Prediction of Large Springback in the Forming of Long Profiles Implementing Reverse Stretch and Bending

Abstract

1. Introduction

2. Materials and Methods

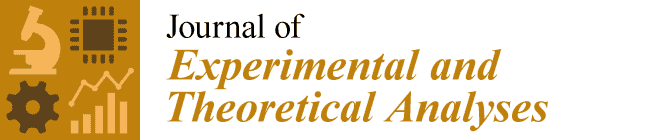

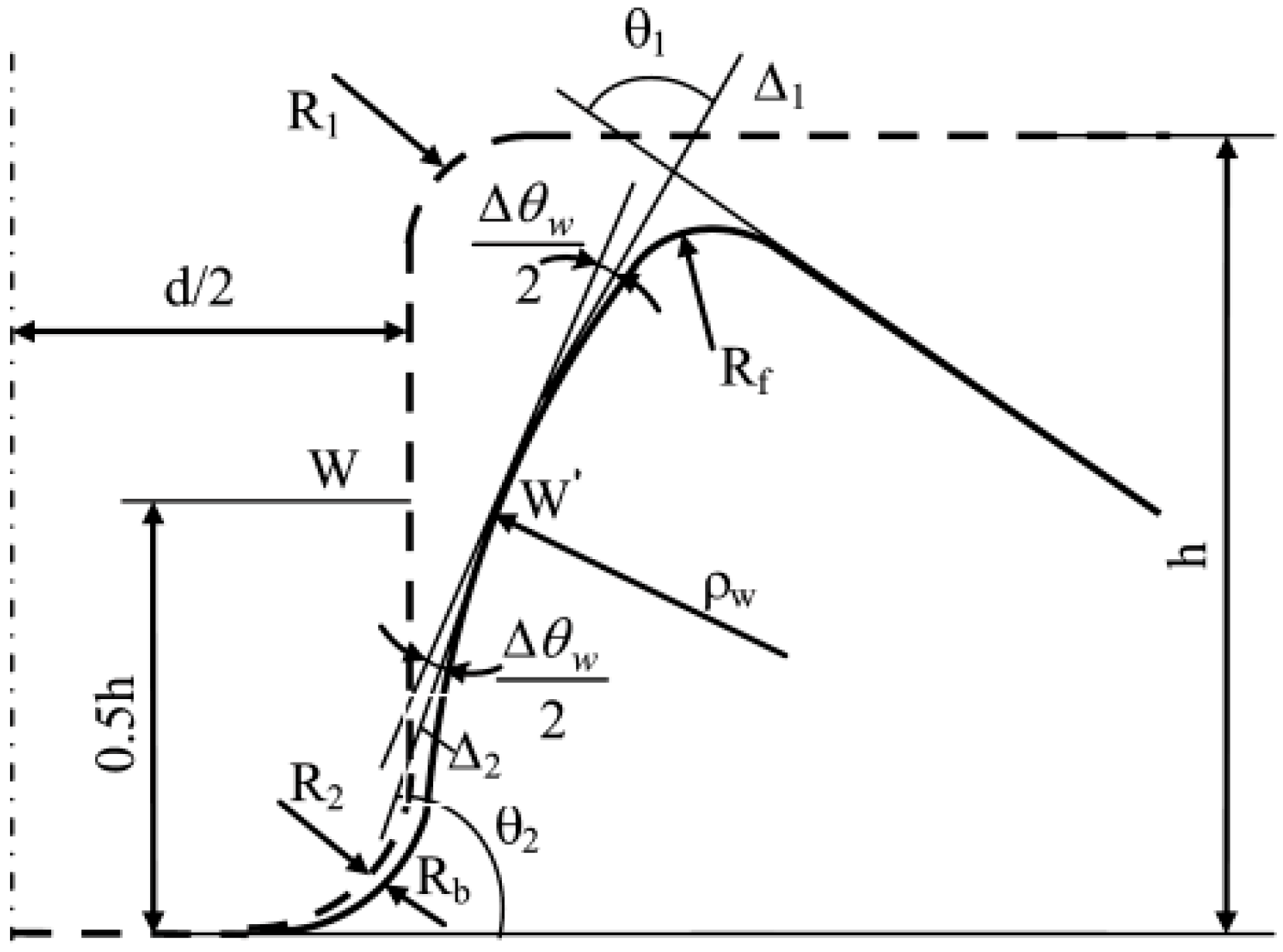

2.1. Formulation of Springback

