Sol–Gel Entrapped Lewis Acids as Catalysts for Biodiesel Production

Abstract

1. Introduction

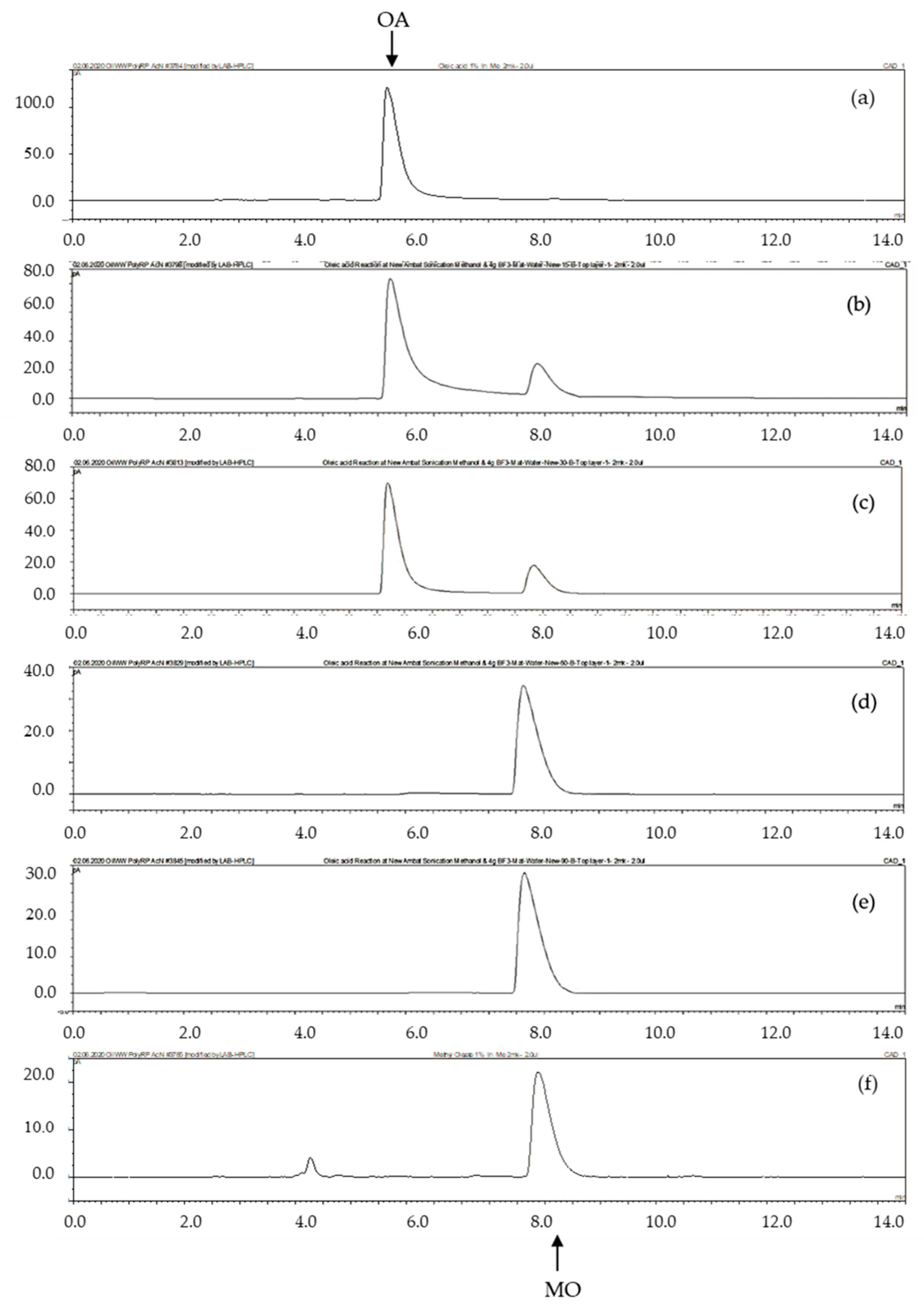

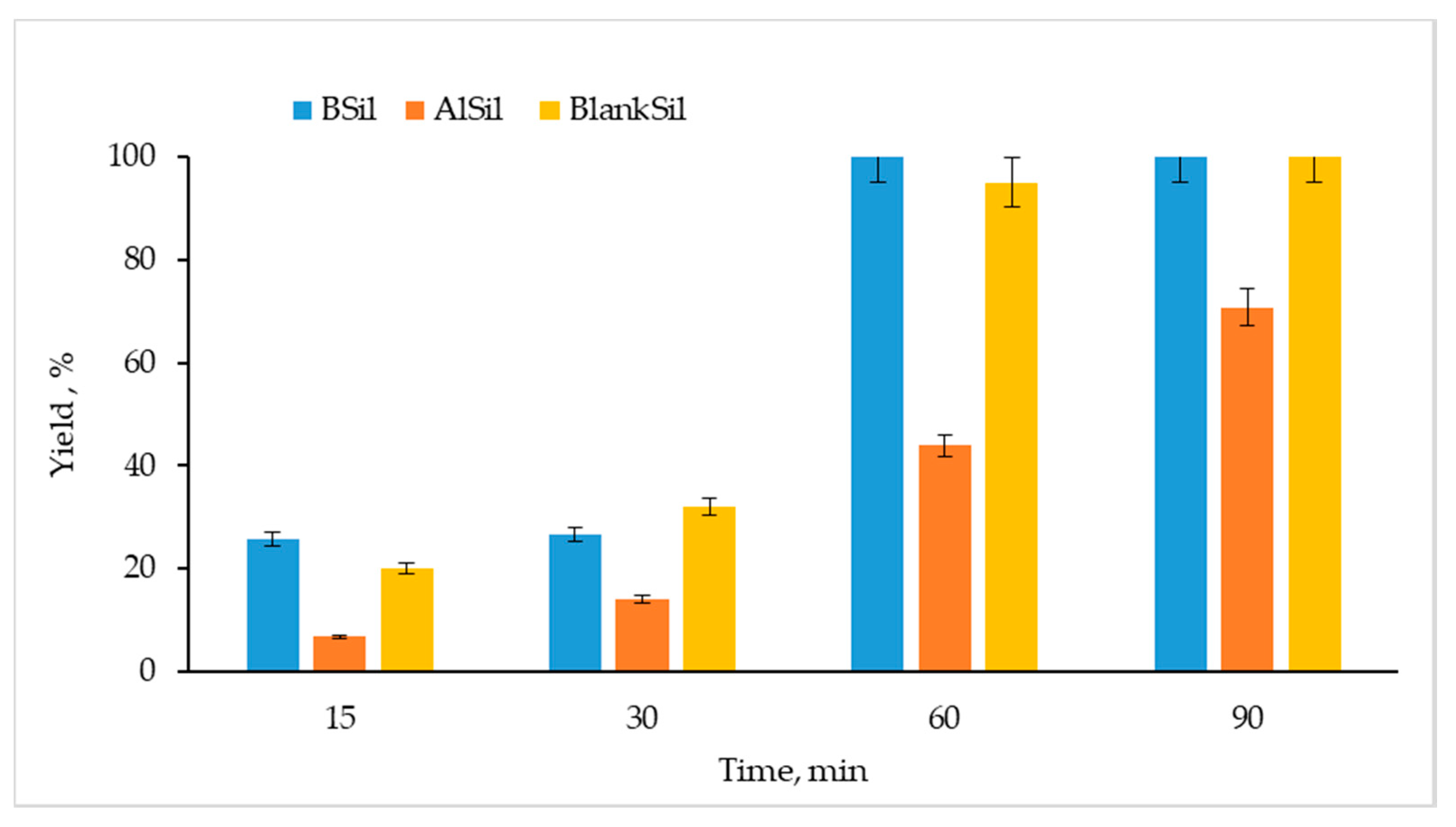

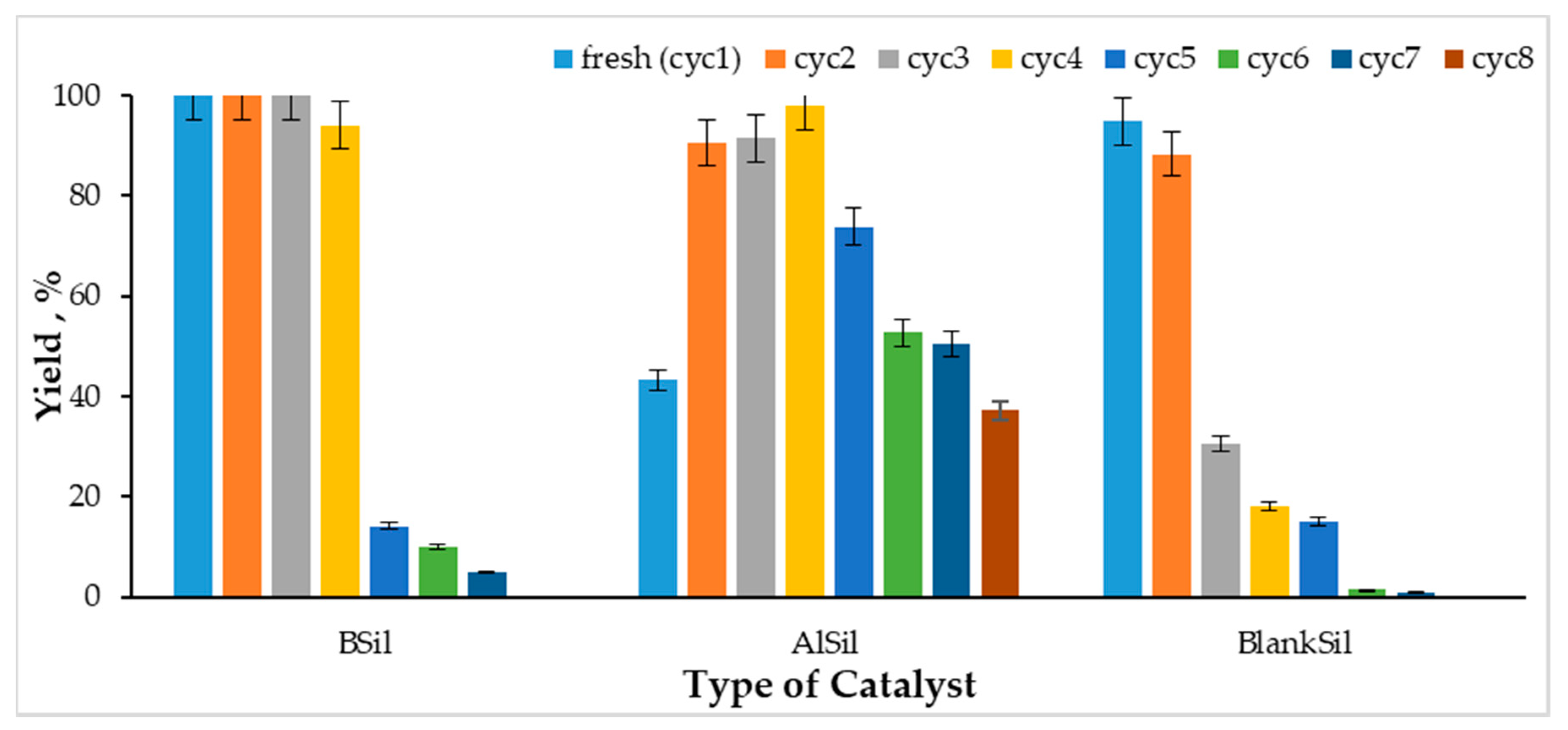

2. Results and Discussion

2.1. Catalyst Characterization

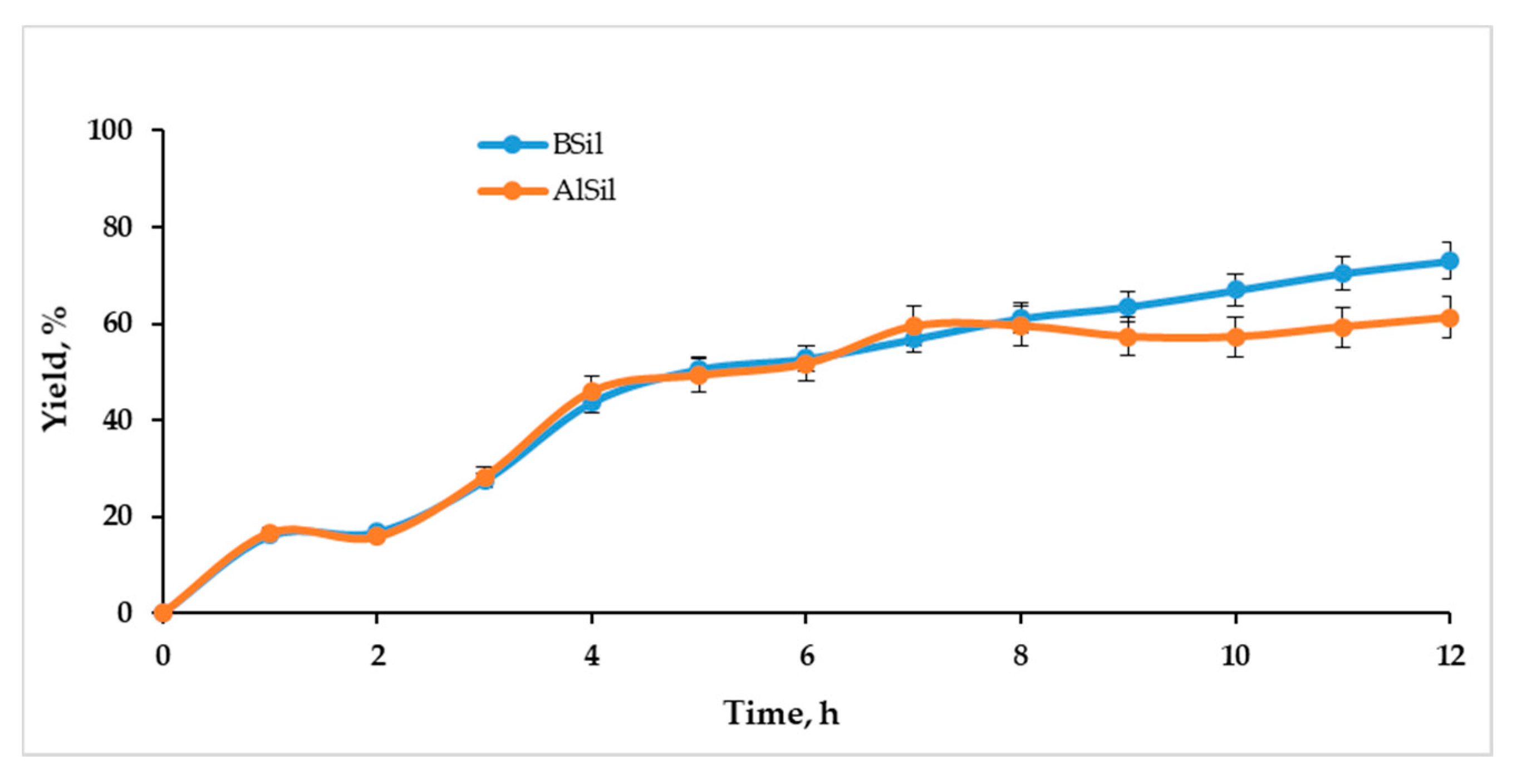

2.2. Catalytic Tests

3. Materials and Methods

3.1. Catalyst Preparation

3.1.1. Preparation of BSil

3.1.2. Preparation of AlSil

3.1.3. Preparation of BlankSil

3.2. Characterization of Prepared Matrices

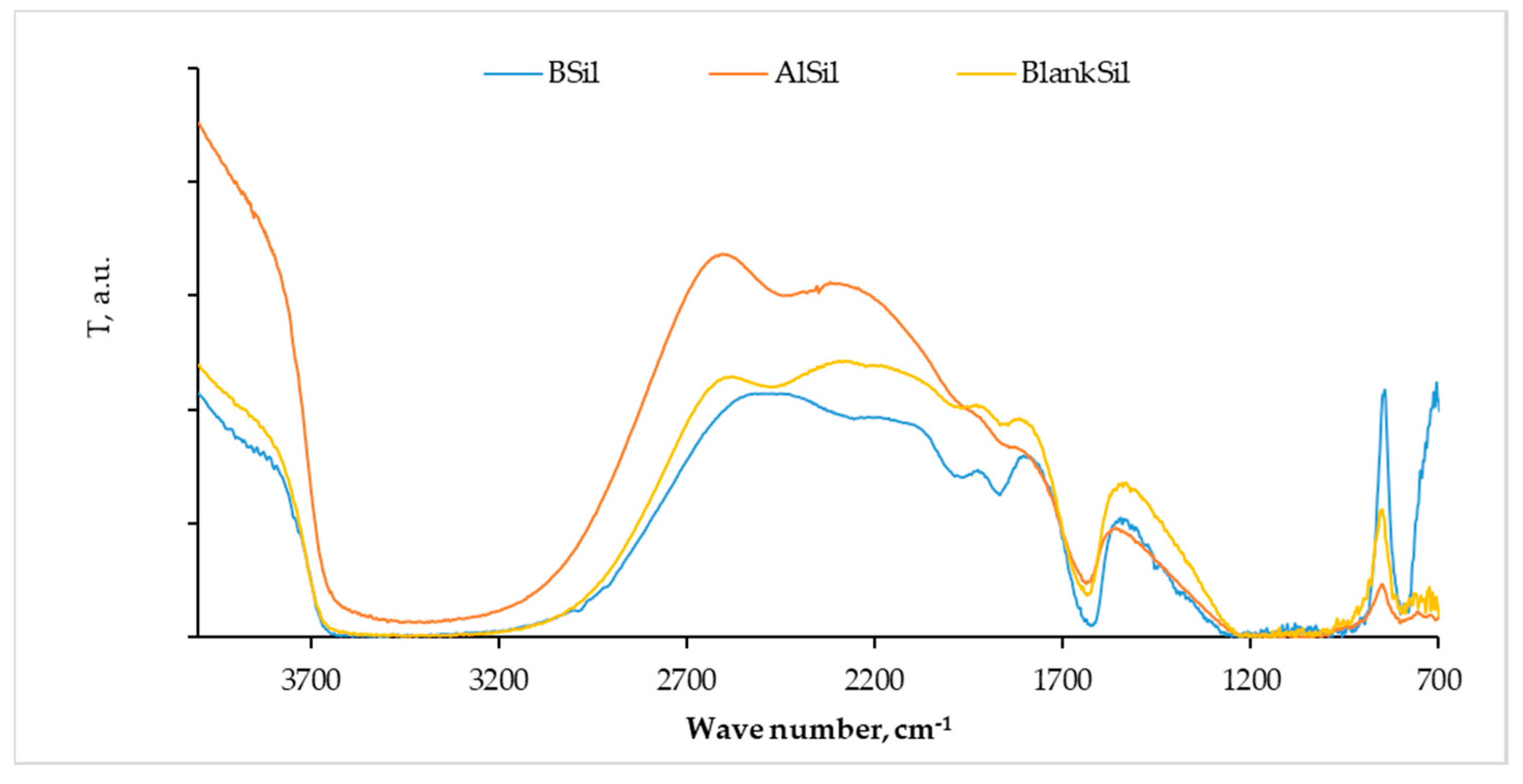

3.2.1. FTIR analysis of the immobilized catalysts

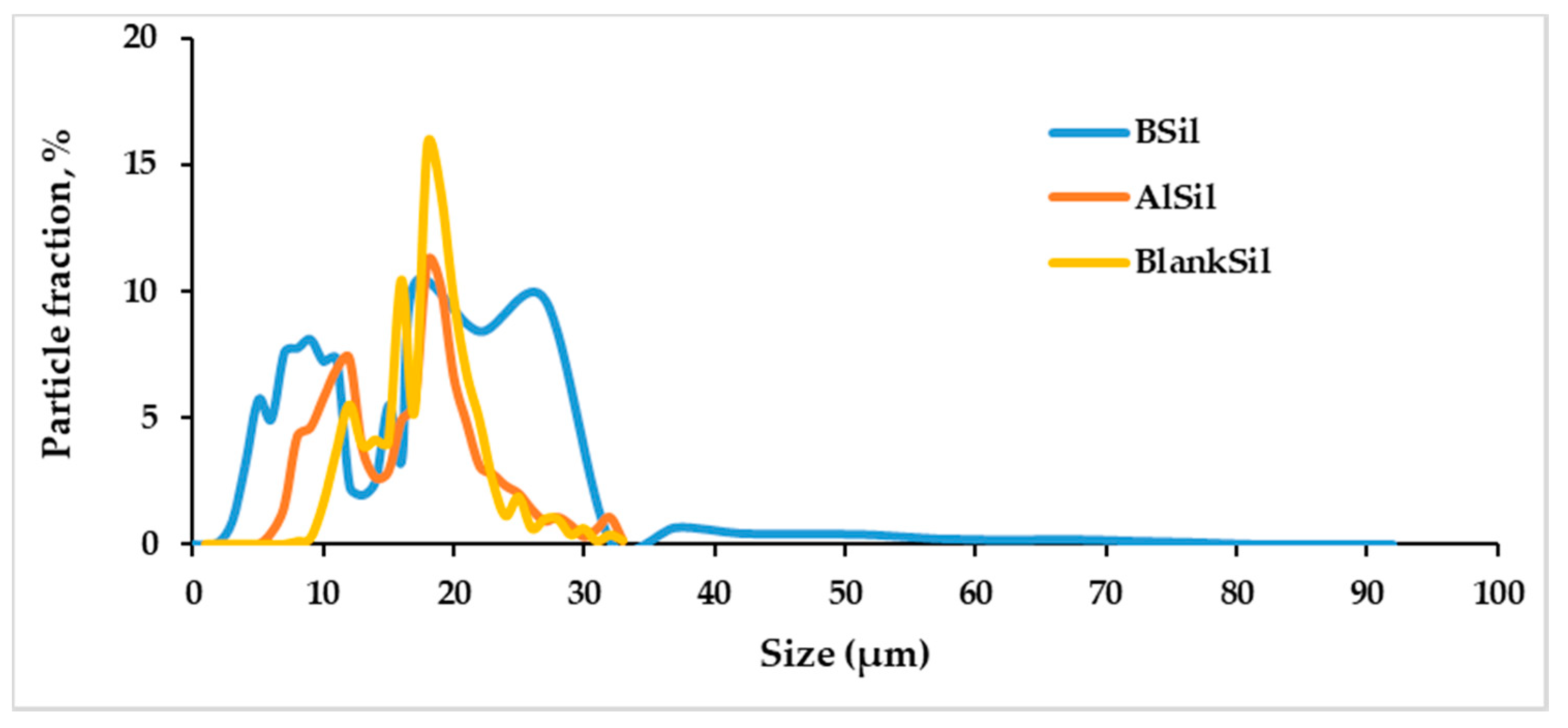

3.2.2. Particle Sizing Counter Analysis of the Immobilized Catalysts

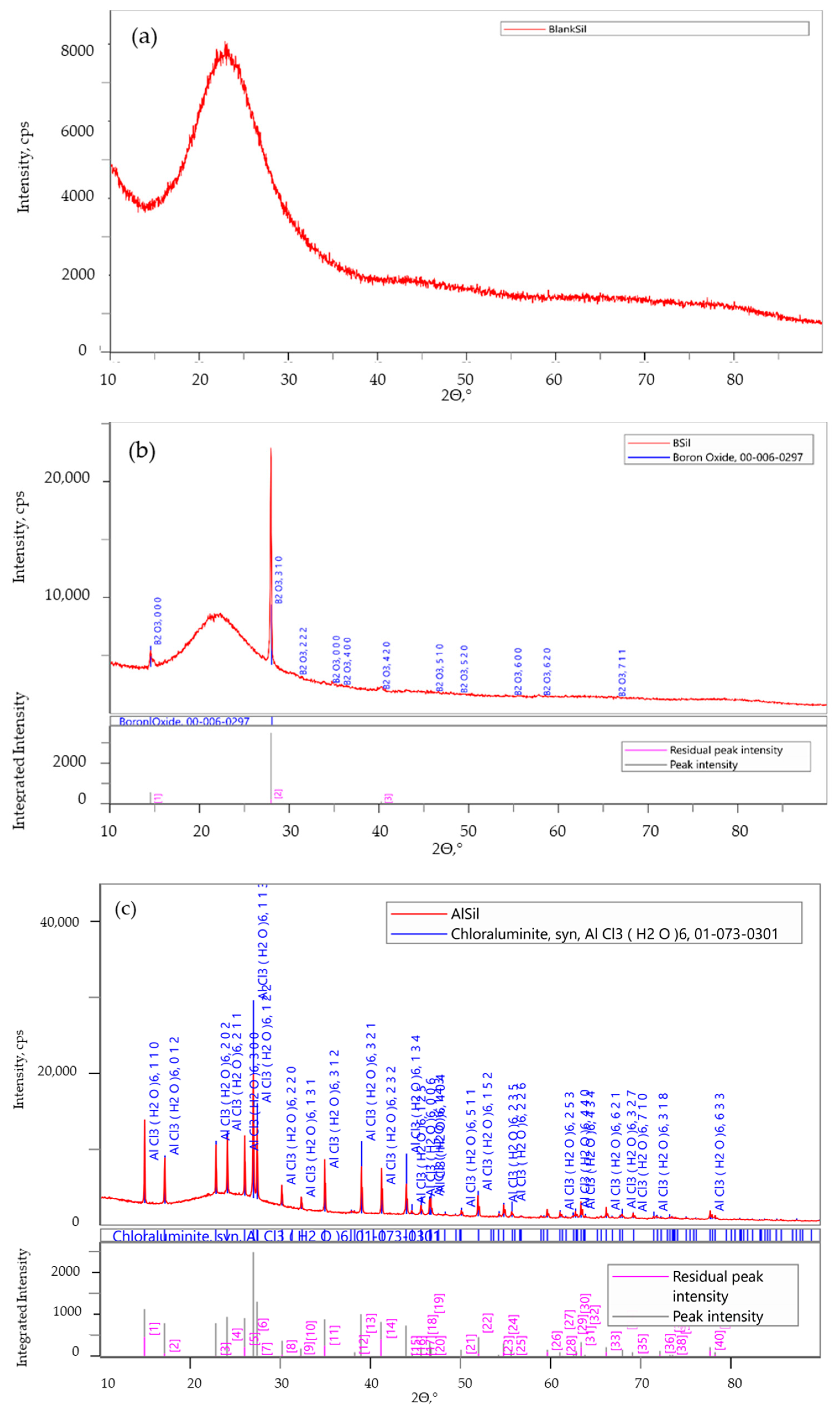

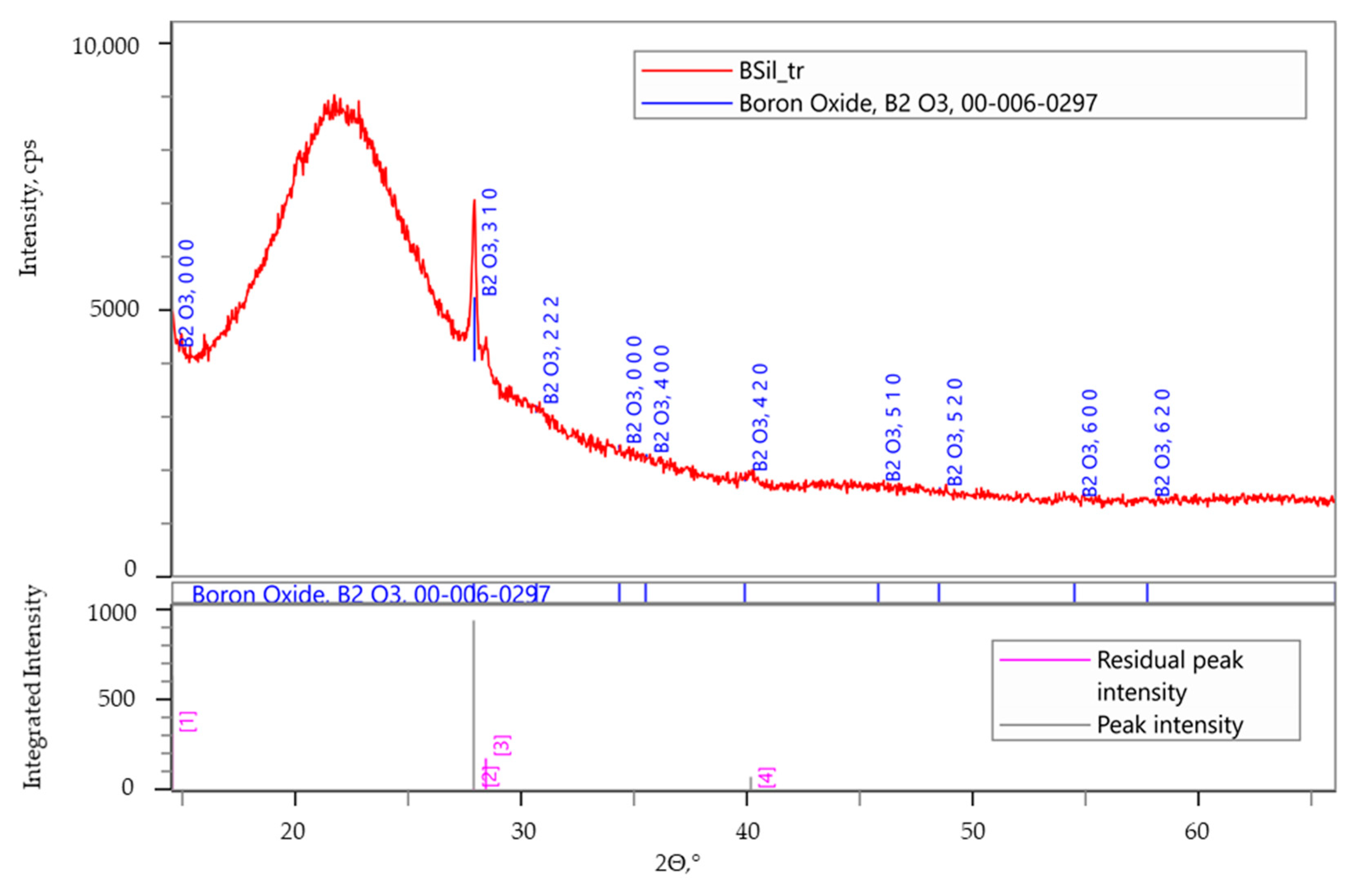

3.2.3. XRD Analysis of the Immobilized Catalysts

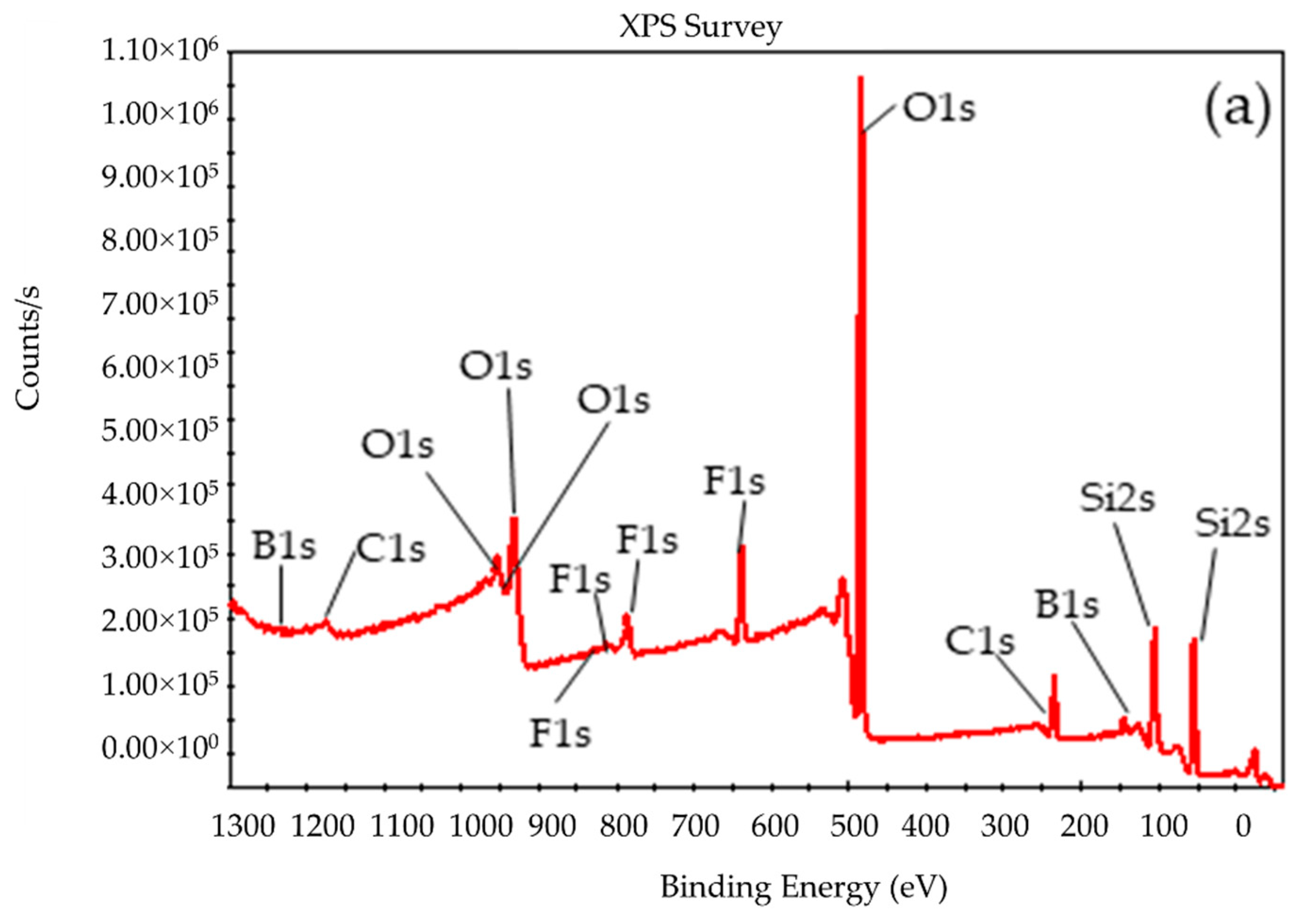

