A Review of Methods for Improving Microwave Heating Uniformity

Abstract

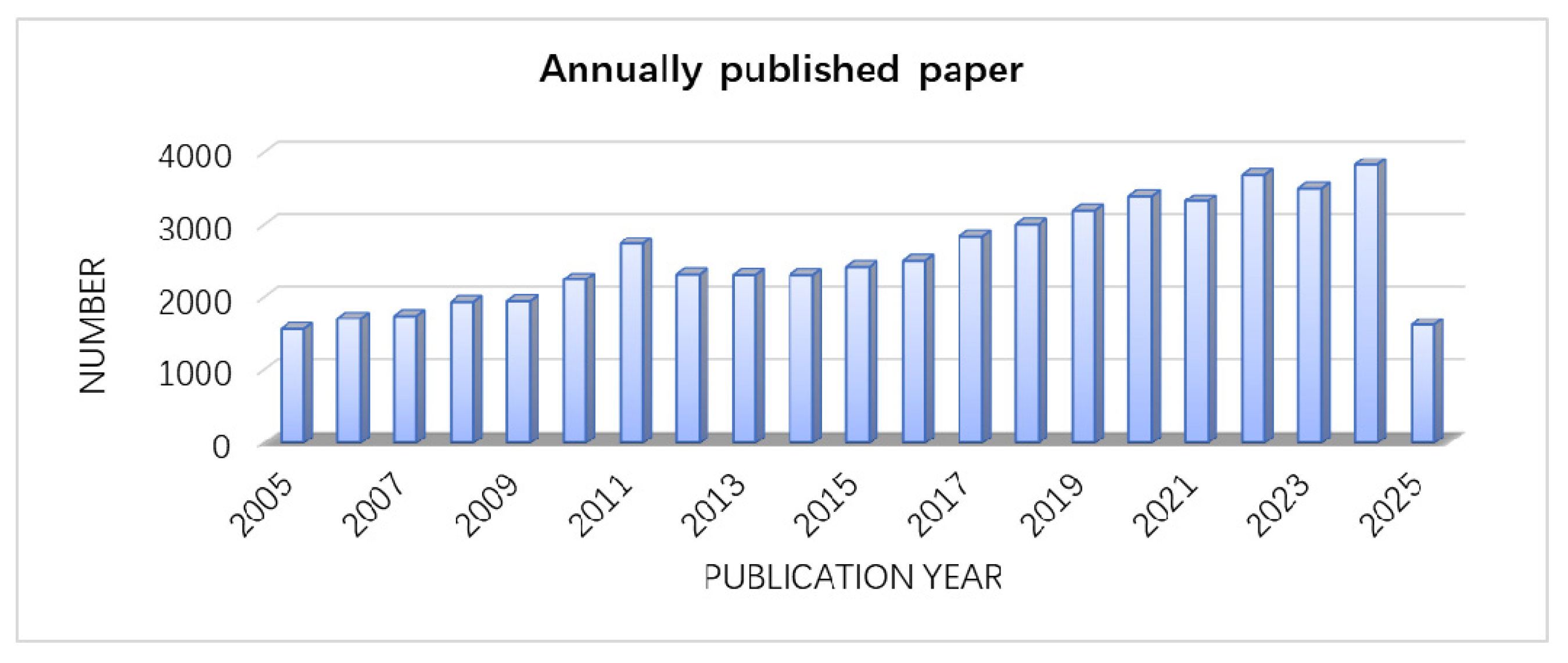

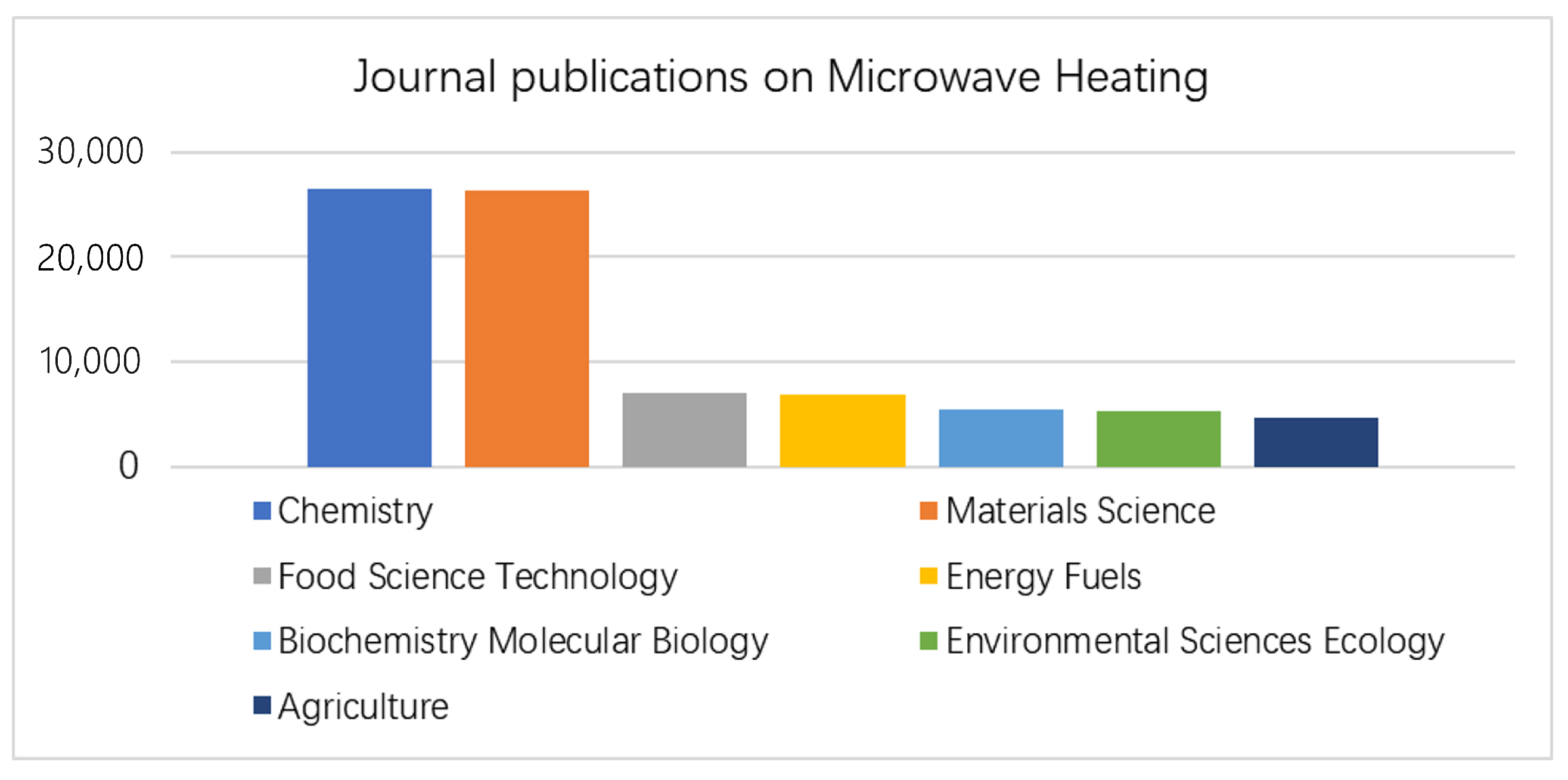

1. Introduction

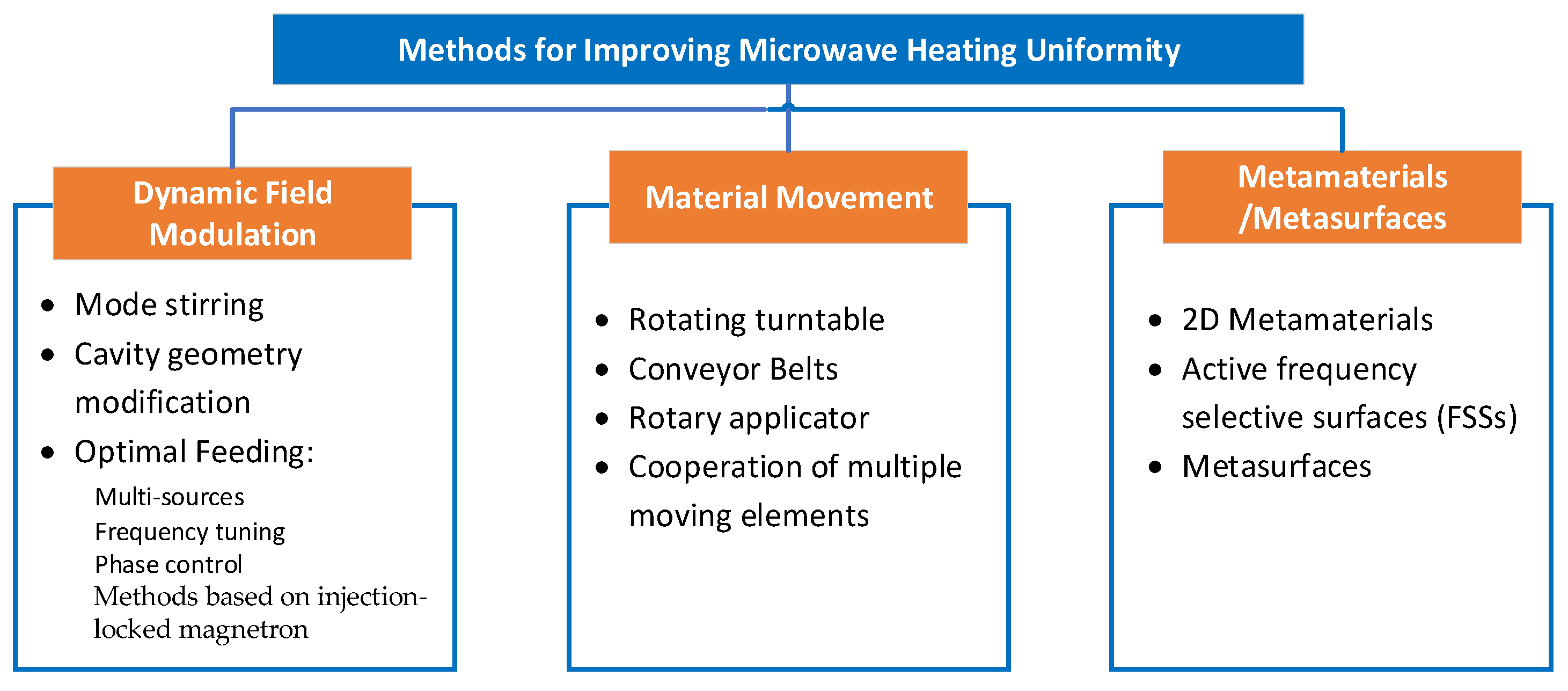

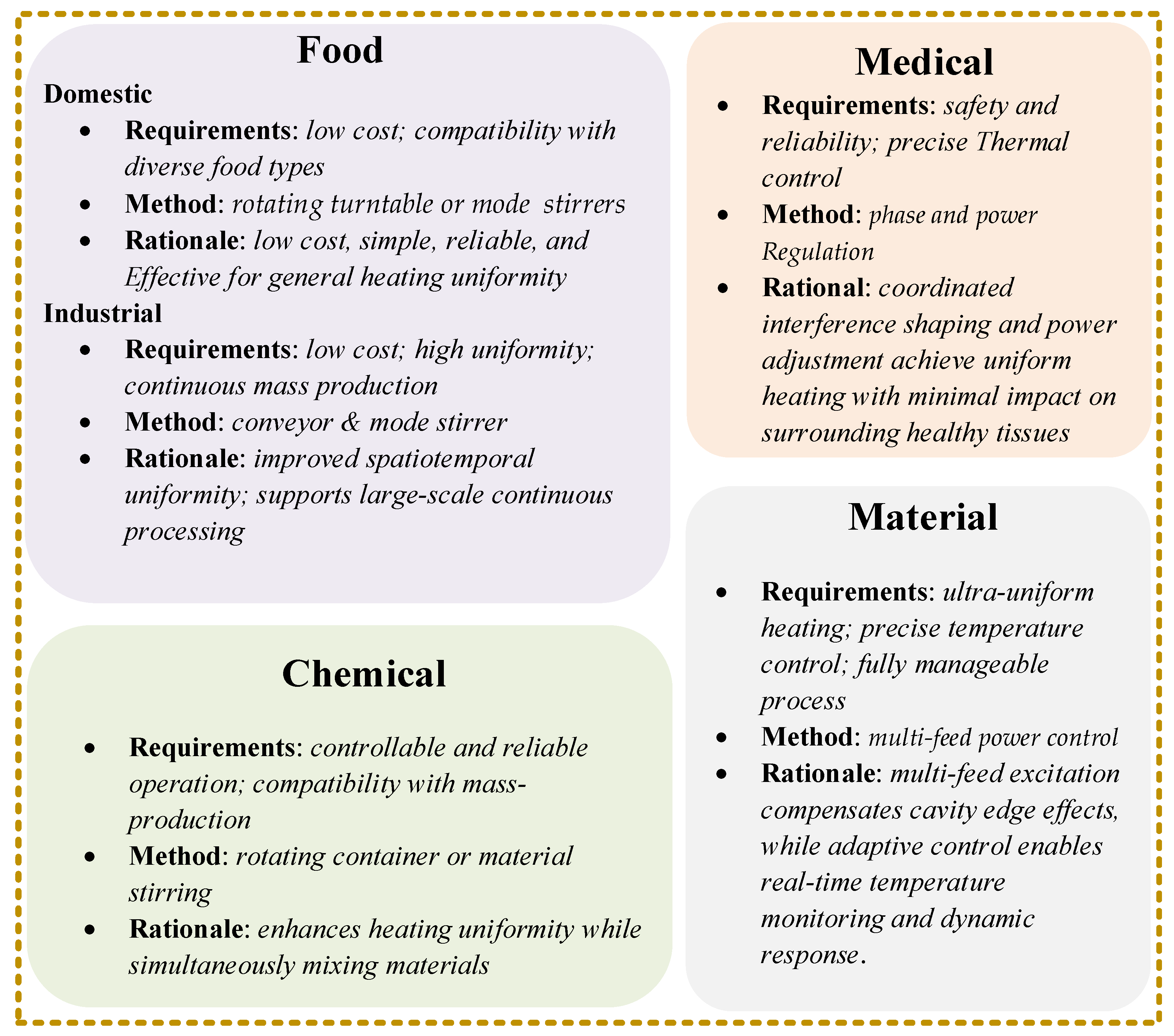

2. Strategies for Dynamic Field Modulation to Enhance Heating Uniformity

2.1. Mode Stirring-Based Techniques

2.2. Cavity Geometry Modification-Based Techniques

2.3. Optimal Feeding-Based Methods

2.3.1. Multiple Sources and Rotary Feeding Ports

2.3.2. Frequency-Tuning Strategies

2.3.3. Phase-Controlled Method

2.3.4. Methods Based on Injection-Locked Magnetron

3. Enhancing Uniformity via Material Movement

3.1. Rotating Turntable

3.2. Conveyor Belts and Other Moving Elements

3.3. Cooperation of Mode Stirrer and Material Movement

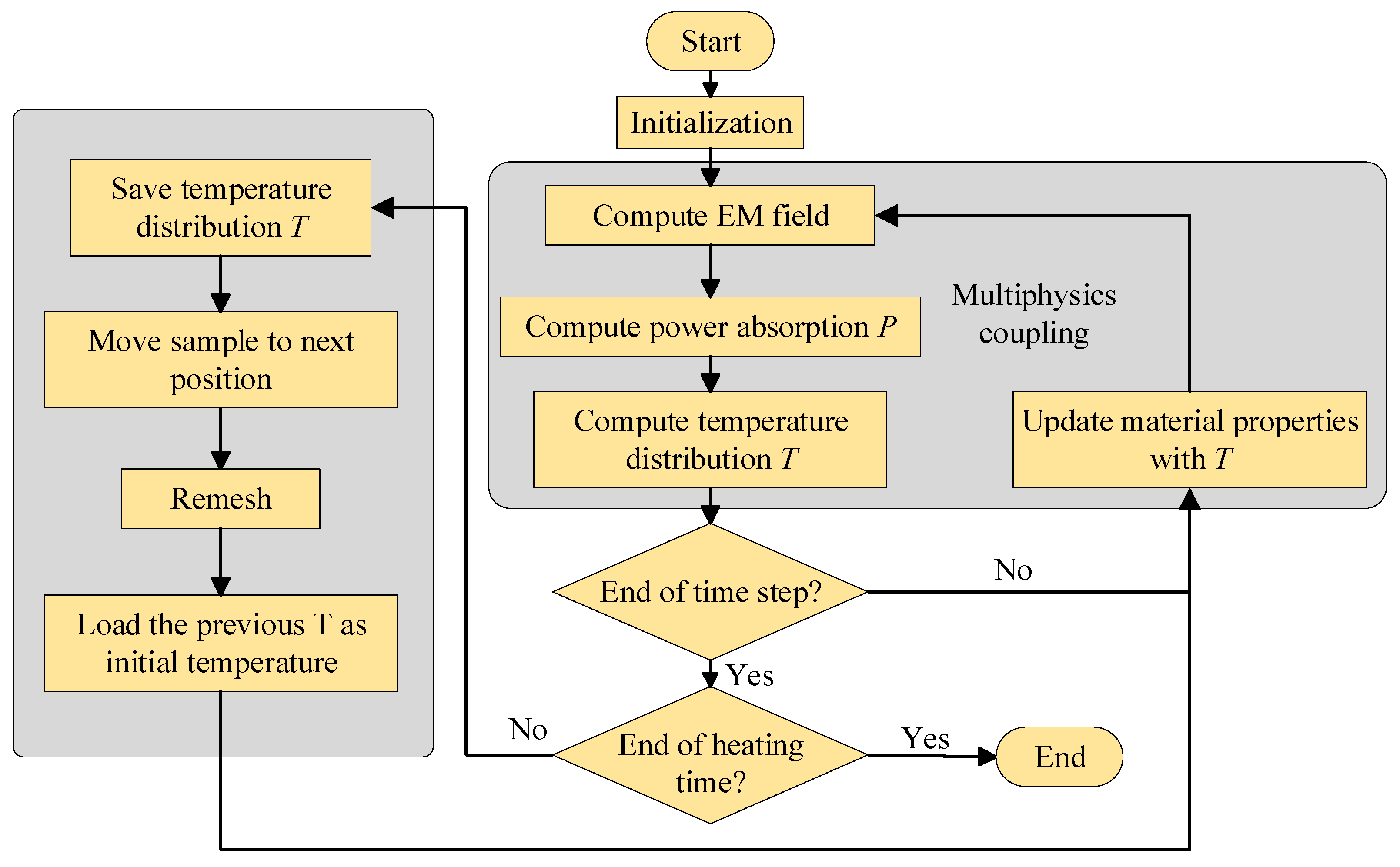

3.4. Numerical Modeling for Heating Systems with Moving Components

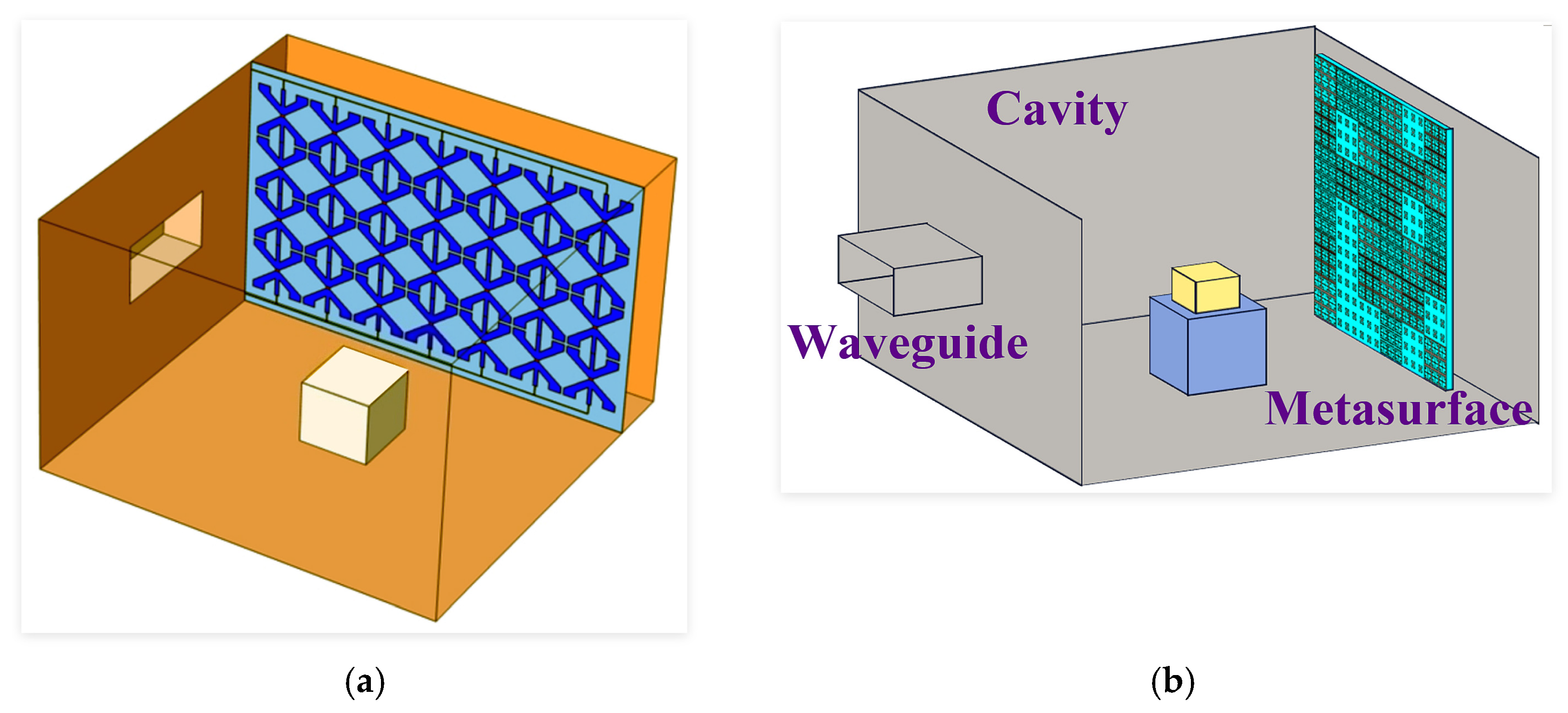

4. Innovative Approaches Based on Metamaterials/Metasurfaces

4.1. Metamaterial-Based Method

4.2. Frequency Selective Surface-Based Method

4.3. Metasurface-Based Method

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ferrera-Lorenzo, N.; Fuente, E.; Suárez-Ruiz, I.; Ruiz, B. KOH Activated Carbon from Conventional and Microwave Heating System of a Macroalgae Waste from the Agar–Agar Industry. Fuel Process. Technol. 2014, 121, 25–31. [Google Scholar] [CrossRef]

- Hong, Y.; Lin, B.; Li, H.; Dai, H.; Zhu, C.; Yao, H. Three-Dimensional Simulation of Microwave Heating Coal Sample with Varying Parameters. Appl. Therm. Eng. 2016, 93, 1145–1154. [Google Scholar] [CrossRef]

