1. Introduction

The classic theory of adhesion of parabolic elastic solids by Johnson, Kendall and Roberts (JKR) [

1,

2,

3] is based on the principle of virtual work, stating that a mechanical system is in equilibrium if any small perturbation does not change the energy of the system. This energetic criterion was first applied to the equilibrium of cracks in brittle elastic bodies by Griffith [

4,

5]. Johnson, Kendall and Roberts realized that the boundary of an adhesive contact is equivalent to the Griffith crack and applied the same criterion of energy balance to adhesive contacts. When applied to cracks or adhesive contacts, this criterion means that the tip of a crack is in equilibrium if the elastic energy released due to a small increase in the crack is equal to the work of adhesion needed to create new free surfaces. In its pure form, the energy balance criterion is applicable only to elastic bodies. However, the criterion is so simple and attractive that it is used also in considering the propagation of cracks (or, equivalently, adhesive contacts) in dissipative media. One introduces a modified “effective separation energy”, which is needed not only for the creation of new surfaces but also for performing work against dissipative forces (due to viscosity, plasticity, etc.). For example, Barquins and Maugis postulated the existence of an effective work of adhesion depending on the crack propagation velocity [

6]. Energetic analysis of viscoelastic adhesive contacts was provided by Greenwood and Johnson in their seminal 1981 work [

7]. Their approach, based on fracture mechanics and viscoelastic crack modeling, demonstrated that effective work of adhesion depends on the time-dependent material response and differs between attachment and detachment. The analysis of viscoelastic crack propagation by Greenwood and Johnson [

7] was based in large part on the theoretical framework developed earlier by Schapery [

8], who provided a general formulation for crack initiation and growth in viscoelastic media.

In 2021, Popov suggested how the energetic criterion can be applied to viscoelastic contacts in a rigorous way, without the introduction of any empirical effective work of adhesion [

9], formulated in the framework of the Method of Dimensionality Reduction (MDR). While this formulation significantly simplifies analysis using MDR, it reaches conclusions that are conceptually aligned with those of Greenwood and Johnson. As the MDR maps the true three-dimensional contact problem onto a contact with viscoelastic foundation, it makes the main ideas especially simple and, much more importantly, allows the simple consideration of arbitrary loading scenarios. The proposed energetic criterion was based on the observation that the process of crack opening is mediated by very fast processes involving the short-ranged adhesive potential and the material’s glass modulus, while the dissipative properties of the material affect the contact on a longer timescale. This allows the energy balance to be applied to attachment and detachment with only slight modifications of the classic JKR theory. This approach promises to be a powerful first-principles tool for analyzing viscoelastic adhesive contacts but is not without limitations. First and foremost, it is based on the assumption that adhesive interaction has a purely conservative character (i.e., the viscoelasticity is related exclusively to the volume of the medium but not to the surface forces). In [

9], this property is characterized as “non-entropic surface interaction”. Secondly, only the limiting case of adhesive contacts with very short-ranged adhesive forces is considered (smaller than any other characteristic dimension of the contact), which is characterized as “JKR-type adhesion” as opposed to the DMT-type adhesion [

10,

11] with long-rage adhesive interactions.

In the present paper, we describe the energetic criterion formulated in [

9] in more detail and apply it to

quasistatic adhesive contacts of viscoelastic bodies. As a working example of viscoelastic material, we consider the “standard viscoelastic body” [

12]. Throughout our analysis, we use the Method of Dimensionality Reduction, which is described in [

13]. This allows for a much simpler formulation and flexible extension of the theory than in the work of [

14], who arrived at similar conclusions using the much more complex methods of classic contact mechanics.

In addition to its theoretical importance, understanding viscoelastic adhesion has far-reaching practical implications in a variety of application areas. These include soft robotics, where reversible and programmable adhesion is critical; biomedical adhesives, such as skin patches and tissue scaffolds; and microelectronics, where controlled adhesion is essential for material integration at small scales.

