Perspectives on Thermal Gradients in Porous ZrO2-7–8 wt.% Y2O3 (YSZ) Thermal Barrier Coatings (TBCs) Manufactured by Air Plasma Spray (APS)

Abstract

1. Introduction

1.1. Overall Characterics of Porous APS YSZ TBCs

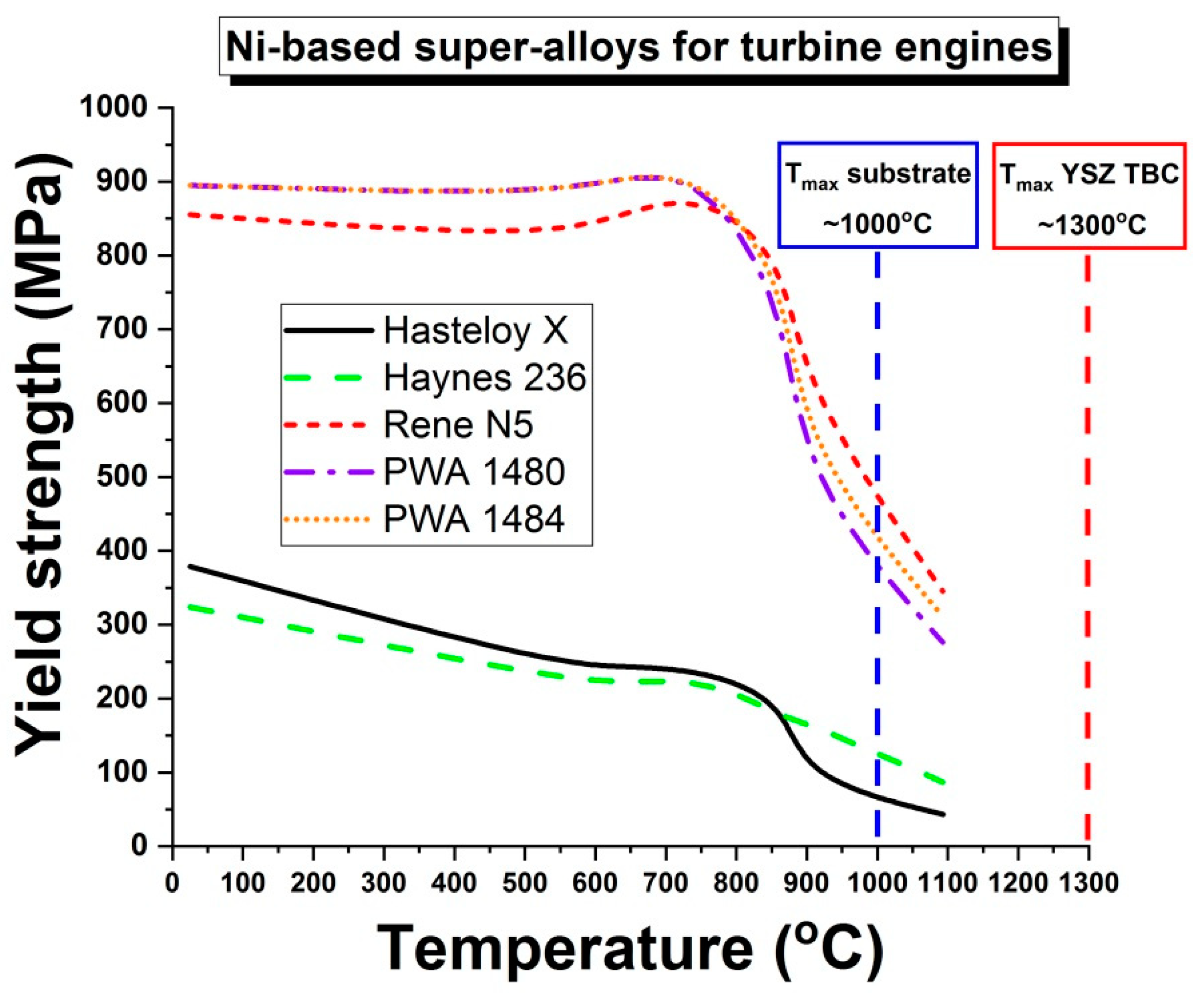

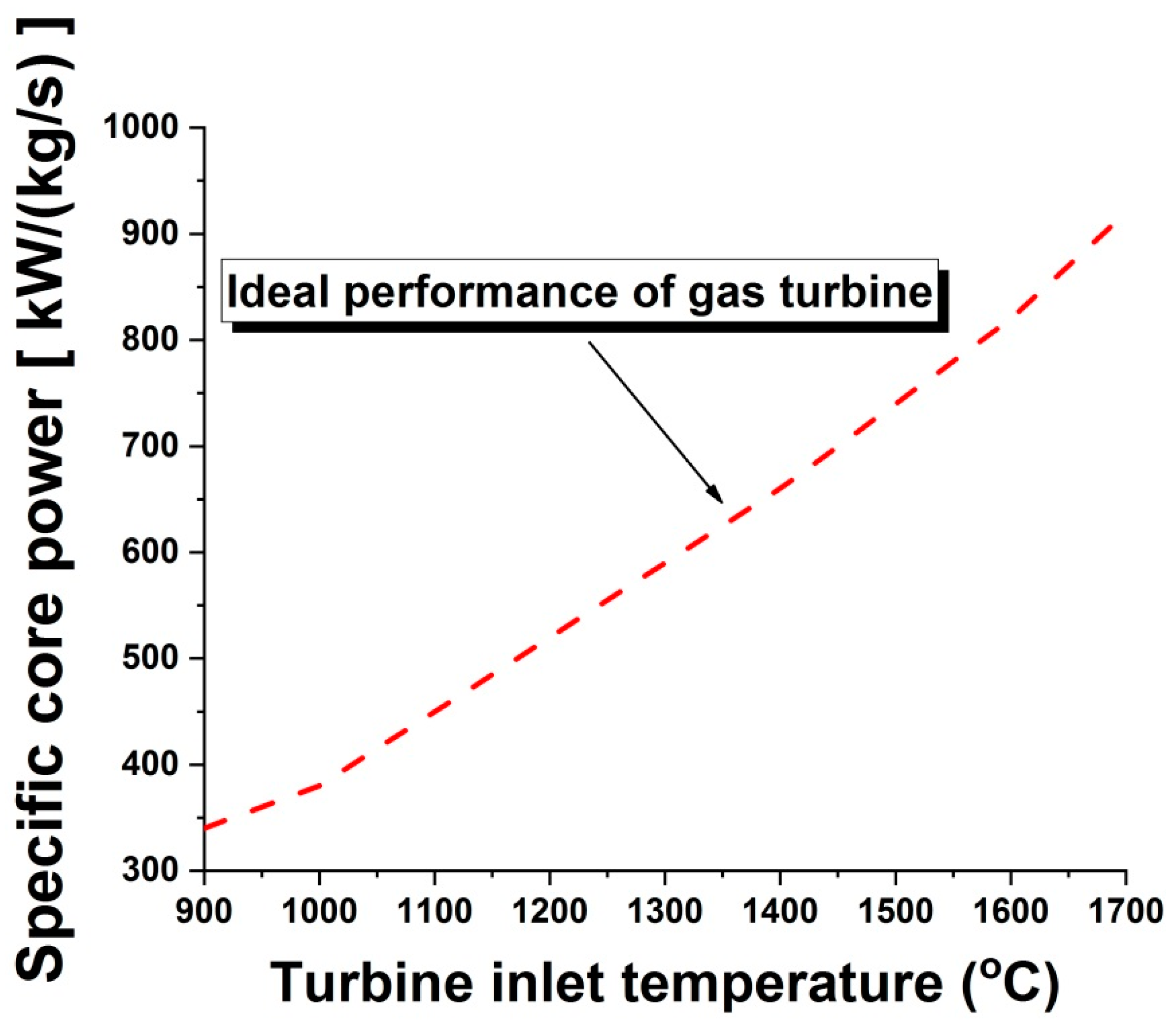

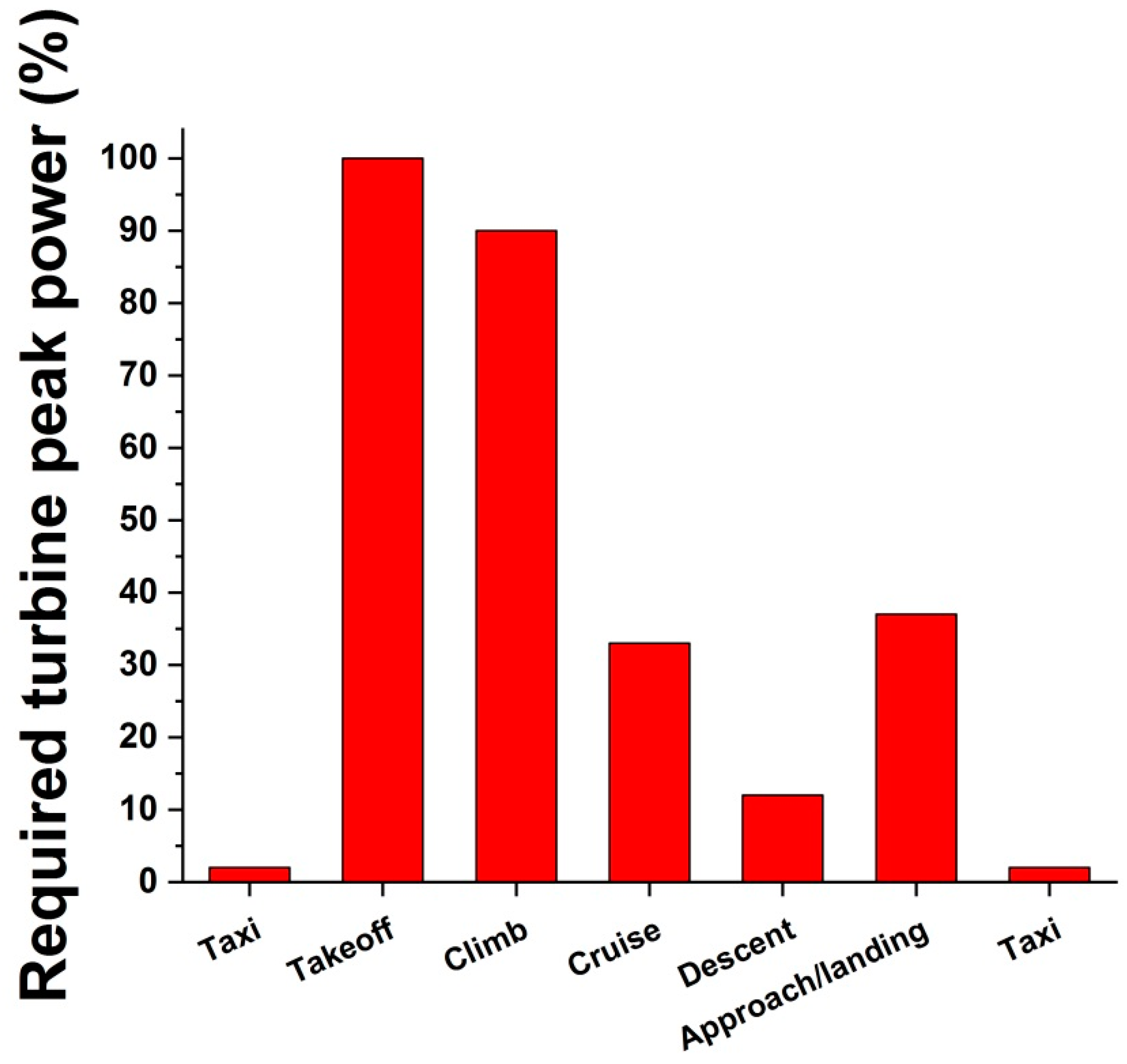

1.2. Maximum Operational Temperatures across APS YSZ TBC/Substrate Systems

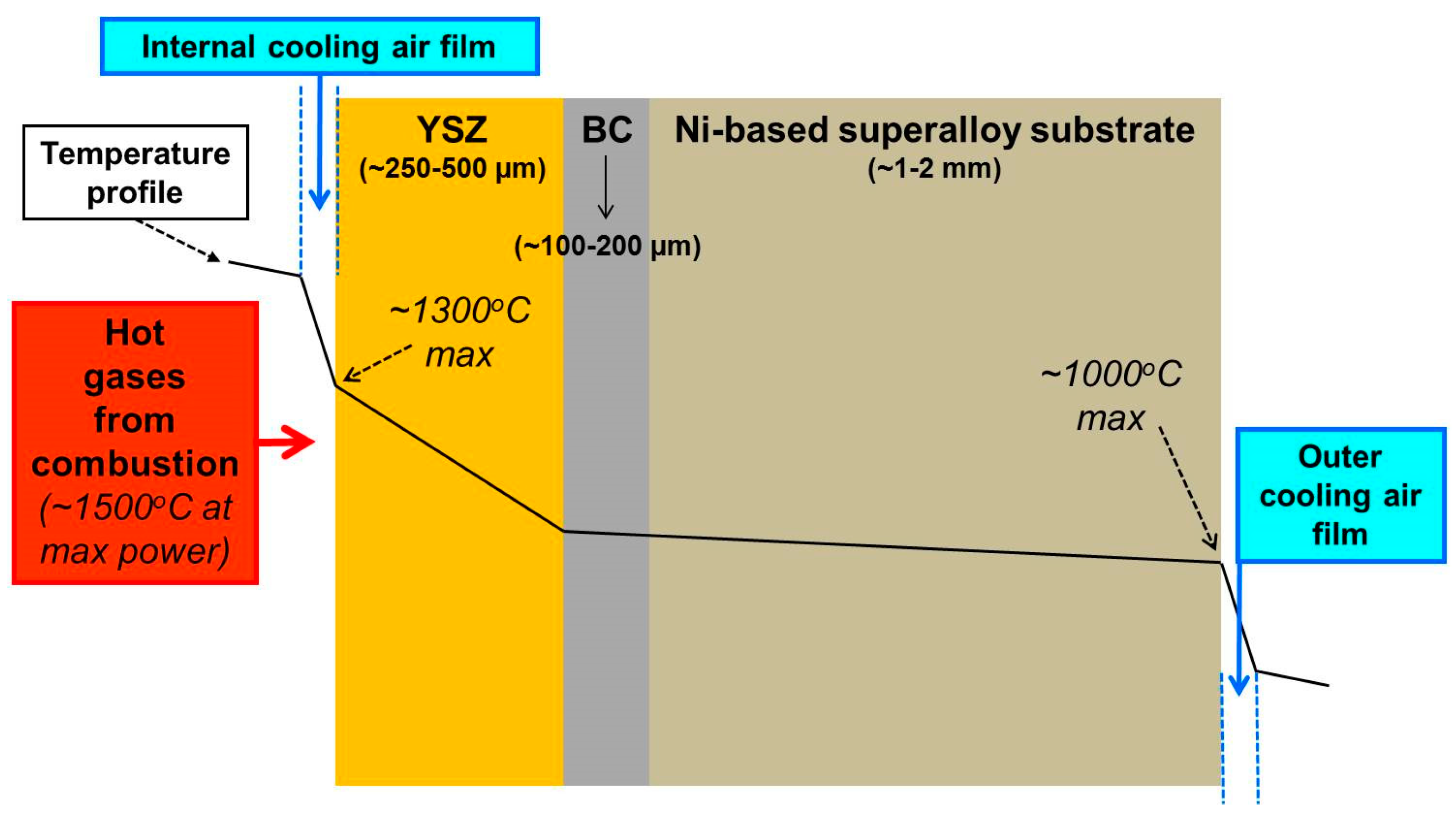

1.3. Thermal Gradients across APS YSZ TBC/Substrate Systems