2.1.1. Change in Slope Under Bending

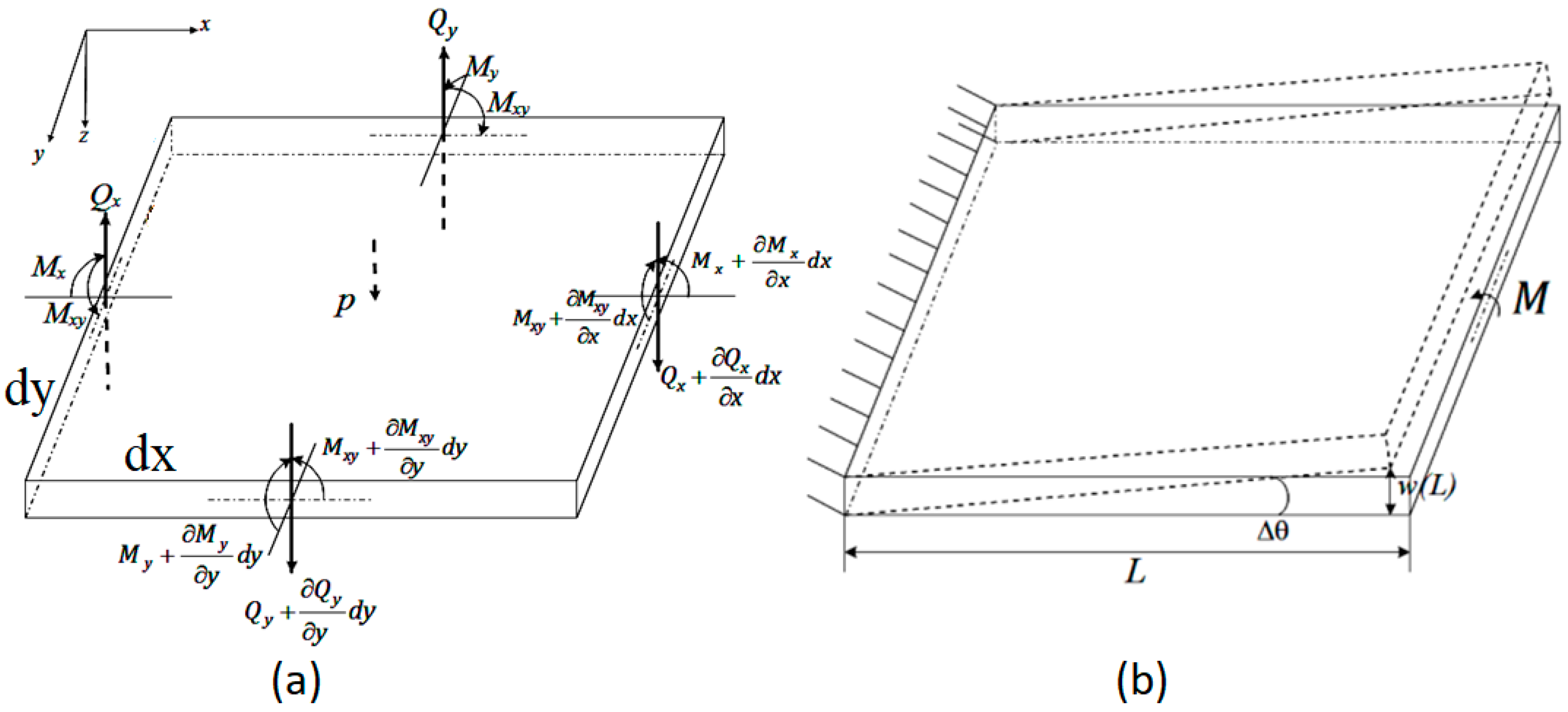

2.1.2. Stretch Under Membrane Loading

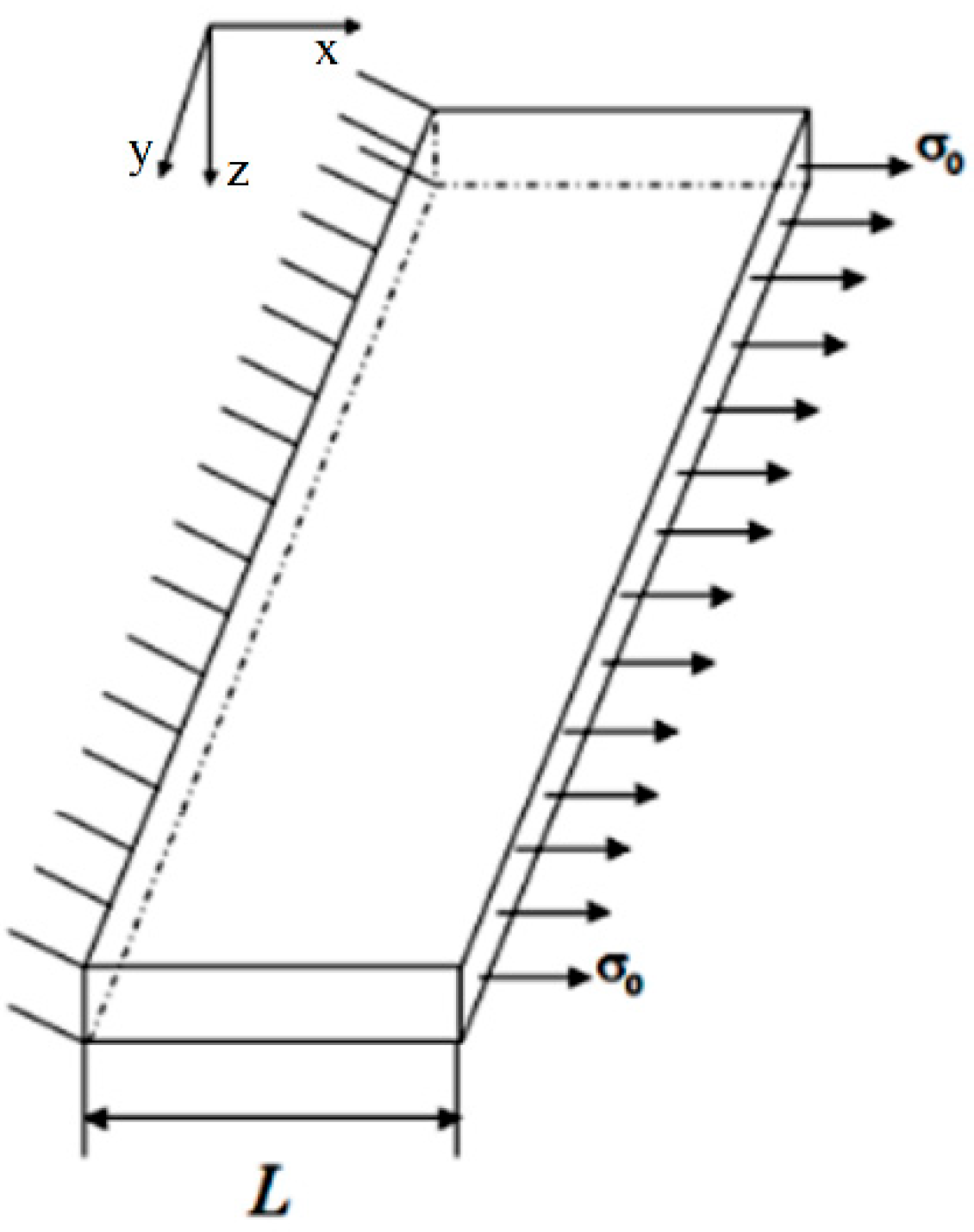

2.2. Material and Testing

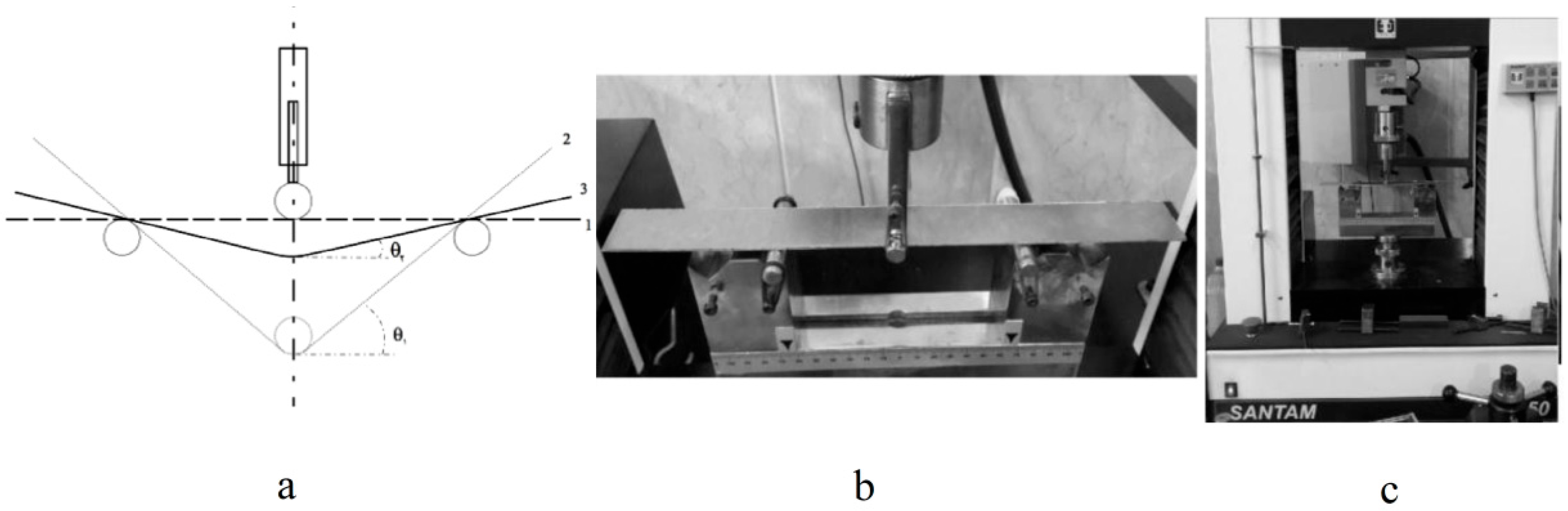

2.2.1. Three-Point Bending Sample

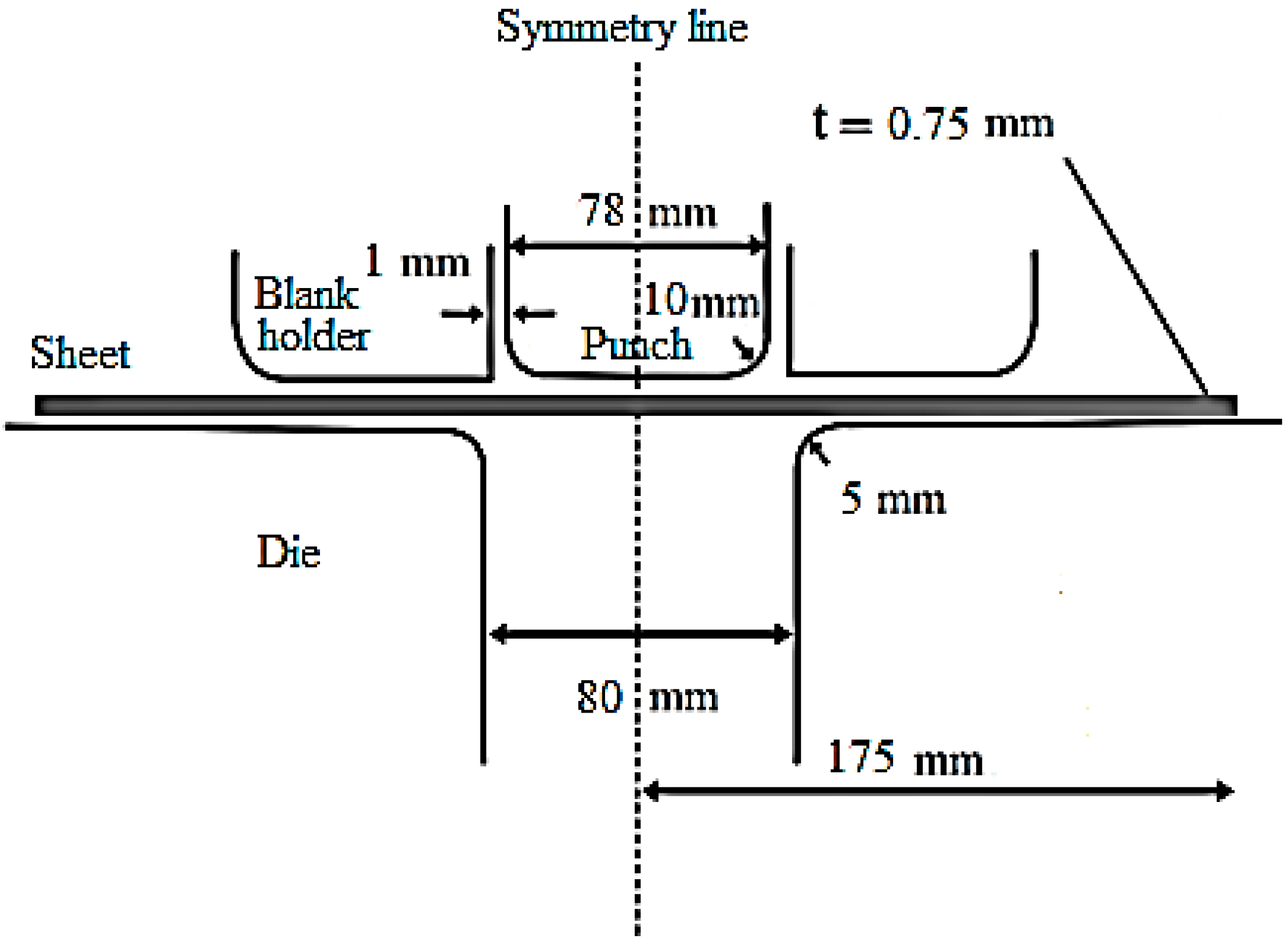

