BIM and LCA Integration: A Systematic Literature Review

Abstract

1. Introduction

2. Review Approach

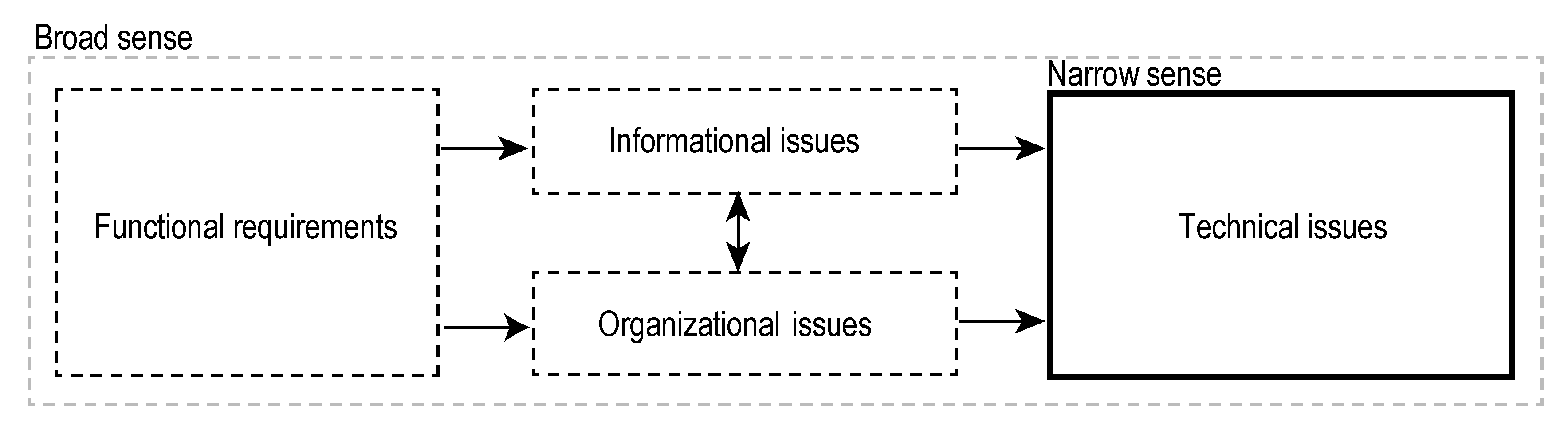

2.1. State-of-the-Art

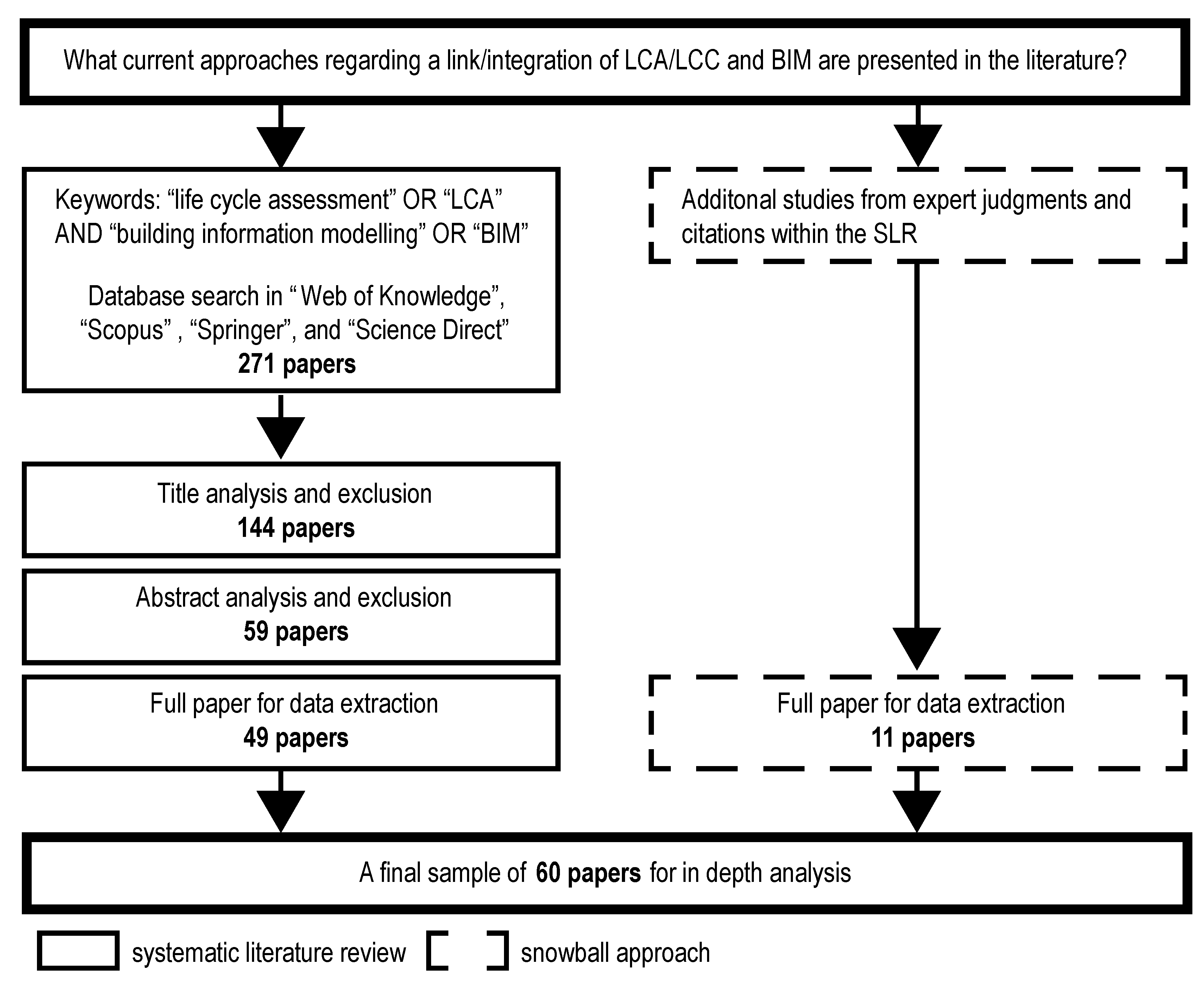

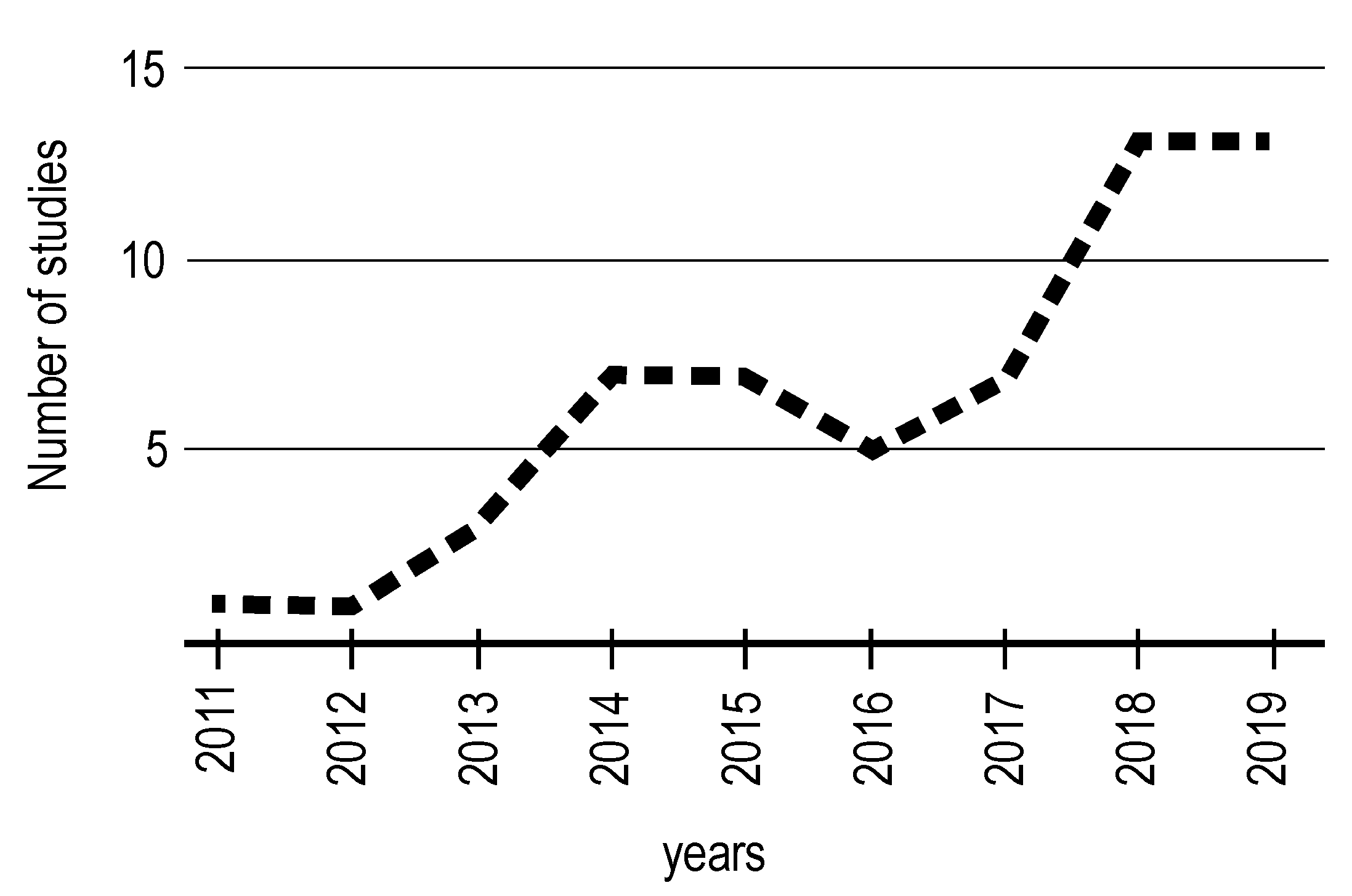

2.2. Materials and Methods

2.3. Data Analysis and Research Approach

3. Results

3.1. Technical Issues

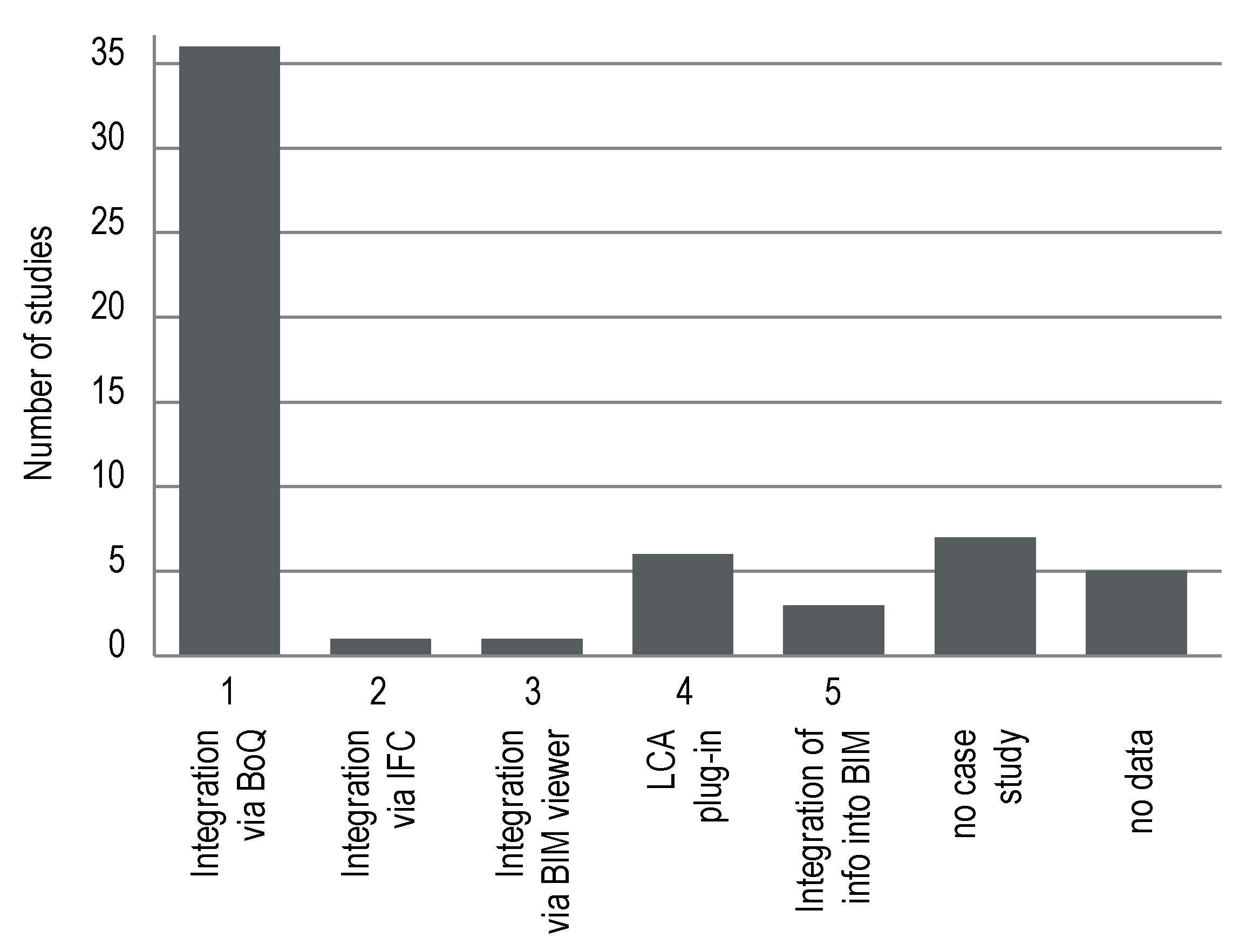

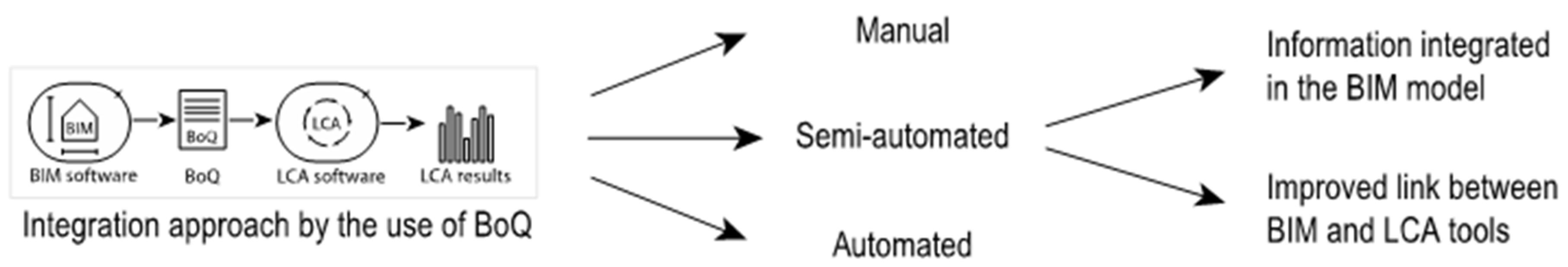

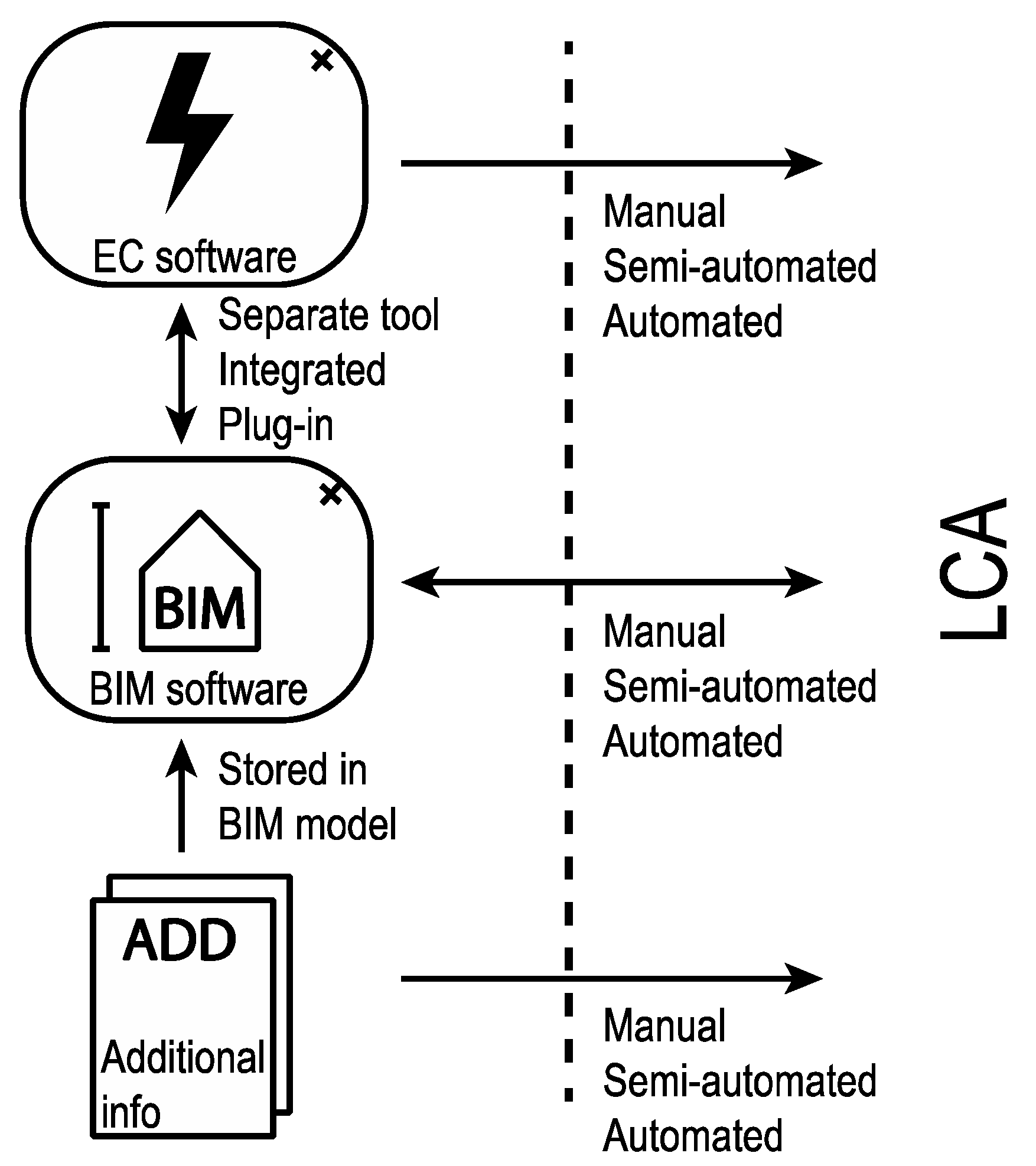

3.1.1. Classification of the Integration Process/Interoperability

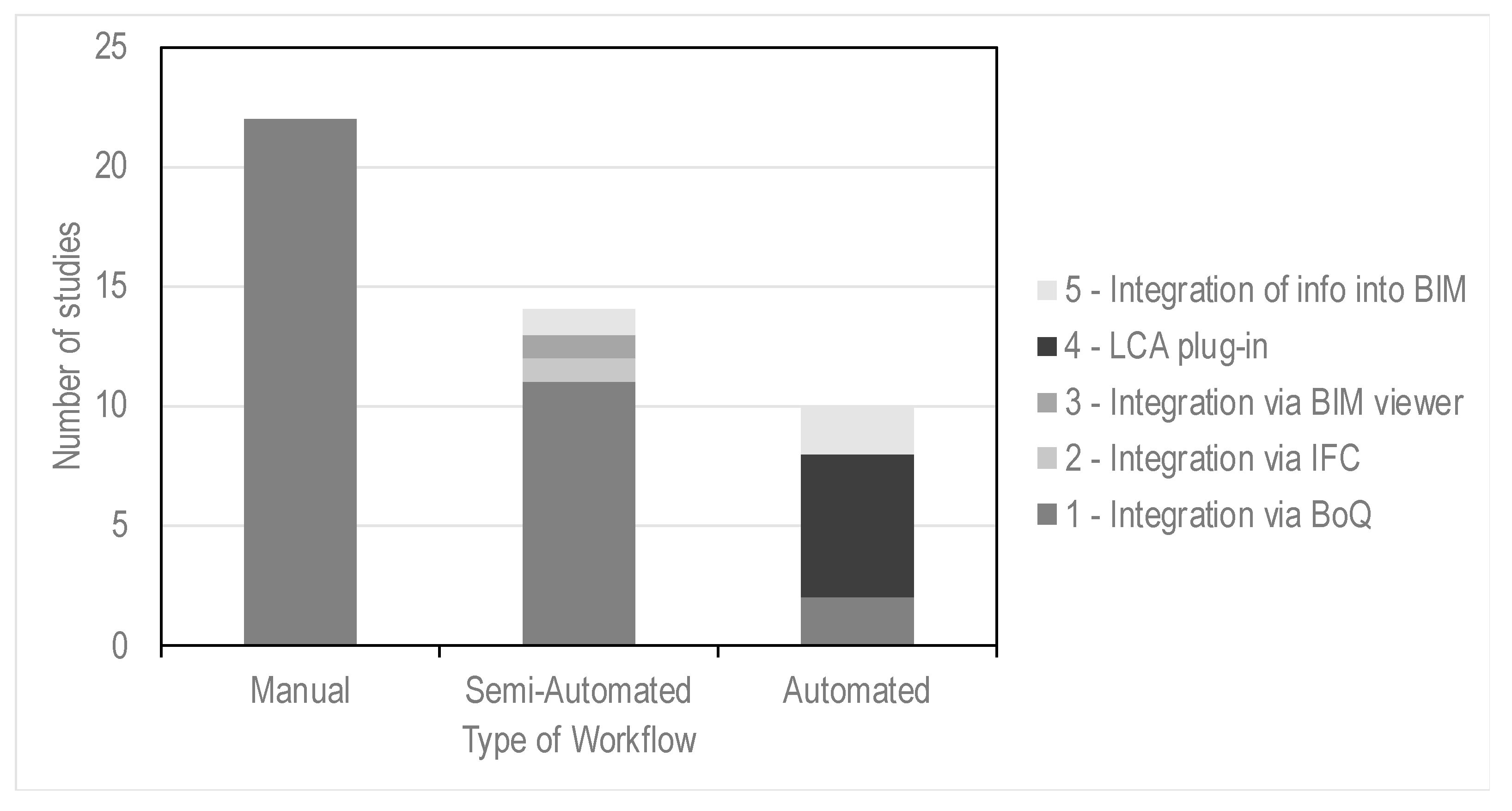

3.1.2. Automatization of the Integration Process

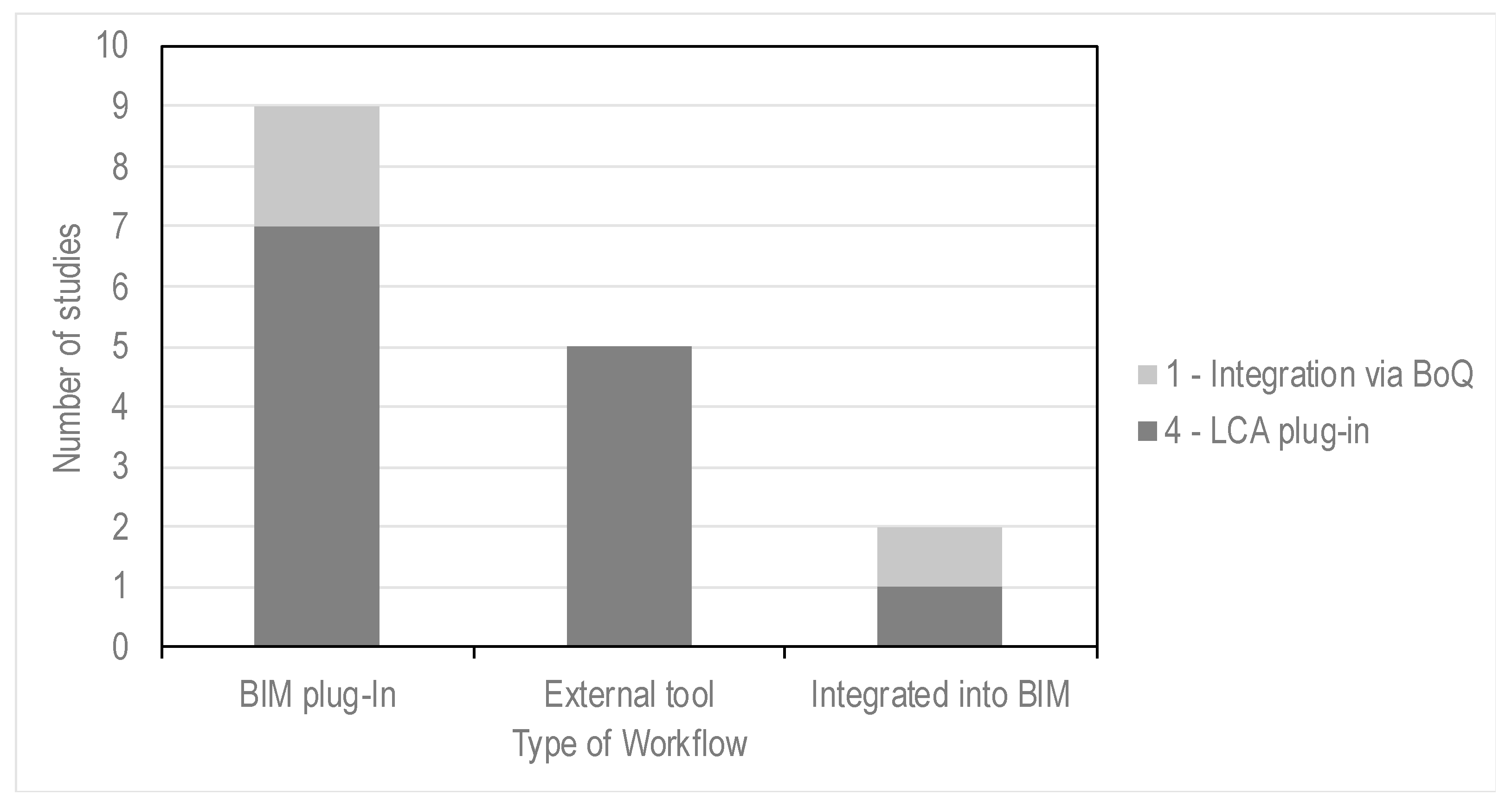

3.1.3. Tools

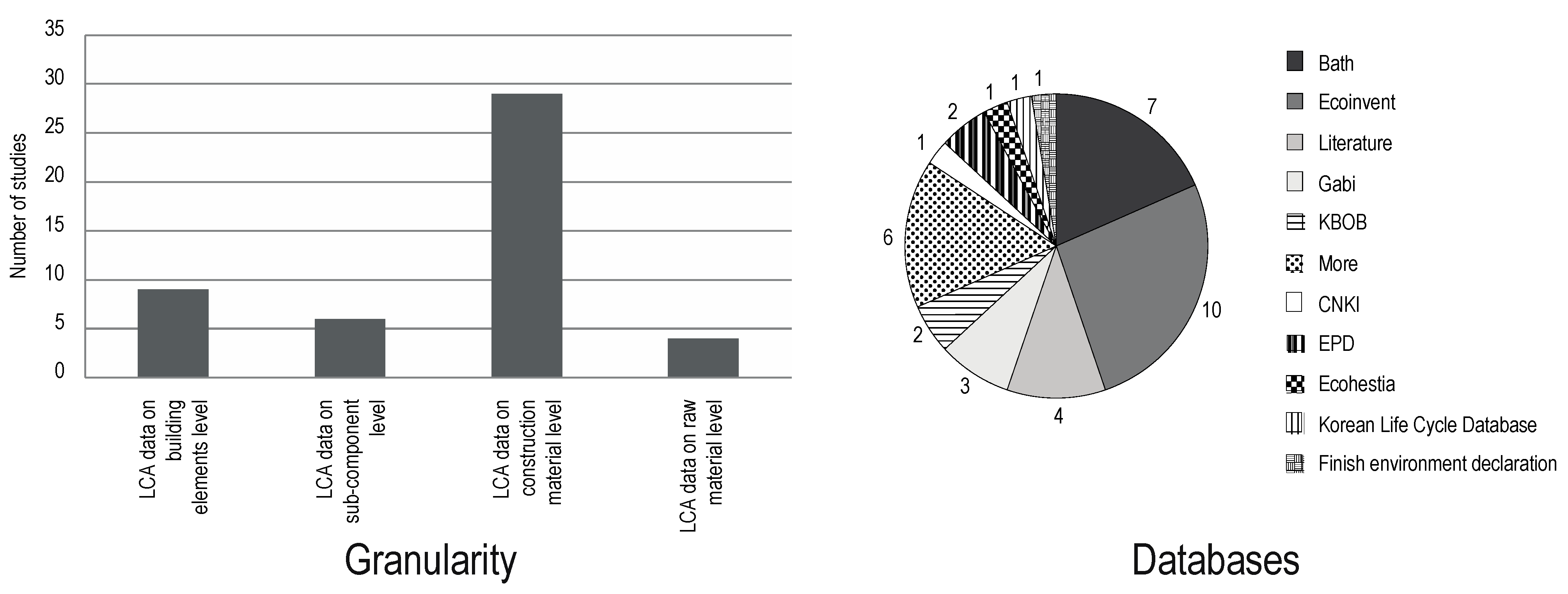

3.2. Informational Issues