1.4. Rationale and Objectives

2. Materials and Methods

2.1. APS YSZ TBC Manufacturing and Properties

2.2. APS YSZ TBC Microstructure

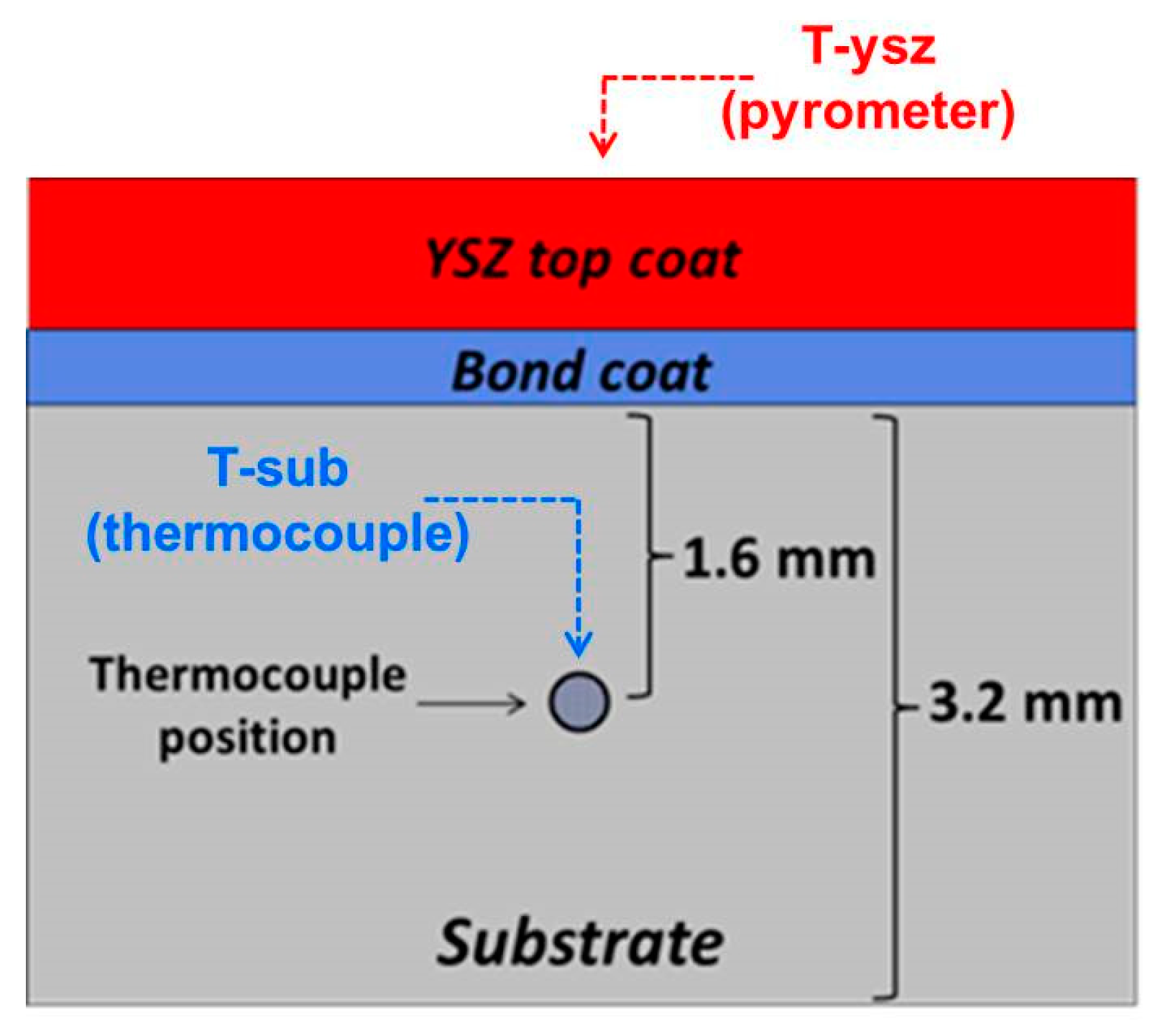

2.3. Laser-Rig Thermal Gradient Testing

3. Results and Discussion

3.1. Porous APS YSZ TBC Microstructures and Laser-Rig Thermal Gradient Setup

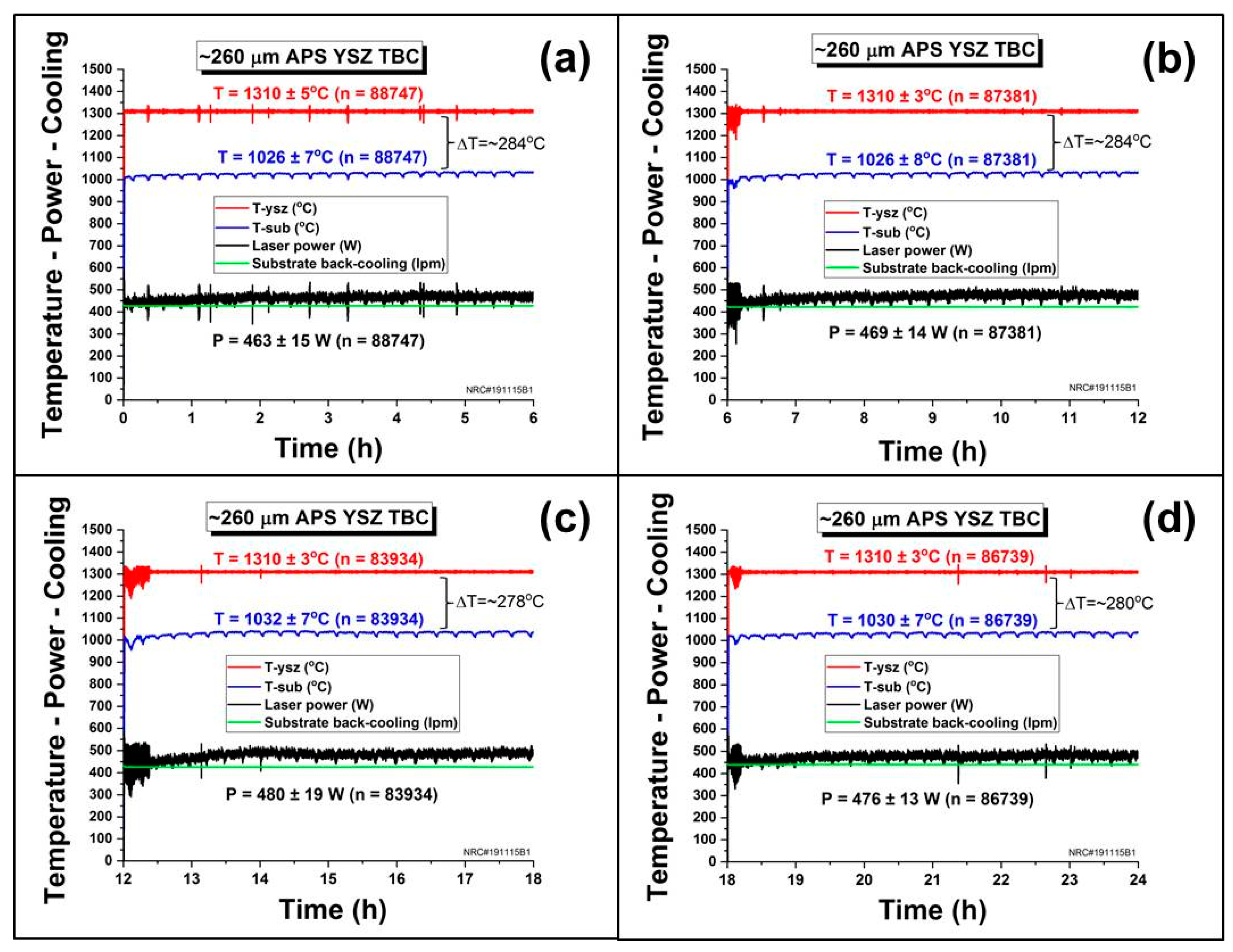

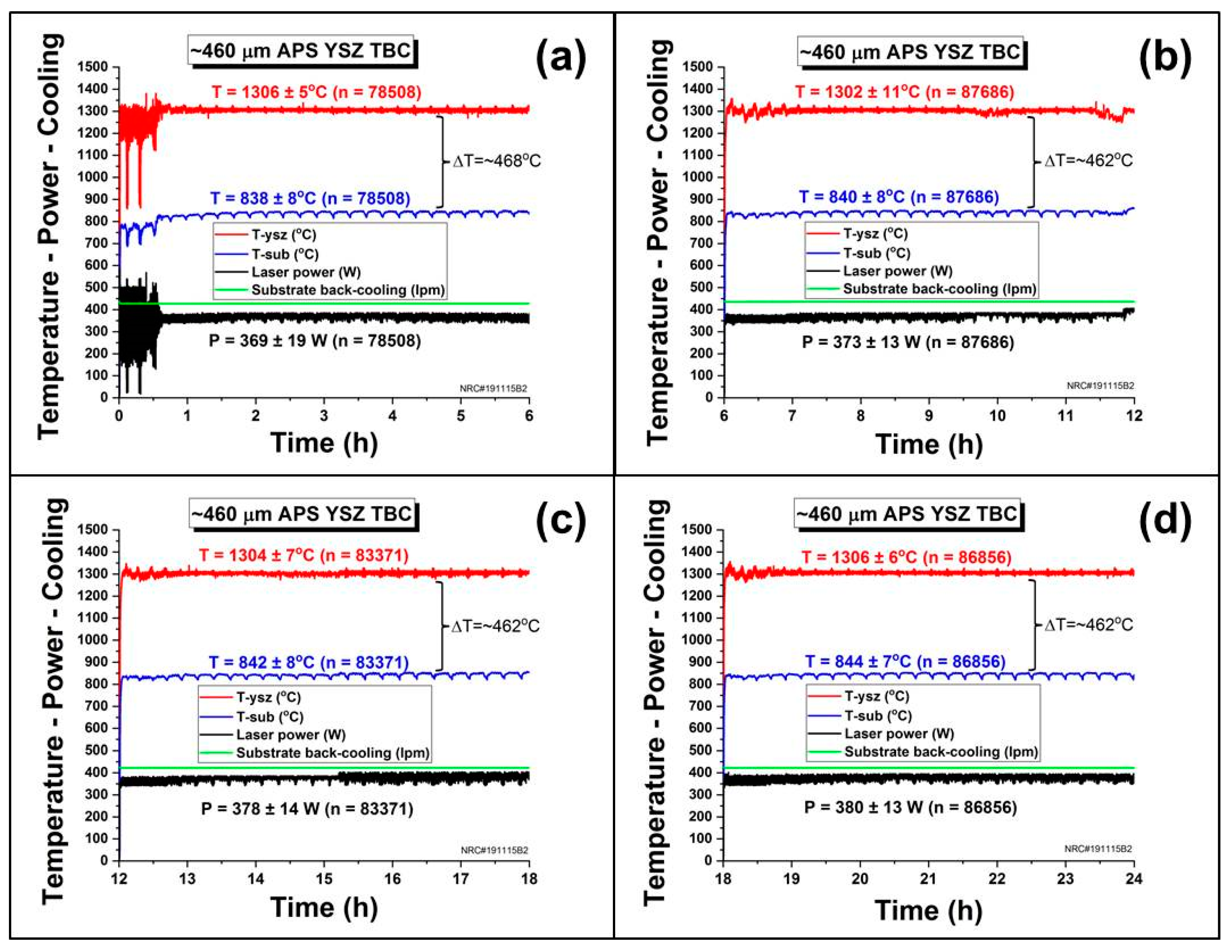

3.2. Laser-Rig Thermal Gradient Testing

3.3. Porous APS YSZ TBC—Thermal Resistance

3.4. Understanding the Porous APS YSZ TBC Stability at High Temperatures