2.2.2. U-Shape Deep Drawing Sample

3. Results and Discussion

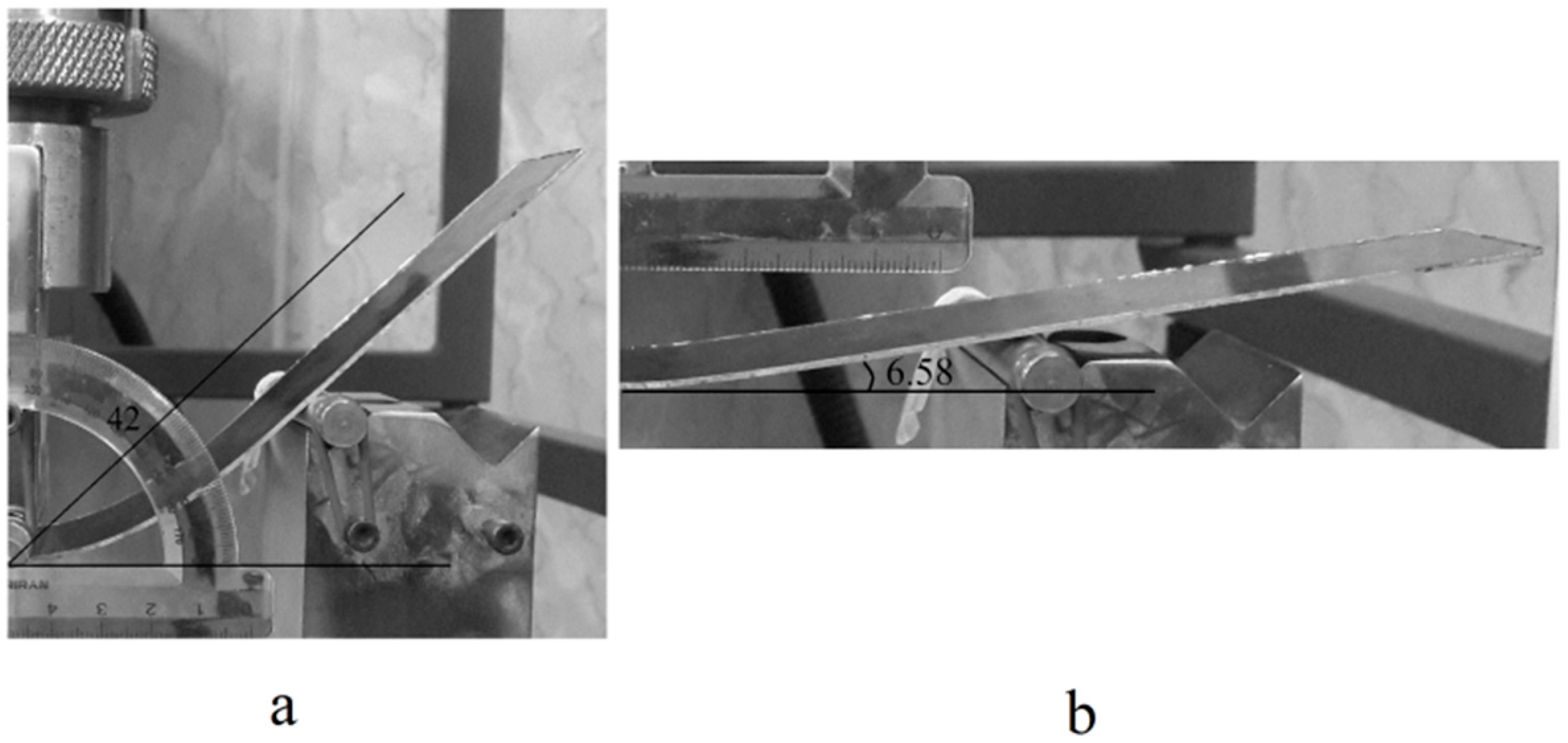

3.1. Three-Point Bending Test

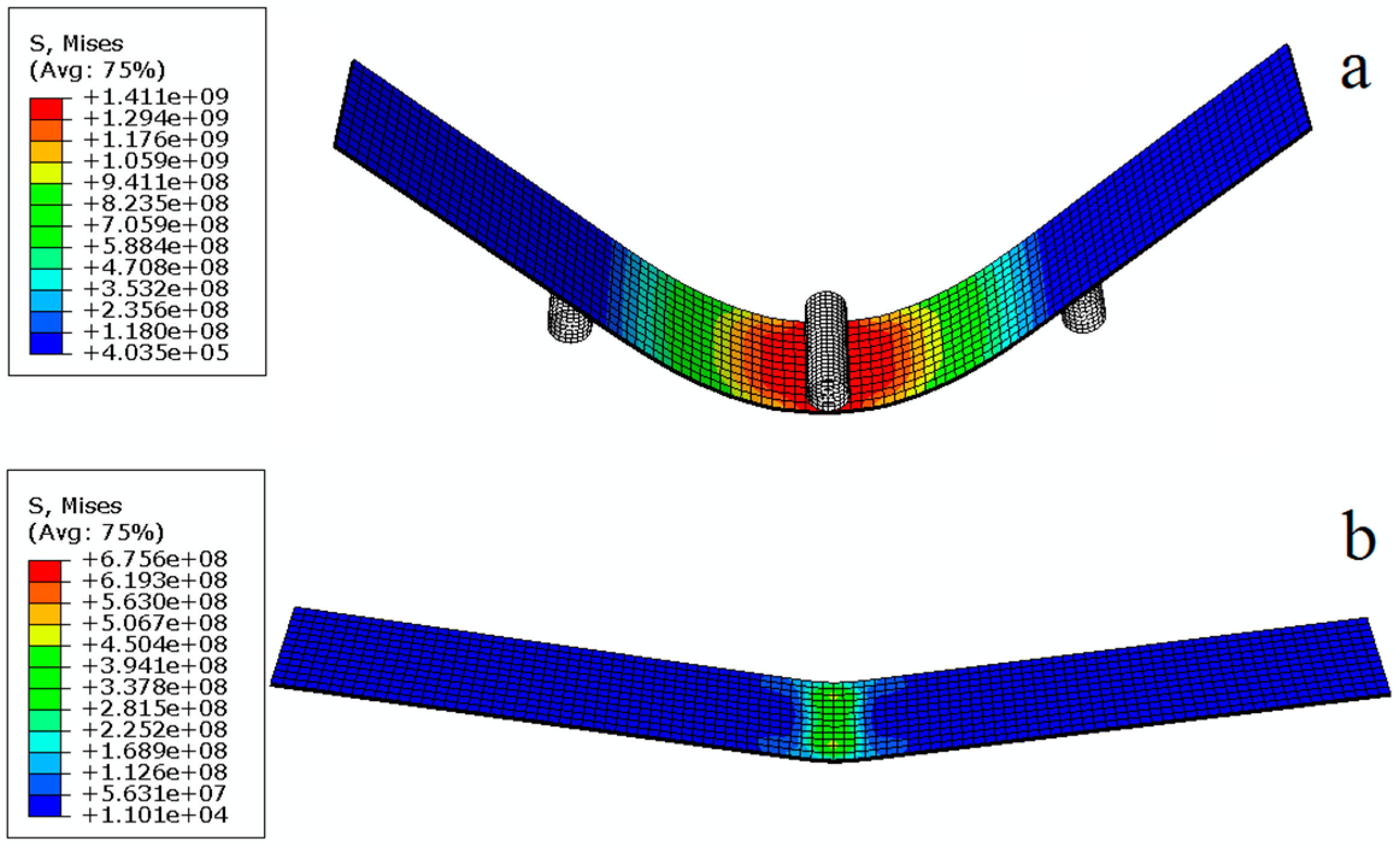

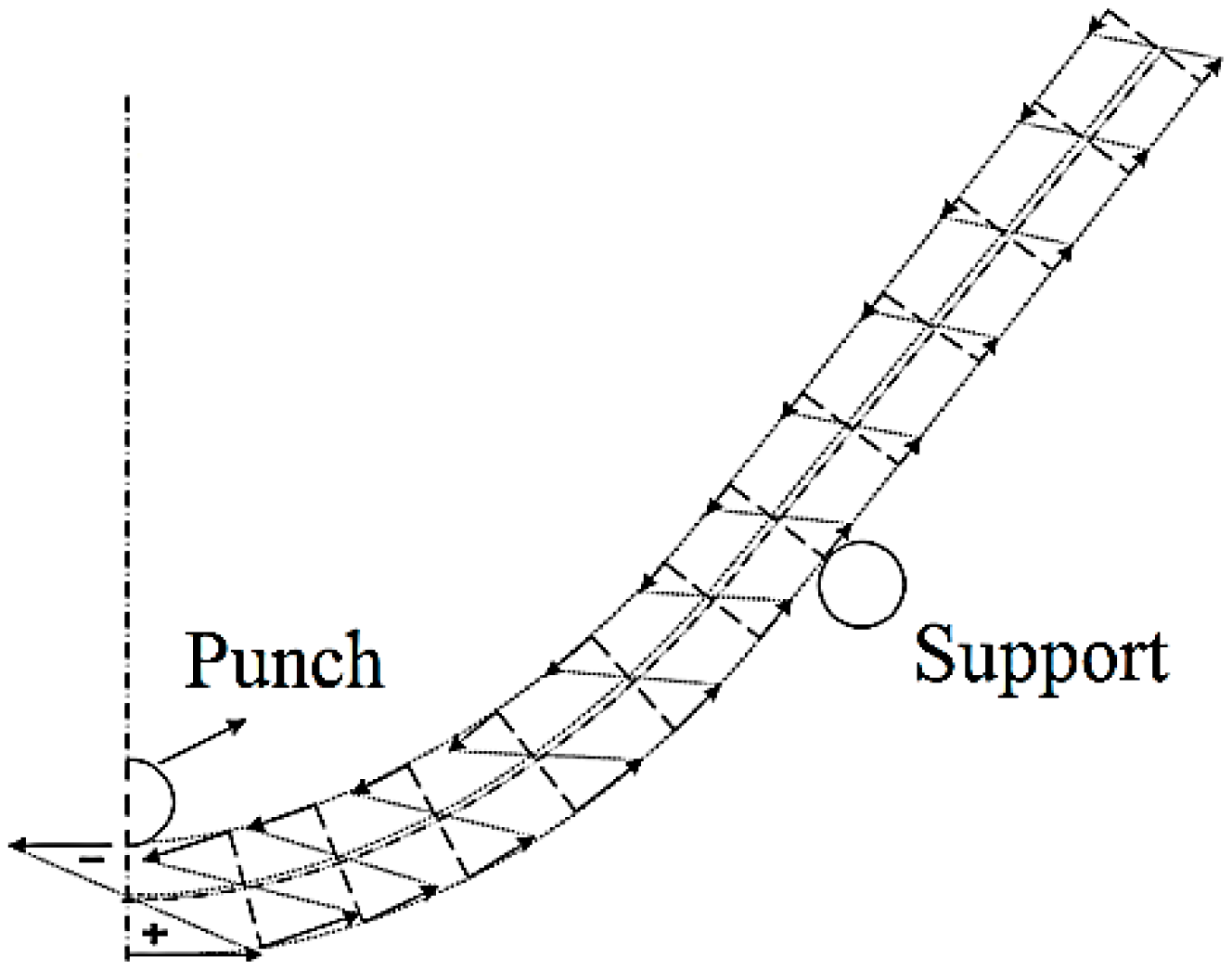

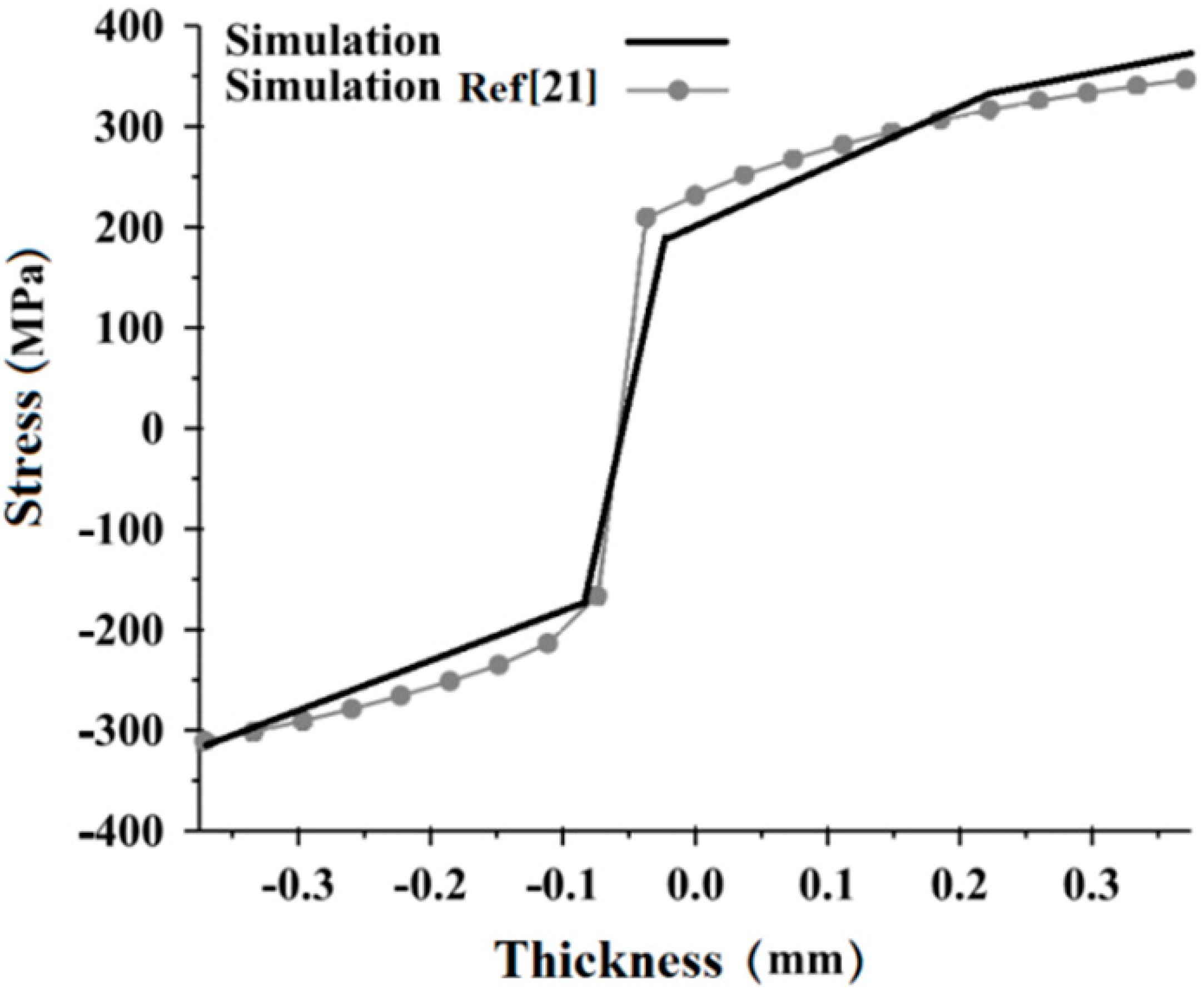