3.2.4. X-ray Photoelectron Spectroscopy (XPS) Analysis of the Immobilized Catalysts

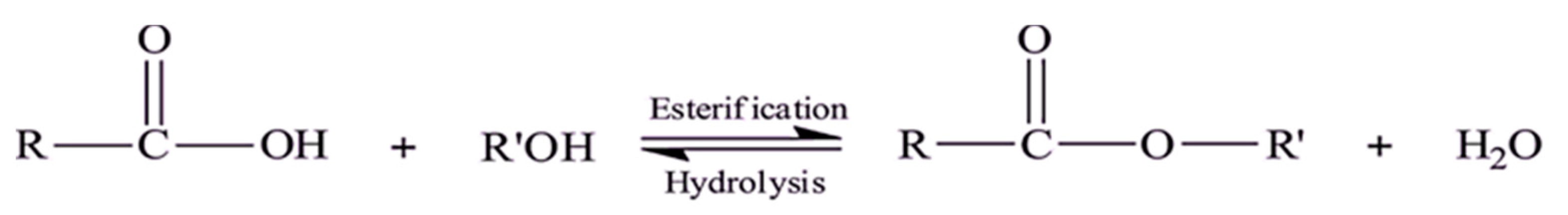

3.3. Esterification of OA under Ultrasonic Activation in a Batch Mode

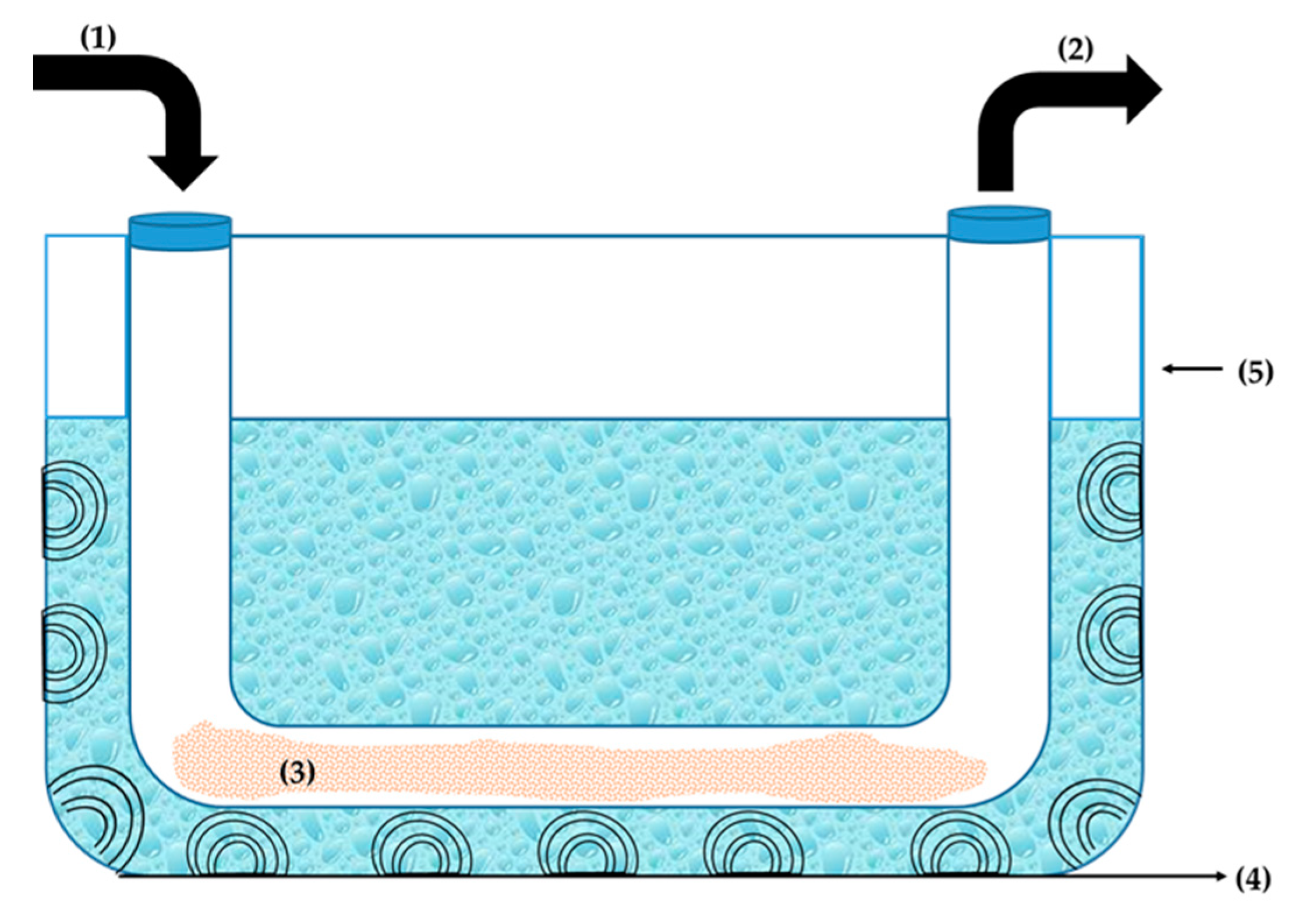

3.4. Continuous Esterification of OA under Ultrasonic Activation in A Fixed-Bed Reactor

3.5. HPLC Analysis of the Samples

3.6. Statistical Analysis

4. Conclusions

5. Patent

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yusuf, N.N.A.N.; Kamarudin, S.K.; Yaakub, Z. Overview on the current trends in biodiesel production. Energy Convers. Manag. 2011, 52, 2741–2751. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumar Sharma, P.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Thangarasu, V.; Siddharth, R.; Ramanathan, A. Modeling of process intensification of biodiesel production from Aegle Marmelos Correa seed oil using microreactor assisted with ultrasonic mixing. Ultrason. Sonochem. 2020, 60, 104764. [Google Scholar] [CrossRef] [PubMed]