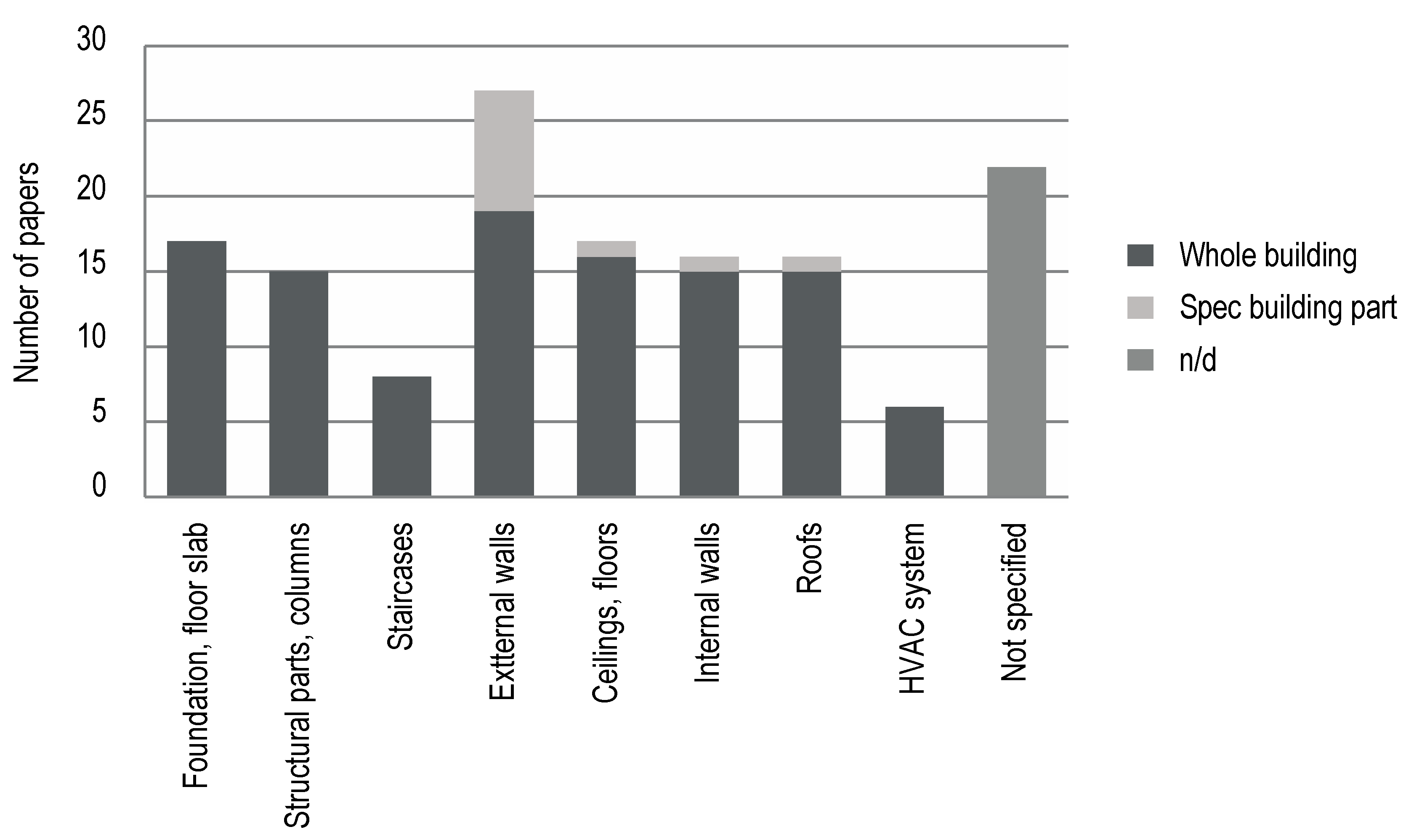

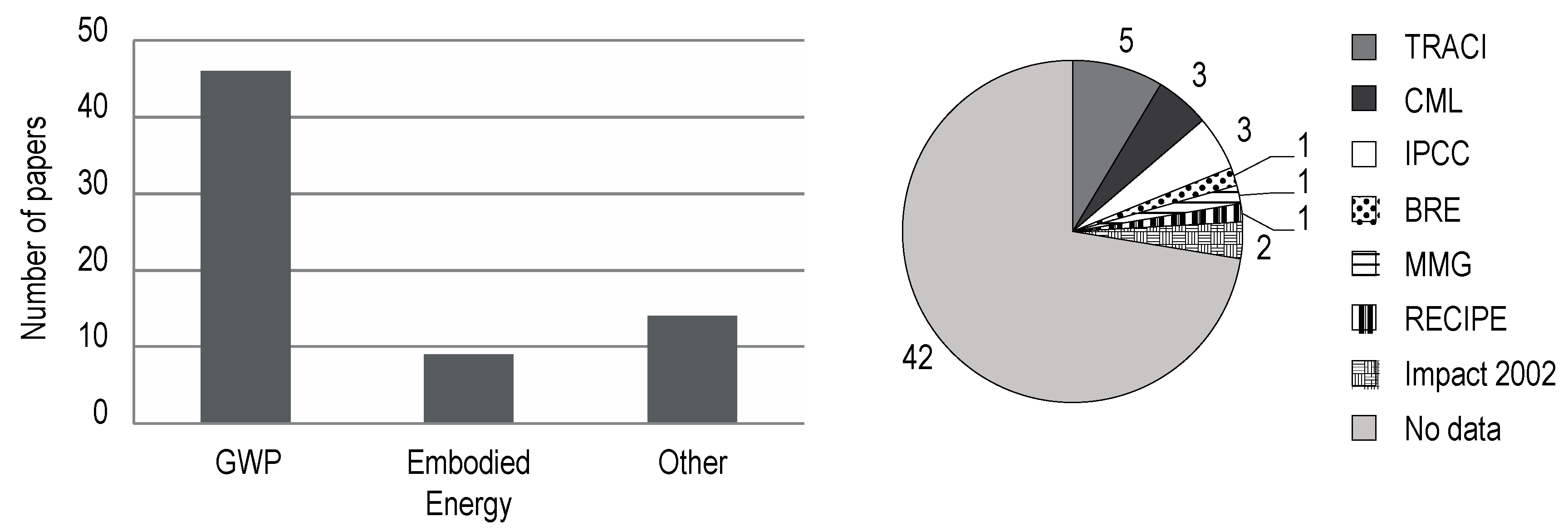

3.3. Functional Requirements for LCAs

4. Discussion

4.1. Technical Issues

4.2. Informational Issues

4.3. Functional Requirement for the LCA

4.4. Organizational Issues

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- UNEP Sustainable Buildings|UNEP-UN Environment Programme. Available online: https://www.unenvironment.org/explore-topics/resource-efficiency/what-we-do/cities/sustainable-buildings (accessed on 10 April 2020).

- Ramesh, T.; Prakash, R.; Shukla, K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernandez, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Röck, M.; Ruschi Mendes