3.5. Thermal Gradient Values at Maximum T-ysz and T-sub Limits

3.6. Thermal Gradient Values for Porous APS YSZ TBCs Reported in the Literature

3.7. Final Remarks on Thermal Gradients

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Rolls-Royce. The Jet Engine. Available online: http://www.valentiniweb.com/Piermo/meccanica/mat/Rolls%20Royce%20-%20The%20Jet%20Engine.pdf (accessed on 20 July 2020).

- Farokhi, S. Aircraft Propulsion, 2nd ed.; John Wiley & Sons Ltd.: Chichester, West Sussex, UK, 2015; pp. 7–9, 483–488. [Google Scholar]

- Hardwicke, C.U.; Lau, Y.-C. Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review. J. Therm. Spray Technol. 2013, 22, 564–576. [Google Scholar] [CrossRef]

- Padture, N.P. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Lima, R.S.; Guerreiro, B.M.H.; Curry, N.; Leitner, M.; Körner, K. Environmental, Economical, and Performance Impacts of Ar-H2 and N2-H2 Plasma-Sprayed YSZ TBCs. J. Therm. Spray Technol. 2019, 29, 74–89. [Google Scholar] [CrossRef]

- Smith, J.; Scheibel, J.; Classen, D.; Paschke, S.; Elbel, S.; Fick, K.; Carlson, D. Thermal Barrier Coating Validation Testing for Industrial Gas Turbine Combustion Hardware. J. Eng. Gas Turbines Power 2015, 138, 031508. [Google Scholar] [CrossRef]

- Kulkarni, A.; Wang, Z.; Nakamura, T.; Sampath, S.; Goland, A.; Herman, H.; Allen, J.; Ilavsky, J.; Long, G.; Frahm, J.; et al. Comprehensive microstructural characterization and predictive property modeling of plasma-sprayed zirconia coatings. Acta Mater. 2003, 51, 2457–2475. [Google Scholar] [CrossRef]

- Tan, Y.; Longtin, J.P.; Sampath, S.; Wang, H. Effect of the Starting Microstructure on the Thermal Properties of As-Sprayed and Thermally Exposed Plasma-Sprayed YSZ Coatings. J. Am. Ceram. Soc. 2009, 92, 710–716. [Google Scholar] [CrossRef]

- Helminiak, M.A.; Yanar, N.M.; Pettit, F.; Taylor, T.A.; Meier, G.H. Factors affecting the microstructural stability and durability of thermal barrier coatings fabricated by air plasma spraying. Mater. Corros. 2012, 63, 929–939. [Google Scholar] [CrossRef]

