different methodologies have shown that the proposed FRM model is superior in portraying system frequency response over the simplified model that did not take the multivariate and nonlinear characteristics into account. Moreover, the proposed tree-based learning technique has shown its advantage in portraying the system state with more accurate feature interpretation over the neural-network based technique.

- (5)

- The proposed hybrid model (FRM plus UC) can portray different hypothetical cases, such as renewable penetration into the power system, for system operators to foresee the challenges they could face.

2. Construction of the CPS1 Compliant Model

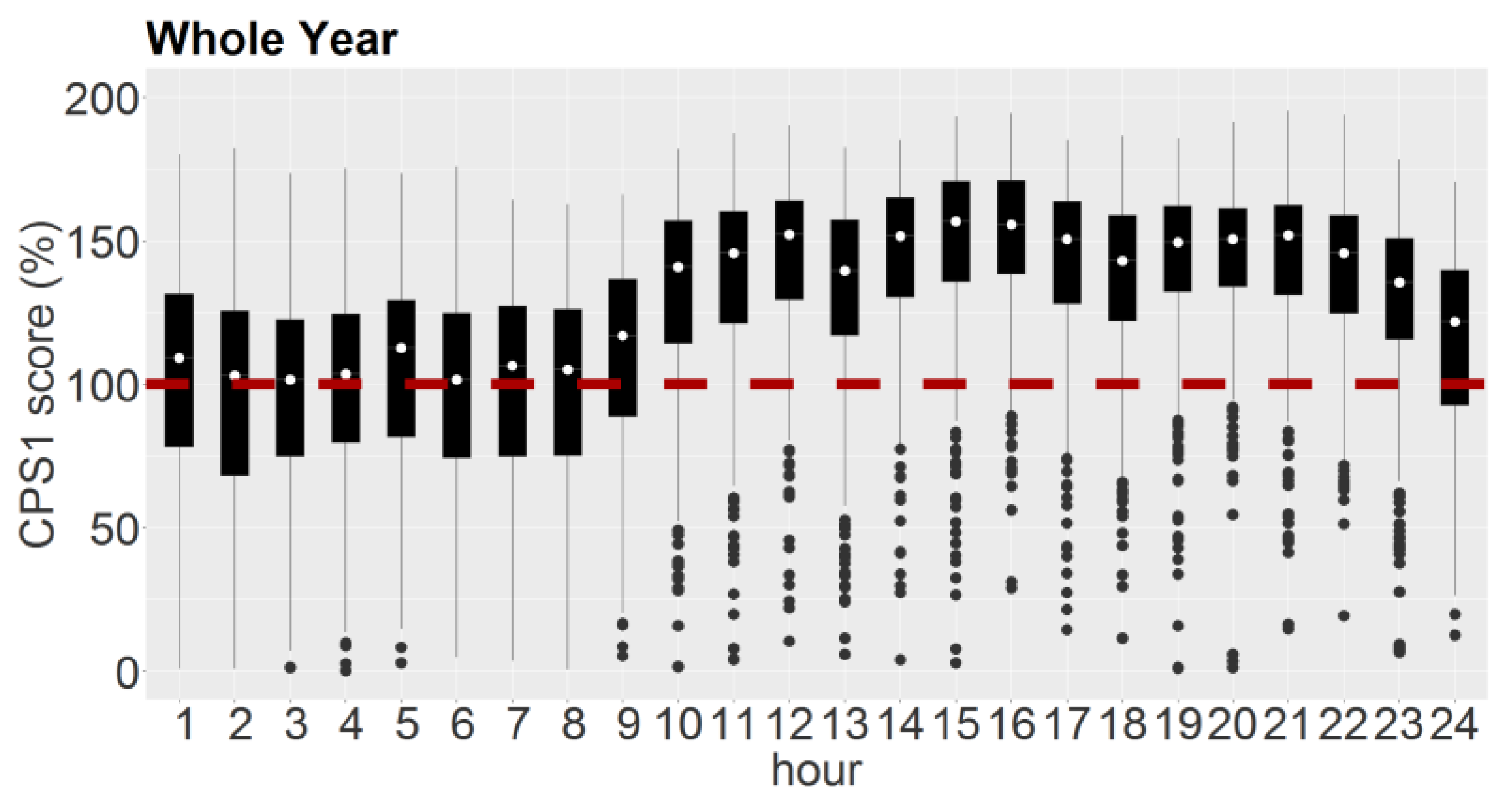

2.1. Exploratory Data Analysis for CPS1 in Taipower System (Feature Definition)

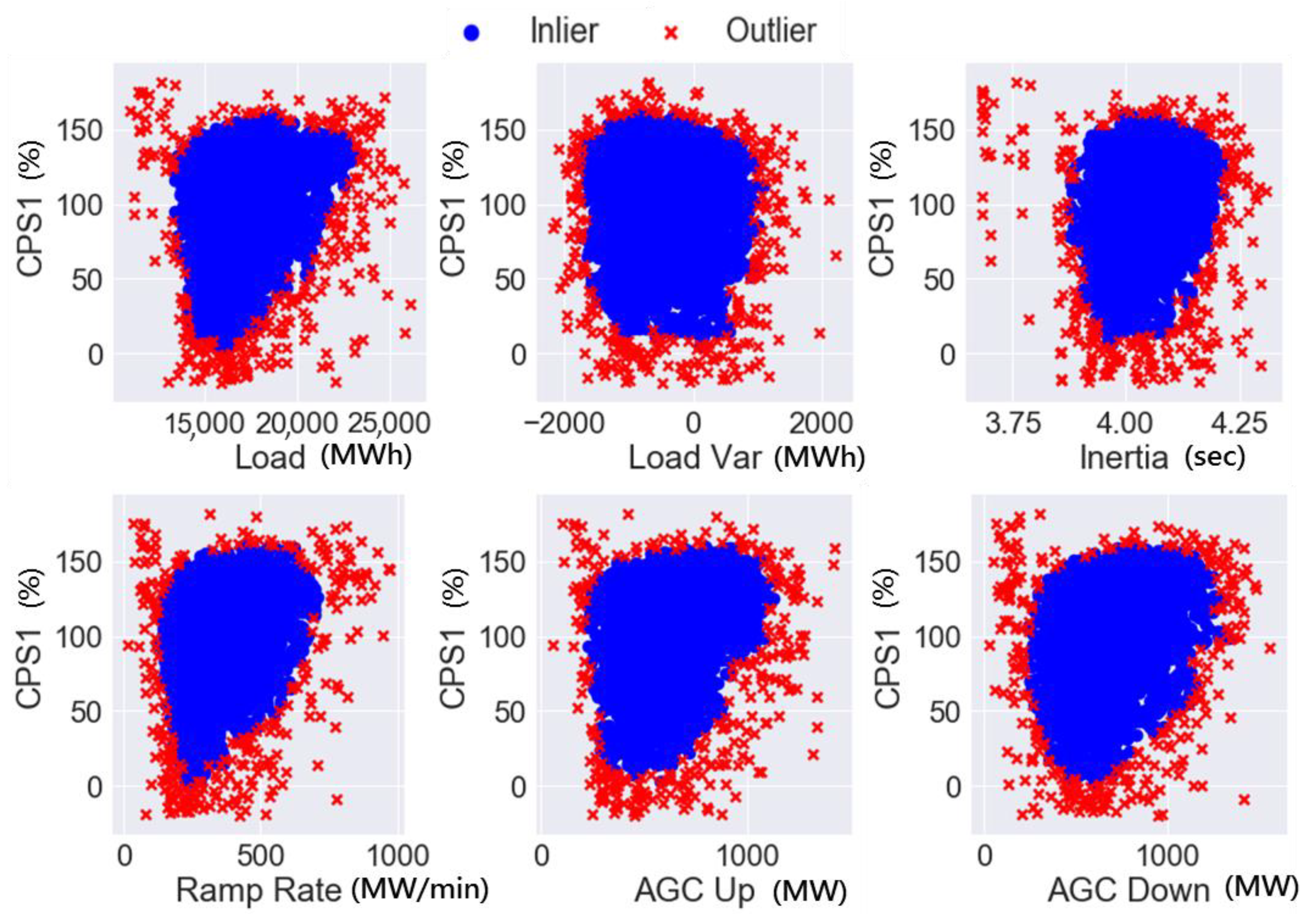

2.2. Outlier Detection

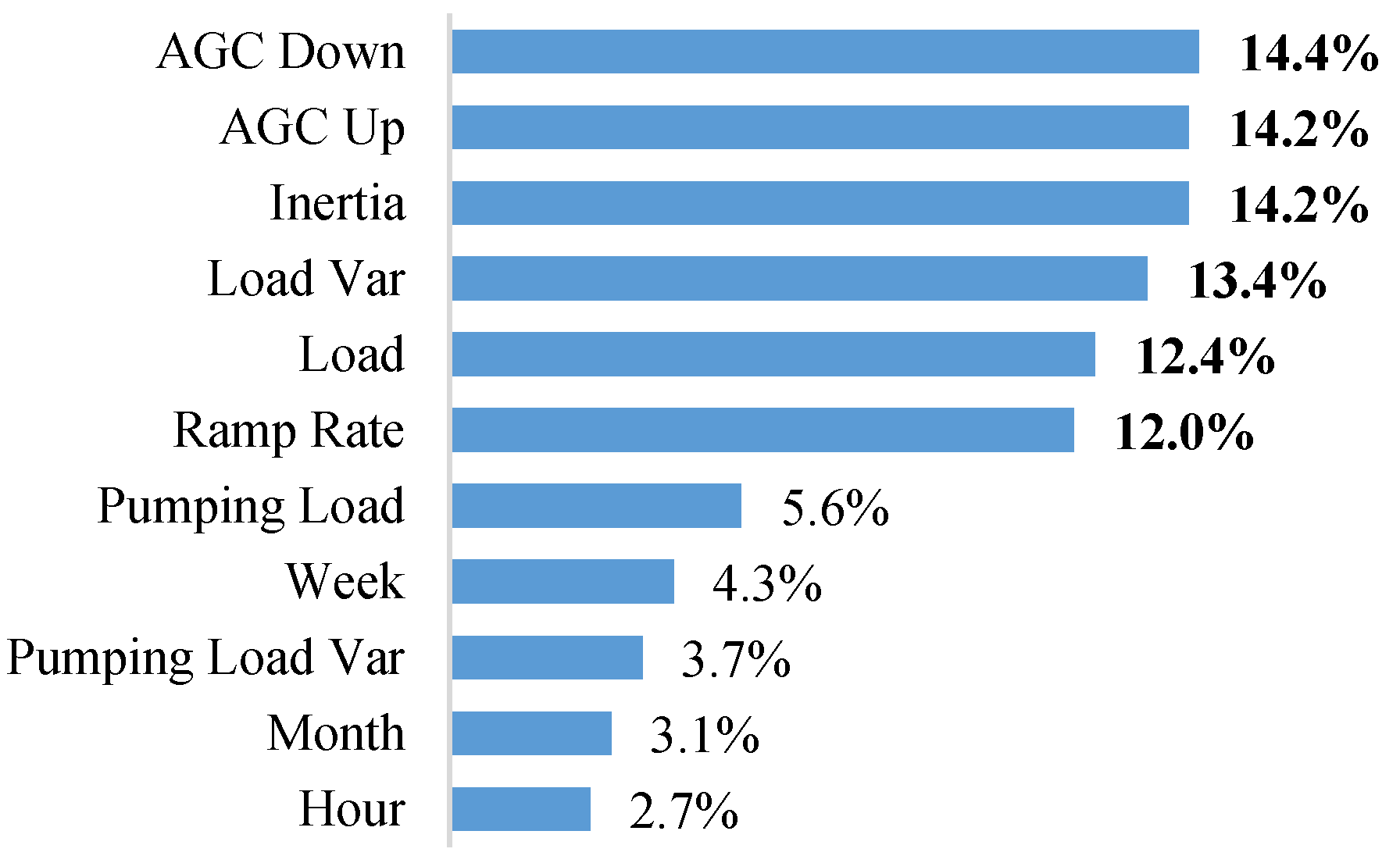

2.3. Feature Selection

2.4. CPS1 Model Construction

3. UC Optimization Program for the Taipower System

3.1. Objective Function

3.2. UC Constraints

- (i)

- The balancing requirement of supply-side and demand-side considering the PSHU:

