Design and Flight Test of an Air-Launched Medical Aid Delivery Uncrewed Aerial Vehicle

Abstract

1. Introduction

2. Background

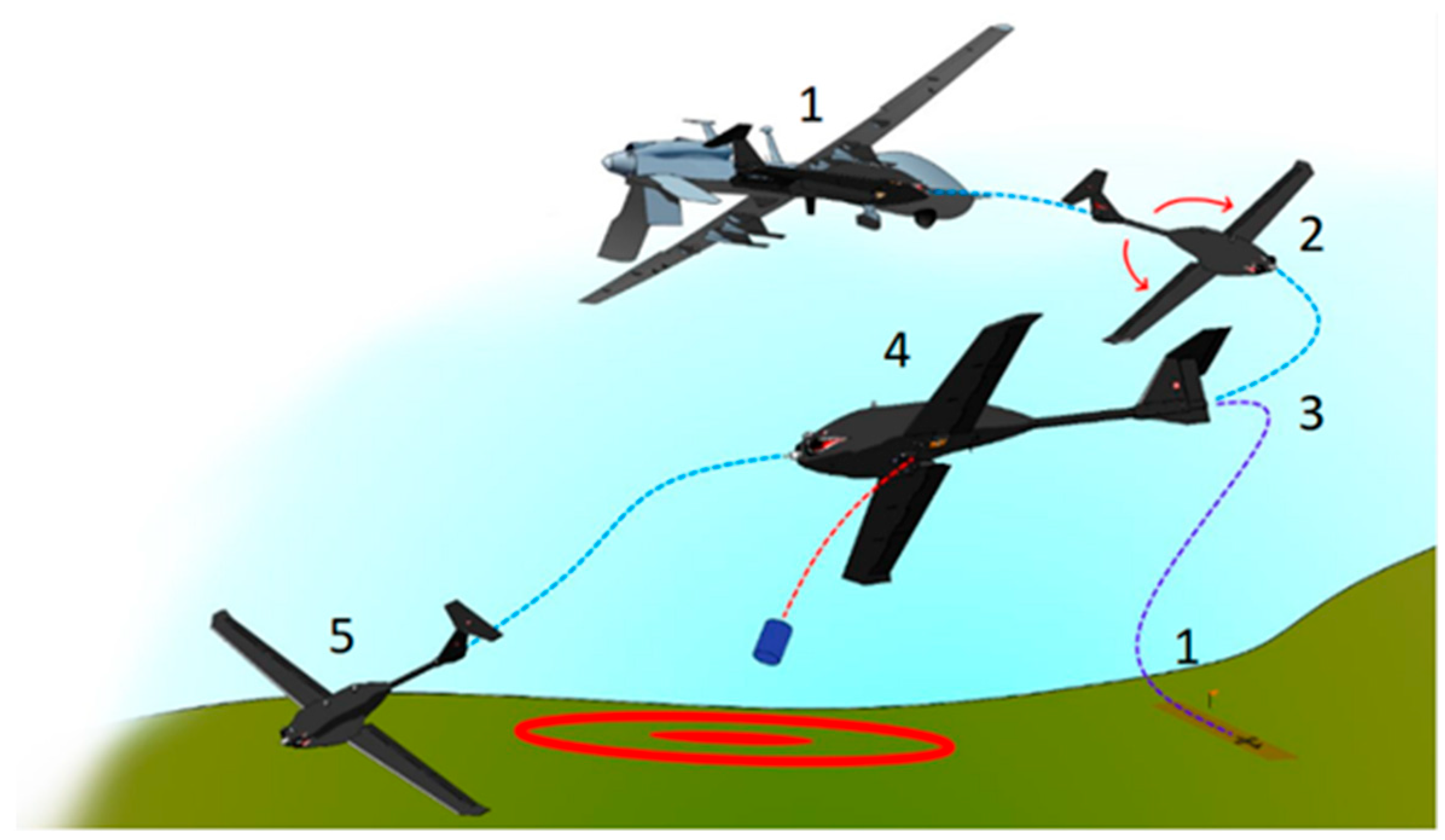

3. Concept of Operations

3.1. Design Requirements

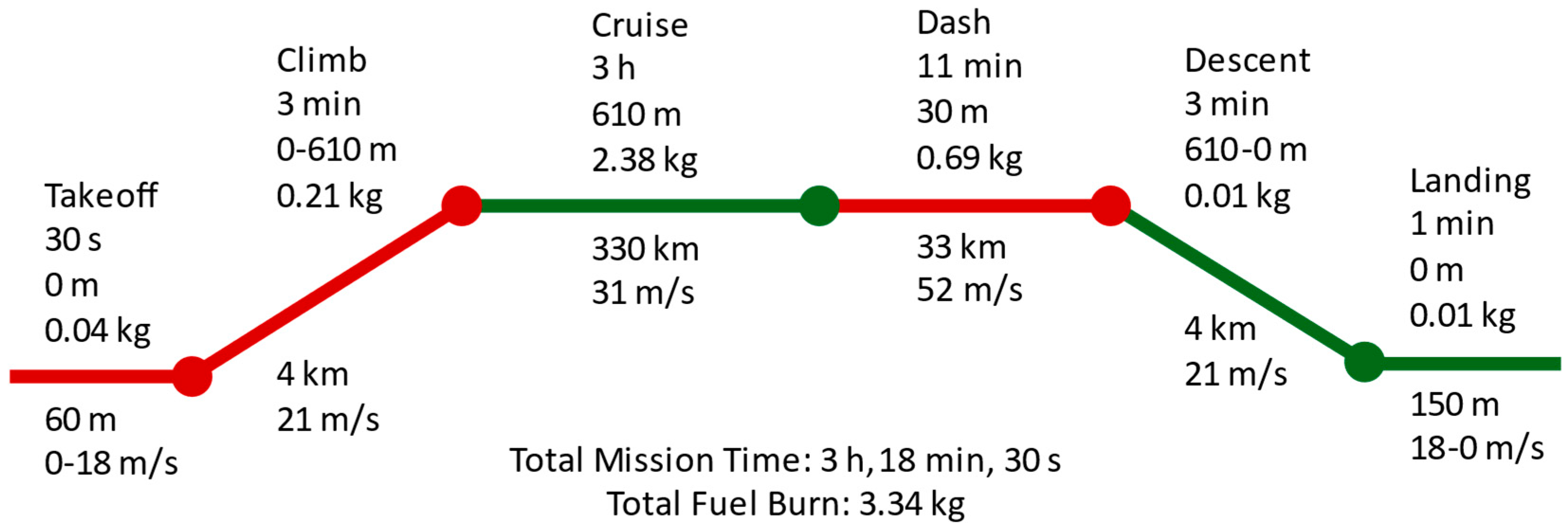

3.2. ConOps and Mission Performance

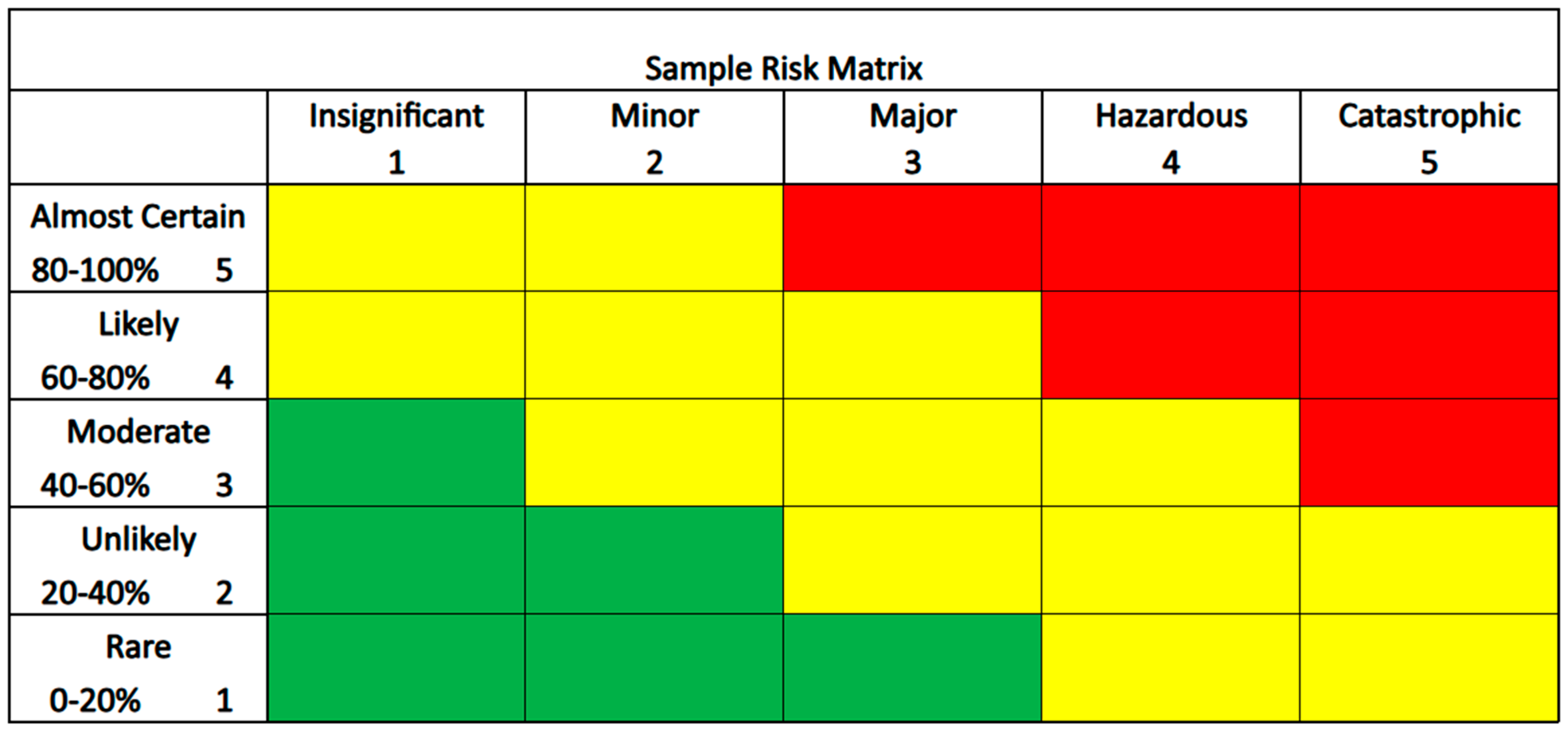

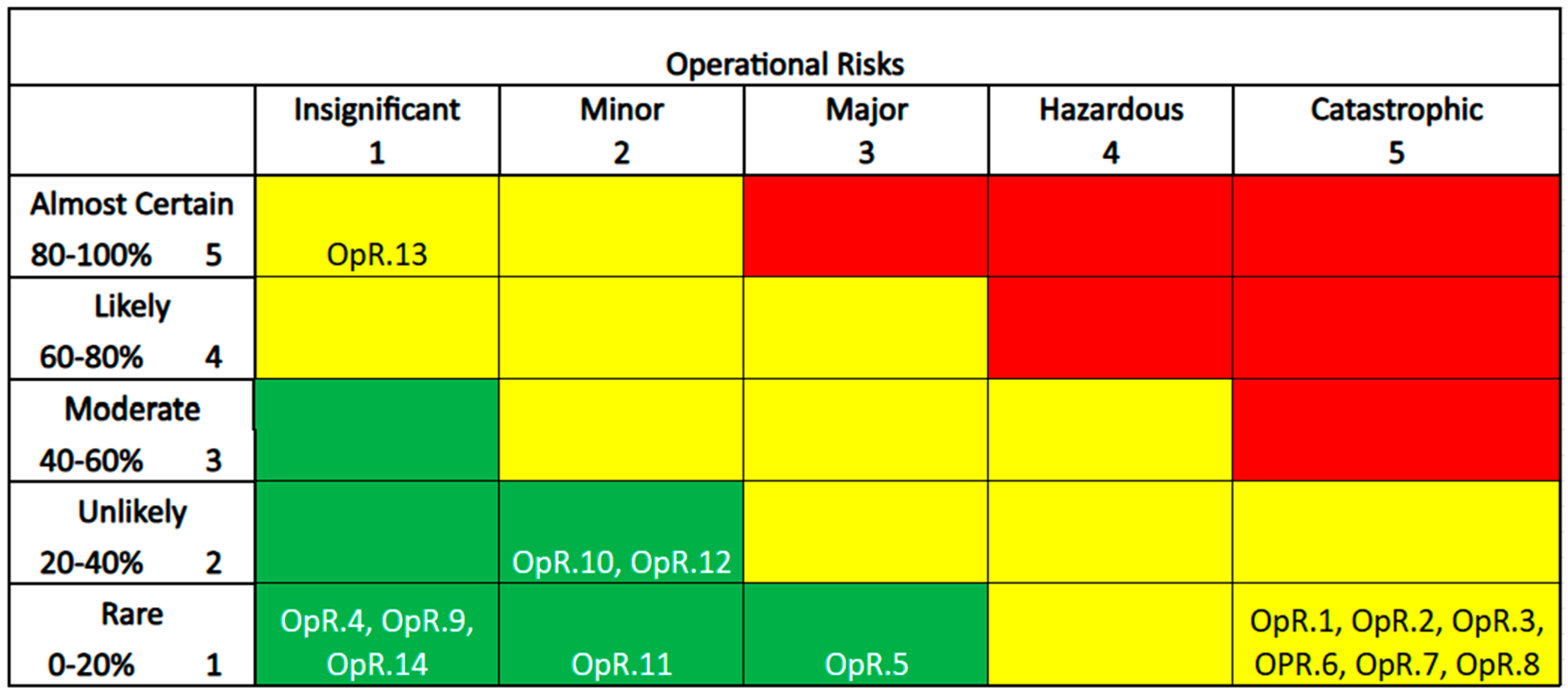

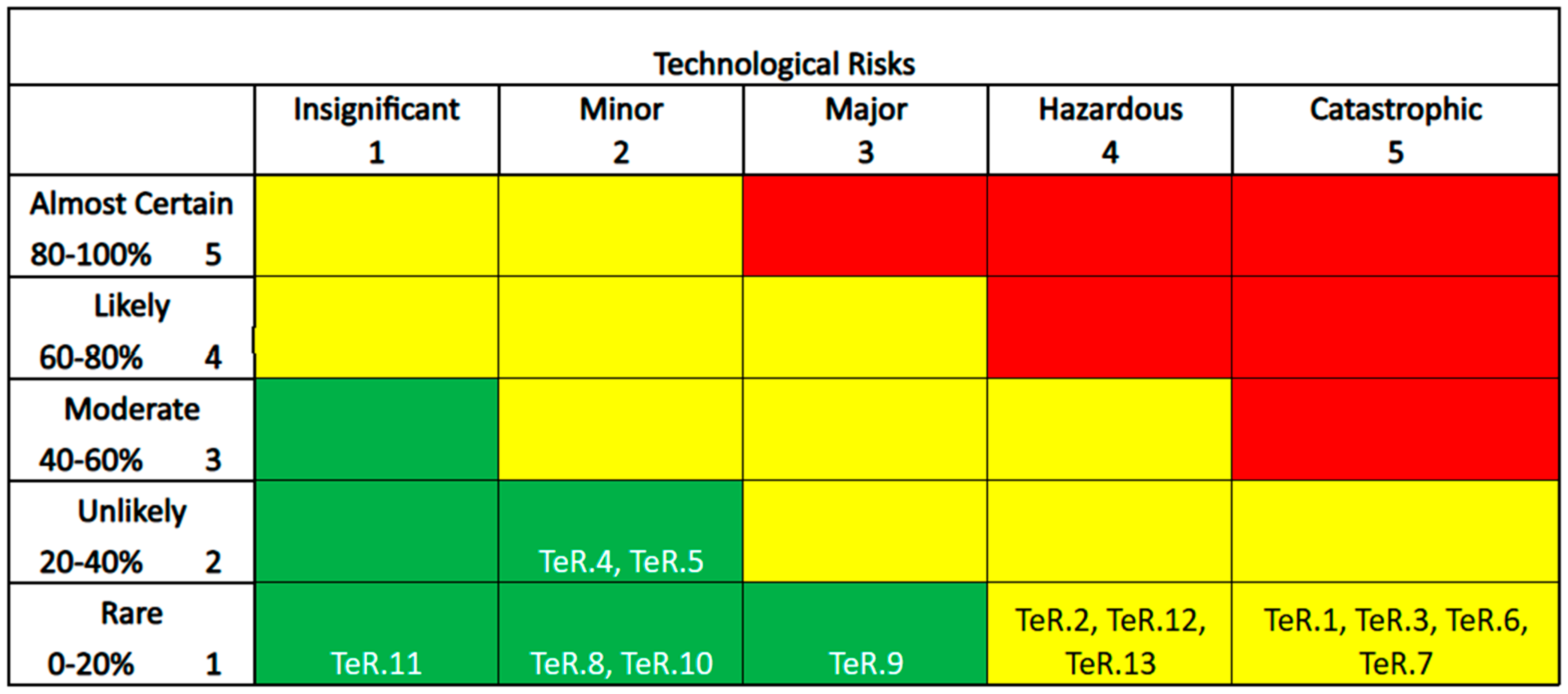

3.3. Risks

- Identify risks associated with high-level aircraft systems;

- Identify the function affected by each risk;

- Determine the likelihood of risk occurrence;

- Determine the impact of risk occurrence;

- Determine risk priority;

- Mitigate high- and medium-priority risks.

