CNT Conductive Epoxy Composite Metamaterials: Design, Fabrication, and Characterization

Abstract

1. Introduction

1.1. Electromagnetic Interference (EMI) Shielding

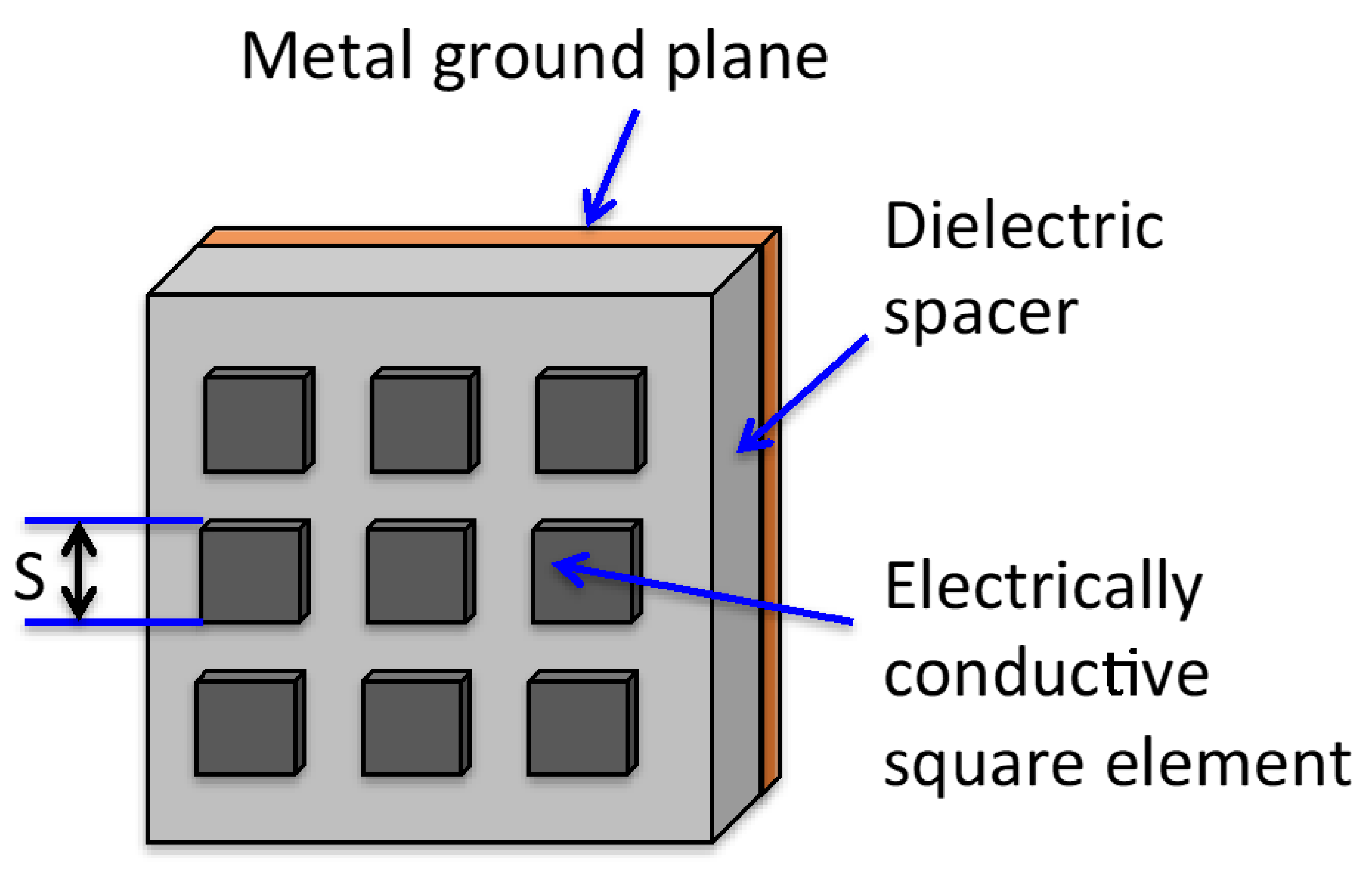

1.2. Metamaterials as EM Absorbers

1.3. CNT Composites in EMI Uses and Microwave Absorption Studies

