LCA Analysis of Grafted Tomato Seedling Production in Turkey

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Importance of the Study Region Antalya for Seedling Production in Turkey

2.2. The Differences Between Grafted Seedlings and Normal Seedlings

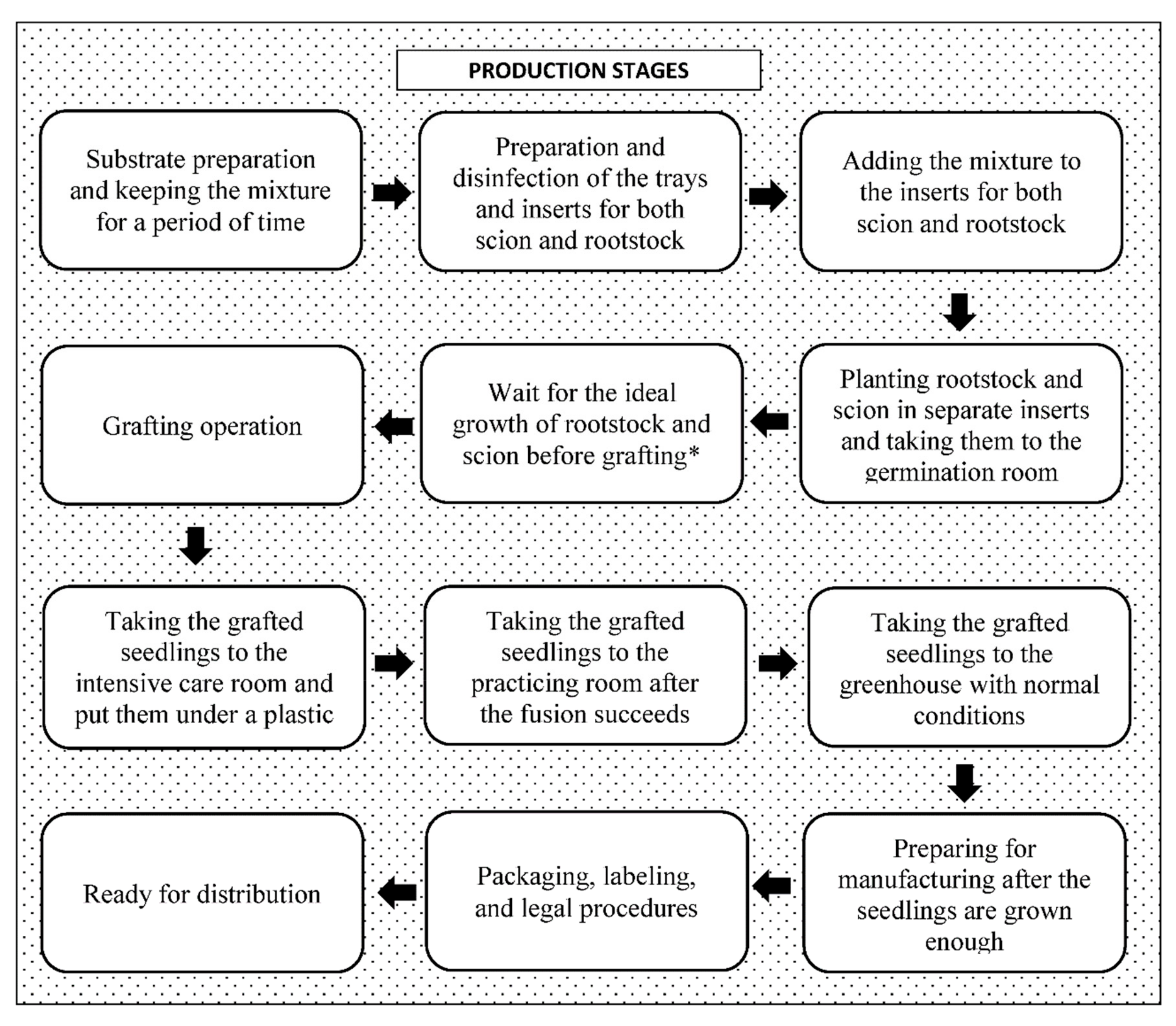

2.3. Production Stages of Grafted Seedlings

2.4. Materials of the Study

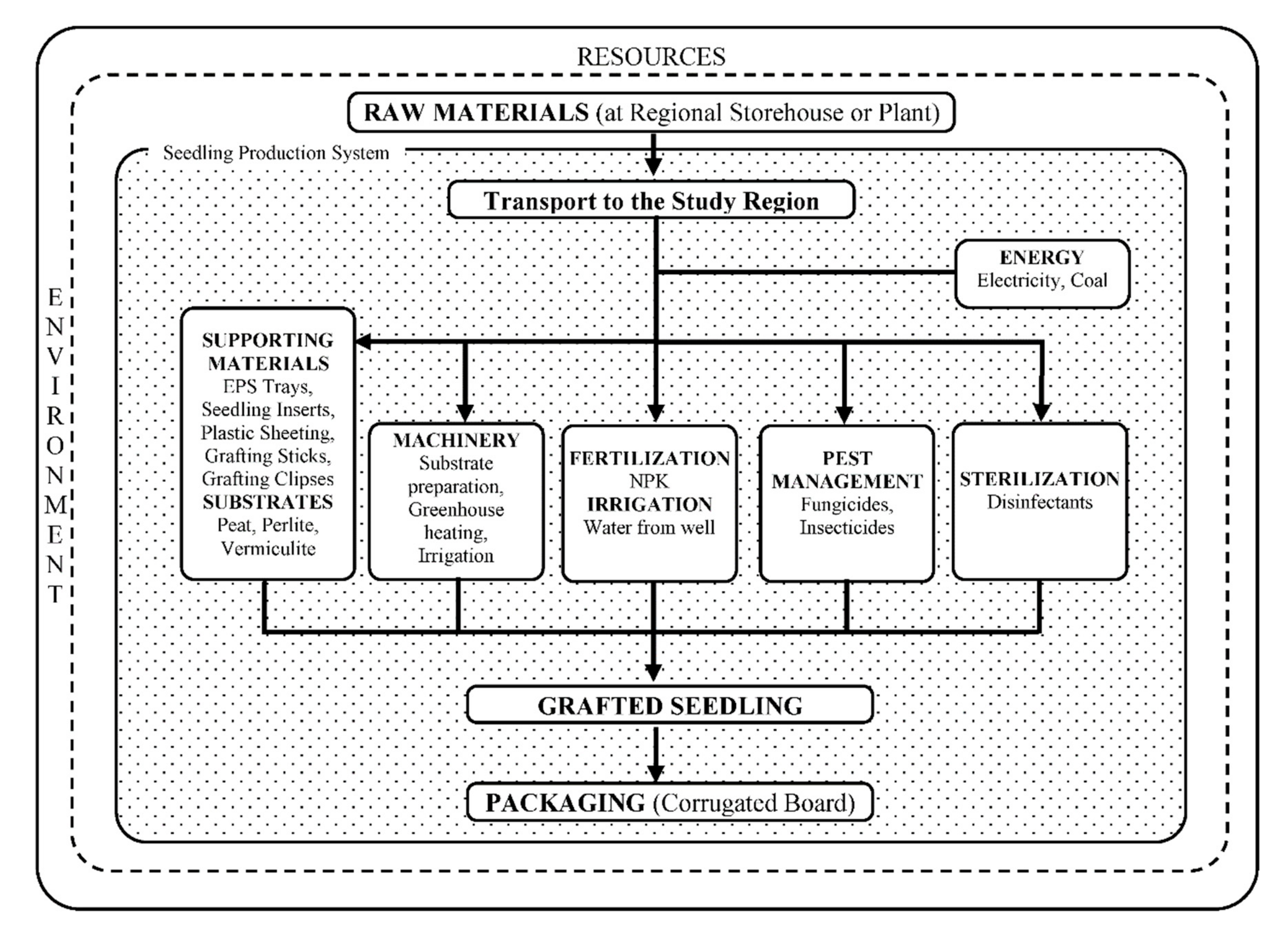

2.5. System Boundary and the Definition Criteria

2.6. The Functional Unit Chosen for the Study

