Building Envelope Renovation for Energy Efficiency in Maputo, Mozambique: Expanded Polystyrene Insulation and Double-Glazed Windows †

Abstract

1. Introduction

2. Literature Review

2.1. EPS in Sustainable Construction

2.2. Energy and Environmental Benefits

2.3. Barriers to Adoption

2.4. Building Performance in Tropical African Climates

3. Materials and Methods

3.1. Study Context and Building Selection

3.2. Simulation Model

- Building Envelope:

- Retrofit Measures:

- ClimateData:

- Occupancy Schedules and Internal Heat Gains

- HVAC Systems and Controls

- Model Validation

3.3. Cost–Benefit and Environmental Analysis

4. Results

4.1. Individual Component Impacts

4.2. Combined Strategy

4.3. Cost–Benefit Analysis

- Retrofit Investment and Financial Feasibility

- Glazing Options: Total Cost of Ownership (TCO) and NPV

5. Discussion

5.1. Energy and Environmental Impact

5.2. Comparison with Other Strategies

5.3. Financial Viability

5.4. Policy Recommendations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cantarero, M.M.V. Of renewable energy, energy democracy, and sustainable development: A roadmap to accelerate the energy transition in developing countries. Energy Res. Soc. Sci. 2020, 70, 101716. [Google Scholar] [CrossRef]

- Cristóvão, L.; Chichango, F.; Massinga, P.; Macanguisse, J. The potential of renewable energy in Mozambique: An overview. J. Energy Technol. Policy 2021, 11, 30–37. [Google Scholar]

- Lazaro, S.A.M.; Baba, V.F. A systematic literature review to explore sustainable energy development practices in Mozambique. Clean Energy 2023, 7, 1330–1343. [Google Scholar] [CrossRef]

- Oswald, F. Recycling and reutilisation opportunities and techniques of the insulation material EPS (Expanded Polystyrene) after the lifetime of EIFS (Exterior Insulation Finishing System). In Sustainability and Toxicity of Building Materials; Elsevier: Amsterdam, The Netherlands, 2024; pp. 335–366. [Google Scholar]

- Lazaro, S.A.M.; Baba, V.F. Air Pollution Resulting from Biomass Combustion in Mozambique: Origins, Consequences, and Measures for Mitigation. Environ. Sci. Proc. 2023, 27, 19. [Google Scholar]

- Agency, I.E. Total CO2 Emissions from Energy. Available online: https://www.iea.org/countries/mozambique/emissions (accessed on 23 November 2024).

- Saiz, A.; Salazar Miranda, A. Understanding Urban Economies, Land Use, and Social Dynamics in the City: Big Data and Measurement; MIT Center for Real Estate Research Paper; MIT Center for Real Estate: Cambridge, MA, USA, 2023. [Google Scholar]

- Ramli Sulong, N.H.; Mustapa, S.A.S.; Abdul Rashid, M.K. Application of expanded polystyrene (EPS) in buildings and constructions: A review. J. Appl. Polym. Sci. 2019, 136, 47529. [Google Scholar] [CrossRef]

- Dissanayake, D.; Jayasinghe, C.; Jayasinghe, M. A comparative embodied energy analysis of a house with recycled expanded polystyrene (EPS) based foam concrete wall panels. Energy Build. 2017, 135, 85–94. [Google Scholar] [CrossRef]

- Kajjoba, D.; Wesonga, R.; Lwanyaga, J.D.; Kasedde, H.; Olupot, P.W.; Kirabira, J.B. Assessment of thermal comfort and its potential for energy efficiency in low-income tropical buildings: A review. Sustain. Energy Res. 2025, 12, 25. [Google Scholar] [CrossRef]

- Maracchini, G.; D’Orazio, M. Improving the livability of lightweight emergency architectures: A numerical investigation on a novel reinforced-EPS based construction system. Build. Environ. 2022, 208, 108601. [Google Scholar] [CrossRef]

- Meddage, D.; Chadee, A.; Jayasinghe, M.; Rathnayake, U. Exploring the applicability of expanded polystyrene (EPS) based concrete panels as roof slab insulation in the tropics. Case Stud. Constr. Mater. 2022, 17, e01361. [Google Scholar] [CrossRef]

