Innovative Turbine Intake Air Cooling Systems and Their Rational Designing

Abstract

:1. Introduction

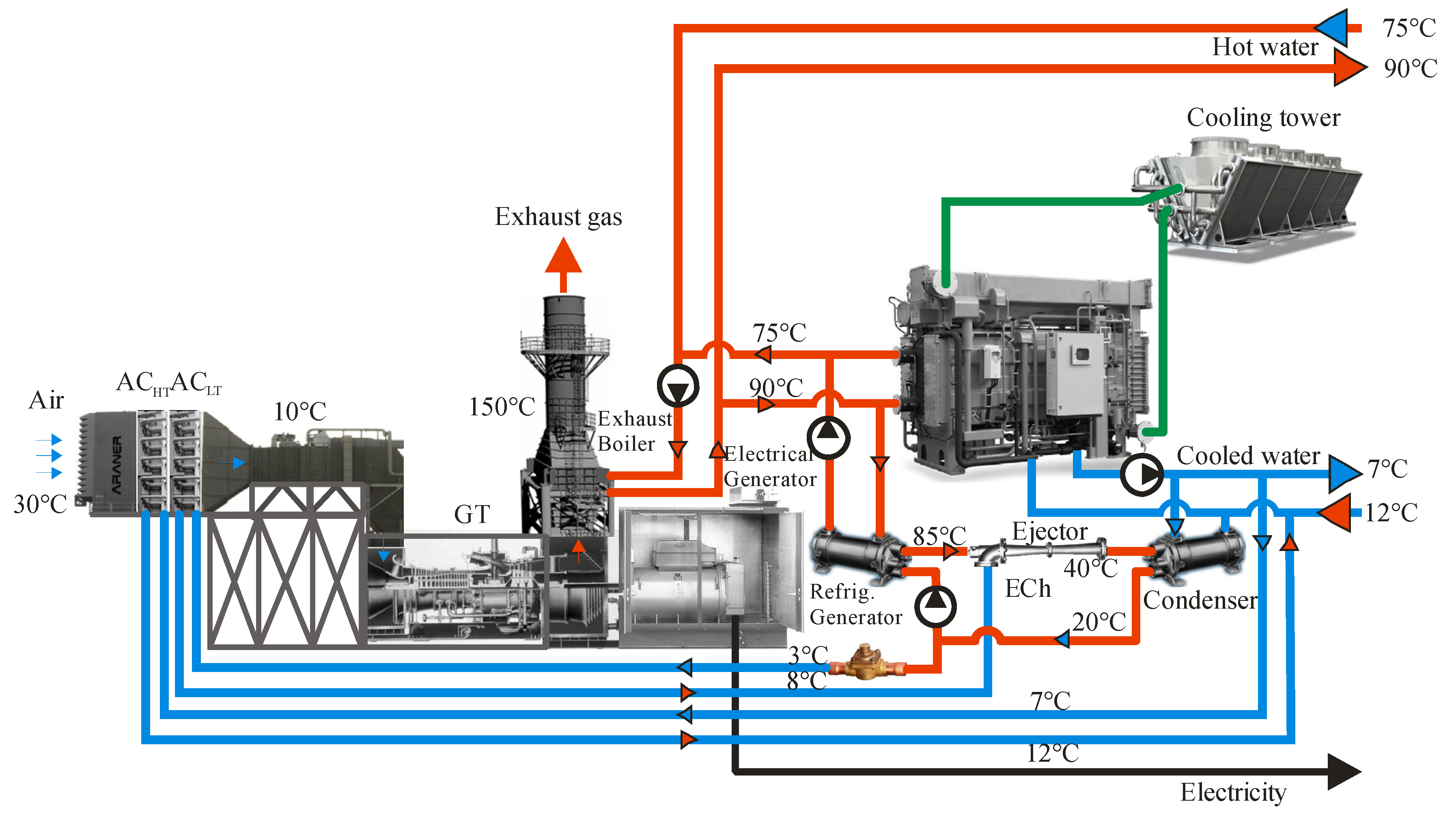

2. Materials and Methods

2.1. General Assumptions and Hypothesis

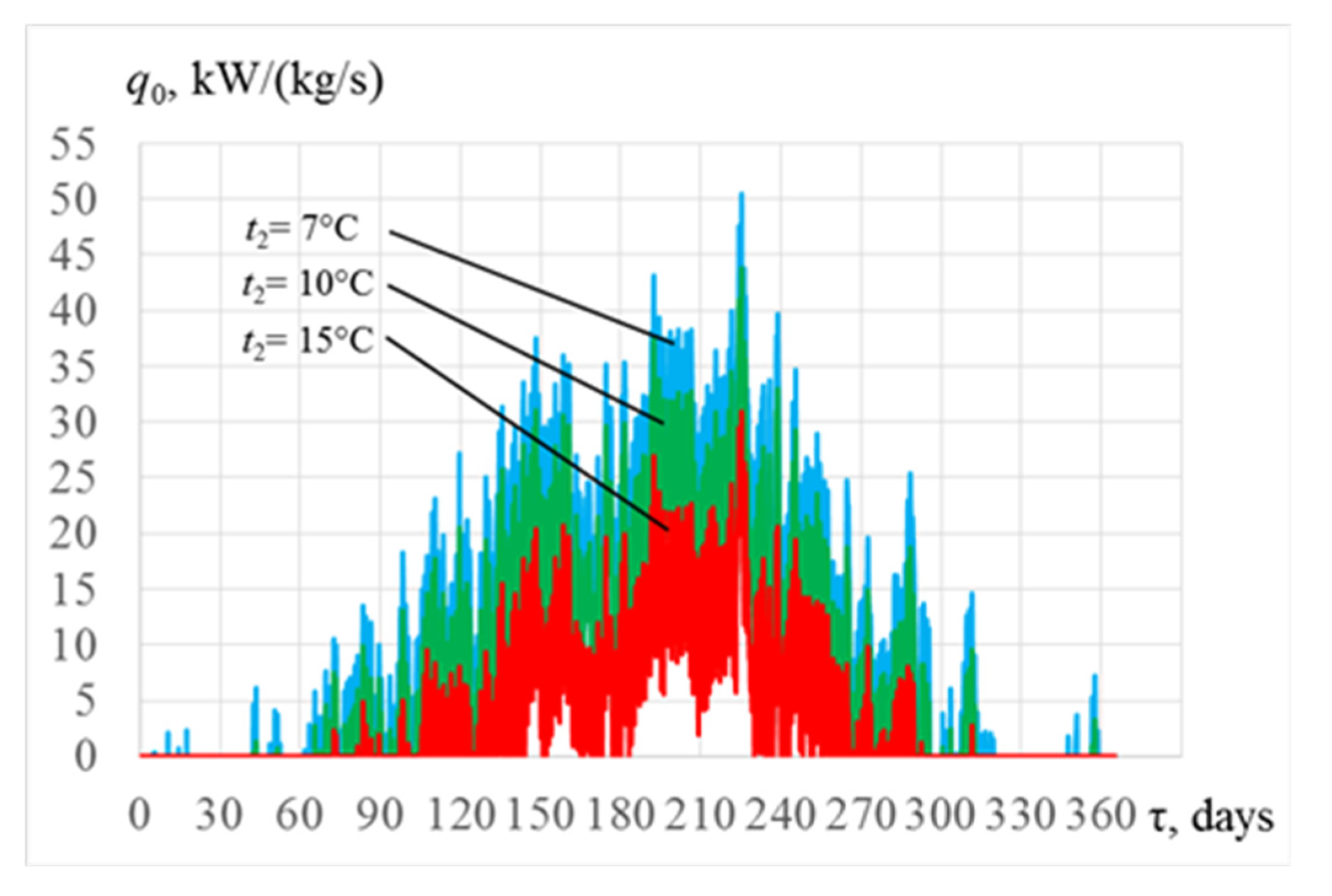