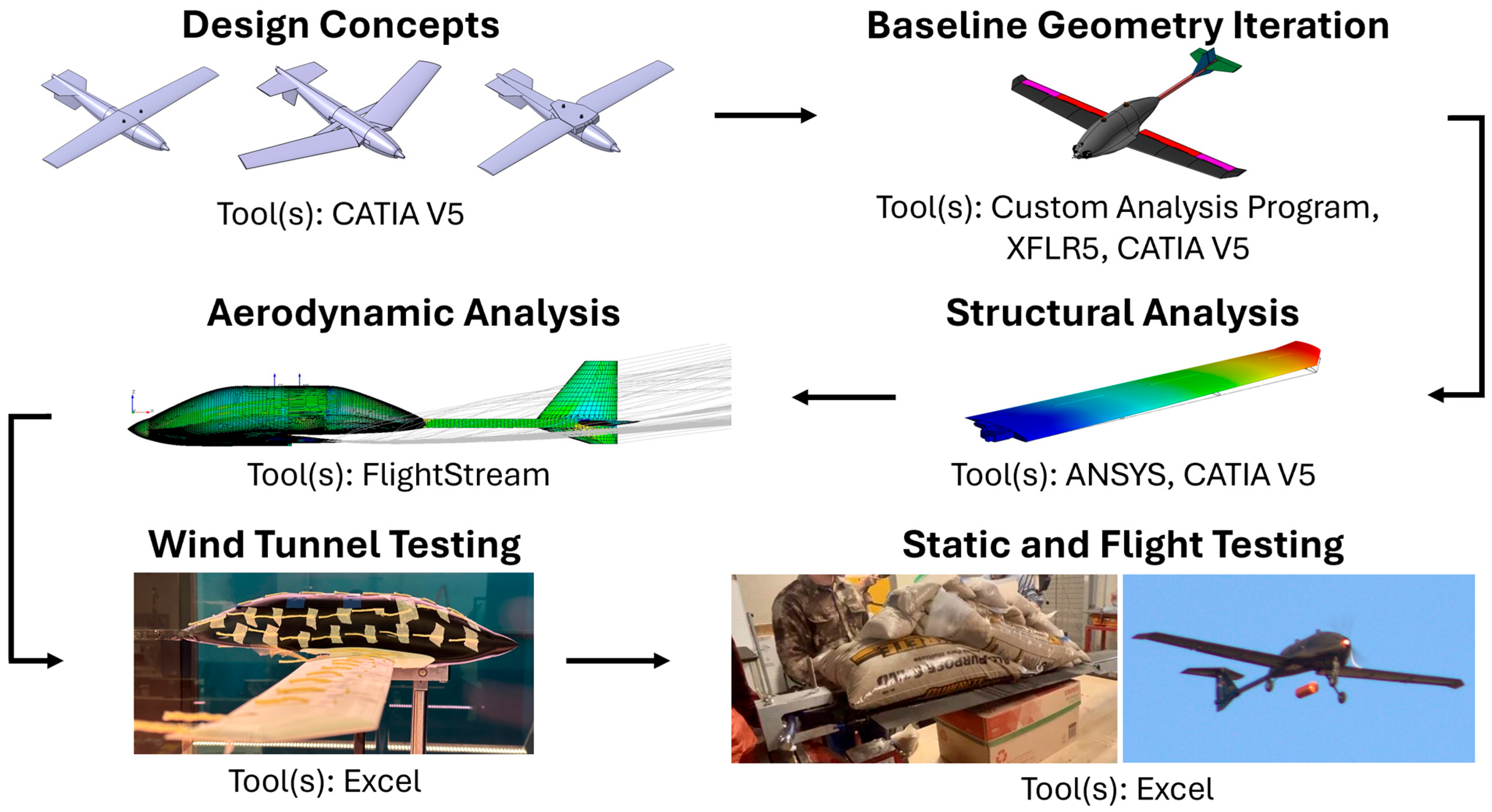

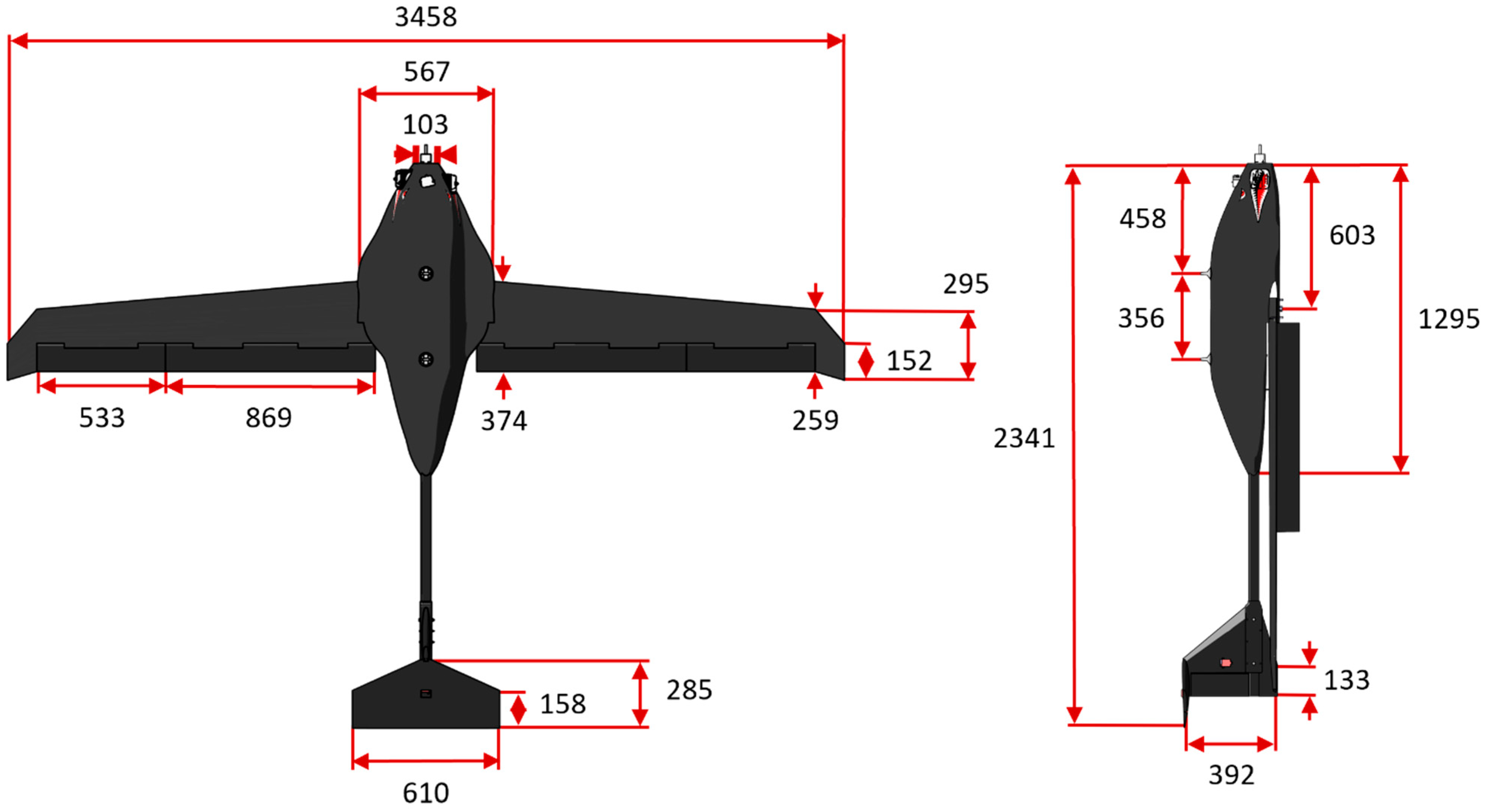

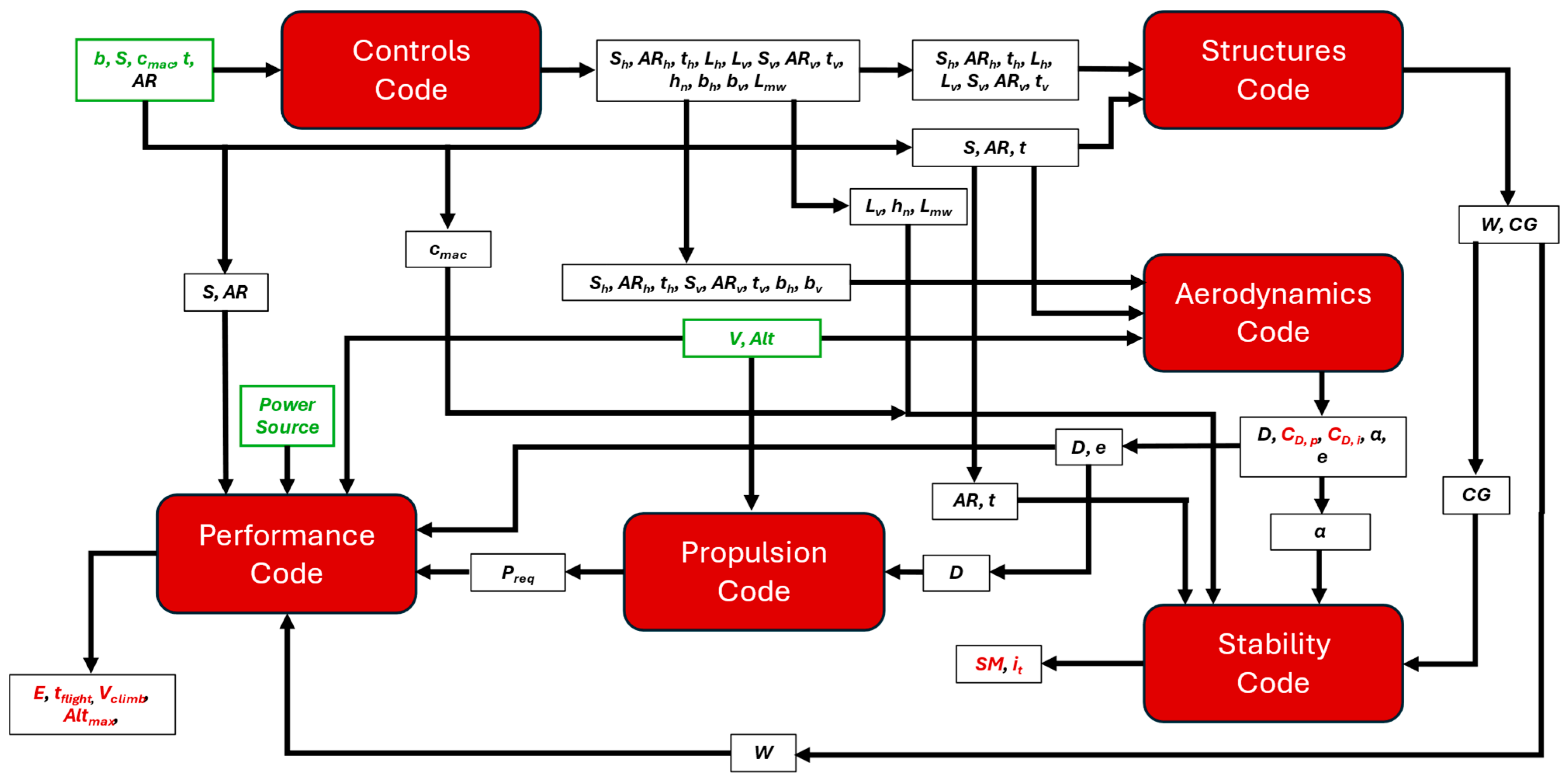

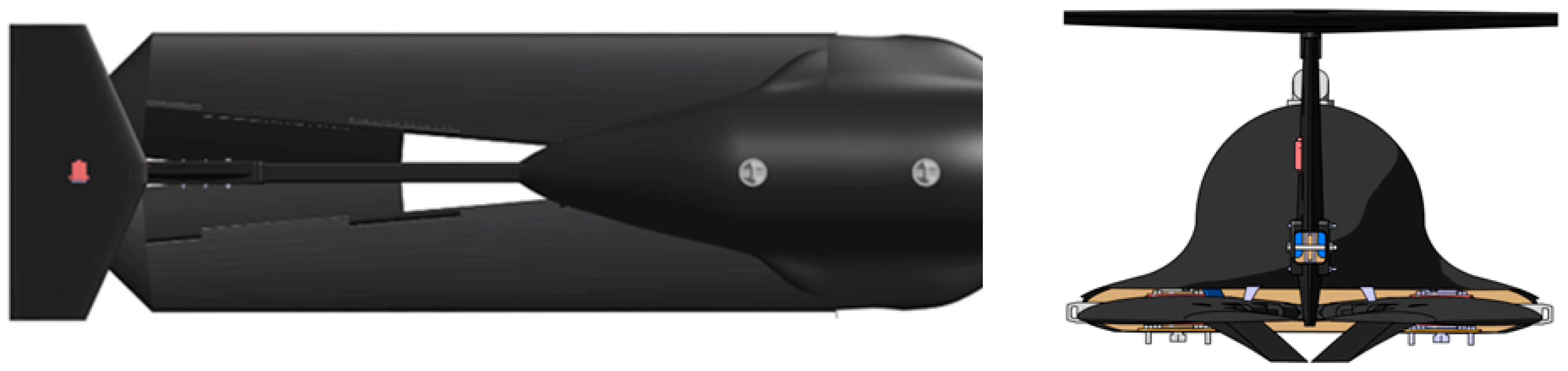

4. Design and Analysis

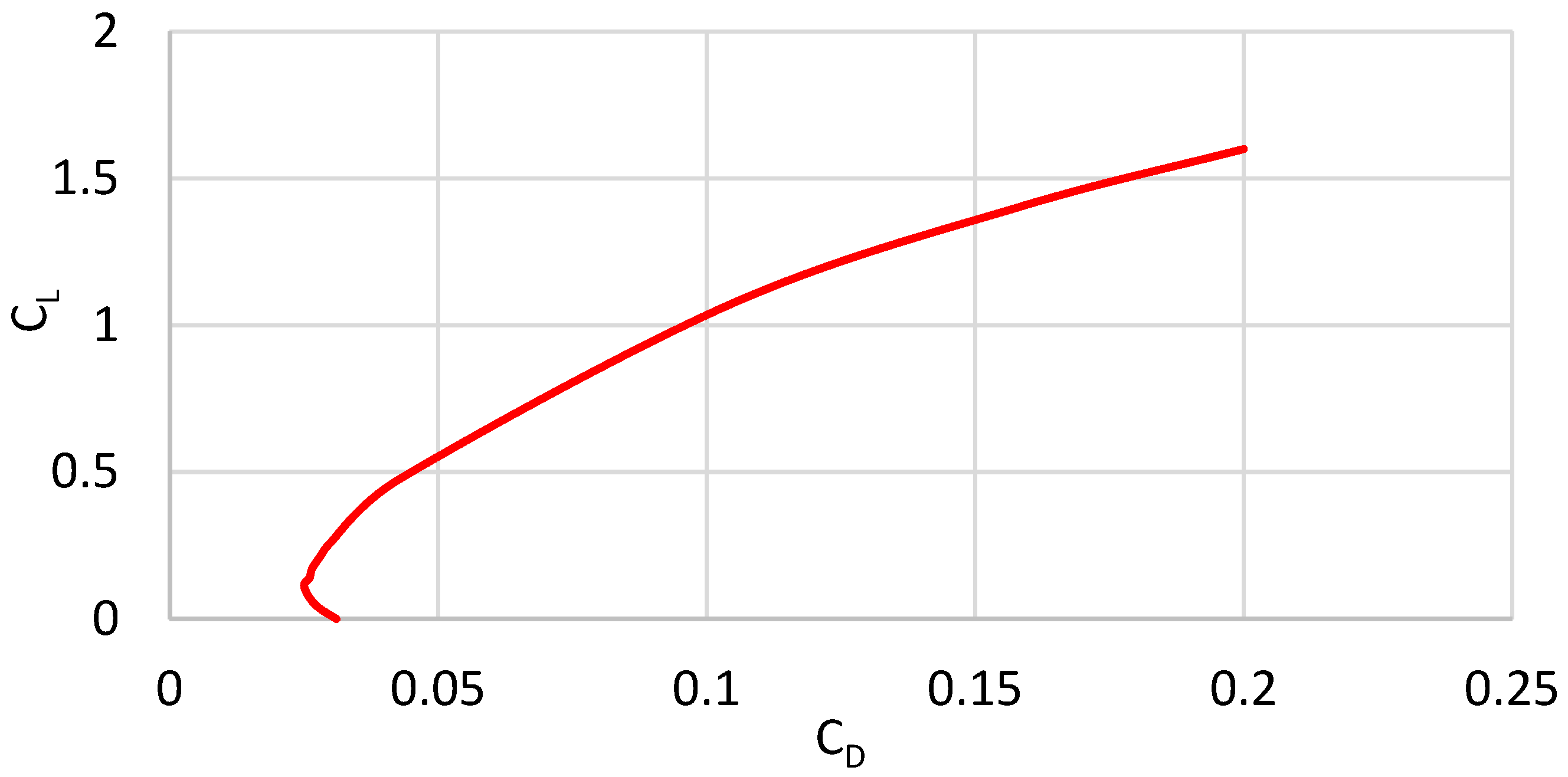

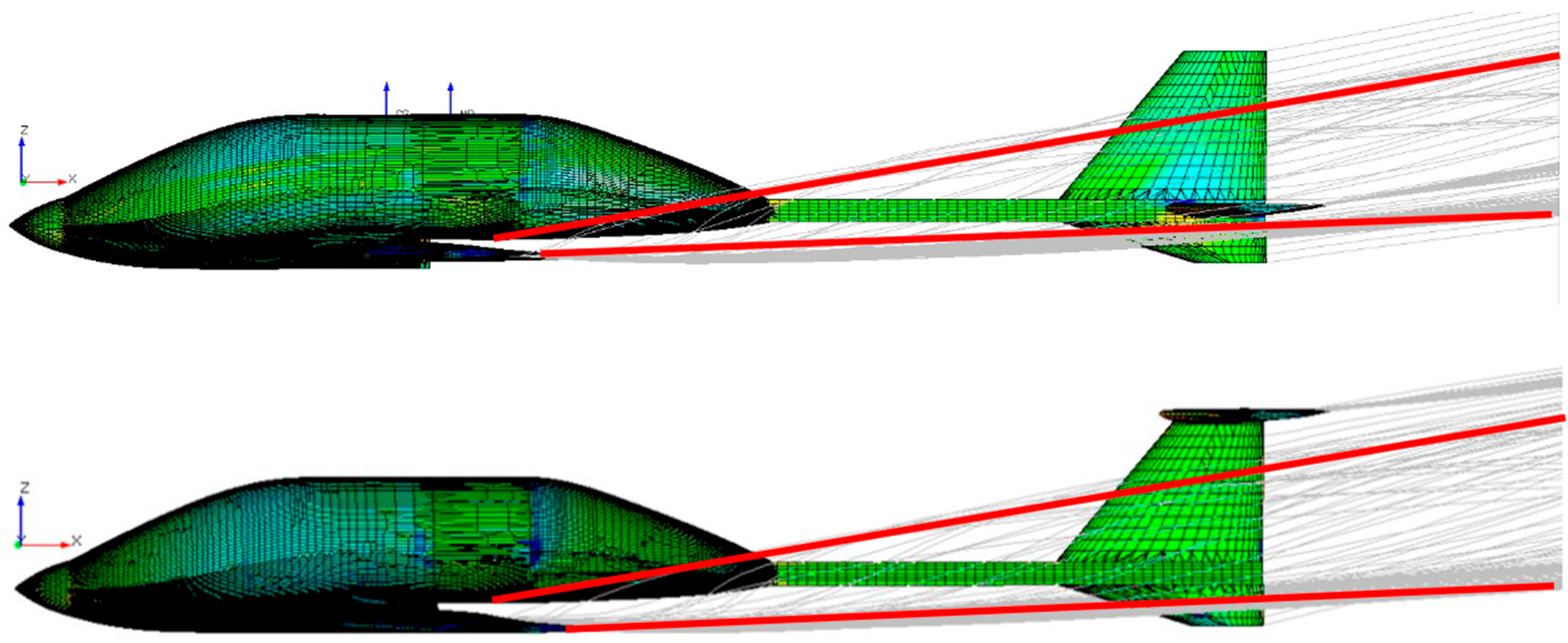

4.1. Aerodynamics

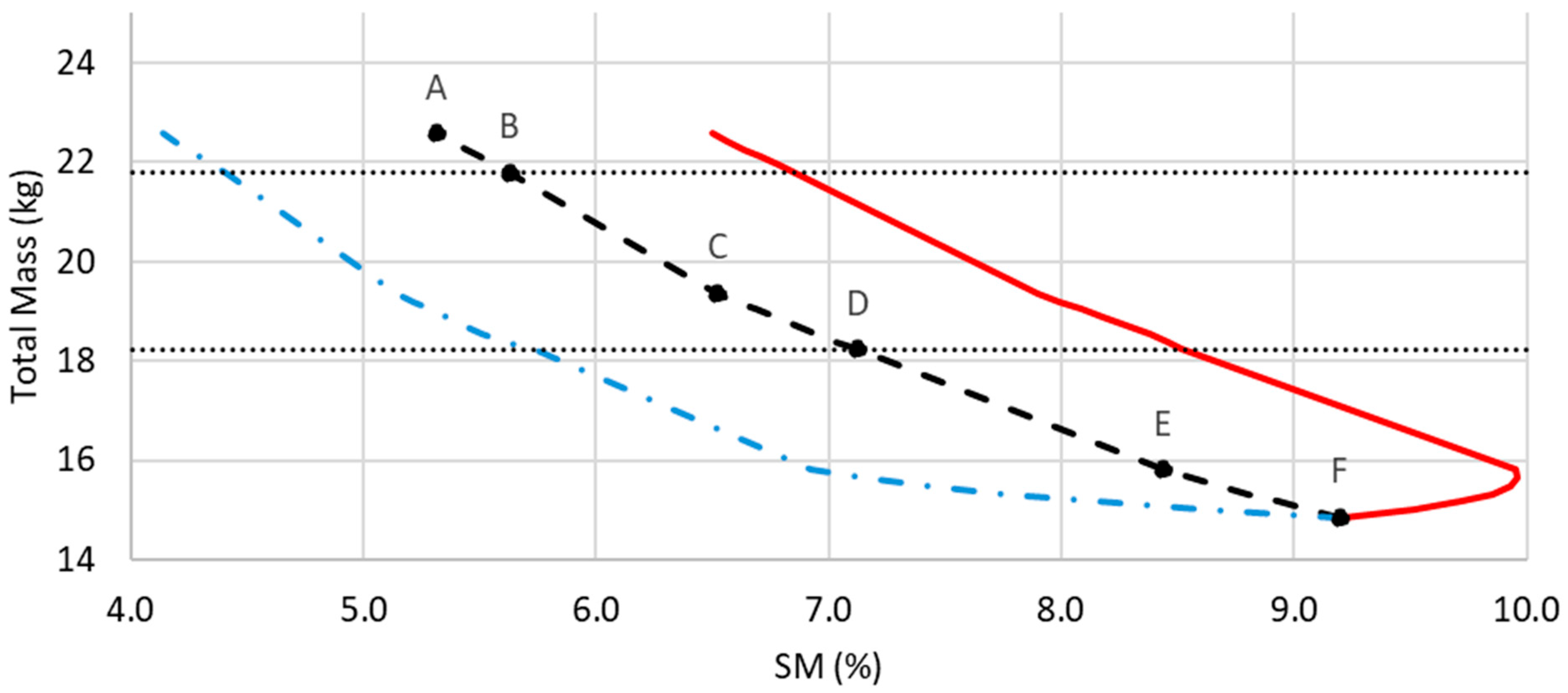

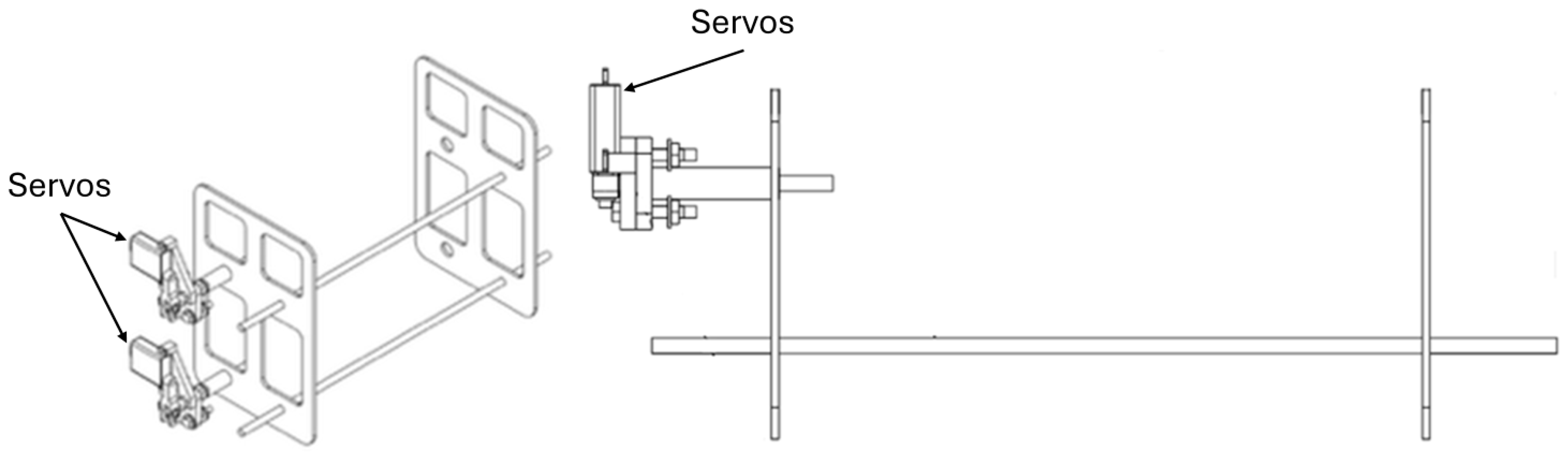

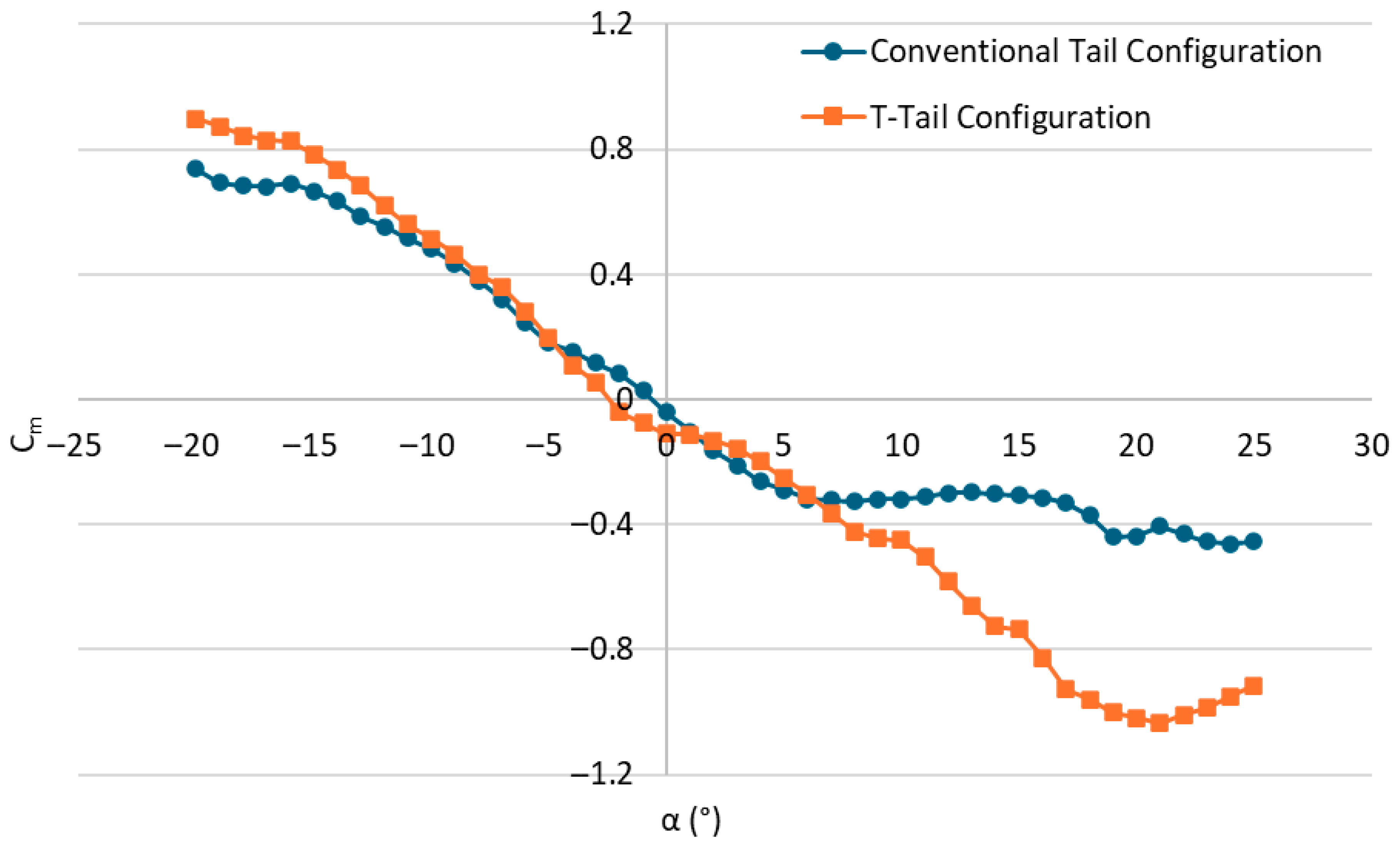

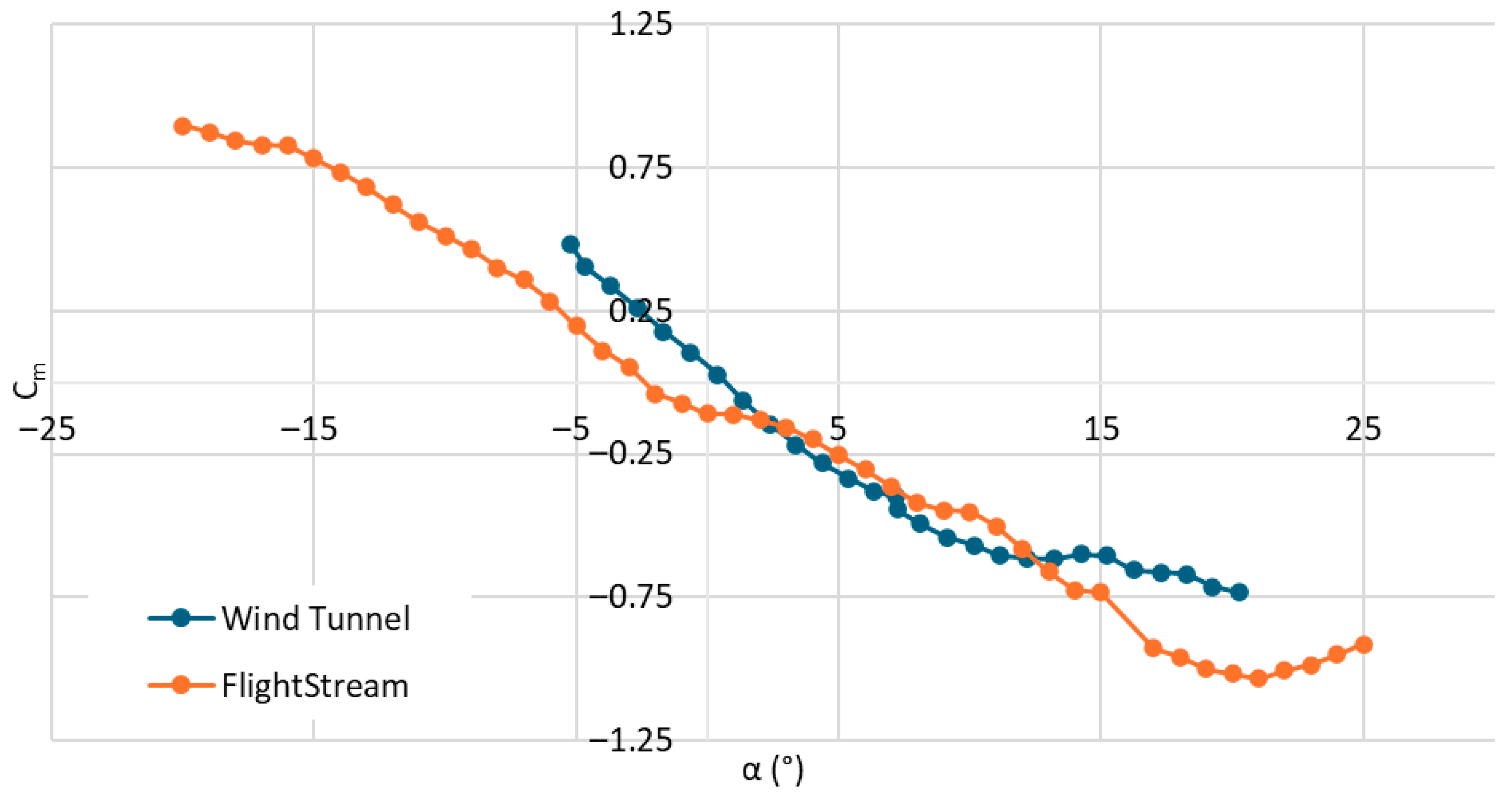

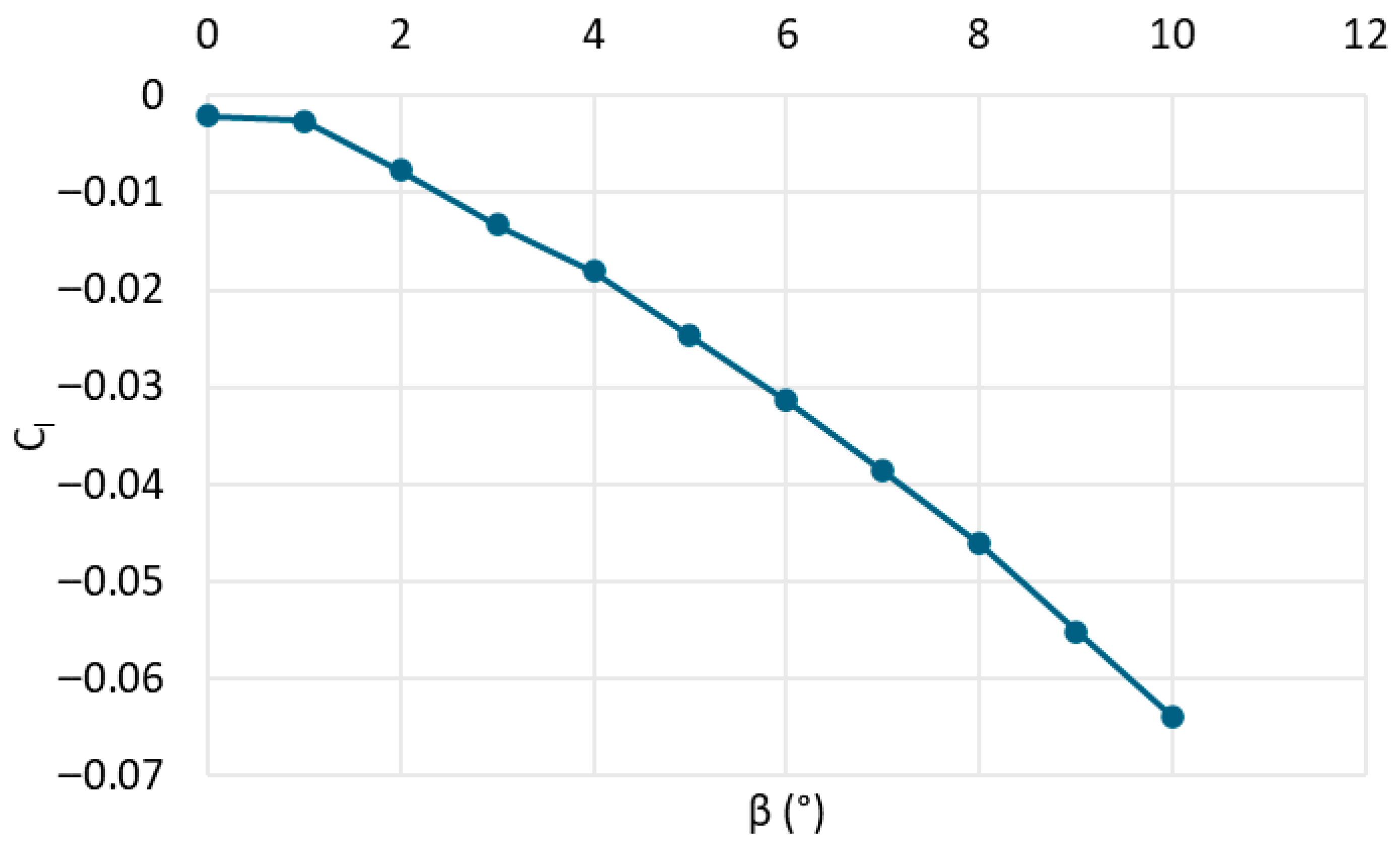

4.2. Stability and Control

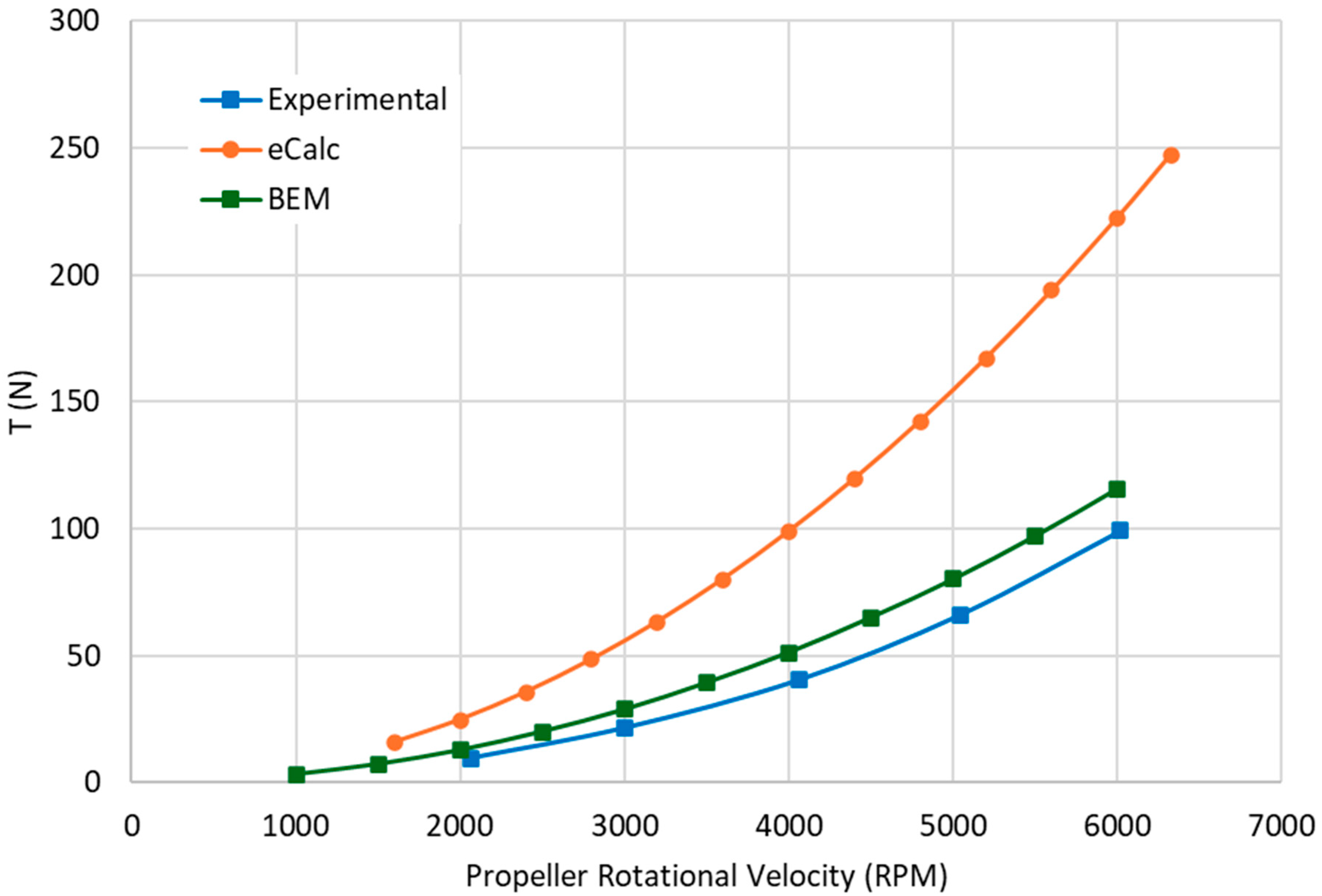

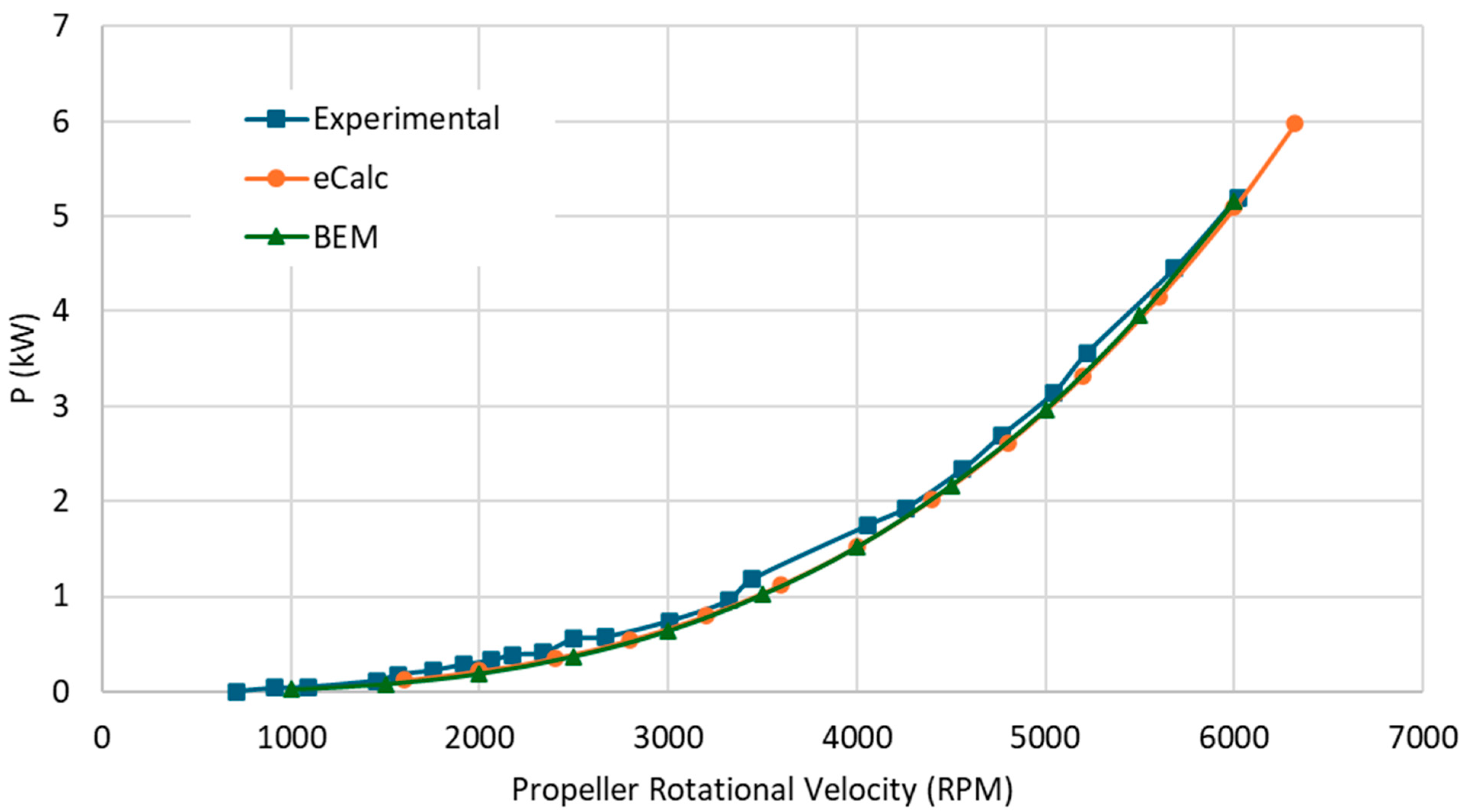

4.3. Propulsion

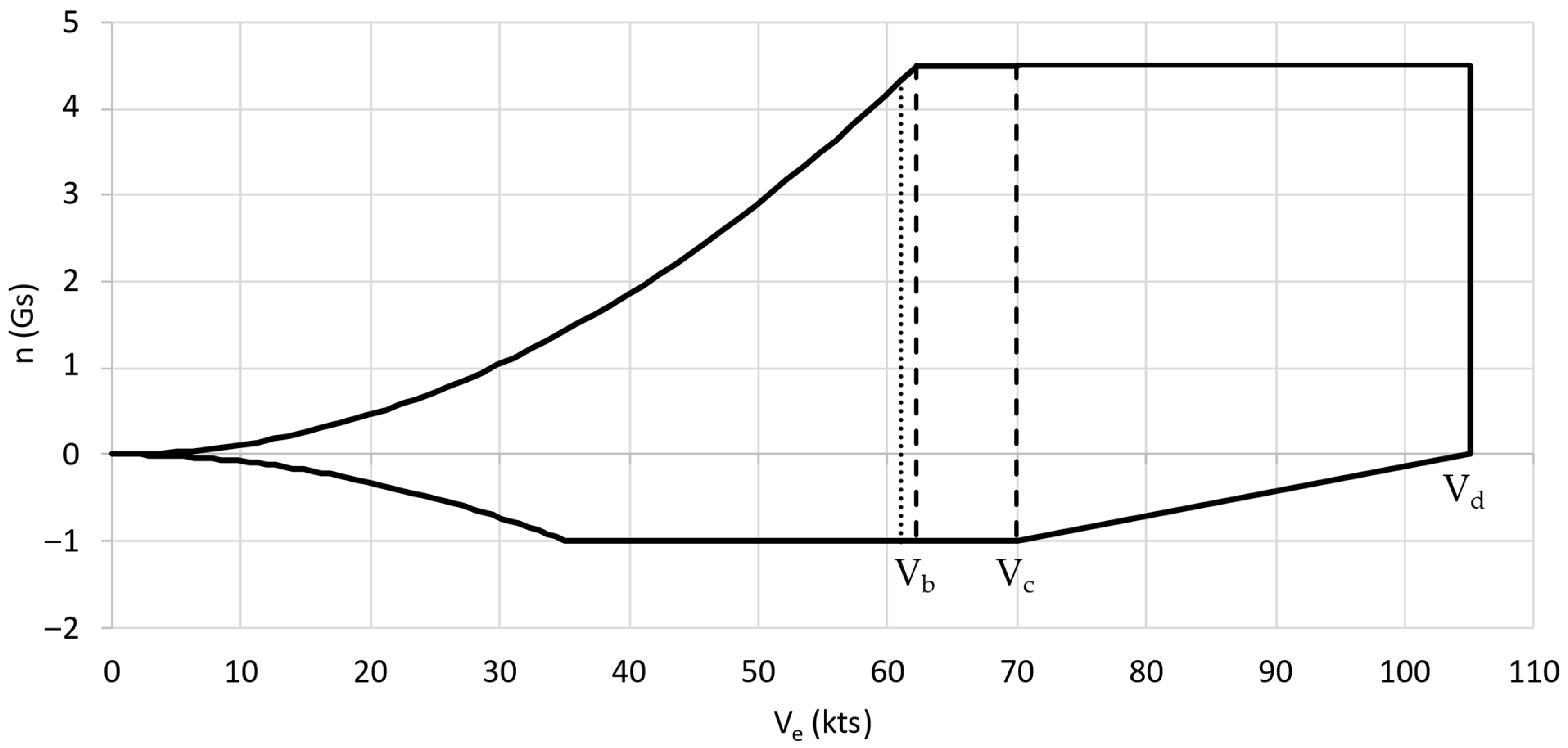

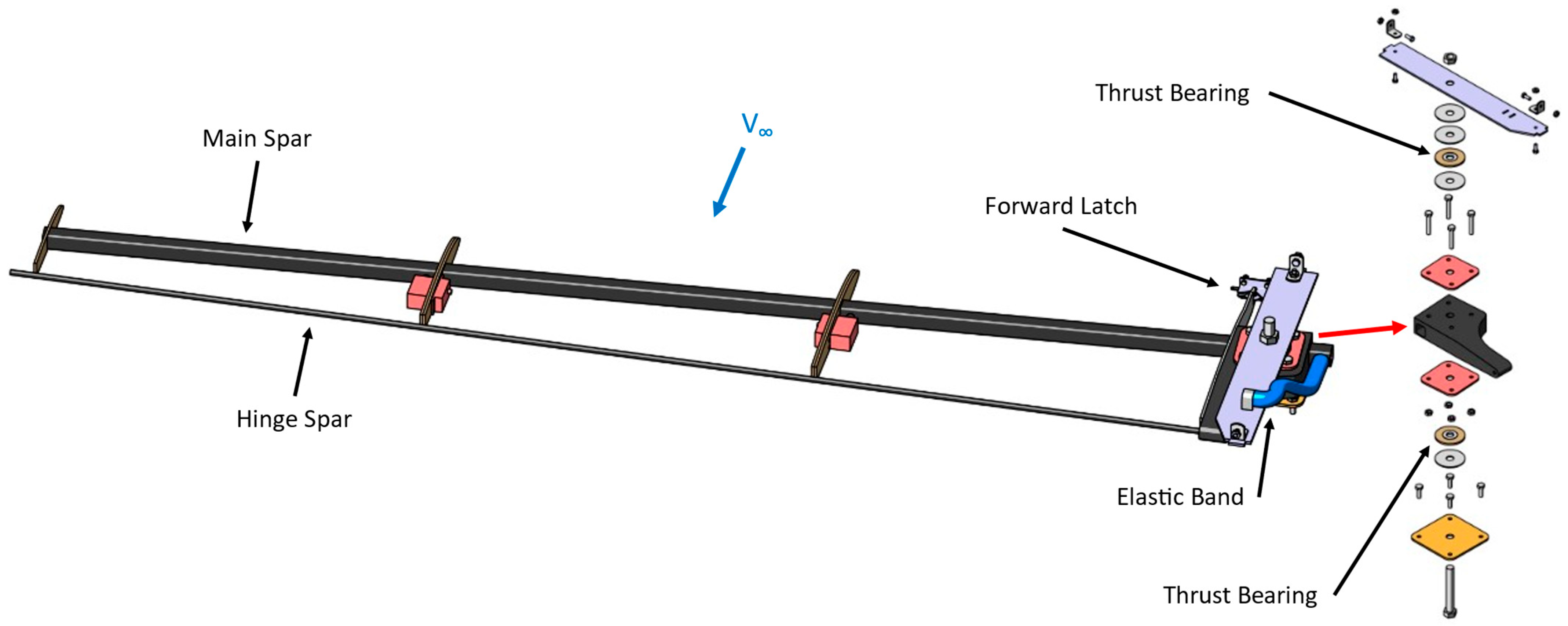

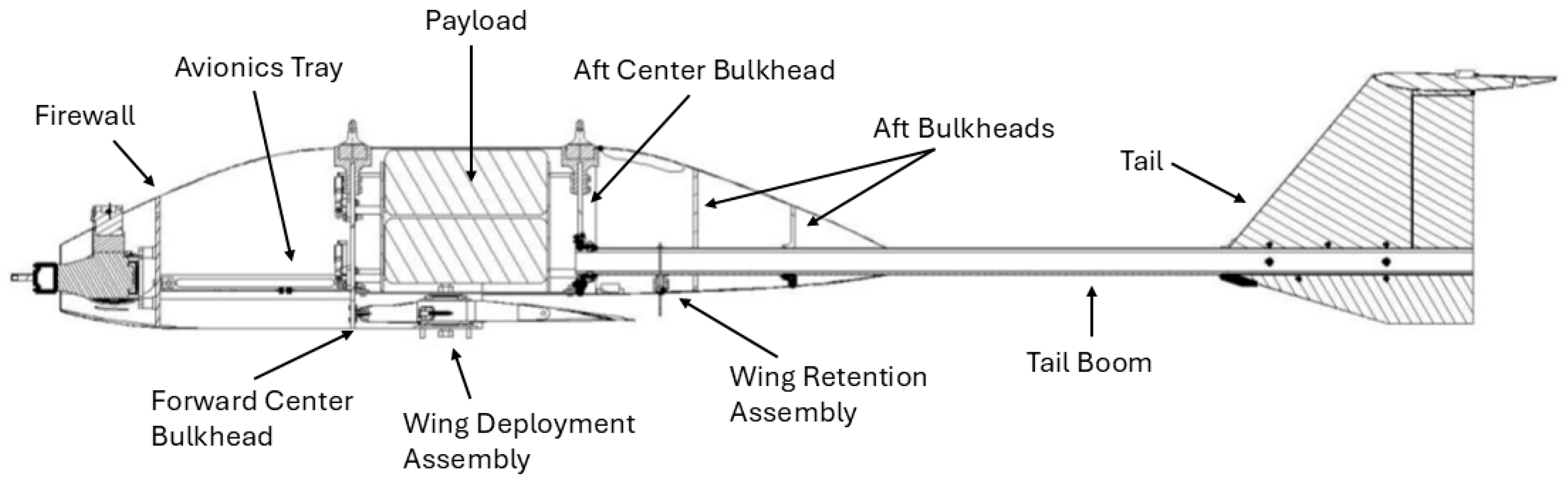

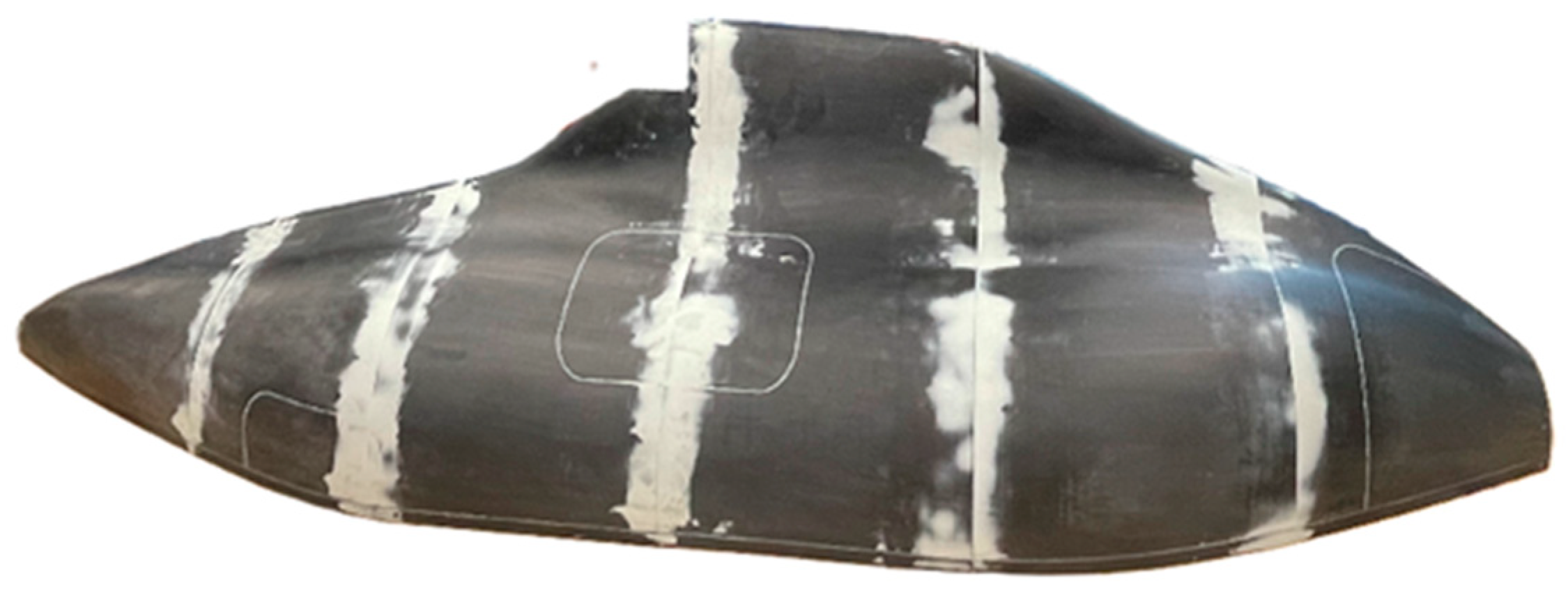

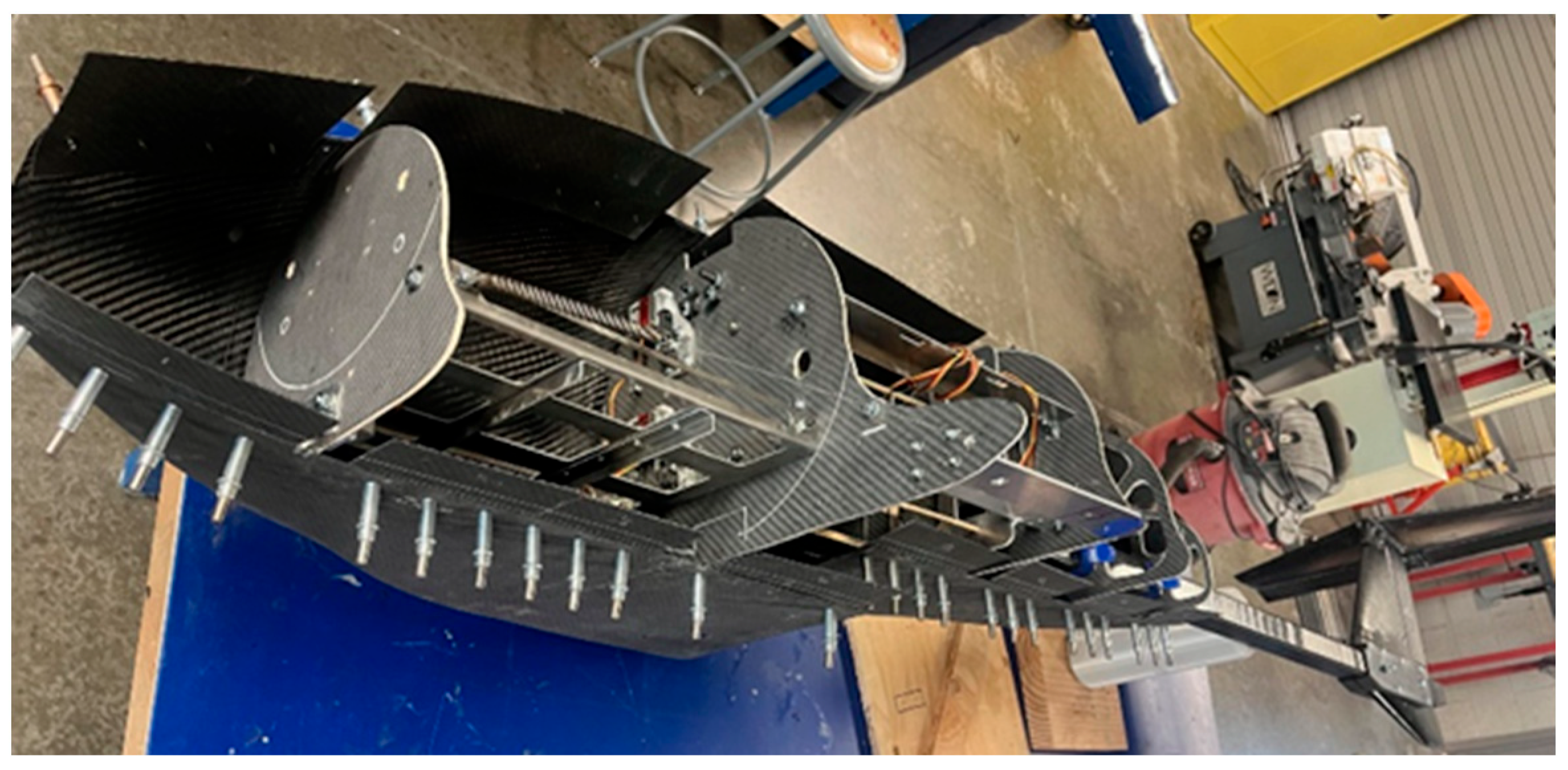

4.4. Structures

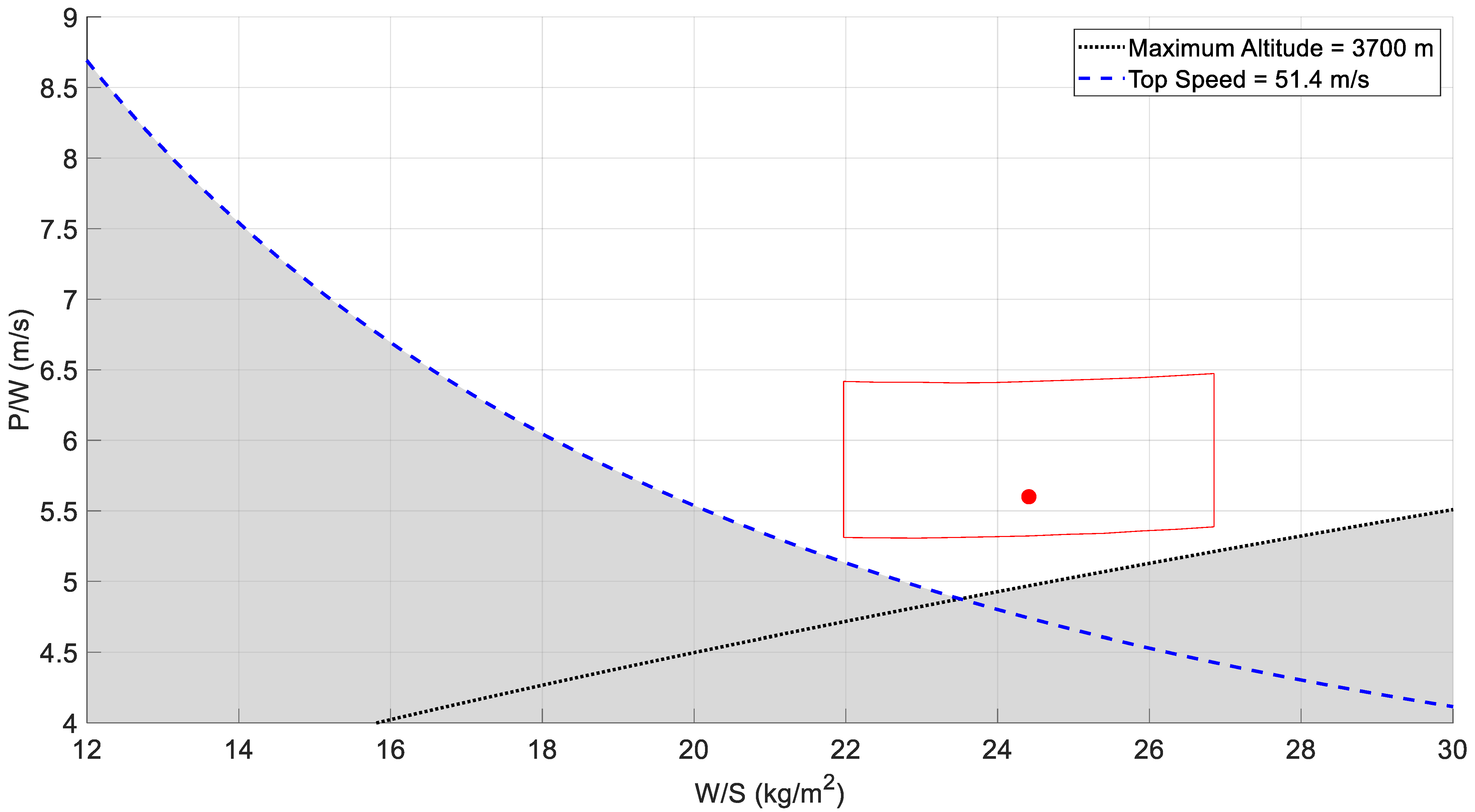

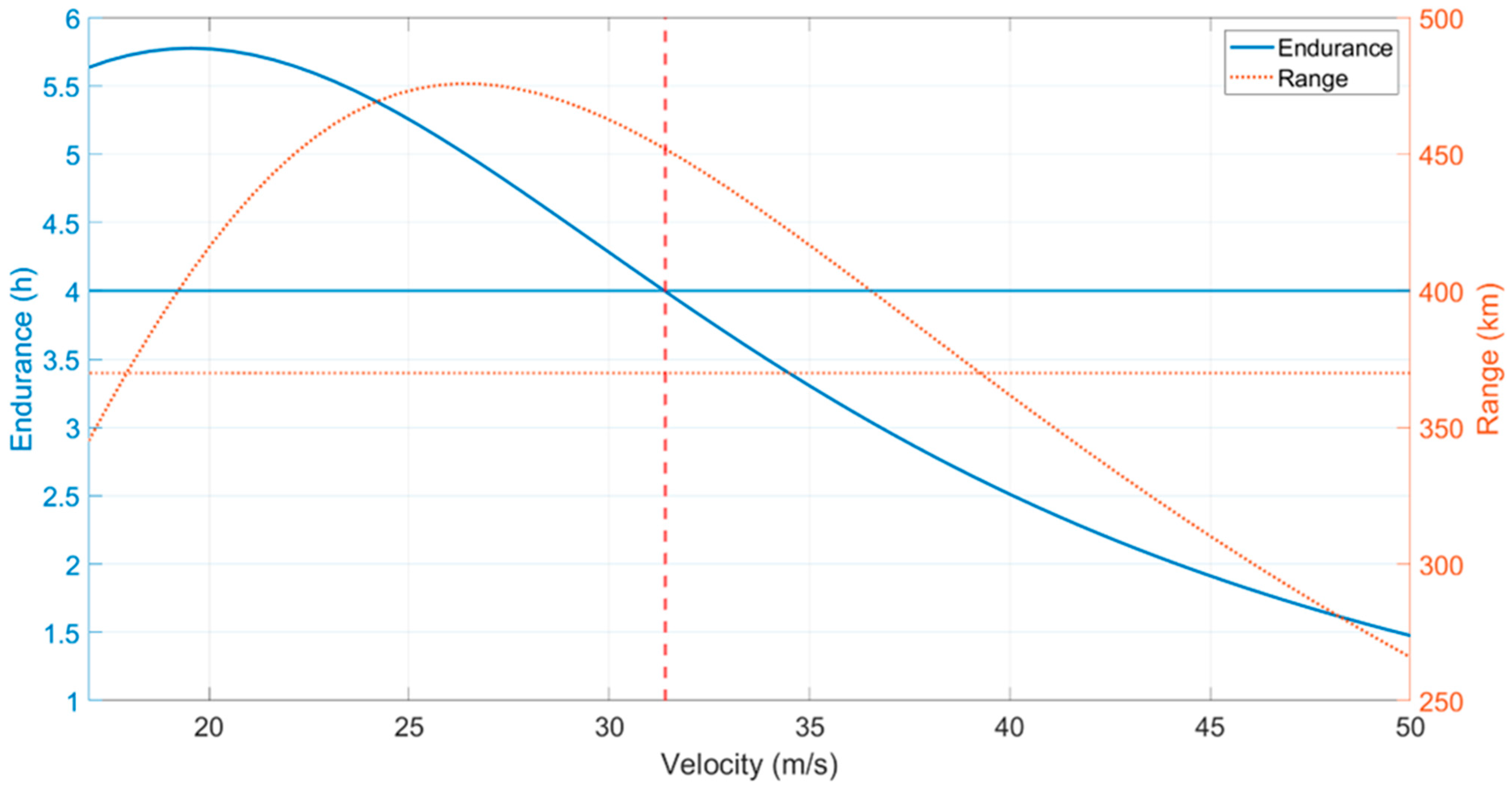

4.5. Performance Predictions

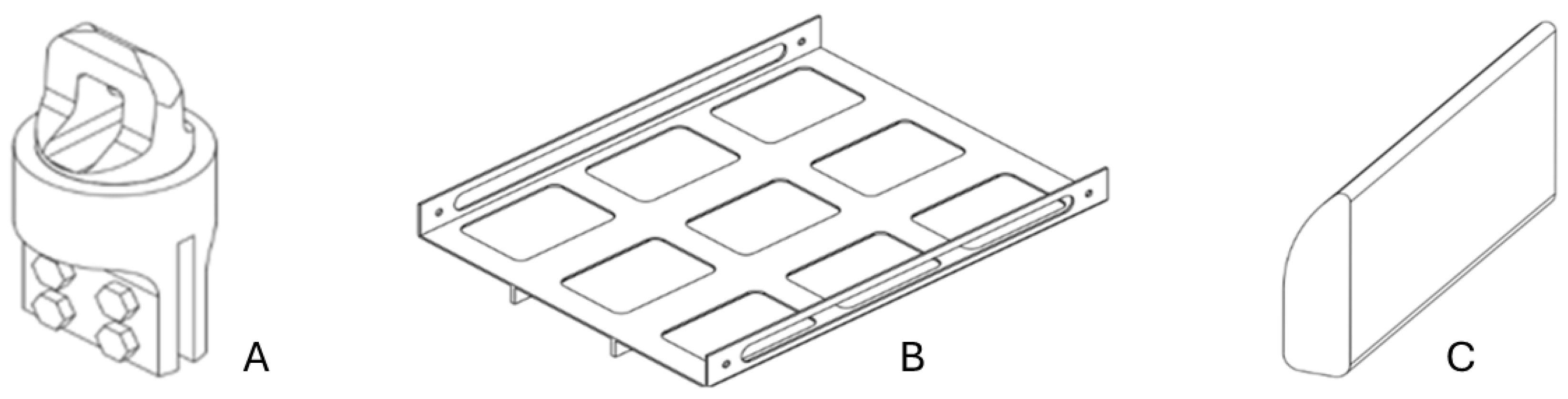

4.6. Manufacturing Highlights

5. Testing

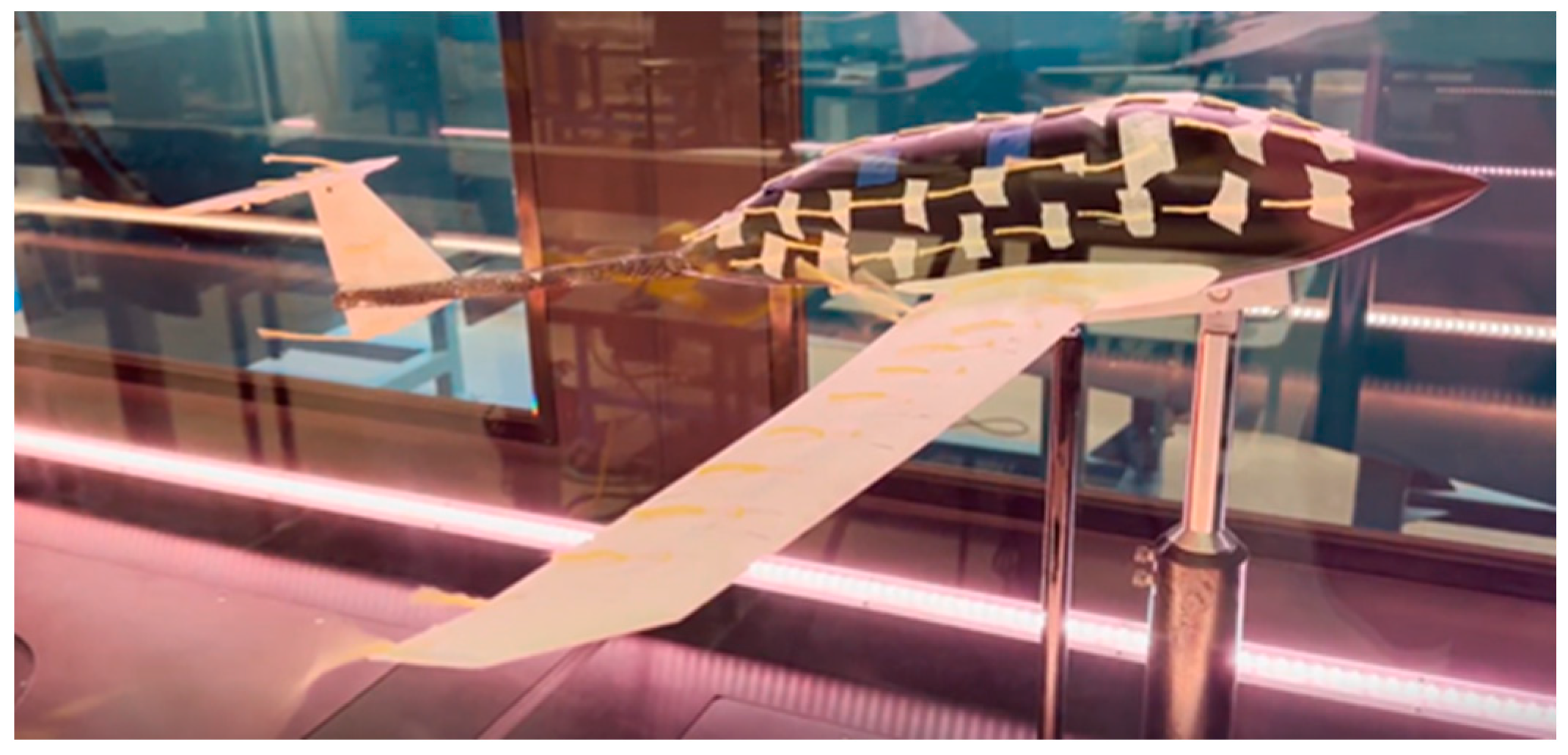

5.1. Subsystem Testing

5.2. Wind Tunnel Testing

5.3. Aircraft Flight Testing

6. Conclusions

6.1. Unique Challenges and Features

6.2. Performance and Risk Assessment

6.3. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures and Abbreviations

| Nomenclatures | |

| α | Angle of attack |

| β | Sideslip angle |

| Λ | Leading edge sweep |

| AR | Aspect ratio |

| ARh | Horizontal tail aspect ratio |

| ARv | Vertical tail aspect ratio |

| b | Wingspan |

| bh | Horizontal tail span |

| bv | Vertical tail span |

| CD | Coefficient of drag |

| CDi | Coefficient of induced drag |

| CDmin | Minimum coefficient of drag |

| CDp | Coefficient of parasitic drag |

| CL | Coefficient of lift |

| Cl | Roll moment coefficient |

| Cm | Pitching moment coefficient |

| cmac | Mean aerodynamic chord length |

| croot | Chord length at wing root |

| ctip | Chord length at wing tip |

| D | Drag force |

| E | Endurance |

| e | Oswald’s span efficiency factor |

| G | Load factor |

| hn | Neutral point moment arm |

| it | Tail incidence angle |

| iw | Wing incidence angle |

