Mixed Reality in Building Construction Inspection and Monitoring: A Systematic Review

Abstract

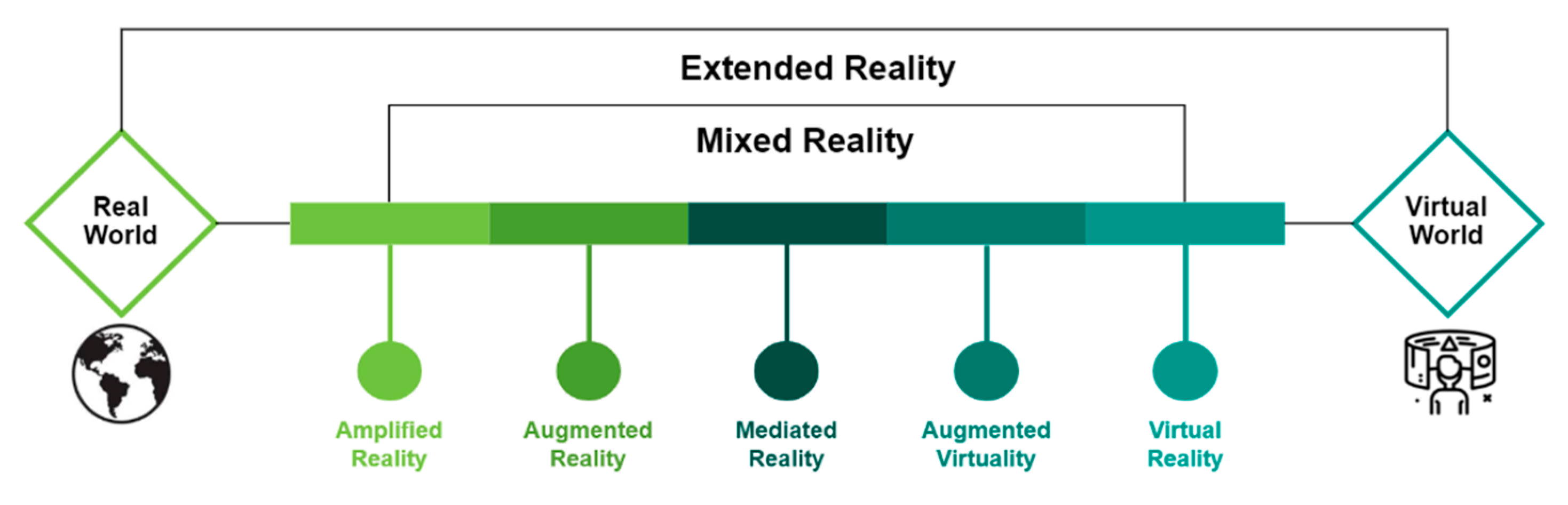

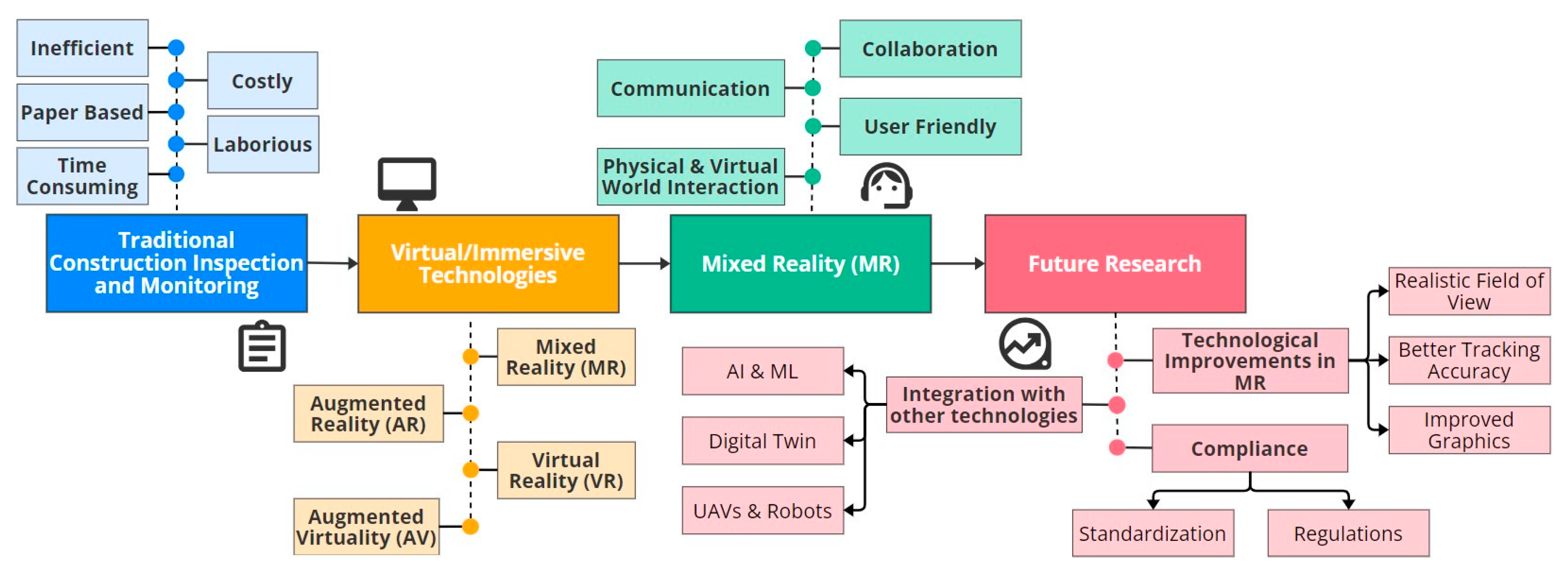

1. Introduction

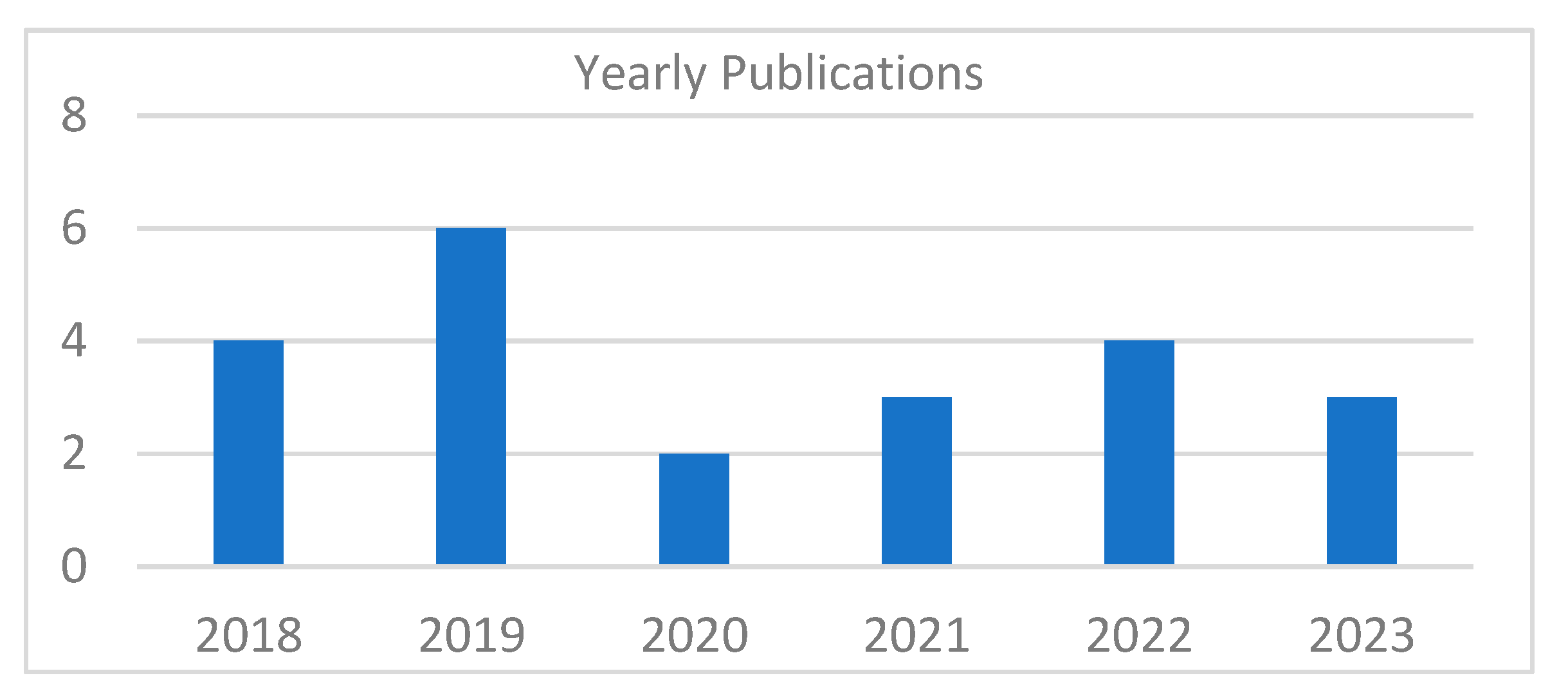

2. Methodology

2.1. Search Strategy

2.2. Screening and Selection

- The study must focus on using MR technology in building construction.

- It should provide insights into applying MR in inspection and monitoring processes.

- The study must be an original research article or a case study.

- In the case of multiple articles, duplicates were removed.

- Articles not written in English were also excluded.

