Microstructure and Mechanical Properties of Nano-Carbon Reinforced Titanium Matrix/Hydroxyapatite Biocomposites Prepared by Spark Plasma Sintering

Abstract

1. Introduction

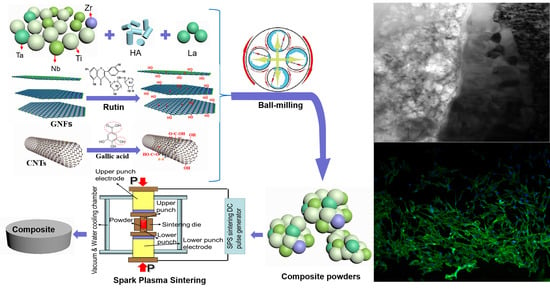

2. Materials and Methods

3. Results

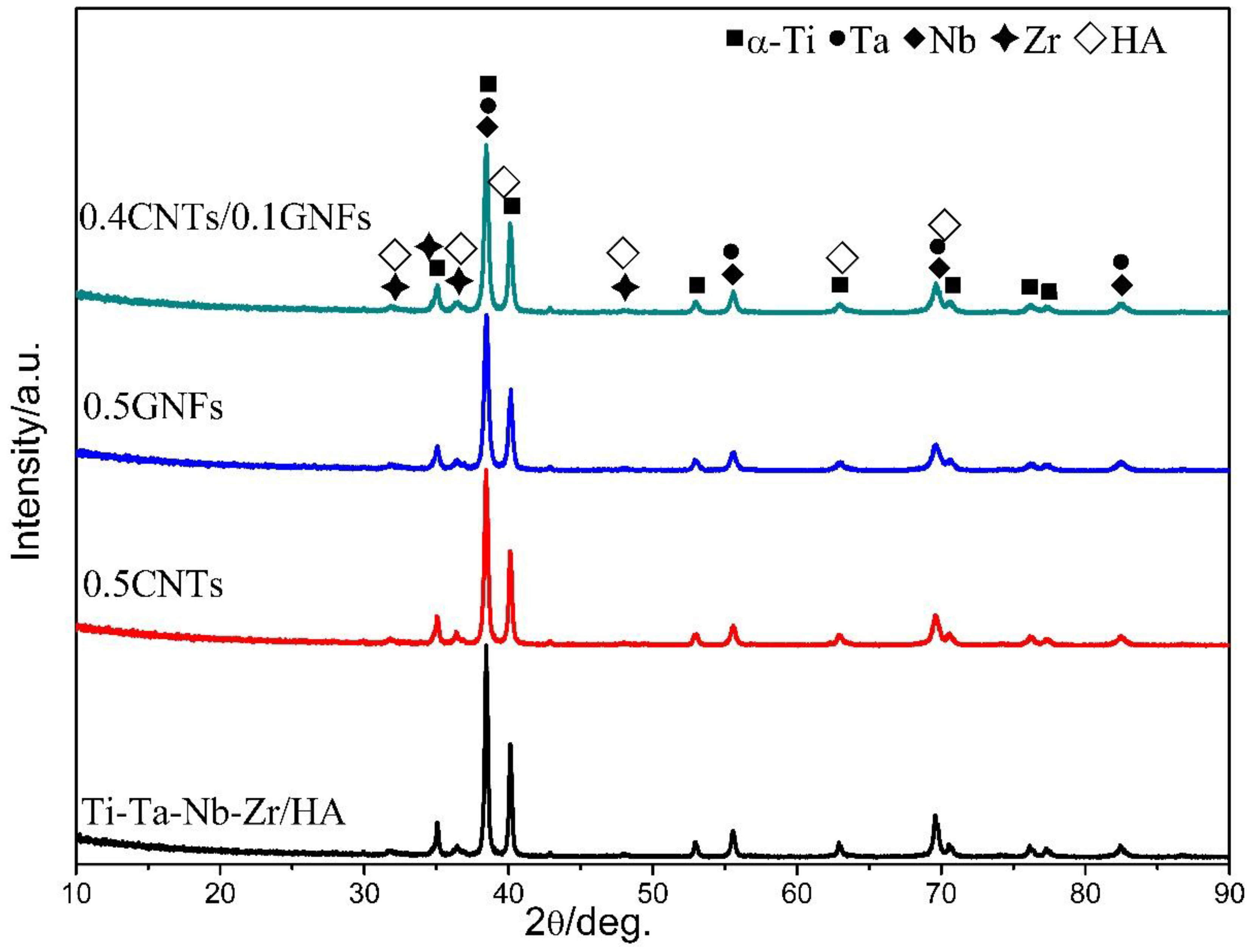

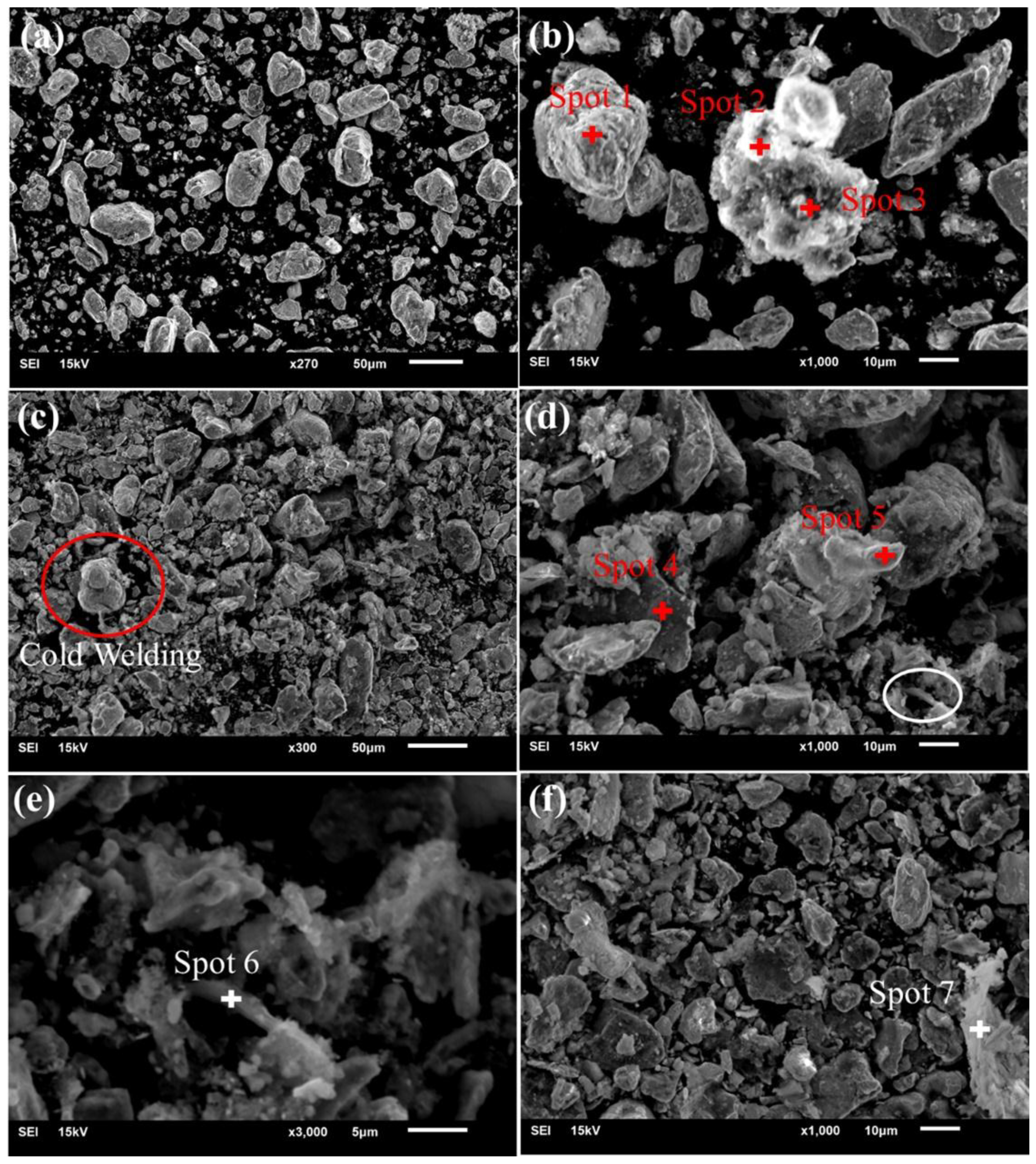