- Smialek, J.L.; Miller, R.A. Revisiting the birth of 7YSZ thermal barrier coatings: Stephan Stecura. Coatings 2018, 8, 255. [Google Scholar] [CrossRef]

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898. [Google Scholar] [CrossRef]

- Borom, M.P.; Johnson, C.A.; Peluso, L.A. Role of environmental deposits and operating surface temperature in spallation of air plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 1996, 86–87, 116–126. [Google Scholar] [CrossRef]

- Morelli, S.; Testa, V.; Bolelli, G.; Ligabue, O.; Molinari, E.; Antolotti, N.; Lusvarghi, L. CMAS corrosion of YSZ thermal barrier coatings obtained by different thermal spray processes. J. Eur. Ceram. Soc. 2020, 40, 4084–4100. [Google Scholar] [CrossRef]

- Brandon, J.; Taylor, R. Phase stability of zirconia-based thermal barrier coatings part I. Zirconia-yttria alloys. Surf. Coat. Technol. 1991, 46, 75–90. [Google Scholar] [CrossRef]

- Thompson, J.; Clyne, T. The effect of heat treatment on the stiffness of zirconia top coats in plasma-sprayed TBCs. Acta Mater. 2001, 49, 1565–1575. [Google Scholar] [CrossRef]

- High-Temperature High-Strength Nickel Base Alloys. Available online: https://www.stainless-steel-world.net/pdf/393.pdf (accessed on 28 June 2020).

- Perepezko, J.H. The Hotter the Engine, the Better. Science 2009, 326, 1068–1069. [Google Scholar] [CrossRef]

- Academies of Sciences, Engineering, and Medicine—Commercial Aircraft Propulsion and Energy Systems Research: Reducing Global Carbon Emissions. Available online: https://www.nap.edu/catalog/23490/commercial-aircraft-propulsion-and-energy-systems-research-reducing-global-carbon (accessed on 20 July 2020).

- Federal Aviation Administration—Advisory Circular—Subject: Ratings and Operating Limitations FOR Turbine Engines (SECTIONS 33.7 and 33.8). Available online: https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC%2033-7.1.pdf (accessed on 20 July 2020).

- Mom, A.; Hersbach, H. Performance of high temperature coatings on F100 turbine blades under simulated service conditions. Mater. Sci. Eng. 1987, 87, 361–367. [Google Scholar] [CrossRef]

- Nelson, W.A.; Orenstein, R.M. TBC experience in land- based gas turbines. J. Therm. Spray Technol. 1997, 6, 176–180. [Google Scholar] [CrossRef]

- Zhu, D.; Miller, R.A. Thermal Conductivity and Elastic Modulus Evolution of Thermal Barrier Coatings under High Heat Flux Conditions. J. Therm. Spray Technol. 2000, 9, 175–180. [Google Scholar] [CrossRef]

- Aircraft Turbine Engine Combustion Section Inspection. Available online: https://www.aircraftsystemstech.com/2017/05/combustion-section-inspection.html (accessed on 26 July 2020).

- Why Your Engine Needs a Hot Section Inspection. Available online: https://www.pwc.ca/en/airtime-blog/articles/technical-tips/why-your-engine-needs-a-hot-section-inspection (accessed on 26 July 2020).

- Rangaswany, S.; Herman, H.; Safai, S. Thermal expansion study on plasma-sprayed oxide coatings. Thin Solid Films 1980, 73, 43–52. [Google Scholar] [CrossRef]

- Yanar, N.M.; Helminiak, M.; Meier, G.H.; Pettit, F. Comparison of the Failures during Cyclic Oxidation of Yttria-Stabilized (7 to 8 Weight Percent) Zirconia Thermal Barrier Coatings Fabricated via Electron Beam Physical Vapor Deposition and Air Plasma Spray. Met. Mater. Trans. A 2010, 42, 905–921. [Google Scholar] [CrossRef]

- Xie, L.; Dorfman, M.; Cipitria, A.; Paul, S.; Golosnoy, I.; Clyne, T. Properties and Performance of High-Purity Thermal Barrier Coatings. J. Therm. Spray Technol. 2007, 16, 804–808. [Google Scholar] [CrossRef]

- Standard powder certificate provided by manufacturer together with powder batch, Treibacher Industrie AG—Certificate of Analysis—AuerCoat YSZ LD Grade B–lot #170901-B–13 September 2018.

- Material Product Data Sheet—8% Yttria Stabilized Zirconia Agglomerated and HOSP Powders. Available online: https://www.oerlikon.com/ecomaXL/files/metco/oerlikon_DSM-0242.3_8YO_ZrO_HOSP.pdf&download=1 (accessed on 26 July 2020).