- Ma, W.; Hong, T.; Xie, T.; Wang, F.; Luo, B.; Zhou, J.; Yang, Y.; Zhu, H.; Huang, K. Simulation and Analysis of Oleic Acid Pretreatment for Microwave-Assisted Biodiesel Production. Processes 2018, 6, 142. [Google Scholar] [CrossRef]

- Shen, L.; Zhou, J.; Zhang, X. In Situ Investigation of the Thermal Characteristics of Microwave Resonance-Induced Focused Hotspots in Dimers for Improving Microwave Heating Uniformity. Case Stud. Therm. Eng. 2024, 54, 104052. [Google Scholar] [CrossRef]

- Lu, D.; Fu, C.; Jiang, X.; Chen, Z.; Qu, F.; Huo, Y.; Leng, Z.; Zhong, J. Sustainable Microwave-Heating Healing Asphalt Concrete Incorporating Functional Aggregates and Waste Ferrite. Transp. Res. Part D Transp. Environ. 2024, 129, 104117. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Microwave Processing: Fundamentals and Applications. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1055–1071. [Google Scholar] [CrossRef]

- Schwenke, A.M.; Hoeppener, S.; Schubert, U.S. Synthesis and Modification of Carbon Nanomaterials Utilizing Microwave Heating. Adv. Mater. 2015, 27, 4113–4141. [Google Scholar] [CrossRef]

- Bengtsson, N.E.; Ohlsson, T. Microwave Heating in the Food Industry. Proc. IEEE 1974, 62, 44–55. [Google Scholar] [CrossRef]

- Costa, R.M.; Oliveira, F.A.R.; Delaney, O.; Gekas, V. Analysis of the Heat Transfer Coefficient during Potato Frying. J. Food Eng. 1999, 39, 293–299. [Google Scholar] [CrossRef]

