1. Introduction

The exponential increase in population and the corresponding needs for food, energy, transportation, housing, and consumer goods have put pressure on the planet’s limits and pushed us rapidly towards resource depletion [

1]. According to Eurostat statistics [

2], the circular utilization of materials in the European Union (EU) in 2022 was around 11.5%. This means that on average, only 11.5% of recycled waste was reintroduced into production processes, compared to 88.5% of raw materials being extracted from nature. In Portugal, the use was lower, totaling just 2.6%, one of the lowest rates in the EU. The construction sector is responsible for the majority of steel consumption in the EU. In 2022, it accounted for 37% of total steel consumption, representing a 1.23% increase compared to the previous year [

3]. Currently, projections predict an increase of more than 30% in global steel demand by 2050 [

4].

Carbon emissions in the steel industry have, in fact, increased over the last five years, and this shows that the path towards carbon neutrality targets, in this sector, is far from being achieved [

5]. The data points to a progressive increase in demand for resources, with steel consumption in the construction sector being one of the main contributors to global greenhouse gas (GHG) emissions.

Various initiatives in both the public and private sectors have contributed to the collective effort to implement the circular economy. This study assessed the sustainability of a process for reconditioning “W”-profile metal road guardrail beams. Guardrails are road retaining devices used on highways to prevent an uncontrolled vehicle from leaving the carriageway and colliding with fixed objects, structures, or other vehicles in the opposite direction. Beams are the horizontal elements of metal guardrails, and 1 km of road can contain up to 4 km of beams if they are used continuously on the sides and center dividers.

Guardrails can be flexible, semi-flexible, or rigid, depending on the road protection characteristics required (

Table 1). Flexible guardrails are characterized by their high deflection capacity when subjected to impacts and can be built with steel cables or metal beams with a “W” profile, fixed to so-called “weak” poles, due to their low mechanical resistance and high deformation capacity. Flexible guardrails are predominantly used on North American highways [

6]. Semi-flexible metal guardrails are so-called because they have mechanical behavior that is intermediate between flexible and rigid guardrails. There are many variations in materials and models, depending on the country where they are used and the manufacturer. It is the most common security guard system used in Portugal [

6]. Semi-flexible guards are composed of three main elements: the beam, the horizontal element; the pole, the vertical element; and the buffer, which serves as the connecting element between the beam and the pole. Some models of semi-flexible guardrail do not have a buffer, and the beam is fixed directly to the pole. Rigid guardrails are made of concrete and are highly resistant to impacts from both light and heavy vehicles [

7].

The metal beams of the guardrails are generally made from hot-rolled steel, 2.5 to 3 mm thick and 2 or 4 m long between poles. The protective coating consists of a process called galvanization, where a thin layer of zinc is applied to protect against corrosion. The hot rolling process involves passing the steel, still in a semi-solid state and at high temperatures, through equipment that gradually reduces its thickness until it can be rolled into coils.

The two main production methods used in the steel industry are basic oxygen blast furnaces (BF-BOFs) and electric arc furnaces (EAFs). In blast furnaces, iron ore is converted into molten iron by burning mineral coal (coke), which is then injected with pure oxygen at high pressure to remove impurities. In this process, it is possible to include a certain amount of scrap metal for production [

8]. In the electric arc method, secondary materials (scrap metal) are melted in a furnace through fusion by the passage of electric current [

9].

A study carried out in United States steel plants [

9] in 2023 showed that BF-BOF plants are much more polluting and energy-intensive (85% of energy produced from coal), compared to EAF plants, which consume 90% less energy and emit 90% fewer GHG emissions.

The growing global demand for steel creates an impasse in terms of sustainability: the most sustainable process is EAFs; however, global scrap production is not sufficient to meet market demand [

8]. Consequently, primary steel, produced from iron ore using the BF-BOF method, remains the primary source of steel consumed worldwide [

8].

Burchart-Korol (2013) [

10] studied steel production in Poland, characterized by 50.4% use of the BF-BOF method and 49.6% use of the EAF method, and found that the most significant environmental impact was on human health, primarily derived from the consumption of fossil fuels and iron ore. In this study, production using the BF-BOF method had the greatest impact on GHG emissions, fossil fuel consumption, and dust emissions. It also concluded that the use of alternative fuels can reduce GHG emissions.

In Italy, Renzulli et al. (2016) [

11] carried out a cradle-to-grave LCA at the EU’s largest integrated steel plant (BF-BOF) in Taranto. This plant’s production was partially paralyzed due to environmental issues. They concluded that most of the impacts were related to energy consumption and the toxicity of the resulting emissions. The impacts associated with blast furnace and coke oven production were the most significant. Another aspect mentioned was the large amount of slag waste generated and not reused, deposited in a mine on the plant’s premises.