- (ii)

- The upper and lower limits of units including thermal, hydro and PSHU:

- (iii)

- The ramp up/down limit of units:

- (iv)

- The states of start-up and shut down of units:

- (v)

- The minimum up/down time constraints of units

- (vi)

- Maximum start-up times per day:

- (vii)

- Hot/warm/cold start-up:

- (viii)

- The efficiency of the conversion of PSHU:

- (ix)

- The reservoir model for PSHU:

3.3. Addional Frequency Control Constraints

3.4. Network Security Constraint

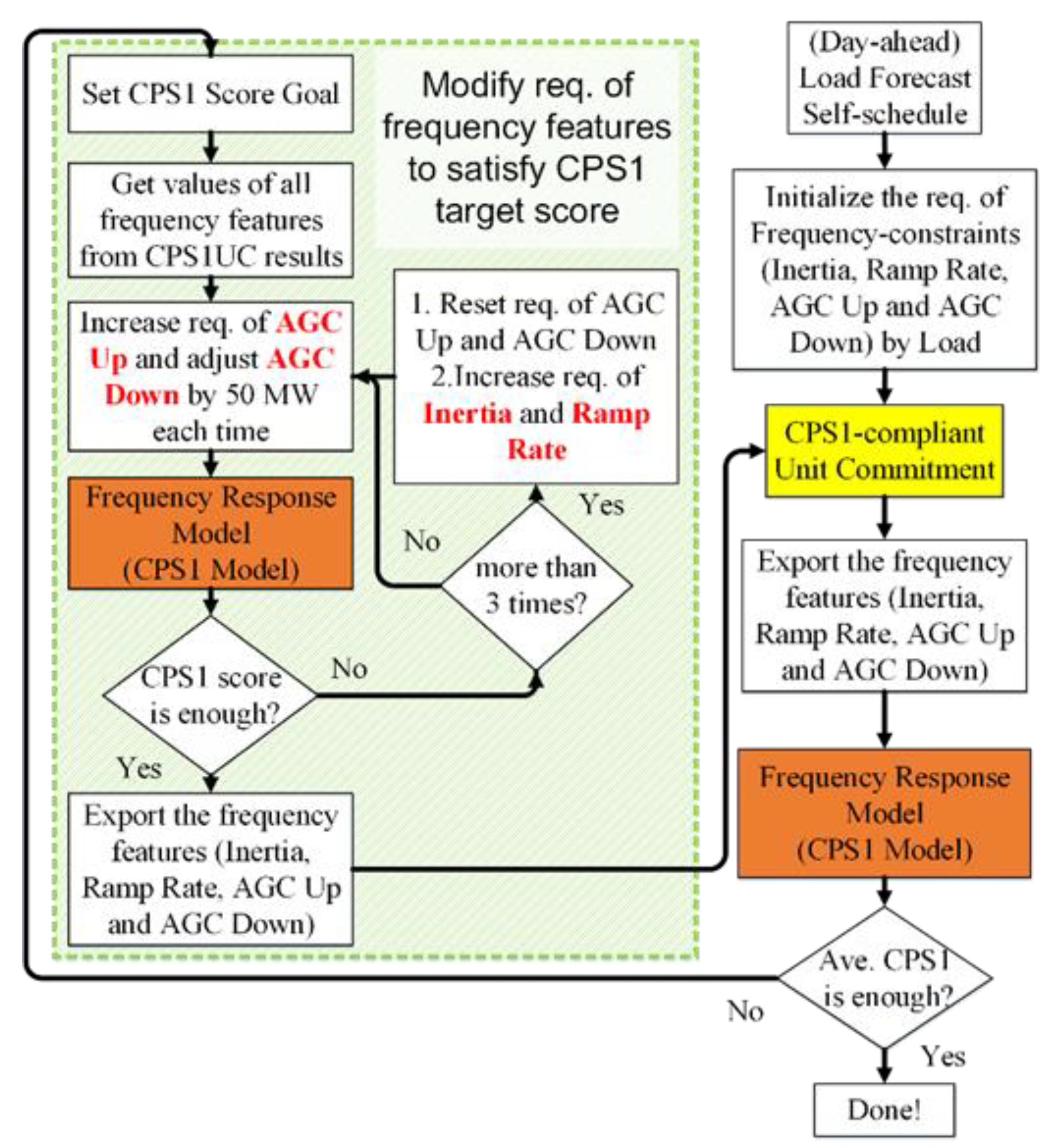

4. Integrating CPS1 Model into the UC Optimization Program

5. Case Studies

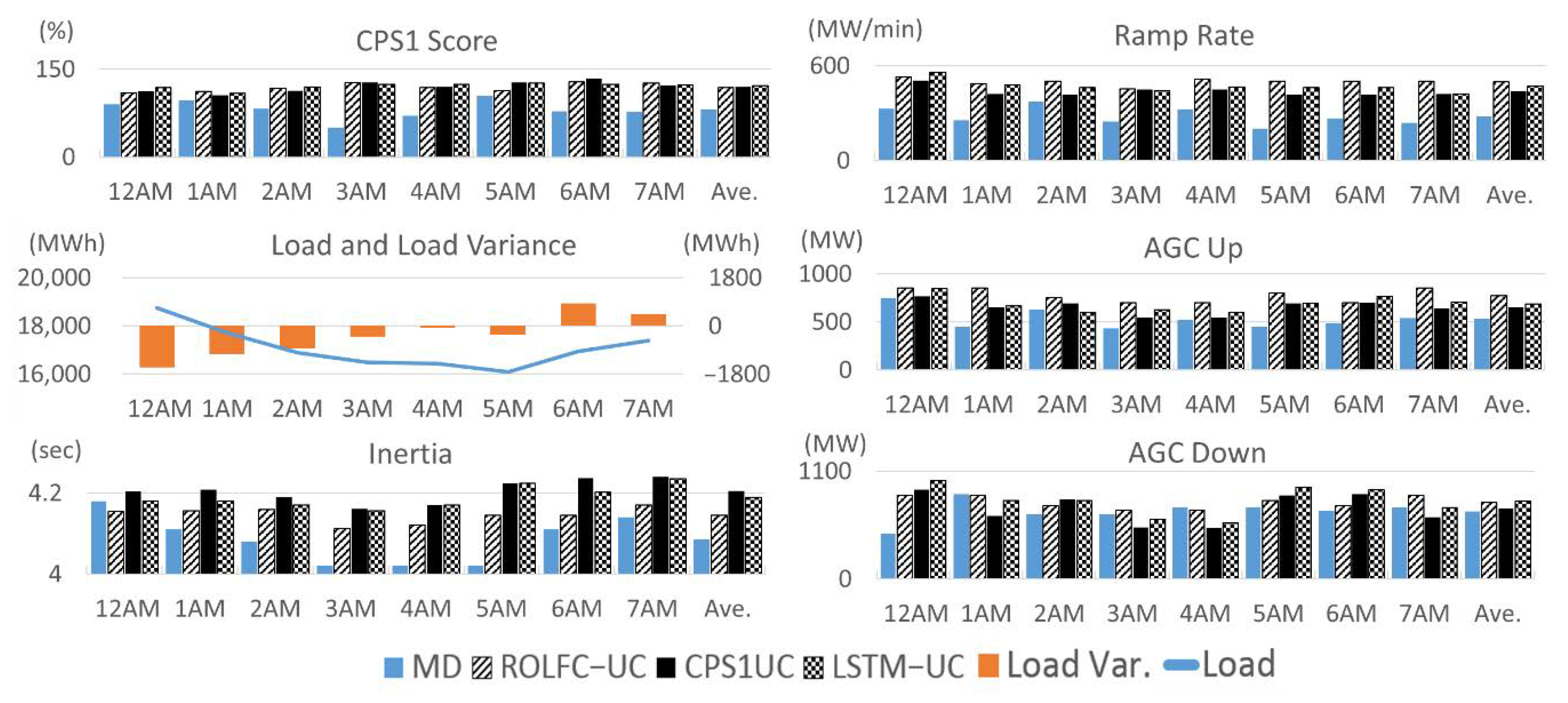

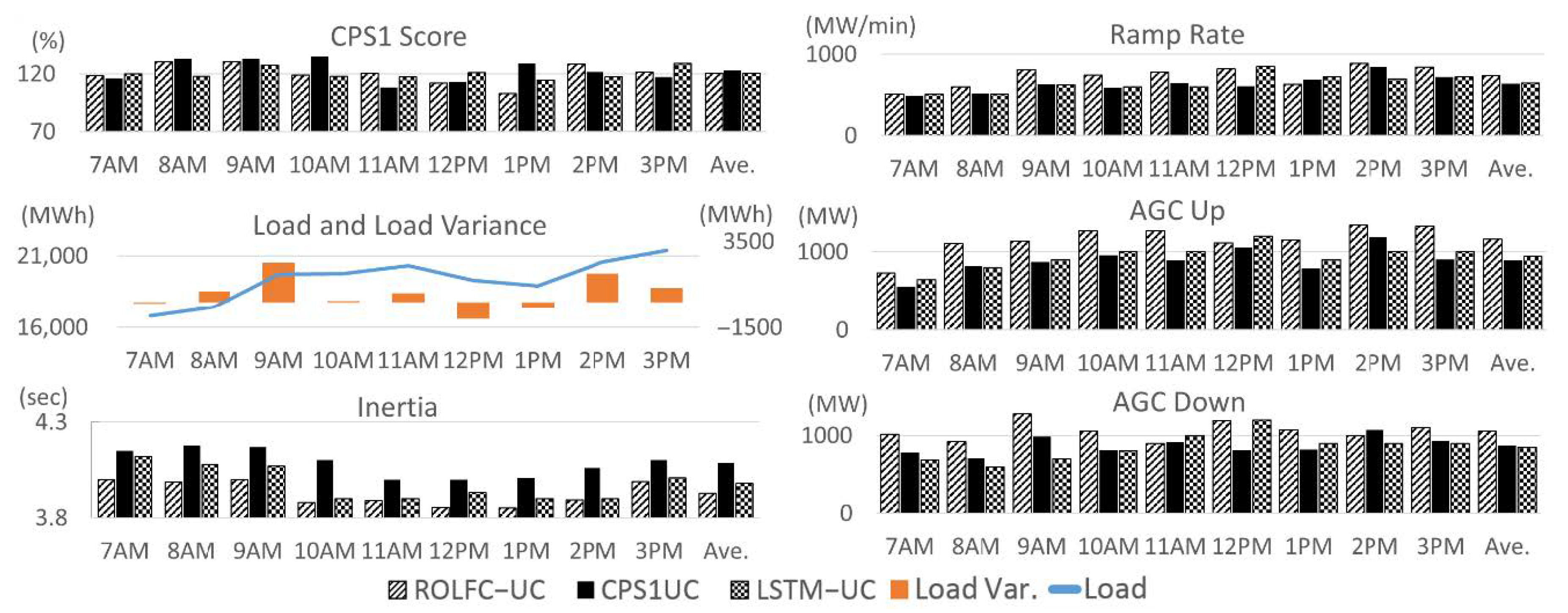

5.1. Historical Operation Case (in the Early Morning (First Shift Period))

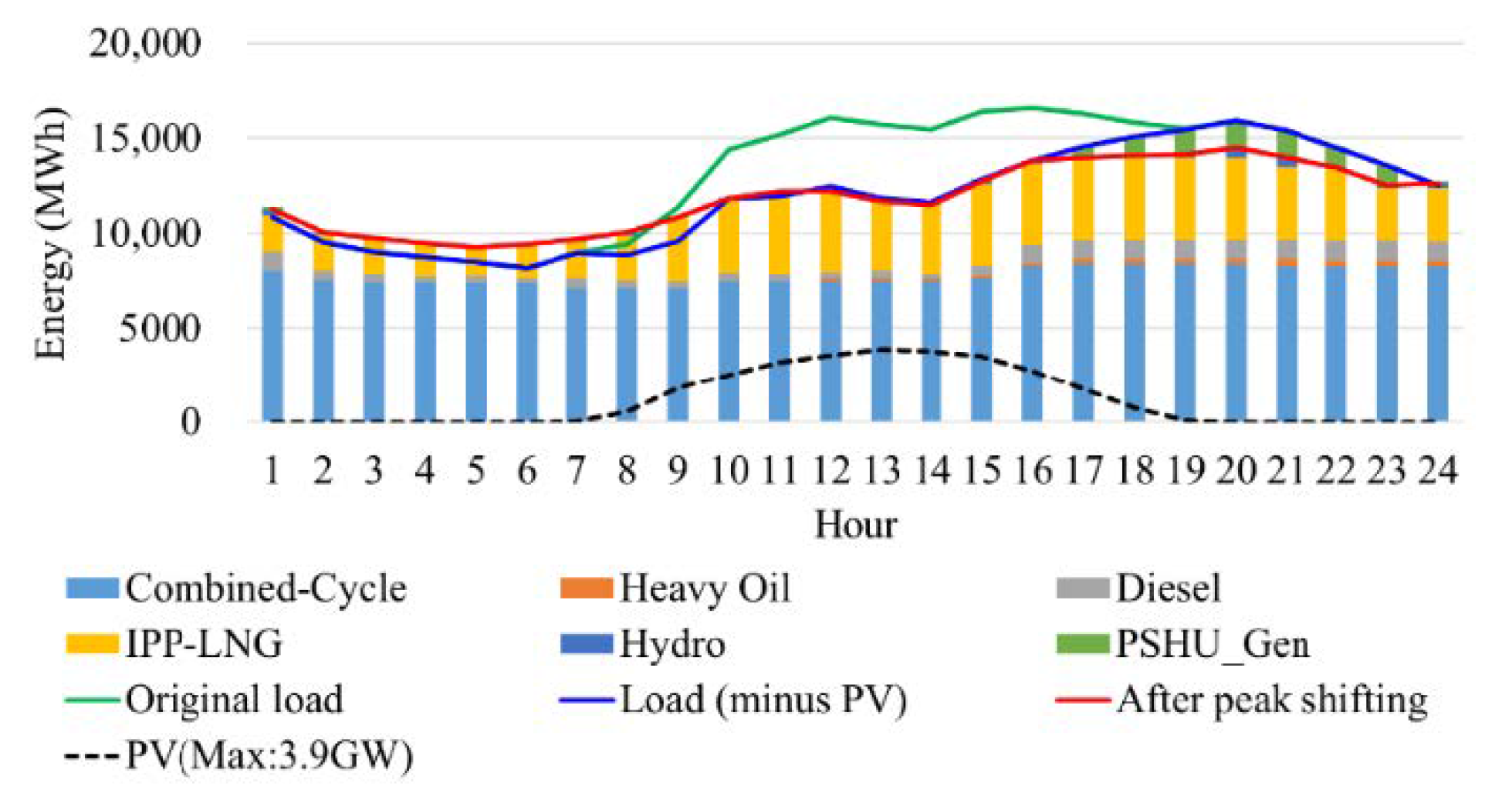

5.2. Hypothetical Case (PV Case)

6. Conclusions

- (1)

- This study commences by formulating a set of procedures and employing an ensemble machine learning technique to analyze the real energy management system (EMS) data of an isolated power system (i.e., 118 generating units) to construct a FRM. The resulting FRM is then integrated with a UC program to determine the unit scheduling result, which minimizes the system operating cost while the frequency compliance is also maintained.

- (2)

- During the period of the controlled frequency with lower compliance, i.e., the early morning or high penetration RES, the system frequency quality could be improved by the proposed UC with the integration of the FRM. Testing result shows that retaining the proper quantity of frequency-sensitive feature, especially Inertia, is the most effective way to keep the high frequency quality.

- (3)

- The dominant features of the LFC (i.e., parameters of units, load damping, system inertia) are hard to capture. The proposed method in this paper assists dispatchers to clearly identify the frequency-sensitive features, and grasp their features effectively.

- (4)

- Power system frequency operation is a nonlinear and complex problem. Compare to the traditional LFC model, the proposed FRM has the advantage of self-learning by feeding in the updated inputs so that the model output is more close to the real system behavior. This feature validates the effectiveness of an artificial intelligent algorithm in a smart grid system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Indices | |

