Hardness Safety Testing of Artificial Turf †

Abstract

:1. Introduction

2. Hardness Testing Methods

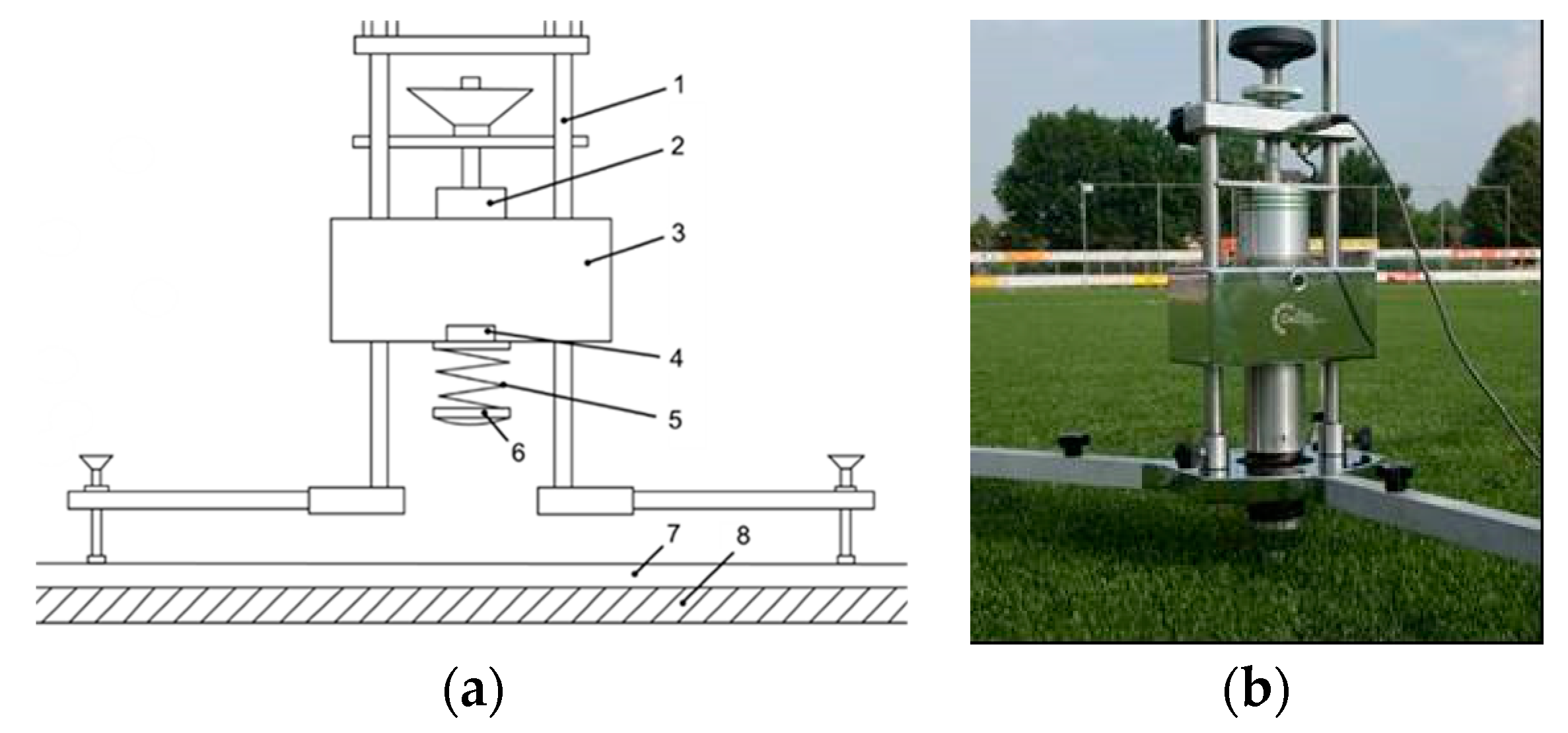

2.1. The Advanced Artificial Athlete

2.2. The Fieldtester

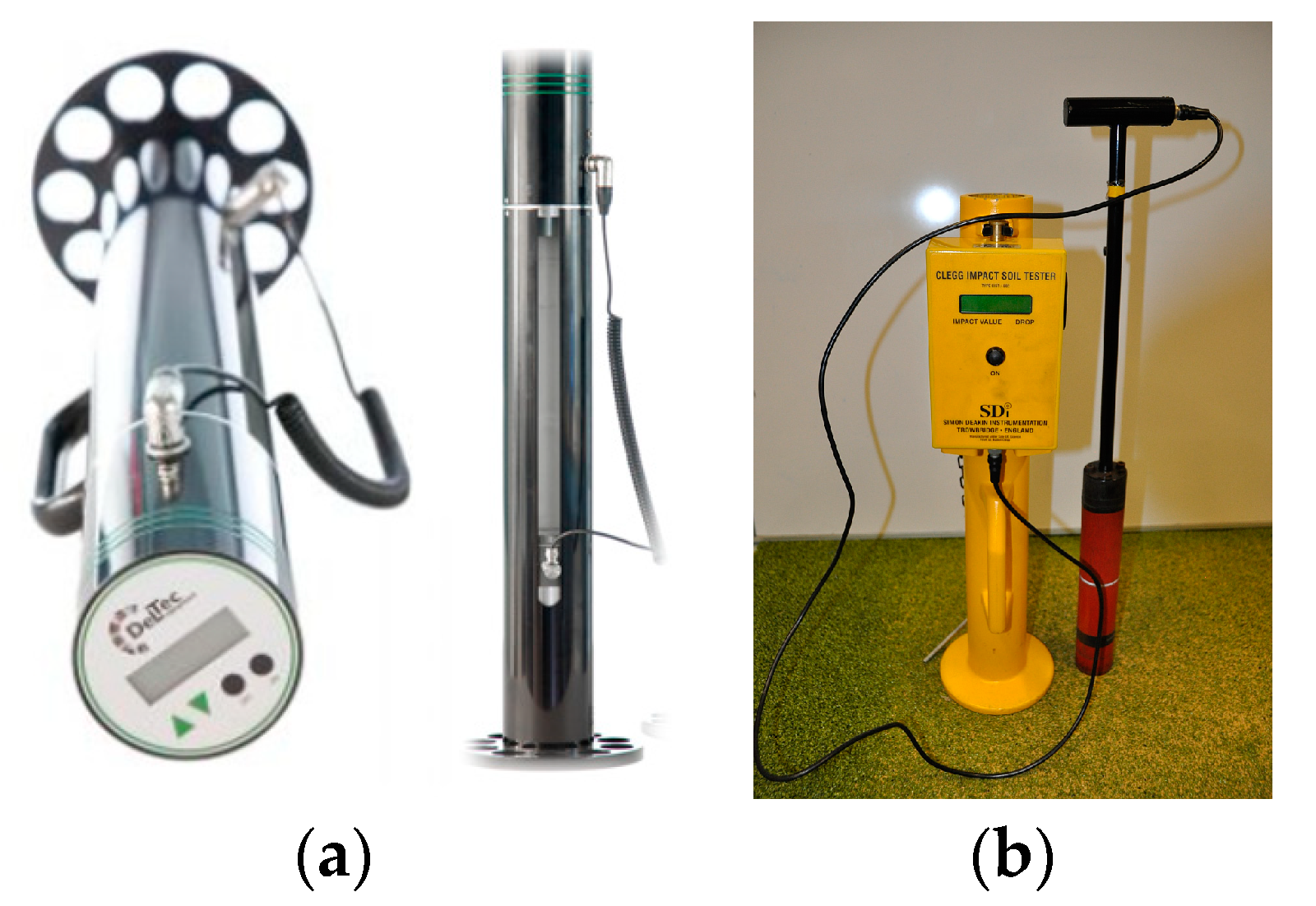