3. Results

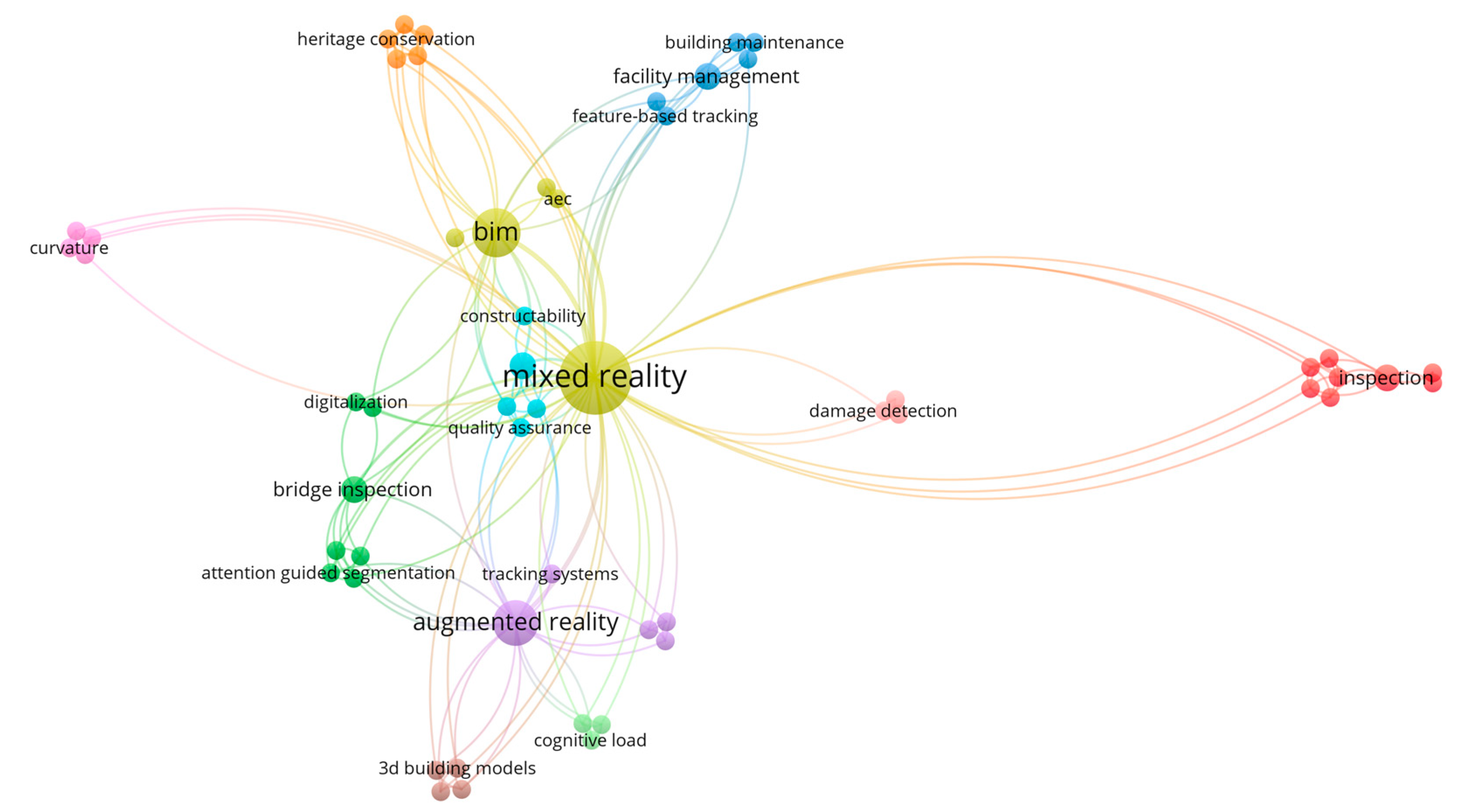

3.1. Visualization

3.2. Integration with Building Information Modeling (BIM)

3.3. Inspections

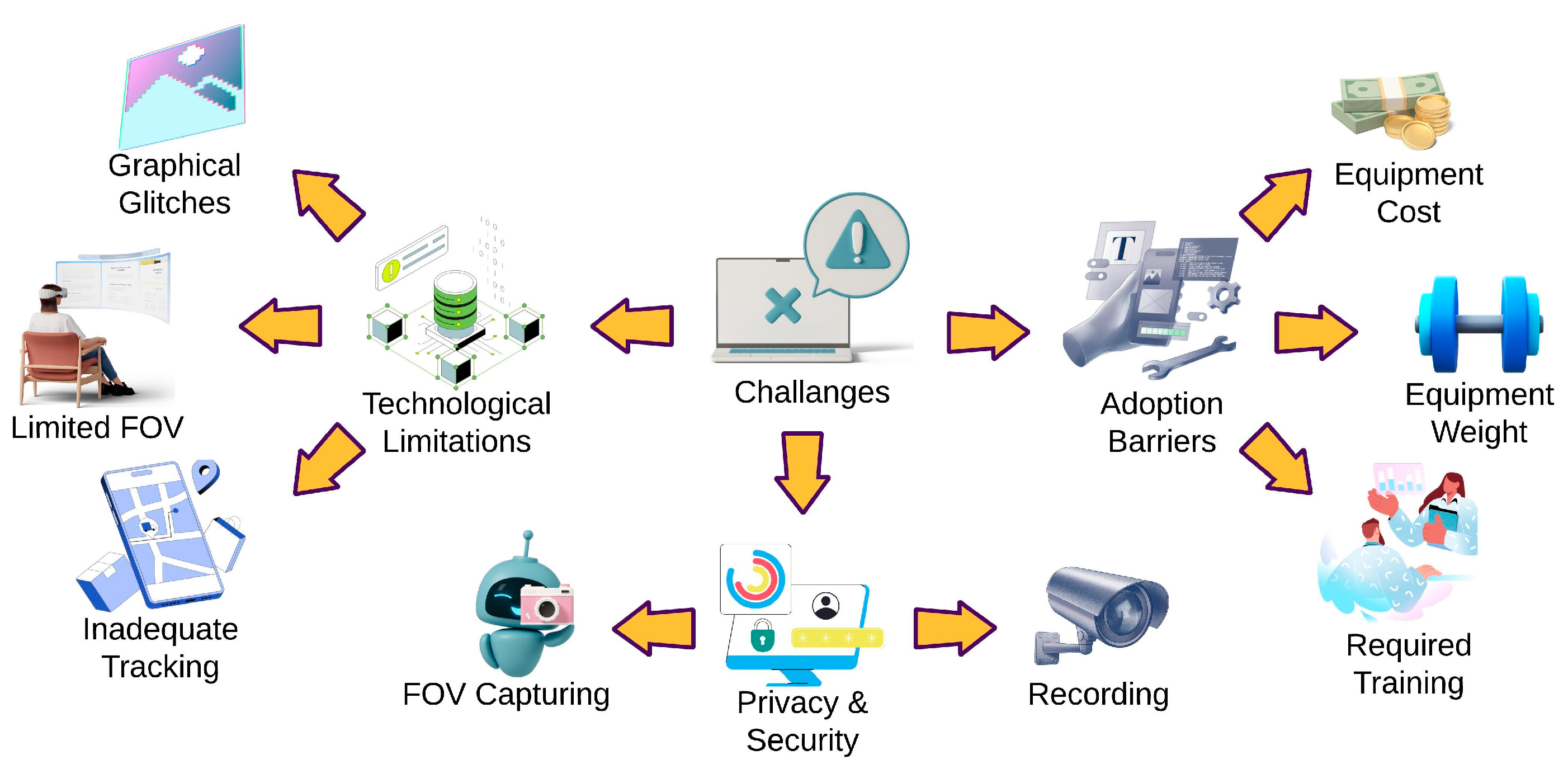

4. Challenges

4.1. Technological Limitations

4.2. Adoption Barriers

4.3. Security and Privacy Concerns

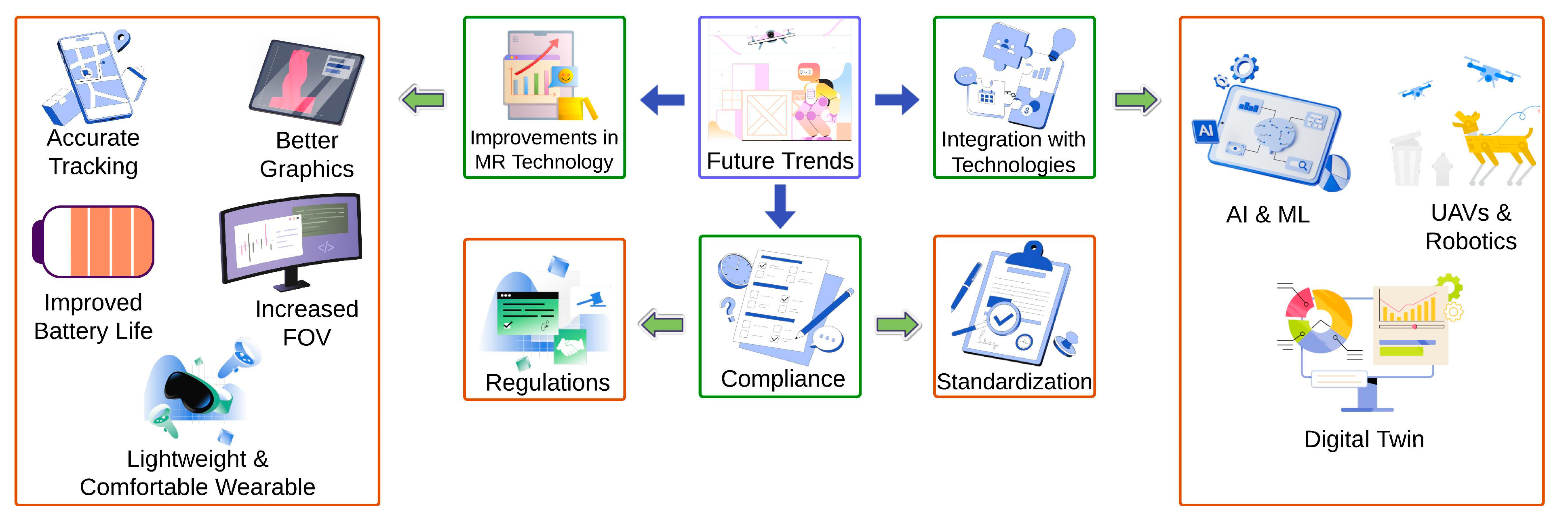

5. Future Trends

5.1. Improvements in MR Technology

5.2. Integration with Other Emerging Technologies

5.3. Increasing Standardization and Regulation

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ofori, G. Nature of the Construction Industry, Its Needs and Its Development: A Review of Four Decades of Research. J. Constr. Dev. Ctries. 2015, 20, 115. [Google Scholar]

- Fulford, R.G. The Implications of the Construction Industry to National Wealth. Eng. Constr. Archit. Manag. 2019, 26, 779–793. [Google Scholar] [CrossRef]

- Rivera, A.; Le, N.; Kashiwagi, J.; Kashiwagi, D. Identifying the Global Performance of the Construction Industry. J. Adv. Perform. Inf. Value 2016, 8, 7–19. [Google Scholar] [CrossRef]

- Basar, O.; Basar, P. Challenges in construction industry. Press. Procedia 2023, 17, 196–197. [Google Scholar] [CrossRef]

- Memon, A.H.; Memon, A.Q.; Khahro, S.H.; Javed, Y. Investigation of Project Delays: Towards a Sustainable Construction Industry. Sustainability 2023, 15, 1457. [Google Scholar] [CrossRef]