2.7. Life Cycle Inventory Categories and Processes

2.7.1. Transportation of Materials

2.7.2. Irrigation Method

2.7.3. Energy

2.7.4. Fertilizers

2.7.5. Pesticides

2.7.6. Disinfectants

2.8. LCA Software and Database

2.9. Impact Assessment Method

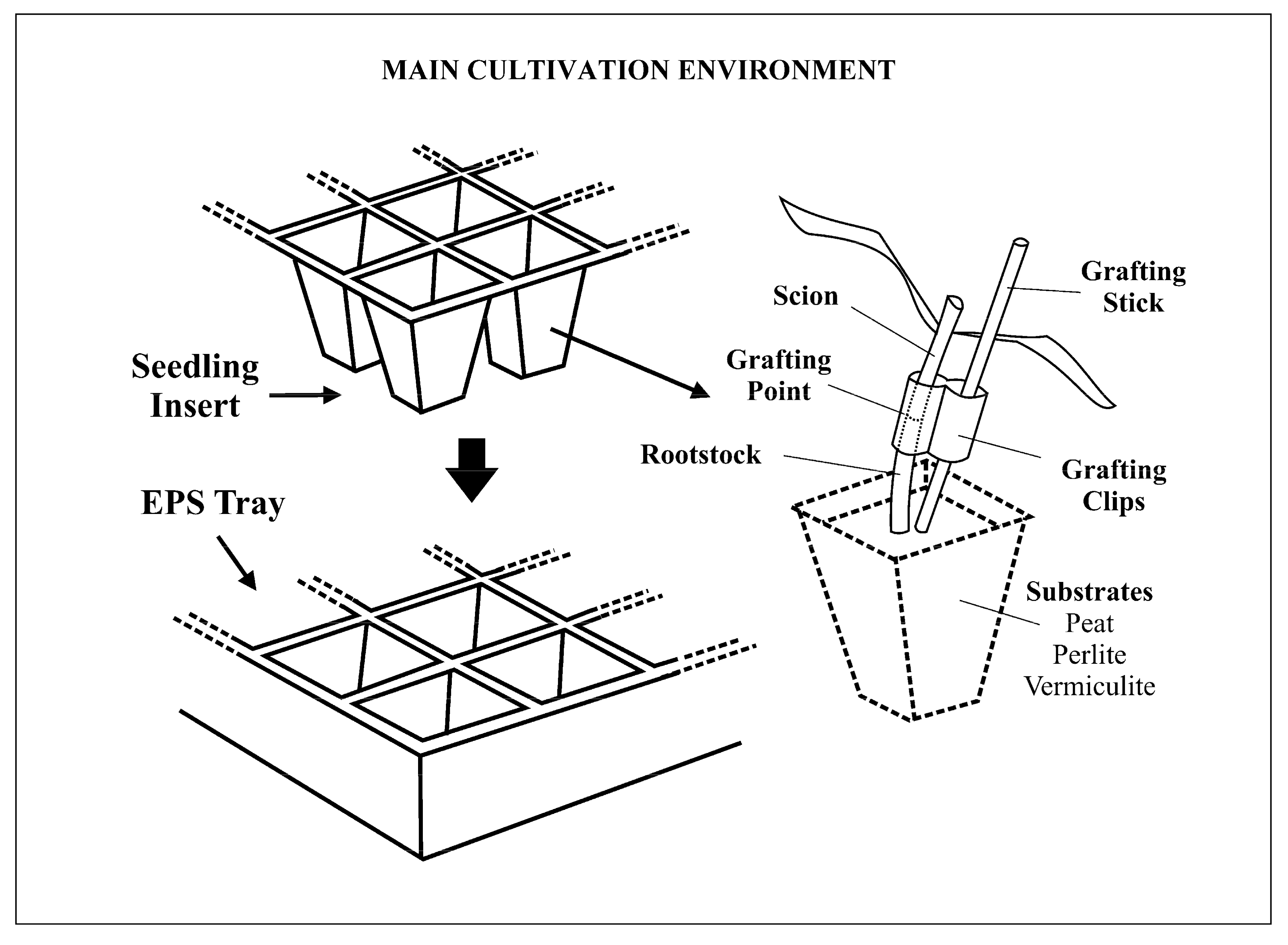

2.10. Cultivation Environment and Terminology

2.11. Supporting Materials and Horticultural Substrates

3. Results and Discussion

3.1. LCA Analysis

3.1.1. An Overview of the Production Processes