2. Basics of the Method of Dimensionality Reduction

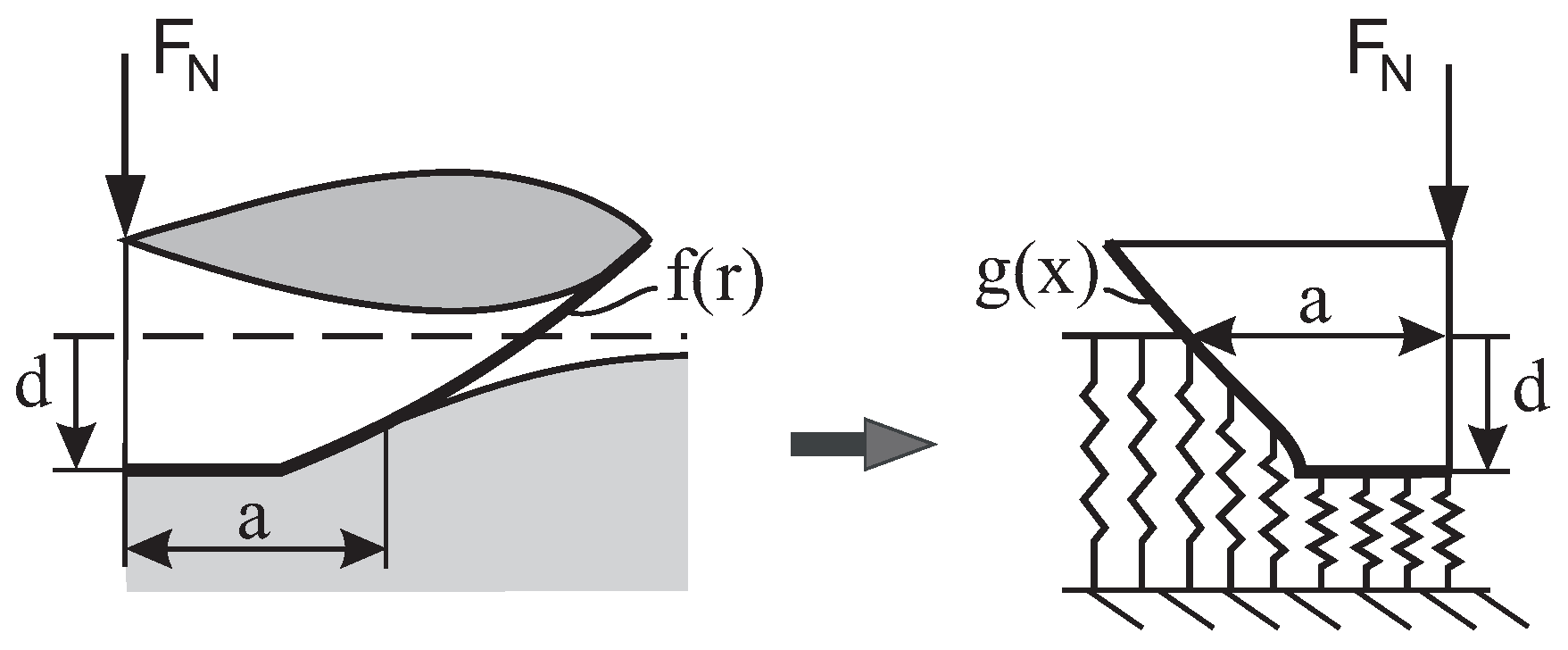

2.1. Elastic Non-Adhesive Contacts

Solving an axially symmetric three-dimensional contact problem of two elastic bodies with the Method of Dimensionality Reduction (MDR) involves the following steps [

13] (see also

Figure 1). First, the shapes of the contacting bodies are reduced to the gap function

, and this profile is transformed into a plane profile

via an Abel transformation:

The profile

is then pushed by an indentation depth

into a one-dimensional elastic foundation, a series of springs with spacing

and stiffness

where the effective elastic modulus

is defined as

where

and

are Young’s moduli, and

and

are the Poisson numbers of the contacting bodies.

The vertical displacement of a spring at the position

and the corresponding spring force are given by the equations

The contact radius

is determined from the condition

and the total normal force is given by the summation (or integration) of the spring forces (5)

In [

8], it is proved that the relationships between the normal force

, the indentation depth

and the contact radius

given by Equations (6) and (7) exactly coincide with those of the initial three-dimensional contact problem.