Saade, M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdóttir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings–The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Häfliger, I.-F.; John, V.; Passer, A.; Lasvaux, S.; Hoxha, E.; Saade, M.R.M.; Habert, G. Buildings environmental impacts’ sensitivity related to LCA modelling choices of construction materials. J. Clean. Prod. 2017, 156, 805–816. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-Based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- BIM Dictionary. Available online: https://bimdictionary.com/terms/search (accessed on 1 May 2020).

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Antón, L.Á.; Diaz, J. Integration of Life Cycle Assessment in a BIM Environment. Procedia Eng. 2014, 85, 26–32. [Google Scholar] [CrossRef]

- Nizam, R.S.; Zhang, C.; Tian, L. A BIM based tool for assessing embodied energy for buildings. Energy Build. 2018, 170, 1–14. [Google Scholar] [CrossRef]

- Wastiels, L.; Decuypere, R. Identification and comparison of LCA-BIM integration strategies. In Proceedings of the IOP Conference Series Earth and Environmental Science, Graz, Austria, 11–14 September 2019; Volume 323. [Google Scholar] [CrossRef]

- Wohlin, C. Guidelines for snowballing in systematic literature studies and a replication in software engineering. In Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering (EASE ’14), London, UK, 13–14 May 2014. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Gomes, V.; da Silva, M.G.; Ugaya, C.M.L.; Lasvaux, S.; Passer, A.; Habert, G. Investigating transparency regarding ecoinvent users’ system model choices. Int. J. Life Cycle Assess. 