Influence of Cavitation and Mixing Conditions on Oil Droplet Size in Simultaneous Homogenization and Mixing (SHM)

Abstract

1. Introduction

2. Background

2.1. Droplet Break-Up in SHM

2.2. Cavitation in HPH Processes

2.3. Influence of Droplet Break-Up on Cavitation

3. Materials and Methods

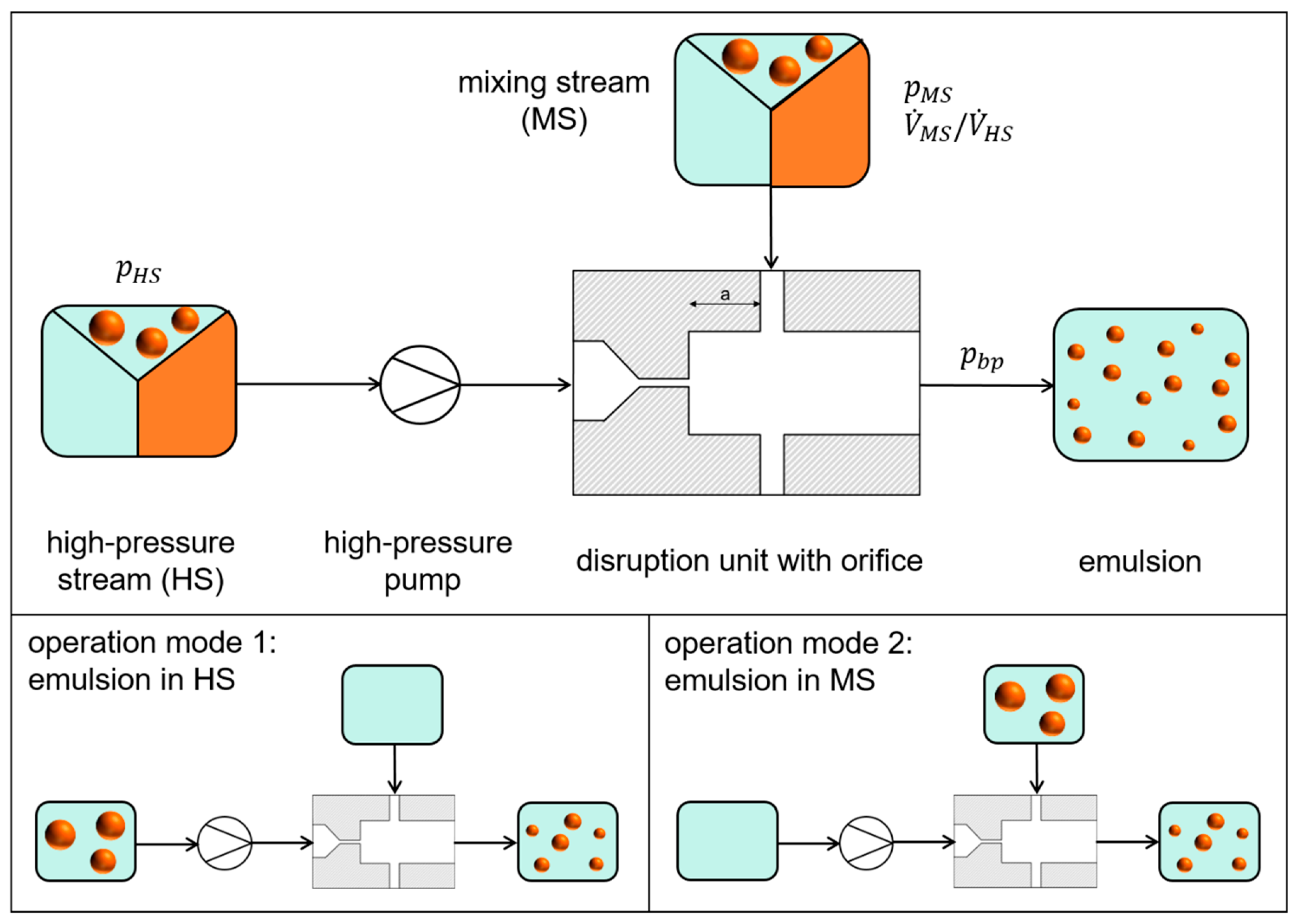

3.1. Plant Setup

3.2. Emulsification Trials

3.3. Shadow-Graphic Images for Cavitation Observations

4. Results and Discussion

4.1. Influence of β on Oil Droplet Size

4.2. Influence of Th Number on Oil Droplet Size

4.3. Influence of Mixing Ratio on Droplet Break-Up

4.4. Influence of Geometry of Mixing Unit on Cavitation Pattern and Droplet Size

5. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Schuchmann, H.P. Advances in Hydrodynamic Pressure Processing for Enhancing Emulsification and Dispersion. In Innovative Food Processing Technologies: Extraction, Separation, Component Modification and Process Intensification; Knoerzer, K., Juliano, P., Smithers, G., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2016; pp. 387–412. [Google Scholar]