3.1. Microstructure and Phase Composition of Nanocomposites Powder

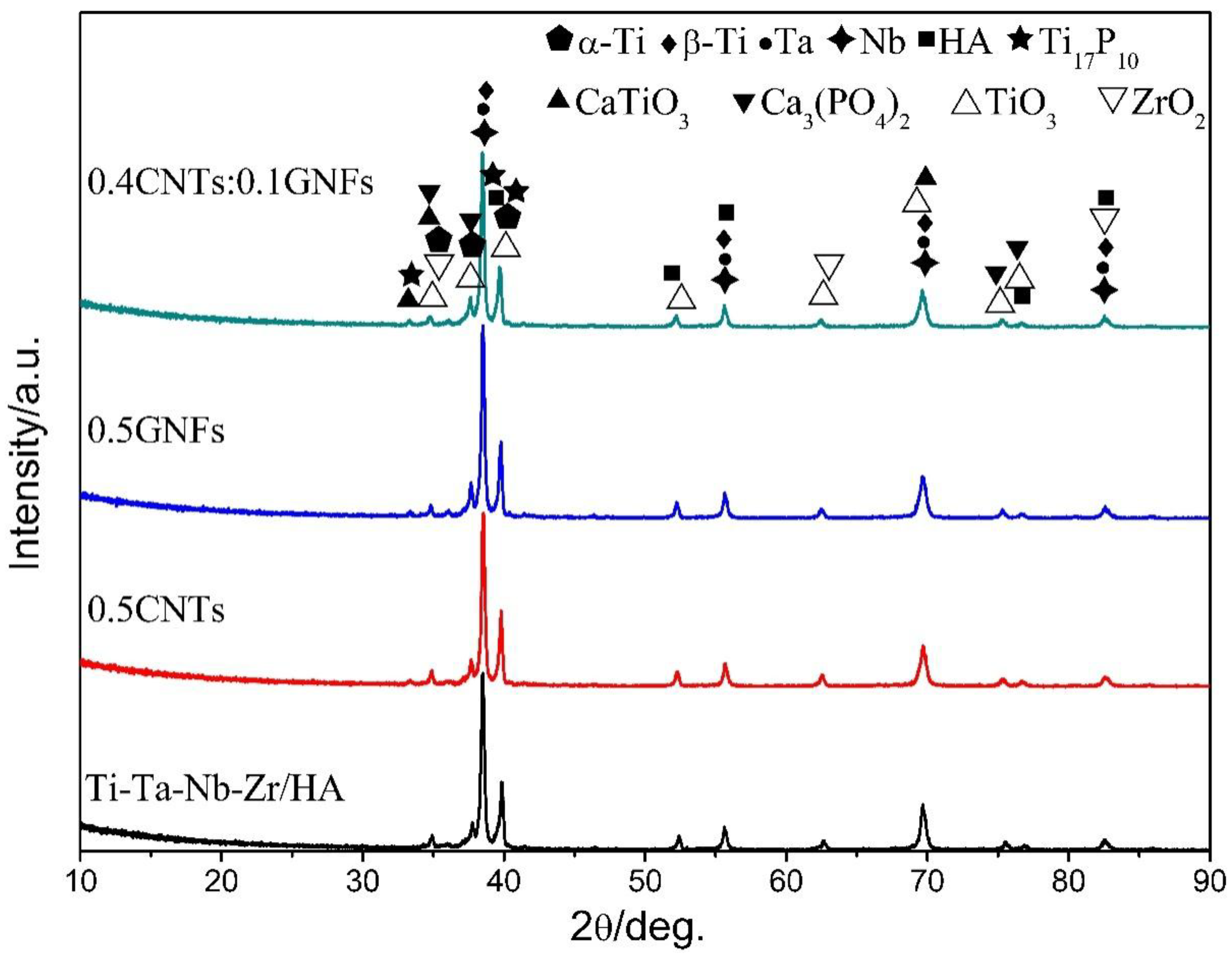

3.2. Microstructure and Phase Analysis of the Sintered Nanocomposites

3.2.1. XRD Results Analysis

3.2.2. SEM Results Analysis

3.2.3. EPMA Results Analysis

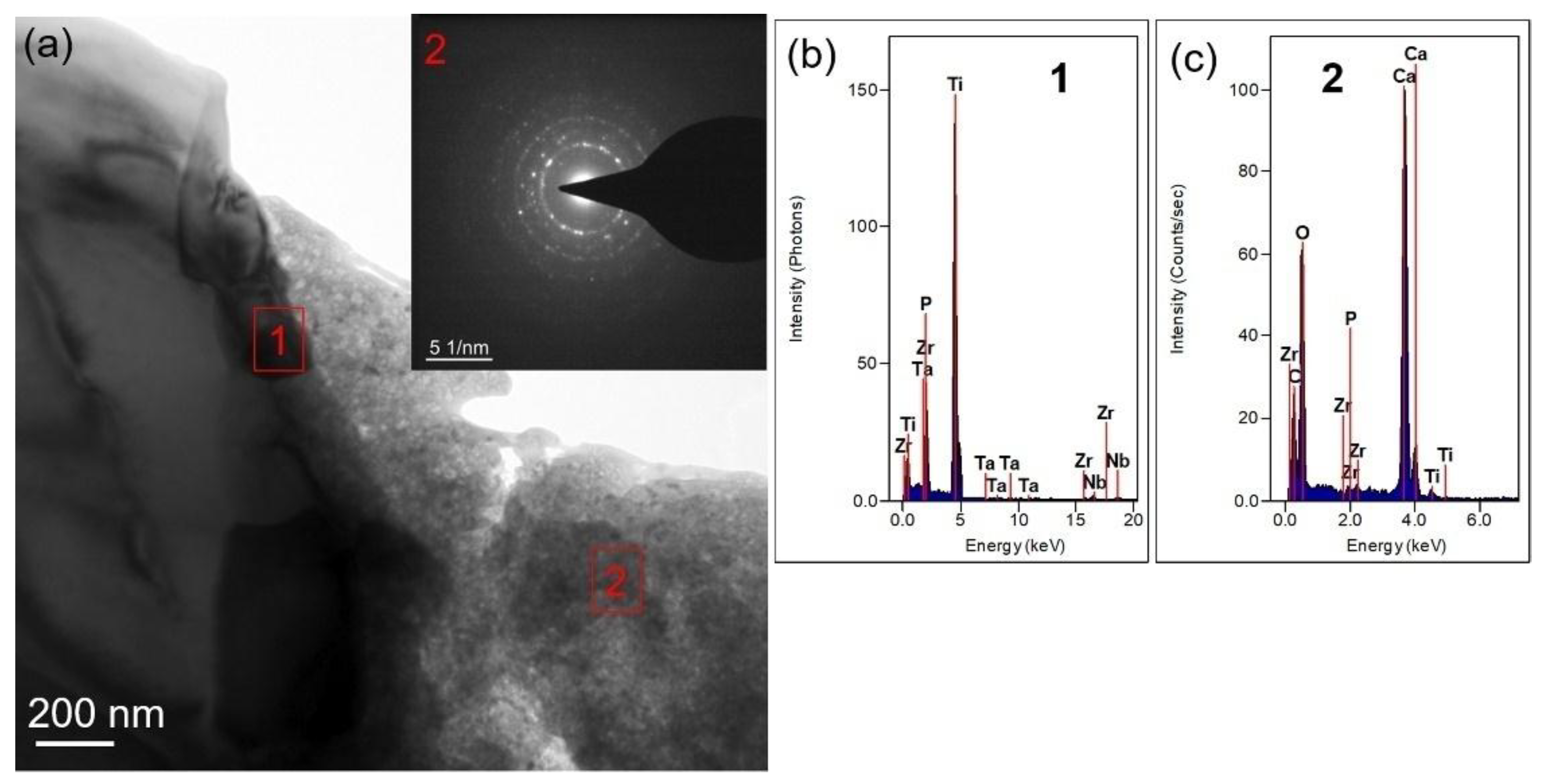

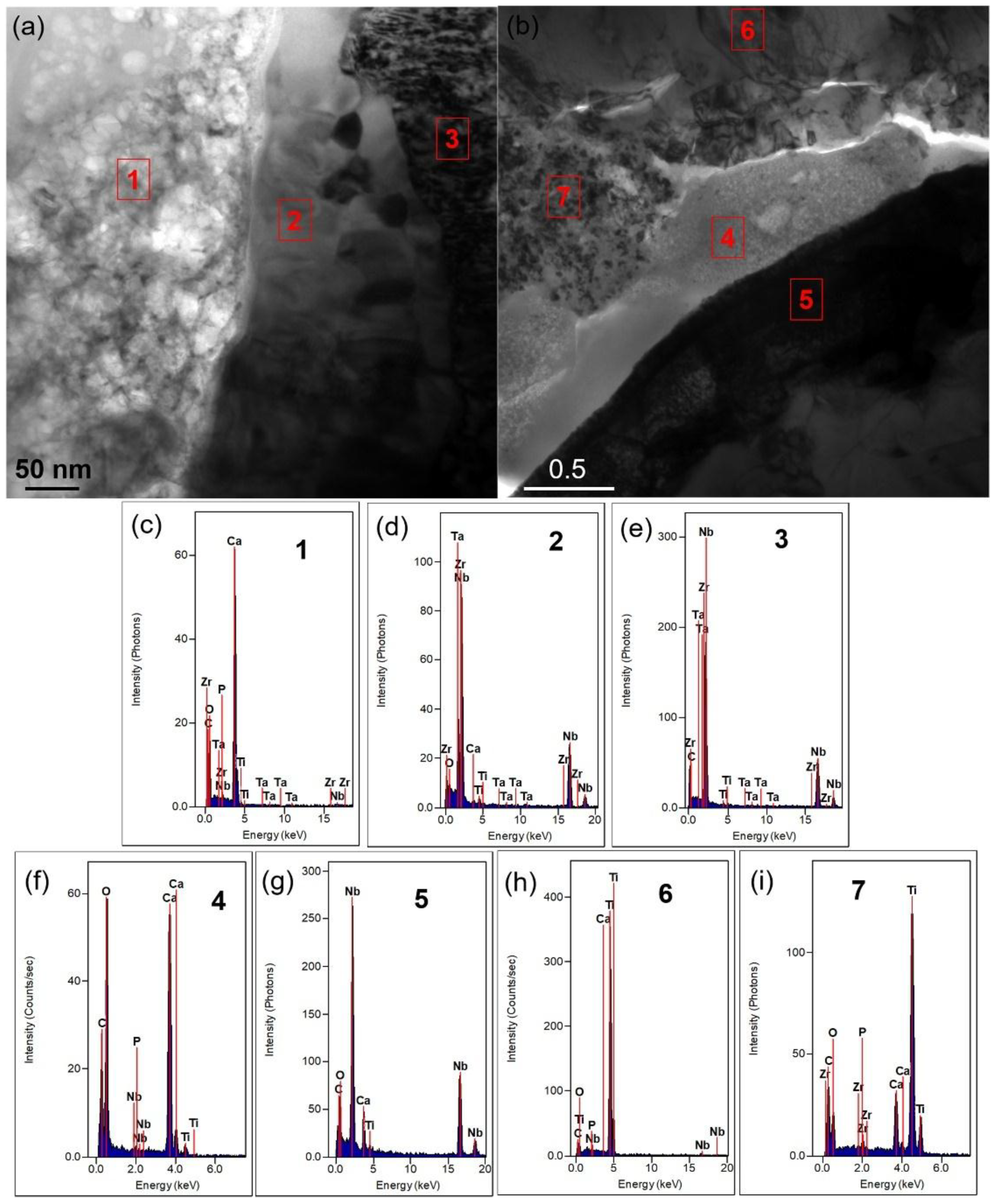