2. Materials and Methods

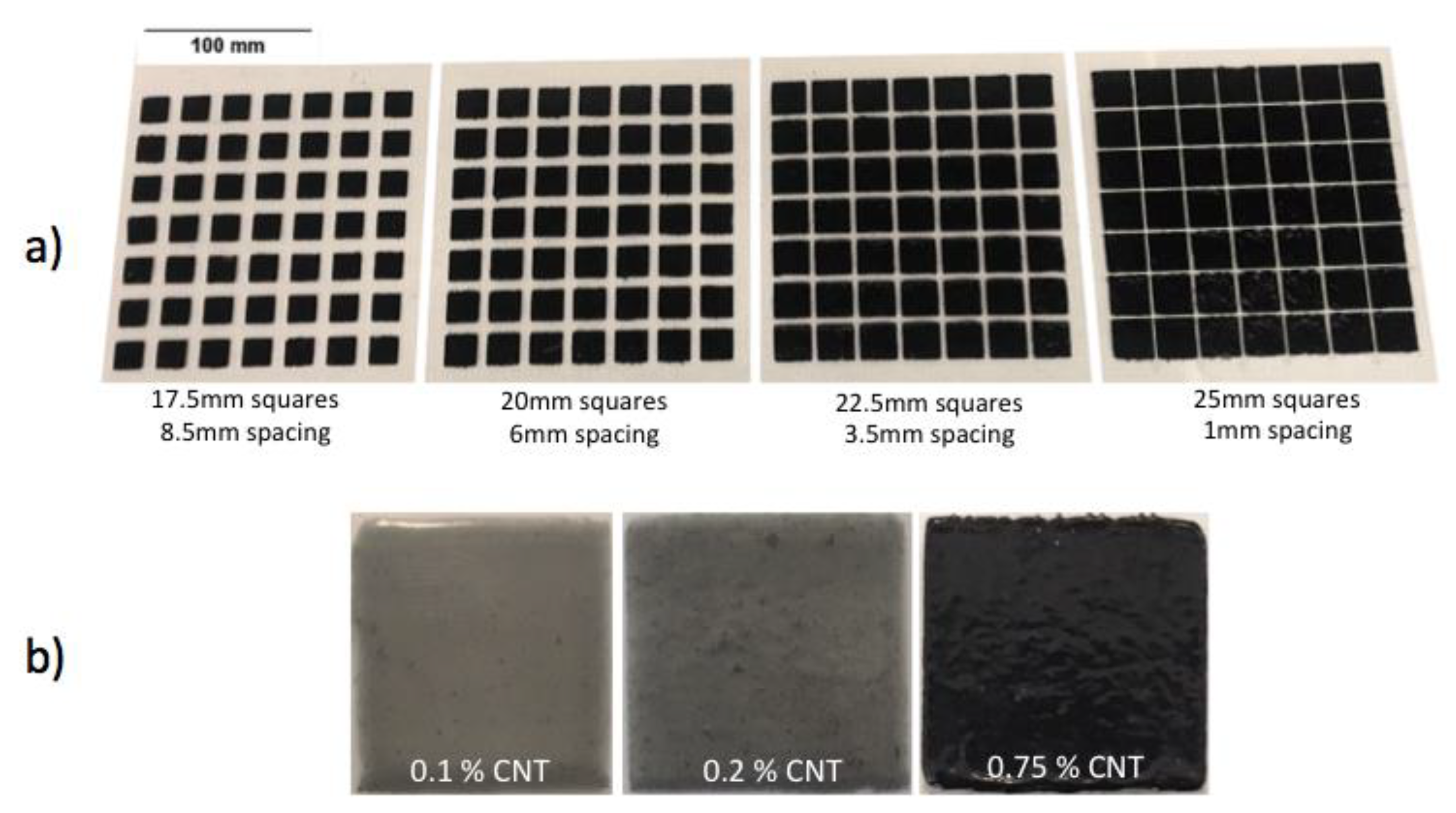

2.1. Fabrication

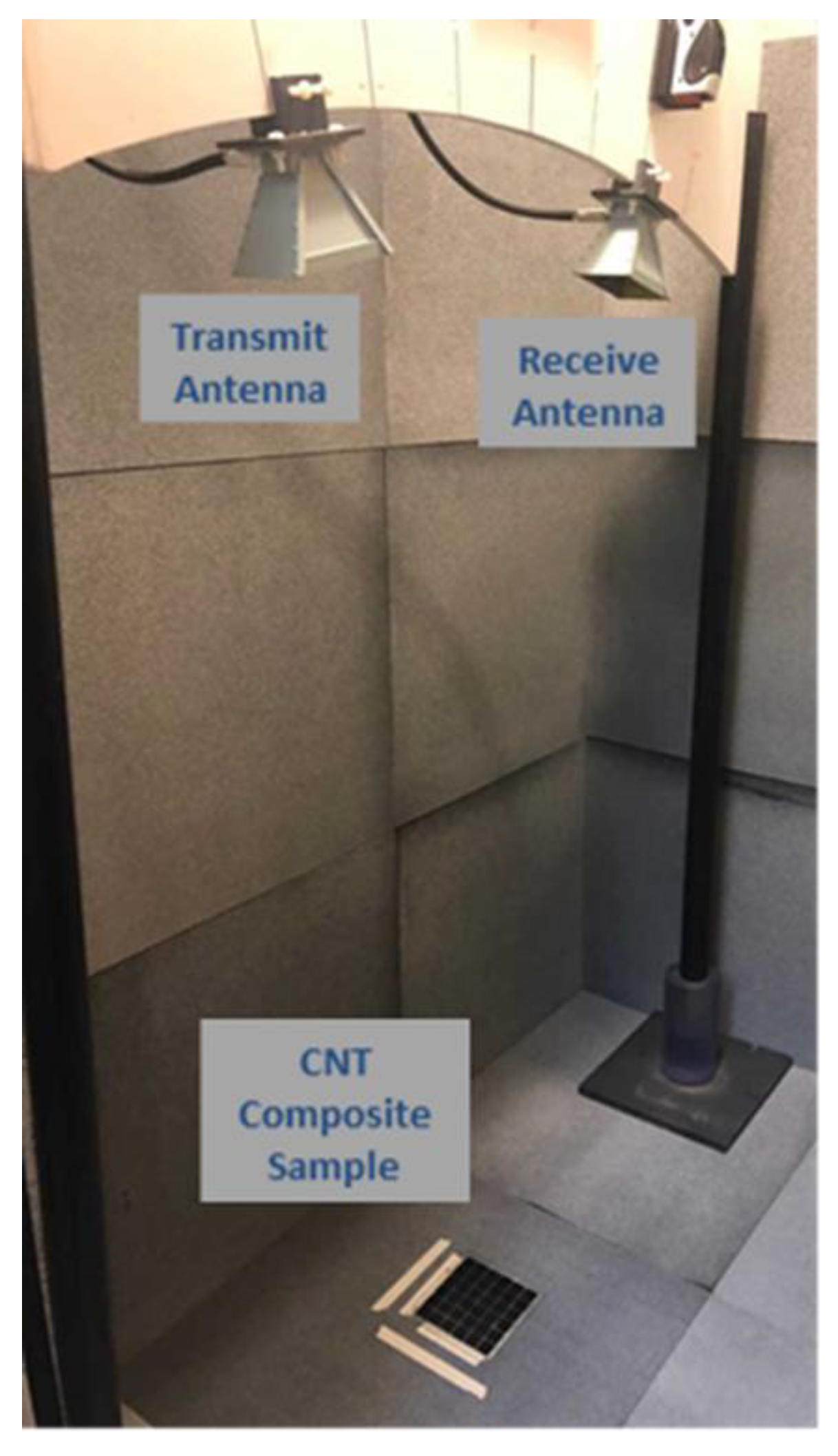

2.2. Microstructural and Electrical Characterization

2.3. Optical Characterization

3. Finite Element Modeling Parameters