3.1.2. Energy Analysis

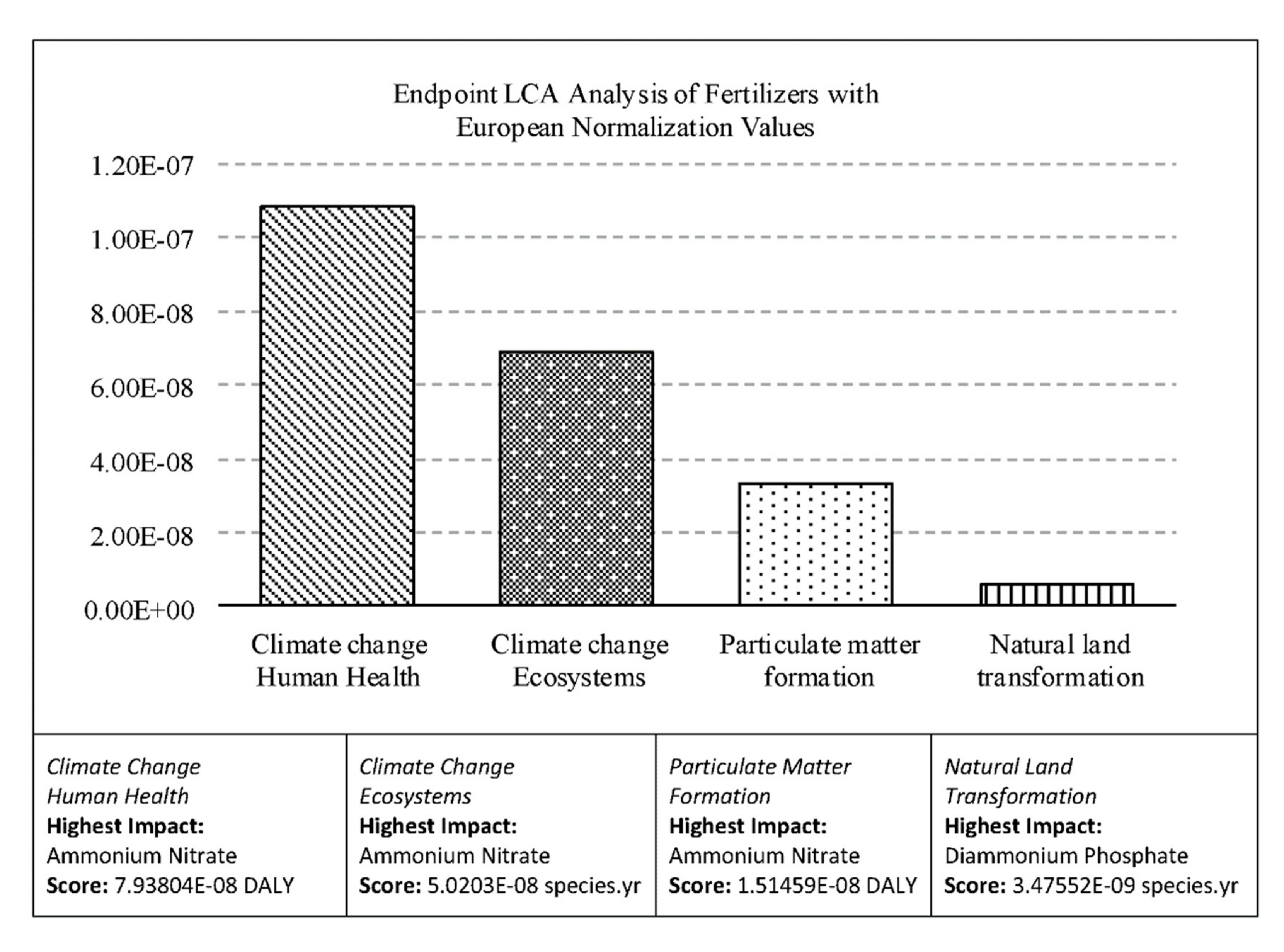

3.1.3. Fertilizer Analysis

3.1.4. Pesticide Analysis

3.1.5. Analysis of the Supporting Materials and the Horticultural Substrates

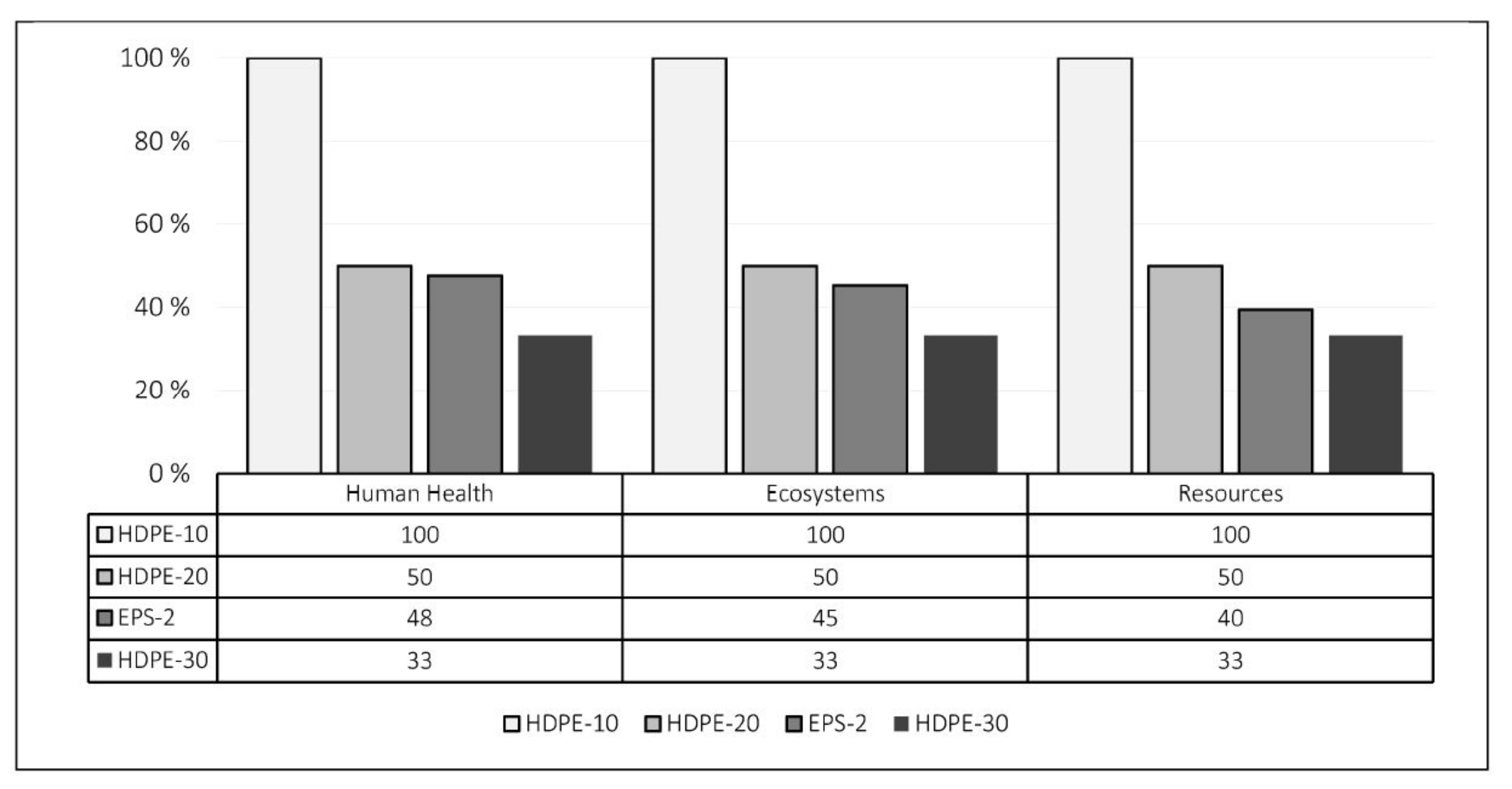

3.1.6. EPS and HDPE Comparison Scenarios

3.2. The Use of Seedlings by the Vegetable Producers

4. Conclusions

Conflicts of Interest

Appendix A

| Provinces in Turkey | Num. of Nurseries | Antalya Towns | Num. of Nurseries |

|---|---|---|---|

| Antalya | 64 | Serik | 14 |

| İzmir | 16 | Kumluca | 13 |

| Mersin | 12 | Demre | 2 |

| Ankara | 9 | Kaş | 1 |

| Adana | 7 | Close to Antalya City Centre | 34 |

| Bursa | 5 | ||

| Other | 39 | ||

| Total | 152 | Total | 64 |

| Processing Category | Included? | Why Excluded? | ||

|---|---|---|---|---|

| Insignificant Environmental Impact | Difficult to Obtain Representative Data | Not Directly Relevant to the Scope and Goal of the Study | ||

| Production, maintenance, and replacement of capital equipment | no | - | - | ✔ |