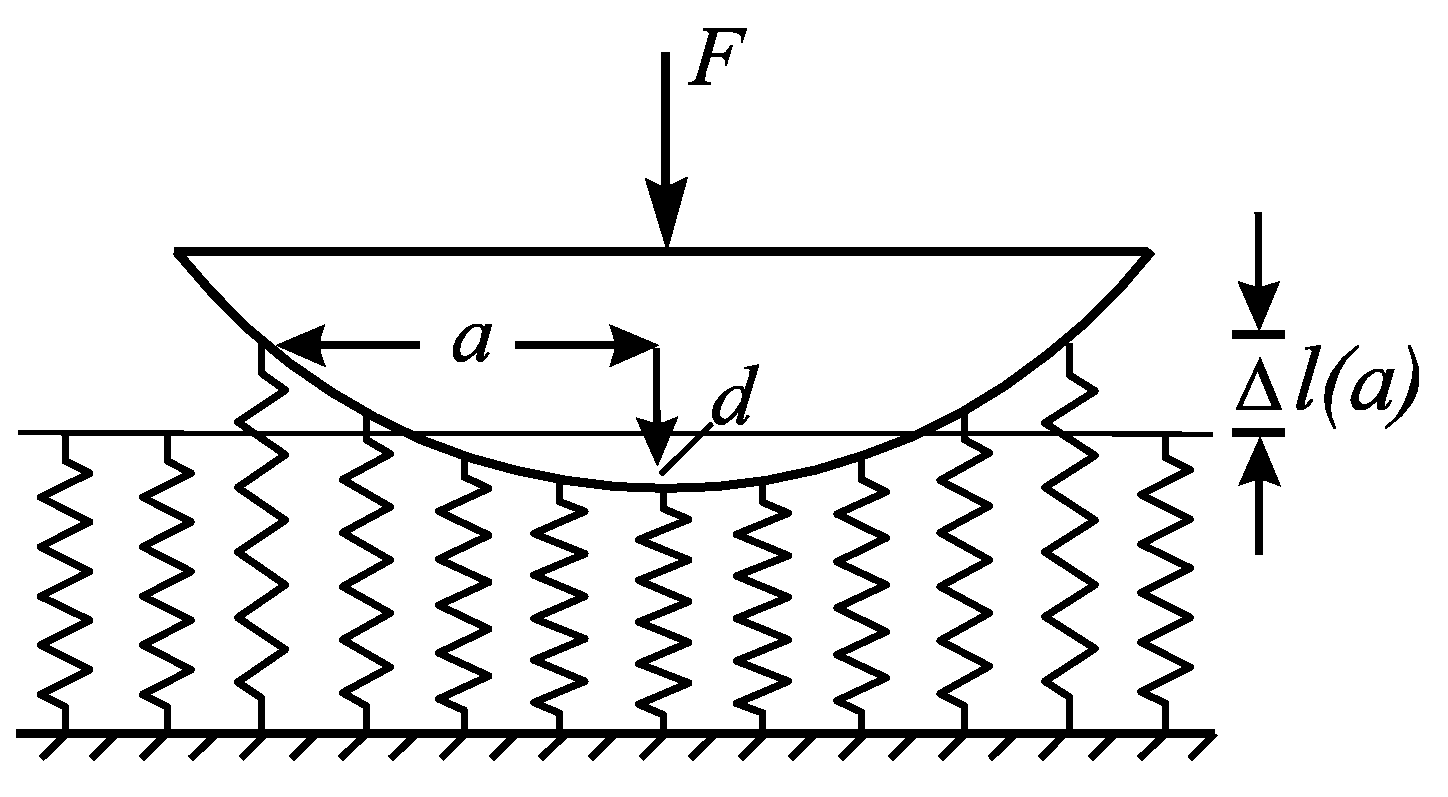

2.2. Elastic Adhesive Contacts

The adhesive contact between two elastic bodies is solved using exactly the same transformation (1) and procedural steps as in the non-adhesive case. The only modification lies in the criterion used to determine the extent of the contact area (i.e., the position of the contact boundary). Rather than applying Equation (6), we consider the following process. The indenter is first pressed into the elastic foundation and then gradually lifted. It is assumed that all springs initially in contact remain attached to the indenter, maintaining a constant contact radius during retraction. In this scenario, the outermost springs bear the maximum tensile load (

Figure 2). When their elongation reaches a critical value,

they detach.

is here the specific work of adhesion. This detachment rule is known as the Heß criterion [

15,

16] {XE “rule of Hess”}. The resulting condition for the contact boundary is expressed as

Both the relationship between the indentation depth and contact radius given by (9) and the normal force given by (7) reproduce the solution by Johnson, Kendall and Roberts [

1].

The rule of Heß, Equation (8), can be derived using the principle of virtual work. According to this principle, the system is in equilibrium when the energy does not change due to small variations in its generalized coordinates. Applied to the boundary of an adhesive contact, it means that the change in the elastic energy due to a small reduction in the contact radius from

to

is equal to the change in the surface energy

, needed to create new surfaces. Since the MDR maps the relationship of force to displacement exactly, the elastic energy is also reproduced exactly. The change in the elastic energy can, therefore, be calculated directly in the MDR model. Due to the detachment of two springs on the left and right edges of the contact, the relaxed elastic energy is

. Balancing the changes in the elastic energy and the work of adhesion

gives

which results in (8).

Note that criterion (8) has to be checked both for the springs that are in contact (if their elongation is larger than the critical one, they detach) and for the springs immediately outside the contact (if their coming into contact produces elongation less than is critical, then they must jump into contact). Thus, the boundary of an adhesive contact can propagate in both directions until it reaches the equilibrium state.

