Abstract

Roll-to-roll production of thin organic and large-area electronic (TOLAE) devices often involves a two-step process per functional layer: a continuous, un-pattered deposition of the film and subsequent structuring process, such as laser ablation. Thin-film organic devices should be protected using ultra-barrier films. To perform laser ablation of functional layers on top of such barrier films, in particular that of transparent electrodes, highly selective laser ablation is required to completely remove the layers without damaging the thin-film barrier layers underneath. When targeting highly selective laser ablation of indium tin oxide (ITO) on top of silicon nitride (SiN) barrier layers with a 1064 nm picosecond or 1030 nm femtosecond laser, we observed the emergence of visible large-scale patterns due to local variations in ablation quality. Our investigations using a very sensitive Raman spectroscopy setup show that the observed ablation variations stem from subtle differences in optical path length within the heat-stabilized plastic substrates. These variations are likely caused by minute, localized changes in the refractive index, introduced during the bi-axial stretching process used in film fabrication. Depending on the optical path length, these variations lead to either constructive or destructive interference between the incoming laser beam and the light reflected from the back surface of the substrate. By performing laser ablation under an angle such that the reflected and incoming laser beam do not spatially overlap, highly selective uniform laser ablation can be performed, even for two stacked optically transparent layers.

1. Introduction

Polyethylene terephthalate (PET) is the preferred substrate in thin organic and large-area electronic (TOLAE) devices due to the combination of its optical transparency and low price [1,2,3]. For applications such as organic light-emitting diodes (OLEDs) and organic or perovskite photovoltaics (OPVs or PSC), the deposition and annealing temperatures during processing require the use of heat-stabilized (bi-axially stretched) PET (150 °C). When process temperatures of up to 220 °C are required, heat-stabilized PEN can be used [4]. Since TOLAE devices are typically extremely sensitive to degradation by the ambient, the devices have to be encapsulated with a thin-film barrier stack from both the top and bottom sides, since the water vapour transmission rate (WVTR) of the substrate itself is approximately six orders of magnitude too high to protect the device with a sufficient lifetime [5,6]. From a cost and practical point of view, an unstructured roll-to-roll (R2R) deposition of each layer is preferred, directly on top of a barrier film. After completion of the device, a second barrier film can be laminated on top and, thereby, limiting the stack to contain two plastic films. Compared to the more conventional three-film approach, where a separate PET or PEN substrate is used as base for device fabrication and after which the whole stack is sealed with two separate barrier films. The fabrication directly on the barrier film leads to a significant cost reduction and in fact a better performance, since PET/PEN substrates by themselves contain small amounts of residual water that will degrade the device over time. For the realization of R2R thin-film electronics, the individual layers have to be structured separately with a stand-alone process, such as laser ablation.

Over the past decades, laser patterning of indium tin oxide (ITO) on glass and PET substrates [7,8,9,10] has been investigated intensively for photovoltaics (PV) and display applications [11,12,13,14,15,16,17,18,19]. Here, the main requirement is the complete removal of the transparent conductive (TC) material in the laser track, and the (partial) damage to the substrate underneath is largely inconsequential. Fewer studies have investigated laser ablation of functional layers deposited directly on top of barrier films [20,21,22,23,24]. Direct laser structuring of layers on top of thin-film barriers is much more challenging as selective removal of the layers is required while barrier properties are to be maintained, i.e., no damage should occur to the thin-film barrier underneath [23,24]. In particular, when a transparent layer has to be structured on top of a transparent barrier layer and no clear wavelength-selective ablation can be performed, careful tuning of the laser ablation process parameters is required, possibly in combination with tuning of the optical properties of the layers. For example, Naithani et al. reported that selective laser ablation can be achieved by changing the optical properties of the barrier film [25].

Previously, we reported on the investigations of direct laser structuring of TC layers, the so-called P1 scribe, deposited on top of R2R-produced barrier films for its use as bottom electrode in R2R PV applications [23]. In that study, a 1064 nm picosecond laser, a 1030 nm femtosecond laser, and a 1950 nm nanosecond laser were used to structure the most commonly used TC layer, indium tin oxide (ITO), on top of a heat-stabilized PET substrate with a stack of an organic planarization layer (OCP, organic coating for planarization) and a single hydrogenated amorphous silicon nitride (SiN) barrier layer, i.e., PET/OCP/SiN. The barrier films have been previously quantified extensively using the optical Ca test [26] and have shown an overall WVTR < 10−6 g.m−2 day−1, determined by the intrinsic properties of the SiN. The extremely low pinhole density present, i.e., ~ 0.03 pinholes/cm2 (determined from a 1250 cm2 barrier film per individual barrier test) make the individual SiN barrier films suitable for TOLAE devices. Logically, for such quality barrier films, any SiN damage caused by laser ablation of the TC layer will have detrimental effects on the overall barrier performance and lifetime of the organic device processed on top.

The process window determination for laser structuring of the TC layer was performed in such a way that a) no damage was introduced to the barrier film—occurring at too high fluence—and b) full electrical isolation in the TC layer was achieved—above a certain fluence level. Although with large differences in ablation threshold, only a narrow laser process window was obtained for the removal of the TC layer with no damage to the barrier underneath [23]. However, during these process investigations, irregular ablation of the TC layer was observed, more specifically for the ps and fs IR lasers in combination with front-side ablation. Locally along the laser track over- and under-ablation was observed, where the SiN suffers from damage or the ITO was not completely removed, respectively. The irregular ablation in combination with the narrow process window severely hampers the applicability of these lasers for TC patterning on barrier films.

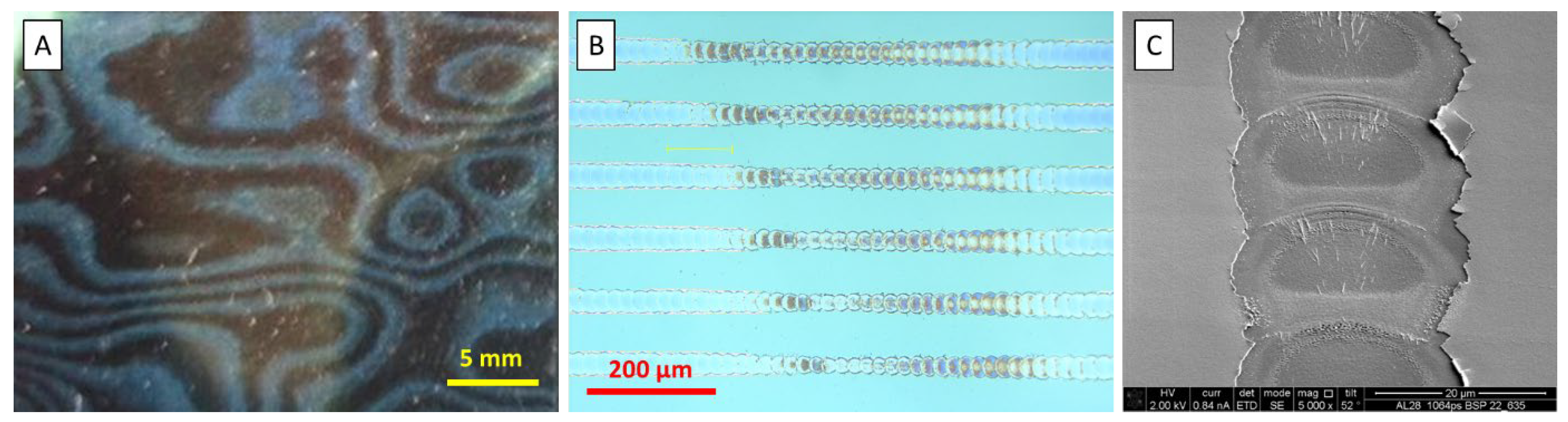

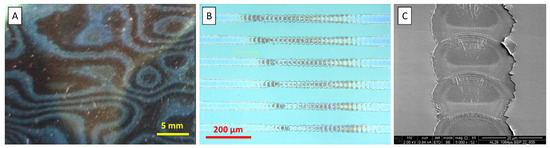

The observed ablation irregularities, when using the 1064 nm picosecond and 1030 nm femtosecond laser, are best described as local changes in ablation diameter and ablation depth within a single laser track. The pattern of irregularities seems to result from a large-scale effect originating within the samples since it spans multiple laser tracks over a large area and is independent of the ablation direction (see Figure 1). A scanning electron microscopy (SEM) image of an ablation track with full removal of the ITO and no damage to underlying SiN is shown in Figure 1C.