- Gomes, R.; Silvestre, J.D.; de Brito, J. Environmental life cycle assessment of the manufacture of EPS granulates, lightweight concrete with EPS and high-density EPS boards. J. Build. Eng. 2020, 28, 101031. [Google Scholar] [CrossRef]

- Salite, D.; Kirshner, J.; Cotton, M.; Howe, L.; Cuamba, B.; Feijó, J.; Macome, A.Z. Electricity access in Mozambique: A critical policy analysis of investment, service reliability and social sustainability. Energy Res. Soc. Sci. 2021, 78, 102123. [Google Scholar] [CrossRef]

- Lazaro, S.A.M.; Li, X. Evaluating the feasibility and challenges of using passive solar systems for achieving thermal comfort in African countries: A review. Int. J. Build. Pathol. Adapt. 2025. [Google Scholar] [CrossRef]

- Aste, N.; Butera, F.M.; Adhikari, R.S.; Leonforte, F. Sustainable Building Design for Tropical Climates. In Innovative Models for Sustainable Development in Emerging African Countries; Aste, N., Della Torre, S., Talamo, C., Adhikari, R.S., Rossi, C., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 37–46. [Google Scholar]

- Prestes Dürrnagel, A.; Rothfuß, E.; Dörfler, T. Revealing a Life-World Perspective for Urban Planning: Conceptual Reflections and Empirical Evidence from Peri-Urban Maputo (Mozambique). Land 2025, 14, 748. [Google Scholar] [CrossRef]

- Lazaro, S.A.M. Sustainable Urban Planning in Mozambique: An Assessmentof Environmental and Social Considerations in Southern Regions. In Proceedings of the Second International Future Challenges in Sustainable UrbanPlanning & Territorial Management: Proceedings of the SUPTM 2024 Conference, Online, 29–31 January 2024; pp. 187–190. [Google Scholar]

- Barber, K.A.; Krarti, M. A review of optimization based tools for design and control of building energy systems. Renew. Sustain. Energy Rev. 2022, 160, 112359. [Google Scholar] [CrossRef]

- Ling, H.M.; Yew, M.C.; Yew, M.K.; Saw, L.H. Analyzing recent active and passive cool roofing technology in buildings, including challenges and optimization approaches. J. Build. Eng. 2024, 89, 109326. [Google Scholar] [CrossRef]

- Ji, Y.; Song, J.; Shen, P. A review of studies and modelling of solar radiation on human thermal comfort in outdoor environment. Build. Environ. 2022, 214, 108891. [Google Scholar] [CrossRef]

- Li, X.; Wu, Y. A review of complex window-glazing systems for building energy saving and daylight comfort: Glazing technologies and their building performance prediction. J. Build. Phys. 2025, 48, 496–540. [Google Scholar] [CrossRef]

- Tapetado, P.; Usaola, J. Capacity credits of wind and solar generation: The Spanish case. Renew. Energy 2019, 143, 164–175. [Google Scholar] [CrossRef]

- Haldorai, A. A Survey of Renewable Energy Sources and their Contribution to Sustainable Development. J. Enterp. Bus. Intell. 2022, 2, 211–222. [Google Scholar] [CrossRef]

- Alamin, E.; Kamaruzaman, N.; Kamar, H.M. A pragmatic retrofitting approach to enhancing the thermal, energy and economic performance of an educational building: A case study in Malaysia. Clean Energy 2023, 7, 1282–1299. [Google Scholar] [CrossRef]

- Hu, Y.-J.; Huang, H.; Wang, H.; Li, C.; Deng, Y. Exploring cost-effective strategies for emission reduction of public buildings in a life-cycle. Energy Build. 2023, 285, 112927. [Google Scholar] [CrossRef]

- Whittaker, D.H. Building a New Economy: Japan’s Digital and Green Transformation; Oxford University Press: New York, NY, USA, 2024. [Google Scholar]

- de Oliveira, C.T.; Luna, M.M.; Campos, L.M. Understanding the Brazilian expanded polystyrene supply chain and its reverse logistics towards circular economy. J. Clean. Prod. 2019, 235, 562–573. [Google Scholar] [CrossRef]

