1. Introduction

Global warming and energy security are among the most critical challenges of the 21st century [

1]. Fossil fuels, which account for 80% of global energy consumption, are primary drivers of greenhouse gas (GHG) emissions and climate change [

2]. This dependency also creates geopolitical tensions due to the uneven distribution of resources. To address these issues, governments and industries worldwide are transitioning to renewable energy sources such as solar, wind, and hydropower [

3].

Hydrogen is emerging as a key energy carrier in this transition, with the potential to decarbonize sectors such as transportation, heavy industry, and energy storage [

4]. It offers high energy density, versatility, and compatibility with renewable energy systems, producing no direct emissions during use. Additionally, hydrogen provides a solution to the intermittency challenges associated with renewable energy by acting as a storage medium [

5].

Despite these advantages, the economic challenge of producing cost-competitive green hydrogen persists, particularly in systems reliant on renewable-powered electrolysis. Optimising production schedules to align with low-cost electricity periods and managing storage levels effectively are essential to reducing costs and ensuring reliability.

This study presents a novel predictive simulation model using AI-driven methods to address these challenges. The model employs Recurrent Neural Networks (RNNs) with Gated Recurrent Units (GRUs) to forecast electricity prices, natural gas flow, and hydrogen storage needs, enabling dynamic production optimization. In addition to standalone models, hybrid ensemble forecasting methods are developed to combine the strengths of linear regression and GRU-based predictions. Through comparative analysis with traditional and hybrid methods, this paper demonstrates the model’s ability to reduce production costs while maintaining operational efficiency. By focusing on the predictive model’s performance and practical applications, this work contributes to advancing the economic viability of green hydrogen.

The predictive simulation model integrates three key components: (1) electricity price forecasting to align electrolyser operation with low-cost periods, (2) natural gas flow prediction to estimate hydrogen demand driven by blending requirements, and (3) dynamic plant modeling to optimise hydrogen production, storage management, and cost outcomes. By combining these forecasts within an integrated scheduling framework, the model enables operational strategies that enhance the economic viability of green hydrogen production.

The remainder of this paper is structured as follows:

Section 2 provides a review of related work, focusing on AI-driven approaches for hydrogen production and energy forecasting.

Section 3 outlines the context of hydrogen production and the methodology employed.

Section 4 details the development and validation of the predictive simulation model.

Section 5 presents the results and discusses the implications of the simulation outcomes. Finally,

Section 6 concludes the paper and identifies avenues for future research.

2. Literature Review

The transition to green hydrogen as a viable alternative to fossil fuels has driven significant research into improving the efficiency, cost-effectiveness, and operational flexibility of hydrogen production systems [

6]. Central to these efforts is the integration of artificial intelligence (AI) techniques to enhance predictive capabilities and optimise production schedules under dynamic energy market conditions [

7].

Recent studies have explored various AI models for electricity price forecasting, a critical input for economic electrolyser operation. Bassey and Ibegbulam [

8] reviewed the application of machine learning in hydrogen production systems, highlighting the suitability of Recurrent Neural Networks (RNNs) for time-series forecasting tasks. Butler and Kalam [

9] demonstrated the efficacy of RNNs with Gated Recurrent Units (GRUs) in capturing electricity price dynamics and enabling dynamic hydrogen production scheduling. Such models outperform traditional statistical approaches, such as linear regression and Auto-Regressive Integrated Moving Average (ARIMA), particularly in modelling volatility and price spikes that are critical for economic optimisation [

9].

Operational modelling of electrolyser systems is another essential research domain. Fang et al. [

10] examined the dynamic behaviours of electrolysers, including ramp-up constraints and minimum runtime requirements, emphasising the need to incorporate these operational features into predictive scheduling frameworks. Complementing this, Tuinema et al. [

11] modelled large-scale electrolysers for grid interaction scenarios, providing insights into real-time frequency response and operational stability.