2.3. The Clegg Impact Soil Tester

2.4. Impact Energy

3. Device Correlations and Behavior

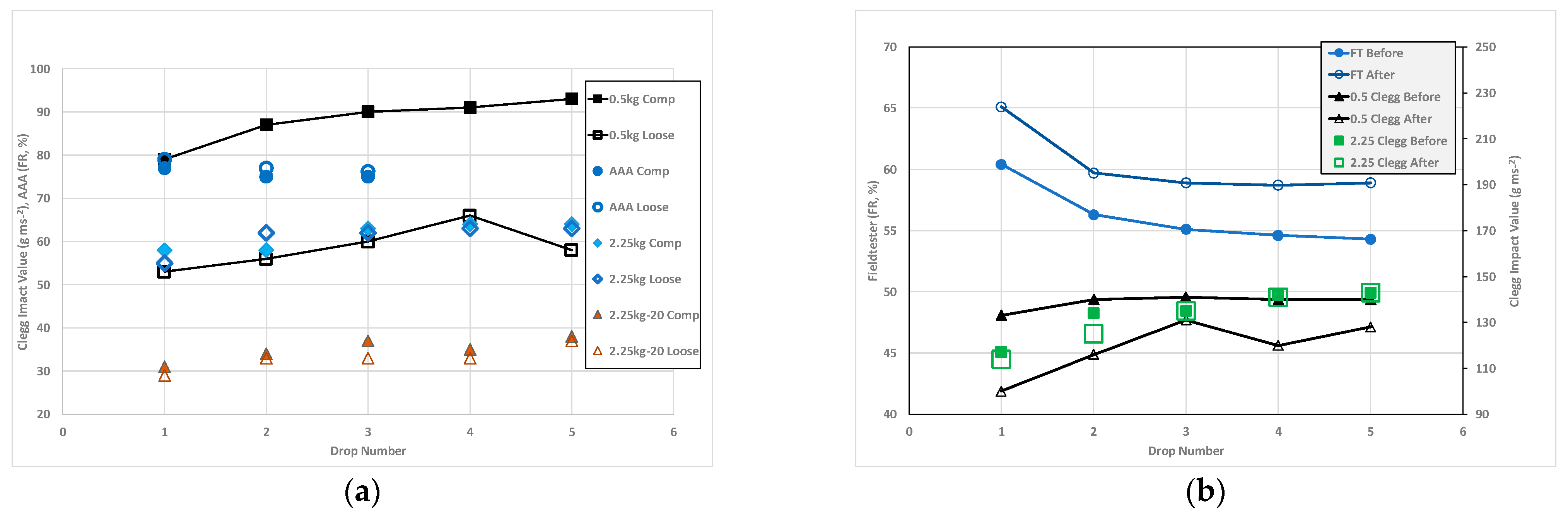

3.1. AAA and 2.25 kg CIST

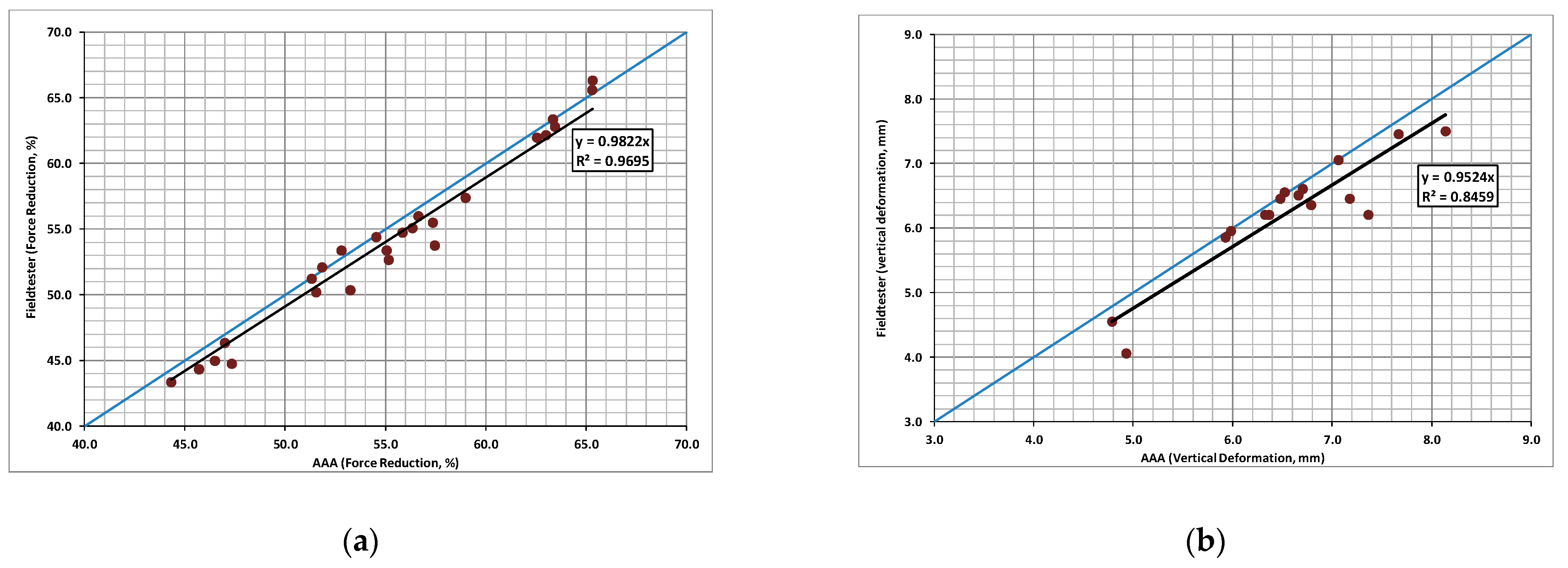

3.2. AAA and Fieldtester

3.3. Surface Hardness and Maintenance Monitoring

4. Discussion

5. Conclusions

Acknowledgments

References

- Fleming, P.R. Artificial turf systems for sport surfaces: Current knowledge and research needs. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2011, 225, 43–64. [Google Scholar] [CrossRef]