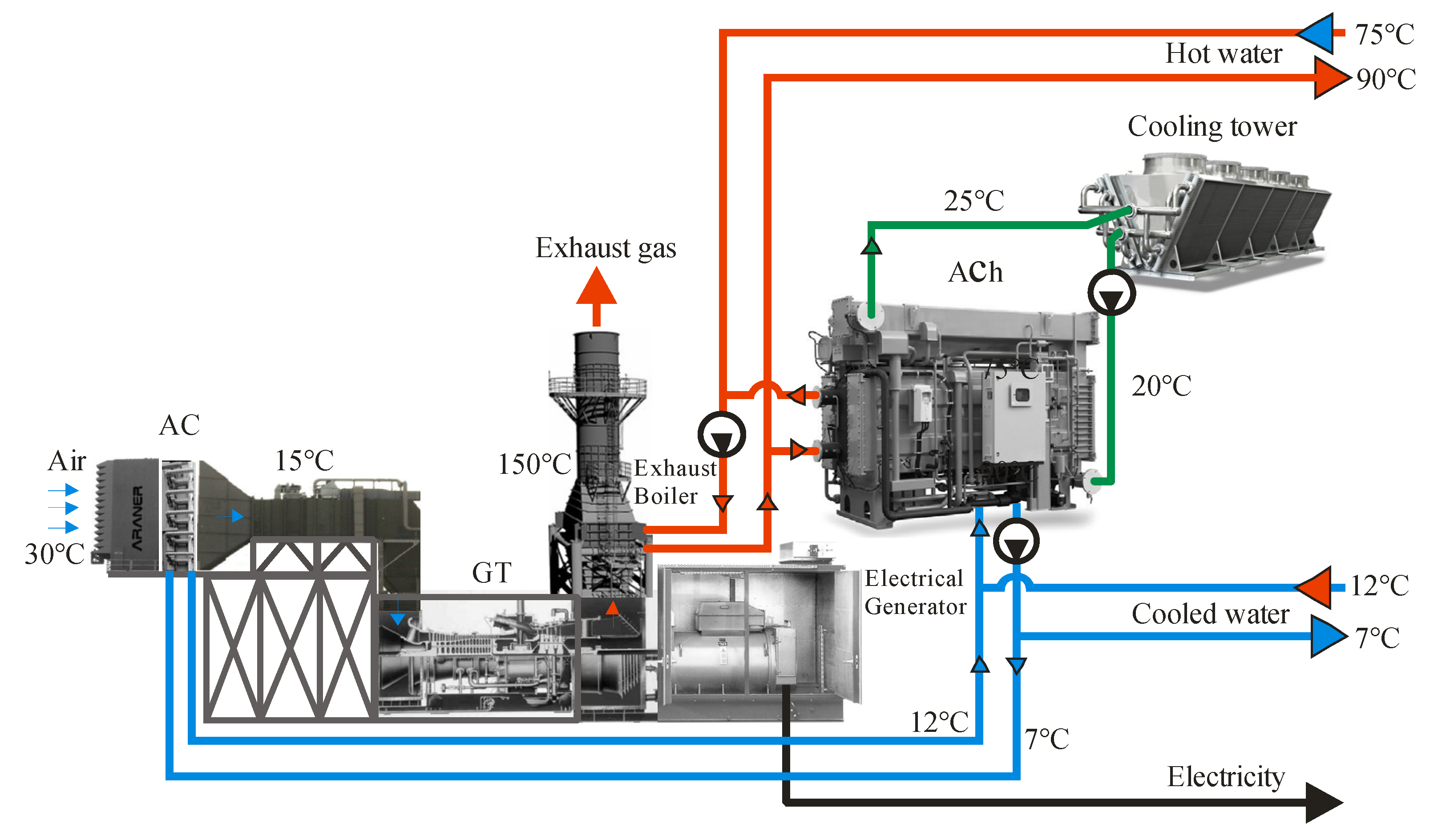

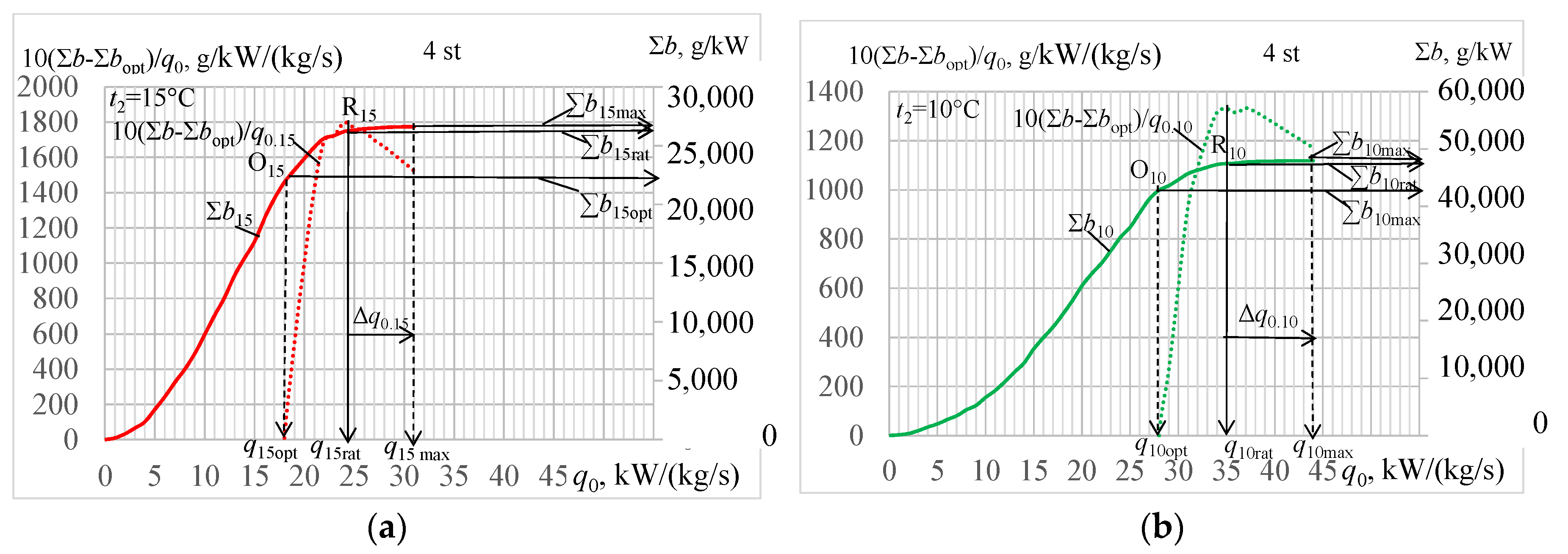

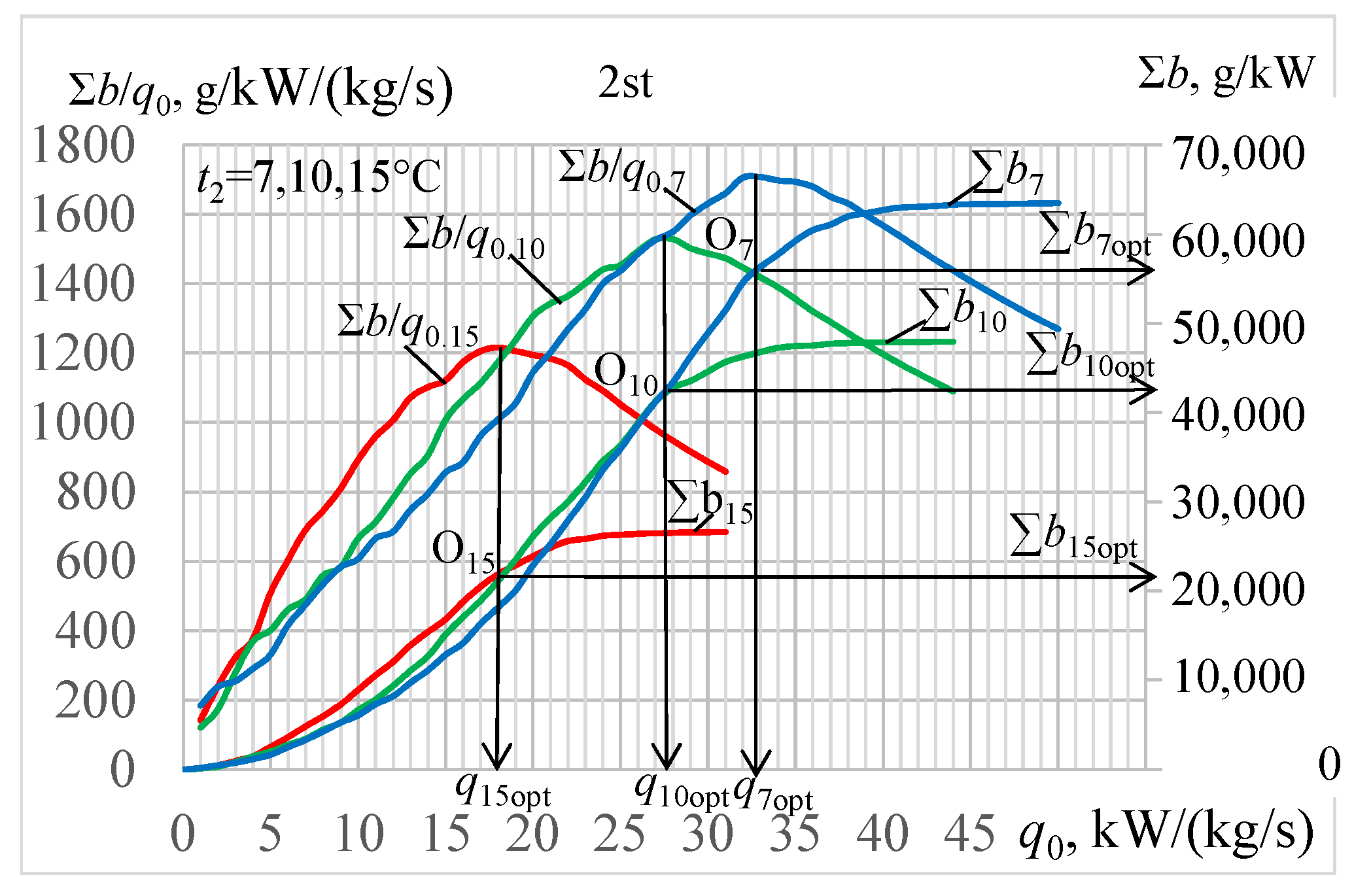

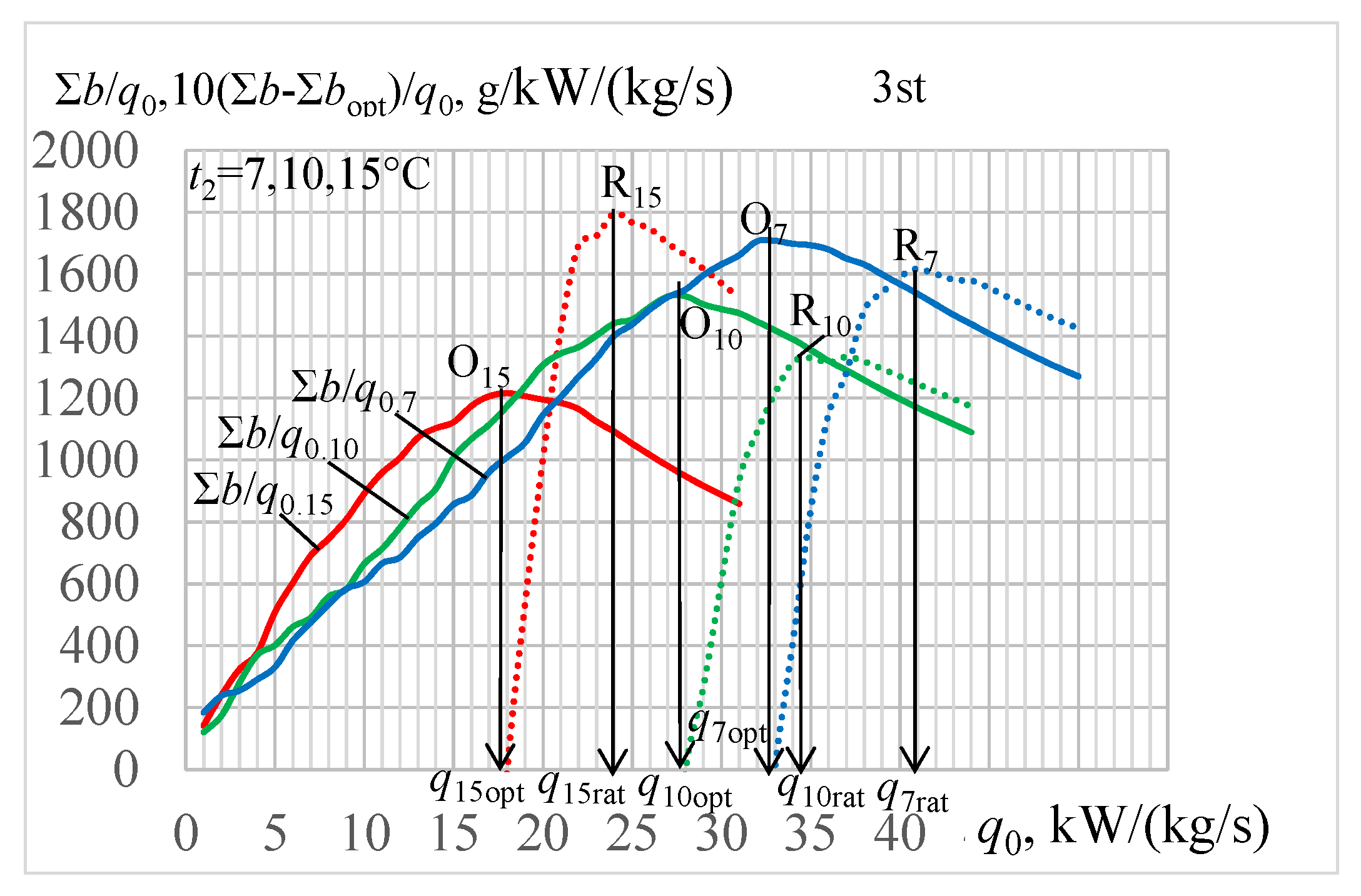

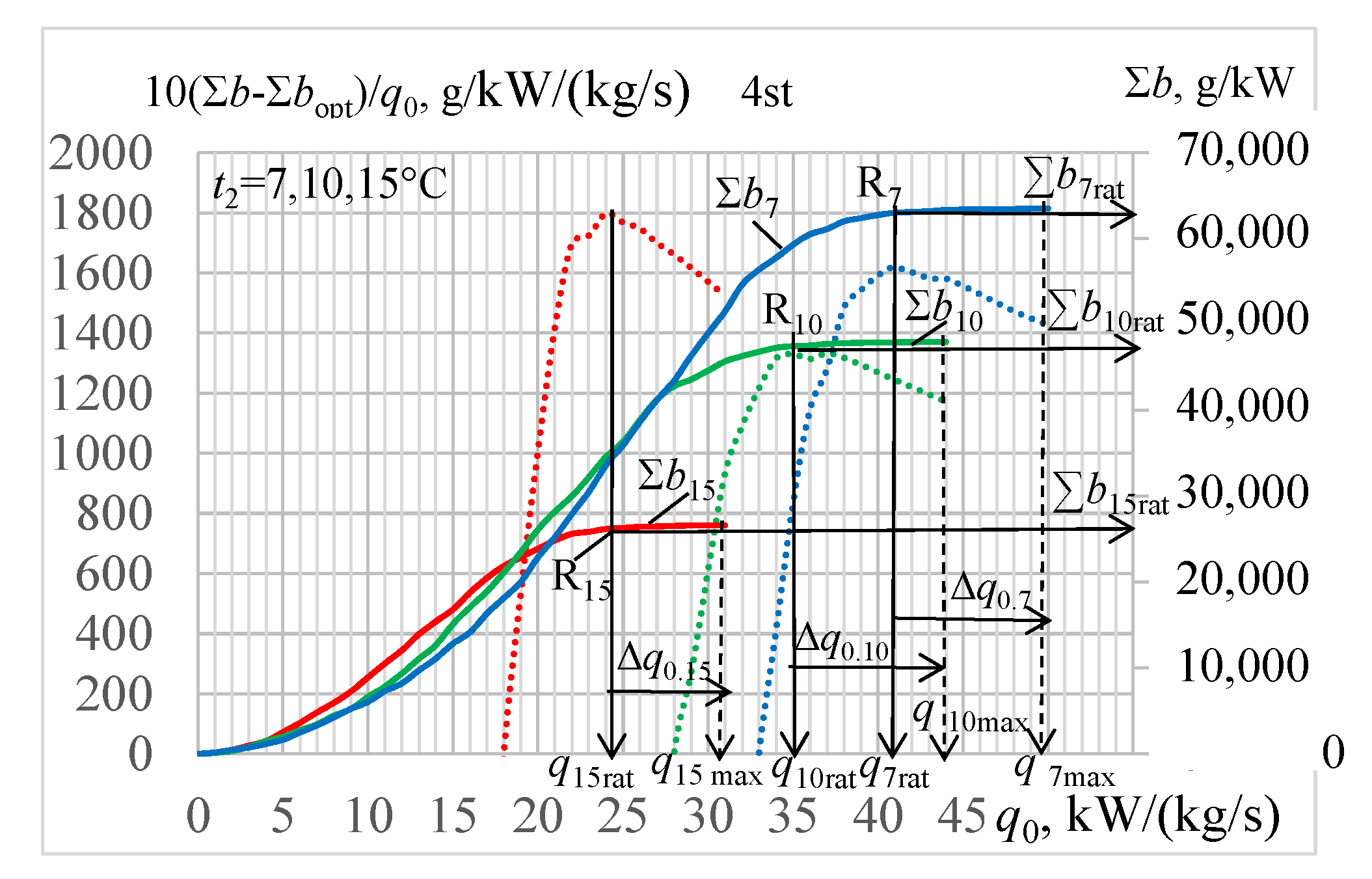

- The lowest temperature of air cooled in ACh of a simple cycle is assumed to be ta2 = 15 °C and limited by minimum temperature difference of 8 °C between cooled air and chilled water leaving ACh at tw = 7 °C (water at the inlet of air cooler): ta2 = tw + 8 °C.