In addition to electricity price forecasting, accurate prediction of natural gas flow is vital for hydrogen blending scenarios. Although direct applications of AI to natural gas flow prediction are limited, Yao et al. [

12] demonstrated the effectiveness of GRU-based models for performance prediction in fuel cell systems, suggesting broader applicability for gas forecasting in energy systems.

From a broader production technology perspective, comparative reviews [

8,

9,

13] have evaluated proton exchange membrane (PEM) and alkaline electrolysis systems, outlining the economic trade-offs in capital costs, efficiency, and operational flexibility. These analyses are particularly relevant in markets such as Australia, where high renewable energy penetration creates significant electricity price volatility, presenting opportunities for dynamic operational optimisation [

14].

Finally, hybrid AI models, including reinforcement learning (RL) approaches, have been proposed for decision-making in highly variable environments such as autonomous navigation and energy dispatch [

15]. Such hybrid architectures hold promise for further enhancing the responsiveness and adaptability of future hydrogen production systems by enabling autonomous scheduling and real-time optimisation under uncertainty.

3. Methodology

The predictive simulation model developed in this study is based on a Proton Exchange Membrane (PEM) electrolyser system. PEM electrolysis was selected due to its high efficiency, rapid response to fluctuating renewable energy inputs, and compatibility with dynamic scheduling frameworks [

16,

17]. The simulated facility consists of a 1.25 MW PEM electrolyser operating from renewable electricity sources, with hydrogen output directed to either storage or natural gas blending networks. Operational constraints such as ramp-up time, minimum runtime, and storage limitations were incorporated into the model to ensure realistic system behaviour.

3.1. Electricity Price Prediction

Electricity prices exhibit significant volatility, particularly in regions with high renewable energy penetration [

18]. To enable dynamic hydrogen production scheduling, two forecasting models were developed:

A basic linear regression model was implemented using lagged electricity price data to predict future prices. This served as a baseline for evaluating more complex methods.

A recurrent neural network employing gated recurrent units (GRU) was constructed to capture temporal dependencies in electricity pricing data. The model inputs included historical electricity prices, day of the week, hour of the day, and a binary indicator for nighttime periods. The dataset covered January to November 2023 for training, with December 2023 reserved for validation.

A long short-term memory (LSTM) model was also trained on the same feature set to assess comparative performance among deep learning architectures.

Two ensemble forecasting strategies were developed by linearly combining predictions from the linear regression and RNN-GRU models. The first applied equal weights (50/50), while the second used a weighted configuration (70% linear regression and 30% RNN-GRU) based on prior performance. These ensembles aimed to balance volatility capture with trend stability.

All models forecasted electricity prices at two-minute intervals to align with market settlement periods. Forecast accuracy was later evaluated using standard error metrics (MAD, IQR, MAPE, and RMSE), and their influence on hydrogen production schedules was quantified through simulation.

3.2. Natural Gas Flow Prediction

Forecasting natural gas flow was essential to estimating hydrogen demand arising from blending operations. A GRU-based model was developed to predict hourly gas flow rates based on historical data collected from January to November 2023, with December 2023 used for validation. Input features included past gas flow values and temporal markers, such as the hour of the day and day of the week.

To benchmark performance, a linear regression model was also implemented using lagged flow values. Additionally, ensemble forecasts combining the GRU and linear regression outputs were tested using 50/50 and 70/30 weighting schemes. However, unlike electricity prices, the gas flow patterns exhibited lower volatility and smoother temporal variation.

Forecast accuracy was evaluated using MAD, IQR, MAPE, and RMSE. Results showed that the GRU model alone offered the best predictive performance, and ensemble methods did not provide significant gains. The predicted flow values were used to determine hydrogen blending targets in the dynamic simulation model.

3.3. Plant Simulation

The plant simulation model integrated the outputs from the electricity price and gas flow forecasting models to dynamically manage electrolyser operation and hydrogen storage. Key operational logic included:

The electrolyser was operated preferentially during periods of forecasted low electricity prices, subject to ramp-up constraints and minimum runtime conditions.