- Raaholt, B.W.; Isaksson, S.; Hamberg, L.; Fhager, A.; Hamnerius, Y. Continuous Tubular Microwave Heating of Homogeneous Foods: Evaluation of Heating Uniformity. J. Microw. Power Electromagn. Energy 2016, 50, 43–65. [Google Scholar] [CrossRef]

- Huang, Z.; Marra, F.; Wang, S. A Novel Strategy for Improving Radio Frequency Heating Uniformity of Dry Food Products Using Computational Modeling. Innov. Food Sci. Emerg. Technol. 2016, 34, 100–111. [Google Scholar] [CrossRef]

- Wu, Y.; Mu, R.; Li, G.; Li, M.; Lv, W. Research Progress in Fluid and Semifluid Microwave Heating Technology in Food Processing. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3436–3454. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, C.; Zheng, X.; Zhao, X.; Shen, L.; Gao, M. Analysis of Microwave Heating Uniformity in Berry Puree: From Electromagnetic-Wave Dissipation to Heat and Mass Transfer. Innov. Food Sci. Emerg. Technol. 2023, 90, 103509. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, W.; Fan, K. Recent Advances in Combined Ultrasound and Microwave Treatment for Improving Food Processing Efficiency and Quality: A Review. Food Biosci. 2024, 58, 103683. [Google Scholar] [CrossRef]

- Mashal, A.; Sitharaman, B.; Li, X.; Avti, P.K.; Sahakian, A.V.; Booske, J.H.; Hagness, S.C. Toward Carbon-Nanotube-Based Theranostic Agents for Microwave Detection and Treatment of Breast Cancer: Enhanced Dielectric and Heating Response of Tissue-Mimicking Materials. IEEE Trans. Biomed. Eng. 2010, 57, 1831–1834. [Google Scholar] [CrossRef]