3.1.1. FE Simulation of Three-Point Bending Process

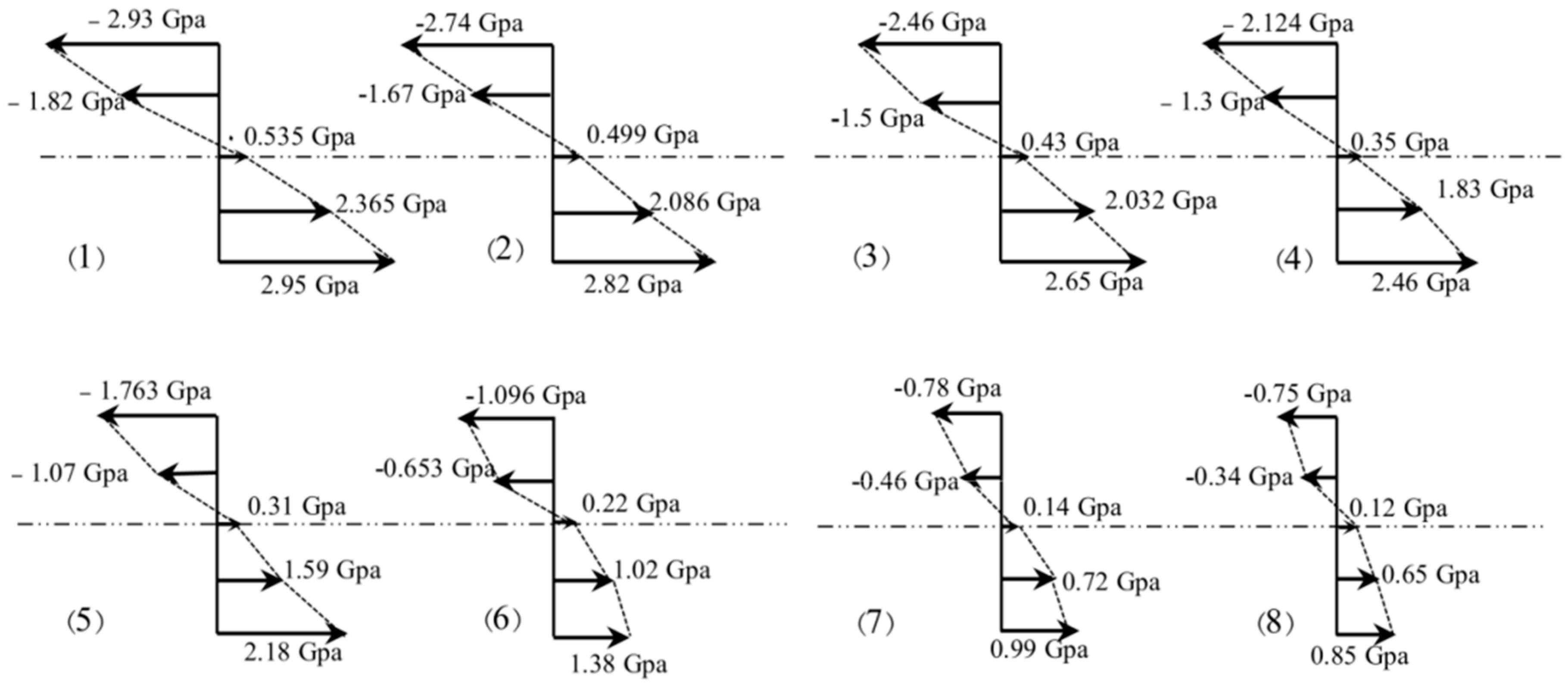

3.1.2. Decomposition of Stress for Three-Point Bending Test

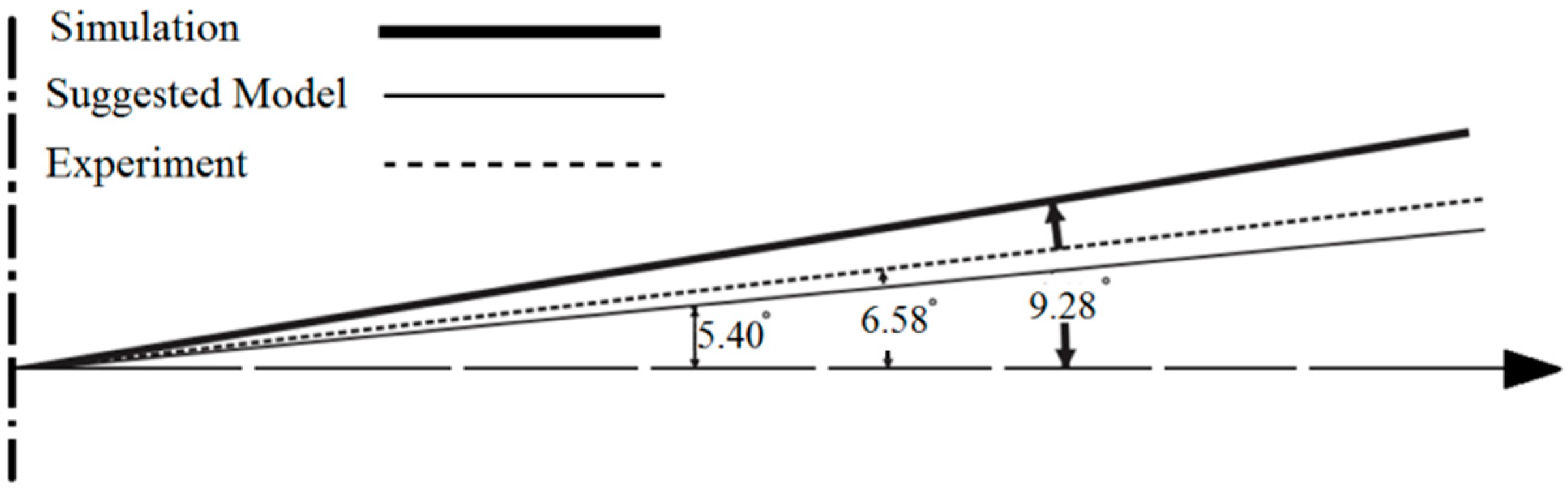

3.1.3. Evaluation of FE Prediction for Three-Point Bending Test

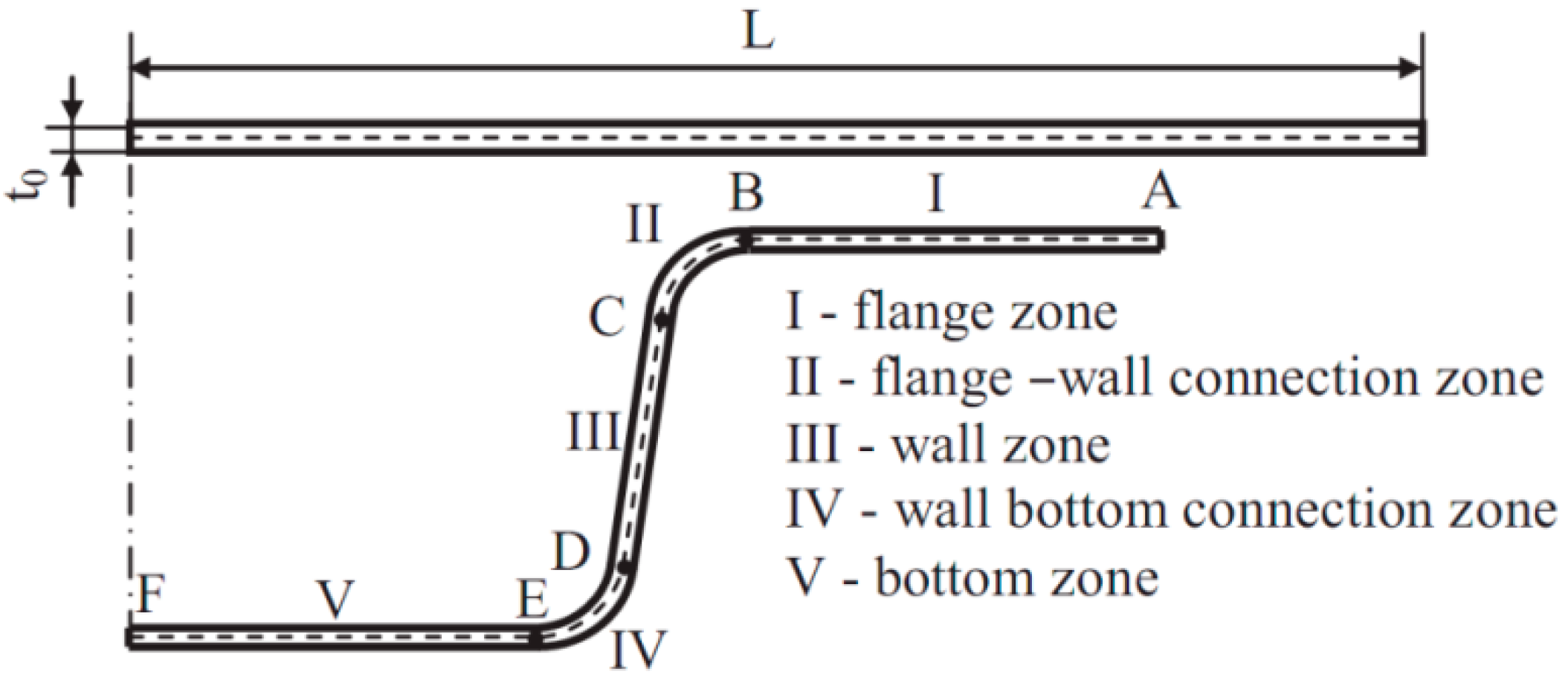