| Electricity for equipment utilized (water pump, machinery, etc.) | yes | - | - | - |

| Coal for greenhouse heating | yes | - | - | - |

| Transportation and production of germinated seeds | no | - | ✔ | - |

| Transportation of raw materials (fertilizers, pesticides, disinfectants, supporting materials, substrates) | yes | - | - | - |

| Production and appliance of fertilizers | yes | - | - | - |

| Production and appliance of pesticides | yes | - | - | - |

| Production and appliance of disinfectants | yes | - | - | - |

| Production and appliance of horticultural substrates | yes | - | - | - |

| Production of support materials | yes | - | - | - |

| Water supply | yes | - | - | - |

| Establishment’s land occupation | no | ✔ | ✔ | - |

References

- Yilmaz, I.; Sayin, C.; Ozkan, B. Turkish greenhouse industry: Past, present, and future. N. Z. J. Crop Hortic. Sci. 2005, 33, 233–240. [Google Scholar] [CrossRef] [Green Version]

- TÜRKTOB. Tohumculuk Sektörü Ulusal Strateji Raporu; TÜRKTOB: Ankara, Turkey, 2017. [Google Scholar]

- Fidebirlik. Fidebirlik Annual Statistics; Fidebirlik: Antalya, Turkey, 2018. [Google Scholar]

- Caffrey, K.R.; Veal, M.W. Conducting an agricultural life cycle assessment: Challenges and perspectives. Sci. World J. 2013, 2013, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nita, A. Empowering impact assessments knowledge and international research collaboration—A bibliometric analysis of environmental impact assessment review journal. Environ. Impact Assess. Rev. 2019, 78, 106283. [Google Scholar] [CrossRef]

- Russell, A.; Ekvall, T.; Baumann, H. Life cycle assessment introduction and overview. J. Clean. Prod. 2005, 13, 1207–1210. [Google Scholar] [CrossRef] [Green Version]

- Skowrońska, M.; Filipek, T. Life cycle assessment of fertilizers: A review. Int. Agrophys. 2014, 28, 101–110. [Google Scholar] [CrossRef]

- Beccaro, G.L.; Cerutti, A.K.; Vandecasteele, I.; Bonvegna, L.; Donno, D.; Bounous, G. Assessing environmental impacts of nursery production: Methodological issues and results from a case study in Italy. J. Clean. Prod. 2014, 80, 159–169. [Google Scholar] [CrossRef]

- Google Scholar. Seedling lca Article Search. Available online: https://scholar.google.com/scholar?q=life+cycle+seedling (accessed on 12 December 2019).

- Science Direct. Seedling lca Paper Search. Available online: https://www.sciencedirect.com/search/advanced?qs=Life%20cycle%20seedling (accessed on 12 December 2019).

- Fert, C. Antalya Ili Merkez İlçede Aşılı ve Aşısız Fide Ile Cam Serada Tek Ürün Domates Üretiminin Ekonometrik Analizi; Akdeniz University: Antalya, Turkey, 2012. [Google Scholar]

- Page, G.; Ridoutt, B.; Bellotti, B. Carbon and water footprint tradeoffs in fresh tomato production. J. Clean. Prod. 2012, 32, 219–226. [Google Scholar] [CrossRef]

- Hendricks, P. Life Cycle Assessment of Greenhouse Tomato (Solanum lycopersicum L.) Production in Southwestern Ontario; McLaughlin Library University of Guelph: Guelph, ON, Canada, 2012. [Google Scholar]

- Wood, A. Compendium of Pesticide Common Names. Available online: http://www.alanwood.net/pesticides/class_insecticides.html (accessed on 11 May 2019).

- Bare, J.; Hofstetter, P.; Pennington, D.W.; de Haes, H.A.U. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000, 5, 319–326. [Google Scholar] [CrossRef] [Green Version]

- Manzo, S.; Dong, Y.; Miraglia, S.; Salling, K.B. How the inclusion of life cycle impacts affects transport cost-benefit analysis. Eur. J. Transp. Infrastruct. Res. 2018, 18, 372–388. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. Recipe 2008: A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level. Int. J. Life Cycle Assess. 2013, 18, 683–697. [Google Scholar]

- Mudge, K.; Janick, J.; Scofield, S.; Goldschmidt, E.E. A History of Grafting. In Horticultural Reviews; Janick, J., Ed.; John Wiley and Sons, Inc: New York, NY, USA, 2009. [Google Scholar]

- Pina, A.; Errea, P. A review of new advances in mechanism of graft compatibility–incompatibility. Sci. Hortic. 2005, 106, 1–11. [Google Scholar] [CrossRef]

- Guan, W.; Hallett, S. Vegetable Grafting: Techniques for Tomato Grafting; Purdue University: West Lafayette, IN, USA, 2016. [Google Scholar]

- Bilderback, T.; Bir, R.E.; Ranney, T.G. Grafting and Budding Nursery Crop Plants. Available online: https://content.ces.ncsu.edu/grafting-and-budding-nursery-crop-plants (accessed on 2 April 2019).