3.2.4. TEM Results Analysis

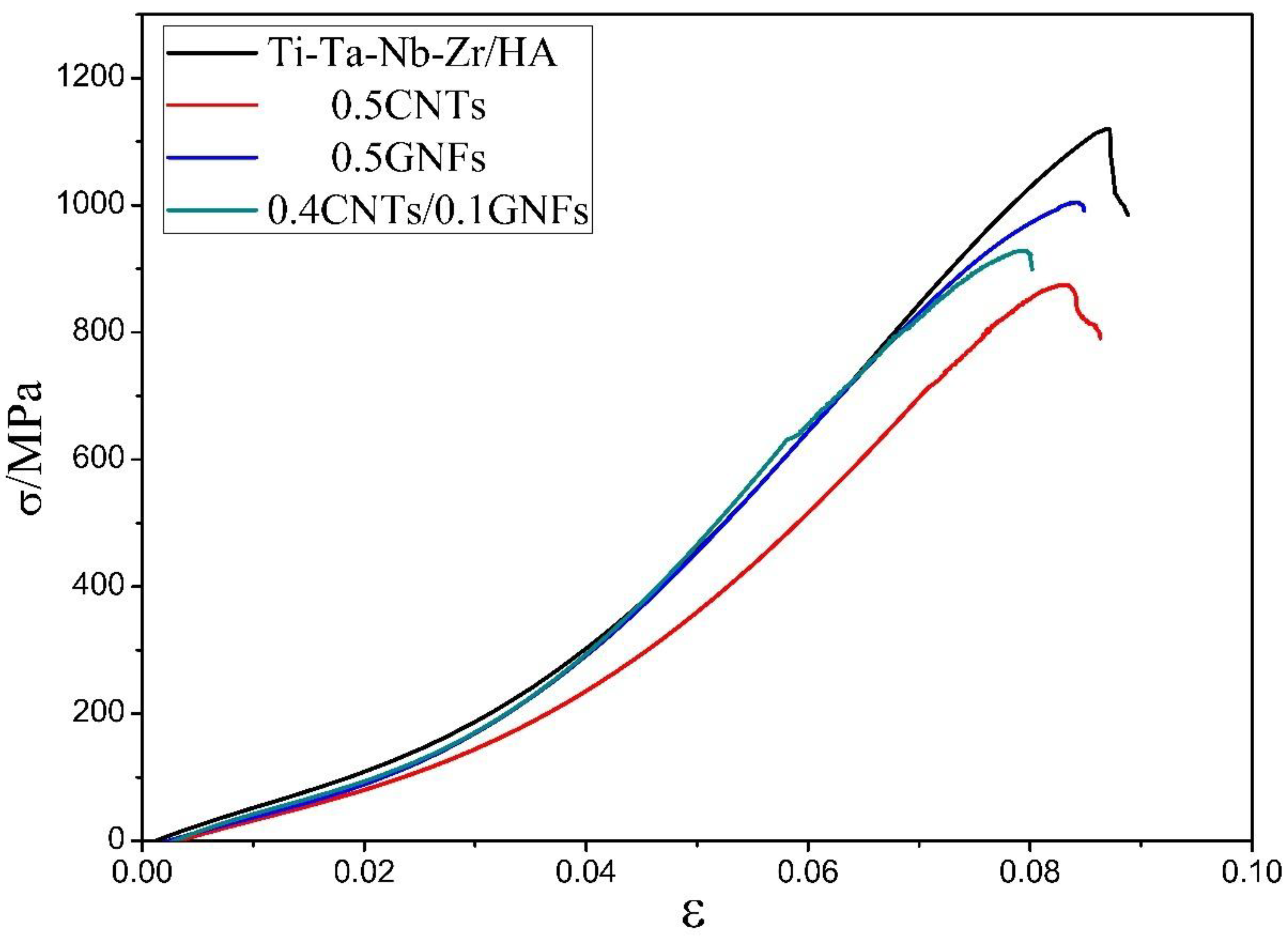

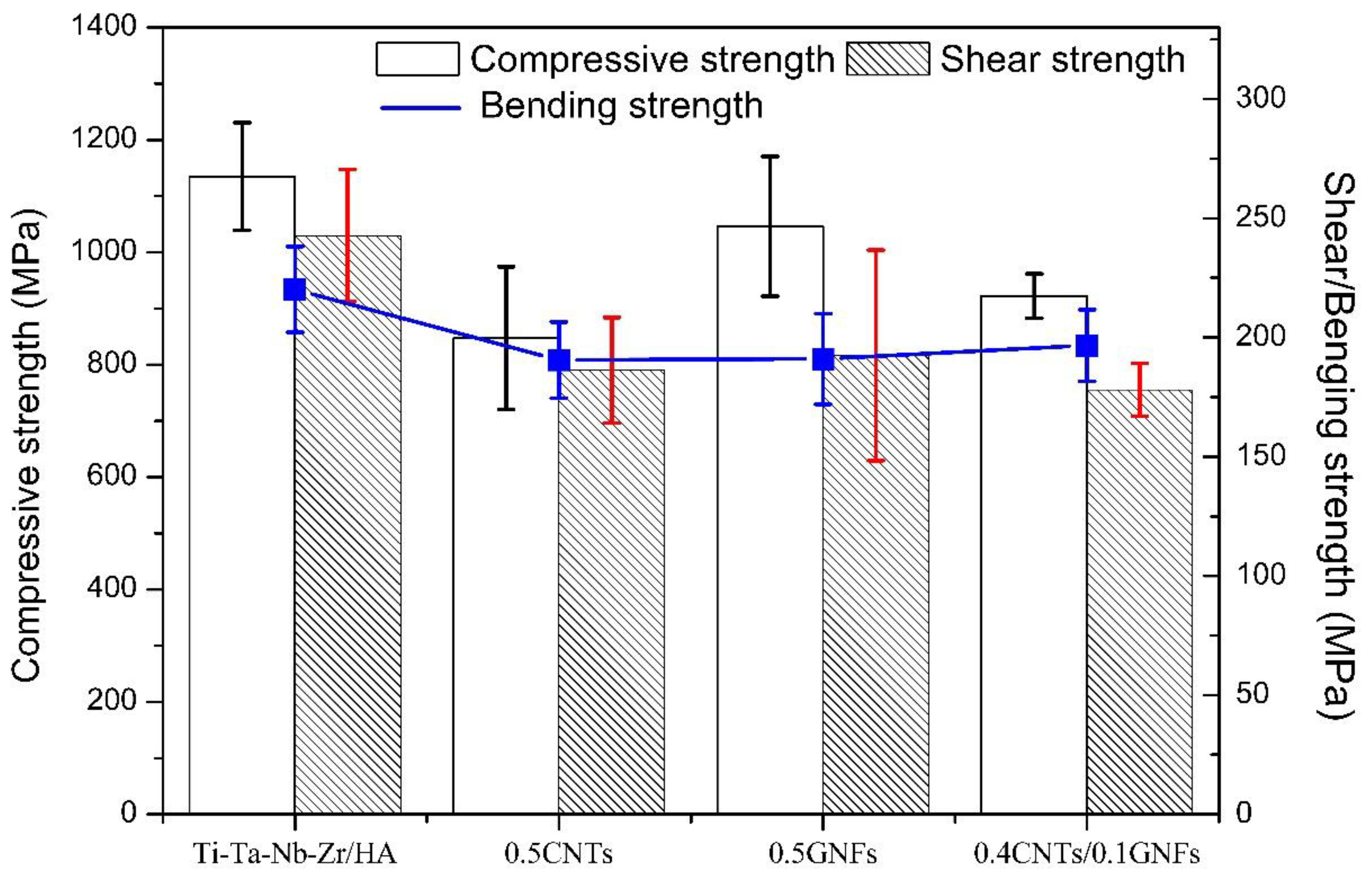

3.3. Mechanical Properties of the Sintered Nanocomposites

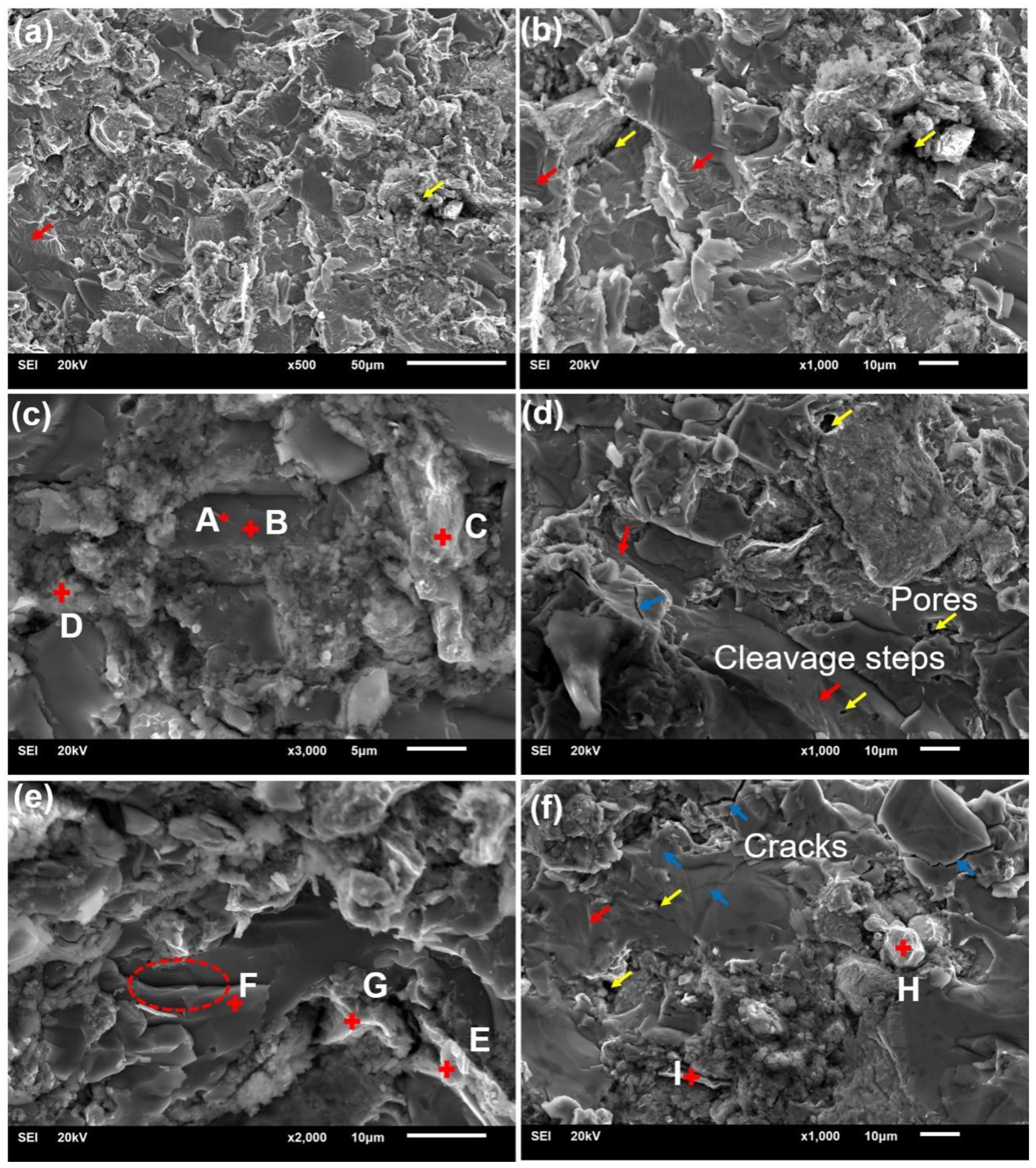

3.4. Fracture Surface Analysis of the Sintered Nanocomposites

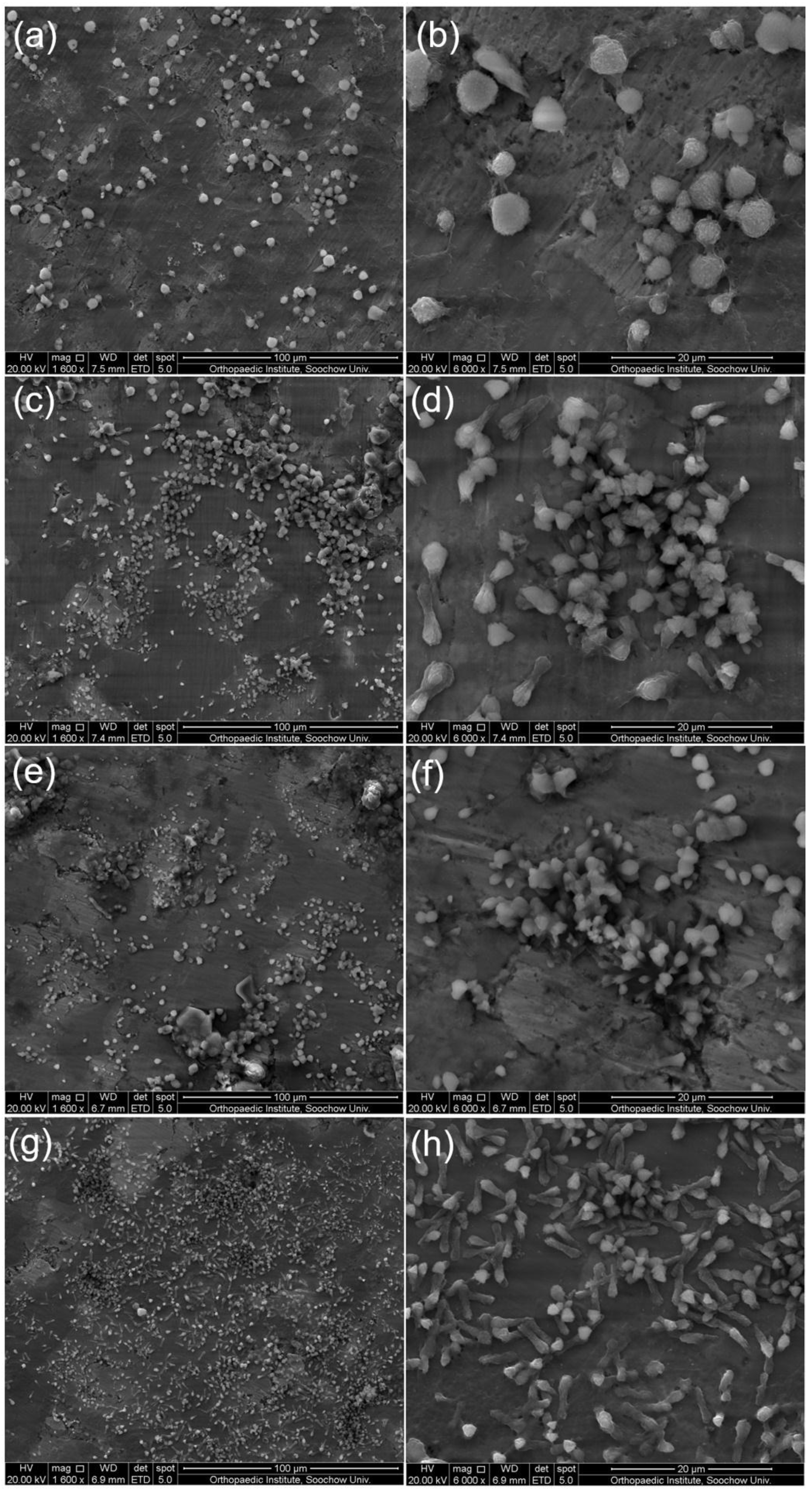

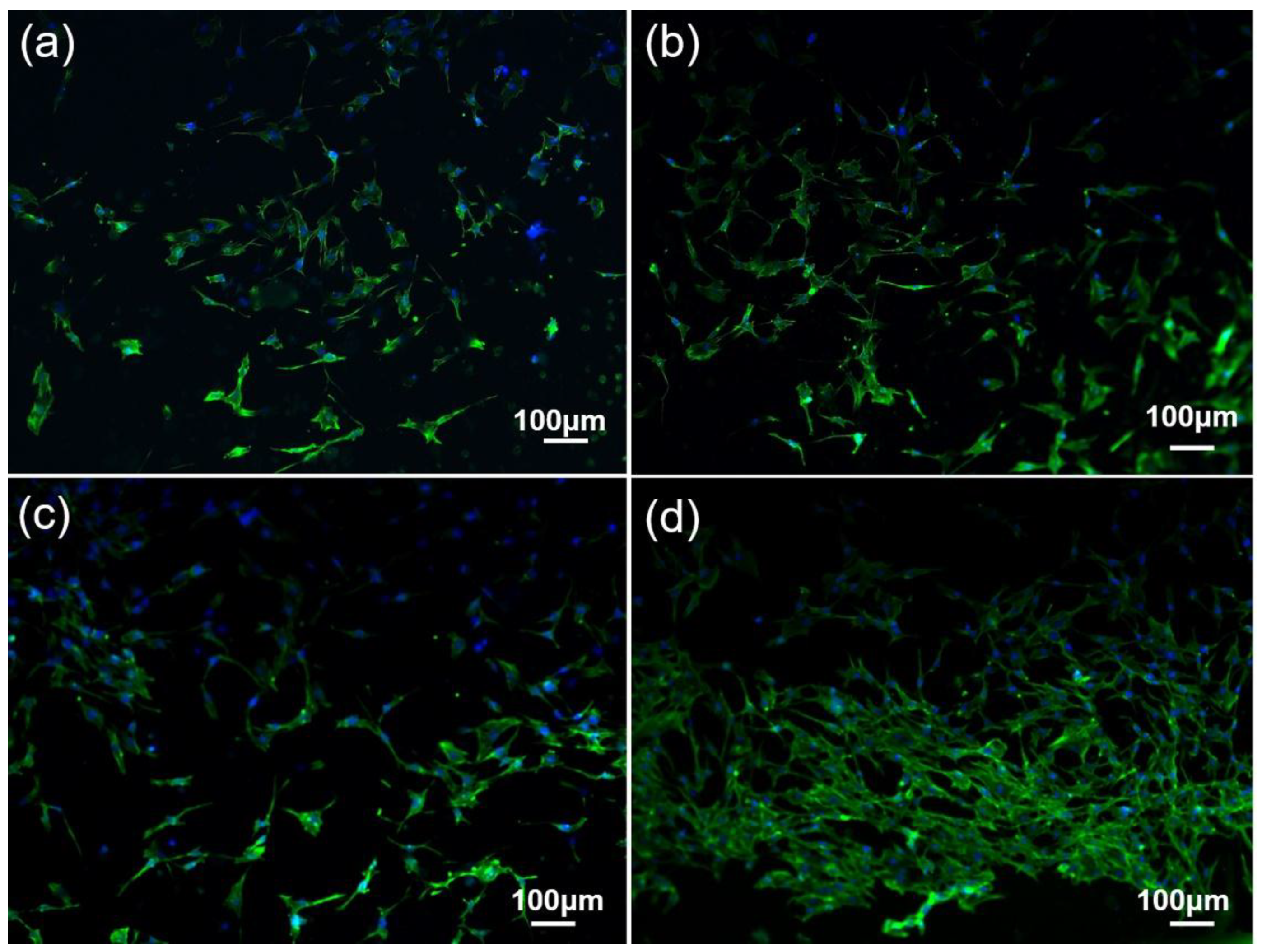

3.5. In Vitrobiocompatibilityassessment of the Sintered Nanocomposites

4. Discussion

5. Conclusions

- Nano-carbon reinforced titanium matrix/HA biocomposites were successfully prepared by spark plasma sintering. Results showed that there are some new phases detected in sintered composites, such as β-Ti, Ti17P10, CaTiO3, Ca3(PO4)2, TiO3, ZrO2, etc., but the reactions that may occur during the preparation process are suppressed to some extent. TEM analysis proved the existence of elemental diffusion and chemical reactions in sintered composites. The shear fracture belonged to cleavage fracture, and there were obvious cleavage steps, pores, and some cracks on the surface of the composites.