| g | index for unit |

| h | index for time period |

| i | index for samples in GBDT |

| m | index for decision tree number in GBDT |

| p | index for sample in iForest |

| res | index for reservoir |

| s | index for segment |

| Parameters | |

| tp | time period in hour |

| maximum limit of AGC range of each unit | |

| minimum limit of AGC range for each unit | |

| requirement of AGC Up reserve in each period | |

| requirement of AGC Down reserve in each period | |

| total number of units | |

| inertia of each generator | |

| required inertia of system in each period | |

| load requirement in period | |

| must up time period of each generator | |

| must down time period of each generator | |

| maximum start-up time of each traditional generator per day | |

| capacity of each traditional generator | |

| power generation of renewables | |

| n | total sample in iForest |

| minimum output limit of each unit | |

| maximum output limit of each unit | |

| penalty price for shortage of energy | |

| penalty price for shortage of AGC Up reserve | |

| penalty price for shortage of AGC Down reserve | |

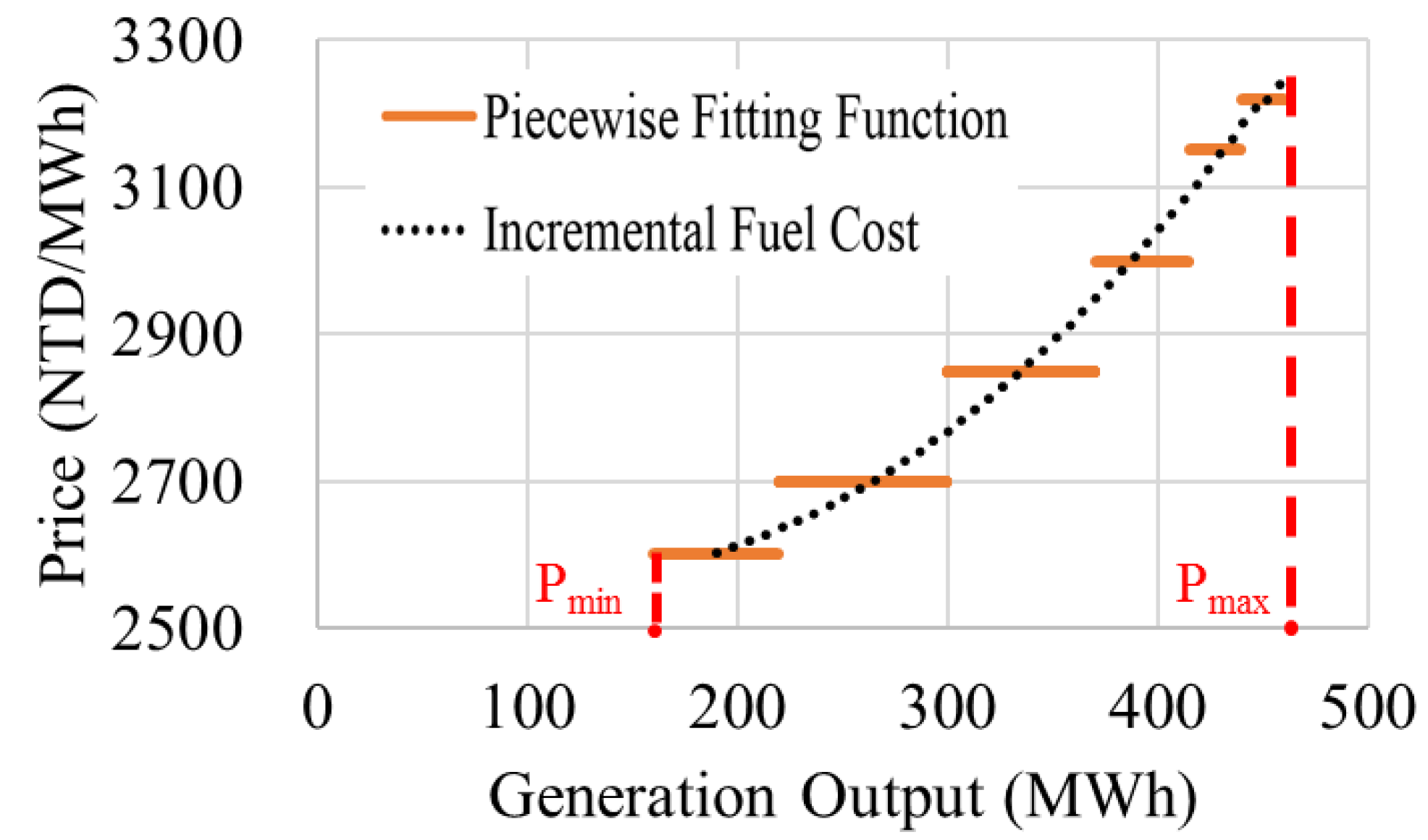

| cost of scheduled power generation of each unit at minimum level | |

| fuel cost of each segment of each unit in period | |

| water level of each reservoir | |

| ramp rate supplied by unit in period | |

| required ramp rate of system in each period | |

| total number of segments | |

| cost of each unit for hot start-up status in period | |

| cost of each unit for warm start-up status in period | |

| cost of each unit for cold start-up status in period | |

| time interval between hot start-up and warm start-up of each generator | |

| time interval between warm start-up and cold start-up of each generator | |

| learning rate | |

| conversion efficiency of each PSHU generator | |

| electric-water ratio of each hydro generator | |

| Variables | |

| scheduled quantity of AGC Up of each unit in period | |

| scheduled quantity of AGC Down of each unit in period | |

| scheduled power generation of each segment of each unit in period | |

| scheduled pumping load of PSHU | |

| scheduled power generation of PSHU | |

| terminal regions of a decision tree in GBDT | |

| slack factor of requirement for energy in period | |

| slack factor of requirement for AGC up reserve in period | |

| slack factor of requirement for AGC down reserve in period | |

| input of ith sample in GBDT | |

| actual CPS1 value in GBDT | |

| estimated residual in GBDT | |

| Binary Variables | |

| hot start-up status of each unit in period | |

| warm start-up status of each unit in period | |

| cold start-up status of each unit in period | |

| start-up status of each generator in period | |

| shutdown status of each generator in period | |

| status of each generator | |

| status of AGC mode of each unit in period | |

| sensitivity of line flows in the period , in kth case | |

| capacity limit of transmission line in the period , in kth case | |

| Functions | |

| c(n) | average path length of iTree constructed by total n samples |

| E(h(p)) | mean height of multiple iTrees h(p) |

| estimated model of GBDT | |

| h(p) | path length of pth sample in iTree |

| loss function of GBDT | |

| s(p, n) | outlier score |

References

- Luh, P.B.; Yu, Y.; Zhang, B.; Litvinov, E.; Zheng, T.; Zhao, F.; Zhao, J.; Wang, C. Grid integration of intermittent wind generation: A Markovian approach. IEEE Trans. Smart Grid 2014, 5, 732–741. [Google Scholar] [CrossRef]

- Su, W.; Wang, J.; Roh, J. Stochastic energy scheduling in microgrids with intermittent renewable energy resources. IEEE Trans. Smart Grid 2014, 5, 1876–1883. [Google Scholar] [CrossRef]

- Zheng, Q.P.; Wang, J.; Liu, A.L. Stochastic optimization for unit commitment—A review. IEEE Trans. Power Syst. 2015, 30, 1913–1924. [Google Scholar] [CrossRef]

- Zhang, N.; Hu, Z.; Dai, D.; Dang, S.; Yao, M.; Zhou, Y. Unit commitment model in smart grid environment considering carbon emissions trading. IEEE Trans. Smart Grid 2016, 7, 420–427. [Google Scholar] [CrossRef]

- Mitani, T.; Aziz, M.; Oda, T.; Uetsuji, A.; Watanabe, Y.; Kashiwagi, T. Annual Assessment of Large-Scale Introduction of Renewable Energy: Modeling of Unit Commitment Schedule for Thermal Power Generators and Pumped Storages. Energies 2017, 10, 738. [Google Scholar] [CrossRef] [Green Version]

- NERC Reliability Standard BAL-001-1-Real Power Balancing Control Performance. Available online: http://www.nerc.com/pa/Stand/Reliability%20Standards/BAL-001-1.pdf (accessed on 25 October 2019).

- Ela, E.; Milligan, M.; Kirby, B. Operating Reserves and Variable Generation; NREL/TP-5500-51928; National Renewable Energy Lab (NREL): Golden, CO, USA, 2011.