Figure 1.

A photograph of a laser-scribed area in ITO on barrier film with many laser scribes in parallel at a pitch of 100 µm (A), where a large-area pattern was observed originating from local variations in ablation along the ablation tracks. An optical microscopy image from the individual laser tracks showing the variations in ablation diameter and depth (B). A SEM image of a single laser track at optimized laser settings for the 1064 nm ps laser at 47% pulse overlap and 38 µm spot size, showing complete removal of the ITO layer and the exposed SiN layer intact underneath (C).

Comparable laser ablation studies in the literature do not show these strong variations along the laser track, likely due to the fact that all have been performed with the TC layers directly on top of plastic or glass substrates and that there are no damage-critical thin layers directly underneath [8,27,28,29]. In this situation, a higher fluence setting for ablation does not cause damage; instead, it ensures a more reliable ablation. In the literature, laser-induced damage or patterns [30,31,32,33,34,35] are either ripples on the surface with a period distance which is similar to the laser wavelength range or patterns induced by the bi-axial stretching of the PET, so-called naps and walls [36]. The periodicity of these wall structures is in the range from 1 µm up to 8 µm. The patterns we observed have a periodicity at a much larger scale ranging from 1 mm up to 1 cm.

2. Materials and Methods

An R2R-produced barrier film with a WVTR < 10−6 g·m−2·day−1 and ITO as transparent conductor was used for the TC layer ablation experiments. The barrier film consisted of a heat-stabilized PET of 125 µm thickness, an organic coating for planarization (OCP) of 22.3 µm thickness by ink-jet printing, and a low-temperature hydrogenated silicon nitride (SiN) inorganic barrier layer of 150 nm thickness by plasma-enhanced chemical vapour deposition (PECVD), denoted as PET/OCP/SiN. Samples from the roll-to-roll barrier film were cut and coated with a 135 nm thick ITO layer by sputtering.

A 1064 nm picosecond laser (Talisker Ultra, Coherent) was used to laser structure ITO (P1 scribe) directly on top of the SiN layer. The pulse duration was 15 ps. Using a Galvo scanner system with 163 mm F-theta optics, we focused the linear polarized beam to a spot size of 38 µm (1/e2) on the target. The optimized laser settings for ablation of ITO on SiN without barrier damage were determined according to previously reported extensive methodology [23] and fixed at a fluence level of 635 mJ/cm2 at 47% pulse overlap with an ablation speed of 200 mm/s. A square area of 3 × 3 cm2 was fully covered with laser scribes of 3 cm in length, at a 100 µm pitch. To look in detail at the optical properties of the barrier films and the emerged interference patterns upon ITO ablation, Raman spectroscopy was used.

A Raman spectroscopy setup (Renishaw InVia Raman, Gloucestershire, United Kingdom). was used having a laser with 633 nm wavelength exciting the sample through an optical microscope objective. The lateral resolution and depth specificity is determined by the choice of microscope objective. The light coming back from the sample, the majority of which is reflected laser light, passes a filter which eliminates all light with a wavelength ≤ 633 nm. All wavelengths longer than 633 nm are detected by the system and analyzed with dedicated software.

The accompanying software can analyze the spectrum with a mathematical method by splitting up the detected spectrum in several components (the so-called principal components, PCs) that build up the total spectrum. Each of these components can represent a physical property of the sample. The PCs are orthogonal functions that contain the most variance in the original spectrum. The equation of the PCs can be written as follows [37]:

where is the original Raman spectroscopy data, , …… are the orthogonal principle components of the original data, and , ,…… are the coordinate values or scores that project the original Raman spectroscopy on the new orthogonal principle components. After scanning an area of a sample by Raman, the changes in each of the principal components was plotted in a mapping, giving a colour difference for the amount of change in that component. Hence, for each element or property of the spectrum (physical or mathematical) a mapping was made of the strength or variation in that component over the sample area, and only PC3(λ) showed similar features as the observed large-scale pattern, which were subsequently analyzed in more detail.

The properties of the individual layers provided in Table 1 were determined by ellipsometry (VASE ellipsometer, J.A. Woollam, East Brisbane, QLD, Australia) and stylus profilometer (Dektak, Bruker, Billerica, MA, USA). The PET data was provided by the supplier (Dupont Teijin Films, Chester, VA, USA).

Table 1.

Layer thickness and refractive index of the individual layers in the stack.

3. Results and Discussion

3.1. White Light Interferometry

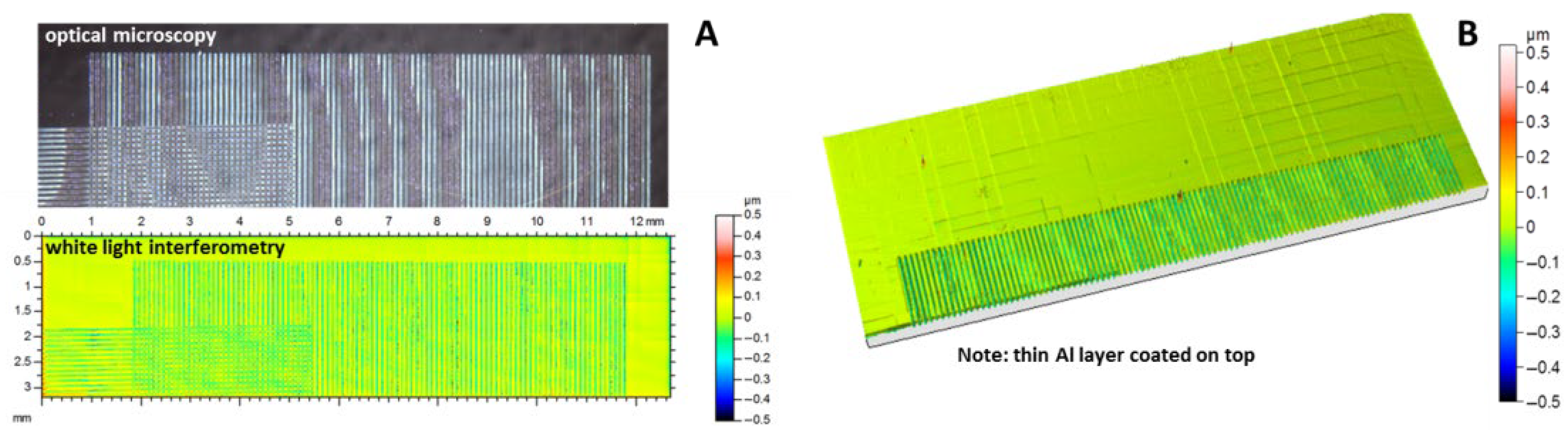

To investigate whether the variable ablation quality patterns were caused by height variations in the OCP layer, white light interferometry was performed at the edge of a laser-ablated area consisting of laser ablation tracks in both the x- and y-directions, with a partial overlapping area with both ablation directions, as shown in Figure 2. The pattern is clearly visible in the ablated region by optical microscopy. The image by white light interferometry also shows the pattern in the ablation tracks area, albeit less visible compared to the optical microscope. However, the pattern does not continue outside the laser track area, which would have been the case if the pattern was due to height variations present in the samples and/or thickness variations in the OCP. To ensure the measurement only probed the top surface of the sample, we evaporated a thin Al layer on top. The results are shown in Figure 2B, and also here no variation is observed outside the laser track area. The rectangular lines in the image outside the laser track area are artificial and caused by the stitching of many images. The measurements also show that the height variations in the top of the substrate over several mm2 areas are within 0.2 µm. Therefore, fluence variations introduced by in- and out-of-focus conditions can be excluded as the root cause for the ablation variations.