- Davila Delgado, J.M.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and Automated Systems in Construction: Understanding Industry-Specific Challenges for Adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Liang, H.; Lee, S.-C.; Bae, W.; Kim, J.; Seo, S. Towards UAVs in Construction: Advancements, Challenges, and Future Directions for Monitoring and Inspection. Drones 2023, 7, 202. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Davila Delgado, J.M.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial Intelligence in the Construction Industry: A Review of Present Status, Opportunities and Future Challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Speicher, M.; Hall, B.D.; Nebeling, M. What Is Mixed Reality? In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems, Glasgow, UK, 4–9 May 2019; ACM: New York, NY, USA, 2019; pp. 1–15. [Google Scholar]

- Nguyen, D.-C.; Nguyen, T.-Q.; Jin, R.; Jeon, C.-H.; Shim, C.-S. BIM-Based Mixed-Reality Application for Bridge Inspection and Maintenance. Constr. Innov. 2022, 22, 487–503. [Google Scholar] [CrossRef]

- Ochoa, S.F.; Bravo, G.; Pino, J.A.; Rodríguez-Covili, J. Coordinating Loosely-Coupled Work in Construction Inspection Activities. Group Decis. Negot. 2011, 20, 39–56. [Google Scholar] [CrossRef]

- Halder, S.; Afsari, K. Robots in Inspection and Monitoring of Buildings and Infrastructure: A Systematic Review. Appl. Sci. 2023, 13, 2304. [Google Scholar] [CrossRef]

- Al-Adhami, M. Extended Reality Approach for Construction Quality Control. In Proceedings of the CIB World Building Congress 2019, Hong Kong, China, 17–21 June 2019; 9. [Google Scholar]

- Ciampa, E.; Vito, L.D.; Pecce, M.R. Practical Issues on the Use of Drones for Construction Inspections. J. Phys. Conf. Ser. 2019, 1249, 012016. [Google Scholar] [CrossRef]

- Jahanshahi, M.R.; Masri, S.F. Adaptive Vision-Based Crack Detection Using 3D Scene Reconstruction for Condition Assessment of Structures. Autom. Constr. 2012, 22, 567–576. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, C.; Tang, X.; Wang, S.; Zhang, Z. A Review of Vision-Laser-Based Civil Infrastructure Inspection and Monitoring. Sensors 2022, 22, 5882. [Google Scholar] [CrossRef]

- Ding, L.; Li, K.; Zhou, Y.; Love, P.E.D. An IFC-Inspection Process Model for Infrastructure Projects: Enabling Real-Time Quality Monitoring and Control. Autom. Constr. 2017, 84, 96–110. [Google Scholar] [CrossRef]

- Seo, J.; Han, S.; Lee, S.; Kim, H. Computer Vision Techniques for Construction Safety and Health Monitoring. Adv. Eng. Inform. 2015, 29, 239–251. [Google Scholar] [CrossRef]