- Wu, Q.; Sun, Z.; Jiang, L.; Jiang, L. “Bottom-up” abatement on climate from the “top-down” design: Lessons learned from China’s low-carbon city pilot policy. Empir. Econ. 2024, 66, 1223–1257. [Google Scholar] [CrossRef]

| Component | Layers (From Exterior to Interior) | Total Thickness (mm) | U-Value (W/m2·K) |

|---|---|---|---|

| External Walls | Cement plaster (20 mm), Hollow blocks (225 mm), Cement plaster (10 mm) | 255 | 1.862 |

| Internal Walls | Cement plaster (12 mm), Hollow blocks (200 mm), Cement plaster (12 mm) | 224 | 1.408 |

| Roof (Pitched) | Cement plaster (20 mm), Reinforced concrete (319 mm), Ceramic tile (20 mm) | 359 | 3.218 |

| Doors | Plywood (3 mm), Foam-core plywood (34 mm), Plywood (3 mm) | 40 | 0.230 |

| Floor (ground) | Ceramic tile (10 mm), Concrete slab (150 mm), Compacted soil (304.8 mm) | 474.8 | 1.508 |

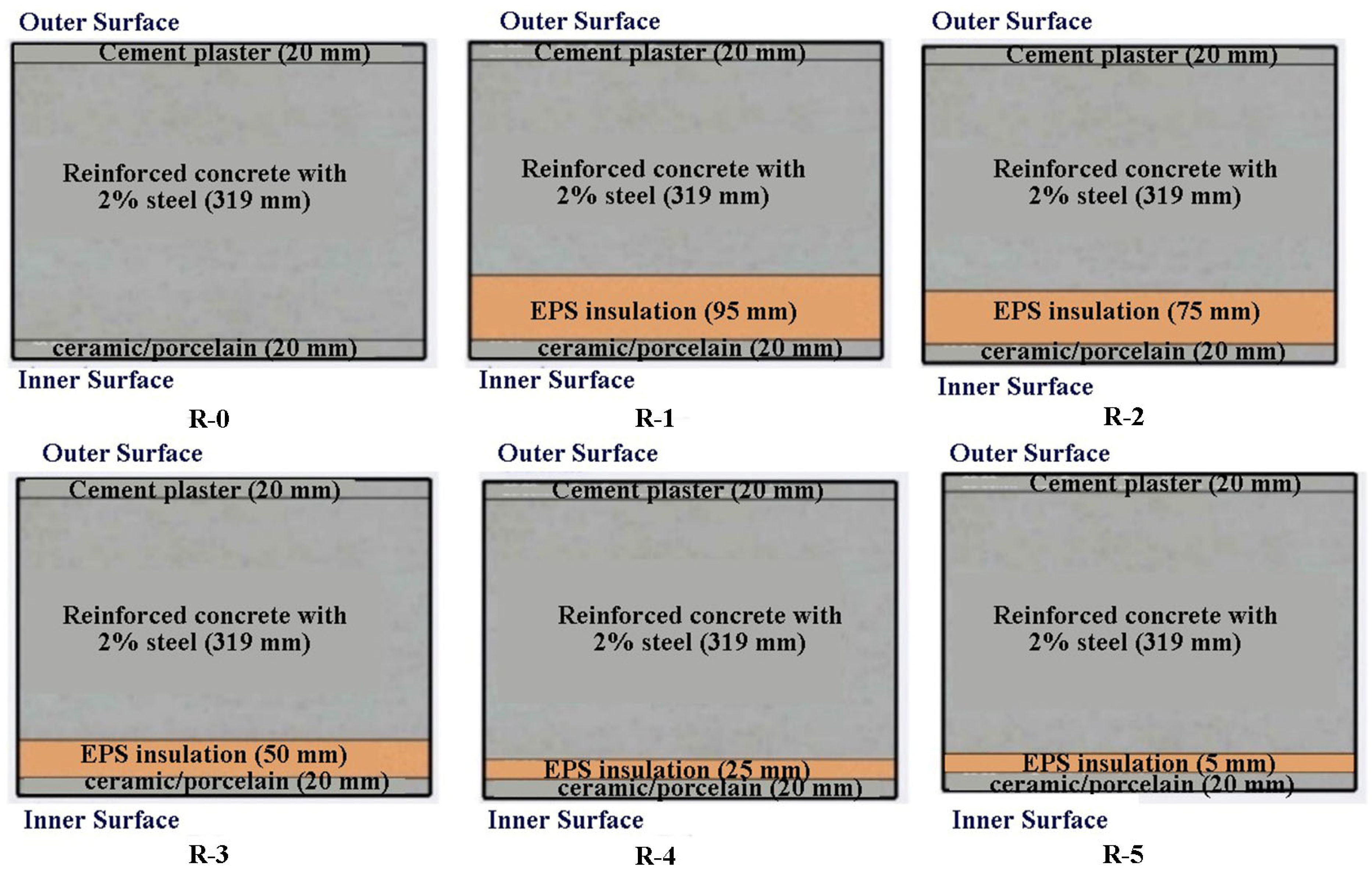

| Configuration | Layers (From Exterior to Interior) | Insulation Thickness (mm) | Total Thickness (mm) | U-Value (W/m2·K) |

|---|---|---|---|---|

| R-0 (Base Case) | Cement plaster, Reinforced concrete, Ceramic tile | 0 | 359 | 3.218 |

| R-1 | Cement plaster, Reinforced concrete, EPS, Ceramic tile | 95 | 454 | 0.424 |

| R-2 | Cement plaster, Reinforced concrete, EPS, Ceramic tile | 75 | 434 | 0.520 |