3.2. Deep Drawing Forming of Long U-Shape Profiles

3.2.1. Simulation for U-Shape Profiles Forming

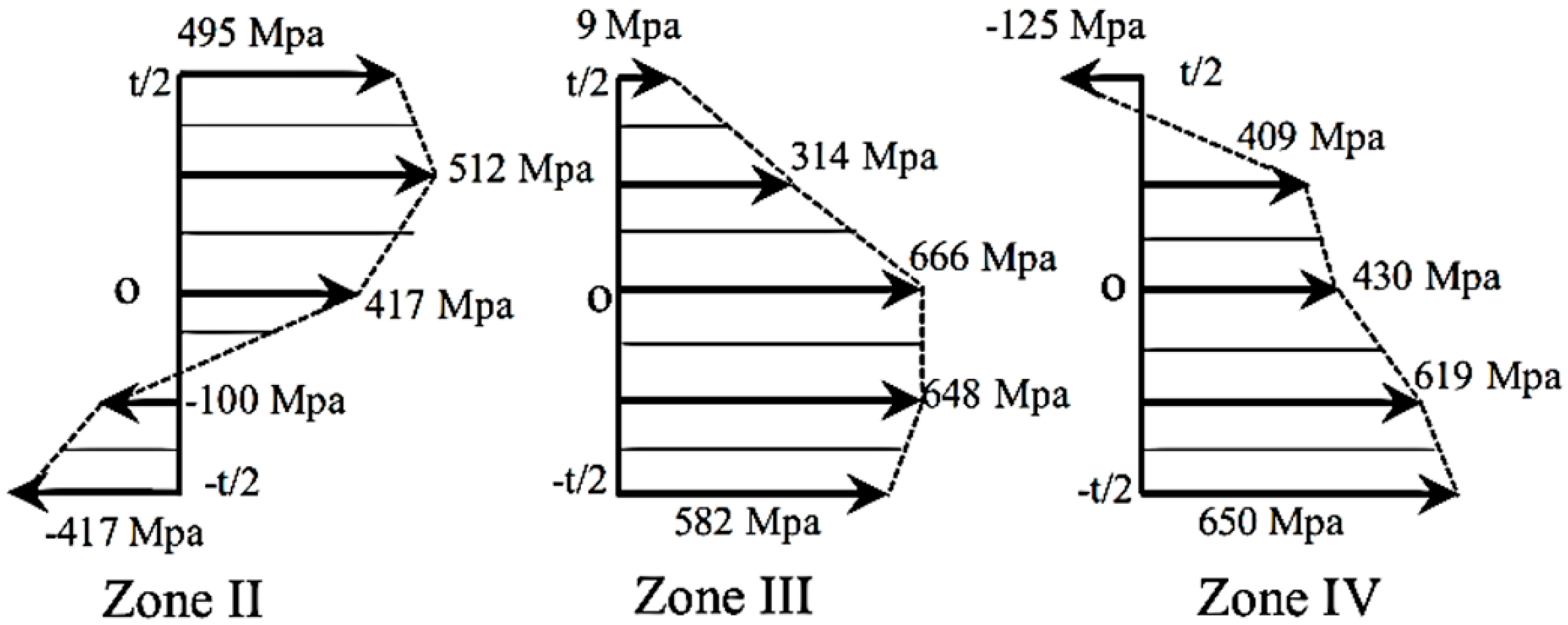

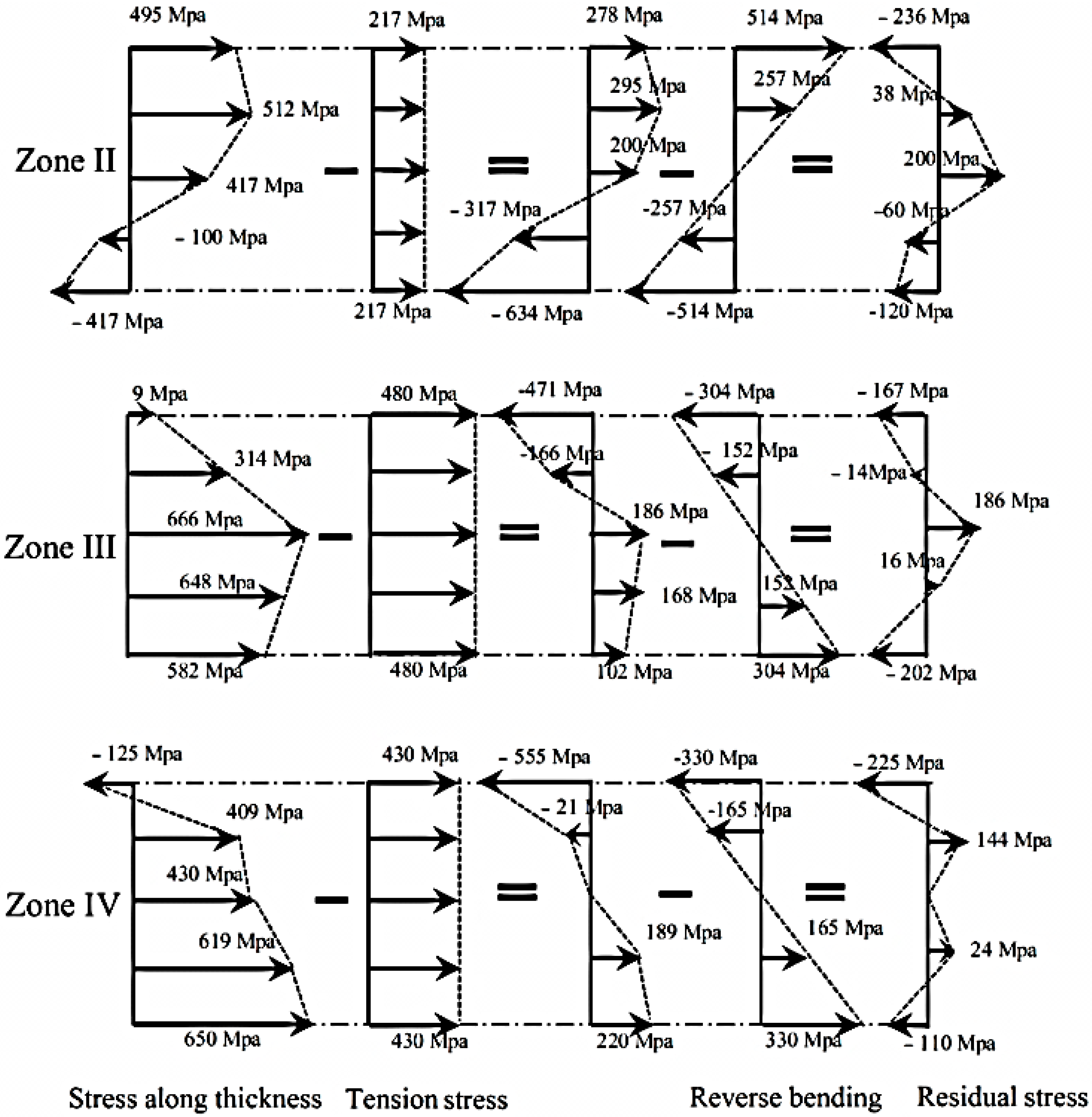

3.2.2. Decomposition of Stress for Deep Drawing Process

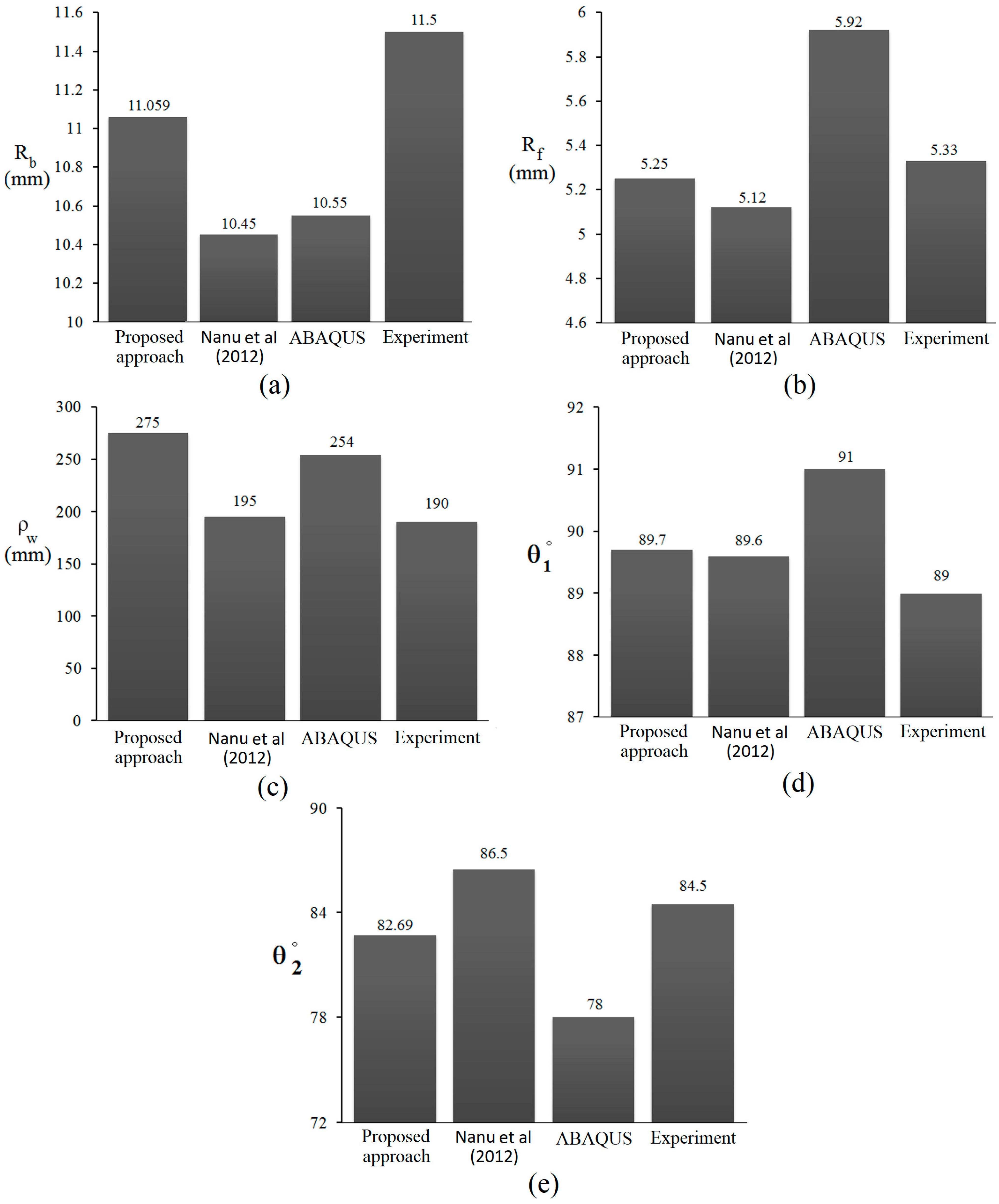