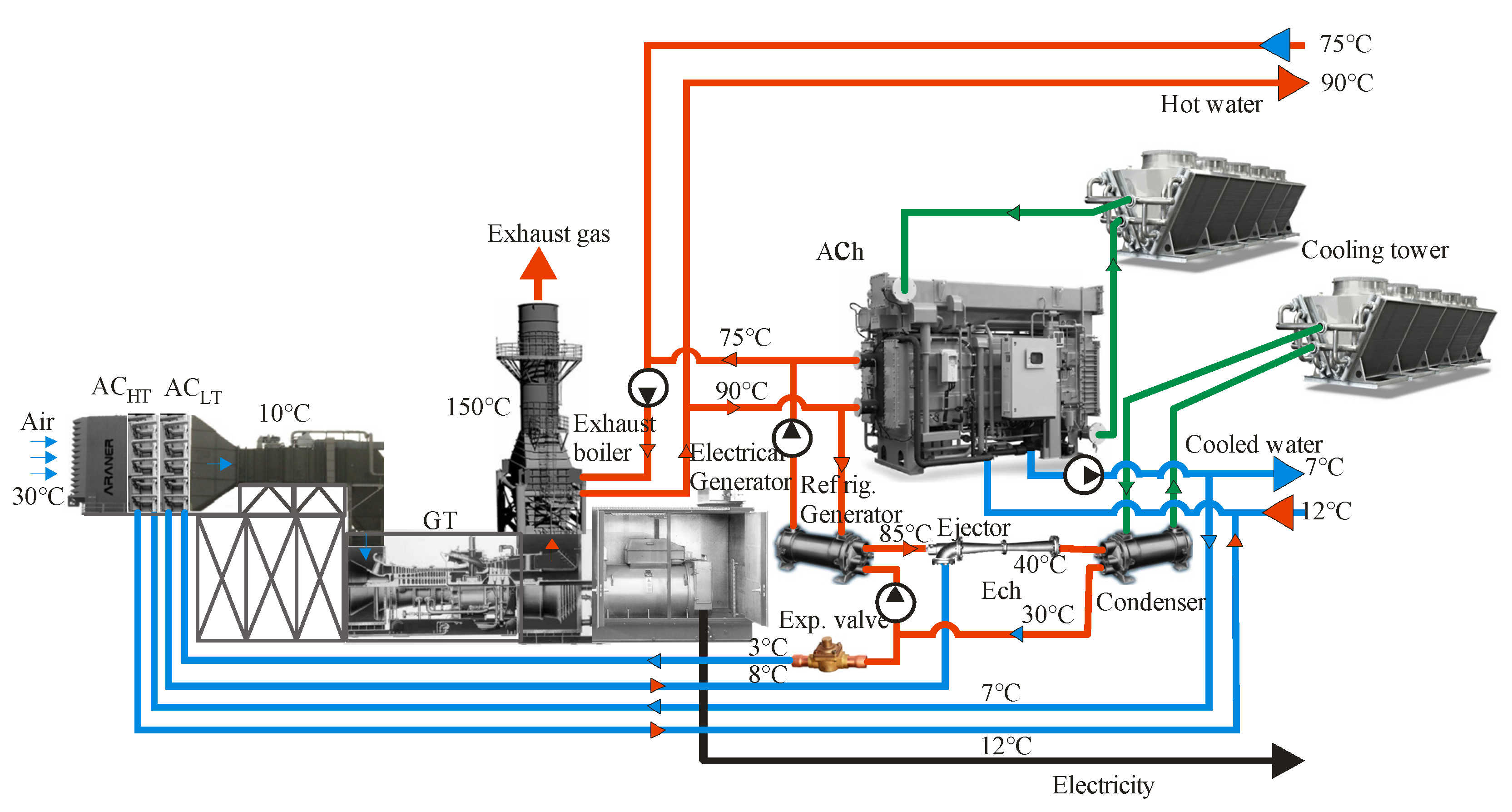

- In the case of using a refrigerant as a coolant in the air cooler the temperature difference between heat exchanging fluids is lower, 4 or 5 °C, falling in dependence of the refrigerant boiling point in air cooler within t0 of 2 to 5 °C. This leads to lower values of minimum temperature ta2 of air cooled in refrigerant chiller, for instance, 7 to 10 °C in ECh: ta2 = t0 + (4 or 5) °C.

- The last assumption regulates a joint operation of ACh and ECh in a two stage cooling air mode: to 15 °C in ACh and further subcooling to 10 °C in ECh of a stage absorption-ejector chiller (SAECh) and in cascade mode at lowered ambient air temperatures tamb when ambient air temperature drops to tamb = 15 °C the excessive (not consumed) cooling capacity of ACh is used for cooling the condenser of ECh as a low cascade of cascade absorption-ejector chiller (CAECh).

- As well as proposed absorption-ejector TIAC systems are the advanced versions of typical basic absorption TIAC system, the economic comparison with the last might be done taking into account only the cost of extra heat exchangers of ECh (refrigerant evaporator-air cooler, refrigerant condenser, and ejector) with unchanged maintenance cost, personal, etc. Because of fluctuations in cost of heat exchangers of different manufacturers and a fuel especially the economic analysis is to be conducted for the concrete case. Thus, the considered method of designing focuses to provide just initial basic data as rational technical characteristics for further complicated detailed economic analysis.