| Lh | Horizontal tail moment arm |

| Lmw | Wing moment arm |

| Lv | Vertical tail moment arm |

| P | Power |

| Preq | Power required |

| S | Planform wing area |

| Sh | Horizontal tail area |

| Sv | Vertical tail area |

| T | Thrust |

| t | Wing taper ratio |

| tflight | Flight time |

| th | Horizontal tail taper ratio |

| tv | Vertical tail taper ratio |

| V | Speed |

| Vb | Gust maneuver speed |

| Vc | Cruise speed |

| Vclimb | Climb speed |

| Vd | Dive speed |

| Ve | Equivalent air speed |

| Vne | Maximum allowable (Never Exceed) speed |

| Vy | Speed for maximum climb rate |

| W | Maximum takeoff weight |

| Abbreviations | |

| 3D | Three Dimensional |

| Alt | Flight altitude |

| Altmax | Maximum flight altitude |

| AS | Aerodynamic and Stability and Control Requirement |

| BEM | Blade Element and Momentum |

| CAD | Computer-Aided Design |

| CFD | Computational Fluid Dynamics |

| CG | Center of Gravity |

| ConOps | Concept of Operations |

| EFI | Electronic Fuel Ignition |

| ESC | Electronic Speed Controller |

| FAA | Federal Aviation Administration |

| FOS | Factor of Safety |

| FP | Flight Performance Requirement |

| FTA | Flight Test Article |

| h | Hours |

| in. | Inches |

| kg | Kilograms |

| km | Kilometers |

| kts | Knots |

| kW | Kilowatts |

| lbs | Pounds |

| m | Meters |

| MEDAID | Multiple Environment Deployable Aerial Item Delivery |

| min | Minutes |

| mm | Millimeters |

| MOS | Margin of Safety |

| m/s | Meters per Second |

| MSL | Mean Sea Level |

| N | Newtons |

| N/A | Not Applicable |

| NATO | North Atlantic Treaty Organization |

| OP | Operational Requirement |

| OpR | Operational Risk |

| PLA | Polylactic Acid |

| Re | Reynolds Number |

| RPM | Revolutions per Minute |

| s | Seconds |

| SA | Safety Requirement |

| SAE | Society of Automotive Engineers |

| SM | Static Margin |

| ST | Structures Requirement |

| TACOM | Tayouto Cogata Mujinki |

| TeR | Technological Risk |

| UAV | Unmanned Aerial Vehicle |

| W | Watts |

Appendix A

| Requirement Identifier | Explicit (E) or Derived (D) | Requirement | If Derived, Why? |

|---|---|---|---|