- Compared with the traditional hot press sintering, the mechanical properties of the composites prepared by SPS, such as density (>98%), compressive strength (847–1134 MPa), shear strength (178–228 MPa) and bending strength (190–220.15 MPa), have been significantly improved. The compressive strength and shear strength of 0.5-GNFs composite in all Nano-C reinforced Titanium matrix/HA composites were slightly higher. Because entanglement and agglomeration is more prone to occur in tubular CNTs than lamellar GNFs.

- The strengthening and toughening mechanisms existing in nano-carbon reinforced titanium matrix/HA composites mainly included second phase strengthening, grain refinement strengthening, solution strengthening, graphene extraction, carbon nanotubes bridging, crack tail stripping, etc. In vitro cells proliferation test showed that nano-carbon reinforced titanium matrix/HA composites have good biocompatibility. Moreover, the addition of nano-carbon in the titanium matrix/HA composites was beneficial to promote cell adhesion and proliferation.

Author Contributions

Funding

Conflicts of Interest

Ethical Statements

References

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New developments of Ti-based alloys for biomedical applications. Materials 2014, 7, 1709. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Denizard, O.; Diffoot-Carlo, N.; Navas, V.; Sundaram, P.A. Biocompatibility studies of human fetal osteoblast cells cultured on gamma titanium aluminide. J. Mater. Sci. Mater. Med. 2008, 19, 153–158. [Google Scholar] [CrossRef] [PubMed]

- Chieruzzi, M.; Pagano, S.; Moretti, S.; Pinna, R.; Milia, E.; Torre, L.; EramoN, S. Nanomaterials for tissue engineering in dentistry. Nanomaterials 2016, 6, 134. [Google Scholar] [CrossRef] [PubMed]

- Geng, Z.; Yuan, Q.; Zhuo, X.L.; Li, Z.Y.; Cui, Z.D.; Zhu, S.L.; Liang, Y.Q.; Liu, Y.D.; Bao, H.J.; Li, X.; et al. Synthesis, Characterization, and biological evaluation of nanostructured hydroxyapatite with different dimensions. Nanomaterials 2017, 7, 38. [Google Scholar] [CrossRef] [PubMed]

- Miranda, G.; Araújo, A.; Bartolomeu, F.; Buciumeanu, M.; Carvalho, O.; Souza, J.C.M.; Silva, F.S.; Henriques, B. Design of Ti6Al4V-HA composites produced by hot pressing for biomedical applications. Mater. Des. 2016, 108, 488–493. [Google Scholar] [CrossRef]

- Parratt, K.; Yao, N. Nanostructured biomaterials and their applications. Nanomaterials 2013, 3, 242–271. [Google Scholar] [CrossRef] [PubMed]

- Balbinotti, P.; Gemelli, E.; Buerger, G.; Lima, S.A.; DeJesus, J.; DeCamargo, N.H.A.; Henriques, V.A.R.; Soares, G.D.A. Microstructure development on sintered Ti/HA biocomposites produced by powder metallurgy. Mater. Res. 2011, 14, 384–393. [Google Scholar] [CrossRef]

- Mohseni, E.; Zalnezhad, E.; Bushroa, A.R. Comparative investigation on the adhesion of Hydroxyapatite coating on Ti-6Al-4V implant: A review paper. Int. J. Adhes. Adhes. 2014, 48, 238–257. [Google Scholar] [CrossRef]

- Singh, A.; Singh, G.; Chawla, V. Characterization of vacuum plasma sprayed reinforced Hydroxyapatite coatings on Ti-6Al-4V alloy. Trans. Indian Met. 2017, 20, 1–20. [Google Scholar] [CrossRef]

- Arifin, A.; Sulong, A.B.; Muhamad, N.; Syarif, J.; Ramli, M.I. Material processing of Hydroxyapatite and Titaniumalloy (HA/Ti) composite as implant materials using powder metallurgy: A review. Mater. Des. 2014, 55, 165–175. [Google Scholar] [CrossRef]

- Bovand, D.; Yousefpour, M.; Rasouli, S.; Bagherifard, S.; Bovand, N.; Tamayol, A. Characterization of Ti-HA composite fabricated by mechanical alloying. Mater. Des. 2015, 65, 447–453. [Google Scholar] [CrossRef]

- Zhao, G.; Xia, L.; Zhong, B.; Wen, G.; Song, L.; Wang, X. Effect of milling conditions on the properties of HA/Ti feedstock powders and plasma-sprayed coatings. Surf. Coat. Technol. 2014, 251, 38–47. [Google Scholar] [CrossRef]

- Akmal, M.; Raza, A.; Khan, M.M.; Khan, M.I.; Hussain, M.A. Effect of nano-hydroxyapatite reinforcement in mechanically alloyed NiTi composites for biomedical implant. Mater. Sci. Eng. C Mater. 2016, 68, 30–36. [Google Scholar] [CrossRef] [PubMed]

- Nomura, N.; Sakamoto, K.; Takahashi, K.; Kato, S.; Abe, Y.; Doi, H.; Tsutsumi, Y.; Kobayashi, M.; Kobayashi, E.; Kim, W.J.; et al. Fabrication and mechanical properties of porous Ti/HA composites for bone fixation devices. Mater. Trans. 2010, 51, 1449–1454. [Google Scholar] [CrossRef]

- Kumar, A.; Biswas, K.; Basu, B. On the toughness enhancement in hydroxyapatite-based composites. Acta Mater. 2013, 61, 5198–5215. [Google Scholar] [CrossRef]

- Zhang, L.; He, Z.Y.; Zhang, Y.Q.; Jiang, Y.H.; Zhou, R. Rapidly sintering of interconnected porous Ti-HA biocomposite with high strength and enhanced bioactivity. Mater. Sci. Eng. C 2016, 67, 104–114. [Google Scholar] [CrossRef] [PubMed]

- He, Y.H.; Zhang, Y.Q.; Jiang, Y.H.; Zhou, R. Effect of HA (hydroxyapatite) content on the microstructure, mechanical and corrosion properties of (Ti,13Nb,13Zr)-xHA biocomposites synthesized by sparkle plasma sintering. Vacuum 2016, 131, 176–180. [Google Scholar] [CrossRef]

- Pei, X.; Zeng, Y.; He, R.; Li, Z.J.; Tian, L.Y.; Wang, J.; Wan, Q.B.; Li, X.Y.; Bao, H. Single-walled carbon nanotubes/hydroxyapatite coatings on titanium obtained by electrochemical deposition. Appl. Surf. Sci. 2014, 295, 71–80. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.W.; Yue, C.G.; Zhang, T.H.; Li, P.; Xing, Z.W.; Chen, Y. A tough graphene nanosheet/hydroxyapatite composite with improved in vitro biocompatibility. Carbon 2013, 61, 105–115. [Google Scholar] [CrossRef]

- Hu, Z.R.; Tong, G.Q.; Xu, R.; Zhao, L.R.; Chen, C.J.; Zhang, M.; Sun, Y.L.; Guo, H.F.; Xu, J.L. Laser sintered graphene reinforced titaniummatrix nanocomposites. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016. [Google Scholar]