- Goh, B.H.H.; Ong, H.C.; Chong, C.T.; Chen, W.H.; Leong, K.Y.; Tan, S.X.; Lee, X.J. Ultrasonic assisted oil extraction and biodiesel synthesis of spent coffee ground. Fuel 2020, 261, 116121. [Google Scholar] [CrossRef]

- Mishra, V.K.; Goswami, R. A review of production, properties and advantages of biodiesel. Biofuels 2018, 9, 273–289. [Google Scholar] [CrossRef]

- Fidel, T.-R.; Mora, L.; Toldrá, F. Trends in Biodiesel Production from animal fat waste. Appl. Sci. 2020, 10, 3644. [Google Scholar] [CrossRef]

- Wongwuttanasatian, T.; Jookjantra, K. Effect of dual-frequency pulsed ultrasonic excitation and catalyst size for biodiesel production. Renew. Energy 2020, 152, 1220–1226. [Google Scholar] [CrossRef]

- Meher, L.C.; Vidya Sagar, D.; Naik, S.N. Technical Aspects of Biodiesel Production by Transesterification—A Review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Masri, A.N.; Abdul Mutalib, M.I.; Yahya, W.Z.N.; Aminuddin, N.F.; Leveque, J.M. Rapid esterification of fatty acid using dicationic acidic ionic liquid catalyst via ultrasonic-assisted method. Ultrason. Sonochem. 2020, 60, 104732. [Google Scholar] [CrossRef]

- Chen, Y.; Truong, V.N.T.; Bu, X.; Xie, G. A review of effects and applications of ultrasound in mineral flotation. Ultrason. Sonochem. 2020, 60, 104739. [Google Scholar] [CrossRef]

- Mason, T.J. Large scale sonochemical processing: Aspiration and actuality. Ultrason. Sonochem. 2000, 7, 145–149. [Google Scholar] [CrossRef]

- Kolet, M.; Zerbib, D.; Molina, K.; Nakonechny, F.; Nisnevitch, M. Biodiesel Production using Lewis catalysts under ultrasonic activation. Isr. J. Chem. 2020, 60, 644–651. [Google Scholar] [CrossRef]

