4.2.1. Fault Detection with Statistical Moments

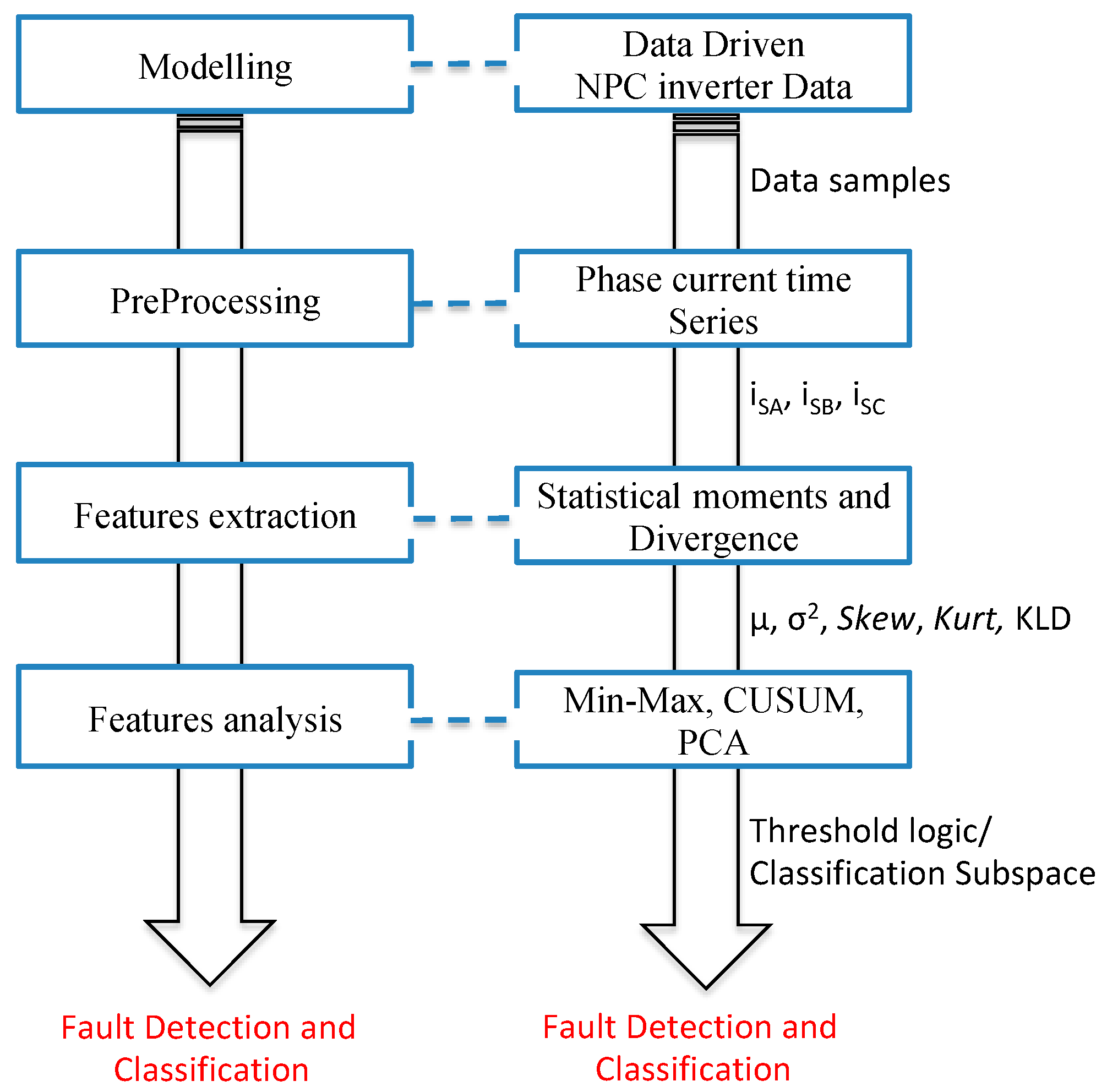

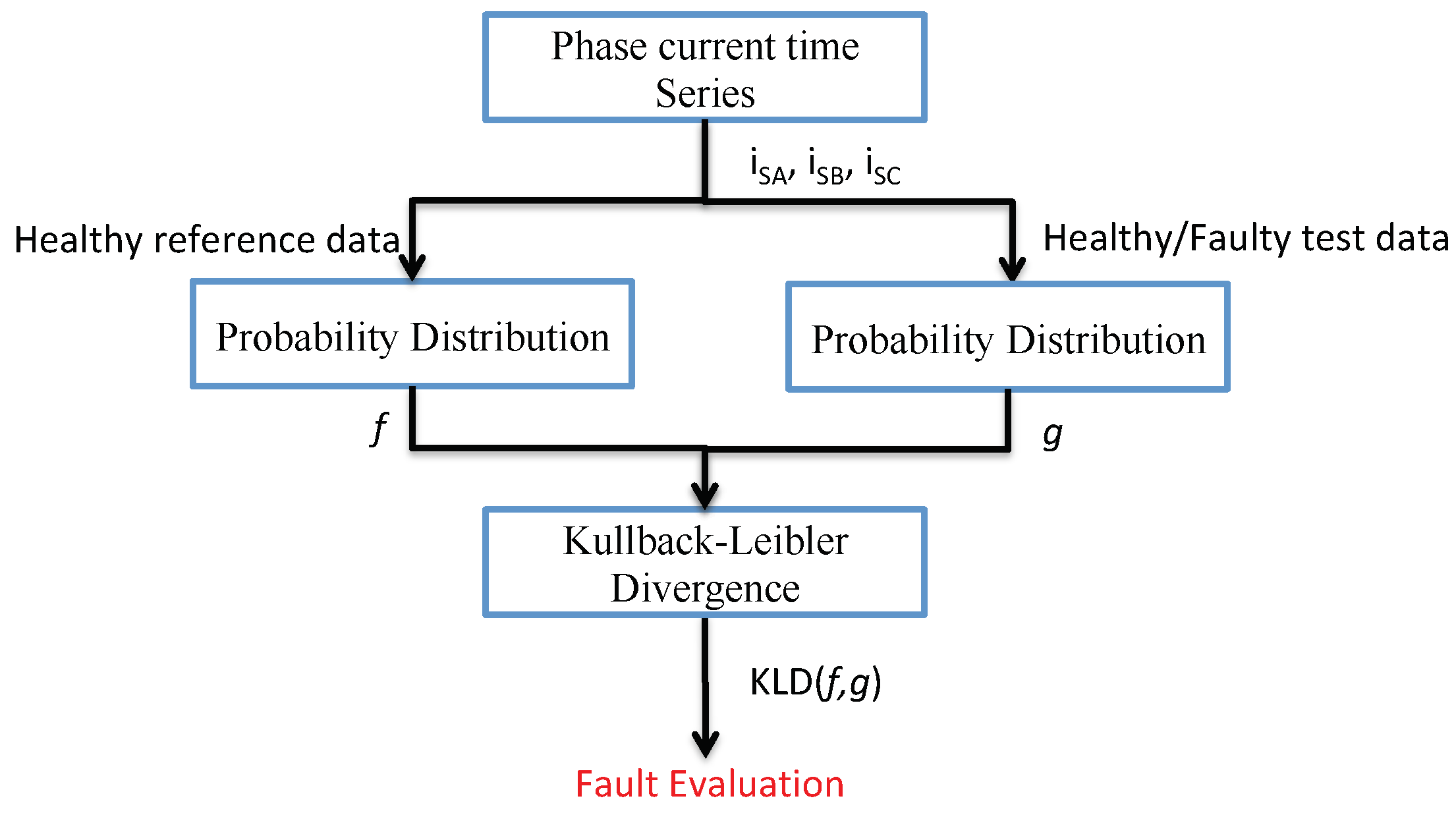

For this analysis, all the operating conditions previously described were applied and the extracted features were probabilistically evaluated using:

The probability of detection (PD). It highlights the ability for correctly detecting a fault when it occurs.