- Cinar, A.H. Serada ve Açık Alanlarda Domates Yetiştiriciliği; Hasad Publishing: Istanbul, Turkey, 2015; p. 254. [Google Scholar]

- Boulard, T.; Raeppel, C.; Brun, R.; Lecompte, F.; Hayer, F.; Carmassi, G.; Gaillard, G. Environmental impact of greenhouse tomato production in France. Agron. Sustain. Dev. 2011, 31, 757. [Google Scholar] [CrossRef] [Green Version]

- NREL. Life Cycle Greenhouse Gas Emissions from Solar Photovoltaics (Fact Sheet); NREL (National Renewable Energy Laboratory): Golden, CO, USA, 2012. [Google Scholar]

- BAKA. Yenilenebilir Enerji Mali Destek Programı—2018 Yılı Teklif Çağrısı - Başvuru Rehberi; BAKA: Isparta, Turkey, 2018. [Google Scholar]

- Da Silva, M.J.; Magalhães, P.S.G. A liquid injection dosing system for site-specific fertiliser management. Biosyst. Eng. 2017, 163, 150–158. [Google Scholar] [CrossRef]

- Ercolano, M.R.; Gomez, L.D.; Andolfi, A.; Simister, R.; Troise, C.; Angelino, G.; Borrelli, C.; McQueen-Mason, S.J.; Evidente, A.; Frusciante, L.; et al. Residual biomass saccharification in processing tomato is affected by cultivar and nitrogen fertilization. Biomass Bioenergy 2015, 72, 242–250. [Google Scholar] [CrossRef]

- US EPA. Pyrethrins and Pyrethroids; US EPA: Washington, DC, USA, 2015. [Google Scholar]

- Al-Alam, J.; Bom, L.; Chbani, A.; Fajloun, Z.; Millet, M. Analysis of dithiocarbamate fungicides in vegetable matrices using hplc-uv followed by atomic absorption spectrometry. J. Chromatogr. Sci. 2017, 55, 429–435. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tan, R.B.H.; Khoo, H.H. Life cycle assessment of eps and cpb inserts: Design considerations and end of life scenarios. J. Environ. Manag. 2005, 74, 195–205. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations. Good Agricultural Practices for Greenhouse Vegetable Production in the South East European Countries: Principles for Sustainable Intensification of Smallholder Farms; FAO: Rome, Italy, 2017; p. 192. [Google Scholar]

- Hannay, F. Rigid Plastics Packaging: Materials, Processes and Applications; iSmithers Rapra Publishing: Shrewsbury, UK, 2002; p. 12. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fidebirlik. Fidebirlik Faq. Available online: http://www.fidebirlik.org.tr/sss-liste/ (accessed on 5 April 2019).

- Fidebirlik. Fidebirlik Member Count. Available online: http://www.fidebirlik.org.tr/uyelik/fidebirlikin-yillara-ve-illere-gore-uye-sayisi/ (accessed on 15 April 2019).

- Muhamad, H.; Hashim, Z.; Subramaniam, V.; Tan, Y.; Wei, P.; Chong, C.L.; May, C. Life cycle assessment of oil palm seedling production (part 1). J. Oil Palm Res. 2010, 22, 878–886. [Google Scholar]

| Input | Amount | Input | Amount |

|---|---|---|---|

| Energy | Pesticides | ||

| Electricity | 0.026368171 kWh | Organophosphorus Compounds (F) | 0.00014156 g |

| Coal for Greenhouse Heating | 0.259842137 kWh | Cyclic N Compounds (F) | 0.00002389 g |

| FERTILIZERS | [thio] Carbamate Compounds (F) | 0.00000741 g | |

| Ammonium Nitrate | 0.131839585 g | Acetamide Anillide Compounds (F) | 0.00002953 g |

| Diammonium Phosphate | 0.059936818 g | Triazine Compounds (F) | 0.00000265 g |

| Monoamonnium Phosphate | 0.018759378 g | Dithiocarbamate Compounds (F) | 0.00015926 g |

| Potassium Nitrate | 0.236245177 g | Phthalimide Compounds (F) | 0.00012387 g |

| Potassium Sulphate | 0.050896546 g | Pyrethroid Compounds (I) | 0.00010009 g |

| Transport | Tetramic Acid Compounds (I) | 0.00008848 g | |

| Transport of Raw Materials | 0.501835584 kg.km | Tetronic Acid Compounds (I) | 0.00004645 g |

| Disinfectants | Macrocyclic Lactone Compounds (I) | 0.00000657 g | |

| Hydrogen Peroxide | 0.05529750 g | Supporting Materials | |

| Peracetic Acid | 0.03317850 g | Seedling Insert (Polypropylene) | 1.5115741 g |

| Alcohol (Isopropanol) | 0.02211900 g | EPS Tray (EPS Foam) | 3.662499 g |

| Horticultural Substrates | Grafting Sticks (Polypropylene) | 0.25 g | |

| Peat | 5.271428571 g | Grafting Clips (Silicone) | 0.6 g |

| Expanded Perlite | 1.142142857 g | Plastic Sheeting (Polyethylene) | 0.666111574 g |

| Expanded Vermiculite | 4.539285714 g | Packaging (Corrugated Board) | 0.00835 g |

| Irrigation (Water from Well) | 0.950 liters | ||

| Impact Category Name | Abbrev. | Midpoint Indicator | Damage | Endpoint |

|---|---|---|---|---|

| Climate Change Human Health | CCHH | infra-red radiative forcing | Damage | Human Health 1 |

| Ozone Depletion | OD | decrease in ozone protection | Damage | Human Health |

| Human Toxicity | HT | hazard-weighted dose | Damage | Human Health |

| Photochemical Oxidant Formation | POF | ozone concentration | Damage | Human Health |