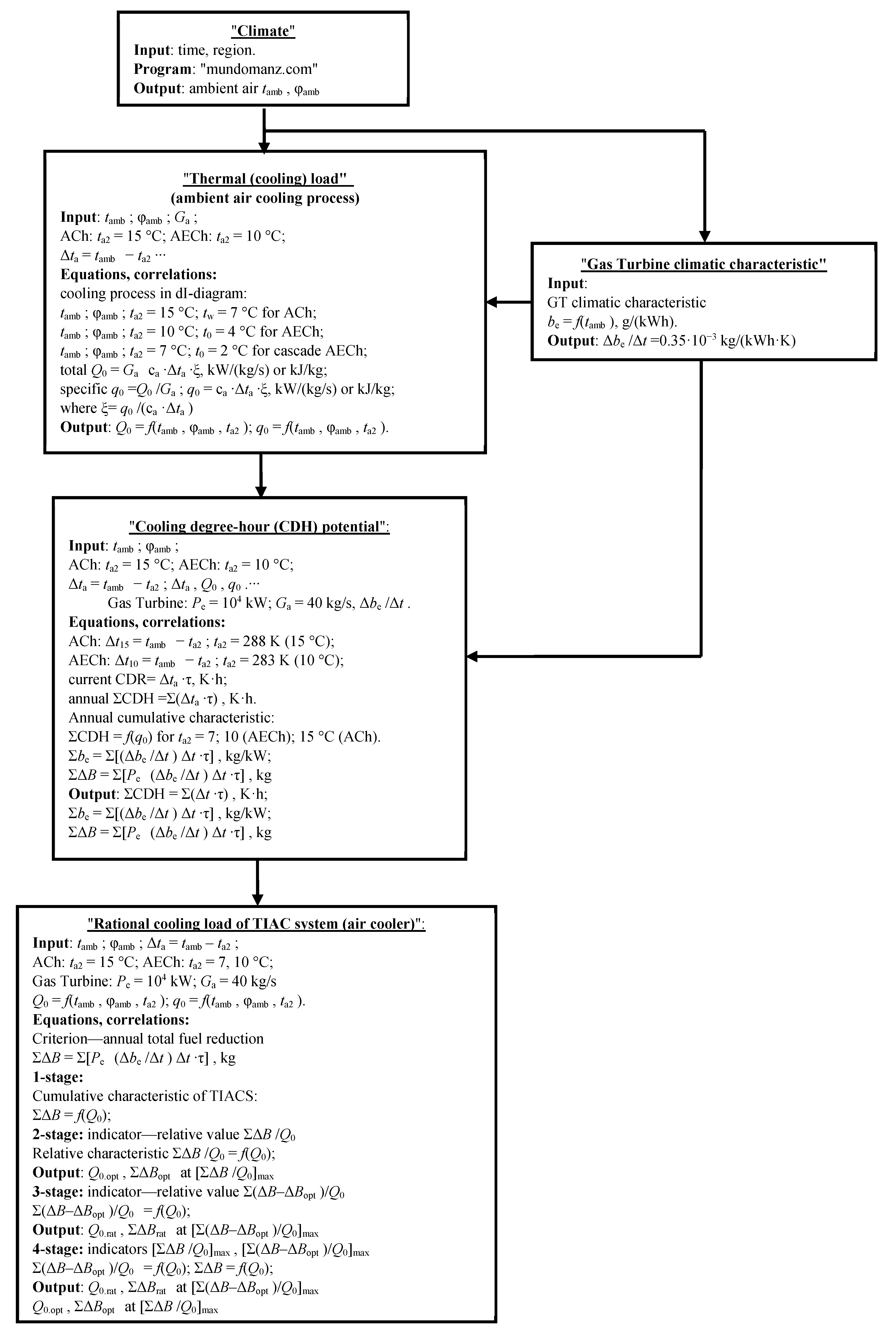

2.2. The Computation Algorithm

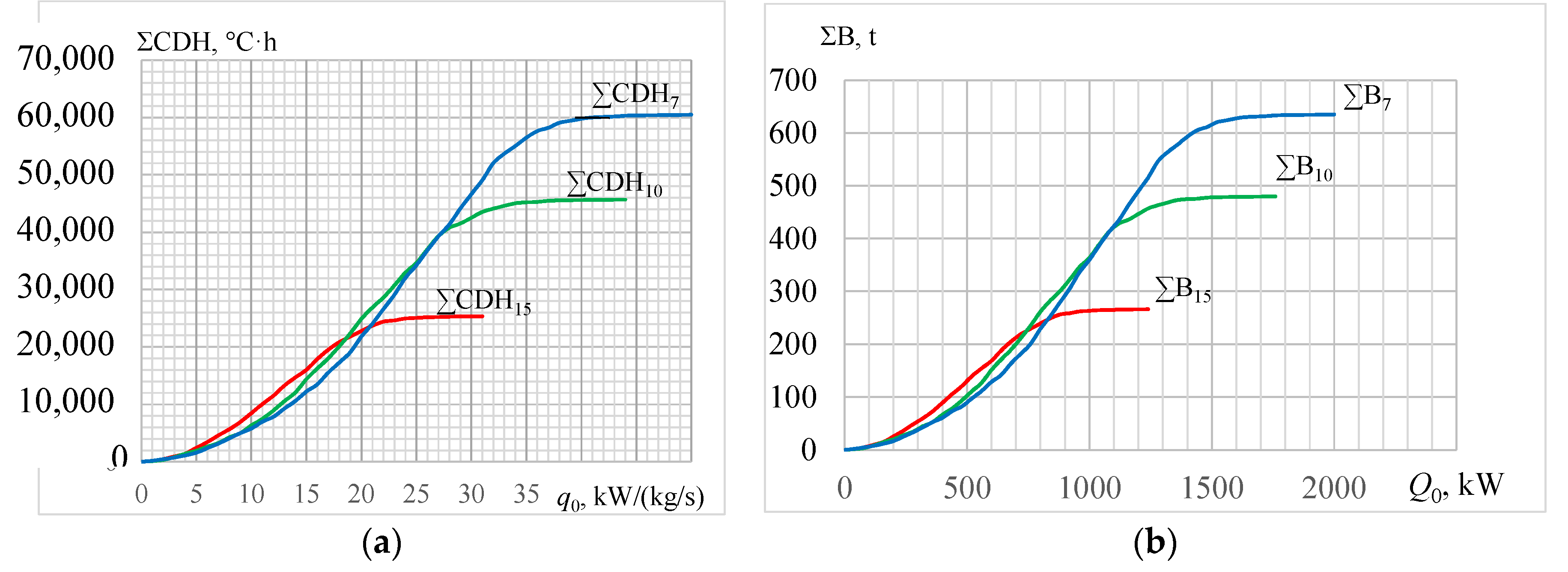

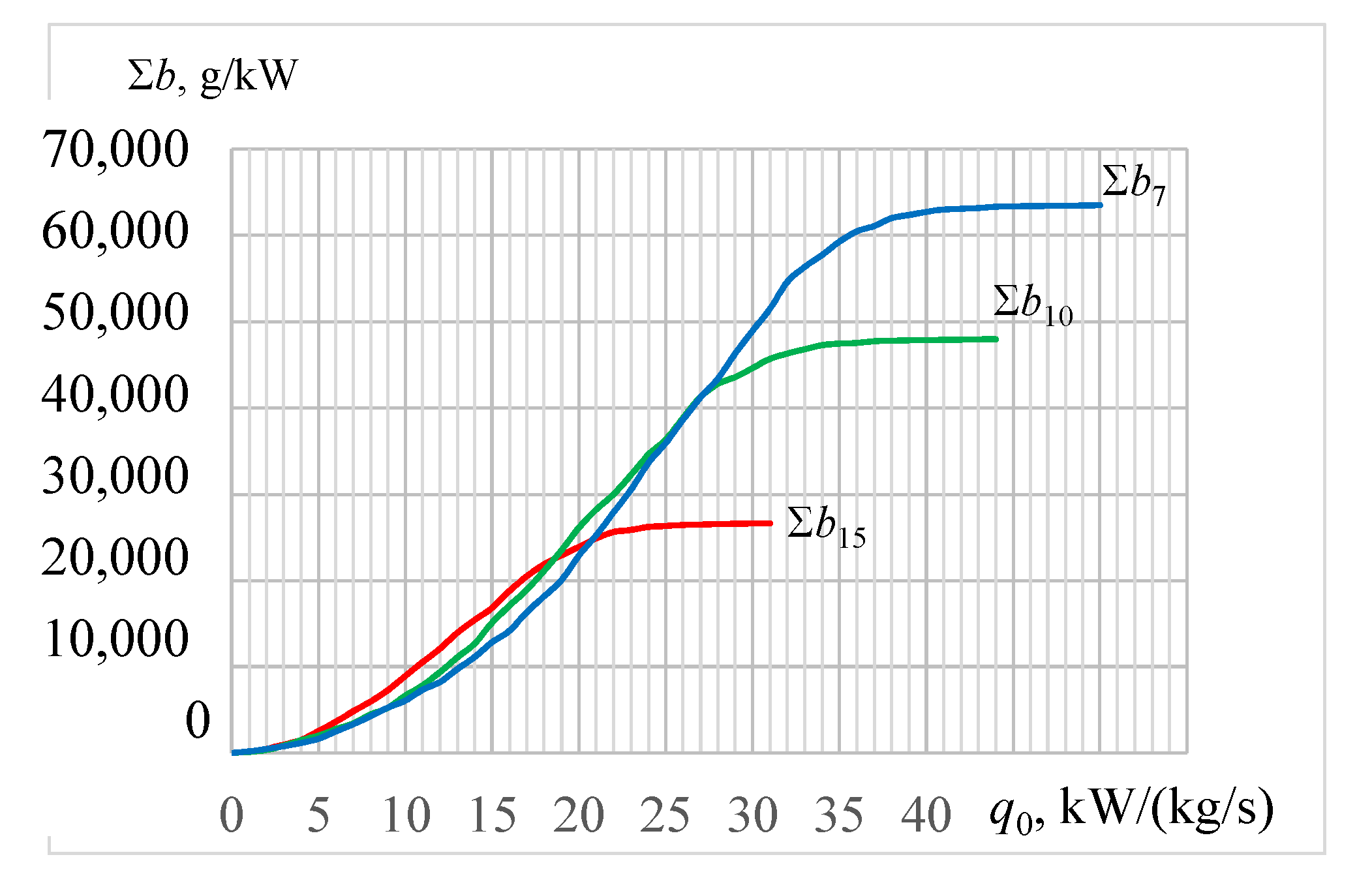

- current values of total fuel reduction per an houror specific fuel reduction (for 1 kW turbine power output)B = CDH (Δbe/Δt)∙Peb = CDH (Δbe/Δt)

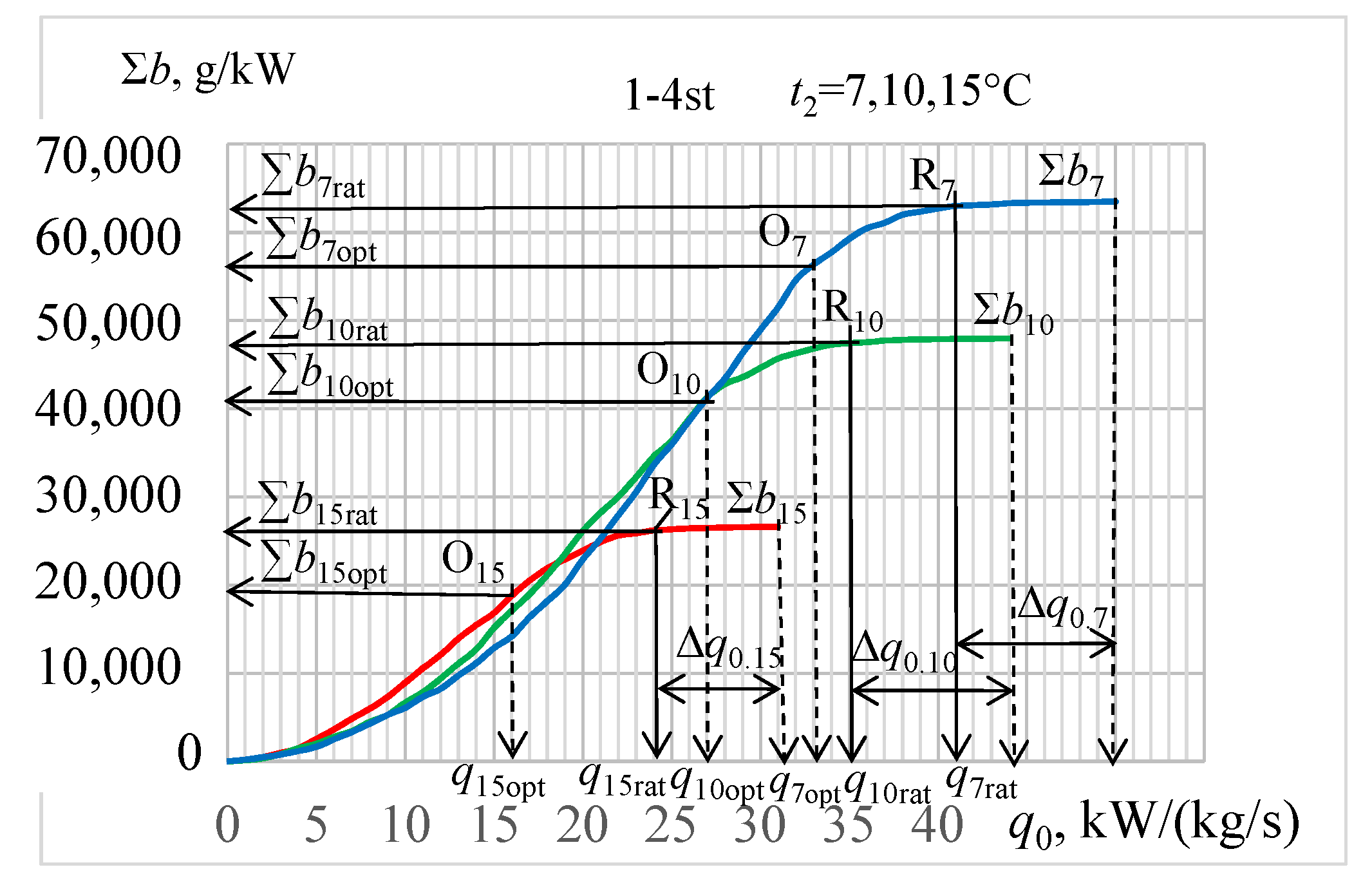

- annual total fuel reductionor annual specific fuel reduction (for 1 kW turbine power output)ΣB = ΣCDH (Δbe/Δt)∙PeΣb = ΣCDH (Δbe/Δt)