The probability of false alarm (PFA). It measures the probability of considering a healthy situation as a fault.

These probabilities are calculated and plotted as the Receiver Operating Characteristics (ROC) curve [

20]. The performances are obtained considering all the possible detection threshold values.

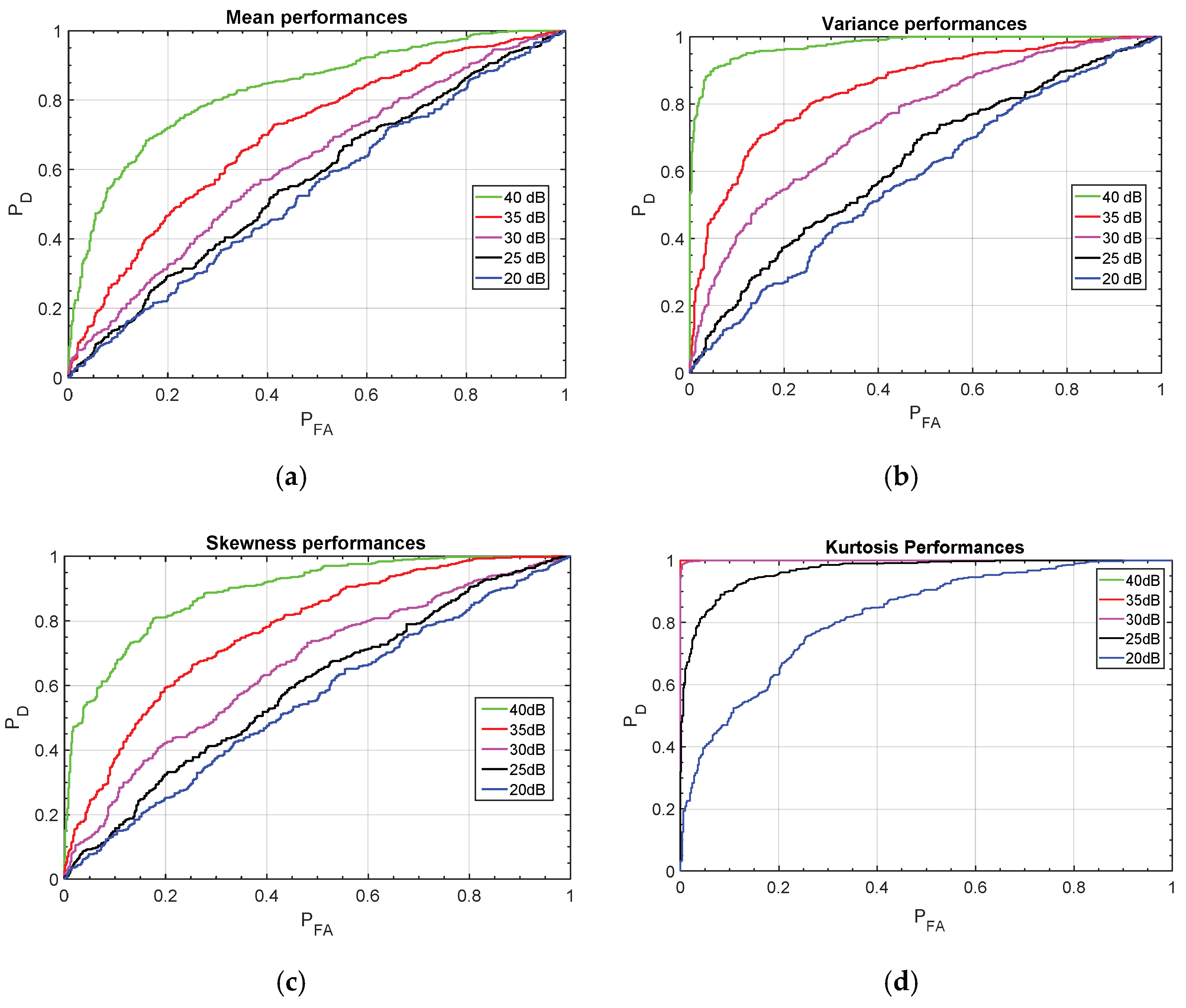

Figure 9 shows the evolution regarding the SNR value for a 60 rad/s rotational speed. It clearly shows that the detection performances are poorer when the noise level increases (SNR decreases). Among the four criteria, the kurtosis offers the best performances even while the noise varies.

With these ROC curves, we can derive an optimal fault detection threshold for these features, which leads to the best trade-off value between PD and PFA. It is clear that, while the noise conditions become more severe (SNR decreases), the optimal fault detection will lead to PD < 0.7 and PFA > 0.3.

