Online High Performance Genetic Algorithm Based Sliding Mode Control for Controllable Pitch Propeller

Abstract

:1. Introduction

2. CPP System Description and Modeling

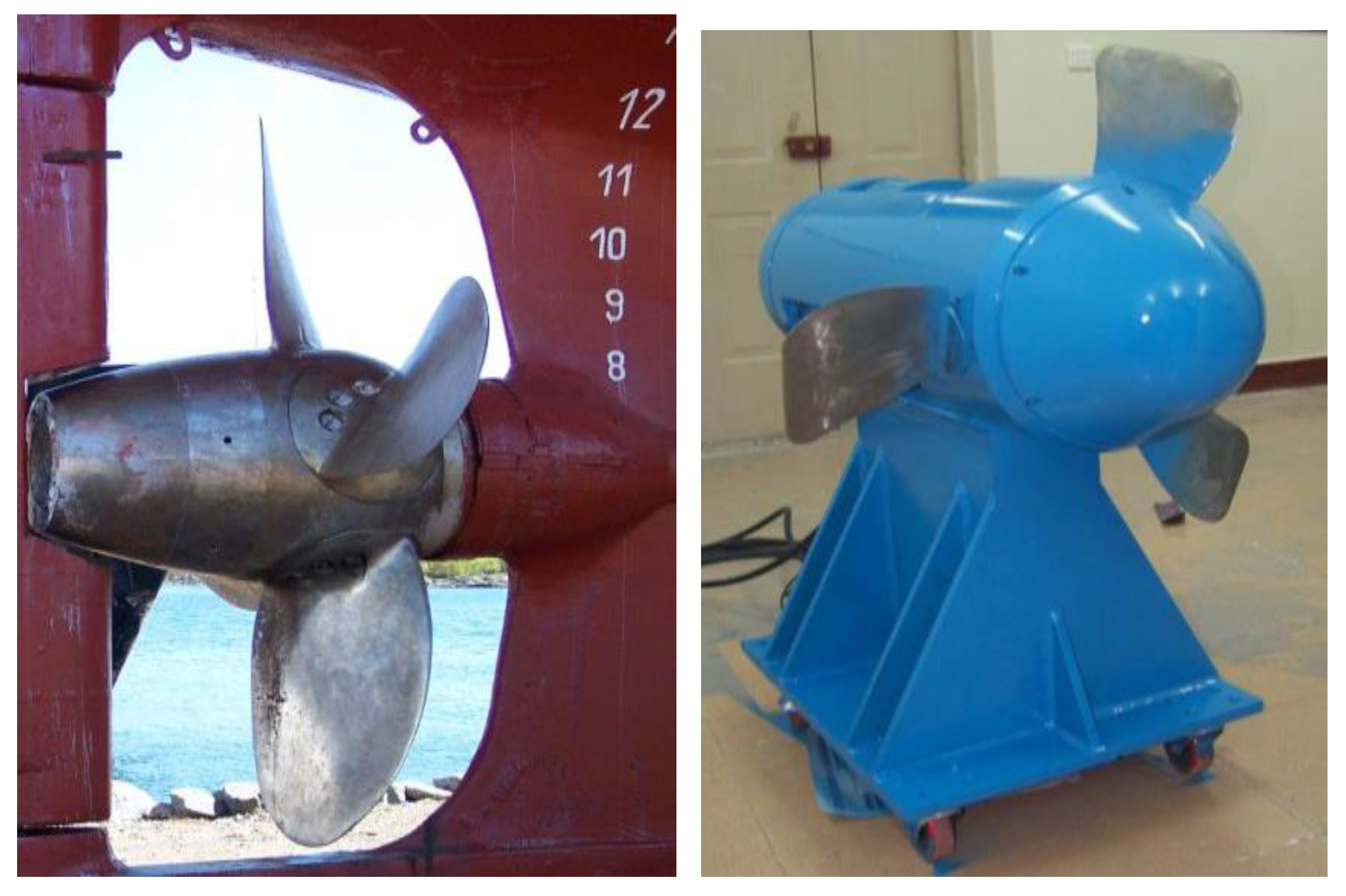

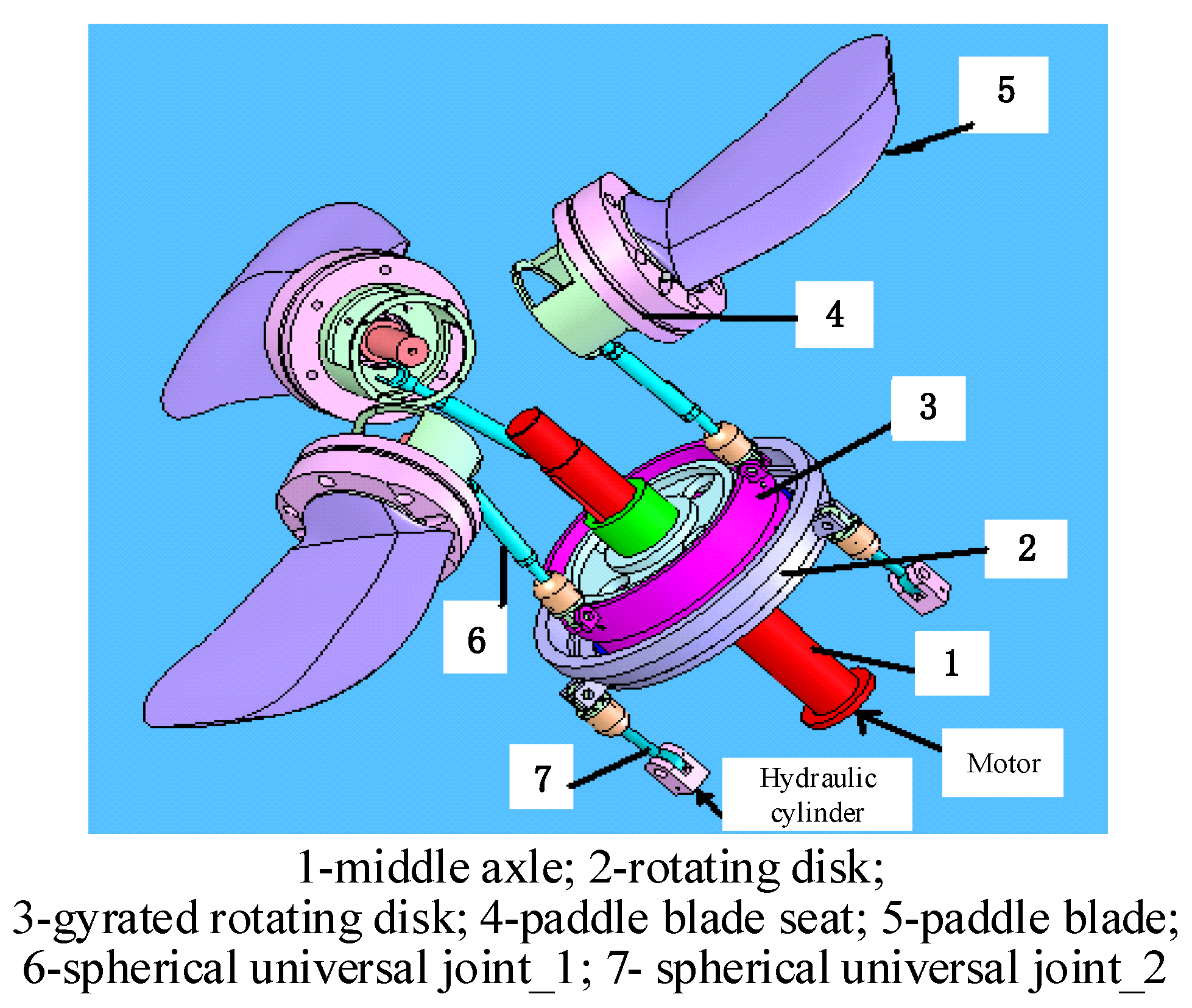

2.1. Description of the CPP System

- (a)

- Normal forward propulsion. The rotating disk moves axially in parallel when the three hydraulic cylinders are kept in the same position.

- (b)

- Arbitrary direction propulsion. The inside part of the rotating disk moves in a periodic way by keeping the three hydraulic cylinders in different positions.

- (1)

- The ship can operate in a forward or arbitrary direction with the CPP system, without changing the direction of rotation of the engine.

- (2)

- A non-reversible engine can be used for both forward and astern operation of the ship.

- (3)

- Since the pitch of the propeller determines the amount of thrust generated by the propeller, a change in the pitch angle can bring certain changes in the speed of the ship without changing the speed or rpm of the main engine.