Excess hydrogen produced during low-cost periods was stored, with storage levels dynamically adjusted based on production and blending demand forecasts.

The simulation penalised unmet hydrogen demand if the production and storage systems could not satisfy the blending requirements, reflecting operational inefficiencies.

3.4. Ensemble Model Development

To improve forecasting robustness and account for model-specific biases, ensemble forecasting approaches were implemented:

An equal-weighted average (50/50) of linear regression and RNN-GRU predictions.

A weighted combination assigning 70% to linear regression outputs and 30% to RNN-GRU outputs, optimised to balance trend-following accuracy and volatility capture.

The ensemble models were evaluated alongside individual models to assess improvements in forecasting accuracy and their impact on hydrogen production optimisation.

4. Model Development and Validation

This section describes the training, development, and validation processes applied to the predictive forecasting models and the dynamic plant simulation. The integration of electricity price and natural gas flow forecasts within the plant simulation framework is illustrated in

Figure 1, which outlines the overall predictive simulation architecture developed in this study.

4.1. Forecasting Model Development

Forecasting models were developed for both electricity price and natural gas flow using supervised learning techniques. For electricity price prediction, two approaches were implemented. The first was a linear regression model trained using lagged electricity prices, serving as a baseline to evaluate the performance of more complex models. The second was a recurrent neural network incorporating gated recurrent units (RNN-GRU), which utilised historical pricing data alongside temporal features including day of week, hour of day, and a binary night-time indicator to capture cyclical and nonlinear behaviour.

A similar GRU-based architecture was employed for natural gas flow forecasting. This model was trained on historical gas flow data, structured in time-series format, to anticipate blending demand with short-term accuracy. In both cases, the forecasting models were trained using operational data from January to November 2023 and validated against out-of-sample data from December 2023.

Electricity prices are forecasted at hourly resolution, 5 days ahead;

Natural gas flow forecasts assume residential blending patterns (~2000 households);

Hydrogen blending ratio is fixed at 10% by energy content;

Participation is limited to the spot electricity market (no PPAs or hedging strategies);

No participation in ancillary service markets (e.g., FCAS).

Minimum electrolyser runtime: 2 h;

Electrolyser ramp-up/down time constraint: 10 min;

Hydrogen storage capacity fixed at 500 kg;

Storage must supply blending during non-production periods without exceeding maximum capacity;

Electricity price threshold for operation set based on cost analysis ($40/MWh).

The predictive scheduling framework assumes participation in the South Australian spot electricity market (NEM region). No fixed-price Power Purchase Agreements (PPAs) or ancillary service participation (e.g., FCAS markets) are modelled. Electricity price exposure is purely based on dynamic spot market fluctuations, allowing the model to explore maximum flexibility and economic optimisation potentials under real-time conditions.

4.2. Model Training Procedures

Prior to training, input features were standardised to improve convergence behaviour, and time-series windows of 48 steps (approximately 96 min) were used for sequence models. The RNN-GRU models were trained using the Adam optimiser, with early stopping applied based on validation loss stagnation, using a patience value of 10 epochs. Batch sizes of 1024 were selected to ensure computational efficiency while preserving generalisability.

The linear regression model, by contrast, was trained directly on lagged price data without additional temporal features or sequence windows, allowing for a transparent benchmark comparison.

4.3. Validation Metrics

To evaluate model performance, four metrics were applied: Mean Absolute Deviation (MAD), Interquartile Range (IQR), Mean Absolute Percentage Error (MAPE), and Root Mean Square Error (RMSE). MAD and RMSE captured absolute error and error magnitude, respectively, while MAPE measured relative error. The IQR was used to assess each model’s ability to capture price and flow variability, particularly under volatile market conditions. All metrics were computed using the December 2023 validation dataset for consistency across models.