- Etim, A.O.; Musonge, P.; Eloka-Eboka, A.C. Effectiveness of biogenic waste-derived heterogeneous catalysts and feedstock hybridization techniques in biodiesel production. Biofuels Bioprod. Biorefin. 2020, 14, 620–649. [Google Scholar] [CrossRef]

- Talha, N.S.; Sulaiman, S. Overview of catalysts in biodiesel production. ARPN J. Eng. Appl. Sci. 2016, 11, 439–448. [Google Scholar] [CrossRef]

- Priambodo, R.; Chen, T.C.; Lu, M.C.; Gedanken, A.; Liao, J.D.; Huang, Y.H. Novel Technology for Bio-Diesel Production from Cooking and Waste Cooking Oil by Microwave Irradiation; Elsevier B.V.: Amsterdam, The Netherlands, 2015; Volume 75. [Google Scholar] [CrossRef][Green Version]

- Romero, R.; Martínez, S.L.; Natividad, R. Biodiesel Production by Using Heterogeneous Catalysts. Altern. Fuel 2011, 358, 3–20. [Google Scholar] [CrossRef]

- Mucino, G.G.; Romero, R.; Ramirez, A.; Martinez, S.L.; Baeza-Jimenez, R.; Natividad, R.; Muciño, G.G.; Romero, R.; Ramírez, A.; Martínez, S.L.; et al. Biodiesel production from used cooking oil and sea sand as heterogeneous catalyst. Fuel 2014, 138, 143–148. [Google Scholar] [CrossRef]

- Borah, M.J.; Das, A.; Das, V.; Bhuyan, N.; Deka, D. Transesterification of waste cooking oil for biodiesel production catalyzed by Zn substituted waste egg shell derived CaO nanocatalyst. Fuel 2019, 242, 345–354. [Google Scholar] [CrossRef]

- Attia, N.K. Biodiesel Production from Spirulina-Platensis Microalgae by In-Situ Transesterification Process. J. Sustain. Bioenergy Syst. 2013, 3, 224–233. [Google Scholar] [CrossRef]

- Hou, X.; Qi, Y.; Qiao, X.; Wang, G.; Qin, Z.; Wang, J. Lewis acid-catalyzed transesterification and esterification of high free fatty acid oil in subcritical methanol. Korean J. Chem. Eng. 2007, 24, 311–313. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Abdul Aziz, A.R.; Sulaiman, N.M.N. The effects of catalysts in biodiesel production: A review. J. Ind. Eng. Chem. 2013, 19, 14–26. [Google Scholar] [CrossRef]

- Demirbas, A.; Karki, B. Biodiesel–A Realistic Fuel Alternative for Diesel Engines, 1st ed.; British Library Cataloguing, Springer: London, UK, 2008; ISBN 9781846289941. [Google Scholar] [CrossRef]

- Hogg, J.M.; Coleman, F.; Ferrer-Ugalde, A.; Atkins, M.P.; Swadźba-Kwaśny, M. Liquid coordination complexes: A new class of Lewis acids as safer alternatives to BF3 in synthesis of polyalphaolefins. Green Chem. 2015, 17, 1831–1841. [Google Scholar] [CrossRef]

- Guan, Q.; Shang, H.; Liu, J.; Gu, J.; Li, B.; Miao, R.; Chen, Q.; Ning, P. Biodiesel from transesterification at low temperature by AlCl3 catalysis in ethanol and carbon dioxide as cosolvent: Process, mechanism and application. Appl. Energy 2016, 164, 380–386. [Google Scholar] [CrossRef]