- Chung, W. Anticipatory Fuzzy Automatic Generation Control Scheme Using Very Short-Term ANN ACE Forecasting. Ph.D. Dissertation, Purdue University, West Lafayette, IN, USA, 2005. [Google Scholar]

- Ahmadi, H.; Ghasemi, H. Security-constrained unit commitment with linearized system frequency limit constraint. IEEE Trans. on Power Syst. 2014, 29, 1536–1545. [Google Scholar] [CrossRef]

- Pérez-Illanes, F.; Álvarez-Miranda, E.; Rahmann, C.; Campos-Valdés, C. Robust unit commitment including frequency stability constraints. Energies 2016, 9, 957. [Google Scholar] [CrossRef] [Green Version]

- Farrokhabadi, M.; Canizares, C.; Bhattacharya, K. Unit commitment for isolated microgrids considering frequency control. IEEE Trans. Smart Grid 2018, 9, 3270–3280. [Google Scholar] [CrossRef]

- Bao, Y.-Q.; Li, Y.; Wang, B.; Hu, M.; Zhou, Y. Day-Ahead Scheduling Considering Demand Response as a Frequency Control Resource. Energies 2017, 10, 82. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; McCalley, J.D. Estimation of regulation reserve requirement based on control performance standard. IEEE Trans. Power Syst. 2018, 33, 1173–1183. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, C.; Wu, C.; Lu, C. Control performance based dynamic regulation reserve allocation for renewable integrations. IEEE Trans. Sustain. Energy 2019, 10, 1271–1279. [Google Scholar] [CrossRef]

- Ahmad, A.; Javaid, N.; Alrajeh, N.; Khan, Z.A.; Qasim, U.; Khan, A. A Modified Feature Selection and Artificial Neural Network-Based Day-Ahead Load Forecasting Model for a Smart Grid. Appl. Sci. 2015, 5, 1756–1772. [Google Scholar] [CrossRef]

- Mujeeb, S.; Alghamdi, T.A.; Ullah, S.; Fatima, A.; Javaid, N.; Saba, T. Exploiting Deep Learning for Wind Power Forecasting Based on Big Data Analytics. Appl. Sci. 2019, 9, 4417. [Google Scholar] [CrossRef] [Green Version]

- Mellit, A.; Pavan, A.M.; Ogliari, E.; Leva, S.; Lughi, V. Advanced Methods for Photovoltaic Output Power Forecasting: A Review. Appl. Sci. 2020, 10, 487. [Google Scholar] [CrossRef] [Green Version]

- Moradzadeh, A.; Zakeri, S.; Shoaran, M.; Mohammadi-Ivatloo, B.; Mohammadi, F. Short-Term Load Forecasting of Microgrid via Hybrid Support Vector Regression and Long Short-Term Memory Algorithms. Sustainability 2020, 12, 7076. [Google Scholar] [CrossRef]

- López Gómez, J.; Ogando Martínez, A.; Troncoso Pastoriza, F.; Febrero Garrido, L.; Granada Álvarez, E.; Orosa García, J.A. Photovoltaic Power Prediction Using Artificial Neural Networks and Numerical Weather Data. Sustainability 2020, 12, 10295. [Google Scholar] [CrossRef]

- Domingues, R.; Filippone, M.; Michiardi, P.; Zouaoui, J. A comparative evaluation of outlier detection algorithms: Experiments and analyses. Pattern Recognit. 2018, 74, 406–421. [Google Scholar] [CrossRef]

- Liu, F.T.; Ting, K.M.; Zhou, Z. Isolation Forest. In Proceedings of the 2008 Eighth IEEE International Conference on Data Mining, Pisa, Italy, 15–19 December 2008; pp. 413–422. [Google Scholar]

- Sagi, O.; Rokach, L. Ensemble learning: A survey. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2018, 8, e1249. [Google Scholar] [CrossRef]

- Friedman, J. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Hastie, T.; Tibishirani, R.; Friedman, J. The Elements of Statistical Learning, 2nd ed.; Springer: New York, NY, USA, 2009. [Google Scholar]

- The Architecture of Power Supply for Taipower. Available online: http://www.moeaboe.gov.tw (accessed on 12 January 2020).

- Guan, X.; Luh, P.B.; Yan, H.; Rogan, P. Optimization-based scheduling of hydrothermal power systems with pumped-storage units. IEEE Trans. Power Syst. 1994, 9, 1023–1031. [Google Scholar] [CrossRef]

- Alemany, J. Short-term scheduling of combined cycle units using mixed integer linear programming solution. Energy Power Eng. 2013, 5, 161–170. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.; Hu, T.; Hsu, K.; Tsai, C.; Wu, C. Analysis of simulated bidding results for ancillary services of Taiwan power system: Using thermal power plants as an example. Mon. J. Taipower’s Eng. 2014, 795, 103–110. [Google Scholar]

- Alvarez, G.E.; Marcovecchio, M.G.; Aguirre, P.A. Security-constrained unit commitment problem including thermal and pumped storage units: An MILP formulation by the application of linear approximations techniques. Electr. Power Syst. Res. 2018, 154, 67–74. [Google Scholar] [CrossRef]

- SIEMENS. Siemens PTI.PSS/E 35 Program Operation Manual; SIEMENS: New York, NY, USA, 2019. [Google Scholar]

- Hui, H. Reliability Unit Commitment in ERCOT Nodal Market. Ph.D. Dissertation, University Texas, Arlington, TX, USA, 2013. [Google Scholar]

- Chiu, H.; Lin, Y.; Chang-Chien, L.; Wu, C. Modeling of the CPS1 for the Frequency Constrained Unit Commitment. In Proceedings of the 2019 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Macao, China, 1 December 2019; pp. 1–5. [Google Scholar]

| Feature | Label | Definition | Unit |

|---|---|---|---|

| Input | |||

| x1 | Hour | Hour of day | Hour |

| x2 | Week | Week | Week |

| x3 | Month | Month | Month |

| x4 | Load | Load demand during each hour | MWh |

| x5 | Load Var | Load variance between two adjacent hours | MWh |

| x6 | Ramp Rate | Capability of changing output in minute | MW/min |

| x7 | AGC Up | Margin of up-regulation (secondary control) | MW |

| x8 | AGC Down | Margin of down-regulation (secondary control) | MW |

| x9 | Inertia | Inertia of power plant unit | second |

| x10 | Pumping Load | Pumping load demand of Pumped-Storage Hydro Units (PSHUs) | MWh |

| x11 | Pumping Load Var | Pumping load variance of Pumped-Storage Hydro Units (PSHUs) | MWh |

| Output | |||

| y1 | CPS1 | CPS1 score (Equation (1)) | % |

| Manual Dispatch | ROLFC-UC | LSTM-UC | CPS1UC (Proposed) | |

|---|---|---|---|---|

| Frequency Response Model | NaN | reduced-order LFC | LSTM (Neural Network) | GBDT (tree based) |