- Song, Y.; Chen, Y.; Liu, W.W.; Li, W.L.; Wang, Y.G.; Zhao, D.; Liu, X.B. Microscopic mechanical properties of titanium composites containing multi-layer graphene nanofillers. Mater. Des. 2016, 109, 256–263. [Google Scholar] [CrossRef]

- Hu, Z.; Tong, G.; Nian, Q.; Xu, R.; Saei, M.; Chen, F.; Chen, C.J.; Zhang, M.; Guo, H.F.; Xu, J.L. Laser sintered single layer graphene oxide reinforced titanium matrix nanocomposites. Compos. Part B Eng. 2016, 93, 352–359. [Google Scholar] [CrossRef]

- Oyefusi, A.; Olanipekun, O.; Neelgund, G.M.; Peterson, D.; Stone, G.M.; Williams, E.; Carson, L.; Regisford, G.; Oki, A. Hydroxyapatite grafted carbon nanotubes and graphene nanosheets: Promising bone implant materials. Spectrochim. Acta A 2014, 132, 410–416. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.Z.; Huang, W.M.; Wang, Z.F.; Shang, F.J.; Huang, W.; Zhang, B.Y. Thermal and mechanical properties of graphene-titanium composites synthesized by microwave sintering. Acta Metall. Sin. Engl. 2016, 29, 707–713. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Aamir, M. Synergetic effect of graphene nanoplatelets (GNPs) and multi-walled carbon nanotube (MW-CNTs) on mechanical properties of pure magnesium. J. Alloys Compd. 2014, 603, 111–118. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Zhang, J.Y.; Asif, M. Use of high energy ball milling to study the role of graphene nanoplatelets and carbon nanotubes reinforced magnesiumalloy. J. Alloys Compd. 2015, 646, 223–232. [Google Scholar] [CrossRef]

- Xiong, C.; Li, T.; Zhu, Y.; Zhao, T.K.; Dang, A.; Li, H.; Ji, X.L.; Shang, Y.D.; Khan, M. Two-step approach of fabrication of interconnected nanoporous 3D reduced graphene oxide-carbon nanotube-polyaniline hybrid as a binder-free supercapacitor electrode. J. Alloys Compd. 2016, 695, 1248–1259. [Google Scholar] [CrossRef]

- Liang, A.Y.; Jiang, X.S.; Hong, X.; Jiang, Y.X.; Shao, Z.Y.; Zhu, D.G. Recent developments concerning the dispersion methods and mechanisms of graphene. Coatings 2018, 8, 33. [Google Scholar] [CrossRef]

- Li, F.; Jiang, X.S.; Shao, Z.Y.; Zhu, D.G.; Zhu, M.H. Microstructure and mechanical properties of graphene-reinforced titanium matrix/nano-hydroxyapatite nanocomposites. Materials 2018, 11, 608. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Tan, M.J. Mixing of carbon nanotubes (CNTs) and aluminum powder for powder metallurgy use. Powder Technol. 2011, 208, 42–48. [Google Scholar] [CrossRef]

- Hadi, M.; Shafyei, A.; Meratian, M. A comparative study of microstructure and high temperature mechanical properties of a β-stabilized TiAl alloy modified by lanthanum and erbium. Mater. Sci. Eng. A 2015, 624, 1–8. [Google Scholar] [CrossRef]

- Lou, W.W.; Dong, Y.W.; Zhang, H.L.; Wu, G. Preparation and characterization of lanthanum-incorporated hydroxyapatite coatings on titanium substrates. Int. J. Mol. Sci. 2015, 16, 21070–21086. [Google Scholar] [CrossRef] [PubMed]

- Kuma, A.; Dhara, S.; Biswas, K.; Basu, B. In vitro bioactivity and cytocompatibility properties of spark plasma sintered HA-Ti composites. J. Biomed. Mater. Res. B 2013, 101, 223–236. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.X.; Pei, X.B.; Yang, S.Y.; Qin, H.; Cai, H.; Hu, S.S.; Sui, L.; Wan, Q.B.; Wang, J. Graphene oxide/hydroxyapatite composite coatings fabricated by electrochemical deposition. Surf. Coat. Technol. 2016, 286, 72–79. [Google Scholar] [CrossRef]

- Shi, Y.Y.; Li, M.; Liu, Q.; Jia, Z.J.; Xu, X.C.; Cheng, Y.; Zheng, Y.F. Electrophoretic deposition of graphene oxide reinforced chitosan-hydroxyapatite nanocomposite coatings on Ti substrate. J. Mater. Sci. Mater. Med. 2016, 27, 48. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Woo, K.D.; Kim, S.H.; Lee, S.M.; Kim, J.Y.; Ko, H.R.; Kim, S.M. Mechanical properties and bio-compatibility of Ti-Nb-Zr-HA biomaterial fabricated by rapid sintering using HEMM powders. Korean J. Mater. Res. 2011, 21, 384–390. [Google Scholar] [CrossRef]

- He, Y.H.; Zhang, Y.Q.; Jiang, Y.H.; Zhou, R. Microstructure evolution and enhanced bioactivity of Ti-Nb-Zr alloy by bioactive hydroxyapatite fabricated via spark plasma sintering. RSC Adv. 2016, 6, 100939–100953. [Google Scholar] [CrossRef]

- Zhu, S.L.; Yang, X.J.; Cui, Z.D. Effect of hydroxyapatite content on the microstructure, thermal and mechanical properties of Ti-based glassy alloy/hydroxyapatite composite prepared by spark plasma sintering. Intermetallics 2011, 19, 572–576. [Google Scholar] [CrossRef]

- Berezhnaya, A.; Mittova, V.; Kostyuchenko, A.; Mittova, I. Solid-phase interaction in the hydroxyapatite/titanium heterostructures upon high-temperature annealing in air and argon. Inorg. Mater. 2008, 44, 1214–1217. [Google Scholar] [CrossRef]

- Lu, Y.P.; Li, M.S.; Li, S.T.; Wang, Z.G.; Zhu, R.F. Plasma-sprayed hydroxyapatite + titania composite bond coat for hydroxyapatite coating on titanium substrate. Biomaterials 2004, 25, 4393–4403. [Google Scholar] [CrossRef] [PubMed]

- Han, C.J.; Qian, W.; Bo, S.; Li, W.; Wei, Q.S.; Wen, S.F.; Liu, J.; Shi, Y.S.; Mech, J. Microstructure and property evolutions of titanium/nano-hydroxyapatite composites in-situ prepared by selective laser melting. Behav. Biomed. 2017, 71, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Chang, Q.; Ru, H.Q.; Chen, D.L.; Yang, J.L.; Hu, S.L. Effect of iron on the sinterability and properties of HA/Ti-Fe composites. Adv. Mater. Res. 2014, 898, 271–274. [Google Scholar] [CrossRef]

- Kumar, A.; Biswas, K.; Basu, B. Fretting wear behaviour of hydroxyapatite-titanium composites in simulated body fluid, supplemented with 5 g L−1 bovine serum albumin. J. Phys. D Appl. Phys. 2013, 46, 404004. [Google Scholar] [CrossRef]

- Li, M.; Liu, Q.; Jia, Z.; Xu, X.; Cheng, Y.; Zheng, Y.F.; Xi, T.F.; Wei, S.C. Graphene oxide/hydroxyapatite composite coatings fabricated by electrophoretic nanotechnology for biological applications. Carbon 2014, 67, 185–197. [Google Scholar] [CrossRef]

- Wang, X.P.; Kong, F.; Han, B.Q.; Chen, Y.Y. Electrochemical corrosion and bioactivity of Ti-Nb-Sn-hydroxyapatite composites fabricated by pulse current activated sintering. J. Mech. Behav. Biomed. 2017, 75, 222–227. [Google Scholar] [CrossRef]