Liang et al. (2019) [

12] carried out a cradle-to-grave LCA at a steel mill in China producing hot-rolled steel. The study evaluated the base scenario of the current production method (70% BF-BOF and 30% EAF) and compared it with alternative scenarios where, among other things, mineral coal was replaced by vegetable coal and the rate of secondary materials in the process was increased. As a result, it concluded that the BF-BOF process was responsible for most of the impacts in the categories studied, with 73% of the Abiotic Depletion Potential (ADP), 54% of the Eutrophication Potential (EP), and 69% of the Global Warming Potential (GWP). It was also described that switching from mineral coal to vegetable coal and increasing the EAF component in the process were able to reduce the total impacts by 14% and 25%, respectively, compared to the base scenario.

The scientific literature on the LCA of guardrails is scarce. Hyde and Engel (2000) [

13] conducted a study at the University of Massachusetts, in which a Life Cycle Cost Assessment (LCCA) of the connecting blocks between poles and beams was performed using recycled materials, known as offset blocks. Blocks made from plastic, wood, and steel were compared. The life cycle phases were identified, as were the main material and energy flows, and environmental impacts; however, these were not quantified or compared with one another. The aim of this study was to compare the economic benefits of using offset blocks made from recycled materials.

Bolin and Smith (2013) [

14] published an LCA study comparing the environmental impacts associated with guardrail poles made from galvanized steel and wood treated with chromated copper arsenate from cradle to gate. In this study, only the guardrail poles were assessed. They concluded that the use of wooden poles generally results in lower environmental impacts compared to galvanized steel poles.

Gerrieri et al. (2015) [

15] studied an Italian road and noted that ancillary road equipment, including guardrails, received limited attention in the context of highway LCA. The study considered the complete set of guardrails and a functional unit of 1 km of highway. The impact categories studied were Global Warming Potential, Acidification Potential, Tropospheric Ozone Formation Potential, and Eutrophication Potential. The contributions of the guardrails were compared with those of the pavement and traffic in the use phase to establish their relative impacts. They concluded that the most significant overall impact occurs in the use stage, with vehicle traffic; however, they also noted that guardrails should not be neglected in highway LCA studies, since their contribution was in the same order as or even higher than the contribution of the pavement, in the impact categories Global Warming Potential and Eutrophication Potential.

Liu et al. (2023) [

16] analyzed the carbon footprint of double and triple-wave “W”-type metal guardrails used on Chinese highways. The study was carried out on the complete set of guardrails. The functional unit adopted was 1 km of highway, and the type of steel used was cold-rolled steel. As a result, they observed that for 1 km of highway, the double-wave guard resulted in higher emissions than the triple-wave guard.

Herein, the aim of this study is to evaluate the environmental impacts associated with a reconditioning process for the reuse of metal guardrail beams developed in Portugal. The reconditioning process studied was developed through a partnership between a research institution and private companies in the road concession and construction sectors, with the aim of reusing the beams on highways instead of using new and purpose-made metals. Currently, beams damaged in accidents or removed during roadworks in Portugal are sent to waste managers, where the metals present are recycled. To better understand the potential benefits of this approach, its environmental impacts were compared with data obtained from an environmental product declaration (EPD) issued for metal guardrail beams [

17].

2. Materials and Methods

The methodology adopted in the study was Life Cycle Assessment (LCA), where the mass and energy flows of the reconditioning process were analyzed and the resulting impacts were compared with data from the production of new beams. The data from the reconditioned beams were collected during the prototyping stage of the process development. The LCA data for the new beam production were obtained from an EPD from Sweden.

The impact assessment method used was compatible with that used in the development of the EPD, which served as a reference. The four stages described in standards ISO 14040 [

18] and 14044 [

19] were covered: Goal and Scope Definition, Life Cycle Inventory (LCI), Life Cycle Impacts Assessment (LCIA), and Interpretation.

2.1. Goal and Scope Definition

The unit declared in the LCA study was determined based on the unit declared in the EPD, which was 1 ton of reconditioned beams, produced from used and damaged beams that would be sent for treatment as waste.

The system boundary adopted in the study is restricted to the product stage, cradle to gate (A1–A3). This boundary was defined in relation to the primary objective of the study: to assess the environmental impacts associated with the production stage of the reconditioned beam, for comparison with the production stage of the beam from primary materials. The end-of-life stages (C1–C4) of both reconditioned and new beams are not considered. Allocation was not used in the inputs and outputs of the Life Cycle Inventory (LCI).