| Particulate Matter Formation | PMF | PM10 intake | Damage | Human Health |

| Ionizing Radiation | IR | absorbed dose | Damage | Human Health |

| Climate Change Ecosystems | CCE | infra-red radiative forcing | Terrestrial Damage | Ecosystems 2 |

| Terrestrial Acidification | TA | base saturation | Terrestrial Damage | Ecosystems |

| Freshwater Eutrophication | FE | algae growth | Freshwater Damage | Ecosystems |

| Terrestrial Ecotoxicity | TET | hazard-weighted concentration | Terrestrial Damage | Ecosystems |

| Freshwater Ecotoxicity | FET | hazard-weighted concentration | Freshwater Damage | Ecosystems |

| Marine Ecotoxicity | MET | hazard-weighted concentration | Marine water Damage | Ecosystems |

| Agricultural Land Occupation | ALO | occupied area | Terrestrial Damage | Ecosystems |

| Urban Land Occupation | ULO | occupied area | Terrestrial Damage | Ecosystems |

| Natural Land Transformation | NLT | transformed area | Terrestrial Damage | Ecosystems |

| Fossil Depletion | FD | energy content | Damage | Resources Surplus Cost 3 |

| Cat | Fertilizers | Supp. Materials | Pesticides | Transp. | Irrigation | Soil | Energy | Disinfectants |

|---|---|---|---|---|---|---|---|---|

| CCHH | 0.78 | 11.46 | 0.00 (L) | 0.08 | 0.15 | 2.61 | 84.85 (H) | 0.06 |

| OD | 2.71 | 36.94 | 0.02 (L) | 0.65 | 0.37 | 19.82 | 39.19 (H) | 0.30 |

| HT | 0.92 | 3.87 | 0.01 (L) | 0.06 | 0.51 | 1.57 | 93.01 (H) | 0.07 |

| POF | 0.49 | 14.19 | 0.00 (L) | 0.20 | 0.10 | 4.86 | 80.11 (H) | 0.05 |

| PMF | 0.85 | 7.83 | 0.00 (L) | 0.14 | 0.15 | 4.23 | 86.76 (H) | 0.04 |

| IR | 0.60 | 11.51 | 0.01 (L) | 0.12 | 1.04 | 2.70 | 83.86 (H) | 0.16 |

| CCE | 0.78 | 11.46 | 0.00 (L) | 0.08 | 0.15 | 2.61 | 84.85 (H) | 0.06 |

| TA | 0.87 | 7.59 | 0.00 (L) | 0.10 | 0.12 | 3.56 | 87.73 (H) | 0.04 |

| FE | 1.17 | 41.07 | 0.01 (L) | 0.07 | 0.23 | 2.30 | 55.03 (H) | 0.12 |

| TET | 1.97 | 8.29 | 0.01 (L) | 0.20 | 0.86 | 8.45 | 80.05 (H) | 0.17 |

| FET | 0.91 | 15.61 | 0.01 (L) | 0.16 | 5.13 | 5.05 | 73.02 (H) | 0.11 |

| MET | 1.85 | 10.28 | 0.01 (L) | 0.13 | 0.76 | 7.96 | 78.87 (H) | 0.12 |

| ALO | 0.52 | 8.31 | 0.00 (L) | 0.01 | 0.42 | 2.11 | 88.59 (H) | 0.03 |

| ULO | 1.01 | 1.77 | 0.00 (L) | 0.21 | 0.98 | 4.66 | 91.34 (H) | 0.03 |

| NLT | 3.21 | 4.84 | 0.01 (L) | 0.39 | 0.64 | 14.59 | 76.19 (H) | 0.13 |

| FD | 0.06 | 0.67 | 0.00 (L) | 0.01 | 0.06 | 0.20 | 98.99 (H) | 0.01 |

| Res. | CCHH | OD | HT | IR | CCE | TA | FE | TET | FET | MET | FD |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Elect. | 8.72 | 41.72 | 8.43 | 73.65 (H) | 8.72 | 7.03 | 12.19 | 12.83 | 14.23 | 18.69 | 3.67 |

| Coal | 91.28 (H) | 58.28 (H) | 91.57 (H) | 26.35 | 91.28 (H) | 92.97 (H) | 87.81 (H) | 87.17 (H) | 85.77 (H) | 81.31 (H) | 96.33 (H) |

| Cat | Organo Phosphorus | Cyclic N | [thio] Carbamate | Acetamide Anillide | Triazine | Dithio Carbamate | Pyrethroid | Phthalimide | Uns. |