- Li, S.; Chen, Z.; Guo, W.; Tan, L.; Wu, Q.; Ren, X.; Fu, C.; Wang, Q.; Huang, Z.; Meng, X. H2S-Mediated Gas Therapy and HSP90 Downregulation Synergically Enhance Tumor Microwave Thermal Therapy. Adv. Funct. Mater. 2024, 34, 2314742. [Google Scholar] [CrossRef]

- Liu, H.; E, J.; Deng, Y.; Xie, C.; Zhu, H. Experimental Study on Pyrolysis Characteristics of the Tobacco Stem Based on Microwave Heating Method. Appl. Therm. Eng. 2016, 106, 473–479. [Google Scholar] [CrossRef]

- Guo, Q.; Sun, D.-W.; Cheng, J.-H.; Han, Z. Microwave Processing Techniques and Their Recent Applications in the Food Industry. Trends Food Sci. Technol. 2017, 67, 236–247. [Google Scholar] [CrossRef]

- Choi, E.J.; Park, H.W.; Chung, Y.B.; Park, S.H.; Kim, J.S.; Chun, H.H. Effect of Tempering Methods on Quality Changes of Pork Loin Frozen by Cryogenic Immersion. Meat Sci. 2017, 124, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Fan, Q.-Y.; Zhou, Y.; Zhang, M.; Ma, B.; Yang, T.; Long, H.; Yu, Z.; Li, Z. Microwave Ablation of Primary Malignant Pelvic Bone Tumors. Front. Surg. 2019, 6, 5. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, L.; Moser, M.A.J.; Zhang, W.; Zhang, B. A Review of Antenna Designs for Percutaneous Microwave Ablation. Phys. Med. 2021, 84, 254–264. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Wang, L.; Bao, X.; Cheng, Q.S.; Ye, X.; He, M. Dual-Frequency Microwave Ablation Antenna with Tunable Directional-Ratio for Tumor Treatment. IEEE Trans. Antennas Propag. 2025, 73, 6357–6366. [Google Scholar] [CrossRef]