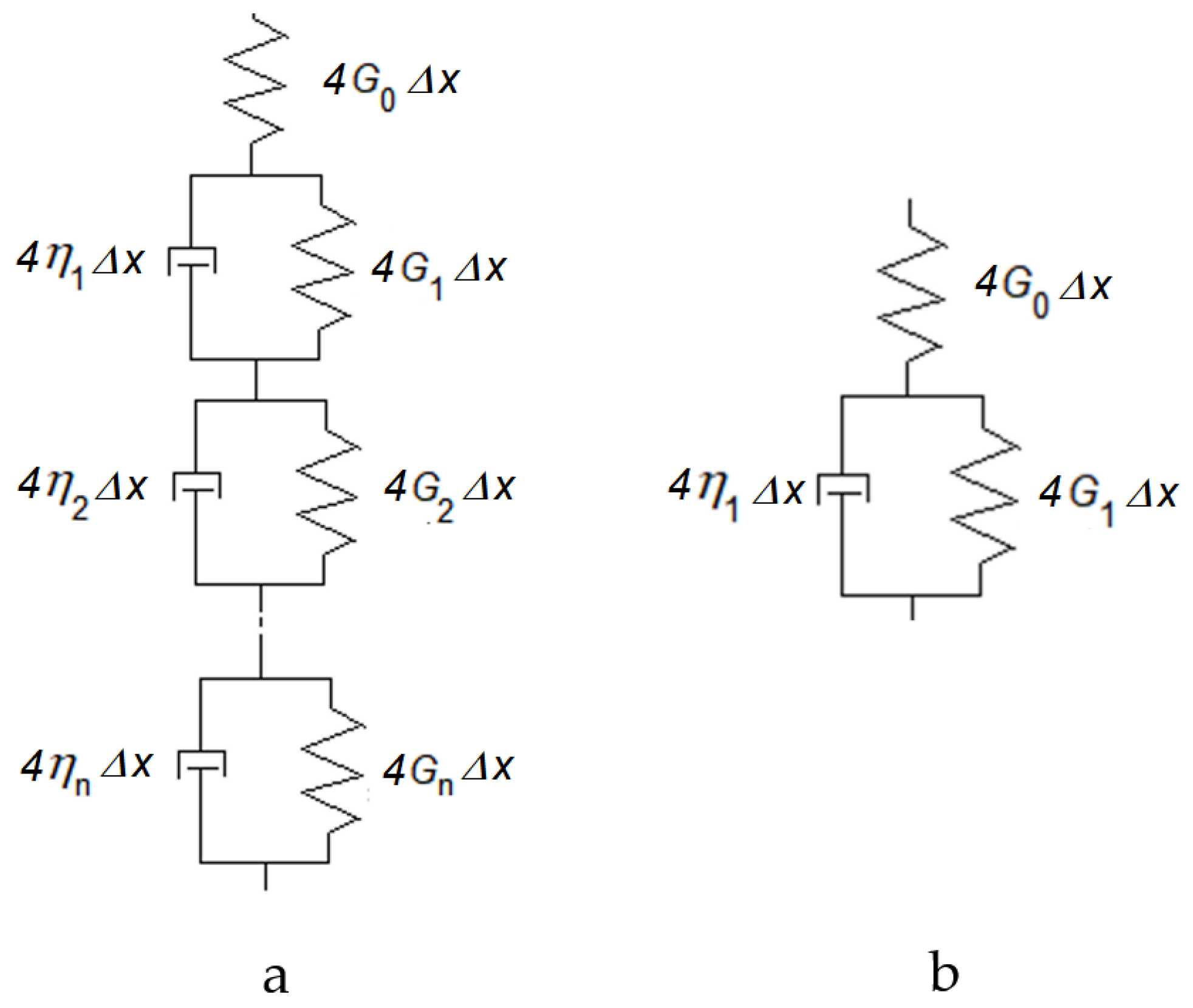

2.3. Viscoelastic Non-Adhesive Contacts

The Method of Dimensionality Reduction can also be applied to viscoelastic contacts by replacing the spring elements with corresponding rheological elements, as defined in [

17]. Linear rheology can always be represented by a generalized creep element consisting of a number of Kelvin elements connected in series. In the case of an incompressible medium

, where

is the shear modulus. Correspondingly, the generalized creep elements consist of springs with stiffness

and a damping constant

, where

is dynamic viscosity (

Figure 3a).

It has been shown [

17] that the indentation of the MDR-transformed profile

into a viscoelastic foundation exactly replicates the original three-dimensional contact problem for a viscoelastic medium with the corresponding rheological properties. For qualitative analysis, a commonly used model is the “standard viscoelastic element”, which consists of a purely elastic spring (representing the glass modulus) in parallel with a Kelvin–Voigt element, as illustrated in

Figure 3b. This simplified model will also serve as the basis for much of the subsequent analysis in this paper.

3. Energetic Criterion for Viscoelastic Adhesive Contacts

The general approach closely parallels that used for elastic adhesive contact. However, in the case of viscoelastic materials, each spring in the elastic foundation is replaced by a corresponding creep element, as depicted in

Figure 3a. When the body is lifted, the element located at the edge of the contact undergoes an elongation

. This total elongation is composed of the individual deformations of all the sub-elements within the creep element:

, where

is the elongation of spring

,

is the elongation of the Kelvin element

, and so on.