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AC | air cooler |

| ACHT | high-temperature air cooler |

| ACLT | low-temperature air cooler |

| ACh | absorption lithium-bromide chiller |

| AECh | absorption-ejector chiller |

| CAECh | cascade absorption-ejector chiller |

| CDH | cooling degree hour; CDH = Δt·τ |

| COP | coefficient of performance |

| ECh | ejector chiller |

| GT | gas turbine |

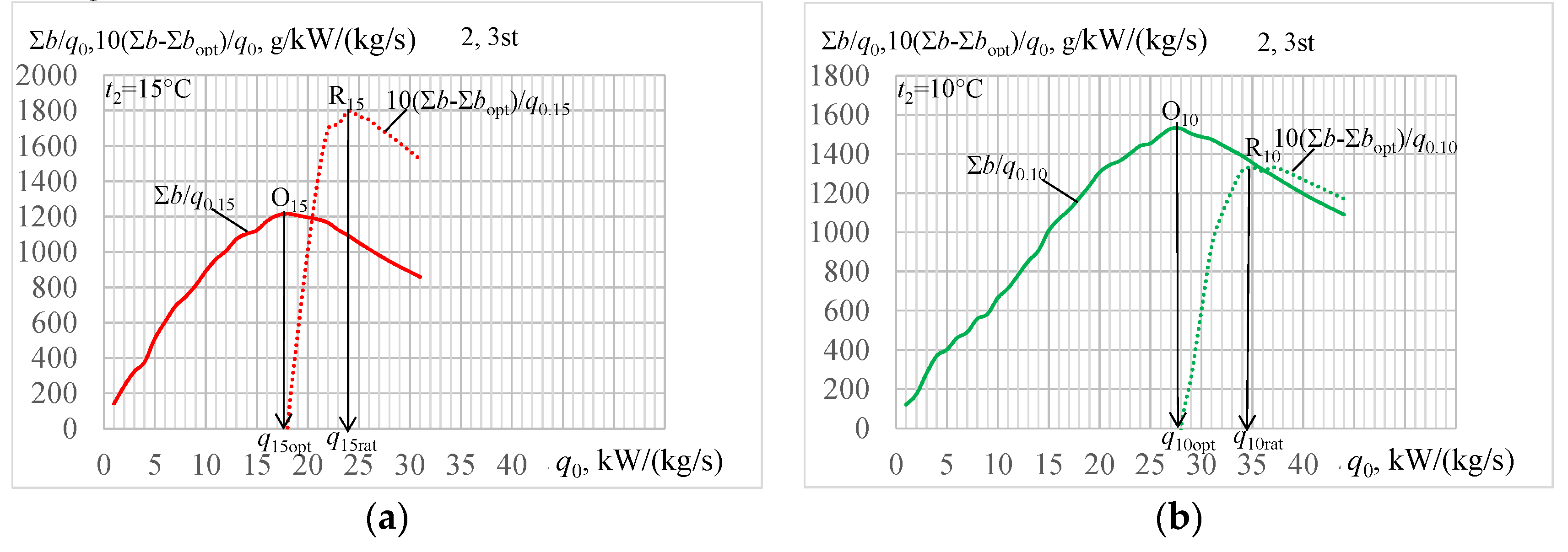

| O | optimal point for maximum rate of annual fuel reduction increment |

| R | rational point for close to maximum annual fuel reduction |

| SAECh | stage absorption-ejector chiller |

| SCAECh | stage-cascade absorption-ejector chiller |

| TIAC | turbine intake air cooling |

| Symbols | |

| B | total mass fuel consumption decrease, B = CDH (Δbe/Δt)∙Pe. |

| be | specific fuel consumption |

| ca | specific heat of humid air |

| CDH | CDH = Δt·τ |

| damb | ambient air absolute humidity |

| Ga | air mass flow rate |

| Pe | power output |

| Q0 | total cooling capacity, heat flow rate |

| q0 | specific cooling capacity—per unit air mass flow rate |

| t | temperature |

| tamb | ambient air temperature |

| ta2 | outlet air temperature |

| t0 | refrigerant boiling temperature |

| ξ | specific heat ratio of the total heat (latent and sensible) rejected from air to its sensible heat |

| τ | time interval |

| φamb | ambient air relative humidity |

| Δbe | specific fuel consumption decrease |

| Δt | air temperature decrease |

| ∑B7,10,15 | annual total fuel reduction due to cooling turbine intake air to temperatures 7, 10, 15 °C |

| ∑b7,10,15 | annual specific fuel reduction (per 1 kW turbine power output) due to cooling turbine intake air to temperatures 7, 10, 15 °C |

| Subscripts | |

| a | air |

| amb | ambient |

| max | maximum |

| opt | optimal |

| rat | rational |

Appendix A

References

- Tiwari, A.K.; Hasan, M.M.; Islam, M. Effect of Ambient Temperature on the Performance of a Combined Cycle Power Plant. Trans. Can. Soc. Mech. Eng. 2013, 37, 1177–1188. [Google Scholar] [CrossRef] [Green Version]

- Günnur, Ş.; Mustafa, N.; Hayati, M.; Halit, D.; Mustafa, K.; Mevlüt, K.; Fadıl, K.; Nuran, Y.; Mohammad, R.A.B. The effect of ambient temperature on electric power generation in natural gas combined cycle power plant—A case study. Energy Rep. 2018, 4, 682–690. [Google Scholar]

- Lin, A.; Sun, Y.; Zhang, H.; Lin, X.; Yang, L.; Zheng, Q. Fluctuating characteristics of air-mist mixture flow with conjugate wall-film motion in a compressor of gas turbine. Appl. Therm. Eng. 2018, 142, 779–792. [Google Scholar] [CrossRef]

- ISO 3046-1:2002. Reciprocating Internal Combustion Engines—Performance—Part 1: Declarations of Power, Fuel and Lubricating Oil Consumptions, and Test Methods—Additional Requirements for Engines for General Use; ISO: Geneva, Switzerland, 2014; Available online: https://www.iso.org/standard/28330.html (accessed on 14 June 2020).

- Payrhuber, K.; Trapp, C. GE’s New Jenbacher Gas Engines with 2-Stage Turbocharging. In Proceedings of the 7 Internationale Energiewirtschaftstagung an der TU Wien IEWT, Wien, Austria, 16–18 February 2011. 14p. [Google Scholar]

- Trapp, C.; Laiminger, S.; Chvatal, D.; Wimmer, A.; Schneßl, E.; Pirker, G. Die neue Gasmotorengeneration von GE Jenbacher—Mit zweistufiger Aufladung zu höchsten Wirkungsgraden. In Proceedings of the 32nd Internationales Wiener Motorensymposium, Wien, Austria, 5–6 May 2011. [Google Scholar]

- Radchenko, A.; Mikielewicz, D.; Forduy, S.; Radchenko, M.; Zubarev, A. Monitoring the Fuel Efficiency of Gas Engine in Integrated Energy System. In Proceedings of the Advances in Intelligent Systems and Computing, Kharkiv, Ukraine, 28–30 November 2019; Volume 1113, pp. 361–370. [Google Scholar]

- Farouk, N.; Sheng, L.; Hayat, Q. Effect of Ambient Temperature on the Performance of Gas Turbines Power Plant. Int. J. Comput. Sci. 2013, 10, 439–442. [Google Scholar]

- Baakeem, S.S.; Orfi, J.; Al Ansary, H. Performance of a Typical Simple Gas Turbine Unit under Saudi Weather Conditions. Int. J. Fluid Mechan. Therm. Sci. 2015, 1, 59–71. [Google Scholar]

- De Sa, A.; Al Zubaidy, S. Gas turbine performance at varying ambient temperature. Appl. Therm. Eng. 2011, 31, 2735–2739. [Google Scholar] [CrossRef]

- Shukla, A.K.; Singh, O. Thermodynamic investigation of parameters affecting the execution of steam injected cooled gas turbine based combined cycle power plant with vapor absorption inlet air cooling. Appl. Therm. Eng. 2017, 122, 380–388. [Google Scholar] [CrossRef]