4. Results and Discussion

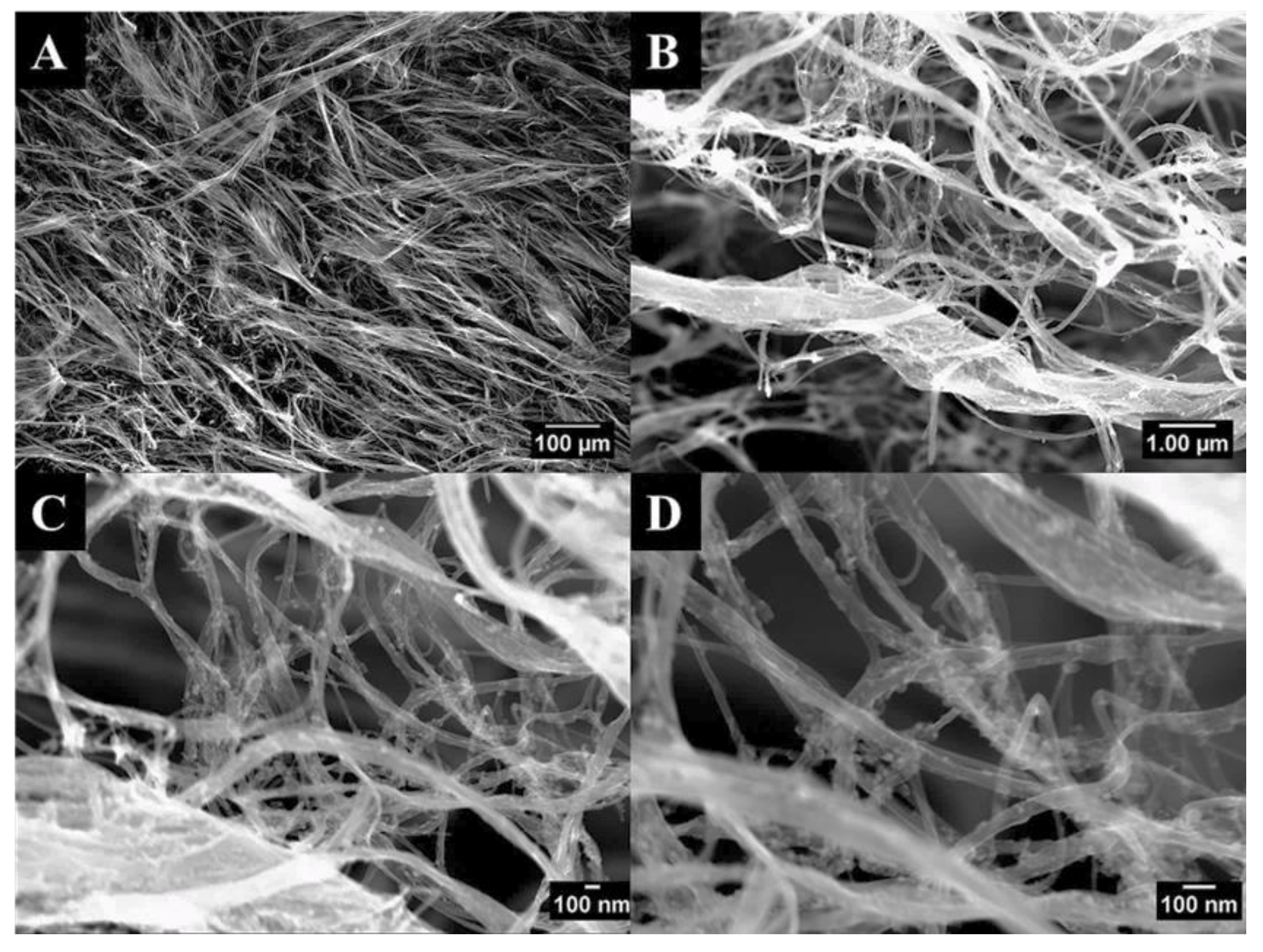

4.1. CNT Epoxy Composites Microstructural Characterization

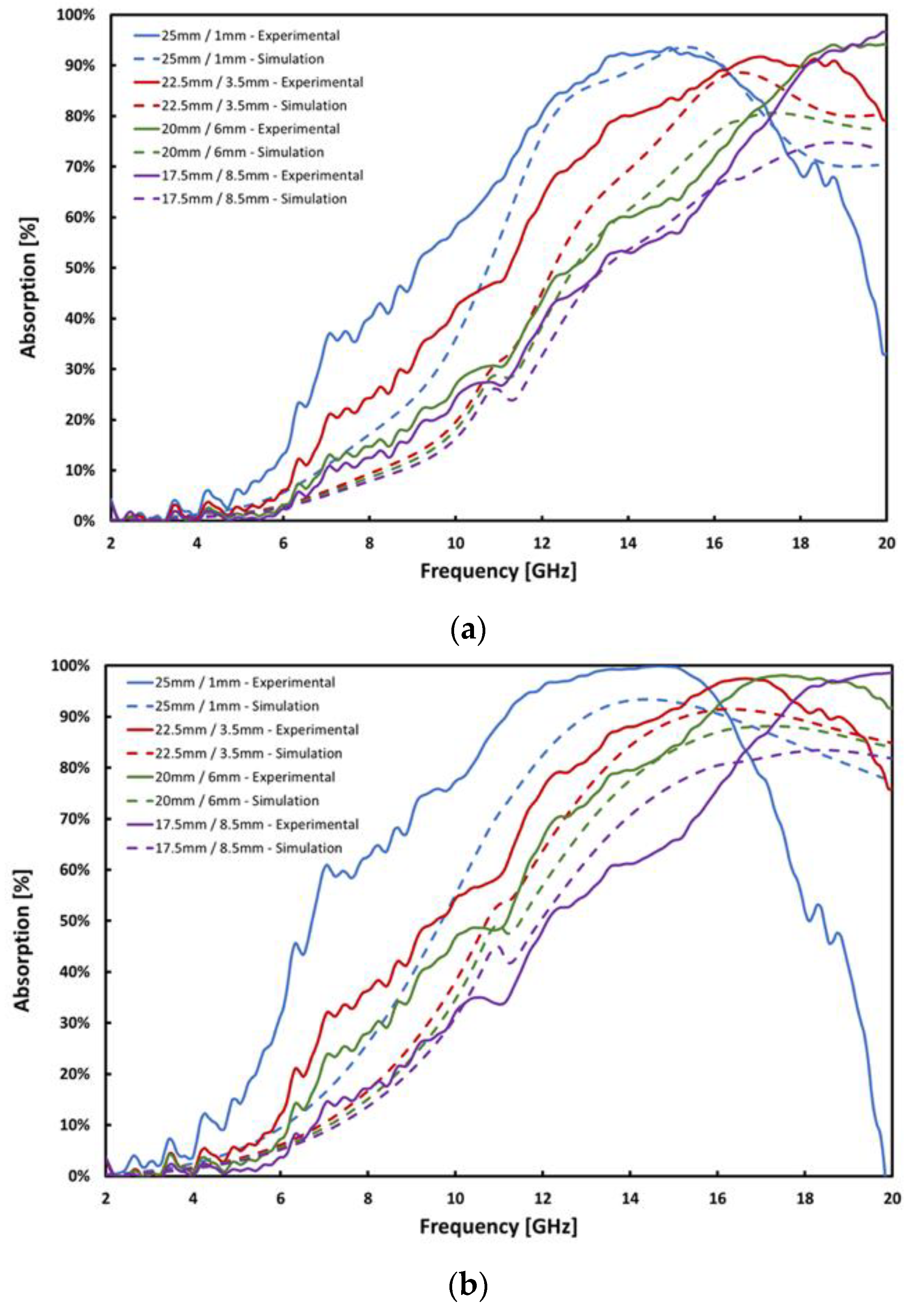

4.2. Optical Characterization of CNT Epoxy Metamaterials

4.3. Finite Element Model Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sunitha, J.N. Development and Evaluation of Electrically Conductive Polymer Composites and Their Characterization. Ph.D. Thesis, University of Mysore, Karnataka, India, 2016. [Google Scholar]

- Thomassin, J.-M.; Jérôme, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R: Rep. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Singh, A.K.; Shishkin, A.; Koppel, T.; Gupta, N. A review of porous lightweight composite materials for electromagnetic interference shielding. Compos. Part B: Eng. 2018, 149, 188–197. [Google Scholar] [CrossRef]