4.4. Ensemble Validation

Following individual model validation, ensemble models were constructed to improve robustness and reduce the influence of individual model bias. Two ensembles were evaluated: a simple hybrid using an equal-weighted average of the linear regression and RNN-GRU predictions, and a weighted hybrid assigning 70% weight to the linear regression output and 30% to the RNN-GRU forecast. These hybrid models were evaluated using the same error metrics, with their performance improvements compared directly to those of the standalone models.

4.5. Plant Simulation Validation

The validated forecasts were applied within the plant simulation model to dynamically schedule hydrogen production. Simulation outcomes included hydrogen production quantities, storage level trajectories, and the extent to which blending demand was met or exceeded. The simulation imposed operational constraints such as electrolyser ramp-up time and minimum runtime, and penalised unmet blending demand to reflect operational inefficiencies. Comparative simulations were conducted using each forecasting strategy to quantify the effect of forecast accuracy on production cost and system responsiveness.

The predictive hydrogen production model integrates dynamic electricity pricing, natural gas blending demand forecasts, and electrolyser operational constraints. The following formulations define the scheduling framework used to optimise hydrogen production and storage operations.

= hydrogen required for blending at time t (kg);

= natural gas flow rate at time t (kg);

= blending ratio (e.g., 0.10 for 10%).

4.6. Performance Metric Definitions

The predictive models were evaluated using four statistical performance metrics: Mean Absolute Deviation (MAD), Interquartile Range (IQR), Mean Absolute Percentage Error (MAPE), and Root Mean Square Error (RMSE). These metrics are defined mathematically as follows:

where

3 and

1 are the 75th and 25th percentiles of the predicted value distribution, respectively.

Root Mean Square Error (

RMSE):

Hybrid Ensemble Forecasts:

The hybrid ensemble predictions were computed by linearly combining individual model forecasts. For the two ensemble configurations:

Weighted Hybrid (70/30 weighting):

These metrics were calculated for all model outputs during validation against the December 2023 dataset.

5. Results and Discussion

The forecasting models and plant simulation were evaluated using operational data from December 2023, which was not seen during training. This section presents the results of the electricity price and gas flow forecasts, the ensemble model comparisons, and the outcomes of the hydrogen production simulation. Discussion focuses on the implications of forecast accuracy for operational efficiency, cost reduction, and system responsiveness.

5.1. Electricity Price Forecasting Results

The performance of the electricity price prediction models is summarised in

Table 1. Linear regression achieved strong baseline performance with a mean absolute deviation (MAD) of 30.69 AUD/MWh and a mean absolute percentage error (MAPE) of 39.05%. The RNN-GRU model captured greater price variability, reflected in a higher interquartile range (IQR) of 75.99 AUD/MWh, but exhibited larger absolute errors, with a MAD of 54.44 AUD/MWh and a MAPE of 90.15%.

The simple hybrid ensemble (50% linear regression, 50% RNN-GRU) demonstrated improved robustness, reducing RMSE to 100.91 AUD/MWh compared to either model individually. Further improvement was achieved with the weighted hybrid ensemble (70% linear regression, 30% RNN-GRU), which lowered the MAD to 34.01 AUD/MWh and achieved a MAPE of 49.90%, offering a strong balance between trend following and volatility capture.

In addition to benchmarking against traditional models, a Long Short-Term Memory (LSTM) network was evaluated using the same dataset and input features. The LSTM model demonstrated significantly higher mean absolute deviation (MAD) and root mean square error (RMSE) compared to the RNN-GRU, suggesting poorer predictive reliability under the volatile conditions of the South Australian electricity market. Notably, the LSTM model’s mean absolute percentage error (MAPE) could not be calculated reliably due to zero-price intervals causing division errors. These findings further support the selection of RNN-GRU for dynamic hydrogen production scheduling. Full comparative results, including the LSTM model, are presented in

Table 1The results indicate that hybrid ensemble methods provided a significant improvement in forecast stability, achieving lower overall error metrics without sacrificing the ability to track price volatility. The weighted hybrid ensemble, in particular, effectively mitigated the tendency of the RNN-GRU model to over-predict during periods of extreme volatility.