| R-3 | Cement plaster, Reinforced concrete, EPS, Ceramic tile | 50 | 409 | 0.725 |

| R-4 | Cement plaster, Reinforced concrete, EPS, Ceramic tile | 25 | 384 | 1.197 |

| R-5 | Cement plaster, Reinforced concrete, EPS, Ceramic tile | 5 | 364 | 1.962 |

| Parameter | Base Case: Single Glazing Aluminium Frame | Proposed Retrofit: Double Glazing Wood Frame |

|---|---|---|

| Glazing Configuration | 6 mm glass | 6 mm glass/13 mm air gap/6 mm glass |

| Frame Material | Aluminium | Wood |

| U-Value (W/m2·K) | 6.121 | 2.540 |

| Solar Heat Gain Coeff. (SHGC) | 0.810 | 0.698 |

| Visible Transmittance (VT) | 0.881 | 0.781 |

| Room | Weekday Schedule | Weekend Schedule | Equipment and Heat Gains | Notes |

|---|---|---|---|---|

| Double Bedroom | 9:00 PM–6:30 AM | 10:00 PM–9:00 AM | 70 W/person (sensible), 45 W/person (latent), 5 W/m2 | Same as weekday |

| Main Bedroom | 8:00 PM–6:30 AM | 10:00 PM–9:00 AM | Fans: 50 W, 3 W/m2 | Same as weekday |

| Living Room | 8:00 AM–10:00 PM, 4:00 PM–12:00 AM | 4:00 PM–12:00 AM | Fans: 50 W, TV: 120 W (4 h), Computer: 150 W (2 h) | Same as weekday |

| Kitchen-Dining | 5:00 AM–7:00 AM, 1:00–2:00 PM, 8:00–9:00 PM | 9:00–10:00 AM, 2:00–4:00 PM, 8:00–10:00 PM | Cooking: 150 W (2 h), Refrigerator: 150 W, 5 W/m2 | Same as weekday |

| Month | Energy Monthly Consumption (kWh) | Difference (kWh) (mi − si) | Difference % | |