The core concept behind applying the energy criterion to viscoelastic bodies lies in recognizing the different relaxation timescales within a rheological element. When the system is deformed, elastic energy is stored across all components of the viscoelastic element. Upon detachment from the indenter, only the energy stored in the purely elastic spring, , associated with the glass modulus, can relax instantaneously and contribute to the formation of new surfaces, i.e., perform the work of adhesion. In contrast, the energy stored in the Kelvin elements relaxes more slowly and cannot be utilized during the brief moment of detachment, which occurs at the molecular level and is effectively instantaneous from a macroscopic perspective. Consequently, the material’s immediate response is governed by its glass modulus, making the detachment process effectively conservative.

This justifies the application of the energy balance criterion, where the quickly releasable elastic energy,

, is equated to the specific work of adhesion,

:

which has exactly the same form as the detachment criterion (10) for the elastic case, with the only difference being that

is now the

glass modulus of the medium and

is only

part of the total elongation. Note that we consider here the case of energetic interfaces; thus, we assume that

is a well-defined material parameter that does not depend on the velocity of detachment. Solving Equation (11) with respect to

gives

This criterion does not depend on the rheology of the medium. However, how large the elongation part is does depend on the rheology and on the loading history.

4. Quasistatic Indentation and Detachment

In the following, we consider a displacement-controlled quasistatic indentation of a rigid parabolic indenter

into a viscoelastic half-space described with the “standard viscoelastic model” with a stiff spring

and Kelvin element

(

Figure 3b). The corresponding MDR profile is, in this case, according to Equation (1), given by

4.1. Indentation Phase

At the first touch, an adhesive neck will appear by propagation of the boundary of adhesive contact. As the initial length of all rheological elements is zero and during the attachment process only the spring

is instantly deformed, the boundary of adhesive contact propagates until the following condition is fulfilled:

Thus, the initial contact radius is given by the following equation:

Associated with this instant attachment is an instant drop in force by

However, as soon as the springs are stretched, this force begins to relax. At the end of the relaxation process, the stiffness of each rheological element is

, and the normal force is equal to

with

Thus, the quasistatic value of the normal force appearing after the initial touch is given by the usual JKR equation but with an effective work of adhesion given by Equation (18).

Consider now an arbitrary indentation

. Now, the condition for the boundary of an adhesive contact takes the following form:

and the force in the relaxed state is give by

These two equations exactly coincide with the JKR equations with replacements

Thus, during the indentation phase, the contact is characterized by a soft (relaxed) elastic modulus and a very low effective work of adhesion (suppressed by the factor ).

4.2. Detachment Phase

A very important difference from the elastic case is that, due to the relaxation, the edge springs during the indentation phase are

not in a critical state. Thus, if the indentation is stopped and the indenter is quasistatically lifted, the stiff springs

have first to achieve the critical elongation (12) before the detachment process starts. During this phase, the contact size remains constant. This is the well-known “sticking zone” [

18,

19].

The detachment starts when the elongation of spring

reaches the critical value

given by (12). At this moment, the elongation of spring

will be

. Thus, the whole elongation of the rheological element will be

The condition for the contact radius thus reads

with

For elements at position

, we have the following equations for the vertical displacement of the whole element and the force:

and for the total normal force

Equations (23) and (26) are exactly equivalent to the JKR theory with replacements

Thus, during the detachment phase, the contact is characterized by a soft (relaxed) elastic modulus and a very high effective work of adhesion (enhanced by factor

), which was found by de Gennes using other arguments [

20].

5. Limits of Applicability of the Energy Criterion

An essential assumption for the applicability of the energetic criterion described in this paper is timescale separation—elastic detachment is a quick process, while the subsequent viscous relaxation a slow one. The physical substantiation of the scale separation is the short range of adhesive forces, which is assumed to be much smaller than any other dimension of the contact problem. In real systems, the range of adhesive force might be small but finite, and this will impose some restrictions on the applicability of the above theory. For this sake, we must consider the three-dimensional shape of the adhesive gap. This gap is different for the indentation and the pull-off phases.

5.1. Gap Shape During the Indentation Phase

During the indentation phase, the elongation of the last spring in contact is given by Equation (12), while the next spring (outside the contact) has zero elongation. Thus, at the boundary of adhesive contact, there is a jump in vertical displacement

According to the rules of the Method of Dimensionality Reduction, the displacement of the surface outside the contact in the original three-dimensional contact problem is given by Equation (7) (Equation (2.14) in [

7])

A jump of

at point

leads to an asymptotic form of a gap

With jump (28), this equation becomes

The process of detachment is completed when the distance between the surfaces of the gap becomes

, where

is the characteristic interaction range of adhesive forces:

Thus, to complete detachment, the tip of the crack should advance by the distance

If the propagation velocity of the boundary of adhesive contact is

, this happens during time

Detachment can be considered “instant” if this time is much smaller than the relaxation time

of the elastomer:

Hence, the velocity must be larger than

5.2. Gap Shape During the Detachment Phase

In the detachment phase, the jump of the elongation of the boundary element is given by Equation (22):

Thus, criterion (32) takes the form

and the velocity condition (36) is replaced by

Using the values

,

,

,

, and

for estimation, we obtain the following estimations for the critical velocities:

Thus, the almost arbitrary pull-off velocities used in the experiment guarantee the scale separation at the pull-off stage. During the indentation phase, more detailed consideration might be necessary, depending on the rheology (relaxation time).