| OP.1.0 | D | The aircraft shall weigh less than 55.0 lbs (24.9 kg), including the weight of the payload. | FAA rule for small UAV, 14 CFR Part 107 |

| OP.2.0 | D | The set up and deployment shall be equal to or less than 5 min. | Usability: meets standards set by competitors |

| OP.3.0 | D | The aircraft shall be operable for reuse after landing on a designated runway. | Usability for testing as a Capstone project |

| OP.4.0 | E | The aircraft shall be deployable from the ground or air deployable from standard 14.0 in. (356 mm) lugs when mounted to host aircraft. | |

| OP.5.0 | E | The aircraft shall be deployable from host aircraft at an altitude of 1525 m and an airspeed of 41 m/s. | |

| OP.5.1 | D | Deployment from host aircraft shall occur at an altitude ≥305 m AGL. | Altitude required to regain steady flight after air deployment |

| OP.5.2 | D | Deployment from host aircraft shall occur in flight conditions with crosswind gusts less than 7.7 m/s. | Derived from NATO Standard AEP-83 |

| OP.5.3 | D | Deployment from host aircraft shall occur in flight conditions within a β range of −5° to 5°. | Safe range for control while wings deploy |

| OP.5.4 | D | Deployment from host aircraft shall only occur overground where a crash of the aircraft would not cause damage to civilian or military operations. | Mitigates risks associated with crashes during air deployment |

| OP.6.0 | E | The aircraft shall be able to carry and deploy two 2.3 kg canisters. | |

| OP.6.1 | E | The aircraft shall be able to deploy one canister at a time. | |

| OP.6.2 | D | The aircraft shall be able to deploy both canisters within 8 s. | Competitive advantage |

| OP.6.3 | E | The payload shall be deployable at all operational flight speeds. | |

| OP.6.4 | D | The payload shall be deployable at a pitch angle of ±5°. | Necessary for mission accomplishment |

| OP.6.5 | D | The payload shall be deployable at a roll angle of ±5°. | Necessary for mission accomplishment |

| OP.6.6 | D | The payload shall be deployable at a yaw angle of ±5°. | Necessary for mission accomplishment |

| OP.6.7 | E | The payload shall land within a 6.1 m radius of the intended drop point. | |