- Walstra, P. Principles of emulsion formation. Chem. Eng. Sci. 1993, 48, 333–349. [Google Scholar] [CrossRef]

- Köhler, K.; Aguilar, F.A.; Hensel, A.; Schubert, K.; Schubert, H.; Schuchmann, H.P. Design of a Microstructured System for Homogenization of Dairy Products with High Fat Content. Chem. Eng.Technol. 2007, 30, 1590–1595. [Google Scholar] [CrossRef]

- Köhler, K.; Schuchmann, H.P. Simultanes Emulgieren und Mischen. CIT 2012, 84, 1538–1544. [Google Scholar] [CrossRef]

- Köhler, K.; Karasch, S.; Schuchmann, H.P.; Kulozik, U. Energiesparende Homogenisierung von Milch mit etablierten sowie neuartigen Verfahren. CIT 2008, 80, 1107–1116. [Google Scholar] [CrossRef]

- Gall, V.; Runde, M.; Schuchmann, H.P. Extending Applications of High-Pressure Homogenization by Using Simultaneous Emulsification and Mixing (SEM)—An Overview. Processes 2016, 4, 46. [Google Scholar] [CrossRef]

- Köhler, K.; Santana, A.S.; Braisch, B.; Preis, R.; Schuchmann, H.P. High pressure emulsification with nano-particles as stabilizing agents. Chem. Eng. Sci. 2010, 65, 2957–2964. [Google Scholar] [CrossRef]

- Köhler, K.; Hensel, A.; Kraut, M.; Schuchmann, H.P. Melt emulsification—Is there a chance to produce particles without additives? Particuology 2011, 9, 506–509. [Google Scholar] [CrossRef]

- Bisten, A.; Schuchmann, H.P. Optical Measuring Methods for the Investigation of High-Pressure Homogenisation. Processes 2016, 4, 41. [Google Scholar] [CrossRef]

- Kelemen, K.; Crowther, F.E.; Cierpka, C.; Hecht, L.L.; Kähler, C.J.; Schuchmann, H.P. Investigations on the characterization of laminar and transitional flow conditions after high pressure homogenization orifices. Microfluid. Nanofluid. 2014, 18, 599–612. [Google Scholar] [CrossRef]

- Bisten, A.; Rudolf, D.; Karbstein, H.P. Comparison of flow patterns and droplet deformations of modified sharp-edged and conical orifices during high-pressure homogenisation using µPIV. Microfluid. Nanofluid. 2018, 22, 607. [Google Scholar] [CrossRef]

- Innings, F.; Trägårdh, C. Analysis of the flow field in a high-pressure homogenizer. Exp. Therm. Fluid. Sci. 2007, 32, 345–354. [Google Scholar] [CrossRef]

- Håkansson, A.; Fuchs, L.; Innings, F.; Revstedt, J.; Trägårdh, C.; Bergenståhl, B. High resolution experimental measurement of turbulent flow field in a high pressure homogenizer model and its implications on turbulent drop fragmentation. Chem. Eng. Sci. 2011, 66, 1790–1801. [Google Scholar] [CrossRef]

- Håkansson, A. Emulsion Formation by Homogenization: Current Understanding and Future Perspectives. Annu. Rev. Food. Sci. Technol. 2019, 10, 239–258. [Google Scholar] [CrossRef] [PubMed]

- Franc, J.-P.; Michel, J.-M. Fundamentals of Cavitation; Fluid Mechanics and Its Applications, v. 76; Kluwer Academic Publishers: Dordrecht, The Netherlands; Boston, MA, USA, 2005. [Google Scholar]

- Yan, Y.; Thorpe, R.B. Flow regime transitions due to cavitation in the flow through an orifice. Int. J. Multiph. Flow 1990, 16, 1023–1045. [Google Scholar] [CrossRef]

- Schlender, M.; Minke, K.; Spiegel, B.; Schuchmann, H.P. High-pressure double stage homogenization processes: Influences of plant setup on oil droplet size. Chem. Eng. Sci. 2015, 131, 162–171. [Google Scholar] [CrossRef]

- Schlender, M.; Spengler, A.; Schuchmann, H.P. High-pressure emulsion formation in cylindrical coaxial orifices: Influence of cavitation induced pattern on oil drop size. Int. J. Multiph. Flow 2015, 74, 84–95. [Google Scholar] [CrossRef]

- Gall, V.; Ruetten, E.; Karbstein, H.P. Cavitation patterns in high-pressure homogenization nozzles with cylindrical orifices: Influence of mixing stream in Simultaneous Homogenization and Mixing. ECMF. (accepted).