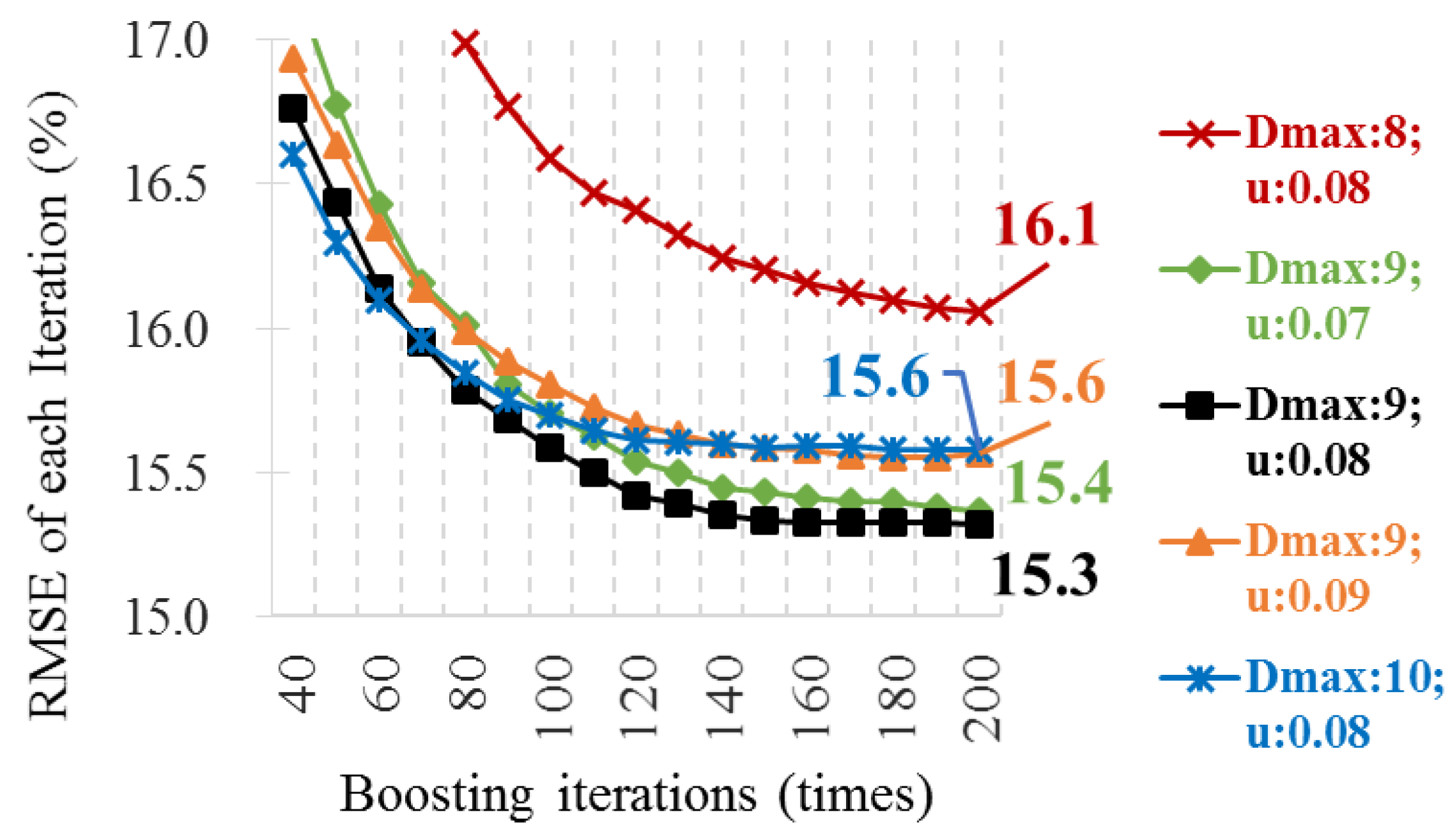

| RMSE of CPS1 on training set (%) | NaN | NaN | 23.2 | 15.3 |

| RMSE of CPS1 on testing set (%) | NaN | NaN | 25.5 | 17.2 |

| Total Operating Cost (NTD) | 842 M | 852 M | 848 M | 846 M |

| ROLFC-UC | LSTM-UC | CPS1UC | |

|---|---|---|---|

| Frequency Response Model (FRM) | reduced-order LFC | LSTM (neural network) | GBDT (tree-based) |

| RMSE of CPS1 on training set (%) | NaN | 23.2 | 15.3 |

| RMSE of CPS1 on testing set (%) | NaN | 25.5 | 17.2 |

| Total Operating Cost (NTD) | 772 M | 759 M | 757 M |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, H.-W.; Chang-Chien, L.-R.; Wu, C.-C. Construction of a Frequency Compliant Unit Commitment Framework Using an Ensemble Learning Technique. Energies 2021, 14, 310. https://doi.org/10.3390/en14020310

Chiu H-W, Chang-Chien L-R, Wu C-C. Construction of a Frequency Compliant Unit Commitment Framework Using an Ensemble Learning Technique. Energies. 2021; 14(2):310. https://doi.org/10.3390/en14020310

Chicago/Turabian StyleChiu, Hsin-Wei, Le-Ren Chang-Chien, and Chin-Chung Wu. 2021. "Construction of a Frequency Compliant Unit Commitment Framework Using an Ensemble Learning Technique" Energies 14, no. 2: 310. https://doi.org/10.3390/en14020310

APA StyleChiu, H.-W., Chang-Chien, L.-R., & Wu, C.-C. (2021). Construction of a Frequency Compliant Unit Commitment Framework Using an Ensemble Learning Technique. Energies, 14(2), 310. https://doi.org/10.3390/en14020310