- Saini, P.; Choudhary, V.; Singh, B.; Mathur, R.; Dhawan, S. Polyaniline–MWCNT nanocomposites for microwave absorption and EMI shielding. Mater. Chem. Phys. 2009, 113, 919–926. [Google Scholar] [CrossRef]

- Mohammed, J.; Carol, T.T.T.; Hafeez, H.; Basandrai, D.; Bhadu, G.R.; Godara, S.K.; Narang, S.; Srivastava, A. Electromagnetic interference (EMI) shielding, microwave absorption, and optical sensing properties of BaM/CCTO composites in Ku-band. Results Phys. 2019, 13, 102307. [Google Scholar] [CrossRef]

- Munir, A. Microwave Radar Absorbing Properties of Multiwalled Carbon Nanotubes Polymer Composites: A Review. Adv. Polym. Technol. 2015, 36, 362–370. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, G.-L. Microwave Absorption Properties of Carbon Nanotubes-Epoxy Composites in a Frequency Range of 2–20 GHz. Open J. Compos. Mater. 2013, 3, 17–23. [Google Scholar] [CrossRef]

- Center for Metamaterials and Integrated Plasmonics, Homepage. Available online: http://metamaterials.duke.edu/ (accessed on 20 September 2020).

- McMahan, M.T. Metamaterial Absorbers for Microwave Detection. Master’s Thesis, Department of Physics, Naval Postgraduate School, Monterey, CA, USA, 2015. [Google Scholar]

- Hewitt, C.; Alves, F.; Luscombe, J.; Grbovic, D. Application of equivalent medium parameters in finite element models of microwave metamaterials. J. Appl. Phys. 2018, 123, 115101. [Google Scholar] [CrossRef]

- Wakatsuchi, H.; Kim, S.; Rushton, J.J.; Sievenpiper, D.F. Waveform-Dependent Absorbing Metasurfaces. Phys. Rev. Lett. 2013, 111, 245501. [Google Scholar] [CrossRef]

- Kim, S.; Shrekenhamer, D.; Will, J.; Awadallah, R.; Miragliotta, J. High impedance holographic metasurfaces for conformal and high gain antenna applications. In Proceedings of the 2018 15th IEEE Annual Consumer Communications & Networking Conference (CCNC), Las Vegas, NV, USA, 12–15 January 2018; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Ozturk, Y.; Yilmaz, A. Multiband and Perfect Absorber with Circular Fishnet Metamaterial and its Variations. Appl. Computational Electromagnetics Soc. J. 2016, 31, 12. [Google Scholar]

- Tütüncü, B.; Torpi, H.; Urul, B. A comparative study on different types of metamaterials for enhancement of microstrip patch antenna directivity at the Ku-band (12 GHz). Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 1171–1179. [Google Scholar] [CrossRef]

- Mattish, R.; Alves, F.; Grbovic, D. Using homogeneous equivalent parameters in finite element models of curved metamaterial structures. Prog. Electromagn. Res. Lett. 2018, 79, 103–108. [Google Scholar] [CrossRef]

- Alves, F.; Kearney, B.; Grbovic, D.; Lavrik, N.V.; Karunasiri, G. Strong terahertz absorption using SiO2/Al based metamaterial structures. Appl. Phys. Lett. 2012, 100, 111104. [Google Scholar] [CrossRef]

- Grbovic, D.; Alves, F.; Kearney, B.; Waxer, B.; Perez, R.; Omictin, G. Metal-organic hybrid resonant terahertz absorbers with SU-8 photoresist dielectric layer. J. Micro/Nanolithography, MEMS, MOEMS 2013, 12, 041204. [Google Scholar] [CrossRef][Green Version]

- Kearney, B.; Alves, F.; Grbovic, D.; Karunasiri, G. Al/SiOx/Al single and multiband metamaterial absorbers for terahertz sensor applications. Opt. Eng. 2013, 52, 013801. [Google Scholar] [CrossRef][Green Version]

- Leader Tech Inc. The Three Most Popular EMI Shielding Metals and What You Should Know about Them—LeaderTech Inc. Blog. Available online: http://leadertechinc.com/blog/the-three-most-popular-shielding-metals-and-what-you-should-know-about-them (accessed on 26 August 2020).