Figure 2.

A comparison of the optical microscopy photograph with the image obtained on height variations, measured by white light interferometry (A). To ensure that the information is only obtained from the top surface of the sample and not at the other interfaces, a thin Al layer was evaporated on top, and the same scan of the sample was performed (B). The pattern observed in the laser tracks does not continue outside the laser area. Note: the rectangular pattern in the image is artificial and due to a stitching of many images.

3.2. Raman Spectroscopy and Principal Component Analysis

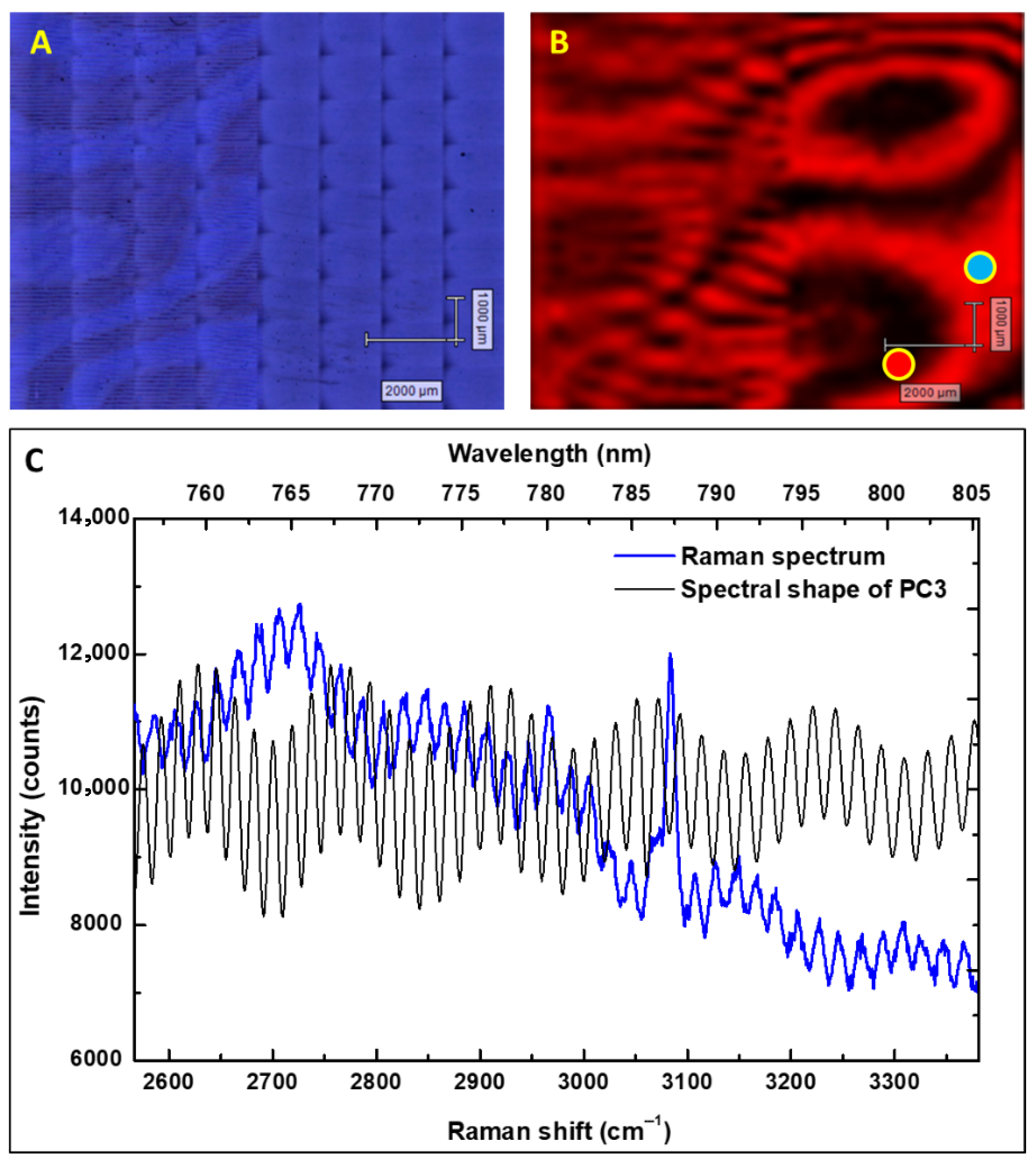

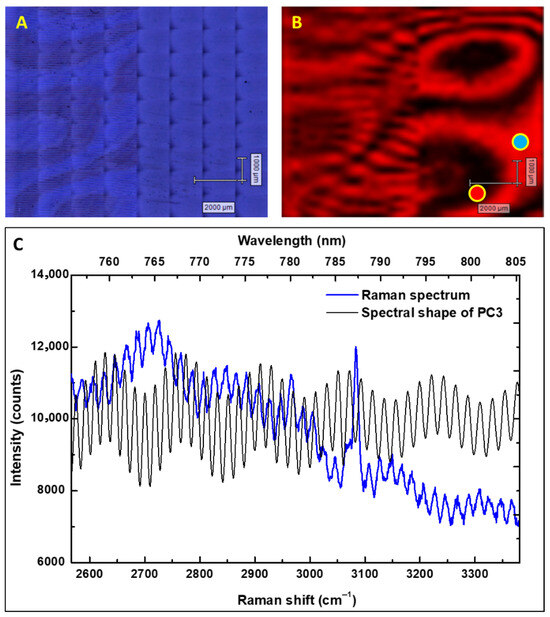

To investigate in detail the optical properties of the substrates, the laser-structured samples were investigated by Raman spectroscopy. To compare a laser-patterned area with the non-patterned area adjacent to it (see Figure 3A), a large area mapping by Raman was carried out over the sample. The stitched optical microscopy image obtained by the Raman setup is shown in Figure 3A. Here, the stitched areas (repetitive dark areas) and the emerging fringe-pattern due to the laser scribing can be clearly identified. Principal component analysis was applied to the obtained Raman spectrum. Figure 3C shows the Raman spectrum detected from a single point (blue line). The majority of the spectrum is caused by a small fluorescence originating in the sample, and the peak close to 3100 cm−1 is a Raman peak originating from the PET substrate. The spectral shape of the principal component PC3(λ), shown by the black line in Figure 3C, represents the interference for the small amount of fluorescence present in the Raman spectrum. In Figure 3B, the same mapping as the optical microscopy image is shown, but in this case, each pixel has a colour defined by the variation observed in the PC3(λ) score. Albeit that the score mapping appears to be distorted in the laser-scribed area due to the presence of laser tracks and the associated rougher surface area, from the stitched optical microscopy image and the PC3(λ) score mapping, it can be observed that the emerging pattern present in the laser-scribed area continues in the adjacent un-patterned area when looking at the score mapping of PC3(λ), i.e., a component related to interference in the measured fluorescence.

Figure 3.

A stitched image obtained by optical microscopy of the area used for the Raman spectroscopy, showing laser tracks with ablation variations at the left-hand side and intact TC layer at the right-hand side (A). A score mapping of the third principal component, PC3(λ) (B), where the red dot is the location with the minimum score for PC3(λ) in the mapped area, and the blue dot is the maximum score location. The graph shows an example of the spectrum detected from a single point in the Raman mapping (C). For each pixel, a spectrum is recorded (blue line). This spectrum is mathematically split up in principal components. Here, principal component 3—PC3(λ)—is depicted by the black line, which is related to interference in the fluorescence signal.