- Kolet, M.; Zerbib, D.; Nakonechny, F.; Nisnevitch, M. Production of Biodiesel from Brown Grease. Catalyst 2020, 10, 1189. [Google Scholar] [CrossRef]

- Venkateswara Rao, A.; Bhagat, S.D. Synthesis and physical properties of TEOS-based silica aerogels prepared by two step (acid-base) sol–gel process. Solid State Sci. 2004, 6, 945–952. [Google Scholar] [CrossRef]

- Ciriminna, R.; Fidalgo, A.; Pandarus, V.; Beland, F.; Ilharco, L.M.; Pagliaro, M. The Sol–Gel Route to Advanced Silica-Based Materials and Recent Applications. Chem. Rev. 2012, 113, 6592–6620. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Zhao, Y.; Li, K.; Zhang, H.; Fan, L.; Lu, Z. Efficient production of biodiesel from ionic liquid catalyzed esterification using ultrasonic-microwave combined intensification. Chem. Eng. Process. Process. Intensif. 2020, 149, 107870. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Chen, J.Y.; Li, W.C.; Lu, A.H. B2O3: A heterogeneous metal-free Lewis acid catalyst for carbon dioxide fixation into cyclic carbonates. J. CO2 Util. 2019, 29, 172–178. [Google Scholar] [CrossRef]

- Carlson, C.G.; Hall, J.E.; Huang, Y.Y.; Kotila, S.; Rauk, A.; Tavares, D.F. The preparation of esters of formic acid using boron oxide. Can. J. Chem. 1987, 65, 2461–2463. [Google Scholar] [CrossRef]

- Murakami, Y.; Otsuka, K.; Wada, Y.; Morikawa, A. The Partial Oxidation of Ethane over a B2O3–Al2O3 Catalyst. Chem. Soc. Jpn. 1990, 63, 340–346. [Google Scholar] [CrossRef]

- Ejikeme, P.M.; Anyaogu, I.D.; Ejikeme, C.L.; Nwafor, N.P.; Egbuonu, C.A.C.; Ukogu, K.; Ibemesi, J.A.; Chemistry, I.; Polytechnic, F. Catalysis in biodiesel production by transesterification process-an insight. E J. Chem. 2010, 7, 1120–1132. [Google Scholar] [CrossRef]

- Beekman, S.M. Process for Preparing Alcohol Solutions of Aluminum Chlorhydroxides For Antiperspirant Use and for Other Uses and Compositions Containing the Same 1975. Available online: https://www.freepatentsonline.com/3876758.html (accessed on 15 October 2020).

- Fawaz, E.G.; Salam, D.A.; Daou, T.J. Esterification of linoleic acid using HZSM-5 zeolites with different Si/Al ratios. Microporous Mesoporous Mater. 2020, 294, 109855. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Q.; Sun, X.; Wu, C.; Gao, Z. Kinetics studies of biodiesel production from waste cooking oil using FeCl3-modified resin as heterogeneous catalyst. Renew. Energy 2017, 107, 522–530. [Google Scholar] [CrossRef]

- Alsharifi, M.; Znad, H.; Hena, S.; Ang, M. Biodiesel production from canola oil using novel Li/TiO2 as a heterogeneous catalyst prepared via impregnation method. Renew. Energy 2017, 114, 1077–1089. [Google Scholar] [CrossRef]

- Gardy, J.; Hassanpour, A.; Lai, X.; Ahmed, M.H.; Rehan, M. Biodiesel production from used cooking oil using a novel surface functionalised TiO2 nano-catalyst. Appl. Catal. B Environ. 2017, 207, 297–310. [Google Scholar] [CrossRef]

- Abukhadra, M.R.; Salam, M.A.; Ibrahim, S.M. Insight into the catalytic conversion of palm oil into biodiesel using Na+/K+ trapped muscovite/phillipsite composite as a novel catalyst: Effect of ultrasonic irradiation and mechanism. Renew. Sustain. Energy Rev. 2019, 115, 109346. [Google Scholar] [CrossRef]

- Negm, N.A.; Betiha, M.A.; Alhumaimess, M.S.; Hassan, H.M.A.; Rabie, A.M. Clean transesterification process for biodiesel production using heterogeneous polymer-heteropoly acid nanocatalyst. J. Clean. Prod. 2019, 238, 117854. [Google Scholar] [CrossRef]

- Dai, Y.M.; Wang, Y.F.; Chen, C.C. Synthesis and characterization of magnetic LiFe5O8-LiFeO2 as a solid basic catalyst for biodiesel production. Catal. Commun. 2018, 106, 20–24. [Google Scholar] [CrossRef]

- Suranani, S.; Maralla, Y.; Gaikwad, S.M.; Sonawane, S.H. Process intensification using corning® advanced-flow™ reactor for continuous flow synthesis of biodiesel from fresh oil and used cooking oil. Chem. Eng. Process. Process. Intensif. 2018, 126, 62–73. [Google Scholar] [CrossRef]

| Atomic % | BSil New | BSil Used |

|---|---|---|

| B1s | 8.97 | 6.45 |

| Si2p | 25.99 | 28.38 |

| F1s | 7.43 | 7.37 |

| O1s | 57.61 | 57.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolet, M.; Atrash, M.; Molina, K.; Zerbib, D.; Albo, Y.; Nakonechny, F.; Nisnevitch, M. Sol–Gel Entrapped Lewis Acids as Catalysts for Biodiesel Production. Molecules 2020, 25, 5936. https://doi.org/10.3390/molecules25245936

Kolet M, Atrash M, Molina K, Zerbib D, Albo Y, Nakonechny F, Nisnevitch M. Sol–Gel Entrapped Lewis Acids as Catalysts for Biodiesel Production. Molecules. 2020; 25(24):5936. https://doi.org/10.3390/molecules25245936

Chicago/Turabian StyleKolet, Mirit, Melad Atrash, Karen Molina, Daniel Zerbib, Yael Albo, Faina Nakonechny, and Marina Nisnevitch. 2020. "Sol–Gel Entrapped Lewis Acids as Catalysts for Biodiesel Production" Molecules 25, no. 24: 5936. https://doi.org/10.3390/molecules25245936

APA StyleKolet, M., Atrash, M., Molina, K., Zerbib, D., Albo, Y., Nakonechny, F., & Nisnevitch, M. (2020). Sol–Gel Entrapped Lewis Acids as Catalysts for Biodiesel Production. Molecules, 25(24), 5936. https://doi.org/10.3390/molecules25245936