In addition to benchmarking against traditional models, a Long Short-Term Memory (LSTM) network was evaluated using the same dataset and input features. The LSTM model demonstrated competitive performance but showed slightly higher mean absolute deviation (MAD) and mean absolute percentage error (MAPE) compared to the RNN-GRU. This result supports the selection of RNN-GRU for dynamic production scheduling, balancing predictive accuracy with computational efficiency. Full comparative results, including the LSTM model, are presented in

Table 1.

5.2. Natural Gas Flow Forecasting Results

Natural gas flow forecasting was evaluated using linear regression, RNN-GRU, and hybrid ensemble approaches.

Table 2 summarises the performance metrics. The RNN-GRU model demonstrated superior predictive accuracy, achieving a mean absolute deviation (MAD) of 13.40 GJ and a mean absolute percentage error (MAPE) of 18.59%. It also captured gas flow variability effectively, reflected in an interquartile range (IQR) of 38.06 GJ.

In contrast, linear regression exhibited significant prediction error, with a MAD of 96.31 GJ and a MAPE exceeding 155%, indicating poor alignment with actual flow dynamics. Hybrid ensembles (50/50 and 70/30 weightings) were also evaluated but failed to outperform the standalone RNN-GRU model. Ensemble methods increased both absolute and relative errors, suggesting that for the smoother and less volatile gas flow dataset, RNN-GRU alone provided the optimal balance between accuracy and responsiveness.