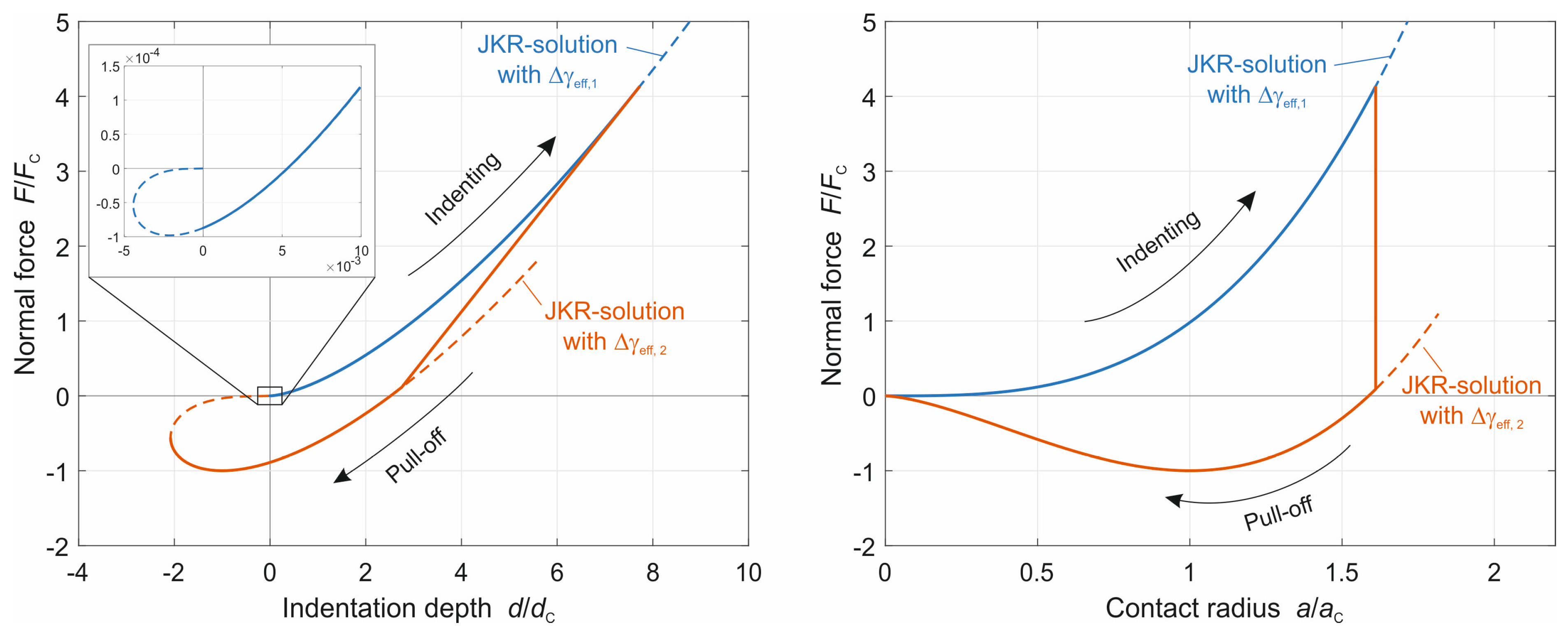

6. Discussion

We have shown how (and when) a purely energetic criterion can be used to determine detachment and attachment conditions in adhesive contact with a viscoelastic body. Under the restrictions described in

Section 5, two timescales can be identified: the time of detachment and the time of relaxation of the elastomer. If the time of detachment is much smaller than the time of relaxation, it can be considered to be nearly instant. In this case, only the part of elastic energy that is stored in the stiff spring

, characterizing the instant rigidity of the body, is available for the creation of surface energy. We have shown that if the indenter is now pressed into the medium and pulled-off “quasistatically”, which means slowly enough for complete relaxation of the medium but quickly enough so that no relaxation occurs during the detachment process, then the force–displacement relationship and the force–contact radius relationship can be found analytically. They are given by Equations (19) and (20) for indentation and by Equations (23) and (26) for detachment. By reversing the direction of motion (from indentation to pull-off), the contact radius remains constant until a critical condition is achieved, which leads to the appearance of the “sticking zone”.