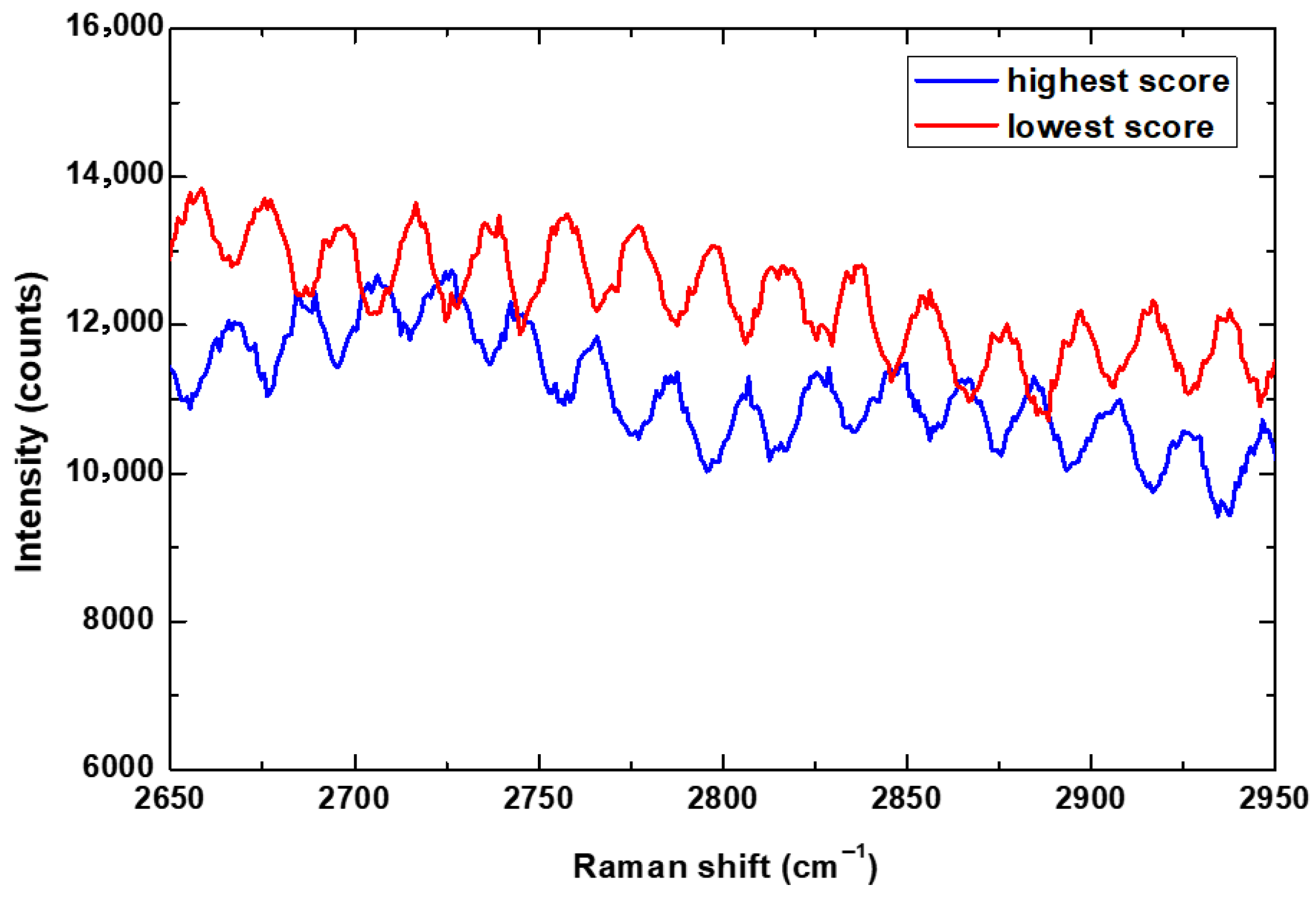

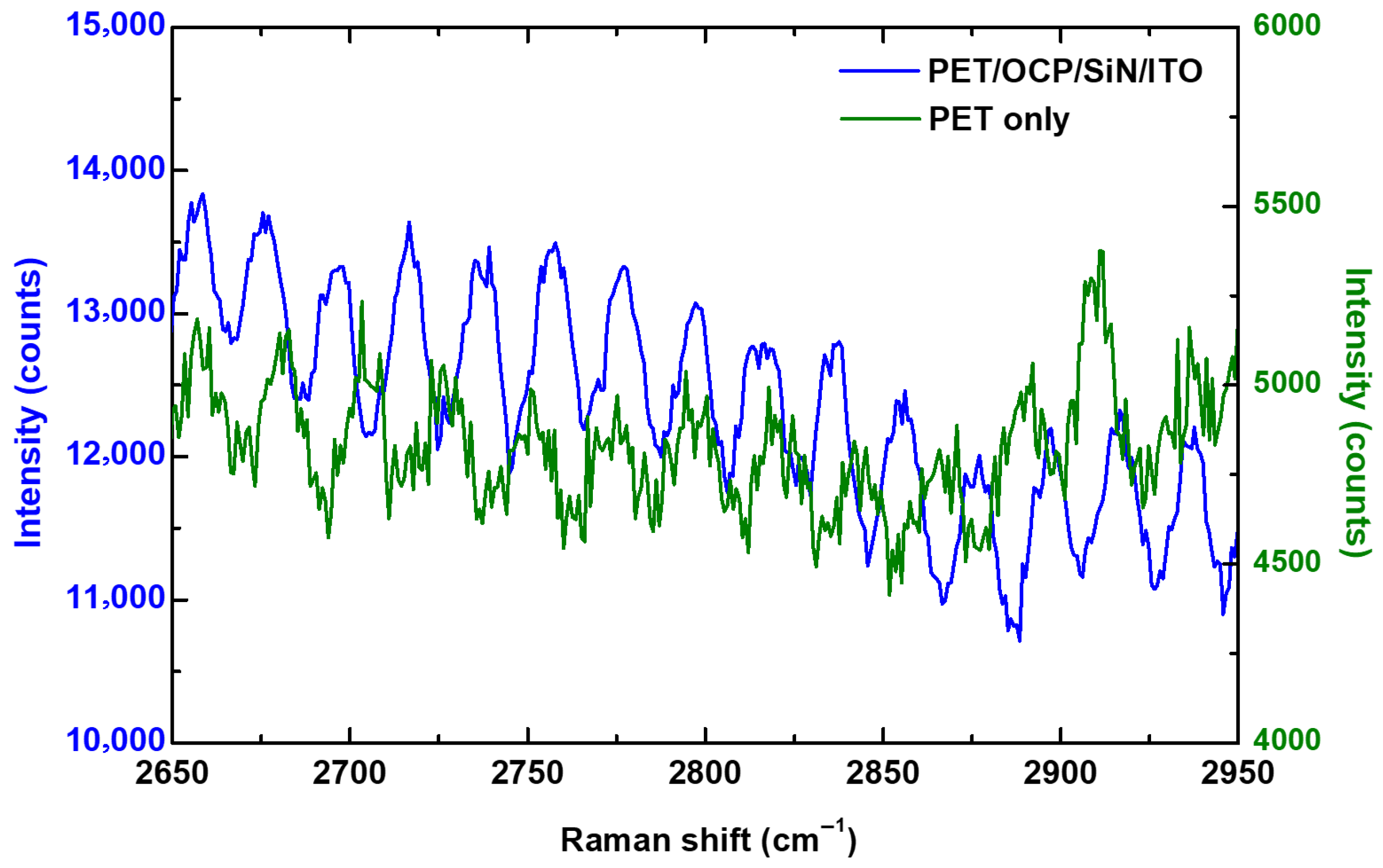

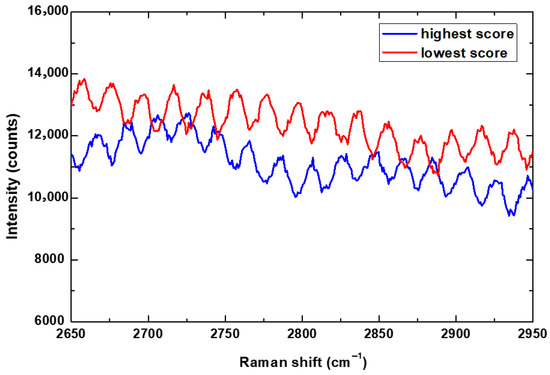

To understand the nature of the PC3(λ) score value, the Raman spectrum was plotted for the maximum and minimum PC3(λ) score locations, as shown in Figure 4, and the actual locations on the sample are depicted by the blue and red dots in the previous Figure 3B. In Figure 4, only a part of the spectrum is plotted for the range 2650–2950 cm−1 (corresponding to 760.6–778.3 nm). Besides the small difference in the absolute value of the Raman spectrum at both locations, it can be observed that the interference pattern in fluorescence is present at both locations but has shifted with respect to each other. When we fit the derivative (to remove absolute value differences) of the interference pattern with a sine function, we obtain a wavelength of 20.01 +/−0.02 cm−1 and 20.00 +/−0.02 cm−1 for the highest and lowest PC3(λ) score location, respectively. These wavelengths are identical within the error of measurement and, thereby, unrelated to the PC3(λ) score. In fact, for the maximum and minimum locations in the mapping, the shift in interference is exactly equal to half the wavelength (10 cm−1) of the interference pattern, implying that the PC3(λ) score gives a value for phase shift in the interference pattern in the fluorescence spectrum.

Figure 4.

Part of the Raman spectrum between 2650 and 2950 cm−1 (760.6–778.3 nm) at the location of the highest and lowest scores, depicted by the blue and red dots in Figure 3B, where the shift in the interference by fluorescence is 10 cm−1, equal to half the wavelength of the interference spectrum.

In general, the optical path length within a stack of layers is determined by a summation of the product of the refractive index (n) and thickness (d) of the individual layers:

From the number of fringes (k) present between two chosen wavelengths (λ1 and λ2) in an interference spectrum, the OPL can be determined by the Swanepoel method [32], where

For the range chosen in Figure 4 between 2650 and 2950 cm−1 (corresponding to λ1 = 760.6 nm and λ2 = 778.3 nm), there are exactly 15 fringes (k), resulting in an OPL = 250.1 µm for the fluorescence. The difference in optical path length (ΔOPL) to induce the shift in the interference spectrum can be calculated by the relative shift in wavelength of the spectrum between a peak and valley. The wavelength for the interference spectrum equals 20 cm−1, corresponding to 1.18 nm. Hence, the difference between peak and valley is 0.59 nm, and for the wavelength of 770 nm (2810.8 cm−1) this equals a ΔOPL= 192 nm only, corresponding to a very small variation of 0.08% in optical path length.