| OP.6.8 | D | The payload deployment system shall have a 95% success rate after the deployment command. | Competitive advantage |

| OP.7.0 | E | The unit cost at the 100th unit shall cost less than or equal to USD 50,000. | |

| OP.7.1 | E | The total project expenditure shall cost less than or equal to USD 7000. | |

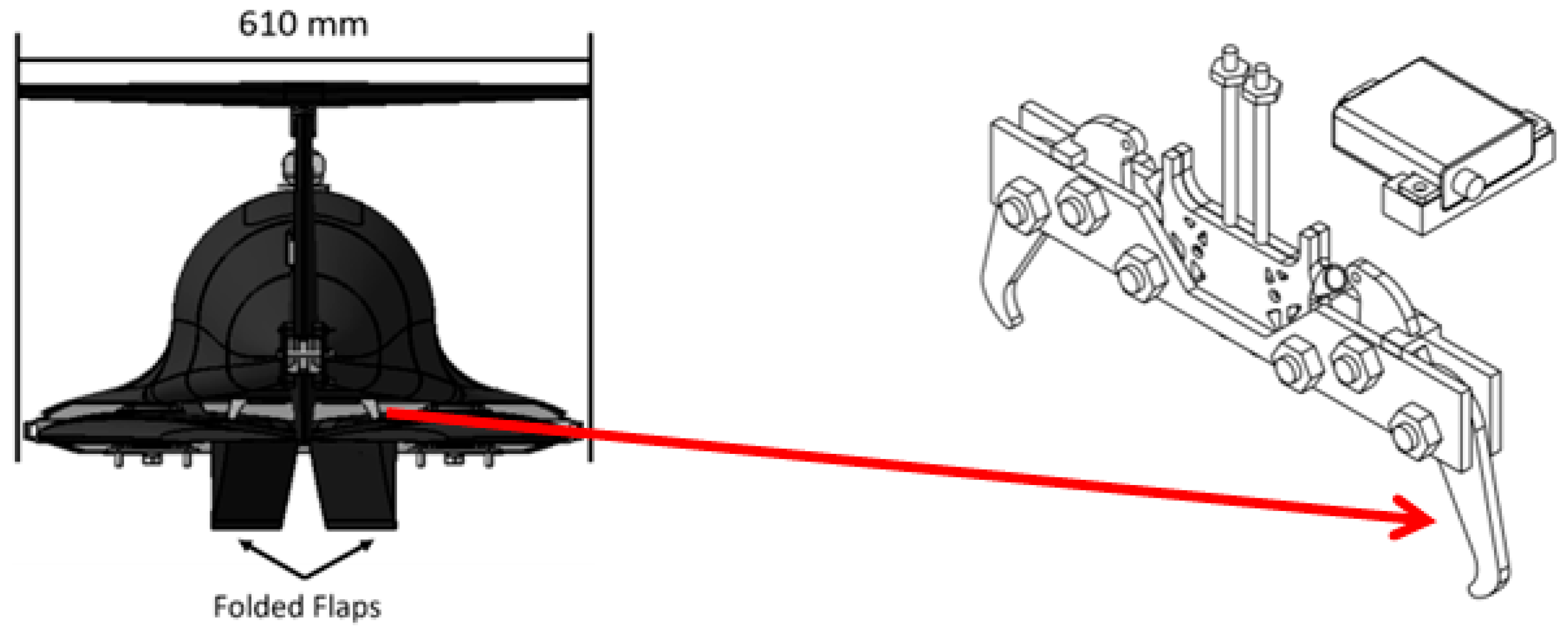

| OP.8.0 | E | The aircraft shall have a maximum width of 610 mm when measured from rightmost edge to leftmost edge when in the stored configuration. | |

| OP.8.1 | D | The aircraft shall fully deploy the wings within 2 seconds. | Necessary for mission accomplishment |

| OP.8.2 | D | The wing deployment mechanism shall be locked while attached to the host aircraft. | Mitigates risk of wings deploying while attached to host aircraft |

| Requirement Identifier | Explicit (E) or Derived (D) | Requirement | If Derived, Why? |

|---|---|---|---|

| SA.1.0 | D | Airworthiness shall be determined by the condition for safe operation as determined in 14 CFR 107.15. | Governing regulations for a small UAV |

| SA.1.1 | D | Routine maintenance shall be limited to inspections of airworthiness as determined by Safety Requirement 1.0 (SA.1.0). | Low impact on daily operations |

| SA.1.2 | D | The aircraft shall be disassembled for inspection and maintenance of all moving parts. | Maintainability, from usability requirement |

| SA.2.0 | D | The flight demonstrator test pilot shall follow safety guidelines listed in AMA document #706 and all subsequent documents referenced in AMA document #706. | Governing regulations for flying at AMA fields |

| SA.3.0 | D | The aircraft shall immediately perform a power-off landing if thrust is lost. | Safe operation based of risk identification |

| SA.3.1 | D | There shall be a preprogrammed landing sequence if control is lost for the flight demonstrator. | Ensures aircraft will return to ground if control is lost |

| SA.4.0 | D | There shall be at least three signal receivers in different locations across the aircraft. | Ensures backups for control of aircraft while in flight |

| Requirement Identifier | Explicit (E) or Derived (D) | Requirement | If Derived, Why? |

|---|---|---|---|