- Sweeney, C.B.; Lackey, B.A.; Pospisil, M.J.; Achee, T.C.; Hicks, V.K.; Moran, A.G.; Teipel, B.R.; Saed, M.A.; Green, M.J. Welding of 3D-Printed Carbon Nanotube–Polymer Composites by Locally Induced Microwave Heating. Sci. Adv. 2017, 3, e1700262. [Google Scholar] [CrossRef]

- Pandit, R.B.; Prasad, S. Finite Element Analysis of Microwave Heating of Potato––Transient Temperature Profiles. J. Food Eng. 2003, 60, 193–202. [Google Scholar] [CrossRef]

- Basak, T.; Aparna, K.; Meenakshi, A.; Balakrishnan, A.R. Effect of Ceramic Supports on Microwave Processing of Porous Food Samples. Int. J. Heat Mass Transf. 2006, 49, 4325–4339. [Google Scholar] [CrossRef]

- Pitchai, K.; Birla, S.L.; Subbiah, J.; Jones, D.; Thippareddi, H. Coupled Electromagnetic and Heat Transfer Model for Microwave Heating in Domestic Ovens. J. Food Eng. 2012, 112, 100–111. [Google Scholar] [CrossRef]

- Vaz, R.H.; Pereira, J.M.C.; Ervilha, A.R.; Pereira, J.C.F. Simulation and Uncertainty Quantification in High Temperature Microwave Heating. Appl. Therm. Eng. 2014, 70, 1025–1039. [Google Scholar] [CrossRef]

- Su, T.; Zhang, W.; Zhang, Z.; Wang, X.; Zhang, S. Energy Utilization and Heating Uniformity of Multiple Specimens Heated in a Domestic Microwave Oven. Food Bioprod. Process. 2022, 132, 35–51. [Google Scholar] [CrossRef]

- Ravikumar, M.; Srinath, M.K.; Ganesha Prasad, M.S. Thermal Modelling of Microwave Dehydration of Fruit Slice. Case Stud. Therm. Eng. 2023, 51, 103543. [Google Scholar] [CrossRef]

- Gao, T.; Sun, D.-W.; Tian, Y.; Ma, J.; Cheng, J.-H. Multiphysics Modelling of Constant Power Microwave Heating of Model Juice. Int. J. Therm. Sci. 2024, 198, 108888. [Google Scholar] [CrossRef]

- Sun, J.; Wang, W.; Yue, Q. Review on Microwave-Matter Interaction Fundamentals and Efficient Microwave-Associated Heating Strategies. Materials 2016, 9, 231. [Google Scholar] [CrossRef]

- Galema, S.A. Microwave Chemistry. Chem. Soc. Rev. 1997, 26, 233–238. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Non-Uniform Temperature Distribution During Microwave Heating of Food Materials—A Review. Food Bioprocess Technol. 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Amini, A.; Latifi, M.; Chaouki, J. Electrification of Materials Processing via Microwave Irradiation: A Review of Mechanism and Applications. Appl. Therm. Eng. 2021, 193, 117003. [Google Scholar] [CrossRef]

- Jacob, J.; Chia, L.H.L.; Boey, F.Y.C. Thermal and Non-Thermal Interaction of Microwave Radiation with Materials. J. Mater. Sci. 1995, 30, 5321–5327. [Google Scholar] [CrossRef]

- Vasudev, H.; Singh, G.; Bansal, A.; Vardhan, S.; Thakur, L. Microwave Heating and Its Applications in Surface Engineering: A Review. Mater. Res. Express 2019, 6, 102001. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave Food Processing—A Review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Salazar-González, C.; San Martín-González, M.F.; López-Malo, A.; Sosa-Morales, M.E. Recent Studies Related to Microwave Processing of Fluid Foods. Food Bioprocess Technol. 2012, 5, 31–46. [Google Scholar] [CrossRef]

- Menéndez, J.A.; Arenillas, A.; Fidalgo, B.; Fernández, Y.; Zubizarreta, L.; Calvo, E.G.; Bermúdez, J.M. Microwave Heating Processes Involving Carbon Materials. Fuel Process. Technol. 2010, 91, 1–8. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–Material Interaction Phenomena: Heating Mechanisms, Challenges and Opportunities in Material Processing. Compos. Part A Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Zaker, A.; Chen, Z.; Wang, X.; Zhang, Q. Microwave-Assisted Pyrolysis of Sewage Sludge: A Review. Fuel Process. Technol. 2019, 187, 84–104. [Google Scholar] [CrossRef]

- Farag, S.; Sobhy, A.; Akyel, C.; Doucet, J.; Chaouki, J. Temperature Profile Prediction within Selected Materials Heated by Microwaves at 2.45GHz. Appl. Therm. Eng. 2012, 36, 360–369. [Google Scholar] [CrossRef]

- Sebera, V.; Nasswettrová, A.; Nikl, K. Finite Element Analysis of Mode Stirrer Impact on Electric Field Uniformity in a Microwave Applicator. Dry. Technol. 2012, 30, 1388–1396. [Google Scholar] [CrossRef]

- Hu, J.; Xu, H.; Shi, R.; Gantumur, M.-A.; Jiang, Z.; Hou, J. Emerging Thermal Modifying Methods in Milk Protein: A Review. Trends Food Sci. Technol. 2024, 146, 104407. [Google Scholar] [CrossRef]

- Plaza-Gonzalez, P.; Monzo-Cabrera, J.; Catala-Civera, J.M.; Sanchez-Hernandez, D. Effect of Mode-Stirrer Configurations on Dielectric Heating Performance in Multimode Microwave Applicators. IEEE Trans. Microw. Theory Tech. 2005, 53, 1699–1706. [Google Scholar] [CrossRef]

- Cuccurullo, G.; Giordano, L.; Metallo, A.; Cinquanta, L. Influence of Mode Stirrer and Air Renewal on Controlled Microwave Drying of Sliced Zucchini. Biosyst. Eng. 2017, 158, 95–101. [Google Scholar] [CrossRef]

- Ye, J.; Lan, J.; Xia, Y.; Yang, Y.; Zhu, H.; Huang, K. An Approach for Simulating the Microwave Heating Process with a Slow-Rotating Sample and a Fast-Rotating Mode Stirrer. Int. J. Heat Mass Transf. 2019, 140, 440–452. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, X.; Qiu, Y. Double Pendulum Mode Stirrer for Improved Multimode Microwave Heating Performance. Int. J. RF Microw. Comput.-Aided Eng. 2021, 31, e22866. [Google Scholar] [CrossRef]

- Wang, J.; Yao, B.; Zheng, Q.; Liu, Y.; Xiang, T.; Zhong, R. Improvement of Microwave Heating Efficiency and Uniformity by Controllable Rotary Columns Array. IEEE Trans. Microw. Theory Tech. 2023, 71, 3517–3529. [Google Scholar] [CrossRef]

- Wu, Y.; Yan, B.; Yang, Y.; Zhu, H.; Huang, K. Accordion Microwave Oven for Uniformity and Efficiency Heating. Int. J. RF Microw. Comput.-Aided Eng. 2020, 30, e22190. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, Y.; Yang, X.-Q. Shape Optimization of Microwave Cavity Using Arbitrary Lagrangian–Euler Method to Improve the Heating Uniformity. IEEE Trans. Microw. Theory Tech. 2022, 70, 1932–1942. [Google Scholar] [CrossRef]