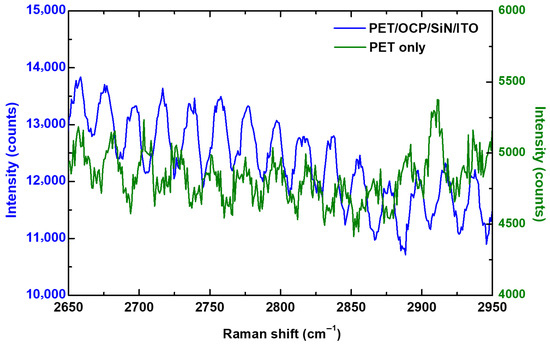

To determine the origin of the variations in optical path length, bare PET substrates that were used in the fabrication of the barrier films were investigated. The Raman spectrum is provided in Figure 5 together with the spectrum of the full barrier stack with ITO. A similar large-area pattern in the PC3(λ) score mapping was observed. As can be seen in Figure 5, the interference pattern has a slightly different periodicity due to the significant different optical path length. The wavelength for the fluorescence interference spectrum was 22.83 cm−1 (1.36 nm). By using the Swanepoel method on the interference spectrum, we obtained an optical path length for bare PET (OPLPET) of 216.7 µm. When subtracting the OPLPET from that obtained on the full stack (OPL), the thickness of the OCP can be deduced using Equation (1). Using a measured refractive index of 1.50 for OCP and a PET film thickness of 125 µm, we obtain a value of 21.9 µm for the OCP layer thickness, very close to the measured average value of 22.3 ± 0.1 µm (average of 72 measurements from six separate barrier films). The results clearly indicate that the origin of optical path length variations is present in the PET substrate.

Figure 5.

The Raman spectrum between 2650 and 2950 cm−1 for barrier films with ITO and bare PET.

The minute variations of 0.08% in optical path length present within the PET substrates can be either the result of local thickness variations in the film (which would correspond to a 100 nm thickness variation for 125 µm film), a local refractive index variation (corresponding to a 0.001 variation for a refractive index of 1.58), or due to a combination of both parameters. Looking at the pattern, it is difficult to link the observations to possible thickness variations in the PET when taking the large-scale and high-speed fabrication process into account where the molten PET is forced through a die to form a film. Instead, perhaps a more logical explanation would be that the very small variations in optical path length result from local refractive index differences, where the refractive index is linked to local molecular orientation or to induced stresses in the film occurring upon recrystallization of the PET during the heat treatment and bi-axial stretching to improve the thermal stability.