- Chung, D. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Aqel, A.; El-Nour, K.M.A.; Ammar, R.A.; Al-Warthan, A. Carbon nanotubes, science and technology part (I) structure, synthesis and characterisation. Arab. J. Chem. 2012, 5, 1–23. [Google Scholar] [CrossRef]

- Alothman, Z.A.; Wabaidur, S.M. Application of carbon nanotubes in extraction and chromatographic analysis: A review. Arab. J. Chem. 2019, 12, 633–651. [Google Scholar] [CrossRef]

- Park, S.-H.; Theilmann, P.T.; Asbeck, P.M.; Bandaru, P.R. Enhanced Electromagnetic Interference Shielding Through the Use of Functionalized Carbon-Nanotube-Reactive Polymer Composites. IEEE Trans. Nanotechnol. 2009, 9, 464–469. [Google Scholar] [CrossRef]

- Gaier, J.R. New materials for EMI shielding. In Proceedings of the International Symposium on Electromagnetic Compatibility, Tokyo, Japan, 2–6 August 1999. [Google Scholar]

- Savi, P.; Giorcelli, M.; Quaranta, S. Multi-Walled Carbon Nanotubes Composites for Microwave Absorbing Applications. Appl. Sci. 2019, 9, 851. [Google Scholar] [CrossRef]

- Li, N.; Huang, Y.; Du, F.; He, X.; Lin, X.; Gao, H.; Ma, Y.; Li, F.; Chen, Y.; Eklund, P.C. Electromagnetic Interference (EMI) Shielding of Single-Walled Carbon Nanotube Epoxy Composites. Nano Lett. 2006, 6, 1141–1145. [Google Scholar] [CrossRef]

- Zhang, W.; Dehghani-Sanij, A.A.; Blackburn, R.S. Carbon based conductive polymer composites. J. Mater. Sci. 2007, 42, 3408–3418. [Google Scholar] [CrossRef]

- Bellucci, S.; Balasubramanian, C.; Micciulla, F.; Rinaldi, G. CNT composites for aerospace applications. J. Exp. Nanosci. 2007, 2, 193–206. [Google Scholar] [CrossRef]

- Nanowerk Carbon Nanotubes—What They Are, How They Are Made, What They Are Used for. Available online: https://www.nanowerk.com/nanotechnology/introduction/introduction_to_nanotechnology_22.php (accessed on 26 August 2020).

- Pang, H.; Xu, L.; Yan, D.-X.; Li, Z.-M. Conductive polymer composites with segregated structures. Prog. Polym. Sci. 2014, 39, 1908–1933. [Google Scholar] [CrossRef]

- Resistivity. Available online: https://eng.libretexts.org/Bookshelves/Materials_Science/Supplemental_Modules_(Materials_Science)/Electronic_Properties/Resistivity (accessed on 26 August 2020).

- Che, B.D.; Nguyen, B.Q.; Nguyen, L.-T.T.; Nguyen, H.T.; Nguyen, V.Q.; Van Le, T.; Nguyen, N.H. The impact of different multi-walled carbon nanotubes on the X-band microwave absorption of their epoxy nanocomposites. Chem. Central J. 2015, 9, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Earp, B.; Simpson, J.; Phillips, J.; Grbovic, D.; Vidmar, S.; McCarthy, J.; Luhrs, C.C. Electrically Conductive CNT Composites at Loadings below Theoretical Percolation Values. Nanomaterials 2019, 9, 491. [Google Scholar] [CrossRef] [PubMed]

- Sandler, J.; Shaffer, M.; Prasse, T.; Bauhofer, W.; Schulte, K.; Windle, A. Development of a dispersion process for carbon nanotubes in an epoxy matrix and the resulting electrical properties. Polymer 1999, 40, 5967–5971. [Google Scholar] [CrossRef]