2018, 24, 1–5. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Passer, A.; Mittermayr, F. (Sprayed) concrete production in life cycle assessments: A systematic literature review. Int. J. Life Cycle Assess. 2020, 25, 188–207. [Google Scholar] [CrossRef]

- Liu, S.; Meng, X.; Tam, C.M. Building information modeling based building design optimization for sustainability. Energy Build. 2015, 105, 139–153. [Google Scholar] [CrossRef]

- Alireza, A.F.F.; Rashidi, T.H.; Akbarnezhad, A.; Waller, S.T. BIM-Enabled sustainability assessment of material supply decisions. Eng. Constr. Arch. Manag. 2017, 24, 668–695. [Google Scholar] [CrossRef]

- Jrade, A.; Jalaei, F. Integrating building information modelling with sustainability to design building projects at the conceptual stage. Build. Simul. 2013, 6, 429–444. [Google Scholar] [CrossRef]

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of life-Cycle assessment to early stage building design for reduced embodied environmental impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Georges, L.; Haase, M.; Wiberg, A.H.; Kristjansdottír, T.; Risholt, B. Life cycle emissions analysis of two nZEB concepts. Build. Res. Inf. 2014, 43, 82–93. [Google Scholar] [CrossRef]

- Yang, X.; Hu, M.; Wu, J.; Zhao, B. Building-Information-Modeling enabled life cycle assessment, a case study on carbon footprint accounting for a residential building in China. J. Clean. Prod. 2018, 183, 729–743. [Google Scholar] [CrossRef]