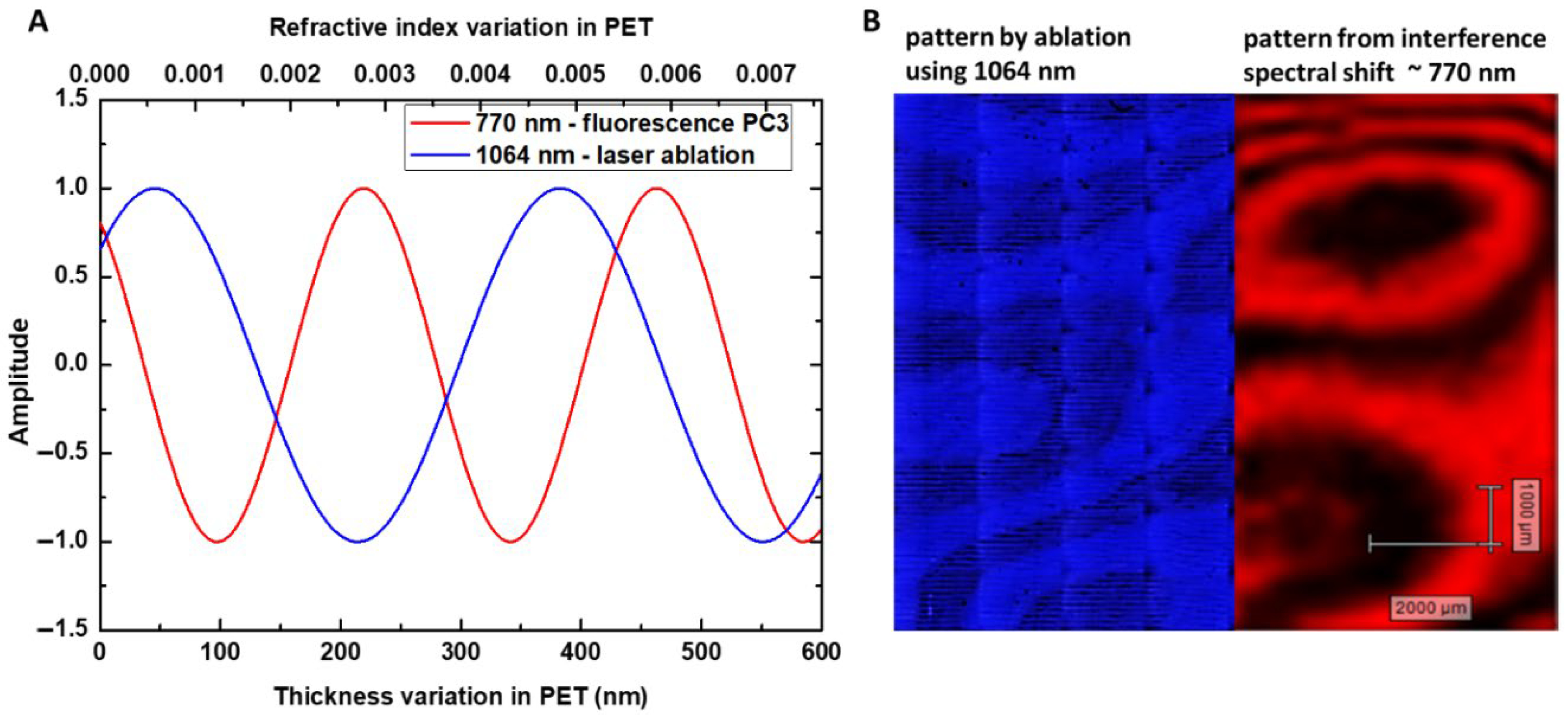

To understand how the small variations in the optical path length in the PET can influence the laser ablation uniformity, it is essential to realize that the majority of the laser light is passing through the transparent layers and some of that light reflects from the rear of the substrate. Previously, we did not observe these ablation inconsistencies when using a 1950 nm nanosecond laser [23], likely due to the much higher absorption of the ITO at this wavelength relative to 1064 nm [38]. At 1064 nm, the reflected light from the rear of the substrate can interfere with the incoming laser light of the same laser pulse (the laser pulse duration is approximately 15 ps, and the duration for light to travel twice through the stack is about 1.5 ps). Logically, the locations where we observed maxima and minima in the PC3(λ) score from fluorescence at approximately 770 nm will not be the same maxima and minima locations for the 1064 nm laser light source used for ablation due to the longer wavelength of the light. Furthermore, the OPL (250.0 µm) that was determined for the fluorescent light from the interference spectrum is not identical to that of the light travelled through the stack in the case of laser ablation, which can be determined using Equation (1) and resulting in 231.48 µm for a single pass through the layer stack. Using these two wavelengths of 770 nm and 1064 nm and associated optical path lengths, the phase shift in the light was modelled using a sine function provided in Equation (3).

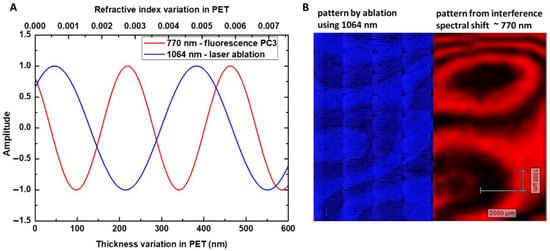

The obtained optical periodicity is represented in Figure 6A, where the sine function for 770 and 1064 nm is plotted as a function of potential thickness variations and refractive index variations in a 125 µm PET substrate. Clearly, a different periodicity is present between the observed fluorescence interference around 770 nm and that expected for 1064 nm laser ablation, where the periodicity for 1064 nm is approximately 1.4 times larger. This also implies that the large-area pattern observed by the PC3(λ) score mapping and that obtained by laser ablation are likely not identical. We verified this by combining the optical microscopy image of the 1064 nm laser patterned side of the sample in Figure 3A with that of the ~770 nm interference shift (PC3(λ) score) mapping at the un-patterned side in Figure 3B. The combined image is provided in Figure 6B. At the interface between the two images, we can see that the large-area pattern is indeed not identical; at some locations, a dark area in the optical microscopy image (corresponding to more damage by ablation) lines up with low values in the PC3(λ) score mapping and at other locations with a high value. In short, as expected, the periodicity in the large-area pattern is different for both wavelengths, and the periodicity of the pattern emerging from laser ablation is larger compared to that seen in the PC3(λ) score mapping. Despite having a different periodicity, both patterns observed at the two wavelengths originate from the same variations in optical path length in the PET substrate.

Figure 6.

Sine modulation representing the fluorescence interference spectral shift around 770 nm emission and the representation for 1064 nm laser light that is reflected from the rear of the substrate (A). For both graphs, a different periodicity is obtained, which can also be observed when the optical microscopy image of the laser-patterned area is compared to the PC3(λ) score mapping of the adjacent un-patterned area (B). At the interface of both images, the large-area patterns do not perfectly line up with each other and show a different periodicity.

When the theory of constructive and destructive interference between incoming laser light and reflected laser light from the rear of the substrate is correct, we can try to minimize or eliminate this effect. For example, as mentioned previously, by choosing a laser with 1950 nm wavelength where ITO has a much larger absorption and no ablation variation was observed. Other potential solutions could be incorporating a near-infrared absorbing sacrificial layer underneath the transparent electrode to achieve optically selective ablation of the sacrificial layer together with the TC layer on top, or an index matching material could be placed underneath the PET foil during laser ablation to minimize the reflections from the rear side.