- (4)

- In the case of astern operation, the efficiency is higher with the CPP system than that with fixed pitch propellers.

2.2. Modeling of the CPP System

3. Online HPGA Based Sliding Mode Controller

3.1. Online High Performance Genetic Algorithm

- (1)

- In the process of horizontal gene transfer, the crossing length is calculated based on the fitness of the donor and recipient chromosome, which makes this operator a self-adaptive one.

- (2)

- In the traditional genetic algorithm, the crossover probability and mutation probability are all required to be determined with experienced knowledge. Also, improper initialization of the parameters will result in stagnation. In the online HPGA method, where there are much fewer parameters, and so it does not require a lot of special skill or expertise.

- (3)

- The online HPGA is simpler and less complex compared with the traditional GA, and thus it is easy to use to perform this optimization method in practical engineering applications.

| Algorithm 1 The online HPGA |

| Input: Initialization input date: population size m, number of the generation n 1: Create the first population (create random population with size of m); 2: for i=0 to n do 3: Get the CHBest, CHWorst, FitnessBest, FitnessWorst; 4: for j=0 to m do 5: ; 6: CHNew=CHRecipient; 7: P=Random Position (0, length of CH); 8: count=0; 9: for count=0 to L do 10: CHNew(p)=CHRecipient(p); 11: p=(p+1) % Length of CH; 12: count=count+1; 13: end for 14: Pmr=NSGBNLCH; 15: if Fitness(CHNew)>Fitness(CHRecipient) then 16: CHmutated=Mutate(CHRecipient, Pmr); 17: CHnon-mutated=CHNew; 18: else 19: CHmutated=Mutate(CHNew, Pmr); 20: CHnon-mutated=CHRecipient; 21: end if 22: if Fitness(CHmutated)>Fitness(CHnon-mutated) then 23: CHRecipient is replaced by CHmutated; 24: else 25: CHRecipient is replaced by CHnon-mutated; 26: end if 27: end for 28: end for 29: return The chromosome with the best fitness. |

3.2. Chattering-Free Sliding Mode Control Online High Performance Genetic Algorithm

3.3. Online HPGA Based Sliding Mode Control for the CPP System

4. Validation of the Online HPGA Based Sliding Mode Control Strategy

4.1. Numerical Simulation

4.2. Numerical Simulation Experiment on the Scale Model of the CPP System

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| CPP | Controllable Pitch Propeller |

| HPGA | High Performance Genetic Algorithm |

| SMC | Sliding Mode Control |

| CF-SMC | Chattering-Free Sliding Mode Controller |

| PID | Proportional-Integral-Derivative |

| RFNN | Recurrent-Fuzzy-Neural-Network |

| GA | Genetic Algorithm |

References

- Martelli, M.; Figari, M.; Altosole, M.; Vignolo, S. Controllable pitch propeller actuating mechanism, modelling and simulation. J. Eng. Marit. Environ. 2014, 228, 29–43. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, Z.; Qi, W. Numerical study on the influence of boss cap fins on efficiency of controllable-pitch propeller. J. Mar. Sci. Appl. 2013, 12, 13–20. [Google Scholar] [CrossRef]

- Cohen, R.; Miculescu, D.; Reilley, K.; Pakmehr, M.; Feron, E. Online performance optimization of a DC motor driving a variable pitch propeller. J. Natl. Cancer Inst. 2013, 105, 14. [Google Scholar]

- Prats, M.A.M.; Carrasco, J.M.; Galvan, E.; Sanchez, J.A.; Franquelo, L.G.; Batlsta, C. Improving transition between power optimization and power limitation of variable speed, variable pitch wind turbines using fuzzy control techniques. In Proceedings of the Conference of the IEEE Industrial Electronics Society, Nagoya, Japan, 22–28 October 2000; pp. 1497–1502. [Google Scholar]

- Mirzaei, M.; Soltani, M.; Poulsen, N.K.; Niemann, H.H. An MPC approach to individual pitch control of wind turbines using uncertain LIDAR measurements. In Proceedings of the 2013 European Control Conference (ECC), Zürich, Switzerland, 17–19 July 2013; pp. 490–495. [Google Scholar]

- Balsamo, F.; De Luca, F. Continuous optimization of controllable pitch propeller for fast ferries. In Proceedings of the 9th HSMV Symposium on High Speed Marine Vechicles, Naples, Italy, 25–27 May 2011; p. 8. [Google Scholar]