- Dominguez-Tortajada, E.; Plaza-Gonzalez, P.; Diaz-Morcillo, A.; Balbastre, J.V. Optimisation of Electric Field Uniformity in Microwave Heating Systems by Means of Multi-Feeding and Genetic Algorithms. Int. J. Mater. Prod. Technol. 2007, 29, 149–162. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Jeong, C.-H.; Lim, D.-M.; Lee, W.-S. Kilowatt-Level Power-Controlled Microwave Applicator with Multiple Slotted Waveguides for Improving Heating Uniformity. IEEE Trans. Microw. Theory Tech. 2020, 68, 2867–2875. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Lee, W.-S. Uniform Microwave Heating System Design and Evaluation with an Orthogonally Slot-Loaded Array Waveguide. Microw. Opt. Technol. Lett. 2020, 62, 3419–3424. [Google Scholar] [CrossRef]

- Cheng, C.; Yang, B.; Li, B.; Xiao, Q.; Gao, H. Double-Layered Model Predictive Optimization Control Strategy for Temperature Uniformity of Microwave Heating Process. Case Stud. Therm. Eng. 2022, 40, 102544. [Google Scholar] [CrossRef]

- Yang, B.; Han, Z.; Cheng, C.; Gao, H.; Wu, Z. Temperature Uniformity Optimization with Power-Frequency Coordinated Variation in Multi-Source Microwave Based on Sequential Quadratic Programming. High Temp. Mater. Process. 2023, 42, 20220279. [Google Scholar] [CrossRef]

- Yang, B.; Chen, X.; Cheng, C.; Han, Z.; Chen, Y.; Zhang, H. Optimization of Variable Power Heating Efficiency and Temperature Uniformity for Multi-Source Microwave Gaming Based on Gradient Descent Algorithm. J. Therm. Anal. Calorim. 2025, 150, 9265–9278. [Google Scholar] [CrossRef]

- Seo, J.; Han, G.; Hwang, H. Uniform Temperature Distribution in Microwave Heating Achieved via Rotating Electric Field. Sci. Rep. 2025, 15, 17960. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; He, J.; Hong, T.; Yang, Q.; Wu, Y.; Yang, Y.; Huang, K. A Rotary Radiation Structure for Microwave Heating Uniformity Improvement. Appl. Therm. Eng. 2018, 141, 648–658. [Google Scholar] [CrossRef]

- He, J.; Yang, Y.; Zhu, H.; Li, K.; Yao, W.; Huang, K. Microwave Heating Based on Two Rotary Waveguides to Improve Efficiency and Uniformity by Gradient Descent Method. Appl. Therm. Eng. 2020, 178, 115594. [Google Scholar] [CrossRef]

- Fathi, Z.; Tucker, D.A.; Lewis, W.A.; Wei, J.B. Industrial Applications of Variable Frequency Microwave Energy in Materials Processing. MRS Online Proc. Libr. 1996, 430, 21–28. [Google Scholar] [CrossRef]

- Antonio, C.; Deam, R.T. Comparison of Linear and Non-Linear Sweep Rate Regimes in Variable Frequency Microwave Technique for Uniform Heating in Materials Processing. J. Mater. Process. Technol. 2005, 169, 234–241. [Google Scholar] [CrossRef]

- Taghian Dinani, S.; Feldmann, E.; Kulozik, U. Effect of Heating by Solid-State Microwave Technology at Fixed Frequencies or by Frequency Sweep Loops on Heating Profiles in Model Food Samples. Food Bioprod. Process. 2021, 127, 328–337. [Google Scholar] [CrossRef]

- Tang, Z.; Hong, T.; Liao, Y.; Chen, F.; Ye, J.; Zhu, H.; Huang, K. Frequency-Selected Method to Improve Microwave Heating Performance. Appl. Therm. Eng. 2018, 131, 642–648. [Google Scholar] [CrossRef]

- Yuanyuan, W.; Junqing, L.; Fengming, Y.; Tao, H.; Yang, Y.; Huacheng, Z.; Zhengming, T. Study of the High Heating Efficiency and Uniformity by Multi-Port Sweep Frequency Microwave Irradiations. J. Microw. Power Electromagn. Energy 2021, 55, 316–332. [Google Scholar] [CrossRef]

- Yang, R.; Fathy, A.E.; Morgan, M.T.; Chen, J. Development of a Complementary-Frequency Strategy to Improve Microwave Heating of Gellan Gel in a Solid-State System. J. Food Eng. 2022, 314, 110763. [Google Scholar] [CrossRef]

- Yang, R.; Fathy, A.E.; Morgan, M.T.; Chen, J. Development of Online Closed-Loop Frequency Shifting Strategies to Improve Heating Performance of Foods in a Solid-State Microwave System. Food Res. Int. 2022, 154, 110985. [Google Scholar] [CrossRef]

- Yang, R.; Chen, J. Heating Performance of Dual-Source Microwave Heating Using Different Frequency Shifting Strategies in a Solid-State System. Food Res. Int. 2024, 175, 113781. [Google Scholar] [CrossRef]

- Du, M.; Zhang, Z.; Huang, J.; Zhu, H.; Yang, Y. Study of Multi-Frequency Heating Based on the Nonlinear Response Characteristics of Magnetron to Improve Uniformity. J. Microw. Power Electromagn. Energy 2023, 57, 71–88. [Google Scholar] [CrossRef]

- Kalinke, I.; Pusl, F.; Kulozik, U. Enhancing Uniformity and Energy Efficiency of Microwave Heating for Different Cavity Loads: Frequency-Shifting Strategies Using Feedback Signals from Solid-State Microwave Generators. Innov. Food Sci. Emerg. Technol. 2024, 97, 103814. [Google Scholar] [CrossRef]

- Campañone, L.A.; Bava, J.A.; Mascheroni, R.H. Modeling and Process Simulation of Controlled Microwave Heating of Foods by Using of the Resonance Phenomenon. Appl. Therm. Eng. 2014, 73, 914–923. [Google Scholar] [CrossRef]

- Bows, J.R.; Patrick, M.L.; Janes, R.; Dibben, D.C. Microwave Phase Control Heating. Int. J. Food Sci. Technol. 1999, 34, 295–304. [Google Scholar] [CrossRef]

- Wang, C.; Yao, W.; Zhu, H.; Yang, Y.; Yan, L. Uniform and Highly Efficient Microwave Heating Based on Dual-Port Phase-Difference-Shifting Method. Int. J. RF Microw. Comput.-Aided Eng. 2021, 31, e22784. [Google Scholar] [CrossRef]