|---|---|---|---|---|---|---|---|---|---|

| CCHH | 19.13 | 2.08 | 0.91 | 4.21 | 0.37 (L) | 8.24 | 38.07 (H) | 7.91 | 19.09 |

| OD | 18.15 | 2.22 | 1.01 | 4.97 | 0.44 (L) | 9.84 | 34.24 (H) | 8.04 | 21.07 |

| HT | 16.93 | 2.12 | 0.88 | 4.31 | 0.38 (L) | 8.39 | 41.02 (H) | 6.90 | 19.08 |

| POF | 18.82 | 2.13 | 0.94 | 4.49 | 0.38 (L) | 8.62 | 36.78 (H) | 8.17 | 19.66 |

| PMF | 18.08 | 2.08 | 0.90 | 4.41 | 0.38 (L) | 7.92 | 39.45 (H) | 7.46 | 19.32 |

| IR | 24.56 | 1.98 | 0.88 | 3.97 | 0.29 (L) | 6.46 | 32.28 (H) | 11.04 | 18.53 |

| CCE | 19.13 | 2.08 | 0.91 | 4.21 | 0.37 (L) | 8.24 | 38.07 (H) | 7.91 | 19.09 |

| TA | 17.98 | 2.06 | 0.90 | 4.46 | 0.38 (L) | 7.57 | 39.98 (H) | 7.26 | 19.39 |

| FE | 19.96 (H) | 3.02 | 1.00 | 4.11 | 0.36 (L) | 18.82 | 17.80 | 15.53 | 19.39 |

| TET | 14.83 | 2.03 | 0.86 | 4.39 | 0.40 (L) | 7.43 | 46.09 (H) | 4.83 | 19.13 |

| FET | 18.08 | 2.32 | 0.94 | 4.95 | 0.39 (L) | 9.19 | 34.31 (H) | 9.63 | 20.20 |

| MET | 15.97 | 2.10 | 0.88 | 4.38 | 0.39 (L) | 8.19 | 42.74 (H) | 6.19 | 19.16 |

| FD | 23.84 | 1.98 | 1.31 | 3.56 | 0.27 (L) | 12.70 | 28.16 (H) | 9.99 | 18.19 |

| Cat | Peat | Perlite | Verm. | Plastic Sheeting | Grafting Sticks | Clips | Seedling Insert | EPS Tray | Packaging |

|---|---|---|---|---|---|---|---|---|---|

| CCHH | 8.33 | 4.02 | 6.22 | 6.35 | 2.07 | 5.70 | 12.56 | 54.72 (H) | 0.03 (L) |

| OD | 16.32 | 9.32 | 9.29 | 0.94 | 0.26 | 36.41 (H) | 1.60 | 25.81 | 0.04 (L) |

| HT | 17.10 | 5.01 | 6.80 | 4.66 | 1.39 | 13.50 | 8.45 | 42.93 (H) | 0.16 (L) |

| POF | 14.67 | 1.85 | 8.99 | 4.69 | 1.39 | 3.14 | 8.41 | 56.85 (H) | 0.02 (L) |

| PMF | 15.99 | 2.96 | 16.14 | 5.47 | 1.64 | 5.75 | 9.96 | 42.05 (H) | 0.03 (L) |

| IR | 10.11 | 3.67 | 5.22 | 7.81 | 2.15 | 8.83 | 13.07 | 49.07 (H) | 0.07 (L) |

| CCE | 8.34 | 4.02 | 6.22 | 6.35 | 2.07 | 5.70 | 12.56 | 54.72 (H) | 0.03 (L) |

| TA | 12.18 | 2.91 | 16.83 | 5.68 | 1.67 | 5.19 | 10.12 | 45.40 (H) | 0.03 (L) |

| FET | 3.30 | 0.89 | 1.12 | 3.73 | 2.78 | 4.29 | 16.88 | 66.87 (H) | 0.14 (L) |

| TET | 15.03 | 30.14 | 5.30 | 2.43 | 0.88 | 4.19 | 5.32 | 36.50 (H) | 0.22 (L) |

| FET | 11.20 | 5.09 | 8.16 | 8.17 | 1.80 | 5.00 | 10.90 | 49.58 (H) | 0.09 (L) |

| MET | 9.83 | 16.35 | 17.46 | 3.38 | 1.06 | 5.48 | 6.42 | 39.94 (H) | 0.07 (L) |

| ALO | 2.66 (L) | 4.44 | 13.16 | 21.95 | 4.72 | 15.28 | 28.66 (H) | 5.18 | 3.95 |

| ULO | 33.06 (H) | 8.65 | 30.81 | 3.40 | 0.87 | 8.63 | 5.28 | 8.94 | 0.36 (L) |

| NLT | 32.95 (H) | 17.35 | 24.79 | 2.77 | 0.53 | 7.37 | 3.22 | 10.61 | 0.41 (L) |

| FD | 12.93 | 4.19 | 5.41 | 6.87 | 1.81 | 17.59 | 10.99 | 40.10 (H) | 0.11 (L) |

| Polymer | Energy (GJ tonne−1) | Water (kL tonne−1) | CO2−e a (t tonne−1) | Usage b (ktonne) | Closed-Loop Recycling | Effectiveness in Current Recycling Processes |

|---|---|---|---|---|---|---|

| PET | 82.7 | 66 | 3.4 | 2160 | yes | high |

| HDPE | 76.7 | 32 | 1.9 | 5468 | some | high |

| PS | 87.4 | 140 | 3.4 | 2600 | In theory | poor |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mencet Yelboğa, M.N. LCA Analysis of Grafted Tomato Seedling Production in Turkey. Sustainability 2020, 12, 25. https://doi.org/10.3390/su12010025

Mencet Yelboğa MN. LCA Analysis of Grafted Tomato Seedling Production in Turkey. Sustainability. 2020; 12(1):25. https://doi.org/10.3390/su12010025

Chicago/Turabian StyleMencet Yelboğa, Makbule Nisa. 2020. "LCA Analysis of Grafted Tomato Seedling Production in Turkey" Sustainability 12, no. 1: 25. https://doi.org/10.3390/su12010025

APA StyleMencet Yelboğa, M. N. (2020). LCA Analysis of Grafted Tomato Seedling Production in Turkey. Sustainability, 12(1), 25. https://doi.org/10.3390/su12010025