- Dullens, F.P.M. Modeling and Control of a Controllable Pitch Propeller. Master’s Thesis, Technische University, Eindhoven, The Netherlands, 2009. [Google Scholar]

- Cazenave, T.; Pakmehr, M.; Feron, E. Peak-Seeking Control of a DC Motorhinolaryngology Driving a Variable Pitch Propeller. In Proceedings of the AIAA Guidance, Navigation, and Control Conference, Portland, OR, USA, 8–11 August 2011; p. 10. [Google Scholar]

- Biegel, B.; Juelsgaard, M.; Kraning, M.; Boyd, S.; Stoustrup, J. Wind turbine pitch optimization. In Proceedings of the International Conference on Control Applications (CCA), Denver, CO, USA, 28–30 September 2011; pp. 1327–1334. [Google Scholar]

- Muljadi, E.; Butterfield, C.P. Pitch-controlled variablespeed wind turbine generation. IEEE Trans. Ind. Appl. 2001, 37, 240–246. [Google Scholar] [CrossRef] [Green Version]

- Fridman, L. Sliding mode enforcement after 1990: Main results and some open problems. In Sliding Modes after the First Decade of the 21st Century; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–57. [Google Scholar]

- Meng, Z.; Ren, W.; You, Z. Distributed finite-time attitude containment control for multiple rigid bodies. Automatica 2010, 46, 2092–2099. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, S.; Wang, Y. Smooth Sliding Mode Control and Its Application in Ship Boiler Drum Water Level. Math. Probl. Eng. 2016, 2016, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Mien, V.; Kang, H.J.; Shin, K.S. Adaptive fuzzy quasi-continuous high-order sliding mode controller for output feedback tracking control of robot manipulators. J. Mech. Eng. Sci. 2014, 228, 90–107. [Google Scholar] [CrossRef]

- Cao, L.; Chen, X. Input-output linearization minimum sliding mode error feedback control for spacecraft formation with large perturbations. J. Aerosp. Eng. 2015, 229, 352–368. [Google Scholar] [CrossRef]

- Jin, L.; Liu, Y. Study on adaptive slid mode controller for improving handling stability of motorized electric vehicles. Math. Probl. Eng. 2014, 2014, 10. [Google Scholar] [CrossRef]

- Wai, R.J. Sliding-mode controller for PM synchronous servo motor drive using recurrent fuzzy neural network. IEEE Trans. Ind. Electron. 2001, 48, 926–944. [Google Scholar]

- Utki, V.I. Sliding Modes in Control and Optimization; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar]

- Bartolini, G.; Ferrara, A.; Usai, E. Chattering avoidance by second-order sliding-mode control. IEEE Trans. Autom. Control 1998, 43, 241–246. [Google Scholar] [CrossRef]

- Levant, A. Robust exact differentiation via sliding mode technique. Automatica 1998, 34, 379–384. [Google Scholar] [CrossRef]

- Levant, A. Universal SISO sliding-mode controllers with finite-time convergence. IEEE Trans. Autom. Control 2001, 46, 1447–1451. [Google Scholar] [CrossRef] [Green Version]

- Levant, A. Homogeneity approach to high-order sliding mode design. Automatica 2005, 41, 823–830. [Google Scholar] [CrossRef]

- Levant, A. Principles of 2-sliding mode design. Automatica 2007, 43, 576–586. [Google Scholar] [CrossRef] [Green Version]

- Shtessel, Y.B.; Shkolnikov, I.A.; Brown, M.D. An asymptotic second order smooth sliding mode control. Asian J. Control 2003, 5, 498–504. [Google Scholar] [CrossRef]

- Du, H.; Yu, X.; Chen, M.Z.Q.; Li, S. Chattering-free discrete-time sliding mode control. Automatica 2016, 68, 87–91. [Google Scholar] [CrossRef]

- Feng, Y.; Han, F.; Yu, X. Chattering free full-order sliding-mode control. Automatica 2014, 50, 1310–1314. [Google Scholar] [CrossRef]

- Gong, M.; Wang, S.; Liu, W.; Yan, J.; Jiao, L. Evolutionary computation in China: A literature survey. CAAI Trans. Intell. Technol. 2016, 1, 334–354. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Z.; Yang, Y.; Lv, M. Online Estimation of State of Power for Lithium-Ion Batteries in Electric Vehicles Using Genetic Algorithm. IEEE Access 2018, 6, 20868–20880. [Google Scholar] [CrossRef]