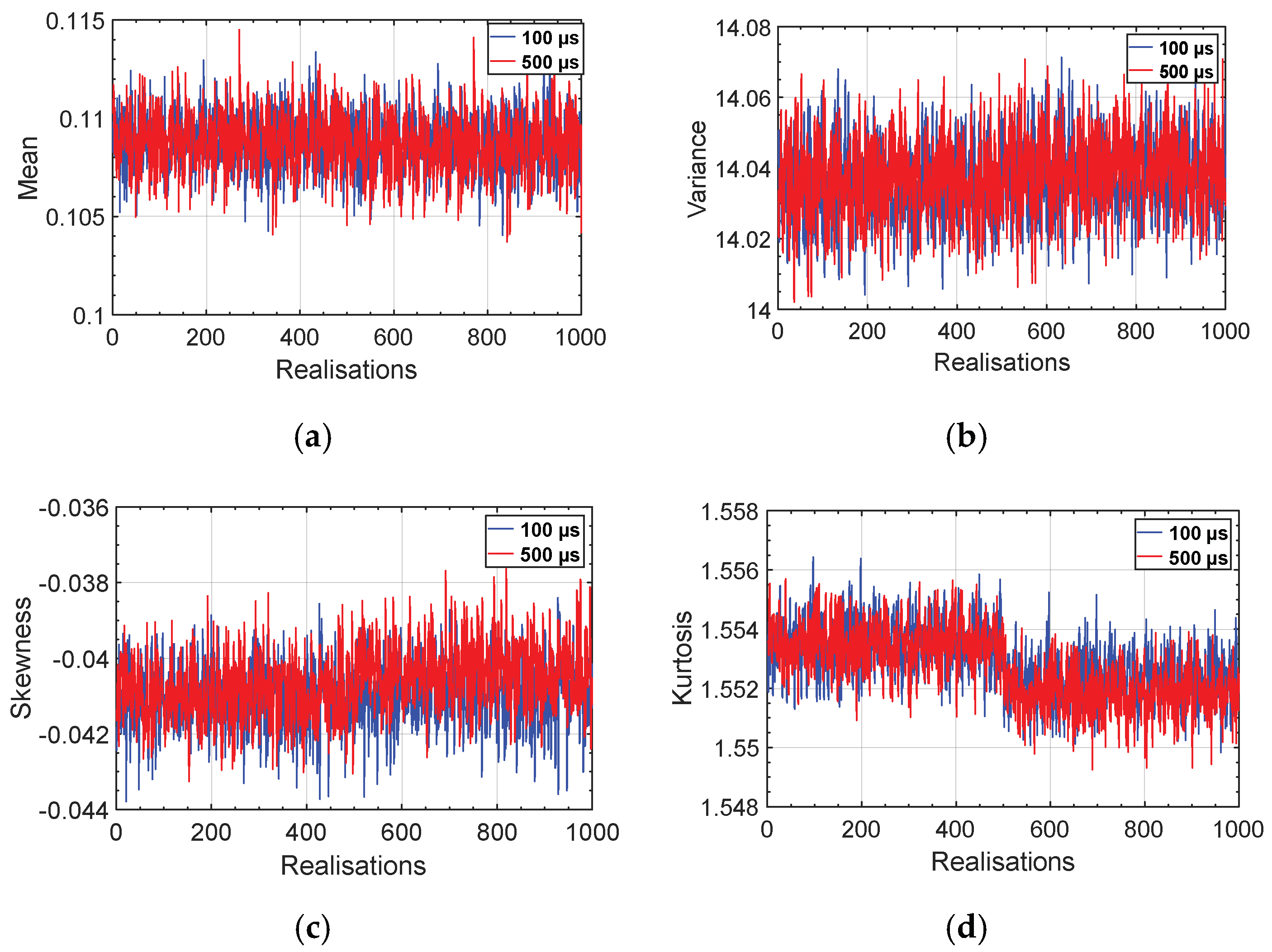

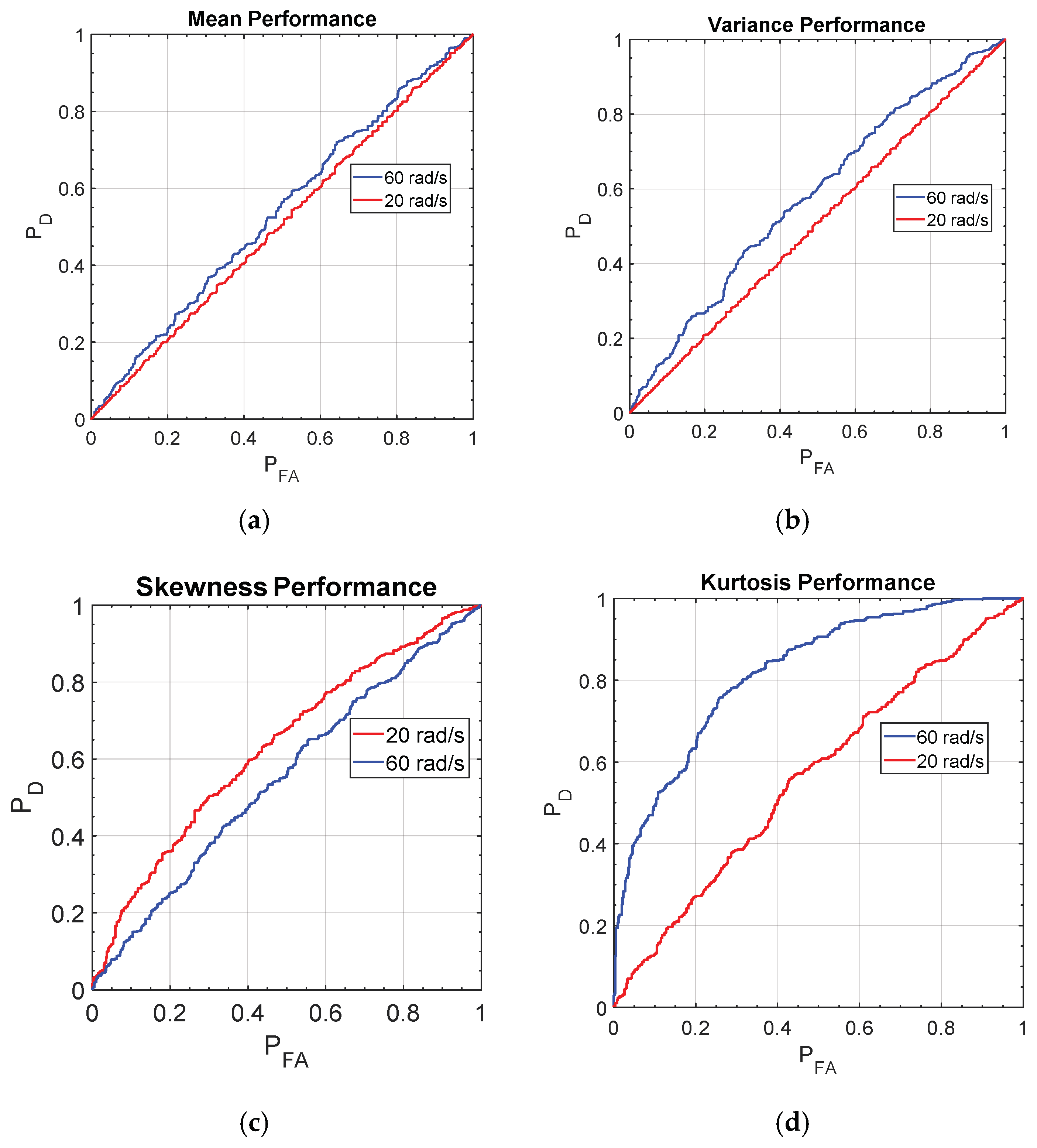

Figure 10 displays the influence of the drive rotational speed on the first four statistical moments for SNR = 20 dB.

Figure 10 shows the degradation of the detection performances when the speed is reduced and the noise is increased. Most of the statistical criteria fail to detect the fault under these conditions. The optimal threshold will generally lead to poor performances P

D = 0.56 and P

FA = 0.44, which is far from the usual industrial settings (P

D > 0.8 and P

FA < 0.05). Even the performances for the kurtosis are not satisfying and should be improved in such severe operating conditions.

In most of the faulty cases, the mean value is not a relevant fault indicator. It will not be retained in the following analysis.

To summarize the detection ability for the 10 selected Open Switch fault cases in all the operating conditions (load, noise, and speed), we present in

Table 2 the number of faults correctly detected using at least one of the three significant statistical criteria (

σ2,

Skew,

Kurt).

For this analysis, we consider that the fault is correctly detected if PD > 0.8 and its PFA < 0.05.

Table 2 confirms that the detection with the three statistical moments (variance, skewness, and kurtosis) is satisfying for high SNR (SNR ≥ 30 dB) and for high-speed conditions (≥40 rad/s). In these cases, most of the OSFs are detected from the lowest to the highest durations.

Boxes in blue color show cases where performance is considered insufficient with a probability of detection PD < 0.5. In the other conditions (SNR < 30 dB, 20 rad/s), lots of faults are not detected. To enhance the detection performances in such conditions, we propose to improve the features statistical analysis.

4.2.2. Fault Detection Improvement with CUSUM

To improve the detection in fault detection and the diagnosis process, we propose to combine the statistical features with a Cumulative Sum (CUSUM) analysis.

CUSUM is a well-known technique that has been widely used to detect abrupt changes [

21,

22,

23] in signal processing. It is based on the log-likelihood ratio and has been theoretically defined for mean or variance variation in the considered signal. Optimally, it can be defined for Gaussian signals as the sum of the sufficient statistics

sk such as:

where N is the number of realizations and

sk can be considered in the case of mean changes (

) or variance changes (

) for the statistical moments signals such as:

where

μh and

μf are, respectively, the mean values in the healthy and faulty conditions,

σh and

σf are, respectively, the standard deviation values in healthy and faulty conditions, and

xk stands for the statistical moment under consideration for the

kth observation over N. While computing the CUSUM

SN, we can then set a threshold

Th = 0.99

Smax where

Smax = max(

SN) is the maximum value of

SN in a healthy case. If the CUSUM value is higher than

Th, then it means that a faulty behavior has been detected.