- Kurzhals, H.A.; Reuter, H. Untersuchungen über die physikalisch-technischen Vorgänge beim Homogenisieren von Milch in Hochdruck-Homogenisiermaschinen. CIT 1979, 51, 325. [Google Scholar] [CrossRef]

- Köhler, K.; Aguilar, F.A.; Hensel, A.; Schubert, H.; Schuchmann, H.P. Design of a Micro-Structured System for the Homogenization of Dairy Producs at High Fat Content- Part III: Influence of Geometric Parameters. Chem. Eng. Techol. 2009, 32, 1120–1126. [Google Scholar] [CrossRef]

- Winkelmann, M.; Schuler, T.; Uzunogullari, P.; Winkler, C.A.; Gerlinger, W.; Sachweh, B.; Schuchmann, H.P. Influence of mixing on the precipitation of zinc oxide nanoparticles with the miniemulsion technique. Chem. Eng. Sci. 2012, 81, 209–219. [Google Scholar] [CrossRef]

- Sato, K.; Taguchi, Y.; Hayashi, S. High Speed Observation of Periodic Cavity Behavior in a Convergent-Divergent Nozzle for Cavitating Water Jet. JFCMV 2013, 1, 102–107. [Google Scholar] [CrossRef]

- Johansen, F.C. Flow through pipe orifices at low Reynolds numbers. Proc. R. Soc. Lond. A 1930, 126, 231–245. [Google Scholar]

- Innings, F.; Trägårdh, C. Visualization of the drop deformation and break-up process in a high pressure homogenizer. Chem. Eng. Technol. 2005, 28, 882–891. [Google Scholar] [CrossRef]

- Kelemen, K.; Schuch, A.; Schuchmann, H.P. Influence of flow conditions in high pressure orifices on droplet disruption of O/W emulsions. Chem. Eng. Technol. 2014, 37, 1227–1234. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Ficarella, A.; Tarantino, M. Evaluating cavitation regimes in an internal orifice at different temperatures using frequency analysis and visualization. Int. J. Heat Fluid Flow 2013, 39, 160–172. [Google Scholar] [CrossRef]

- Gothsch, T.; Richter, C.; Beinert, S.; Schilcher, C.; Schilde, C.; Büttgenbach, S.; Kwade, A. Effect of cavitation on dispersion and emulsification process in high-pressure microsystems (HPMS). Chem. Eng. Sci. 2016, 144, 239–248. [Google Scholar] [CrossRef]

- Schlender, M.; Minke, K.; Schuchmann, H.P. Sono-chemiluminescence (SCL) in a high-pressure double stage homogenization processes. Chem. Eng. Sci. 2016, 142, 1–11. [Google Scholar] [CrossRef]

- McKillop, A.A.; Dunkley, W.L.; Brockmeyer, R.L.; Perry, R.L. The Cavitation Theory of Homogenization. J. Dairy Sci. 1955, 38, 273–283. [Google Scholar] [CrossRef]

- Jahnke, S. The theory of high-pressure homogenization. In Emulsions and Nanosuspensions for the Formulation of Poorly Soluble Drugs; Benita, S., Bohm, B., Eds.; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Numachi, F.; Yamabe, M.; O-ba, R. Cavitation Effect on the Discharge Coefficient of the Sharp-Edged Orifice Plate. J. Fluids Eng. 1960, 82, 1–6. [Google Scholar] [CrossRef]

- Stanley, C. Experimental Investigation of Cavitation in a Cylindrical Orifice. Ph.D. Thesis, University of New South Wales, Kensington, Australia, 2012. [Google Scholar]

- Soyama, H.; Yanauchi, Y.; Sato, K.; Ikohagi, T.; Oba, R.; Oshima, R. High-speed observation of ultrahigh-speed submerged water jets. Exp. Therm. Fluid Sci. 1996, 12, 411–416. [Google Scholar] [CrossRef]