- Fédération Internationale de Football Association. FIFA Quality Concept for Football Turf: Handbook of Test Methods. 2015. Available online: www.FIFA.com (accessed on 23 September 2019).

- Clegg, B. An impact testing device for in situ base course evaluation. Aust. Road Res. Bur. Proc. 1976, 8, 1–6. [Google Scholar]

- Deltec, Equipment for Testing Fields. Available online: https://www.deltecequipment.com/testing-equipment/ (accessed on 12 October 2019).

- ASTM. F1702 (2018): Standard Test Method for Measuring Impact-Attenuation Characteristics of Natural Playing Surface Systems Using a Lightweight Portable Apparatus; ASTM: West Conshohocken, PA, USA.

- Thanheiser, S.Y.; Grashey-Jansen, S.; Armbruster, G. Hardness measurement of natural and hybrid turf soccer fields. Sports Eng. 2018, 21, 367–37. [Google Scholar] [CrossRef]

- Saunders, N.; Twomey, D.; Otago, L. Clegg hammer measures and human external landing forces: Is there a relationship? Int. J. Sports Sci. Eng. 2011, 5, 231–236. [Google Scholar]

- Twomey, D.M.; Ullah, S.; Petrass, L.A. One, two, three or four: Does the number of Clegg hammer drops alter ground hardness readings on natural grass? Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2013, 228, 33–39. [Google Scholar] [CrossRef]

- Fleming, P.; Young, C.; Dixon, N. Performance Measurements on Synthetic Turf Hockey Pitches. In The Engineering of Sport 5; SEA: Aachen, Germany, 2004; Volume 2, pp. 524–531. ISBN 0-9547861-1-4. [Google Scholar]

- Young, C.; Fleming, P.R.; Dixon, N.; Jones, R.; Roberts, J.R. Correlating Playing Performance Tests with Human perceptions for Synthetic Field Hockey Pitches. In The Engineering of Sport 5; ISEA: Aachen, Germany, 2004; Volume 2, pp. 517–523. ISBN 0-9547861-1-4. [Google Scholar]

- Fleming, P.R.; Forrester, S.E.; McLaren, N.J. Understanding the effects of decompaction maintenance on the infill state and play performance of third-generation artificial grass pitches. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2015, 229, 169–182. [Google Scholar] [CrossRef] [PubMed]

- UEFA Pitch Quality Guidelines, Natural Turf Pitch Management. 2018. Available online: https://www.uefa.com/ (accessed on 12 October 2019).

| Device | Drop Weight (kg) | Drop Ht. (cm) | Diameter (cm) | Load Pulse (ms) | Potential Energy (J) | Impact Vel. (m/s) |

|---|---|---|---|---|---|---|

| AAA 1 | 20 | 5.5 | 7 | ~20 | 11 | 1.04 |

| Fieldtester 1 | ~5 | ~35 | 7 | Unknown | 17 | 2.6 |

| 2.25 kg CIST | 2.25 | 45 | 5 | 2–5 | 10 | 3.0 |

| 0.5 kg CIST | 0.5 | 45 | 5 | 2–5 | 2.2 | 3.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fleming, P.; Watts, C.; Gunn, J.; Forrester, S. Hardness Safety Testing of Artificial Turf. Proceedings 2020, 49, 130. https://doi.org/10.3390/proceedings2020049130

Fleming P, Watts C, Gunn J, Forrester S. Hardness Safety Testing of Artificial Turf. Proceedings. 2020; 49(1):130. https://doi.org/10.3390/proceedings2020049130

Chicago/Turabian StyleFleming, Paul, Charlie Watts, Jon Gunn, and Steph Forrester. 2020. "Hardness Safety Testing of Artificial Turf" Proceedings 49, no. 1: 130. https://doi.org/10.3390/proceedings2020049130

APA StyleFleming, P., Watts, C., Gunn, J., & Forrester, S. (2020). Hardness Safety Testing of Artificial Turf. Proceedings, 49(1), 130. https://doi.org/10.3390/proceedings2020049130