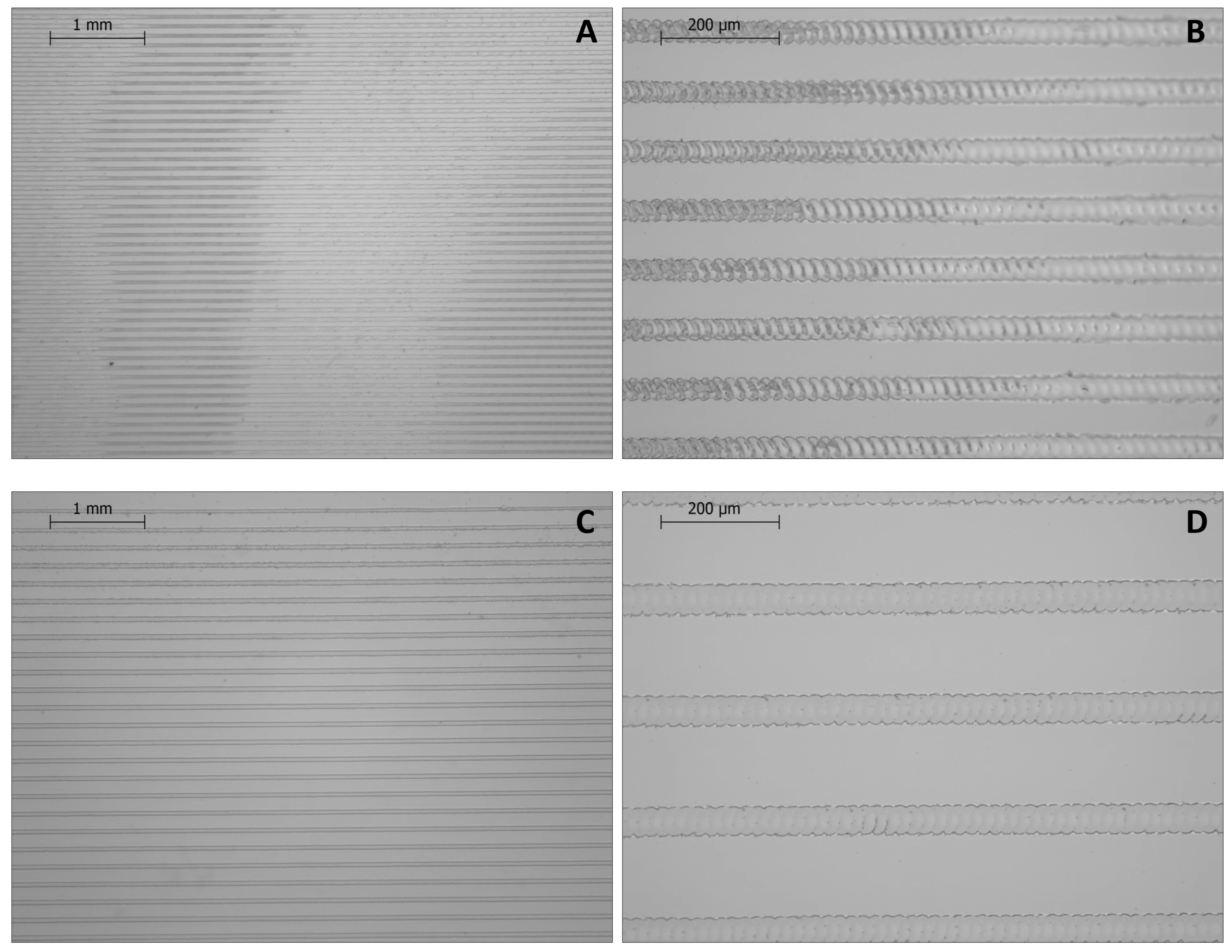

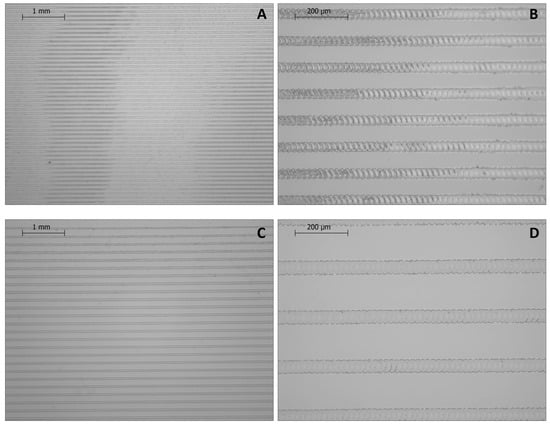

We propose and performed a more basic solution that could be readily applied in the roll-to-roll production of PV without making changes to the stack or the most common laser system for thin film ablation of ITO at 1064 nm: by performing laser ablation under an angle such that the reflected light from the rear does not overlap with the incoming laser spot. Using a 50 µm spot diameter of the laser, along with the ellipticity of the laser spot at the surface and the thickness and refractive index of the individual layers in combination with Snell’s law, we can calculate the overlap at the substrate surface between incoming and reflected light. Below a 16° off-normal angle, the spots overlap at the surface and above 16° no overlap is present. The results are shown in Figure 7, where laser ablation was performed under an off-normal angle of 15°, with a partial overlap between the reflected light and incoming light, and at a 45° angle where no overlap is present. As can be seen from the optical microscopy images, the laser ablation at 15° off-normal still results in fluctuations in ablation diameter and depth, but less severe compared to the previous perpendicular ablation. At 45°, the laser ablation is completely uniform over the full track and reproducible over larger areas with multiple tracks, but with a larger width of the laser track due to the elliptical laser spot at the surface. These results not only confirm the constructive–destructive interference concept due to optical path length variations in the PET substrate but also provide a solution that can be directly implemented for the laser patterning of roll-to-roll–produced thin-film stacks, without the additional need of changing the stack.

Figure 7.

Optical microscopy images of laser-ablated tracks under 15° off-normal incident laser with partial overlap between incoming and reflected beam ((A)—large-area overview, scale bar 1 mm, (B)—ablated tracks in more detail, scale bar 200 µm). Under 15° off-normal angle, a variable ablation quality over larger area is still observed, albeit with less variation compared to the previous perpendicular ablation. When overlap is avoided at an angle of 45°((C)—large-area overview, scale bar 1 mm, (D)—ablated tracks in more detail, scale bar 200 µm), the ablation tracks are uniform and reproducible over larger area, since no interference between incoming and reflected laser light occurs.

4. Conclusions

Laser ablation of ITO on R2R-produced barrier films using a 1064 nm ps laser showed non-uniform ITO ablation with varying ablation depth and diameter along a single ablation track, resulting in electrically non-isolated locations of the ITO and other locations with compromised barrier functionality. The fluctuations in ablation quality resulted in a large-scale pattern spanning many ablation tracks. We employed the highly sensitive optical technique of Raman spectroscopy, in combination with principal component analysis and mapping, to investigate the origin of these ablation quality fluctuations. By looking at the shift in interference pattern from the small fluorescence present in the Raman spectrum, and by comparison with bare PET films, we concluded that the ablation variations was due to minute variations (as small as 0.08%) in optical path length present in bi-axially stretched plastic substrates. These variations are likely caused by refractive index variations. Constructive and destructive interference between the incoming laser light and that reflected by the rear of the substrate occurs depending on the local optical path length, resulting in differences in ablation quality. A straightforward solution was provided by performing laser ablation under an angle, such that the reflected laser light does not spatially overlap with the incoming laser pulse and highly selective laser ablation of (transparent) thin films can be performed without damaging the underlying thin transparent barrier layers.

Author Contributions

Conceptualization, H.B.A.; Methodology, AF, H.F. and E.V.; Formal analysis, E.V. and H.B.A.; Investigation, A.F., H.F., J.S., W.H.M., E.V. and H.B.A.; Writing—original draft, A.F. and H.B.A.; Writing—review & editing, H.F.; Supervision, H.B.A. All authors have read and agreed to the published version of the manuscript.

Funding

Part of this work has received funding from the European Commission, Horizon 2020 Research and Innovation Action, in the framework of the ALABO project, Grant agreement No 644026.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors acknowledge Niels Friedrich-Schilling (Fraunhofer IWS) and Merve Anderson (Heliatek GmbH) for discussions.

Conflicts of Interest

Ahmed Fawzy, Henri Fledderus, Jie Shen, Wiel H. Manders and Hylke B. Akkerman are employed by Holst Centre/TNO; Emile Verstegen is employed by the company Eurofins EAG Laboratories. All Authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Willmann, J.; Stocker, D.; Dörsam, E. Characteristics and evaluation criteria of substrate-based manufacturing. Is roll-to-roll the best solution for printed electronics? Org. Electron. 2014, 15, 1631–1640. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; White, M.S.; Głowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Yan, Y.; Mu, Q.; Zhou, P. Laser rear-side ablation mechanism for ITO removal on PET substrate. Appl. Phys. A Mater. Sci. Process. 2024, 130, 186. [Google Scholar] [CrossRef]

- MacDonald, W.A.; Looney, M.K.; MacKerron, D.; Eveson, R.; Adam, R.; Hashimoto, K.; Rakos, K. Latest advances in substrates for flexible electronics. J. Soc. Inf. Disp. 2007, 15, 1075–1083. [Google Scholar] [CrossRef]

- Lewis, J. Material challenge for flexible organic devices. Mater. Today 2006, 9, 38–45. [Google Scholar] [CrossRef]

- With, P.C.; Helmstedt, U.; Prager, L. Flexible Transparent Barrier Applications of Oxide Thin Films Prepared by Photochemical Conversion at Low Temperature and Ambient Pressure. Front. Mater. 2020, 7, 200. [Google Scholar] [CrossRef]

- Ashkenasi, D.; Rosenfeld, A. Processing multilayer systems using femtosecond, picosecond, and nanosecond laser pulses at different wavelengths. In Proceedings of the Photon Processing in Microelectronics and Photonics, San Jose, CA, USA, 27–30 January 2002. [Google Scholar] [CrossRef]

- Xiao, S.; Fernandes, S.A.; Ostendorf, A. Selective patterning of ITO on flexible PET Substrate by 1064nm picosecond Laser. Phys. Procedia 2011, 12, 125–132. [Google Scholar] [CrossRef]

- Račiukaitis, G.; Brikas, M.; Gedvilas, M.; Rakickas, T. Patterning of indium-tin oxide on glass with picosecond lasers. Appl. Surf. Sci. 2007, 253, 6570–6574. [Google Scholar] [CrossRef]

- Risch, A.; Hellmann, R. Picosecond laser patterning of ITO thin films. Phys. Procedia 2011, 12, 133–140. [Google Scholar] [CrossRef]

- Park, M.; Chon, B.H.; Kim, H.S.; Jeoung, S.C.; Kim, D.; Lee, J.I.; Chu, H.Y.; Kim, H.R. Ultrafast laser ablation of indium tin oxide thin films for organic light-emitting diode application. Opt. Lasers Eng. 2006, 44, 138–146. [Google Scholar] [CrossRef]