- Al-Ibrahim, A.M.; Varnham, A. A review of inlet air-cooling technologies for enhancing the performance of combustion turbines in Saudi Arabia. Appl. Therm. Eng. 2010, 30, 1879–1888. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, Z.; Hao, H.; Chang, L. Application Research of Intake-Air Cooling Technologies in Gas-Steam Combined Cycle Power Plants in China. J. Power Energy Eng. 2014, 2, 304–311. [Google Scholar] [CrossRef]

- Chaker, M.; Meher-Homji, C.B. Inlet Fogging of Gas Turbine Engines: Climatic Analysis of Gas Turbine Evaporative Cooling Potential of International Locations. J. Eng. Gas Turbines Power 2006, 128, 815–825. [Google Scholar] [CrossRef]

- Saghafifar, M.; Gadalla, M. Analysis of Maisotsenko open gas turbine power cycle with a detailed air saturator model. Appl. Energy 2015, 149, 338–353. [Google Scholar] [CrossRef]

- Dizaji, H.S.; Hu, E.J.; Chen, L.; Pourhedayat, S. Using novel integrated Maisotsenko cooler and absorption chiller for cooling of gas turbine inlet air. Energy Convers. Manag. 2019, 195, 1067–1078. [Google Scholar] [CrossRef]

- Rocha, M.; Andreos, R.; Simões-Moreira, J.R. Performance tests of two small trigeneration pilot plants. Appl. Therm. Eng. 2012, 41, 84–91. [Google Scholar] [CrossRef]

- Freschi, F.; Giaccone, L.; Lazzeroni, P.; Repetto, M. Economic and environmental analysis of a trigeneration system for food-industry: A case study. Appl. Energy 2013, 107, 157–172. [Google Scholar] [CrossRef]

- Marques, R.P.; Hacon, D.; Tessarollo, A.; Parise, J.A.R. Thermodynamic analysis of tri-generation systems taking into account refrigeration, heating and electricity load demands. Energy Build. 2010, 42, 2323–2330. [Google Scholar] [CrossRef]

- Ortiga, J.; Bruno, J.C.; Coronas, A. Operational optimization of a complex trigeneration system connected to a district heating and cooling network. Appl. Therm. Eng. 2013, 50, 1536–1542. [Google Scholar] [CrossRef]

- Dr. Fromme International Consulting. Cogeneration & Trigeneration—How to Produce Energy Efficiently: A Practical Guide for Experts in Emerging and Developing Economies, GIZ GmbH, Germany; Dr. Fromme International Consulting: Essen, Germany, 2016; 144p, Available online: https://www.dfic.de/images/pdf/cogeneration-trigeneration-guide.pdf (accessed on 14 June 2020).

- Muszyński, T.; Mikielewicz, D. Comparison of heat transfer characteristics in surface cooling with boiling microjets of water, ethanol and HFE7100. Appl. Therm. Eng. 2016, 93, 1403–1409. [Google Scholar] [CrossRef] [Green Version]

- Chacartegui, R.; Jiménez-Espadafor, F.; Sánchez, D.; Sánchez, T. Analysis of combustion turbine inlet air cooling systems applied to an operating cogeneration power plant. Energy Convers. Manag. 2008, 49, 2130–2141. [Google Scholar] [CrossRef]

- Khaliq, A.; Dincer, I.; Sharma, P.B. Development and analysis of industrial waste heat based trigeneration for combined production of power heat and cold. J. Energy Inst. 2010, 83, 79–85. [Google Scholar] [CrossRef]

- Popli, S.; Rodgers, P.; Eveloy, V. Trigeneration scheme for energy efficiency enhancement in a natural gas processing plant through turbine exhaust gas waste heat utilization. Appl. Energy 2012, 93, 624–636. [Google Scholar] [CrossRef]

- Popli, S.; Rodgers, P.; Eveloy, V. Gas turbine efficiency enhancement using waste heat powered absorption chillers in the oil and gas industry. Appl. Therm. Eng. 2013, 50, 918–931. [Google Scholar] [CrossRef]

- Ameri, M.; Hejazi, S. The study of capacity enhancement of the Chabahar gas turbine installation using an absorption chiller. Appl. Therm. Eng. 2004, 24, 59–68. [Google Scholar] [CrossRef]

- Ehyaei, M.A.; Hakimzadeh, S.; Enadi, N.; Ahmadi, P. Exergy, economic and environment (3E) analysis of absorption chiller inlet air cooler used in gas turbine power plants. Int. J. Energy Res. 2011, 36, 486–498. [Google Scholar] [CrossRef]

- Andi, B.; Venkatesan, J.; Suresh, S.; Mariappan, V. Experimental Analysis of Triple Fluid Vapour Absorption Refrigeration System Driven by Electrical Energy and Engine Waste Heat. Therm. Sci. 2019, 23, 2995–3001. [Google Scholar]

- Elberry, M.; Elsayed, A.; Teamah, M.; Abdel-Rahman, A.; Elsafty, A. Performance improvement of power plants using absorption cooling system. Alex. Eng. J. 2018, 57, 2679–2686. [Google Scholar] [CrossRef]

- Umberto, L. Adsorber efficiency in adsorbtion refrigeration. Renew. Sustain. Energy Rev. 2013, 20, 570–575. [Google Scholar]

- Sur, A.; Das, R.; Sah, R. Influence of initial bed temperature on bed performance of an adsorption refrigeration system. Therm. Sci. 2018, 22, 2583–2595. [Google Scholar] [CrossRef]

- Suamir, I.; Tassou, S. Performance evaluation of integrated trigeneration and CO2 refrigeration systems. Appl. Therm. Eng. 2013, 50, 1487–1495. [Google Scholar] [CrossRef]

- Bohdal, T.; Kuczynski, W. Boiling of R404A Refrigeration Medium Under the Conditions of Periodically Generated Disturbances. Heat Transf. Eng. 2011, 32, 359–368. [Google Scholar] [CrossRef]

- Bohdal, T.; Sikora, M.; Widomska, K.; Radchenko, A.M. Investigation of flow structures during HFE-7100 refrigerant condensation. Arch. Thermodyn. 2015, 36, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Kuczyński, W.; Charun, H. Experimental investigations into the impact of the void fraction on the condensation characteristics of R134a refrigerant in minichannels under conditions of periodic instability. Arch. Thermodyn. 2011, 32, 21–37. [Google Scholar] [CrossRef]

- Kuczyski, W.; Charun, H.; Bohdal, T.; Kuczynski, W. Influence of hydrodynamic instability on the heat transfer coefficient during condensation of R134a and R404A refrigerants in pipe mini-channels. Int. J. Heat Mass Transf. 2012, 55, 1083–1094. [Google Scholar] [CrossRef]

- Radchenko, M.; Mikielewicz, D.; Tkachenko, V.; Klugmann, M.; Andreev, A. Enhancement of the Operation Efficiency of the Transport Air Conditioning System. In Proceedings of the Lecture Notes in Mechanical Engineering, Kharkiv, Ukraine, 9–12 June 2020; pp. 332–342. [Google Scholar]

- Trushliakov, E.; Radchenko, M.; Bohdal, T.; Radchenko, R.; Kantor, S. An Innovative Air Conditioning System for Changeable Heat Loads. In Proceedings of the Lecture Notes in Mechanical Engineering, Odessa, Ukraine, 10–13 September 2019; pp. 616–625. [Google Scholar]

- Mikielewicz, D.; Wajs, J. Performance of the very high-temperature heat pump with low GWP working fluids. Energy 2020, 182, 460–470. [Google Scholar] [CrossRef]

- Forduy, S.; Radchenko, A.M.; Kuczynski, W.; Zubarev, A.; Konovalov, D. Enhancing the Gas Engines Fuel Efficiency in Integrated Energy System by Chilling Cyclic Air. In Proceedings of the Lecture Notes in Mechanical Engineering, Kharkiv, Ukraine, 9–12 June 2020; pp. 500–509. [Google Scholar]

- Butrymowicz, D.; Gagan, J.; Śmierciew, K.; Łukaszuk, M.; Dudar, A.; Pawluczuk, A.; Łapiński, A.; Kuryłowicz, A. Investigations of prototype ejection refrigeration system driven by low grade heat. E3S Web Conf. 2018, 70, 03002. [Google Scholar] [CrossRef]

- Elbel, S.; Lawrence, N. Review of recent developments in advanced ejector technology. Int. J. Refrig. 2016, 62, 1–18. [Google Scholar] [CrossRef]

- Lawrence, N.; Elbel, S. Experimental investigation of a two-phase ejector cycle suitable for use with low-pressure refrigerants R134a and R1234yf. Int. J. Refrig. 2014, 38, 310–322. [Google Scholar] [CrossRef]

- Radchenko, R.; Kornienko, V.; Pyrysunko, M.; Bogdanov, M.; Andreev, A. Enhancing the Efficiency of Marine Diesel Engine by Deep Waste Heat Recovery on the Base of Its Simulation Along the Route Line. In Proceedings of the Advances in Intelligent Systems and Computing, Kharkiv, Ukraine, 28–30 November 2019; Volume 1113, pp. 337–350. [Google Scholar]

- Kornienko, V.; Radchenko, M.; Radchenko, R.; Konovalov, D.; Andreev, A.; Pyrysunko, M. Improving the efficiency of heat recovery circuits of cogeneration plants with combustion of water-fuel emulsions. Therm. Sci. 2020, 154. [Google Scholar] [CrossRef] [Green Version]