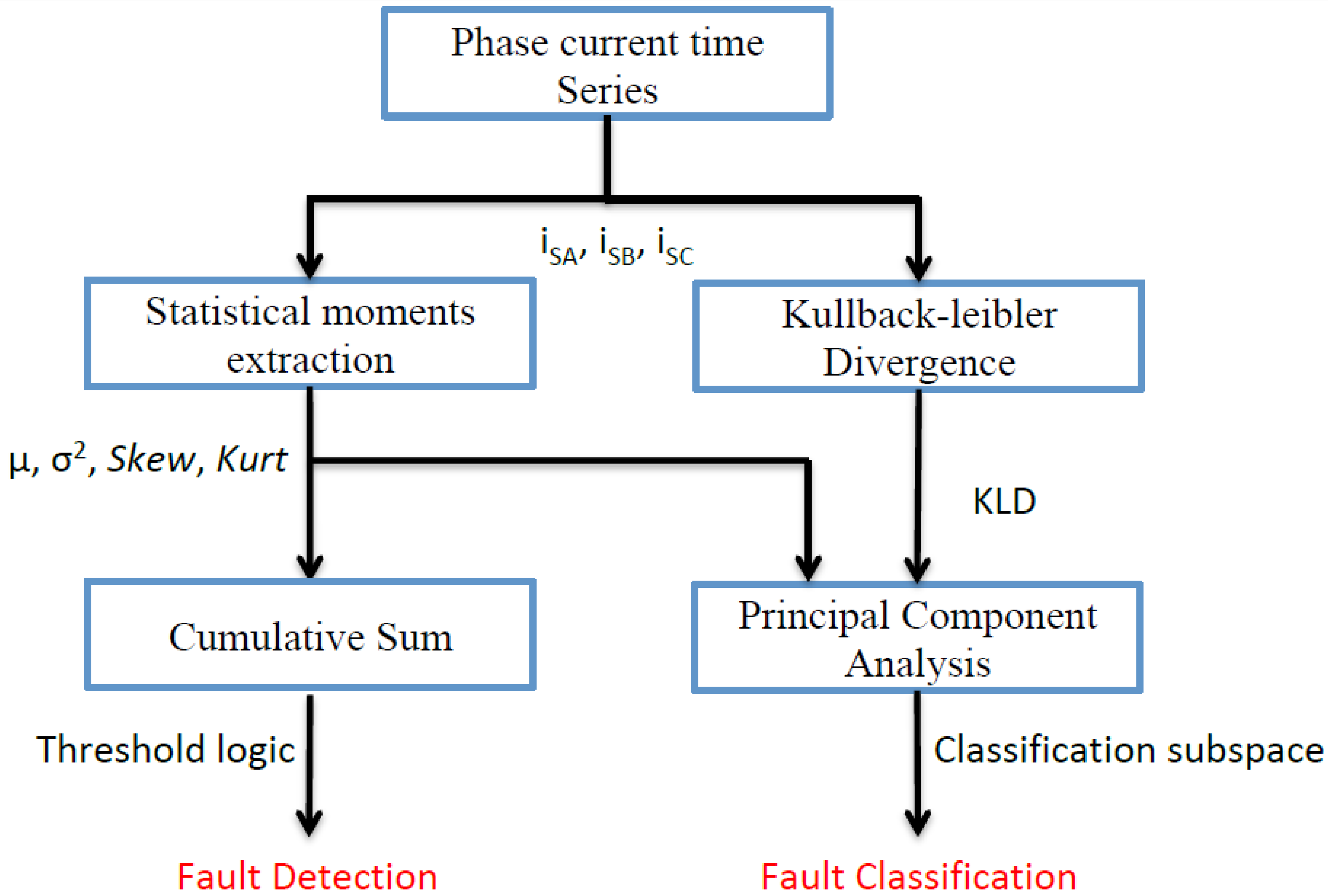

In our work, the considered signals to apply the CUSUM are, hereafter, the ones obtained for 1000 realisations of the previously studied statistical moments (μ, σ2, Skew, Kurt). To consider that the optimal conditions are satisfied, we have first evaluated these realisations-dependent signals using the Kolmogorov-Smirnov test to validate the Gaussian assumption.

Second, the CUSUM is computed for the statistical moment’s signals. As has been concluded in the previous section that the kurtosis is the most sensitive criteria among the four, we focus our next analysis on the CUSUM of this signal. The most severe faulty conditions are particularly studied.