5.3. Plant Simulation Outcomes

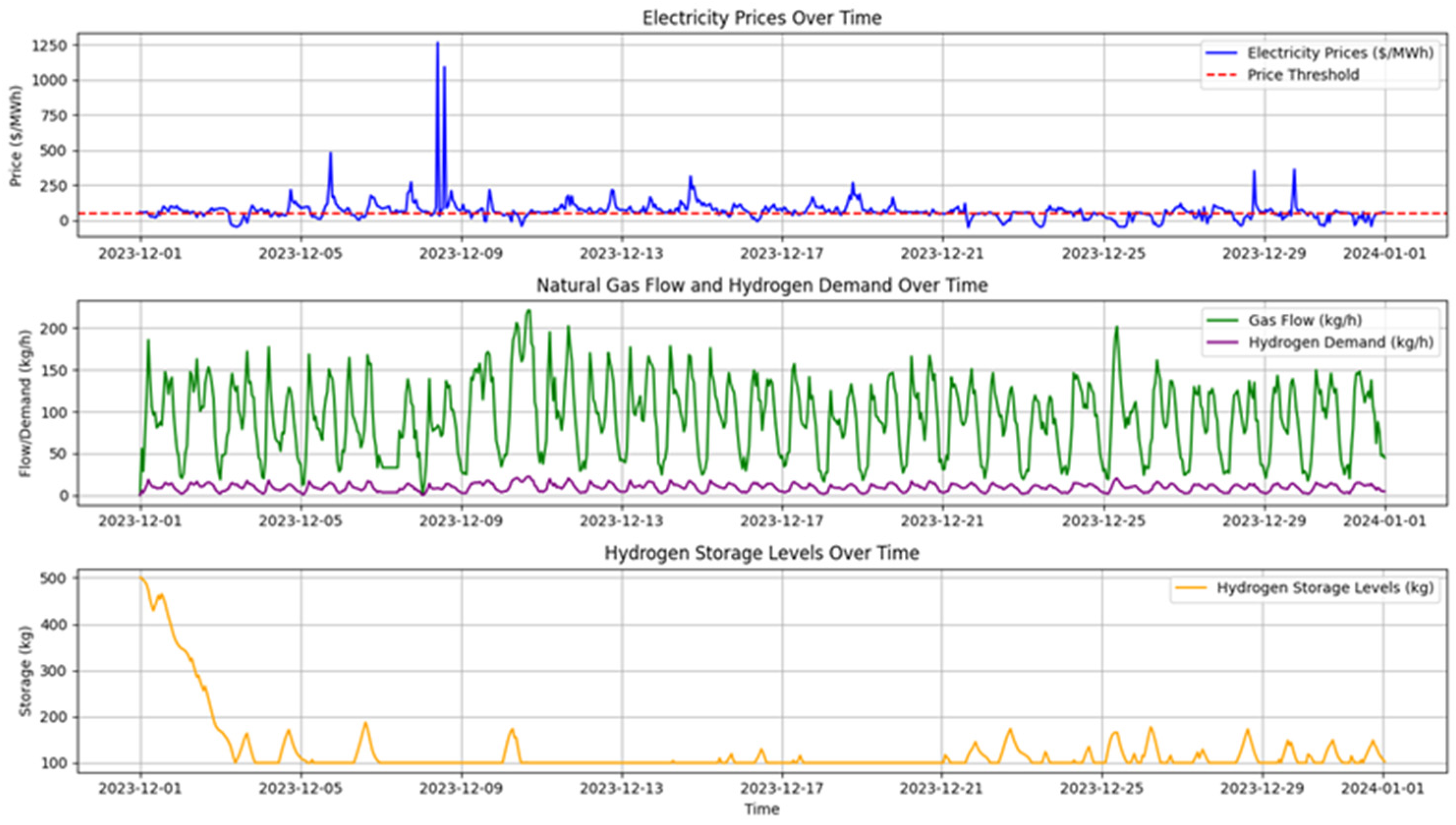

The impact of forecasting accuracy on plant operational performance was evaluated through dynamic simulation of hydrogen production, storage management, and blending delivery across December 2023. Forecast outputs from both electricity price prediction models and natural gas flow models were integrated into the production scheduling framework, and system outcomes were compared across the different forecasting strategies.

Plant simulations based on linear regression electricity forecasts demonstrated good trend-following behaviour but consistently missed short-term price dips. Consequently, the electrolyser operated conservatively, producing hydrogen during broad low-cost periods but failing to fully exploit sudden market troughs. This conservative scheduling pattern led to underutilisation of available storage capacity and occasional shortfalls in meeting hydrogen blending targets during periods of elevated gas demand.

Simulations driven by RNN-GRU electricity forecasts captured short-term volatility more effectively, enabling the electrolyser to respond dynamically to rapid price fluctuations. However, this increased sensitivity also resulted in operational instability, including frequent ramping events and unnecessary cycling, which could potentially increase maintenance costs and reduce electrolyser lifetime over time.

In contrast, hybrid ensemble forecasts, particularly the weighted 70/30 hybrid, produced the most favourable operational outcomes. The weighted ensemble forecasts achieved a balance between trend stability and volatility capture, resulting in smoother hydrogen production profiles. This approach improved storage utilisation, reduced excessive cycling, and minimised the number of instances where blending demand exceeded available hydrogen supply.

Natural gas flow predictions, based on the RNN-GRU model, accurately estimated blending demand across the validation period. The model’s ability to track gradual and peak gas consumption events ensured that hydrogen production could be adjusted proactively, aligning supply with blending requirements while avoiding overproduction or unnecessary storage depletion.

Overall, these simulation outcomes demonstrate the significant operational benefits of integrating hybrid forecasting for electricity pricing and GRU-based forecasting for gas flow within predictive hydrogen production scheduling frameworks.

Table 3 summarises key operational metrics derived from the plant simulation under the best-performing forecast scenario (Weighted Hybrid 70/30 for electricity, RNN-GRU for gas flow).

Figure 2 illustrates the dynamic behaviour of electricity pricing, natural gas flow demand, and hydrogen storage levels across the December 2023 validation period. The alignment of production and storage activities with market fluctuations demonstrates the effectiveness of the predictive scheduling framework.