The LCA study carried out has limitations, as it utilizes data sources from a prototyping project that is still in the development phase and may be modified to achieve a process that can be replicated on an industrial scale. The results of the LCA are compared with data from an EPD (steps A1–A3). The EPD used does not present LCI data and was developed based on currently obsolete Product Category Rules (PCRs). Nevertheless, given the lack of other available studies that could be used as a reference, this specific EPD was still used as a benchmark. The unknown composition of the beams used in the reconditioning process was also considered a limitation of the study.

To overcome the identified limitations, conservative LCI data were used, and the LCA was carried out, where possible, based on the most up-to-date PCR data available. The assumptions adopted in the study are described in

Table 2.

The assumptions used in the study are related to the composition of the beam used, the useful life of the reconditioned beams, and use and end-of-life scenarios, where they are considered equivalent to new beams. The study covers Portuguese, Swedish, and European data.

The reconditioning process and the limits of the system under study are illustrated in

Figure 1.

2.2. Lyfe Cycle Inventory (LCI)

The Life Cycle Inventory (LCI) data were obtained from the reconditioning process applied to a batch of beams. The galvanizing stage was not actually carried out, but it was included in the LCI, as the beams will necessarily receive an anti-corrosion treatment after reconditioning. Foreground data was provided by the Portuguese institutions developing this reconditioning process, which is at a prototype stage. Background data was obtained from the Ecoinvent database version 3.8. The sources of LCI data are listed in

Table 3.

No losses are considered in the process, since the damaged beams are sorted before being transported to the factory, where the reconditioning process takes place, and, in this sense, only beams that can be reconditioned are chosen. The storage facilities are not considered either, as the beams are stored outside until they are sorted and transported.

The Portuguese electricity mix, available in the Ecoinvent database, was used as the electricity input data.

The cleaning stage was modelled using generic data. This method used the area to be degreased as a reference product, in square meters per declared unit. As the database cleaning process data is unclear about the generation of hazardous waste, it was decided to include hazardous waste in the LCI, as a conservative approach.

All the inputs and outputs of the galvanizing process were modelled using the Ecoinvent database. This method used the area to be galvanized as a reference product, in square meters per declared unit. The use of packaging in the production process was not included.

The results of the life cycle inventory are shown in

Table 4. The secondary material data is derived from the final weight of the finished product, minus the amount of zinc added in the galvanizing stage. The quantities are presented according to the declared unit.

The amount of zinc was calculated using the concentration (0.6 kg/m2) per area (4 m2/beam) to be applied in the galvanizing stage and was not reported in the LCI, as it is included in the Ecoinvent process.

The input of secondary material (used beams) was calculated by subtracting the amount of zinc to be applied (54.05 kg) from the declared unit (1 ton) and was only included in the LCI as a reference, due to the system model used (allocation/cut-off). In this model, reused secondary materials are made available without environmental burdens. For this reason, in the LCIA stage, the secondary material input is zero.

It is considered that there is no biogenic carbon in the composition of the final product.

2.3. Lyfe Cycle Impact Assessment (LCIA)

The Life Cycle Impact Assessment (LCIA) methodology was defined since the reconditioning process data would be compared with EPD data. The LCIA method used to assess impacts was EF v3.0 EN15804, which is based on characterization factors defined by the European Commission (EF v3.0) [

20]. The impact indicators are assessed at the midpoint level and are shown in

Table 5.

Resource indicators (ISO 21930:2017 inventory indicators) were not assessed. This methodological choice was made in accordance with the study’s objective, which is to conduct a comparative assessment of environmental sustainability between production methods.

The study used Microsoft Excel spreadsheets and the Ecoinvent database, version 3.8, which is compatible with the version used in the EPD.

3. Results and Discussion

3.1. Life Cycle Impact Assessment (LCIA)

Before presenting the results of the life cycle impact assessment (LCA), it is important to discuss some of the key concepts involved in the LCA of secondary materials. The EN15804+A2:2019 standard [

21] defines that materials recovered from previous use or from waste and used as an input in another product system are considered secondary materials. The PCR [

22], related to the reference EPD, defines that the system boundary to the next product system is the point when the waste has become a usable flow. In this study, that point was defined in the storage area, after the selection of the beams to be reconditioned. For this purpose, the beams to be reconditioned are considered secondary, reusable materials.

According to Etiene et al. (2022) [

23], reusable materials are truly circular materials, and the production phase (A1–A3) is avoided because the reused product is made up of secondary materials that do not need to be transformed.