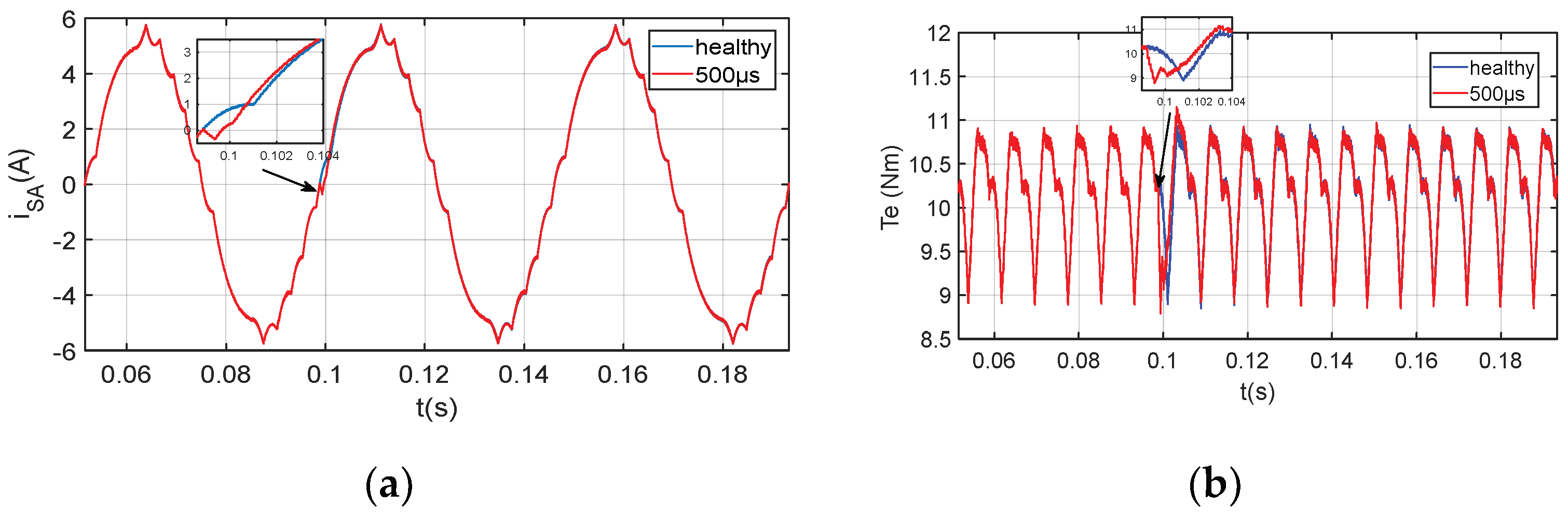

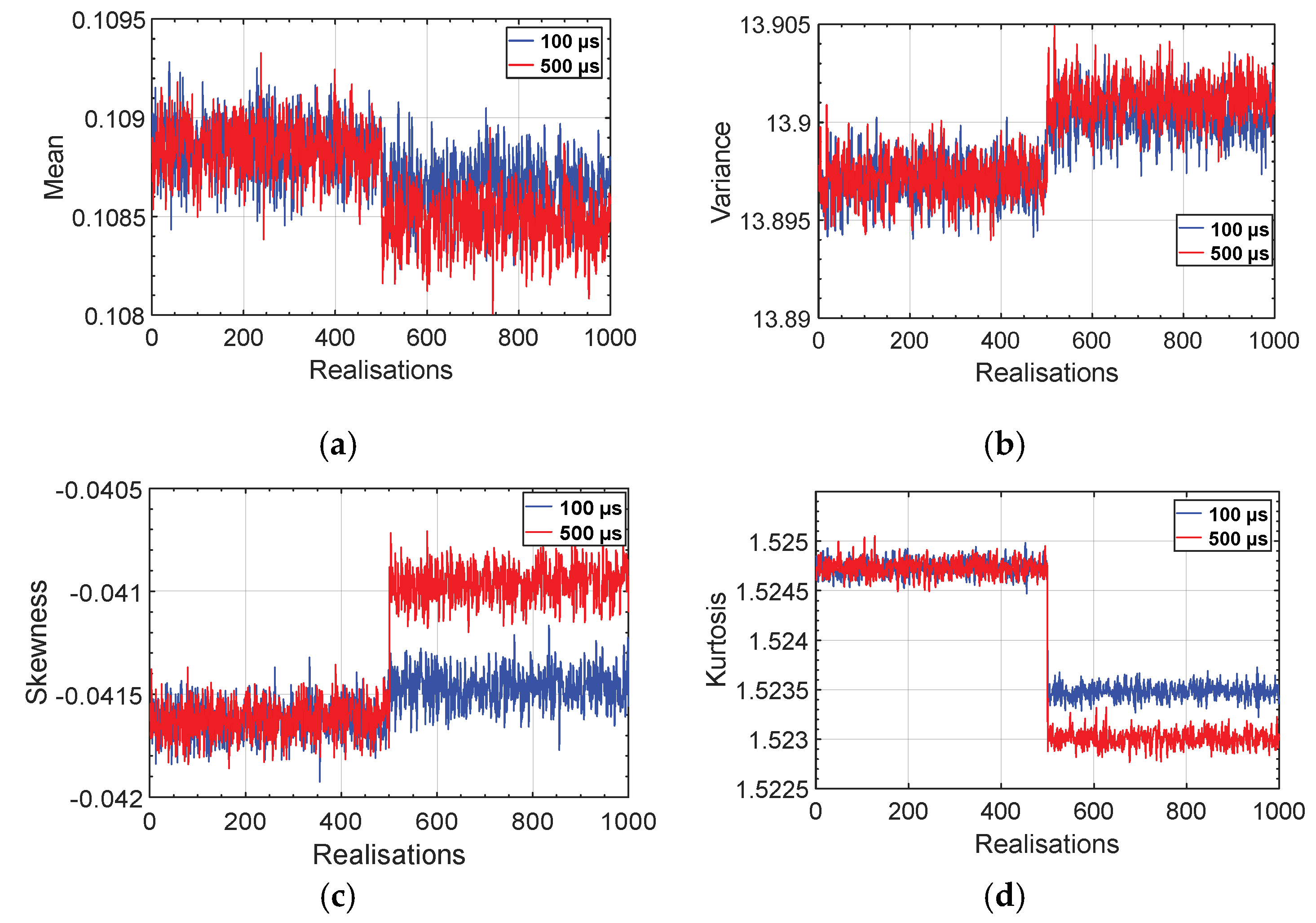

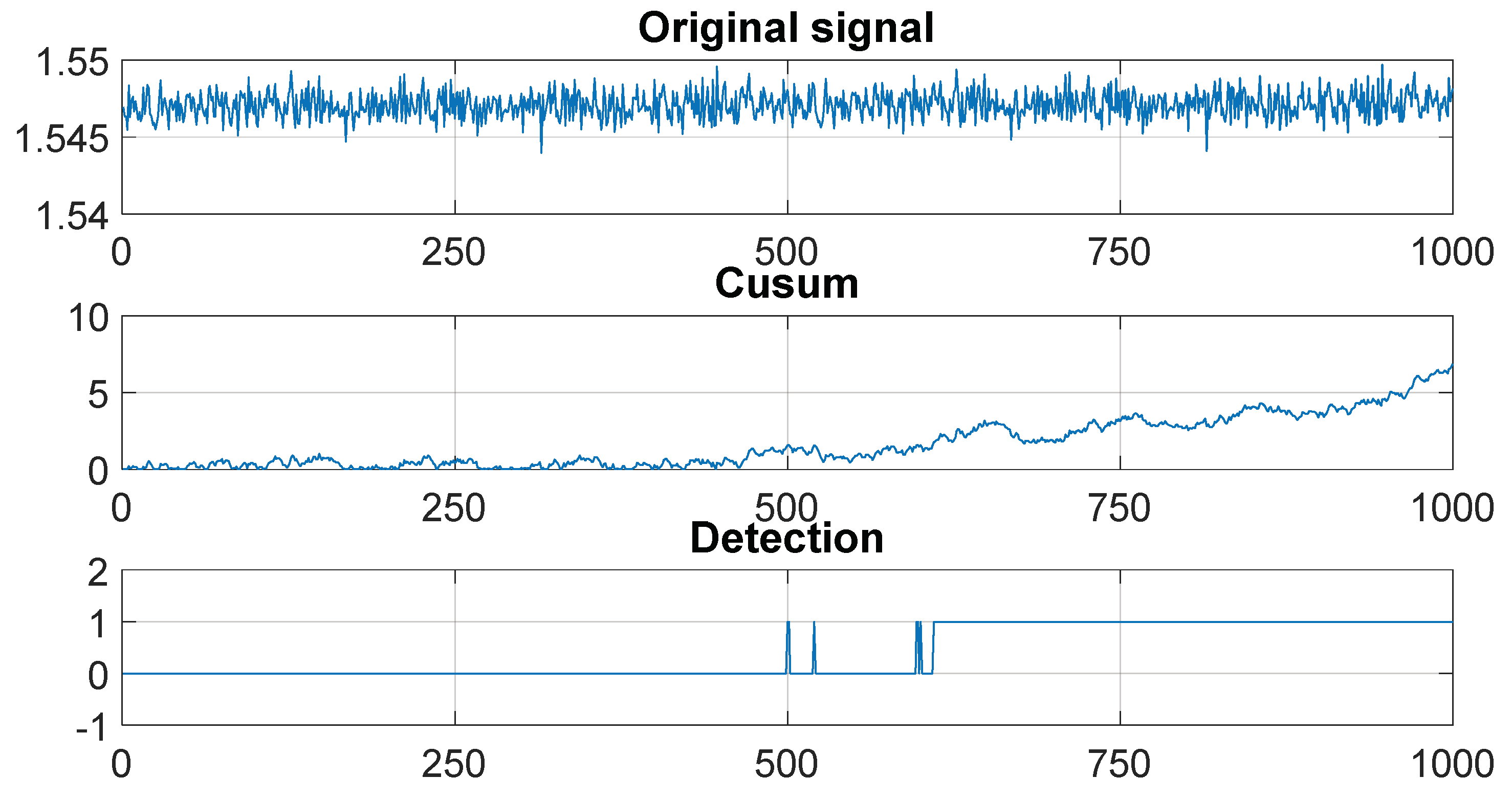

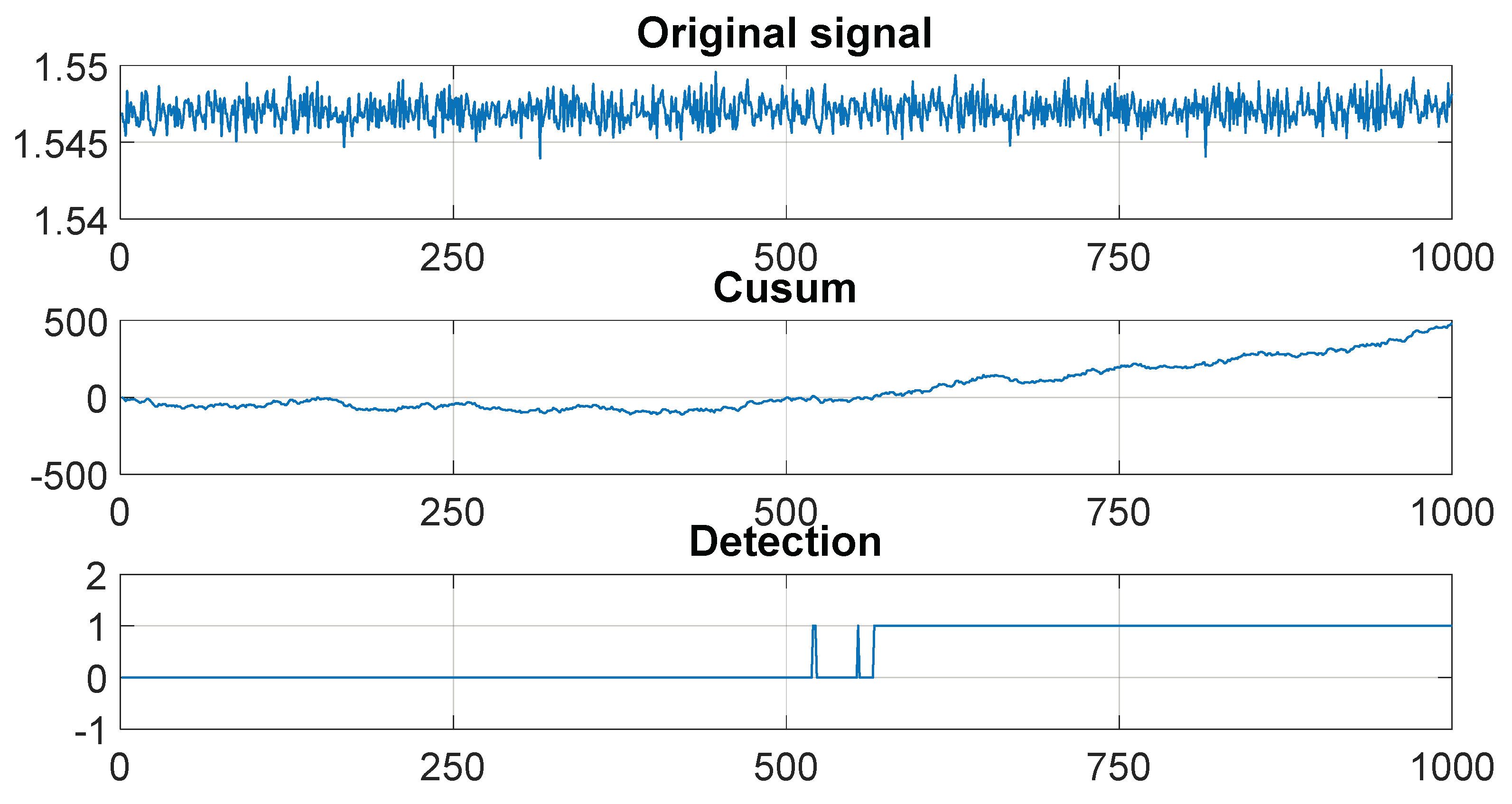

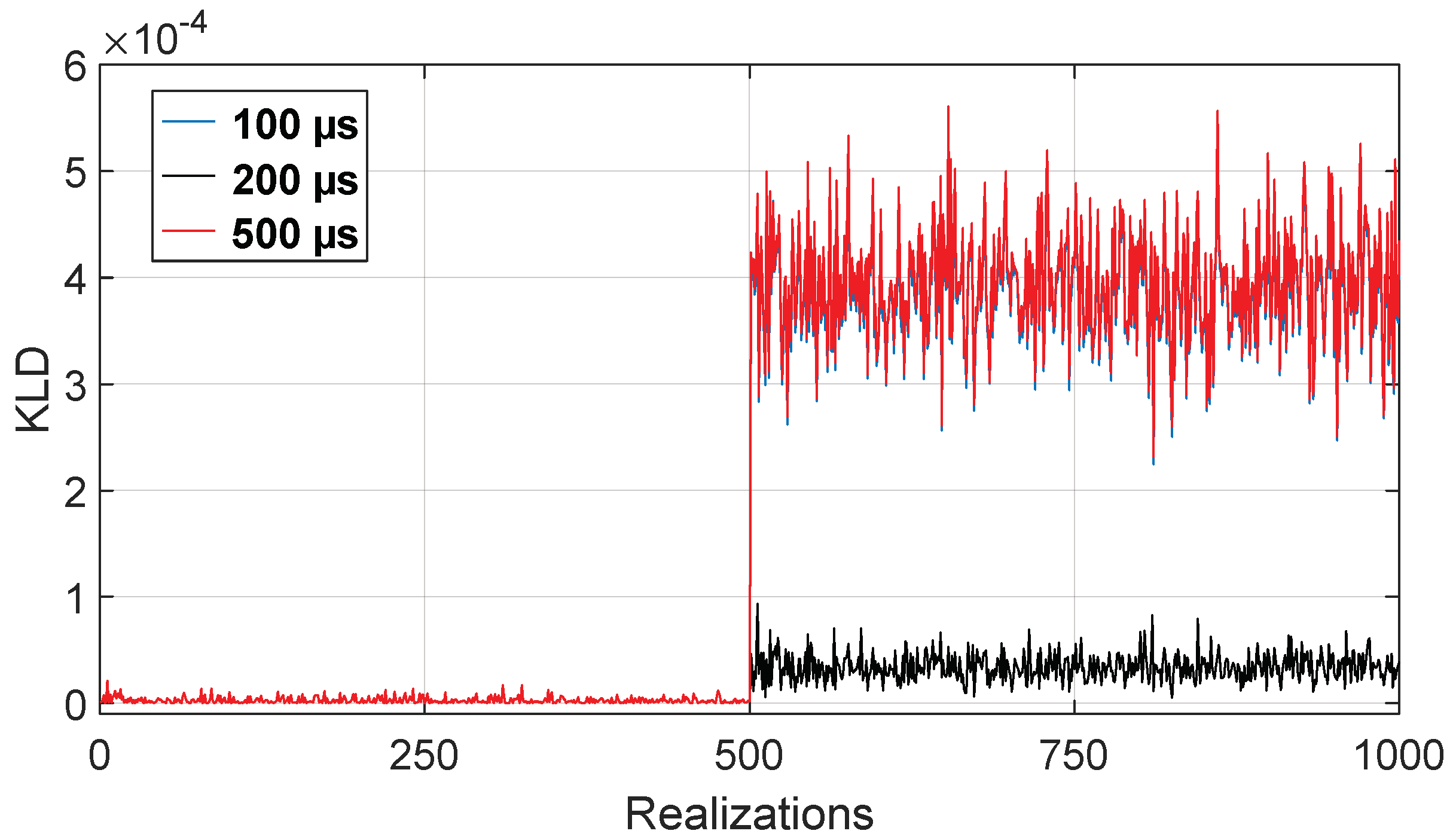

Figure 11 and

Figure 12 show, respectively, the CUSUM results for

and

of the kurtosis signal when SNR = 20 dB at 20 rad/s for 100% of the rated load. For the considered signals, the first 500 samples represent the healthy condition and the last 500 represent the faulty ones.

The fault occurrence can be detected efficiently with both indicators. The kurtosis CUSUM signal starts increasing at the fault detection. Nevertheless, one can notice that several (110) faulty realizations (

Figure 11) are required for

and 65 faulty ones for

(

Figure 12) before fault detection. In the given example, there is no false alarm using

and only one using

.