- Liao, Y.; Lan, J.; Zhang, C.; Hong, T.; Yang, Y.; Huang, K.; Zhu, H. A Phase-Shifting Method for Improving the Heating Uniformity of Microwave Processing Materials. Materials 2016, 9, 309. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yang, B.; Shinohara, N.; Liu, C. Low-noise dual-way magnetron power-combining system using an asymmetric H-plane tee and closed-loop phase compensation. IEEE Trans. Microw. Theory Tech. 2021, 69, 2267–2278. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Yang, M.; Wu, P.; Huang, K.; Liu, C. Experimental studies on a four-way microwave power combining system based on hybrid injection-locked 20-kW S-band magnetrons. IEEE Trans. Plasma Sci. 2019, 47, 243–250. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Wan, J.; Wu, P.; Yang, M.; Huang, K.; Liu, C. Phase-shifterless power controlled combining based on 20-kW S-band magnetrons with an asymmetric injection. IEEE Electron. Device Lett. 2018, 39, 1425–1428. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, X.; Chen, X.; He, D.; He, Z.; Yan, L.; Liu, C. High-Efficiency Isolator-Free Magnetron Power Combining Method Based on H-Plane Tee Coupling and Peer-to-Peer Locking. IEEE Trans. Microw. Theory Tech. 2025, 73, 9429–9441. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Y.; Chen, X.; Liu, C. A Novel Stability Improvement Method of S-Band Magnetron Systems Based on Its Anode Current Feature. IEEE Trans. Microw. Theory Tech. 2024, 72, 5530–5539. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, S.; He, D.; Yan, L.; Hu, J.; Liu, C. Study on Improving Microwave Heating Uniformity Based on Phase–Frequency Simultaneous Modulation Technique. IEEE Microw. Wirel. Technol. Lett. 2025, 35, 1871–1874. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; He, Z.; Liu, C. Experimental Study of Magnetron’s Power-Pulled Characteristic to Realize a Quasi-Dual-Frequency Microwave Output. Electronics 2024, 13, 1323. [Google Scholar] [CrossRef]

- Geedipalli, S.S.R.; Rakesh, V.; Datta, A.K. Modeling the Heating Uniformity Contributed by a Rotating Turntable in Microwave Ovens. J. Food Eng. 2007, 82, 359–368. [Google Scholar] [CrossRef]

- Pedreño-Molina, J.L.; Monzó-Cabrera, J.; Catalá-Civera, J.M. Sample Movement Optimization for Uniform Heating in Microwave Heating Ovens. Int. J. RF Microw. Comput.-Aided Eng. 2007, 17, 142–152. [Google Scholar] [CrossRef]

- Ye, J.; Hong, T.; Wu, Y.; Wu, L.; Liao, Y.; Zhu, H.; Yang, Y.; Huang, K. Model Stirrer Based on a Multi-Material Turntable for Microwave Processing Materials. Materials 2017, 10, 95. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Lan, J.; Hong, T.; Zhu, H. Effect of the Rotating Metal Patch on Microwave Heating Uniformity. J. Microw. Power Electromagn. Energy 2018, 52, 94–108. [Google Scholar] [CrossRef]

- Yang, R.; Chen, J. Identification of Turntable Function in a Solid-State Microwave Heating Process with Diverse Frequency-Shifting Strategies Applied. Innov. Food Sci. Emerg. Technol. 2024, 94, 103670. [Google Scholar] [CrossRef]

- Seehra, M.S.; Kalra, A.; Manivannan, A. Dewatering of Fine Coal Slurries by Selective Heating with Microwaves. Fuel 2007, 86, 829–834. [Google Scholar] [CrossRef]

- Prasad, B.E.; Pandey, K.K. Microwave Drying of Bamboo. Eur. J. Wood Prod. 2012, 70, 353–355. [Google Scholar] [CrossRef]

- Bae, S.-H.; Jeong, M.-G.; Kim, J.-H.; Lee, W.-S. A Continuous Power-Controlled Microwave Belt Drier Improving Heating Uniformity. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 527–529. [Google Scholar] [CrossRef]

- Chao, H.-W.; Hsu, H.-C.; Chang, C.-J.; Jiang, J.-Y.; Chang, T.-H. Rotary Microwave Applicator for Rapid Drying and Uniform Heating. Rev. Sci. Instrum. 2025, 96, 034707. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, H.; Alapati, S.; Che, W.S. Effect of Mode Stirrers in a Multimode Microwave-Heating Applicator with the Conveyor Belt. Int. J. Precis. Eng. Manuf.-Green Tech. 2015, 2, 31–36. [Google Scholar] [CrossRef]

- Yi, Q.; Lan, J.; Ye, J.; Zhu, H.; Yang, Y.; Wu, Y.; Huang, K. A Simulation Method of Coupled Model for a Microwave Heating Process with Multiple Moving Elements. Chem. Eng. Sci. 2021, 231, 116339. [Google Scholar] [CrossRef]

- Zhu, H.; Ye, J.; Gulati, T.; Yang, Y.; Liao, Y.; Yang, Y.; Huang, K. Dynamic Analysis of Continuous-Flow Microwave Reactor with a Screw Propeller. Appl. Therm. Eng. 2017, 123, 1456–1461. [Google Scholar] [CrossRef]

- Yan, L.; Huang, K.; Liu, C.; Chen, X.; Zhao, X. Numerical analysis on microwave heating of fluid. ACTA Electron. Sin. 2001, 31, 667–670. [Google Scholar]

- Chen, J.; Pitchai, K.; Birla, S.; Negahban, M.; Jones, D.; Subbiah, J. Heat and Mass Transport during Microwave Heating of Mashed Potato in Domestic Oven--Model Development, Validation, and Sensitivity Analysis. J. Food Sci. 2014, 79, E1991-2004. [Google Scholar] [CrossRef]

- Liu, S.; Fukuoka, M.; Sakai, N. A Finite Element Model for Simulating Temperature Distributions in Rotating Food during Microwave Heating. J. Food Eng. 2013, 115, 49–62. [Google Scholar] [CrossRef]

- Zhu, H.-C.; Liao, Y.-H.; Xiao, W.; Ye, J.-H.; Huang, K.-M. Transformation Optics for Computing Heating Process in Microwave Applicators with Moving Elements. IEEE Trans. Microw. Theory Tech. 2017, 65, 1434–1442. [Google Scholar] [CrossRef]

- Ye, J.-H.; Zhu, H.-C.; Liao, Y.-H.; Zhou, Y.-P.; Huang, K.-M. Implicit Function and Level Set Methods for Computation of Moving Elements During Microwave Heating. IEEE Trans. Microw. Theory Tech. 2017, 65, 4773–4784. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.; Ye, J.; Zhu, H.; Yuan, J.; Li, X.; Huang, K. Arbitrary Lagrangian-Eulerian Method for Computation of Rotating Target during Microwave Heating. Int. J. Heat Mass Transf. 2019, 134, 271–285. [Google Scholar] [CrossRef]

- Ye, J.; Xu, C.; Zhang, C.; Zhu, H.; Huang, K.; Li, Q.; Wang, J.; Zhou, L.; Wu, Y. A Hybrid ALE/Implicit Function Method for Simulating Microwave Heating with Rotating Objects of Arbitrary Shape. J. Food Eng. 2021, 302, 110551. [Google Scholar] [CrossRef]

- Li, R.; Hong, T.; Liu, R.; Chen, H.; Yang, Y.; Zhu, H. Microwave Heating Multiphysics Computation of Moving Complex-Shaped Samples Based on Ray Casting Method. IEEE Trans. Microw. Theory Tech. 2025, 73, 2628–2639. [Google Scholar] [CrossRef]

- Smith, D.R.; Pendry, J.B.; Wiltshire, M.C.K. Metamaterials and Negative Refractive Index. Science 2004, 305, 788–792. [Google Scholar] [CrossRef]

- Yu, N.; Capasso, F. Flat Optics with Designer Metasurfaces. Nat. Mater. 2014, 13, 139–150. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Yao, B.; Zheng, Q.; Qi, J.; Xiang, T.; Zhong, R. Effect of Photonic Crystal Structure on Heating Efficiency and Uniformity of Rectangular Microwave Reaction Cavity. In Proceedings of the 2022 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Harbin, China, 12–15 August 2022. [Google Scholar]