- Henry, M.; Harrison, P.M.; Wendland, J. Laser direct write of active thin-films on glass for industrial flat panel display manufacture. J. Laser Micro Nanoeng. 2007, 2, 49–56. [Google Scholar] [CrossRef]

- Moorhouse, C.; Karnakis, D.; Kapnopoulos, C.; Laskarakis, A.; Mekeridis, E.; Logothetidis, S. Laser patterning of smart nanomaterials for reel-to-reel production of organic photovoltaic (OPV) devices. J. Laser Micro Nanoeng. 2015, 10, 195–201. [Google Scholar] [CrossRef][Green Version]

- Tseng, S.F.; Hsiao, W.T.; Huang, K.C.; Chiang, D.; Chen, M.F.; Chou, C.P. Laser scribing of indium tin oxide (ITO) thin films deposited on various substrates for touch panels. Appl. Surf. Sci. 2010, 257, 1487–1494. [Google Scholar] [CrossRef]

- Patel, R.S.; Clark, D.; Bovatsek, J. Laser scribing: A key enabling technology for manufacturing of low cost thin film photovoltaic cells. In Proceedings of the ICALEO 2007: 26th International Congress on Laser Materials Processing, Laser Microprocessing and Nanomanufacturing, Orlando, FL, USA, 29 October–1 November 2007. [Google Scholar] [CrossRef]

- Shin, Y.; Jeon, B.; Shin, S.; Lim, S.; Souk, J.; Odajima, T. 49.1: Fabrication of 23” PVA LCD Panel by Laser Ablation Process of ITO. SID Symp. Dig. Tech. Pap. 2009, 40, 727. [Google Scholar] [CrossRef]

- Ishteev, R.; Gostishchev, P.; Tiukhova, M.; Sorokin, A.; Ishteev, A.; Kondratenko, V. Technological parameters of thin-film pulsed laser scribing for perovskite photovoltaics. Clean Energy 2024, 8, 127–135. [Google Scholar] [CrossRef]

- Razza, S.; Pescetelli, S.; Agresti, A.; Di Carlo, A. Laser processing optimization for large-area perovskite solar modules. Energies 2021, 14, 1069. [Google Scholar] [CrossRef]

- Taheri, B.; De Rossi, F.; Lucarelli, G.; Castriotta, L.A.; Di Carlo, A.; Brown, T.M.; Brunetti, F. Laser-Scribing Optimization for Sprayed SnO2-Based Perovskite Solar Modules on Flexible Plastic Substrates. ACS Appl. Energy Mater. 2021, 4, 4507–4518. [Google Scholar] [CrossRef]

- Karnakis, D.; Kearsley, A.; Knowles, M. Ultrafast laser patterning of OLEDs on flexible substrate for solid-state lighting. J. Laser Micro Nanoeng. 2009, 4, 218–223. [Google Scholar] [CrossRef]

- Karnakis, D.; Stephens, T.; Chabrol, G. Maskless selective laser patterning of PEDOT:PSS on barrier/foil for organic electronics applications. In Proceedings of the Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XVIII, San Francisco, CA, USA, 4–7 February 2013. [Google Scholar] [CrossRef]

- Mandamparambil, R.; Fledderus, H.; Van Steenberge, G.; Dietzel, A. Patterning of Flexible Organic Light Emitting Diode (FOLED) stack using an ultrafast laser. Opt. Express 2010, 18, 7575–7583. [Google Scholar] [CrossRef]

- Fledderus, H.; Akkerman, H.B.; Salem, A.; Schilling, N.F.; Klotzbach, U. Patterning of organic photovoltaic on R2R processed thin film barriers using IR laser sources. In Proceedings of the SPIE-The International Society for Optical Engineering, San Francisco, CA, USA, 17 February 2017; Volume 10092. [Google Scholar] [CrossRef]

- Friedrich-Schilling, N.; Fledderus, H.; Peuckert, F.; Kuntze, T.; Gburek, B.; Salem, A.; Akkerman, H.B.; Anderson, M. Development of a Reproducible Laser Structuring Process of Stacked Thin Films on Ultra-Barrier Films for Organic Solar Devices. In Proceedings of the EU PVSEC 2017, Amsterdam, The Netherlands, 25–29 September 2017; pp. 1047–1051. [Google Scholar] [CrossRef]

- Naithani, S.; Mandamparambil, R.; Fledderus, H.; Schaubroeck, D.; Steenberge, G. Van Fabrication of a laser patterned flexible organic light-emitting diode on an optimized multilayered barrier. Appl. Opt. 2014, 53, 2638–2645. [Google Scholar] [CrossRef]

- Nisato, G.; Klumbies, H.; Fahlteich, J.; Müller-Meskamp, L.; Van De Weijer, P.; Bouten, P.; Boeffel, C.; Leunberger, D.; Graehlert, W.; Edge, S.; et al. Experimental comparison of high-performance water vapor permeation measurement methods. Org. Electron. 2014, 15, 3746–3755. [Google Scholar] [CrossRef]

- Chen, M.F.; Chen, Y.P.; Hsiao, W.T.; Gu, Z.P. Laser direct write patterning technique of indium tin oxide film. Thin Solid Films 2007, 515, 8515–8518. [Google Scholar] [CrossRef]

- Schoonderbeek, A.; Schütz, V.; Haupt, O.; Stute, U. Laser processing of thin films for photovoltaic applications. J. Laser Micro Nanoeng. 2010, 5, 248–255. [Google Scholar] [CrossRef][Green Version]

- McDonnell, C.; Milne, D.; Prieto, C.; Chan, H.; Rostohar, D.; O’Connor, G.M. Laser patterning of very thin indium tin oxide thin films on PET substrates. Appl. Surf. Sci. 2015, 359, 567–575. [Google Scholar] [CrossRef]

- Birnbaum, M. Modulation of the reflectivity of semiconductors. J. Appl. Phys. 1965, 36, 657–658. [Google Scholar] [CrossRef]

- Siegrist, M.; Kaech, G.; Kneubühl, F.K. Formation of a periodic wave structure on the dry surface of a solid by TEA-CO2-laser pulses. Appl. Phys. 1973, 2, 45–46. [Google Scholar] [CrossRef]

- Van Driel, H.M.; Sipe, J.E.; Young, J.F. Laser-induced periodic surface structure on solids: A universal phenomenon. Phys. Rev. Lett. 1982, 49, 1955–1958. [Google Scholar] [CrossRef]

- Sipe, J.E.; Young, J.F.; Preston, J.S.; Van Driel, H.M. Laser-induced periodic surface structure. I. Theory. Phys. Rev. B 1983, 27, 1141–1154. [Google Scholar] [CrossRef]

- Young, J.F.; Preston, J.S.; Van Driel, H.M.; Sipe, J.E. Laser-induced periodic surface structure. II. Experiments on Ge, Si, Al, and brass. Phys. Rev. B 1983, 27, 1155–1172. [Google Scholar] [CrossRef]

- Young, J.F.; Sipe, J.E.; Van Driel, H.M. Laser-induced periodic surface structure. III. Fluence regimes, the role of feedback, and details of the induced topography in germanium. Phys. Rev. B 1984, 30, 2001–2015. [Google Scholar] [CrossRef]

- Wagner, F.R. Scanning excimer laser ablation of poly(ethylene terephthalate) (PET) and its application to rapid prototyping of channels for microfluidics. Eng. Mater. Sci. 2000, 2264. [Google Scholar] [CrossRef]

- Li, X.; Yang, T.; Li, S.; Wang, D.; Song, Y.; Zhang, S. Raman spectroscopy combined with principal component analysis and k nearest neighbour analysis for non-invasive detection of colon cancer. Laser Phys. 2016, 26, 035702. [Google Scholar] [CrossRef]

- Serkov, A.A.; Snelling, H.V.; Heusing, S.; Amaral, T.M. Laser sintering of gravure printed indium tin oxide films on polyethylene terephthalate for flexible electronics. Sci. Rep. 2019, 9, 1773. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).