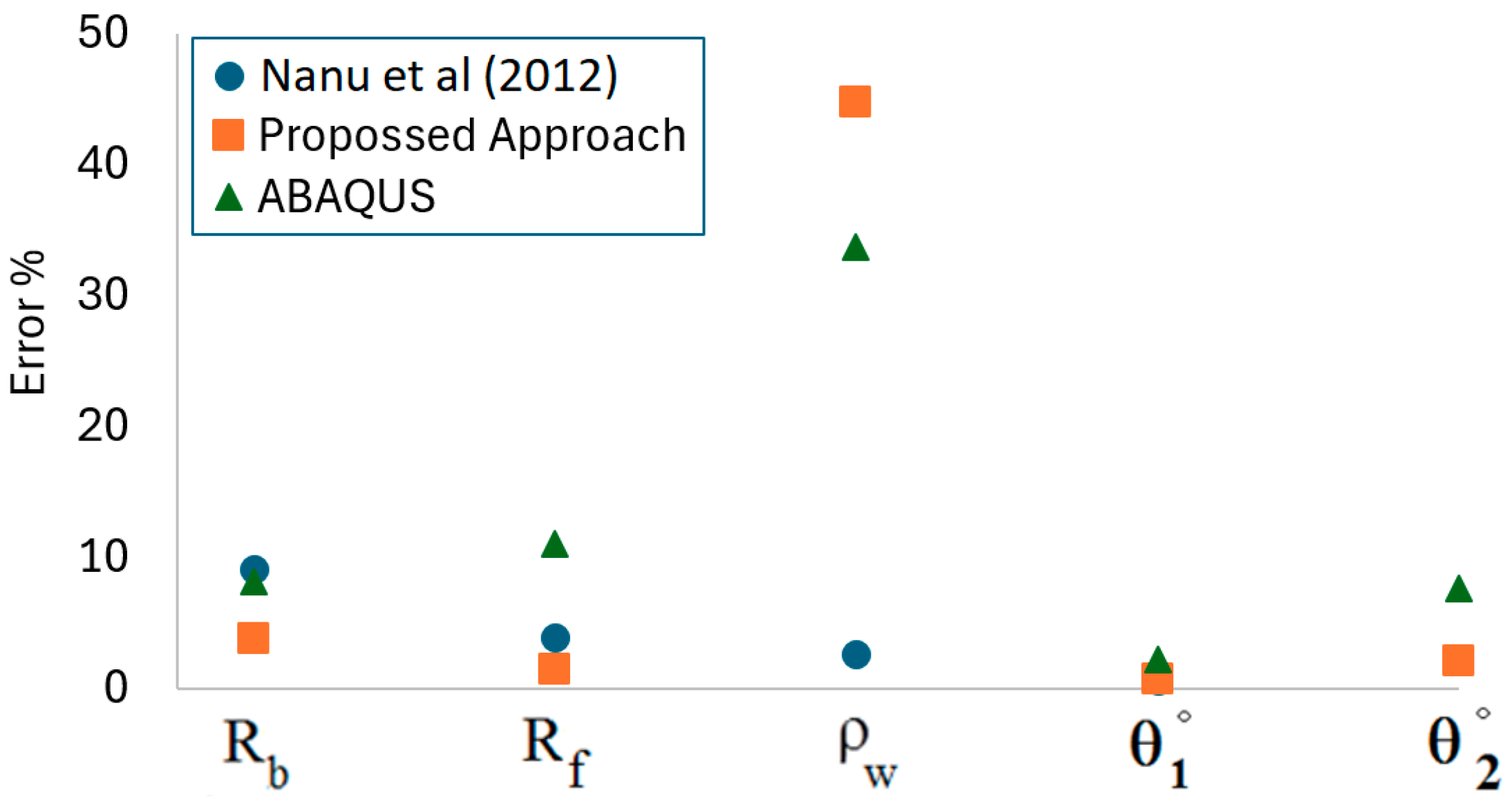

3.2.3. Evaluation of FE Simulation for Deep Drawing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morestin, F.; Boivin, M.; Silva, C. Elasto plastic formulation using a kinematic hardening model for springback analysis in sheet metal forming. J. Mater. Process. Technol. 1996, 56, 619–630. [Google Scholar] [CrossRef]

- Moon, Y.H.; Kim, D.W.; Van Tyne, C.J. Analytical model for prediction of sidewall curl during stretch-bend sheet metal forming. Int. J. Mech. Sci. 2008, 50, 666–675. [Google Scholar] [CrossRef]