In the reconditioning process under study, only the A1 phase is avoided due to the use of secondary materials, while the A2 and A3 phases are necessary for the reuse of beams. Reconditioning was not considered a transformation process but a preparation process for reuse.

In the LCIA, the A1 stage has been avoided, and no environmental impacts were attributed to it. All the impact indicators were assessed according to the declared unit. The LCIA results of A1–A3 modules are shown in

Table 6 in aggregate, as required in PCR [

21].

The LCIA results are shown in

Figure 2 and reveal that electricity consumption is responsible for most of the impacts on the indicators assessed.

The results reveal that 83.55% of the GWP-total indicator is a result of electricity consumption in the reconditioning process, as well as 85.72% of the EP-freshwater, 88.12% of the AP, and 81.10% of the ADP fossil indicators.

Figure 3 illustrates the impacts of electricity more clearly when compared to the total impacts of the reconditioning process.

Electricity’s significant contribution to the ADP fossil indicator (81.10%) was attributed to the composition of the Portuguese electricity mix in the Ecoinvent database, which was used in the modeling. That mix may not be representative of the current energy mix since energy supply varies according to availability and market prices.

The galvanizing stage, due to the use of zinc, is the most representative in the ADP minerals and metals indicator, related to the depletion of mineral resources and metals, with an 85.08% contribution to impacts.

Transport is responsible for 45.82% of the impacts related to particulate matter emissions, 47.07% of the Land use indicator, and 40.32% of ODP, related to ozone depletion. Surprisingly, the transport stage is not very representative in the ADP fossil indicator, related to the depletion of fossil fuels, representing only 15.29% of the impacts.

The cleaning stage has a low relative contribution to the general impacts of the reconditioning process, being most represented in the WDP indicator (19.73%), related to the consumption of water resources, Ecotoxicity freshwater (12.51%), related to freshwater ecotoxicity, and EP-marine (12.31%), related to the eutrophication of marine waters. The impacts of hazardous waste generated in the cleaning stage were not very representative in the indicators studied and were even negative in the GWP-biogenic indicator, related to climate change derived from biogenic carbon.

3.2. Comparative Analysis

The comparative analysis between the production of beams from primary raw materials and the reconditioning process, which uses secondary material, was carried out by comparing the results of LCA in both processes in the product stages (A1-A3), as shown in

Table 7. It is essential to note that comparing the production processes of materials from different countries can introduce uncertainties into the evaluation process, primarily due to the specific characteristics of each region.

In this evaluation, the production of new beams was considered as a reference scenario for comparison with the reconditioning process. The data related to the production of new beams was obtained from an EPD [

17].