- Zancanela, D.C.; Simão, A.M.S.; Francisco, C.G.; Faria, A.N.D.; Ramos, A.P.; Gonçalves, R.R.; Matsubara, E.Y.; Rosolen, J.M.; Ciancaglini, P. Graphene oxide and titanium: Synergistic effects on the biomineralization ability of osteoblast cultures. J. Mater. Sci. Mater. Med. 2016, 27, 71. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.; Kamiya, A.; Zhu, J.; Watazu, A. Properties of titanium biomaterialfabricated by sinter-bonding of titanium/hydroxyapatite composite surfacecoated layer to pure bulk titanium. Mater. Sci. Eng. A 2002, 337, 104–109. [Google Scholar] [CrossRef]

- Nelea, V.; Morosanu, C.; Bercu, M.; Mihailescu, I.N. Interfacial titanium oxide between hydroxyapatite and TiAlFe substrate. J. Mater. Sci. Mater. Med. 2007, 18, 2347–2354. [Google Scholar] [CrossRef] [PubMed]

- Ye, H.; Liu, X.Y.; Hong, H. Characterization of sintered titanium/hydroxyapatite biocomposite using FTIR spectroscopy. J. Mater. Sci. Mater. Med. 2009, 20, 843–850. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.; Lin, P.; Dong, Y.; Xue, X.; Zhu, J.; Yin, Z. Fabrication and characterization of hydroxyapatite reinforced with 20 vol% Ti particles for use as hard tissue replacement. J. Mater. Sci. Mater. Med. 2002, 13, 985–992. [Google Scholar] [CrossRef] [PubMed]

- Anaee, R.A. Behavior of Ti/HA in saliva at different temperatures as restorative materials. J. Bio- Tribo-Corros. 2016, 2, 1–9. [Google Scholar] [CrossRef]

- Arifin, A.; Sulong, A.B.; Muhamad, N.; Syarif, J. Characterization of hydroxyapatite/Ti6Al4V composite powder under various sintering temperature. J. Appl. Sci. 2015, 75, 27–31. [Google Scholar] [CrossRef]

- Woo, K.D.; Kim, S.H.; Kang, D.S.; Kim, D.G. Microstructure and biocompatibility of Ti-Nb-Si-HA composites fabricated by rapid sintering using HEMM powders. Korean J. Mater. Res. 2013, 23, 353–358. [Google Scholar] [CrossRef]

| Sample | HA | La | CNT | GNFs | Nb | Ta | Zr | Ti |

|---|---|---|---|---|---|---|---|---|

| #1 | 5 | 0.3 | 0 | 0 | 27.65 | 11.55 | 4.07 | 51.43 |

| #2 | 5 | 0.3 | 0.5 | 0 | 27.51 | 11.49 | 4.05 | 51.15 |

| #3 | 5 | 0.3 | 0 | 0.5 | 27.51 | 11.49 | 4.05 | 51.15 |

| #4 | 5 | 0.3 | 0.4 | 0.1 | 27.51 | 11.49 | 4.05 | 51.15 |

| Spot | C | O | P | Ca | Ti | Zr | Nb | La | Ta |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 4.47 | 29.86 | 0.65 | 0.89 | 64.01 | 0.04 | 0.07 | - | 0.01 |

| 2 | 58.71 | 31.79 | 2.75 | 4.06 | 1.83 | 0.20 | 0.35 | 0.05 | 0.09 |

| 3 | 18.77 | 47.61 | 2.62 | 3.73 | 26.67 | 0.19 | 0.31 | 0.02 | 0.07 |

| 4 | 17.22 | 40.89 | 2.83 | 3.36 | 17.32 | - | 18.38 | - | - |

| 5 | 26.41 | 27.36 | 1.72 | 1.42 | 1.38 | - | 0.23 | 0.10 | 41.38 |

| 6 | 67.26 | 19.54 | 2.05 | 3.31 | 6.51 | - | 1.34 | - | - |

| 7 | 59.18 | 22.36 | 3.04 | 4.86 | 8.32 | 0.38 | 1.44 | - | 0.41 |

| Region | O | P | Ca | Ti | Zr | Nb | C | La | Ta |

|---|---|---|---|---|---|---|---|---|---|

| Point 1 | 26.24 | 3.74 | 26.20 | 7.34 | - | 14.03 | 22.44 | - | - |

| Point 2 | 49.13 | 1.77 | 18.08 | 5.21 | 1.91 | 2.89 | 18.66 | - | 2.35 |

| Point 3 | 20.40 | 0.02 | 0.27 | 55.45 | 0.08 | 0.17 | 22.19 | 0.93 | 0.48 |

| Sample | Density | Microhardness/HV | Compressive Strength/MPa | Shear Strength/MPa | Bending Strength/MPa | Pressive Modulus/GPa |

|---|---|---|---|---|---|---|

| Ti alloy/HA | 98.56% | 518.6 | 1134.97 | 228.7 | 220.15 | 13.22 |

| 0.5-CNTs | 98.83% | 454 | 847.58 | 186.24 | 190.53 | 10.31 |

| 0.5-GNFs | 99.04% | 400.7 | 1046.05 | 192.55 | 191.06 | 12.47 |

| 0.4 CNTs: 0.1 GNFs | 99.61% | 413.7 | 922.55 | 178.1 | 196.72 | 11.41 |

| Region | C | P | Ca | Ti | O | Nb | Zr | Ta |

|---|---|---|---|---|---|---|---|---|

| A | 24.27 | 0.42 | 0.85 | 74.47 | - | - | - | - |

| B | 25.61 | 1.28 | 0.66 | 72.45 | - | - | - | - |

| C | 44.89 | 2.00 | 1.83 | 4.34 | 24.18 | 22.74 | - | - |

| D | 20.14 | 3.67 | 2.42 | 38.81 | 31.78 | 3.18 | - | - |

| E | 14.89 | - | 0.53 | 50.04 | 31.94 | 1.64 | 0.95 | - |

| F | 11.18 | - | 0.37 | 66.39 | 21.51 | - | 0.55 | - |

| G | 37.37 | - | 4.10 | 5.15 | 26.23 | 26.75 | - | - |

| H | 68.20 | - | 0.54 | 2.48 | 11.98 | - | - | 16.80 |

| I | 48.31 | - | 2.95 | 2.28 | 33.77 | 12.70 | - | - |

| Element | Treatment Condition | 2θ | Crystal Face | Grain Size/Å |

|---|---|---|---|---|

| α-Ti | milled | 40.155/38.590/35.087 | (101)/(002)/(100) | 253/258/235 |

| sintered | 39.770/38.523/34.846 | 303/359/327 | ||

| Ta/Nb | milled | 38.461/69.593/55.649 | (110)/(211)/(200) | 254/164/199 |

| sintered | 38.523/69.680/55.657 | 359/197/289 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Jiang, X.; Shao, Z.; Zhu, D.; Luo, Z. Microstructure and Mechanical Properties of Nano-Carbon Reinforced Titanium Matrix/Hydroxyapatite Biocomposites Prepared by Spark Plasma Sintering. Nanomaterials 2018, 8, 729. https://doi.org/10.3390/nano8090729

Li F, Jiang X, Shao Z, Zhu D, Luo Z. Microstructure and Mechanical Properties of Nano-Carbon Reinforced Titanium Matrix/Hydroxyapatite Biocomposites Prepared by Spark Plasma Sintering. Nanomaterials. 2018; 8(9):729. https://doi.org/10.3390/nano8090729

Chicago/Turabian StyleLi, Feng, Xiaosong Jiang, Zhenyi Shao, Degui Zhu, and Zhiping Luo. 2018. "Microstructure and Mechanical Properties of Nano-Carbon Reinforced Titanium Matrix/Hydroxyapatite Biocomposites Prepared by Spark Plasma Sintering" Nanomaterials 8, no. 9: 729. https://doi.org/10.3390/nano8090729

APA StyleLi, F., Jiang, X., Shao, Z., Zhu, D., & Luo, Z. (2018). Microstructure and Mechanical Properties of Nano-Carbon Reinforced Titanium Matrix/Hydroxyapatite Biocomposites Prepared by Spark Plasma Sintering. Nanomaterials, 8(9), 729. https://doi.org/10.3390/nano8090729