- Vaßen, R.; Traeger, F.; Stöver, D. Correlation Between Spraying Conditions and Microcrack Density and Their Influence on Thermal Cycling Life of Thermal Barrier Coatings. J. Therm. Spray Technol. 2004, 13, 396–404. [Google Scholar] [CrossRef]

- Tan, Y.; Longtin, J.P.; Sampath, S.; Zhu, D. Temperature-Gradient Effects in Thermal Barrier Coatings: An Investigation Through Modeling, High Heat Flux Test, and Embedded Sensor. J. Am. Ceram. Soc. 2010, 93, 3418–3426. [Google Scholar] [CrossRef]

- Vaßen, R.; Kerkhoff, G.; Stöver, D. Development of a micromechanical life prediction model for plasma sprayed thermal barrier coatings. Mater. Sci. Eng. A 2001, 303, 100–109. [Google Scholar] [CrossRef]

- Karger, M.; Vaßen, R.; Stöver, D. Atmospheric plasma sprayed thermal barrier coatings with high segmentation crack densities: Spraying process, microstructure and thermal cycling behavior. Surf. Coat. Technol. 2011, 206, 16–23. [Google Scholar] [CrossRef]

| YSZ Feedstock | ZrO2 | Y2O3 wt.% | SiO2 wt.% (Max) | TiO2 wt.% (Max) | Al2O3 wt.% (Max) | Fe2O3 wt.% (Max) |

|---|---|---|---|---|---|---|

| AuerCoat YSZ LD-B [29] | Balance | 7.6 | 0.01 | 0.05 | 0.0005 | 0.0005 |

| 204B-NS [30] | Balance | 7−8 | 0.3 | 0.2 | 0.2 | 0.2 |

| YSZ TBC Thickness (µm) | Porosity (%) | TC (W/mK) | T-ysz (°C) | T-bc (°C) calculated | T-sub (°C) | ΔTYSZ-SUB (°C) T-ysz−T-sub | ΔTYSZ (°C) T-ysz−TBC | YSZ Gradient (°C/µm) |

|---|---|---|---|---|---|---|---|---|

| ~260 | ~15 1 | ~0.80 1 | ~1310 | ~1075 | ~1030 | ~280 | ~235 | ~0.90 |

| ~460 | ~15 1 | ~0.80 1 | ~1305 | ~895 | ~840 | ~465 | ~410 | ~0.90 |

| Material | Substrate Shape Dimensions | BC Thick (µm) | YSZ Thick (µm) | YSZ Porosity (%) | Thermal Gradient Source | T-ysz (°C) | T-bc (°C) | T-sub (°C) | YSZ Gradient (°C/µm) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Inconel 738 | Puck-shaped diam: 30 mm thick: 3.0 mm | ~150 | ~290 | ~12% | Burner-rig | ~1333 | ~1067 | ~1022 2 | ~0.92 | Vaßen et al. [31] |

| Inconel 738 | Puck-shaped diam: 30 mm thick: 3.0 mm | ~150 | ~260 | ~12% | Burner-rig | ~1322 | ~1047 | ~1002 2 | ~1.06 | Vaßen et al. [31] |

| Inconel 738 | Puck-shaped diam: 30 mm thick: 3.0 mm | ~150 | ~320 | ~12% | Burner-rig | ~1333 | ~1064 | ~1019 2 | ~0.84 | Vaßen et al. [31] |

| Inconel 738 | Puck-shaped diam: 30 mm thick: 3.0 mm | ~150 | ~260 | ~12% | Burner-rig | ~1326 | ~1074 | ~1029 2 | ~0.97 | Vaßen et al. [31] |

| Hastelloy X | Puck-shaped diam: 25.4 mm thick: 3.2 mm | ~64 | ~560 | n.a. 1 | Laser-rig | ~1140 | ~900 | ~840 | ~0.43 | Tan et al. [32] |

| Inconel 738 | Puck-shaped diam: 30 mm thick: 3.0 mm | ~150 | ~300 | ~12% | Burner-rig | ~1280 | ~1045 2 | ~1000 | ~0.78 | Vaßen et al. [33] |

| Inconel 738 | Puck-shaped diam: 25 mm thick: 3.0 mm | ~150 | ~450 | ~15% | Burner-rig | ~1269 | ~1070 | ~1045 | ~0.50 | Karger et al. [34] |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima, R.S. Perspectives on Thermal Gradients in Porous ZrO2-7–8 wt.% Y2O3 (YSZ) Thermal Barrier Coatings (TBCs) Manufactured by Air Plasma Spray (APS). Coatings 2020, 10, 812. https://doi.org/10.3390/coatings10090812

Lima RS. Perspectives on Thermal Gradients in Porous ZrO2-7–8 wt.% Y2O3 (YSZ) Thermal Barrier Coatings (TBCs) Manufactured by Air Plasma Spray (APS). Coatings. 2020; 10(9):812. https://doi.org/10.3390/coatings10090812

Chicago/Turabian StyleLima, Rogerio S. 2020. "Perspectives on Thermal Gradients in Porous ZrO2-7–8 wt.% Y2O3 (YSZ) Thermal Barrier Coatings (TBCs) Manufactured by Air Plasma Spray (APS)" Coatings 10, no. 9: 812. https://doi.org/10.3390/coatings10090812

APA StyleLima, R. S. (2020). Perspectives on Thermal Gradients in Porous ZrO2-7–8 wt.% Y2O3 (YSZ) Thermal Barrier Coatings (TBCs) Manufactured by Air Plasma Spray (APS). Coatings, 10(9), 812. https://doi.org/10.3390/coatings10090812