- Lin, J.-R.; Hu, Z.-Z.; Li, J.-L.; Chen, L.-M. Understanding On-Site Inspection of Construction Projects Based on Keyword Extraction and Topic Modeling. IEEE Access 2020, 8, 198503–198517. [Google Scholar] [CrossRef]

- Chaiyasarn, K. Damage Detection and Monitoring for Tunnel Inspection Based on Computer Vision. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2014. [Google Scholar]

- David Jenkins, M.; Buggy, T.; Morison, G. An Imaging System for Visual Inspection and Structural Condition Monitoring of Railway Tunnels. In Proceedings of the 2017 IEEE Workshop on Environmental, Energy, and Structural Monitoring Systems (EESMS), Milan, Italy, 24–25 July 2017; pp. 1–6. [Google Scholar]

- Koch, C.; Georgieva, K.; Kasireddy, V.; Akinci, B.; Fieguth, P. A Review on Computer Vision Based Defect Detection and Condition Assessment of Concrete and Asphalt Civil Infrastructure. Adv. Eng. Inform. 2015, 29, 196–210. [Google Scholar] [CrossRef]

- Structure-from-Motion (SfM). Computer Vision: A Reference Guide; Ikeuchi, K., Ed.; Springer International Publishing: Cham, Switzerland, 2021; p. 1217. ISBN 978-3-030-63416-2. [Google Scholar]

- Linder, W. Digital Photogrammetry: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-662-06725-3. [Google Scholar]

- Insa-Iglesias, M.; Jenkins, M.D.; Morison, G. 3D Visual Inspection System Framework for Structural Condition Monitoring and Analysis. Autom. Constr. 2021, 128, 103755. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, H.; Yang, Y. Implementation of Augmented Reality for Segment Displacement Inspection during Tunneling Construction. Autom. Constr. 2017, 82, 112–121. [Google Scholar] [CrossRef]

- Allcoat, D.; Hatchard, T.; Azmat, F.; Stansfield, K.; Watson, D.; Von Mühlenen, A. Education in the Digital Age: Learning Experience in Virtual and Mixed Realities. J. Educ. Comput. Res. 2021, 59, 795–816. [Google Scholar] [CrossRef]

- Tamura, H.; Yamamoto, H.; Katayama, A. Mixed Reality: Future Dreams Seen at the Border between Real and Virtual Worlds. IEEE Comput. Graph. Appl. 2001, 21, 64–70. [Google Scholar] [CrossRef]

- Kent, L.; Snider, C.; Gopsill, J.; Hicks, B. Mixed Reality in Design Prototyping: A Systematic Review. Des. Stud. 2021, 77, 101046. [Google Scholar] [CrossRef]

- Sobota, B.; Korečko, Š.; Hudák, M.; Sivý, M. Mixed Reality: A Known Unknown. In Mixed Reality and Three-Dimensional Computer Graphics; Sobota, B., Cvetković, D., Eds.; IntechOpen: London, UK, 2020; ISBN 978-1-83962-622-7. [Google Scholar]

- Moore, H.F.; Gheisari, M. A Review of Virtual and Mixed Reality Applications in Construction Safety Literature. Safety 2019, 5, 51. [Google Scholar] [CrossRef]

- Bahri, H.; Krcmarik, D.; Moezzi, R.; Kočí, J. Efficient Use of Mixed Reality for BIM System Using Microsoft HoloLens. IFAC-Pap. 2019, 52, 235–239. [Google Scholar] [CrossRef]

- Koch, C.; Neges, M.; König, M.; Abramovici, M. Natural Markers for Augmented Reality-Based Indoor Navigation and Facility Maintenance. Autom. Constr. 2014, 48, 18–30. [Google Scholar] [CrossRef]

- Park, C.-S.; Lee, D.-Y.; Kwon, O.-S.; Wang, X. A Framework for Proactive Construction Defect Management Using BIM, Augmented Reality and Ontology-Based Data Collection Template. Autom. Constr. 2013, 33, 61–71. [Google Scholar] [CrossRef]

- Hou, L.; Wang, X.; Truijens, M. Using Augmented Reality to Facilitate Piping Assembly: An Experiment-Based Evaluation. J. Comput. Civ. Eng. 2015, 29, 05014007. [Google Scholar] [CrossRef]

- Yabuki, N.; Onoue, T.; Fukuda, T.; Yoshida, S. A Heatstroke Prediction and Prevention System for Outdoor Construction Workers. Vis. Eng. 2013, 1, 11. [Google Scholar] [CrossRef]

- Wang, X.; Love, P.E.D.; Kim, M.J.; Wang, W. Mutual Awareness in Collaborative Design: An Augmented Reality Integrated Telepresence System. Comput. Ind. 2014, 65, 314–324. [Google Scholar] [CrossRef]