|---|---|---|---|---|

| Actual (kWh) Measured (mi) | Simulated (kWh) (si) | |||

| January | 311.61 | 293.08 | 18.53 | 5.48% |

| February | 291.27 | 310.44 | −19.17 | −6.59 |

| March | 185.78 | 189.04 | −3.26 | −1.22% |

| April | 365.82 | 370.69 | −4.87 | −1.97 |

| May | 383.36 | 384.72 | −1.36 | −0.36 |

| June | 1100.16 | 1106.61 | −6.45 | −0.59 |

| July | 1196.18 | 1228.94 | −32.76 | −2.74 |

| August | 627.86 | 625.79 | 2.07 | 0.33 |

| September | 282.96 | 274.64 | 8.32 | 2.93 |

| October | 315.47 | 326.38 | −10.91 | −3.47 |

| November | 144.42 | 145.68 | −1.26 | −0.87 |

| December | 132.20 | 135.97 | −3.77 | −2.10 |

| Annually | 5337.09 | 5392.04 | ||

| Mean (measured values m˜) | 401.17 | 550.98 | ||

| (NMBE) | −4.65 | |||

| (CV(RMSE)) | 3.64% | |||

| Design Scenario | Energy Consumption (kWh) | Energy Consumption Reduction (%) | CO2 Emissions (×103 kg) | Energy Consumption Reduction (%) |

|---|---|---|---|---|

| Base Case | 5392.04 | - | 3.27 | - |

| Double-Glazed Windows Only | 4894.22 | 9.23 | 2.97 | 9.17 |

| 95 mm EPS Roof Insulation Only | 3767.28 | 30.13 | 2.28 | 30.27 |

| Design Scenario | Energy Consumption (kWh) | Energy Consumption Reduction (%) | CO2 Emissions (×103 kg) | CO2 Emissions Reduction (%) |

|---|---|---|---|---|

| Base Case | 5392.04 | - | 3.27 | - |

| Combined Strategy (95 mm EPS Roof Insulation and Double-Glazed Windows) | 3118.69 | 42.16 | 1.89 | 42.20 |

| Component | Unit Cost (MZN) | Quantity | Total Cost (MZN) | Total Cost (USD) |

|---|---|---|---|---|

| EPS Roof Insulation | 507.02/m2 | 80 m2 | 40,561.60 | 644.00 |

| Double-Glazed Windows | 3800.77/unit | 9 | 34,206.93 | 543.00 |

| Labour (2 workers) | 1128.04/worker | 7 days | 15,793.18 | 250.68 |

| Total Initial Investment | 90,561.71 | 1437.68 |

| Glazing Option | Initial Cost (MZN) | Annual Maintenance (MZN) | Replacement Cost (MZN) | TCO (Nominal, MZN) | NPV (5% Discount, MZN) |

|---|---|---|---|---|---|

| Single Glazing (6 mm) | 10,000.00 | 500.00 | 5000.00 (Yr 10) | 25,000.00 | 15,443.47 |

| Double Glazing (6 mm/13 mm Air) | 34,206.93 | 200.00 | 0.00 (No replacement) | 38,206.93 | 36,670.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazaro, S.A.M.; Li, X.; Baba, V.F. Building Envelope Renovation for Energy Efficiency in Maputo, Mozambique: Expanded Polystyrene Insulation and Double-Glazed Windows. Environ. Earth Sci. Proc. 2025, 34, 9. https://doi.org/10.3390/eesp2025034009

Lazaro SAM, Li X, Baba VF. Building Envelope Renovation for Energy Efficiency in Maputo, Mozambique: Expanded Polystyrene Insulation and Double-Glazed Windows. Environmental and Earth Sciences Proceedings. 2025; 34(1):9. https://doi.org/10.3390/eesp2025034009

Chicago/Turabian StyleLazaro, Samuel Aires Master, Xiangyu Li, and Vanessa Fathia Baba. 2025. "Building Envelope Renovation for Energy Efficiency in Maputo, Mozambique: Expanded Polystyrene Insulation and Double-Glazed Windows" Environmental and Earth Sciences Proceedings 34, no. 1: 9. https://doi.org/10.3390/eesp2025034009

APA StyleLazaro, S. A. M., Li, X., & Baba, V. F. (2025). Building Envelope Renovation for Energy Efficiency in Maputo, Mozambique: Expanded Polystyrene Insulation and Double-Glazed Windows. Environmental and Earth Sciences Proceedings, 34(1), 9. https://doi.org/10.3390/eesp2025034009