- Sou, A.; Hosokawa, S.; Tomiyama, A. Effects of cavitation in a nozzle on liquid jet atomization. Int. J. Heat Mass Transf. 2007, 50, 3575–3582. [Google Scholar] [CrossRef]

- Gogate, P.R.; Pandit, A.B. Hydrodynamic Cavitation Reactors: A State of the Art Review. Rev. Chem. 2001, 17, 1–85. [Google Scholar] [CrossRef]

- Finke, J.H.; Niemann, S.; Richter, C.; Gothsch, T.; Kwade, A.; Büttgenbach, S.; Müller-Goymann, C.C. Multiple orifices in customized microsystem high-pressure emulsification: The impact of design and counter pressure on homogenization efficiency. Chem. Eng. J. 2014, 248, 107–121. [Google Scholar] [CrossRef]

- Freudig, B.; Tesch, S.; Schubert, H. Production of emulsions in high-pressure homogenizers—Part II: Influence of Cavitation on Droplet Breakup. Eng. Life Sci. 2003, 6, 266–270. [Google Scholar] [CrossRef]

- Mohr, K.-H. High-pressure homogenization. Part II. The influence of cavitation on liquid-liquid dispersion in turbulence fields of high energy density. J. Food Eng. 1987, 6, 311–324. [Google Scholar] [CrossRef]

- Håkansson, A. Flow pulsation plays an important role for high-pressure homogenization in laboratory-scale. Chem. Eng. Res. Des. 2018, 138, 472–481. [Google Scholar] [CrossRef]

- Danner, T. Tropfenkoaleszenz in Emulsionen. Ph.D. Thesis, Universität Karlsruhe (TH), Karlsruhe, Germany, 2001. [Google Scholar]

- Tesch, S. Charakterisieren mechanischer Emulgierverfahren: Herstellen und Stabilisieren von Tropfen als Teilschritte Beim Formulieren von Emulsionen. Ph.D. Thesis, Universität Karlsruhe (TH), Karlsruhe, Germany, 2002. [Google Scholar]

- Rahman, A.; Brown, C.W. Effect of pH on the critical micelle concentration of sodium dodecyl sulphate. J. Appl. Polym. Sci. 1983, 28, 1331–1334. [Google Scholar] [CrossRef]

- Pacek, A.W.; Man, C.C.; Nienow, A.W. On the Sauter mean diameter and size distributions in turbulent liquid/liquid dispersions in a stirred vessel. Chem. Eng. Sci. 1998, 53, 2005–2011. [Google Scholar] [CrossRef]

- Schuchmann, H.P.; Köhler, K. (Eds.) Emulgiertechnik; Behr‘s: Hamburg, Germany, 2012; Volume 3. [Google Scholar]

| Emulsion in MS, = 1 | 1.15 ± 0.10 | 3.09 ± 0.11 | 5.52 ± 0.22 |

| Emulsion in MS, = 2 | 1.32 ± 0.13 | 3.32 ± 0.04 | 5.92 ± 0.19 |

| Emulsion in MS, = 5 | 1.82 ± 0.05 | 3.92 ± 0.02 | 7.90 ± 0.14 |

| Emulsion in HS, = 1 | 0.58 ± 0.01 | 2.07 ± 0.12 | 3.78 ± 0.15 |

| Emulsion in HS, = 2 | 0.57± 0.05 | 2.13 ± 0.18 | 3.85 ± 0.27 |

| Emulsion in HS, = 5 | 0.56 ± 0.02 | 2,10 ± 0.10 | 3.89 ± 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gall, V.; Karbstein, H.P. Influence of Cavitation and Mixing Conditions on Oil Droplet Size in Simultaneous Homogenization and Mixing (SHM). ChemEngineering 2020, 4, 64. https://doi.org/10.3390/chemengineering4040064

Gall V, Karbstein HP. Influence of Cavitation and Mixing Conditions on Oil Droplet Size in Simultaneous Homogenization and Mixing (SHM). ChemEngineering. 2020; 4(4):64. https://doi.org/10.3390/chemengineering4040064

Chicago/Turabian StyleGall, Vanessa, and Heike P. Karbstein. 2020. "Influence of Cavitation and Mixing Conditions on Oil Droplet Size in Simultaneous Homogenization and Mixing (SHM)" ChemEngineering 4, no. 4: 64. https://doi.org/10.3390/chemengineering4040064

APA StyleGall, V., & Karbstein, H. P. (2020). Influence of Cavitation and Mixing Conditions on Oil Droplet Size in Simultaneous Homogenization and Mixing (SHM). ChemEngineering, 4(4), 64. https://doi.org/10.3390/chemengineering4040064