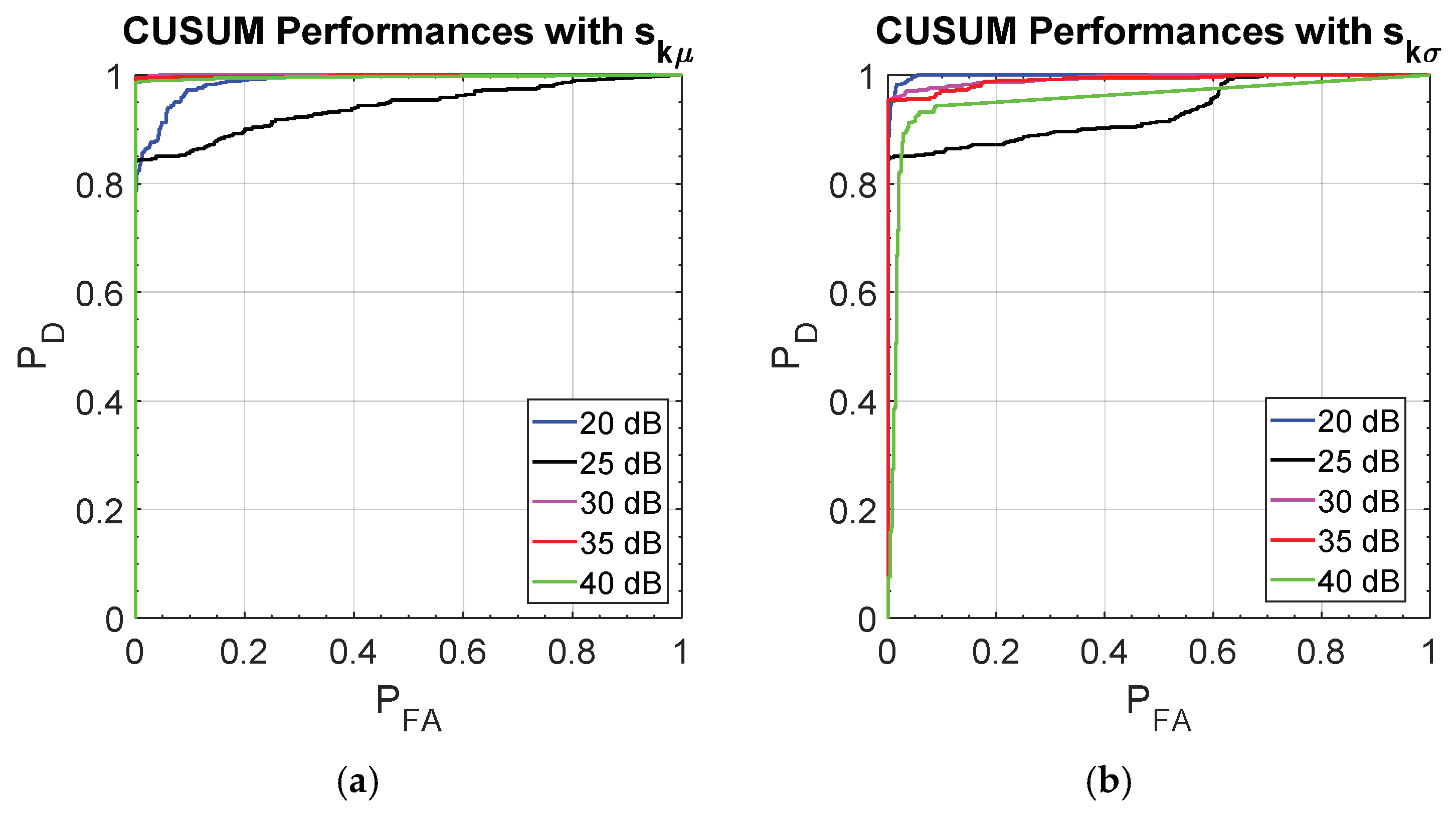

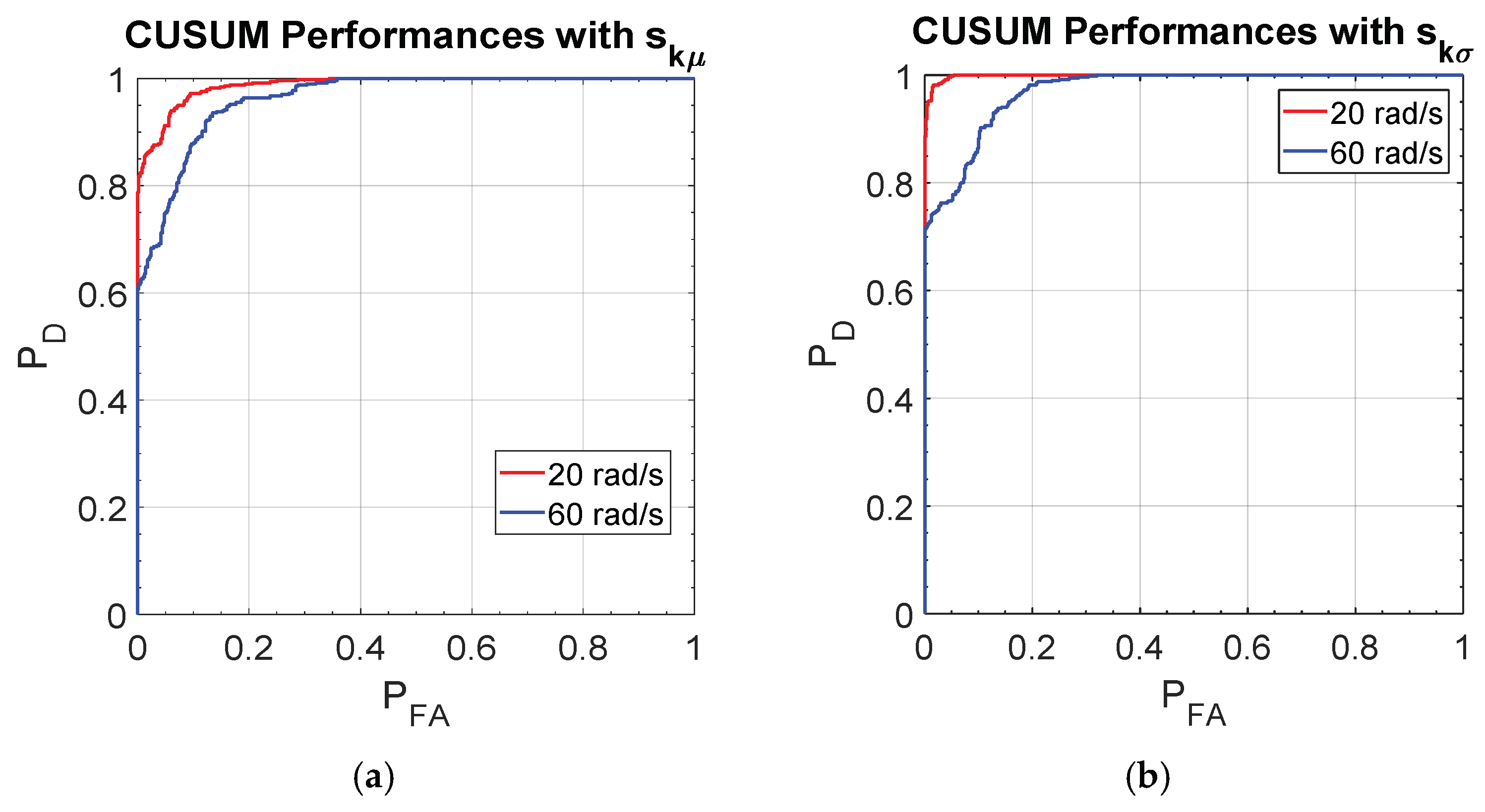

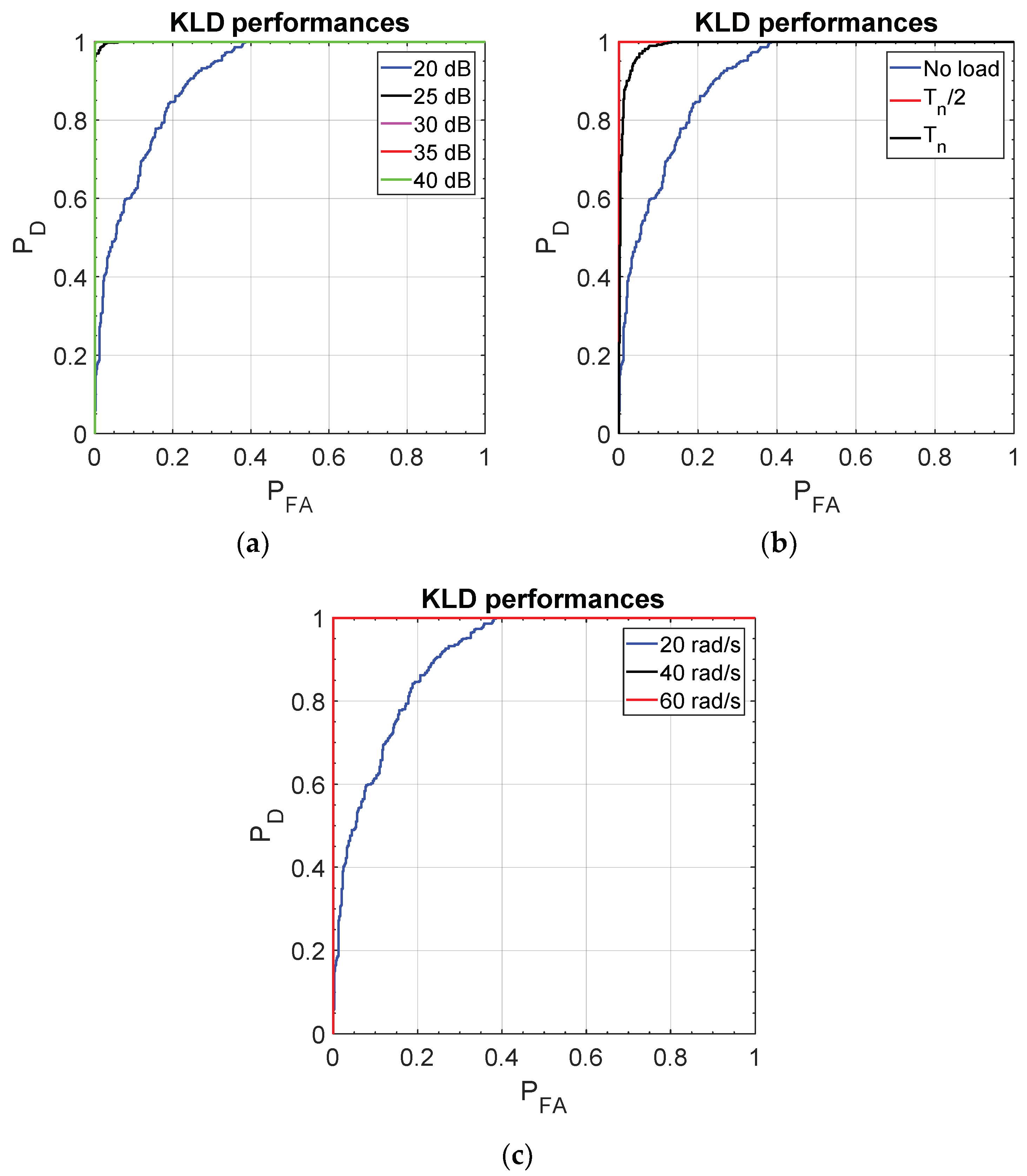

To completely evaluate the detection efficiency using the kurtosis CUSUM, the ROC curves are computed for several operating conditions. As an example,

Figure 13 and

Figure 14 display the fault detection performance results using

and

for the smallest OSF duration (100 µs), 50% of load, and several noise and speed conditions.

These figures clearly show the improved fault detection performances when compared to those obtained with the straight analysis of the first four statistical moments. Even when the speed and the SNR are low (20 rad/s and 20 dB), the detection is possible and the performances are good with a high detection probability and a low probability of false alarm.

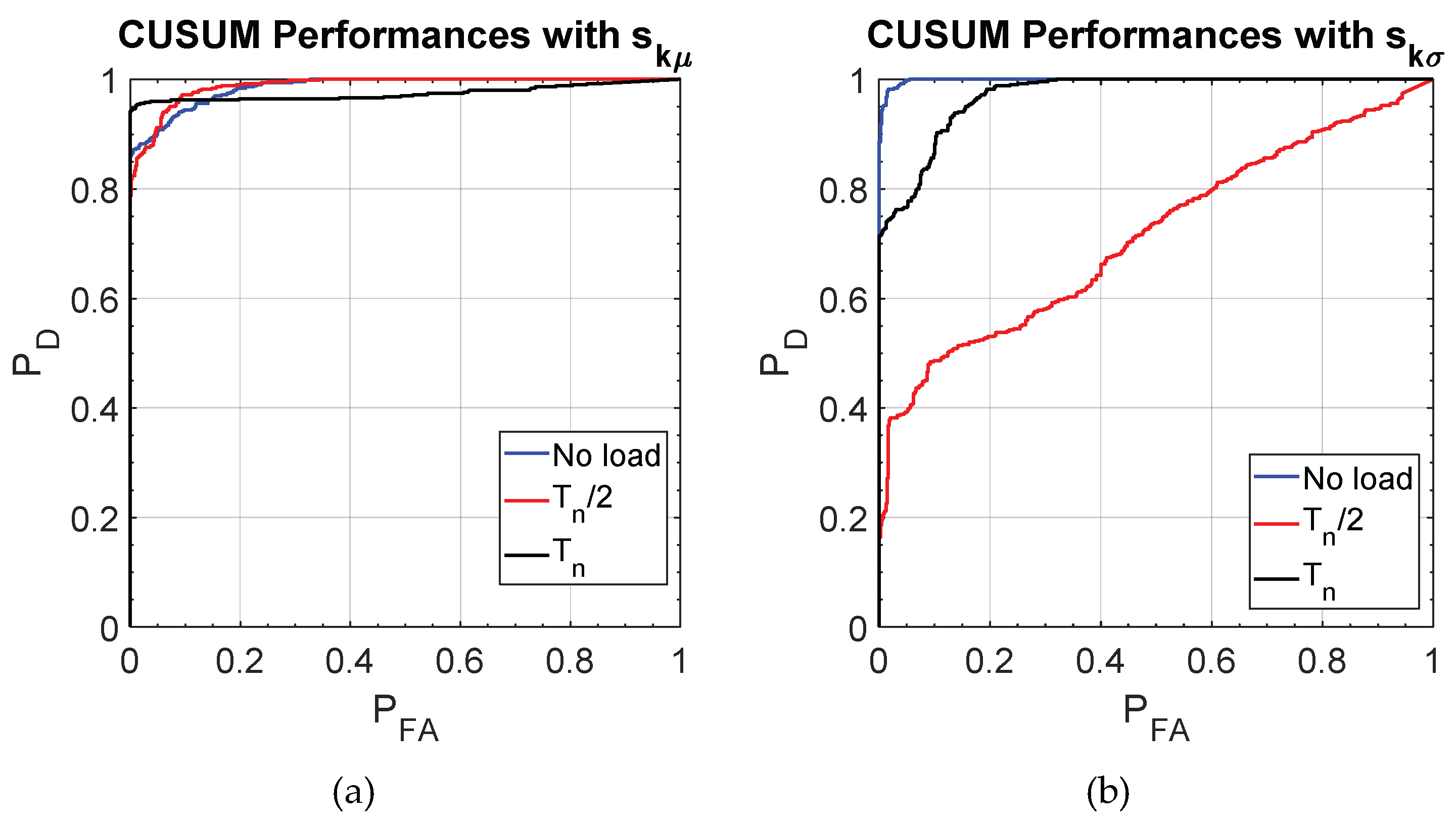

The influence of the load on kurtosis CUSUM for fault detection is plotted in

Figure 15. The results show that

is more sensitive to load variations particularly at half load where the performances are poor. At no load and full load, the performances are good.

As a summary, the fault detection results with the kurtosis CUSUM (with

or

) are presented in

Table 3 and

Table 4 considering the 10 OSF for different operating conditions.

Boxes in blue color show cases where performance is considered as insufficient with a probability of detection PD < 0.5.

Using the cumulative sum, the detection performances are largely improved. All the OSF, even the most incipient one (with 100 µs duration) can at least be detected using one of the CUSUM information based on the kurtosis signal. The detection can be performed but the fault classification, according to the fault duration cannot be obtained.

In the following, we propose a solution to classify the detected faults, according to their durations.