| AS.1.0 | D | The aircraft shall have full control of roll, pitch, and yaw. | Required for full controllability |

| AS.2.0 | D | The aircraft shall have a positive static margin regardless of payload configuration. | Required for aircraft stability |

| AS.3.0 | D | The aircraft shall be statically stable as defined by the nine static stability criteria for low-speed aircraft. | Required for aircraft stability |

| AS.3.1 | D | The aircraft shall tend to return to its initial trimmed air speed after a small disturbance as characterized by the equation: | SSC #1: Speed stability |

| AS.3.2 | D | The aircraft shall tend to return to its initial trimmed sideslip value after a small disturbance as characterized by the equation: | SSC #2: Lateral force due to sideslip |

| AS.3.3 | D | The aircraft shall tend to return to its initial flight path after a small disturbance as characterized by the equation: | SSC #3: Lift force due to angle of attack |

| AS.3.4 | D | The aircraft shall tend to return to its initial angle of attack after a small disturbance as characterized by the equation: | SSC #4: Pitch stability |

| AS.3.5 | D | The aircraft shall tend to yaw to face into relative wind to maintain directional equilibrium as characterized by the equation: | SSC #5: Yaw stability |

| AS.3.6 | D | The aircraft shall tend to return to its initial roll condition after a small disturbance as characterized by the equation: | SSC #6: Roll dampening |

| AS.3.7 | D | The aircraft shall have a positive static margin as characterized by the equation: | SSC #7: Pitch dampening |

| AS.3.8 | D | The aircraft shall tend to return to its initial yaw condition after a small disturbance as characterized by the equation: | SSC #8: Yaw dampening |

| AS.3.9 | D | The aircraft shall tend to offset sideslip by rolling to decrease the sideslip angle as characterized by the equation: | SSC #9: Roll stability |

| Requirement Identifier | Explicit (E) or Derived (D) | Requirement | If Derived, Why? |

|---|---|---|---|

| FP.1.0 | E | The aircraft shall have a dash speed ≥51.4 m/s. | |

| FP.2.0 | E | The aircraft shall operate at an altitude ≥3658 ft. | |

| FP.3.0 | E | The aircraft shall have an endurance ≥ 4 h in optimal flight conditions with no wind. | |