These results are illustrated in

Figure 4. Both the indentation and detachment processes are described by the JKR theory, but indentation only has very low effective adhesive energy, given by (21), and detachment has very high effective separation energy, given by (27). In both cases, the small (relaxed) elastic modulus must be used. The force, the indentation depth and the contact radius in

Figure 4 are normalized by

It is often believed that if the indentation and detachment occur very slowly, then the viscoelastic medium can be considered a soft elastic body. This is true only partially; the

elastic response at a quasistatic deformation is given both during indentation and pull-off by the relaxed modulus. However, the

detachment criterion is different. This is due to the fact that the process of detachment is always quick (nearly instant), even at quasistatic deformation. This leads to pronounced adhesive hysteresis, in complete agreement with the overwhelming experimental evidence. We do not provide here any comparison with experiments but mention that the curves in

Figure 4 are strikingly similar to much of the experimental data (see e.g., [

21,

22]). In particular, all experimental studies show that the indentation process is related to a very small effective work of adhesion, which is several orders of magnitude smaller than the effective work of adhesion observed during the detachment phase.

Enhancement of the effective surface energy during the pull-off phase by factor

, as compared with the thermodynamic value, was obtained earlier [

14,

23,

24] without using the MDR but with methods and arguments that are ultimately equivalent to those presented here.

In an earlier work, the difference in the work of adhesion at attachment and detachment was related to the friction of the boundary line of adhesive contact [

25]. The approach described in this paper sheds a completely new light on the physical origin of two different works of adhesion. In particular, from paper [

25], it remains unclear why the experimentally observed work of adhesion at indentation is orders of magnitude smaller than that at detachment. The approach of the present paper gives a simple explanation to this fundamental experimental fact.

Here, we considered only quasistatic indentation and detachment. The formulated energetic criterion allows arbitrary loading scenarios within the same framework to be considered.

The concept of effective surface energy used in this work is closely related to similar notions in fracture mechanics, where viscoelastic dissipation is commonly treated through energy release rates that incorporate time-dependent effects. The present formulation builds directly on this tradition by offering a simplified, yet rigorous, energetic criterion grounded in the Method of Dimensionality Reduction. Unlike previous approaches, which often required numerical inversion of hereditary integrals, the current method permits straightforward analytical treatment, thus broadening the practical applicability of the rate-dependent adhesion concept.

7. Conclusions

We have shown how the energetic criterion (Griffith criterion) can be applied in an exact and straightforward way to adhesive contacts of viscoelastic bodies. The limits of applicability of the energetic criterion have been analyzed, showing that the restrictions are stronger during the indentation phase than during the detachment phase. The formulated procedure is applicable to arbitrary loading scenarios. In the present paper, only quasistatic indentation and detachment have been considered. It has been shown that both indentation and detachment are described by the JKR theory, but indentation with an effective work of adhesion is suppressed by factor

, and detachment with an effective work of adhesion is enhanced by factor

. Due to the strong suppression of effective energy, indentation occurs almost as if there were no adhesion (almost pure Hertz). Reversing the direction of motion leads first to a sticking zone, followed by a JKR dependence with a very high effective work of adhesion. These results coincide with the earlier results obtained by Barthel with other analytical methods [

24].

Beyond providing analytical tractability, the method offers a clear conceptual insight into why hysteresis arises in viscoelastic adhesive contacts—namely, the delayed relaxation of energy stored in dissipative elements. These results also align closely with experimental observations, particularly the pronounced asymmetry in effective adhesion energy between the approach and retraction phases.

The theoretical framework presented here is not only of academic interest but also relevant for the design and analysis of soft adhesive systems in practical applications, such as biomedical adhesives, flexible electronics and soft robotics. The simplicity and generality of the MDR-based energetic criterion opens the door to systematic studies of more complex loading scenarios and geometries. In this study, we have focused on the ultimate quasistatic limit of adhesive contact. A detailed analysis of adhesion under finite separation rates will be presented in a forthcoming paper. In the general case, the adhesive force is expected to depend not only on the loading history but also, in particular, on the maximum indentation depth—an effect that has been consistently observed in experiments [

26]. Further work at finite velocities could also impact the broader problem of oscillation effects on adhesive contacts [

27] and the interrelation between adhesion and friction [

28].

Funding

This research was partially funded by the German Research Society (DFG), project PO 810/74-1.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No data is reported in this paper.

Acknowledgments

The author is thankful to Qiang Li, Mikhail Popov, Iakov Lyashenko, Ken Nakano and Emanuel Willert for many valuable discussions.

Conflicts of Interest

The author declares no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| MDR | Method of Dimensionality Reduction |

References

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface Energy and the Contact of Elastic Solids. Proc. R. Soc. Lond. A 1971, 324, 301–313. [Google Scholar] [CrossRef]

- Kendall, K. Thin-Film Peeling—The Elastic Term. J. Phys. D Appl. Phys. 1975, 8, 1449–1452. [Google Scholar] [CrossRef]

- Ciavarella, M.; Joe, J.; Papangelo, A.; Barber, J.R. The Role of Adhesion in Contact Mechanics. J. R. Soc. Interface 2019, 16, 20180738. [Google Scholar] [CrossRef]