- Eleftheriadis, S.; Duffour, P.; Mumovic, D. BIM-Embedded life cycle carbon assessment of RC buildings using optimised structural design alternatives. Energy Build. 2018, 173, 587–600. [Google Scholar] [CrossRef]

- Peng, C.; Wu, X. Case Study of Carbon Emissions from a Building’s Life Cycle Based on BIM and Ecotect. Adv. Mater. Sci. Eng. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

- Peng, C. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Oh, M.S.; Na, S. Building information modelling (BIM) based CO2 emissions assessment in the early design stage. Int. J. Civ. Eng. Technol. 2017, 8, 1411–1425. [Google Scholar]

- Wang, J.; Wu, H.; Duan, H.; Zillante, G.; Zuo, J.; Yuan, H. Combining life cycle assessment and Building Information Modelling to account for carbon emission of building demolition waste: A case study. J. Clean. Prod. 2018, 172, 3154–3166. [Google Scholar] [CrossRef]

- Panteli, C.; Kylili, A.; Stasiuliene, L.; Seduikyte, L.; Fokaides, P.A. A framework for building overhang design using Building Information Modeling and Life Cycle Assessment. J. Build. Eng. 2018, 20, 248–255. [Google Scholar] [CrossRef]

- Rezaei, F.; Bulle, C.; Lesage, P. Integrating building information modeling and life cycle assessment in the early and detailed building design stages. Build. Environ. 2019, 153, 158–167. [Google Scholar] [CrossRef]

- Cavalliere, C.; Habert, G.; Dell’Osso, G.R.; Hollberg, A. Continuous BIM-based assessment of embodied environmental impacts throughout the design process. J. Clean. Prod. 2019, 211, 941–952. [Google Scholar] [CrossRef]

- Feng, H.; Liyanage, D.R.; Karunathilake, H.; Sadiq, R.; Hewage, K. BIM-Based life cycle environmental performance assessment of single-Family houses: Renovation and reconstruction strategies for aging building stock in British Columbia. J. Clean. Prod. 2020, 250, 119543. [Google Scholar] [CrossRef]

- Lu, K.; Jiang, X.; Tam, V.W.; Li, M.; Wang, H.; Xia, B.; Chen, Q. Development of a Carbon Emissions Analysis Framework Using Building Information Modeling and Life Cycle Assessment for the Construction of Hospital Projects. Sustainability 2019, 11, 6274. [Google Scholar] [CrossRef]

- Sartori, T.; Calmon, J.L. Analysis of the impacts of retrofit actions on the life cycle energy consumption of typical neighbourhood dwellings. J. Build. Eng. 2019, 21, 158–172. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A.; De Cózar, J.C.G. BIM-Based LCA Method to Analyze Envelope Alternatives of Single-Family Houses: Case Study in Uruguay. J. Arch. Eng. 2018, 24, 05018002. [Google Scholar] [CrossRef]

- Shafiq, N.; Nurrudin, M.F.; Gardezi, S.S.S.; Bin Kamaruzzaman, A. Carbon footprint assessment of a typical low rise office building in Malaysia using building information modelling (BIM). Int. J. Sustain. Build. Technol. Urban Dev. 2015, 6, 1–16. [Google Scholar] [CrossRef]

- Ajayi, S.; Oyedele, L.; Ceranic, B.; Gallanagh, M.; Kadiri, K.O. Life cycle environmental performance of material specification: A BIM-enhanced comparative assessment. Int. J. Sustain. Build. Technol. Urban Dev. 2015, 6, 14–24. [Google Scholar] [CrossRef]

- Abanda, F.; Oti, A.; Tah, J. Integrating BIM and new rules of measurement for embodied energy and CO2 assessment. J. Build. Eng. 2017, 12, 288–305. [Google Scholar] [CrossRef]

- Kumanayake, R.; Luo, H. Development of an Automated Tool for Buildings’ Sustainability Assessment in Early Design Stage. Procedia Eng. 2017, 196, 903–910. [Google Scholar] [CrossRef]

- Bueno, C.; Pereira, L.M.; Fabricio, M.M. Life cycle assessment and environmental-based choices at the early design stages: An application using building information modelling. Arch. Eng. Des. Manag. 2018, 14, 332–346. [Google Scholar] [CrossRef]

- Cavalliere, C.; Dell’Osso, G.R.; Pierucci, A.; Iannone, F. Life cycle assessment data structure for building information modelling. J. Clean. Prod. 2018, 199, 193–204. [Google Scholar] [CrossRef]

- Hollberg, A.; Genova, G.; Habert, G. Evaluation of BIM-based LCA results for building design. Autom. Constr. 2020, 109, 102972. [Google Scholar] [CrossRef]

- Crippa, J.; Boeing, L.C.; Caparelli, A.P.A.; da do de Costa, M.R.M.M.; Scheer, S.; Araujo, A.M.F.; Bem, D. A BIM–LCA integration technique to embodied carbon estimation applied on wall systems in Brazil. Built Environ. Proj. Asset Manag. 2018, 8, 491–503. [Google Scholar] [CrossRef]

- Jalaei, F.; Jrade, A. An Automated BIM Model to Conceptually Design, Analyze, Simulate, and Assess Sustainable Building Projects. J. Constr. Eng. 2014, 2014, 1–21. [Google Scholar] [CrossRef]

- Shadram, F.; Johansson, T.; Lu, W.; Schade, J.; Olofsson, T. An integrated BIM-based framework for minimizing embodied energy during building design. Energy Build. 2016, 128, 592–604. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. Framework for Sustainable Low-Income Housing Projects using Building Information Modeling. J. Environ. Inform. 2016, 28, 25–38. [Google Scholar] [CrossRef]

- Jiang, S.; Lei, W. The Application of BIM in Green Building Energy Saving: Take Helsinki Music Center as an Example. Adv. Mater. Res. 2014, 935, 3–7. [Google Scholar] [CrossRef]

- Najjar, M.K.; Figueiredo, K.; Palumbo, M.; Haddad, A.N. Integration of BIM and LCA: Evaluating the environmental impacts of building materials at an early stage of designing a typical office building. J. Build. Eng. 2017, 14, 115–126. [Google Scholar] [CrossRef]

- Najjar, M.K.; Figueiredo, K.; Hammad, A.W.; Haddad, A.N. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382. [Google Scholar] [CrossRef]

- Raposo, C.; Rodrigues, F.; Rodrigues, H. BIM-based LCA assessment of seismic strengthening solutions for reinforced concrete precast industrial buildings. Innov. Infrastruct. Solut. 2019, 4, 1–10. [Google Scholar] [CrossRef]

- Bueno, C.; Fabricio, M.M. Comparative analysis between a complete LCA study and results from a BIM-LCA plug-in. Autom. Constr. 2018, 90, 188–200. [Google Scholar] [CrossRef]