- Yi, H.; Kim, D.; Van Tyne, C.; Moon, Y. Analytical prediction of springback based on residual differential strain during sheet metal bending. Proc. Inst. Mech. Eng. Part C 2008, 222, 117–129. [Google Scholar] [CrossRef]

- Lee, M.G.; Kim, J.H.; Chung, K.; Kim, S.J.; Wagoner, R.H.; Kim, H.Y. Analytical springback model for lightweight hexagonal close-packed sheet metal. Int. J. Plast. 2009, 25, 399–419. [Google Scholar] [CrossRef]

- Asnafi, N. On springback of double-curved autobody panels. Int. J. Mech. Sci. 2001, 43, 5–37. [Google Scholar] [CrossRef]

- Xue, P.; Yu, T.X.; Chu, E. An energy approach for predicting springback of metal sheets after double-curvature forming, Part I: Axisymmetric stamping. Int. J. Mech. Sci. 2001, 43, 1893–1914. [Google Scholar] [CrossRef]

- Xue, P.; Yu, T.X.; Chu, E. An energy approach for predicting springback of metal sheets after double-curvature forming, Part II: Unequal double-curvature forming. Int. J. Mech. Sci. 2001, 43, 1915–1924. [Google Scholar] [CrossRef]

- Verma, R.K.; Haldar, A. Effect of normal anisotropy on springback. J. Mater. Process. Technol. 2007, 190, 300–304. [Google Scholar] [CrossRef]

- Zhang, D.; Cui, Z.; Ruan, X.; Li, Y. An analytical model for predicting springback and side wall curl of sheet after U-bending. Comput. Mater. Sci. 2007, 38, 707–715. [Google Scholar] [CrossRef]

- Cu, S.; Sun, Y.; Wu, K. Machine learning methods for springback control in roll forming. Int. J. Mater. Form 2025, 18, 7. [Google Scholar] [CrossRef]

- Xu, J.; Yan, J.; Huang, Y.; Ding, D. Simulation and Prediction of Springback in Sheet Metal Bending Process Based on Embedded Control System. Sensors 2024, 24, 7863. [Google Scholar] [CrossRef] [PubMed]

- Takalkar, A.S.; Lenin Babu, M.C. A review on effect of thinning, wrinkling and spring-back on deep drawing process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 233, 1011–1036. [Google Scholar] [CrossRef]

- Kalujniy, O.V.; Kalujniy, V.L.; Aliiev, S.I.; Markov, O.E.; Levchenko, V.M. Investigation of variants of deep drawing of steel hollow parts. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 19. [Google Scholar] [CrossRef]

- Çelik, Y.; Ülke, I.; Yurdakul, M. A springback minimization study using the experimental design methods for 15-5 PH stainless steel material in the hydroforming process. World J. Eng. 2024. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, Y.; Fu, P.; Qi, S.; Zhao, J. On orthotropic elastic constitutive modeling for springback prediction. Exp. Mech. 2024, 64, 3–19. [Google Scholar] [CrossRef]

- Karabulut, S.; Esen, I.; Şahin, E. Springback prediction performance and experimental analysis in the V-bending process of SCGADUB1180 advanced high strength steel. Jordan J. Mech. Ind. Eng. 2024, 18, 441–453. [Google Scholar]

- Hajiahmadi, S.; Moslemi Naeini, H.; Talebi-Ghadikolaee, H.; Safdarian, R.; Zeinolabedin-Beygi, A. Insights into spring-back prediction: A comparative analysis of constitutive models for perforated U-shaped roll-formed steel profiles. Int. J. Adv. Manuf. Technol. 2024, 134, 1915–1933. [Google Scholar] [CrossRef]

- Sarkar, M.Z.; Sargeant, D.; Sharma, R.; Knezevic, M.; Fullwood, D.T.; Miles, M.P. Springback behavior after air bending of pre-strained AA 6016-T4 sheets: Influence of dislocation density and backstress on model accuracy. J. Manuf. Process. 2024, 131, 1437–1450. [Google Scholar] [CrossRef]

- Spišák, E.; Majerníková, J.; Mulidrán, P.; Hajduk, J.; Ruda, F. Springback analysis and prediction of automotive steel sheets used in compression bending. Materials 2025, 18, 774. [Google Scholar] [CrossRef]

- Abdullah, E.; Jalil, A. Enhancing experimental prediction of springback in forming processes using advanced finite element modelling. J. Mach. Eng. 2025, 25, 79–101. [Google Scholar] [CrossRef]

- Nanu, N.; Brabie, G. Analytical model for prediction of springback parameters in the case of U stretch–bending process as a function of stresses distribution in the sheet thickness. Int. J. Mech. Sci. 2012, 64, 11–21. [Google Scholar] [CrossRef]

- Abdullah, E.; Jalil, A. A hybrid advanced analysis approach for predicting spring back phenomena existing in metals. Adv. Sci. Technol. Res. J. 2025, 19, 185–199. [Google Scholar] [CrossRef] [PubMed]

- Aalouch, T.; Touache, A.; Mrabti, I.E.; Bouziane, K.; Hakimi, A.E.; Chamat, A. Investigation of the accurate FEA model of the springback prediction in deep drawing. In Proceedings of the 2024 4th International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Fez, Morocco, 16–17 May 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Rasheed Mohameed, B.; Mhdi Mubarak, E.M.; Alsalihi, N.H. Effect of Die’s Shape, Sheet Thickness and Type of Alloy on the Springback Phenomenon. Eng. Technol. J. 2012, 30, 1446–1461. [Google Scholar] [CrossRef]

- Burchitz, I.A. Improvement of Springback Prediction in Sheet Metal Forming. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2008. [Google Scholar]

- Beer, F.; Johnston, E.; DeWolf, J.; Mazurek, D. Mechanics of Materials, 8th ed.; McGraw-Hill: New York, NY, USA, 2020; ISBN 978-1-260-11327-3. [Google Scholar]

- Ugural, A.C. Stresses in Plates and Shells; McGraw-Hill: New York, NY, USA, 1981. [Google Scholar]

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024. Available online: https://www.astm.org/e0008_e0008m-22.html (accessed on 1 October 2024).

- Hill, R. The Mathematical Theory of Plasticity; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Cui, X.; Xiao, A.; Du, Z.; Yan, Z.; Yu, H. Springback reduction of L-shaped part using magnetic pulse forming. Materials 2020, 10, 390. [Google Scholar] [CrossRef]

| S | Cr | C | Si | Mn | P | Fe |

|---|---|---|---|---|---|---|

| (%) | ||||||

| 0.0098 | 0.153 | 0.733 | 0.191 | 0.654 | 0.0148 | base |

| E (GPa) | σy (MPa) | σu (MPa) | υ (Typical) | Uniform Elongation, εu (%) |

|---|---|---|---|---|

| 210 | 1383 | 1566 | 0.3 | 4.7 |

| C | Si | Mn | P | S | Al | Ti | N | Fe |

|---|---|---|---|---|---|---|---|---|

| (%) | ||||||||

| 0.002 | 0.006 | 0.097 | 0.01 | 0.01 | 0.029 | 0.057 | 0.0032 | <99.78 |

| Young Modulus, E (MPa) | Yield Strength, σy (MPa) | Uniform Elongation, εu (%) | Total Elongation, εtot (%) |

|---|---|---|---|

| 210,000 | 131.2 | 21.42 | 38.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaziri Sereshk, M.R.; Mohamadi Bidhendi, H. Prediction of Large Springback in the Forming of Long Profiles Implementing Reverse Stretch and Bending. J. Exp. Theor. Anal. 2025, 3, 16. https://doi.org/10.3390/jeta3020016

Vaziri Sereshk MR, Mohamadi Bidhendi H. Prediction of Large Springback in the Forming of Long Profiles Implementing Reverse Stretch and Bending. Journal of Experimental and Theoretical Analyses. 2025; 3(2):16. https://doi.org/10.3390/jeta3020016

Chicago/Turabian StyleVaziri Sereshk, Mohammad Reza, and Hamed Mohamadi Bidhendi. 2025. "Prediction of Large Springback in the Forming of Long Profiles Implementing Reverse Stretch and Bending" Journal of Experimental and Theoretical Analyses 3, no. 2: 16. https://doi.org/10.3390/jeta3020016

APA StyleVaziri Sereshk, M. R., & Mohamadi Bidhendi, H. (2025). Prediction of Large Springback in the Forming of Long Profiles Implementing Reverse Stretch and Bending. Journal of Experimental and Theoretical Analyses, 3(2), 16. https://doi.org/10.3390/jeta3020016