- Mu, S.; Liu, Y.; Yang, Z.; Chen, X.; Yao, B.; Wang, J.; Yao, Y. Microwave Heating Chamber Loaded with Photonic Crystal. In Proceedings of the 4th International Conference on Electrical, Control and Instrumentation Engineering (ICECIE), Kuala Lumpur, Malaysia, 26 November 2022. [Google Scholar]

- Xu, C.; Shu, W.; Ye, J.; Yang, Y.; Huang, K.; Zhu, H. Electromagnetic Black Hole for Efficiency Microwave Heating Based on Gradient-Index Metamaterials in Multimode Cavities. IEEE Microw. Wirel. Compon. Lett. 2022, 32, 1235–1238. [Google Scholar] [CrossRef]

- Yan, L.; Xu, L.; Gao, R.X.; Zhang, J.; Yang, X.; Zhao, X. Angularly Independent Frequency Selective Surface with Good Ventilation for Millimeter Wave EM Shielding. IEEE Trans. Electromagn. Compat 2022, 64, 251–254. [Google Scholar] [CrossRef]

- Sun, Z.; Yan, L.; Zhao, X.; Gao, X.K. An Ultrawideband Frequency Selective Surface Absorber with High Polarization-Independent Angular Stability. IEEE Antennas Wirel. Propag. Lett. 2023, 22, 789–793. [Google Scholar] [CrossRef]

- Ai, J.; Hong, J.; Gao, X.K.; Liu, C.; Zhao, X.; Yan, L. Enhanced Equivalent Circuit Model-Aided Broadband Single-Lossy-Single-Lossless-Layer Rasorber Design with High Selectivity. IEEE Antennas Wirel. Propag. Lett. 2025, 24, 1080–1084. [Google Scholar] [CrossRef]

- Kim, D.; Kim, M.; Youn, Y.; Chang, S.; Lee, C.; Kim, J.; Oh, B.; Hong, W. Enhancing Microwave Heating Uniformity Using Reconfigurable Diffractive Beamforming Surface. Microw. Opt. Technol. Lett. 2022, 64, 47–53. [Google Scholar] [CrossRef]

- Wang, C.; Peng, Z.; Yang, F.; Zhu, H.; Yan, L. Uniformity Improvement of Microwave Heating with Switchable Frequency Selective Surface. Case Stud. Therm. Eng. 2024, 61, 104919. [Google Scholar] [CrossRef]

- Xiao, W.; Gao, X.; Wang, Y. Loading an Active Frequency Selective Surface in Microwave Cavities to Enhance Heating Uniformity. IEEE Microw. Wirel. Technol. Lett. 2025, 35, 1642–1645. [Google Scholar] [CrossRef]

- Peng, Z.; Wang, C.; Liu, C.; Zhao, X.; Yan, L. Enhancing Microwave Heating Uniformity in Cavities Using a 2-Bit Coding Metasurface. IEEE Microw. Wirel. Technol. Lett. 2025, 35, 107–110. [Google Scholar] [CrossRef]

- Peng, Z.; Yan, L.; Wang, C.; Zhao, X.; Liu, C. Improvement of Field Uniformity in Microwave Heating Cavity Using beam-splitting Metasurface. In Proceedings of the 2023 XXXVth General Assembly and Scientific Symposium of the International Union of Radio Science (URSI GASS), Sapporo, Japan, 19–26 August 2023. [Google Scholar]

- Liu, C. Microwave—A New Open Access Journal for Microwave Technologies. Microwave 2025, 1, 1. [Google Scholar] [CrossRef]

- He, H.; Liao, C.; He, Z.; Yan, L.; Liu, C. High-Efficiency Ultrawideband Microwave Rectifier Based on Adaptive Harmonic Control. IEEE Trans. Microw. Theory Tech. 2025. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, R.; Liu, C. Low-Power Rectennas in Microwave Wireless Power Transmission. Microwave 2025, 1, 5. [Google Scholar] [CrossRef]

- He, H.; Liao, C.; He, Z.; Yan, L.; Liu, C. An Arbitrary-Frequency Dual-Band High-Efficiency Rectifier Employing a Novel Frequency-Selective Power Allocation Network. IEEE Trans. Power Electron. 2025, 40, 8939–8943. [Google Scholar] [CrossRef]

- Liu, C.; Jing, X. Wireless Power Transmission in a Closed Environment. IEEE Microw. Mag. 2025, 26, 47–64. [Google Scholar] [CrossRef]

- Jing, J.; Yan, L.; Yang, B.; Ren, P.; Mi, J.; Liu, C. Tailored and Tunable Microwave Wireless Power Transfer for Multiple Targets in an Electrically Large Cavity via Frequency Control. IEEE Antennas Wirel. Propag. Lett. 2025. [Google Scholar] [CrossRef]

| Method | Sample Shape | Motion | Remesh Required | Accuracy | Complexity |

|---|---|---|---|---|---|

| Iterative method [95,96] | Arbitrary | Complex | Yes | Low | Low |

| Transformation Optics-based [97] | Arbitrary | Simple | Yes (low freq) | Medium | High |

| IFLSM [98] | Regular | Complex | No | High | Medium |

| ALE-remeshing [99] | Arbitrary | Complex | Yes | Medium | Medium |

| Hybrid ALE/Implicit Function [100] | Arbitrary | Complex | No | High | Medium |

| Ray Casting [101] | Arbitrary | Complex | No | High | Medium |

| Method | Uniformity Improvement | Efficiency Improvement | Practical Constraints |

|---|---|---|---|

| Mode Stirring [49] | 44% to 69% | up to 31% | — |

| Deformable Cavity [50] | 11% to 29% | 28% to 73% | Risk of EM Leakage |

| Cavity Optimization [51] | 45% | 29% | Sample-Specific |

| Multi-Feed [52] | 60% | −14% | — |

| Multi-Feed Control Strategy [56,57] | 42% to 94% (vs. Multi-Feed) | 11% (vs. Multi-Feed) | Complex & High-Cost |

| Feed Rotation [59,60] | 25% to 26% | −19% to 332% | Complex & Unstable |

| Frequency-Tuning [64,68] | 22% to 27% | 11% | — |

| Phase-Controlled [73,74] | 25% to 57% | Marginal | — |

| Material Movement [82] | 37% to 43% | 6% | — |

| Metamaterial-based [105] | 12% to 34% | 15% to 34% | Low Space Efficiency |

| FSS-Based [111] | 27% | 33% | Low Power Capacity (<220 W) |

| Metasurface-Based [113] | 39% | 29% | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, L.; Wang, C.; Yin, X. A Review of Methods for Improving Microwave Heating Uniformity. Microwave 2025, 1, 12. https://doi.org/10.3390/microwave1030012

Yan L, Wang C, Yin X. A Review of Methods for Improving Microwave Heating Uniformity. Microwave. 2025; 1(3):12. https://doi.org/10.3390/microwave1030012

Chicago/Turabian StyleYan, Liping, Chengrong Wang, and Xingrui Yin. 2025. "A Review of Methods for Improving Microwave Heating Uniformity" Microwave 1, no. 3: 12. https://doi.org/10.3390/microwave1030012

APA StyleYan, L., Wang, C., & Yin, X. (2025). A Review of Methods for Improving Microwave Heating Uniformity. Microwave, 1(3), 12. https://doi.org/10.3390/microwave1030012