- Park, C.; Ounaies, Z.; Watson, K.A.; Pawlowski, K.; Lowther, S.E.; Connell, J.W.; Siochi, E.J.; Harrison, J.S.; Clair, T.L.S. Polymer-Single Wall Carbon Nanotube Composites for Potential Spacecraft Applications. In Proceedings of the MRS Symposium Z – Making Functional Materials with Nanotubes, Boston, MA, USA, 26–29 November 2001; Cambridge University Press (CUP): Cambridge, UK, 2001; Volume 706. [Google Scholar]

- Earp, B.; Phillips, J.; Grbovic, D.; Vidmar, S.; Porter, M.; Luhrs, C.C. Impact of Current and Temperature on Extremely Low Loading Epoxy-CNT Conductive Composites. Polymer 2020, 12, 867. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Martin, C.; Sandler, J.; Shaffer, M.S.P.; Schwarz, M.-K.; Bauhofer, W.; Schulte, K.; Windle, A. Formation of percolating networks in multi-wall carbon-nanotube–epoxy composites. Compos. Sci. Technol. 2004, 64, 2309–2316. [Google Scholar] [CrossRef]

- Sandler, J.; Kirk, J.; Kinloch, I.; Shaffer, M.; Windle, A. Ultra-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- Nanocomp. Technologies Nanocomp Technologies’ Products, Dispersed Products. Available online: https://www.miralon.com/dispersed-products (accessed on 21 January 2020).

- Sundarram, S.; Kim, Y.-H.; Li, W. Preparation and characterization of poly(ether imide) nanocomposites and nanocomposite foams. In Manufacturing of Nanocomposites with Engineering Plastics; Elsevier BV: Amsterdam, The Netherlands, 2015; pp. 61–85. [Google Scholar]

- Musil, J.; Žáček, F. Microwave Measurements of Complex Permittivity by Free Space Methods and Their Applications; Elsevier: Amsterdam, The Netherlands, 1986. [Google Scholar]

- Wilson, R. Reflection and Transmission Losses through Common Building Materials. In Propagation Losses through Common Building Materials 2.4 GHz vs 5 GHz; Crawford, J.A., Ed.; Magis Network Inc.: San Diego, CA, USA, 2002. [Google Scholar]

| 0.10% CNT/EA9396 | 0.20% CNT/EA9396 | |

|---|---|---|

| Composite conductivity [S/m] | 0.461 | 0.862 |

| Composite relative permittivity | 35 | 30 |

| Composite thickness [mm] | 0.2 | |

| Acrylic board thickness [mm] | 1.5 | |

| Acrylic refractive index | 1.7 | |

| Acrylic extinction coefficient | 1 | |

| Material | CNT Weight (%) | Absorption [%] | Total Thickness [mm] | Conductivity [S/m] |

|---|---|---|---|---|

| CNT/PANI composite [4] | 25 | 6.3 | 1.5 | 2 × 103 |

| MWCNT/Aero Marine 300/21 [7] | 8 | 26 | 2 | Not reported |

| Nanocyl NC7000 CNT/epoxy [32] | 0.25 | 99 | 2–3 | 3.87 × 107 |

| Resonant metamaterial (Current work) (0.2 wt.%) | 0.2 | 100 | 1.7 | 0.862 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizzo, A.; Luhrs, C.; Earp, B.; Grbovic, D. CNT Conductive Epoxy Composite Metamaterials: Design, Fabrication, and Characterization. Materials 2020, 13, 4749. https://doi.org/10.3390/ma13214749

Rizzo A, Luhrs C, Earp B, Grbovic D. CNT Conductive Epoxy Composite Metamaterials: Design, Fabrication, and Characterization. Materials. 2020; 13(21):4749. https://doi.org/10.3390/ma13214749

Chicago/Turabian StyleRizzo, Alexa, Claudia Luhrs, Brian Earp, and Dragoslav Grbovic. 2020. "CNT Conductive Epoxy Composite Metamaterials: Design, Fabrication, and Characterization" Materials 13, no. 21: 4749. https://doi.org/10.3390/ma13214749

APA StyleRizzo, A., Luhrs, C., Earp, B., & Grbovic, D. (2020). CNT Conductive Epoxy Composite Metamaterials: Design, Fabrication, and Characterization. Materials, 13(21), 4749. https://doi.org/10.3390/ma13214749