- Mehrafsa, A.; Sokhandan, A.; Karimian, G. A high performance genetic algorithm using bacterial conjugation operator (HPGA). Genet. Program. Evolvable Mach. 2013, 14, 395–427. [Google Scholar] [CrossRef]

- Huang, S.C.; Jiau, M.K.; Lin, C.H. Optimization of the carpool service problem via a fuzzy controlled genetic algorithm. IEEE Trans. Fuzzy Syst. 2015, 23, 1698–1712. [Google Scholar] [CrossRef]

- Li, G.; Jiang, H.; He, T. A genetic algorithm based decomposition approach to solve an integrated equipment-workforce-service planning problem. Omega 2015, 50, 1–7. [Google Scholar] [CrossRef]

- Iwankowicz, R.R. An efficient evolutionary method of assembly sequence planning industry. Assem. Autom. 2016, 36, 60–71. [Google Scholar] [CrossRef]

- Chakraborty, S. Controllable Pitch Propeller (CPP) vs. Fixed Pitch Propeller (FPP). Available online: https://www.marineinsight.com/naval-architecture/controllable-pitch-propeller-cpp-vs-fixed-pitch-propeller-fpp/ (accessed on 24 June 2020).

- Servo Valve Operation Manual, Shanghai Hengtuo Hydraulic Control Technology Co. LTD. Available online: http://www.htservo.com.cn/filedownload/59272 (accessed on 24 June 2020).

- Zhao, R.; Liao, D.; Liu, B. Simulation on work roll bending control system of cold rolling mill. J. Univ. Sci. Technol. Liaoning 2014, 9, 33–38. [Google Scholar]

| Symbol | Meaning | Value |

|---|---|---|

| D | Internal diameter | 28 mm |

| d | Diameter of piston rod | 16 mm |

| A | Effective area of piston | 1.13 × 10−4 m2 |

| l | Stroke of the piston | 43 mm |

| Vt | The total capacity of the oil chamber | 7.91 × 10−5 m3 |

| m | Mass of the hydraulic cylinder | 22 Kg |

| Qin | Total oil flow into the control chamber | L/min |

| Qout | Total oil flow out of the control chamber | L/min |

| βe | Elastic modulus of liquid | 70 MPa |

| p | Pressure of the oil in the control chamber | Mpa |

| Ctc | Total leakage coefficient of hydraulic cylinder | 0.2 mL/(min·MPa) |

| Bc | Viscous damping coefficient between piston and load | 500 N/(m/s) |

| K | Spring stiffness of the propeller | N/m |

| F | External force acting on the piston | N |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| α1 | 1 | α3 | 3.45 × 10−5 |

| α2 | 2.353*10−3 | β | 0.2956 |

| Kp | 10.8 | Ti | 1 |

| Td | 0.25 |

| Control Strategy | Lagging Angle | Maxmum Error |

|---|---|---|

| Online HPGA based sliding mode controller | 7° | 0.8 mm |

| PID controller | 15° | 2 mm |

| Control Strategy | Lagging Angle | Maxmum Error |

|---|---|---|

| Online HPGA based sliding mode controller | 10.4° | 0.3 mm |

| PID controller | 45.7° | 5.6 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, Q.; Fu, H. Online High Performance Genetic Algorithm Based Sliding Mode Control for Controllable Pitch Propeller. Processes 2020, 8, 953. https://doi.org/10.3390/pr8080953

Wang Y, Wang Q, Fu H. Online High Performance Genetic Algorithm Based Sliding Mode Control for Controllable Pitch Propeller. Processes. 2020; 8(8):953. https://doi.org/10.3390/pr8080953

Chicago/Turabian StyleWang, Yuchao, Qiusu Wang, and Huixuan Fu. 2020. "Online High Performance Genetic Algorithm Based Sliding Mode Control for Controllable Pitch Propeller" Processes 8, no. 8: 953. https://doi.org/10.3390/pr8080953

APA StyleWang, Y., Wang, Q., & Fu, H. (2020). Online High Performance Genetic Algorithm Based Sliding Mode Control for Controllable Pitch Propeller. Processes, 8(8), 953. https://doi.org/10.3390/pr8080953