| FP.4.0 | E | The aircraft shall have a one-way range ≥370 km in optimal flight conditions with no wind. | |

| FP.5.0 | D | The maximum operating speed shall be less than 90% of the max design speed. | FOS; Vne |

| FP.6.0 | D | The ISA sea level rate of climb for Vy shall be ≥1.5 m/s with no more than takeoff power. | NATO Standard AEP-83 |

| FP.6.1 | D | The minimum Vy shall be measured when the aircraft is at MTOW, with the aircraft in takeoff configuration. | NATO Standard AEP-83 |

| FP.7.0 | D | The aircraft shall operate in conditions with up to 7.7 m/s updraft and downdraft gusts. | NATO Standard AEP-83 |

| FP.8.0 | D | The aircraft shall operate in conditions with up to 7.7 m/s crosswind gusts. | NATO Standard AEP-83 |

| FP.9.0 | E | The aircraft shall operate in temperature conditions from 0 °C to 46 °C. |

| Requirement Identifier | Explicit (E) or Derived (D) | Requirement | If Derived, Why? |

|---|---|---|---|

| ST.1.0 | D | A symmetric limit maneuvering load factor ≥3.8 should be established. | NATO Standard AEP-83 |

| ST.2.0 | D | A symmetric negative limit maneuvering load factor ≤−1.5 shall be established. | NATO Standard AEP-83 |

| ST.3.0 | D | An ultimate load FOS ≥1.5 shall be used for all critical structures. | NATO Standard AEP-83 |

| ST.3.1 | D | In the case of castings, a FOS of ≥2.0 shall be used. | NATO Standard AEP-83 |

| ST.3.2 | D | In the case of fittings, a FOS of ≥1.15 shall be used. | NATO Standard AEP-83 |

| ST.3.3 | D | In the case of bearings at bolted or pinned joints subject to rotation, a FOS of ≥2.0 shall be used. | NATO Standard AEP-83 |

| ST.3.4 | D | In the case of control surface hinge-bearing loads except ball and roller bearing hinges, a FOS of ≥4.45 shall be used. | NATO Standard AEP-83 |

| ST.3.5 | D | In the case of push-pull control system joints, a FOS of ≥2.2 shall be used. | NATO Standard AEP-83 |

| ST.3.6 | D | In the case of attachments in frequently assembled and disassembled structural parts, a FOS of ≥ 1.5 shall be used. | NATO Standard AEP-83 |

| ST.3.7 | D | In the case of wing stow retention critical structures, a FOS ≥2.5 shall be used. | Mitigation for wing deployment risk |