- Hollberg, A.; Ruth, J. LCA in architectural design—A parametric approach. Int. J. Life Cycle Assess. 2016, 21, 943–960. [Google Scholar] [CrossRef]

- Lee, S.-K.; Kim, K.; Yu, J.-H. BIM and ontology-based approach for building cost estimation. Autom. Constr. 2014, 41, 96–105. [Google Scholar] [CrossRef]

- Jalaei, F.; Zoghi, M.; Khoshand, A. Life cycle environmental impact assessment to manage and optimize construction waste using Building Information Modeling (BIM). Int. J. Constr. Manag. 2019, 1–18. [Google Scholar] [CrossRef]

- Kulahcioglu, T.; Dang, J.; Toklu, C. A 3D analyzer for BIM-enabled Life Cycle Assessment of the whole process of construction. HVAC R Res. 2012, 18, 283–293. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Integration of LCA and LCC analysis within a BIM-Based environment. Autom. Constr. 2019, 103, 127–149. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-based life cycle assessment and life cycle costing of an office building in Western Europe. Build. Environ. 2020, 169, 106568. [Google Scholar] [CrossRef]

- Russell-Smith, S.; Lepech, M.D. Dynamic Life Cycle Assessment of Building Design and Retrofit Processes. Comput. Civ. Eng. 2011, 760–767. [Google Scholar] [CrossRef]

- European Committee for Standardization En 15978. Sustainable Construction Work—Assessment Environmental Performance Building—Calculating Method 2011; CEN: Brussels, Belgium, 2011. [Google Scholar]

- Lee, S.; Tae, S.; Roh, S.; Kim, T. Green Template for Life Cycle Assessment of Buildings Based on Building Information Modeling: Focus on Embodied Environmental Impact. Sustainability 2015, 7, 16498–16512. [Google Scholar] [CrossRef]

- Caplehorn, P.; Caplehorn, P. RIBA Plan of Work 2020 Overview. Available online: https://www.architecture.com/-/media/GatherContent/Test-resources-page/Additional-Documents/2020RIBAPlanofWorktemplatepdf.pdf (accessed on 17 June 2020).

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Martínez-Rocamora, A.; Solís-Guzmán, J.; Marrero, M. LCA databases focused on construction materials: A review. Renew. Sustain. Energy Rev. 2016, 58, 565–573. [Google Scholar] [CrossRef]

- Gantner, J.; Lenz, K.; Horn, R.; Von Both, P.; Ebertshäuser, S. Ökobau.dat 3.0–Quo Vadis? Buildings 2018, 8, 129. [Google Scholar] [CrossRef]

- IEA EBC Iea Ebc Annex 72. Available online: http://www.iea-ebc.org/projects/ongoing-projects/ebc-annex-72/ (accessed on 1 May 2020).

- Bribian, I.Z.; Uson, J.A.A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life Cycle Assessment of an Apartment Building: Comparison of an Attributional and Consequential Approach. Energy Procedia 2014, 62, 132–140. [Google Scholar] [CrossRef]

- Shadram, F.; Mukkavaara, J. An integrated BIM-Based framework for the optimization of the trade-off between embodied and operational energy. Energy Build. 2018, 158, 1189–1205. [Google Scholar] [CrossRef]

- Gao, H.; Koch, C.; Wu, Y. Building information modelling based building energy modelling: A review. Appl. Energy 2019, 238, 320–343. [Google Scholar] [CrossRef]

- Shin, Y.-S.; Cho, K. BIM Application to Select Appropriate Design Alternative with Consideration of LCA and LCCA. Math. Probl. Eng. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Yung, P.; Wang, X. A 6D CAD Model for the Automatic Assessment of Building Sustainability. Int. J. Adv. Robot. Syst. 2014, 11, 131. [Google Scholar] [CrossRef]

- Balouktsi, M.; Lützkendorf, T.; Röck, M.; Passer, A.; Reisinger, T.; Frischknecht, R. Survey results on acceptance and use of Life Cycle Assessment among designers in world regions: IEA EBC Annex 72. In Proceedings of the World Sustainable Built Environment Conference, Gothenburg, Sweden, 9–11 June 2020. (in press).

| Life Cycle Stage | Required Data | Sources | Connection to BIM |

|---|---|---|---|

| Product stage A1–A3 | Environmental impacts of materials, Quantity of materials | Environmental Product Declaration (EPD), Databases BIM | Independent or attached |

| Transport to construction site A4 | Distances of transport, Transport means | Spreadsheets Independent applications General assumptions | Independent |

| Construction stage A5 | Energy and materials needed for construction | Spreadsheets Independent applications | Independent |

| Use, Maintenance, Repair, Replacement, Refurbishment B1–B5 | RSL of the building materials EoL scenarios Maintenance scenarios Distances of transport, Transport means | Spreadsheets Databases Spreadsheets Independent applications General assumptions | Independent |

| Operational Energy B6 | Energy use | Calculation via plug-in Export to independent tools | Independent Plug-in Embedded |

| Operational Water B7 | Water use | Spreadsheets Databases Assumptions | Independent |

| Deconstruction C1 | Energy and materials needed for deconstruction and demolition | Databases | Independent |

| Transport to disposal C2 | Distances of transport, Transport means | Spreadsheets Independent applications General assumptions | Independent |

| Waste processing C3 | Energy and material needed for waste processing | Spreadsheets Databases Assumptions | Independent |

| Disposal C4 | Emission caused by disposal | Spreadsheets Databases Assumptions | Independent |

| Benefits and loads beyond the system boundary D | EoL scenarios Energy and material needed for waste processing Potential benefits | Spreadsheets Databases Assumptions | Independent |

| Functional Unit | Declared | Educated Guess |

|---|---|---|

| Whole building | 4 | 21 |

| Whole building—normalized | 6 | 0 |

| Specific building parts | 9 | 1 |

| Other | 3 | |

| No data | 15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Potrč Obrecht, T.; Röck, M.; Hoxha, E.; Passer, A. BIM and LCA Integration: A Systematic Literature Review. Sustainability 2020, 12, 5534. https://doi.org/10.3390/su12145534

Potrč Obrecht T, Röck M, Hoxha E, Passer A. BIM and LCA Integration: A Systematic Literature Review. Sustainability. 2020; 12(14):5534. https://doi.org/10.3390/su12145534

Chicago/Turabian StylePotrč Obrecht, Tajda, Martin Röck, Endrit Hoxha, and Alexander Passer. 2020. "BIM and LCA Integration: A Systematic Literature Review" Sustainability 12, no. 14: 5534. https://doi.org/10.3390/su12145534

APA StylePotrč Obrecht, T., Röck, M., Hoxha, E., & Passer, A. (2020). BIM and LCA Integration: A Systematic Literature Review. Sustainability, 12(14), 5534. https://doi.org/10.3390/su12145534