5.4. Discussion

The results of this study demonstrate the critical role of forecasting accuracy in optimising hydrogen production under dynamic energy market conditions. Accurate prediction of electricity prices and natural gas blending demand enabled the dynamic scheduling model to align production activities with market opportunities, improving both cost efficiency and operational reliability.

The comparative analysis of electricity price forecasting approaches highlighted the advantages of hybrid ensemble models. Simple linear regression forecasts captured general trends but missed volatility-driven price troughs, resulting in conservative scheduling and suboptimal utilisation of storage assets. RNN-GRU models captured volatility more effectively but introduced greater operational cycling, potentially increasing maintenance burdens. By contrast, weighted hybrid forecasts provided a balanced solution, enabling responsive yet stable production planning that minimised start-stop events and reduced electricity costs.

For natural gas flow forecasting, the standalone RNN-GRU model performed adequately without the need for hybridisation. This reflects the relatively smoother temporal patterns of residential gas consumption compared to highly volatile electricity markets. The GRU model’s ability to track gradual demand variations ensured effective matching of hydrogen supply to blending requirements with minimal penalties.

Operational simulation results validated the practical benefits of predictive scheduling. Under the weighted hybrid forecast strategy, the electrolyser operated flexibly during low-price periods, maintained sufficient storage to meet blending demands during non-production windows, and achieved a production cost of AUD 1.72/kg, approaching cost competitiveness targets for green hydrogen [

19].

Nonetheless, certain limitations must be acknowledged. The validation dataset focused exclusively on the South Australian market and a specific electrolyser configuration. Broader validation across different regulatory environments, energy market structures, and electrolyser technologies is necessary to fully generalise these findings. Furthermore, the current scheduling framework prioritises economic optimisation; future research should incorporate environmental impact factors, such as carbon intensity forecasting, into production decision-making.

Additionally, participation in ancillary service markets, such as frequency control ancillary services (FCAS), was not considered in the current model. While providing ancillary services can introduce both new revenue streams and operational risks, modelling these interactions requires detailed market-specific data and complex dispatch algorithms [

20]. Future research should explore the integration of ancillary market participation to better reflect real-world operational strategies and optimise revenue potential for hydrogen production systems.

These insights reinforce the potential for AI-driven predictive models to enable more cost-effective and resilient hydrogen production, supporting broader decarbonisation and energy transition objectives.

6. Conclusions and Future Work

This study developed and validated a predictive simulation framework for optimising green hydrogen production using AI-driven forecasting techniques. Electricity price forecasts, natural gas flow predictions, and storage management models were integrated to enable dynamic production scheduling aligned with market and operational conditions. Comparative evaluations demonstrated that hybrid ensemble models, which combine linear regression and RNN-GRU forecasts, achieved the best balance between predictive stability and volatility responsiveness for electricity pricing. In contrast, standalone RNN-GRU models provided the most accurate natural gas flow forecasts.

Plant simulation results confirmed that accurate forecasting significantly enhances operational outcomes, reducing production costs, improving storage utilisation, and reliably meeting hydrogen blending requirements. Weighted hybrid forecasting strategies for electricity prices, coupled with GRU-based gas demand predictions, delivered the most cost-effective and resilient operational profiles across the December 2023 validation period.

Future research should expand on these findings by:

Extending validation across multiple geographic markets and longer time horizons to assess generalizability;

Incorporating additional forecasting dimensions such as renewable energy availability and water consumption rates into the scheduling model;

Exploring hybrid AI architectures combining RNNs with reinforcement learning to enhance decision-making under dynamic conditions;

Investigating the economic and environmental impacts of predictive hydrogen production models under varying policy frameworks, including carbon pricing and renewable incentives.

These directions offer promising pathways for advancing the economic viability and scalability of green hydrogen production systems through intelligent forecasting and optimisation.