Appendix B

| Effect on Aircraft | Effect on Ground Crew | Effect on External Personnel | Classification |

|---|---|---|---|

| Loss of aircraft | Crew unable to accomplish required tasks, or required crew strength or skill in excess of crew capability, or crew incapacitation, or crew fatalities | Any fatalities | Catastrophic |

| Large reduction in aircraft functional capability | Excessive crew workload increase, crew unable to fully accomplish required tasks, or crew physical distress | Severe injuries | Hazardous |

| Significantly reduced aircraft functional capability | Significant crew workload increase, or conditions impairing crew efficiency, or crew physical discomfort | Physical distress or non-fatal injuries | Major |

| Slightly reduced aircraft functional capability | Slight crew workload increase | Physical discomfort | Minor |

| No effect on aircraft function capability | No effect on crew workload | No effect | Insignificant |

| Identifier | Risk | Likelihood | Effect |

|---|---|---|---|

| OpR.1 | Vibration from engine causing signal loss—wires disconnecting | 1 | 5 |

| OpR.2 | Loss of control when air deployed in conditions with high sideslip | 1 | 5 |

| OpR.3 | Not enough altitude to attain steady flight after air deployment | 1 | 5 |

| OpR.4 | Vertical tail may not fit under some host aircraft due to height | 1 | 1 |

| OpR.5 | Propeller breaking during flight due to strike | 1 | 5 |

| OpR.6 | Fuselage/Boom tail connection breaking during operation due to high loads | 1 | 5 |

| OpR.7 | Wing pin connector failing during flight | 1 | 5 |

| OpR.8 | Vibration from engine causing signal interference—frequencies | 1 | 1 |

| OpR.9 | Propeller breaking during landing | 1 | 1 |

| OpR.10 | Flutter of wings during stored configuration | 2 | 2 |

| OpR.11 | Aircraft striking debris during take-off | 1 | 2 |

| OpR.12 | Flutter of tail boom during flight | 2 | 2 |

| OpR.13 | CG Changing after Payload Deployment | 5 | 1 |

| OpR.14 | Inability to reuse aircraft after landing on a non-designated runway surface | 1 | 1 |

| Identifier | Risk | Likelihood | Effect |

|---|---|---|---|

| TeR.1 | Insufficient engine venting may cause heat damage to subsystems inside fuselage | 1 | 5 |

| TeR.2 | Wing deployment mechanism failing to deploy the wings | 1 | 4 |

| TeR.3 | Wing deployment/locking mechanism failing while mounted to host aircraft wings potentially deploying while still mounted to host aircraft | 1 | 5 |

| TeR.4 | Engine failing midair—unrestartable | 2 | 2 |

| TeR.5 | Engine failing midair—restartable | 2 | 2 |

| TeR.6 | High engine temperature melting composite | 1 | 5 |

| TeR.7 | Exhaust fumes melting/causing failure of composite | 1 | 5 |

| TeR.8 | Payload doors not fully extending due to wing placement | 1 | 2 |

| TeR.9 | Insufficient lift points for mounting/attachment to host aircraft | 1 | 3 |

| TeR.10 | Payload doors become stuck “open” | 1 | 2 |

| TeR.11 | Second payload does not assume correct position after deployment of the first | 1 | 1 |

| TeR.12 | Either payload fail to deploy | 1 | 4 |

| TeR.13 | Wings being overly difficult to restow after deployment—takes more than crew would be able to handle | 1 | 4 |

References

- Bomb, Guided, Fritz X (X-1). Available online: https://bit.ly/47fmHYH (accessed on 4 October 2025).

- Hs 293 A-1 Missile. Available online: https://bit.ly/4qgOfFN (accessed on 4 October 2025).

- Federation of American Scientists. D-21 Strategic Reconnaissance Drone. Available online: https://bit.ly/3J14Yfz (accessed on 4 October 2025).

- Doi, H. TACOM-Air-Launched Multi-Role UAV. In Proceedings of the 24th Congress of International Council of the Aeronautical Sciences, Yokohama, Japan, 29 August–3 September 2004; Volume 24. Available online: https://bit.ly/431C4CA (accessed on 4 October 2025).

- U.S. Army Unmanned Aircraft Systems Roadmap 2010–2035. Available online: https://bit.ly/4pPanqt (accessed on 4 October 2025).

- Parsch, A. Raytheon Coyote. Available online: https://bit.ly/46TZdbs (accessed on 4 October 2025).

- Wang, G.; Xu, G.; Wang, Y.; Yao, Y.; Wang, K.; Hu, X.; Sun, H.; Liu, J. Deployment Modes and Aerodynamic Analysis of UAV Orthogonal Biaxial Folding Wing. Aerospace 2023, 10, 26. [Google Scholar] [CrossRef]

- AeroVironment. Switchblade 300 Block 20 Loitering Munition. Available online: https://bit.ly/3WbNyji (accessed on 17 October 2025).

- Finigan, M.; Kavounas, P.A.; Ho, I.; Smith, C.C.; Witusik, A.; Hopwood, A.; Avent, C.; Ragasa, B.; Roth, B. Design and Flight Test of a Tube-Launched Unmanned Aerial Vehicle. Aerospace 2024, 11, 133. [Google Scholar] [CrossRef]

- Zipline. Zipline Fact Sheet: Zipline Instant Delivery. Available online: https://bit.ly/3ISbLrP (accessed on 4 October 2025).

- INSITU. ScanEagle. Available online: https://bit.ly/3VLFQMC (accessed on 4 October 2025).

- Northrop Grumman. Bat UAS. Available online: https://bit.ly/42oVOQz (accessed on 4 October 2025).

- General Atomics. Sparrowhawk. Available online: https://bit.ly/4o5pwT4 (accessed on 4 October 2025).

- Lockheed Martin Corporation. Stalker VXE30 Product Card. Available online: https://bit.ly/4qcDvsb (accessed on 4 October 2025).

- 14 C.F.R. § 107 A; Small Unmanned Aircraft Systems. National Archives and Records Administration: College Park, MD, USA, 2024. Available online: https://www.ecfr.gov/ (accessed on 4 October 2025).

- ARP4761A; Guidelines for Conducting the Safety Assessment Process on Civil Aircraft, Systems, and Equipment. SAE International: Warrendale, PA, USA, 2023. Available online: https://doi.org/10.4271/ARP4761A (accessed on 4 October 2025).

- XFLR5, version 6.41; Software for Airfoil CFD; XLFR5 2020; Available online: https://www.xflr5.tech/ (accessed on 4 October 2025).

- Gudmundsson, S. General Aviation Aircraft Design Applied Methods and Procedures, 1st ed.; Butterworth-Heineman: Oxford, UK, 2014. [Google Scholar] [CrossRef]

- Hoerner, S. Fluid-Dynamic Drag, 2nd ed.; Sighard, F., Ed.; Hoerner: Bakersfield, CA, USA, 1965; Available online: https://n2t.net/ark:/13960/t57f0bk2j (accessed on 4 October 2025).

- Drela, M. V-Tail to a Standard Tail, March 2003. Available online: https://bit.ly/3IS7xAt (accessed on 4 October 2025).

- Drela, M. Sharon 3.7 V-Tail Tail Volume Coefficient and Rudder Power, October 2006. Available online: https://bit.ly/47aI7Y4 (accessed on 4 October 2025).

- FlightStream, version 2025.0; Software for Aircraft CFD; Altair: Troy, MI, USA, 2025; Available online: https://altair.com/ (accessed on 4 October 2025).

- Müller, M. eCalc Reliable Electric Drive Simulations. Available online: https://ecalc.ch/ (accessed on 4 October 2025).

- 14 C.F.R. § 23 C; Airworthiness Standards: Normal Category Airplanes. National Archives and Records Administration: College Park, MD, USA, 2017. Available online: https://www.ecfr.gov/ (accessed on 4 October 2025).

- 14 C.F.R. § 25 C; Airworthiness Standards: Transport Category Airplanes. National Archives and Records Administration: College Park, MD, USA, 2024. Available online: https://www.ecfr.gov/ (accessed on 4 October 2025).

- Catia V5, version V5-6R2020; CATIA V5; Dassault Systemes: Vélizy-Villacoublay, France, 2024; Available online: https://www.3ds.com/ (accessed on 18 October 2025).

- Ansys Workbench, version 2024 R2; Ansys Workbench; Ansys: Canonsburg, PA, USA, 2024; Available online: https://www.ansys.com/ (accessed on 18 October 2025).

- AEP-83; Light Unmanned Aircraft Systems Airworthiness Requirements. North Atlantic Treaty Organization: Brussels, Belgium, 2014. Available online: https://bit.ly/4pW7B2N (accessed on 4 October 2025).

- MIL-STD-8591; Airborne Stores, Suspension Equipment, and Aircraft-Store Interface (Carriage Phase); Change 1. U.S. Department of Defense: Washington, DC, USA, 2017. Available online: https://bit.ly/4o9thqK (accessed on 27 October 2025).

- Traub, L.W. Scale effects in wind tunnel testing: Extrapolation of the drag coefficient. J. Aircr. 2024, 61, 1482–1489. Available online: https://www.researchgate.net/publication/380932395 (accessed on 4 October 2025). [CrossRef]

| Wing Parameters | Wing Geometry |

|---|---|

| Reference Area (S) | 0.92 m2 |

| Aspect Ratio (AR) | 13 |

| Wingspan (b) | 3.46 m |

| Root Chord Length (croot) | 0.37 m |

| Mean Aerodynamic Chord Length (cmac) | 0.27 m |

| Tip Chord Length (ctip) | 0.15 m |

| Leading Edge Sweep (Ʌ) | 2.50° (50.00° tip) |

| Incidence Angle (iw) | 0.00° |

| Twist | 0.00° |

| Oswald’s Span Efficiency Factor (e) | 0.88 |

| Component | CDi (Induced) | CDp (Parasite) | CD (Interference) | CD (Total) |

|---|---|---|---|---|

| Main Wing | 0.0146 | 0.0094 | 0.0039 | 0.0279 |

| Vertical Tail | N/A | 0.0004 | N/A | 0.0004 |

| Horizontal Tail | 0.0001 | 0.0006 | 0.0000 | 0.0007 |

| Fuselage | N/A | 0.0138 | N/A | 0.0138 |

| Miscellaneous | N/A | 0.0001 | N/A | 0.0001 |

| Total Drag | 0.0147 | 0.0243 | 0.0039 | 0.0429 |

| Tail Surface | Surface Area (m2) | Taper Ratio |

|---|---|---|

| Horizontal Stabilizer | 0.137 | 0.550 |

| Vertical Stabilizer | 0.074 | 0.400 |

| Ventral Fin | 0.021 | 0.346 |

| Surface | Design Percentage of Host Surface Area (%) | Manufactured Percentage of Host Surface Area (%) | Acceptable Range of Host Surface Area (%) |

|---|---|---|---|

| Elevator | 30.0 | 31.0 | 21.5–38.0 |

| Rudder | 35.0 | 21.9 | 20.0–60.0 |

| Aileron | 11.9 | 10.7 | 6.0–15.0 |

| Name | Measured (kg) | Calculated (kg) | Error (%) |

|---|---|---|---|

| Launch UAV [9] | 1.0 | 1.0 | 4.0 |

| Zipline P1 [10] | 8.4 | 8.4 | 0.7 |

| ScanEagle [11] | 26.3 | 28.2 | 7.2 |

| Bat [12] | 95.3 | 95.9 | 0.7 |

| Sparrowhawk [13] | 226.8 | 227.5 | 0.3 |

| Component Group | Commercial Article (kg) | Flight Test Article (kg) |

|---|---|---|

| Fuselage Structure | 3.08 | 1.86 |

| Wings | 4.72 | 5.49 |

| Tail | 1.18 | 1.50 |

| Propulsion System | 6.35 | 5.44 |

| Payload Deployment | 4.81 | 5.03 |

| Avionics | 2.45 | 2.86 |

| Landing Gear | 0.00 | 1.22 |

| Total | 22.59 | 23.40 |

| Name | Published Endurance (h) | Calculated Endurance (h) | Error (%) | Published Range (km) | Calculated Range (km) | Error (%) |

|---|---|---|---|---|---|---|

| Stalker [14] | 4 | 4.18 | 4.4 | 433 | 476 | 9.4 |

| ScanEagle [11] | 18 | 18.27 | 1.5 | 920 | 856 | 7.3 |

| Bat [12] | 8 | 7.92 | 1.0 | - | - | - |

| Prediction Method | Total CD |

|---|---|

| Aircraft Sizing Code | 0.0429 |

| Wind Tunnel | 0.0384 |

| FlightStream | 0.0309 |

| Ground Test | Objective | Requirements Verified |

|---|---|---|

| Payload Deployment | Demonstrate Aircraft can Consistently Deploy both Canisters at any Operational Pitch and Roll Angle | OP.6.0–OP.6.6, OP.6.8 |

| Wing Deployment | Demonstrate Aircraft can Deploy Wings Autonomously under Simulated Operational Aerodynamic Loading | OP.8.0–OP.8.2 |

| Drop | Demonstrate Aircraft and Landing Gear Integrity with Respect to Loads Encountered During Landing | SA.1.0 |

| Wing Static Loading | Demonstrate Wing and Fuselage Integrity with Respect to Loads Encountered During Flight | ST.1.0–ST.3.0 |

| Flight Test | Objective | Requirements Verified |

|---|---|---|

| Maiden Flight | Demonstrate Basic Aircraft Ability: Pitching, Banking, Yawing, Climbing, Descending. Verify No Failure After Flight. | OP.2.0, OP.4.0, OP.5.0, AS.1.0 |

| Priority 1 Test | Demonstrate Aircraft Dynamic Stability with 5 Stability Tests. Verify No Failure After Flight. | FP.6.0, AS.5.0–5.9, ST.1.0, ST.2.0 |

| Priority 2 Test | Demonstrate Aircraft Maximum Speed. Verify No Failure After Flight. | OP.6.0, FP.1.0, FP.5.0 |

| Priority 3 Test | Demonstrate Airborne Payload Deployment Capability. | OP.6.4, OP.7.3, OP.7.7, OP.7.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cherkauer, S.A.; Karle, C.J.; Hiland, E.M.; Brown, C.N.; Wetherbee, I.R.; Richert, J.P.; McCormick, D.C.; Sander, J.M.; Welliver, M.A.; Karlik, J.A.; et al. Design and Flight Test of an Air-Launched Medical Aid Delivery Uncrewed Aerial Vehicle. Aerospace 2025, 12, 977. https://doi.org/10.3390/aerospace12110977

Cherkauer SA, Karle CJ, Hiland EM, Brown CN, Wetherbee IR, Richert JP, McCormick DC, Sander JM, Welliver MA, Karlik JA, et al. Design and Flight Test of an Air-Launched Medical Aid Delivery Uncrewed Aerial Vehicle. Aerospace. 2025; 12(11):977. https://doi.org/10.3390/aerospace12110977

Chicago/Turabian StyleCherkauer, Samuel A., Carson J. Karle, Evan M. Hiland, Cameron N. Brown, Isaac R. Wetherbee, Jordan P. Richert, Danielle C. McCormick, Jacob M. Sander, Max A. Welliver, Jackson A. Karlik, and et al. 2025. "Design and Flight Test of an Air-Launched Medical Aid Delivery Uncrewed Aerial Vehicle" Aerospace 12, no. 11: 977. https://doi.org/10.3390/aerospace12110977

APA StyleCherkauer, S. A., Karle, C. J., Hiland, E. M., Brown, C. N., Wetherbee, I. R., Richert, J. P., McCormick, D. C., Sander, J. M., Welliver, M. A., Karlik, J. A., Barrick, N., Bauer, Z. J., & Roth, B. D. (2025). Design and Flight Test of an Air-Launched Medical Aid Delivery Uncrewed Aerial Vehicle. Aerospace, 12(11), 977. https://doi.org/10.3390/aerospace12110977