- Konovalov, D.; Trushliakov, E.; Radchenko, M.; Kobalava, H.; Maksymov, V. Research of the Aerothermopressor Cooling System of Charge Air of a Marine Internal Combustion Engine Under Variable Climatic Conditions of Operation. In Proceedings of the Grabchenko’s International Conference on Advanced Manufacturing Processes, Odessa, Ukraine, 10–13 September 2019; pp. 520–529. [Google Scholar]

- Konovalov, D.; Kobalava, H.; Maksymov, V.; Radchenko, R.; Avdeev, M. Experimental Research of the Excessive Water Injection Effect on Resistances in the Flow Part of a Low-Flow Aerothermopressor. In Proceedings of the Advances in Design, Simulation and Manufacturing III, Kharkiv, Ukraine, 9–12 June 2020; pp. 292–301. [Google Scholar]

- Kornienko, V.; Radchenko, R.; Stachel, A.; Andreev, A.; Pyrysunko, M. Correlations for Pollution on Condensing Surfaces of Exhaust Gas Boilers with Water-Fuel Emulsion Combustion. In Proceedings of the Grabchenko’s International Conference on Advanced Manufacturing Processes, Odessa, Ukraine, 10–13 September 2019; pp. 530–539. [Google Scholar]

- Kornienko, V.; Radchenko, R.; Konovalov, D.; Andreev, A.; Pyrysunko, M. Characteristics of the Rotary Cup Atomizer Used as Afterburning Installation in Exhaust Gas Boiler Flue. In Proceedings of the Advances in Design, Simulation and Manufacturing III, Kharkiv, Ukraine, 9–12 June 2020; pp. 302–311. [Google Scholar]

- Trushliakov, E.; Radchenko, A.; Radchenko, M.; Kantor, S.; Zielikov, O. The Efficiency of Refrigeration Capacity Regulation in the Ambient Air Conditioning Systems. In Proceedings of the Advances in Design, Simulation and Manufacturing III, Kharkiv, Ukraine, 9–12 June 2020; pp. 343–353. [Google Scholar]

- Mikielewicz, D.; Kosowski, K.; Tucki, K.; Piwowarski, M.; Stępień, R.; Orynycz, O.; Włodarski, W. Gas Turbine Cycle with External Combustion Chamber for Prosumer and Distributed Energy Systems. Energies 2019, 12, 3501. [Google Scholar] [CrossRef] [Green Version]

- Wajs, J.; Mikielewicz, D.; Jakubowska, B. Performance of the domestic micro ORC equipped with the shell-and-tube condenser with minichannels. Energy 2018, 157, 853–861. [Google Scholar] [CrossRef]

- Leonzio, G. An innovative trigeneration system using biogas as renewable energy. Chin. J. Chem. Eng. 2018, 26, 1179–1191. [Google Scholar] [CrossRef]

- Maraver, D.; Sin, A.; Royo, J.; Sebastián, F. Assessment of CCHP systems based on biomass combustion for small-scale applications through a review of the technology and analysis of energy efficiency parameters. Appl. Energy 2013, 102, 1303–1313. [Google Scholar] [CrossRef]

- Cherednichenko, O.; Havrysh, V.; Shebanin, V.; Kalinichenko, A.; Mentel, G.; Nakonieczny, J. Local Green Power Supply Plants Based on Alcohol Regenerative Gas Turbines: Economic and Environmental Aspects. Energies 2020, 13, 2156. [Google Scholar] [CrossRef]

- Cherednichenko, O.; Mitienkova, V. Analysis of the Impact of Thermochemical Recuperation of Waste Heat on the Energy Efficiency of Gas Carriers. J. Mar. Sci. Appl. 2020, 19, 72–82. [Google Scholar] [CrossRef]

- Mikielewicz, D.; Wajs, J.; Andrzejczyk, R.; Klugmann, M. Pressure drop of HFE7000 and HFE7100 during flow condensation in minichannels. Int. J. Refrig. 2016, 68, 226–241. [Google Scholar] [CrossRef]

- Yang, C.; Yang, Z.; Cai, R. Analytical method for evaluation of gas turbine inlet air cooling in combined cycle power plant. Appl. Energy 2009, 86, 848–856. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Zare, V.; Ranjbar, F.; Farshi, L.G. Energy and Exergy Analysis of Simple and Regenerative Gas Turbines Inlet Air Cooling Using Absorption Refrigeration. J. Appl. Sci. 2009, 9, 2399–2407. [Google Scholar] [CrossRef]

- Chaker, M.; Meher-Homji, C.B.; Mee, T.; Nicholson, A. Inlet Fogging of Gas Turbine Engines Detailed Climatic Analysis of Gas Turbine Evaporation Cooling Potential in the USA. J. Eng. Gas Turbines Power 2002, 125, 300–309. [Google Scholar] [CrossRef]

- Coskun, C.; Demiral, D.; Ertürk, M.; Oktay, Z. Modified Degree-Hour Calculation Method. Available online: http://www.intechopen.com/books/solar-power/modified-degree-hour-calculation-method (accessed on 10 June 2020).

- Forsyth, J.L. Gas turbine inlet air chilling for LNG. In Proceedings of the IGT International Liquefied Natural Gas Conference, Houston, TX, USA, 6–19 April 2013; Volume 3, pp. 1763–1778. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-84904725071&origin=inward&txGid=b9d07662f250f4a4511cbfc9c242297a (accessed on 10 June 2020).

- Kalhori, S.B.; Rabiei, H.; Mansoori, Z. Mashad trigeneration potential—An opportunity for CO2 abatement in Iran. Energy Conv. Manag. 2012, 60, 106–114. [Google Scholar] [CrossRef]

- Canova, A.; Cavallero, C.; Freschi, F. Optimal energy management. IEEE Ind. Appl. Mag. 2009, 15, 62–65. [Google Scholar] [CrossRef]

- Rodriguez-Aumente, P.A.; Rodriguez-Hidalgo, M.D.C.; Nogueira, J.I.; Lecuona, A.; Venegas, M.D.C. District heating and cooling for business buildings in Madrid. Appl. Therm. Eng. 2013, 50, 1496–1503. [Google Scholar] [CrossRef]

- Kavvadias, K.; Maroulis, Z. Multi-objective optimization of a trigeneration plant. Energy Policy 2010, 38, 945–954. [Google Scholar] [CrossRef]

- Lozano, M.A.; Ramos, J.C.; Serra, L.M. Cost optimization of the design of CHCP (combined heat, cooling and power) systems under legal constraints. Energy 2010, 35, 794–805. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, M.; Trushliakov, E.; Kantor, S.; Tkachenko, V. Statistical Method to Define Rational Heat Loads on Railway Air Conditioning System for Changeable Climatic Conditions. In Proceedings of the 5th International Conference on Systems and Informatics (ICSAI), Nanjing, China, 10–12 November 2018; pp. 1294–1298. [Google Scholar]

- Radchenko, M.; Radchenko, R.; Tkachenko, V.; Kantor, S.; Smolyanoy, E. Increasing the Operation Efficiency of Railway Air Conditioning System on the Base of Its Simulation Along the Route Line. In Proceedings of the Advances in Intelligent Systems and Computing, Kharkiv, Ukraine, 28–30 November 2019; Volume 1113, pp. 461–467. [Google Scholar]

- Radchenko, A.; Bohdal, Ł.; Zongming, Y.; Portnoi, B.; Tkachenko, V. Rational Designing of Gas Turbine Inlet Air Cooling System. In Proceedings of the Grabchenko’s International Conference on Advanced Manufacturing Processes, Odessa, Ukraine, 10–13 September 2019; pp. 591–599. [Google Scholar]

- Reynolds, O., IV. On the dynamical theory of incompressible viscous fluids and the determination of the criterion. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1895, 186, 123–164. [Google Scholar] [CrossRef]

- Hewitt, G.; Govan, A. Phenomenological modelling of non-equilibrium flows with phase change. Int. J. Heat Mass Transf. 1990, 33, 229–242. [Google Scholar] [CrossRef]

- Available online: http://www.meteomanz.com (accessed on 12 June 2020).

- GPF Software. Available online: https://www.guentner.eu/know-how/product-calculator-gpc/gpc-software/ (accessed on 10 June 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radchenko, A.; Trushliakov, E.; Kosowski, K.; Mikielewicz, D.; Radchenko, M. Innovative Turbine Intake Air Cooling Systems and Their Rational Designing. Energies 2020, 13, 6201. https://doi.org/10.3390/en13236201

Radchenko A, Trushliakov E, Kosowski K, Mikielewicz D, Radchenko M. Innovative Turbine Intake Air Cooling Systems and Their Rational Designing. Energies. 2020; 13(23):6201. https://doi.org/10.3390/en13236201

Chicago/Turabian StyleRadchenko, Andrii, Eugeniy Trushliakov, Krzysztof Kosowski, Dariusz Mikielewicz, and Mykola Radchenko. 2020. "Innovative Turbine Intake Air Cooling Systems and Their Rational Designing" Energies 13, no. 23: 6201. https://doi.org/10.3390/en13236201