- Griffith, A.A. The Phenomena of Rupture and Flow in Solids. Philos. Trans. R. Soc. Lond. A 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Lawn, B.R. Fracture of Brittle Solids, 2nd ed.; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Barquins, M.; Maugis, D. Tackiness of Elastomers. J. Adhes. 1981, 13, 53–65. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Johnson, K.L. The Mechanics of Adhesion of Viscoelastic Solids. Philos. Mag. A 1981, 43, 697–711. [Google Scholar] [CrossRef]

- Schapery, R.A. A Theory of Crack Initiation and Growth in Viscoelastic Media. Int. J. Fract. 1975, 11, 141–159. [Google Scholar] [CrossRef]

- Popov, V.L. Energetic Criterion for Adhesion in Viscoelastic Contacts with Non-Entropic Surface Interaction. (“Energetic criterion for adhesion in viscoelastic contacts with non …”). Rep. Mech. Eng. 2021, 2, 57–64. [Google Scholar] [CrossRef]

- Derjaguin, B.V.; Muller, V.M.; Toporov, Y.P. Effect of Contact Deformations on the Adhesion of Particles. J. Colloid Interface Sci. 1975, 53, 314–326. [Google Scholar] [CrossRef]

- Maugis, D. Adhesion of Spheres: The JKR-DMT Transition Using a Dugdale Model. J. Colloid Interface Sci. 1992, 150, 243–269. [Google Scholar] [CrossRef]

- Popov, V.L. Contact Mechanics and Friction: Physical Principles and Applications, 2nd ed.; Springer: Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Popov, V.L.; Heß, M.; Willert, E. Handbook of Contact Mechanics: Exact Solutions of Axisymmetric Contact Problems; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Haiat, G.; Phan Huy, M.C.; Barthel, E. The adhesive contact of viscoelastic spheres. J. Mech. Phys. Solids 2003, 51, 69–99. [Google Scholar] [CrossRef]

- Heß, M. Über die exakte Abbildung Ausgewählter Dreidimensionaler Kontakte auf Systeme mit Niedrigerer Räumlicher Dimension; Cuvillier: Göttingen, Germany, 2011. [Google Scholar]

- Heß, M. On the Reduction Method of Dimensionality: The Exact Mapping of Axisymmetric Contact Problems with and without Adhesion. Phys. Mesomech. 2012, 15, 264–269. [Google Scholar] [CrossRef]

- Popov, V.L.; Willert, E.; Heß, M. Method of Dimensionality Reduction in Contact Mechanics and Friction: A User’s Handbook. III. Viscoelastic Contacts. Facta Univ. Ser. Mech. Eng. 2018, 16, 99–113. [Google Scholar] [CrossRef]

- Waters, J.F.; Guduru, P.R. Mode-Mixity-Dependent Adhesive Contact of a Sphere on a Plane Surface. (“On the Effect of Shear Loading Rate on Contact Area Shrinking in …”). Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 1303–1325. [Google Scholar] [CrossRef]

- Violano, G.; Chateauminois, A.; Afferrante, L. A JKR-Like Solution for Viscoelastic Adhesive Contacts. Front. Mech. Eng. 2021, 7, 664486. [Google Scholar] [CrossRef]

- de Gennes, P.G. Soft Adhesives. Langmuir 1996, 12, 4497–4500. [Google Scholar] [CrossRef]

- Lyashenko, I.A.; Pohrt, R. Adhesion between rigid indenter and soft rubber layer: Influence of roughness. Front. Mech. Eng. 2020, 6, 49. [Google Scholar] [CrossRef]

- Lyashenko, I.A.; Popov, V.L. The effect of contact duration and indentation depth on adhesion strength: Experiment and numerical simulation. Tech. Phys. 2020, 65, 1695–1707. [Google Scholar] [CrossRef]

- Barthel, E.; Haiat, G. An Approximate Model for the Adhesive Contact of Viscoelastic Spheres. Langmuir 2002, 18, 9362–9370. [Google Scholar] [CrossRef]

- Barthel, E. Adhesive Elastic Contacts: JKR and More. J. Phys. D Appl. Phys. 2008, 41, 163001. [Google Scholar] [CrossRef]

- Popov, V.L.; Li, Q.; Lyashenko, I.A.; Pohrt, R. Adhesion and friction in hard and soft contacts: Theory and experiment. Friction 2021, 9, 1688–1706. [Google Scholar] [CrossRef]

- Vakarelski, I.U.; Toritani, A.; Nakayama, M.; Higashitani, K. Deformation and Adhesion of Elastomer Microparticles Evaluated by AFM. Langmuir 2001, 17, 4739–4745. [Google Scholar] [CrossRef]

- Tricarico, M.; Ciavarella, M.; Papangelo, A. Enhancement of Adhesion Strength through Microvibrations: Modeling and Experiments. J. Mech. Phys. Solids 2025, 196, 106020. [Google Scholar] [CrossRef]

- Nazari, R.; Papangelo, A.; Ciavarella, M. Friction in Rolling a Cylinder on or under a Viscoelastic Substrate with Adhesion. Tribol. Lett. 2024, 72, 50. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).