- Shirazi, A.; Behzadan, A.H. Content Delivery Using Augmented Reality to Enhance Students’ Performance in a Building Design and Assembly Project. Adv. Eng. Educ. 2015, 4, n3. [Google Scholar]

- Riexinger, G.; Kluth, A.; Olbrich, M.; Braun, J.-D.; Bauernhansl, T. Mixed Reality for On-Site Self-Instruction and Self-Inspection with Building Information Models. Procedia CIRP 2018, 72, 1124–1129. [Google Scholar] [CrossRef]

- Ens, B.; Lanir, J.; Tang, A.; Bateman, S.; Lee, G.; Piumsomboon, T.; Billinghurst, M. Revisiting Collaboration through Mixed Reality: The Evolution of Groupware. Int. J. Hum.-Comput. Stud. 2019, 131, 81–98. [Google Scholar] [CrossRef]

- Bhanu, A.; Sharma, H.; Piratla, K.; Chalil Madathil, K. Application of Augmented Reality for Remote Collaborative Work in Architecture, Engineering, and Construction—A Systematic Review. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2022, 66, 1829–1833. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef] [PubMed]

- Araújo, A.G.; Pereira Carneiro, A.M.; Palha, R.P. Sustainable Construction Management: A Systematic Review of the Literature with Meta-Analysis. J. Clean. Prod. 2020, 256, 120350. [Google Scholar] [CrossRef]

- Azhar, S.; Haroon, A.; Rabayah, H. Investigating Mixed Reality Applications in Building Inspection and Maintenance. Transform. Constr. Real. Capture Technol. 2022. [Google Scholar] [CrossRef]

- El Ammari, K.; Hammad, A. Remote Interactive Collaboration in Facilities Management Using BIM-Based Mixed Reality. Autom. Constr. 2019, 107, 102940. [Google Scholar] [CrossRef]

- Feng, C.-W.; Chen, C.-W. Using BIM and MR to Improve the Process of Job Site Construction and Inspection. WIT Trans. Built Environ. 2019, 192, 21–32. [Google Scholar]

- VOSviewer. Visualizing Scientific Landscapes. Available online: https://www.vosviewer.com// (accessed on 22 December 2023).

- Chalhoub, J.; Ayer, S.K. Using Mixed Reality for Electrical Construction Design Communication. Autom. Constr. 2018, 86, 1–10. [Google Scholar] [CrossRef]

- Casini, M. Extended Reality for Smart Building Operation and Maintenance: A Review. Energies 2022, 15, 3785. [Google Scholar] [CrossRef]

- Free Icons, Clipart Illustrations, Photos, and Music. Available online: https://icons8.com (accessed on 21 December 2023).

- Czarski, M.; Ng, Y.T.; Vogt, M.; Juraschek, M.; Thiede, B.; Tan, P.S.; Thiede, S.; Herrmann, C. A Mixed Reality Application for Studying the Improvement of HVAC Systems in Learning Factories. Procedia Manuf. 2020, 45, 373–378. [Google Scholar] [CrossRef]

- Wang, S.; Zargar, S.A.; Yuan, F.-G. Augmented Reality for Enhanced Visual Inspection through Knowledge-Based Deep Learning. Struct. Health Monit. 2021, 20, 426–442. [Google Scholar] [CrossRef]

- Begić, H.; Galić, M. A Systematic Review of Construction 4.0 in the Context of the BIM 4.0 Premise. Buildings 2021, 11, 337. [Google Scholar] [CrossRef]

- Khan, A.; Sepasgozar, S.; Liu, T.; Yu, R. Integration of BIM and Immersive Technologies for AEC: A Scientometric-SWOT Analysis and Critical Content Review. Buildings 2021, 11, 126. [Google Scholar] [CrossRef]

- Raimbaud, P.; Lou, R.; Merienne, F.; Danglade, F.; Figueroa, P.; Hernandez, J.T. BIM-Based Mixed Reality Application for Supervision of Construction. In Proceedings of the 2019 IEEE Conference on Virtual Reality and 3D User Interfaces (VR), Osaka, Japan, 23–27 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1903–1907. [Google Scholar]

- Al-Sabbag, Z.A.; Yeum, C.M.; Narasimhan, S. Enabling Human–Machine Collaboration in Infrastructure Inspections through Mixed Reality. Adv. Eng. Inform. 2022, 53, 101709. [Google Scholar] [CrossRef]

- Wu, S.; Hou, L.; Zhang, G.; Chen, H. Real-Time Mixed Reality-Based Visual Warning for Construction Workforce Safety. Autom. Constr. 2022, 139, 104252. [Google Scholar] [CrossRef]

- Katika, T.; Konstantinidis, F.K.; Papaioannou, T.; Dadoukis, A.; Bolierakis, S.N.; Tsimiklis, G.; Amditis, A. Exploiting Mixed Reality in a Next-Generation IoT Ecosystem of a Construction Site. In Proceedings of the 2022 IEEE International Conference on Imaging Systems and Techniques (IST), Taiwan, China, 21–23 June 2022; pp. 1–6. [Google Scholar]

- Oyama, E.; Tokoi, K.; Suzuki, R.; Nakamura, S.; Shiroma, N.; Watanabe, N.; Agah, A.; Okada, H.; Omori, T. Augmented Reality and Mixed Reality Behavior Navigation System for Telexistence Remote Assistance. Adv. Robot. 2021, 35, 1223–1241. [Google Scholar] [CrossRef]

- Silva, H.; Resende, R.; Breternitz, M. Mixed Reality Application to Support Infrastructure Maintenance. In Proceedings of the 2018 International Young Engineers Forum (YEF-ECE), Costa da Caparica, Portugal, 4 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 50–54. [Google Scholar]

- Riedlinger, U.; Klein, F.; Hill, M.; Lambracht, C.; Nieborowski, S.; Holst, R.; Bahlau, S.; Oppermann, L. Evaluation of Mixed Reality Support for Bridge Inspectors Using BIM Data: Digital Prototype for a Manual Task with a Long-Lasting Tradition. i-com 2022, 21, 253–267. [Google Scholar] [CrossRef]

- Holzwarth, V.; Steiner, S.; Schneider, J.; Vom Brocke, J.; Kunz, A. BIM-Enabled Issue and Progress Tracking Services Using Mixed Reality. In Smart Services Summit; West, S., Meierhofer, J., Ganz, C., Eds.; Progress in IS; Springer International Publishing: Cham, Switzerland, 2021; pp. 49–58. ISBN 978-3-030-72089-6. [Google Scholar]

- Sanna, A.; Manuri, F.; De Pace, F. Special Issue “Wearable Augmented and Mixed Reality Applications”. Information 2019, 10, 289. [Google Scholar] [CrossRef]

- Zhang, C.; Xi, M.; Adcock, M. Improving Visual Search Tasks by Bending the Virtual City Twins: A Preliminary Study in Virtual Reality. In Proceedings of the 33rd Australian Conference on Human-Computer Interaction, Melbourne, VIC, Australia, 30 November–2 December 2021; ACM: New York, NY, USA, 2021; pp. 252–256. [Google Scholar]

- John Samuel, I.; Salem, O.; He, S. Defect-Oriented Supportive Bridge Inspection System Featuring Building Information Modeling and Augmented Reality. Innov. Infrastruct. Solut. 2022, 7, 247. [Google Scholar] [CrossRef]

- Howard, S.; Jang, R.; O’Keeffe, V.; Manning, K.; Trott, R.; Hordacre, A.-L.; Spoehr, J. Visual Inspection with Augmented Reality Head-Mounted Display: An Australian Usability Case Study. Hum. Factors Ergon. Manuf. Serv. Ind. 2023, 33, 272–296. [Google Scholar] [CrossRef]

- Soto, P. Architecture Evaluation for Extended Reality Devices. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2022. [Google Scholar]

- Devagiri, J.S.; Paheding, S.; Niyaz, Q.; Yang, X.; Smith, S. Augmented Reality and Artificial Intelligence in Industry: Trends, Tools, and Future Challenges. Expert Syst. Appl. 2022, 207, 118002. [Google Scholar] [CrossRef]

- Devo, A.; Mao, J.; Costante, G.; Loianno, G. Autonomous Single-Image Drone Exploration with Deep Reinforcement Learning and Mixed Reality. IEEE Robot. Autom. Lett. 2022, 7, 5031–5038. [Google Scholar] [CrossRef]

- Tromp, J.G. Extended Reality & The Backbone: Towards a 3D Mirrorworld. In Roadmapping Extended Reality; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2022; pp. 193–227. ISBN 978-1-119-86581-0. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwar, R.M.I.; Azhar, S. Mixed Reality in Building Construction Inspection and Monitoring: A Systematic Review. Virtual Worlds 2024, 3, 319-332. https://doi.org/10.3390/virtualworlds3030017

Anwar RMI, Azhar S. Mixed Reality in Building Construction Inspection and Monitoring: A Systematic Review. Virtual Worlds. 2024; 3(3):319-332. https://doi.org/10.3390/virtualworlds3030017

Chicago/Turabian StyleAnwar, Rana Muhammad Irfan, and Salman Azhar. 2024. "Mixed Reality in Building Construction Inspection and Monitoring: A Systematic Review" Virtual Worlds 3, no. 3: 319-332. https://doi.org/10.3390/virtualworlds3030017

APA StyleAnwar, R. M. I., & Azhar, S. (2024). Mixed Reality in Building Construction Inspection and Monitoring: A Systematic Review. Virtual Worlds, 3(3), 319-332. https://doi.org/10.3390/virtualworlds3030017