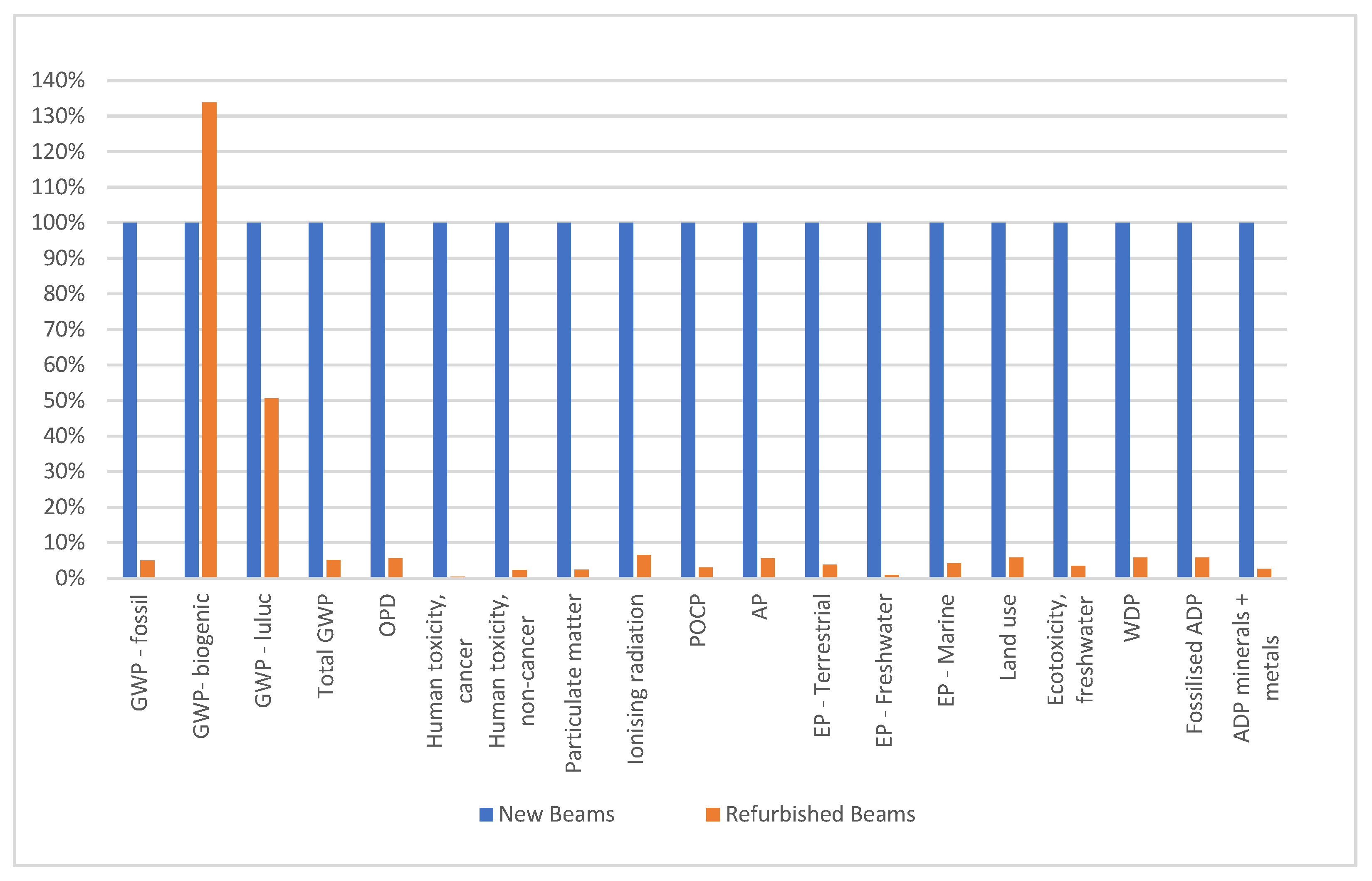

A comparison of the results of both processes reveals that the reconditioning process showed significantly lower results in most of the impact indicators evaluated, compared to the traditional production process used as a reference. The results are illustrated in

Figure 4.

Of the 19 impact indicators assessed, 18 showed lower results compared to the reference scenario. When only the lowest results were assessed, 17 indicators showed a reduction of between 93% and 99.6% in the observed impacts.

The biggest variation was seen in the Human toxicity, cancer indicator, which assesses the potential for cancer incidence, with impacts 99.64% lower than the value found in the reference scenario. This large variation was attributed to the use of secondary materials to replace primary materials. Significant impacts on human health from the production of metals have previously been demonstrated in LCA studies in the steel industry [

10,

11].

The GWP-total indicator resulted in a value 94.91% lower than the reference scenario. ADP fossil and ADP minerals and metals indicators showed 94.22% and 97.33% lower results, respectively, when using secondary materials. Indicators related to impacts on water resources, such as AP, EP, WDP, and Ecotoxicity, were also more than 90% lower than in the traditional production process.

GWP-biogenic indicator was the only one to show higher impacts than the reference scenario, with an increase of 33.7%. When we analyze the relative contributions to the indicator, we see that electricity is responsible for 87.80% of the impacts.

The significant differences in the LCA results between the two processes can be attributed mainly to the impacts of extracting natural resources, producing, and transporting the raw materials used in the manufacture of the Swedish product. The steel used in the reference scenario originates from China, the world’s largest steel producer. Approximately 90% of the Chinese steel production process is characterized by the BF-BOF method [

24], a highly polluting process that is intensive in the consumption of natural resources, fossil fuels, and energy [

9]. According to data declared in the DAP [

17], the raw material is made up of 26% secondary material, i.e., 74% of the raw material comes from primary material, which needs to be extracted, transported, and processed in China, and then transported to Europe and then to the factory to produce beams.

Reconditioned beams, on the other hand, incorporate at least 94.60% locally produced secondary materials, excluding zinc from galvanization, which is a recyclable product.

When we establish the relationship between the reduction in impacts in the reconditioning process with the reuse of secondary materials, we realized that the results obtained in the comparative analysis are in line with LCA studies of the steel industry, where the most significant impacts were detected on human health [

10,

11] due to the consumption of mineral resources, fossil fuels and energy [

11] and where the BF-BOF process was responsible for most of the impacts in the ADP, EP and GWP indicators [

12].

Modelling was carried out with alternative scenarios to assess the effects that the origin of the electricity and the distance from the storage centers could have on the LCA results. The modelling consisted of replacing the energy sources and transport distances, with the other data remaining unchanged.

3.3. Alternative Scenarios

3.3.1. Influence of Electricity

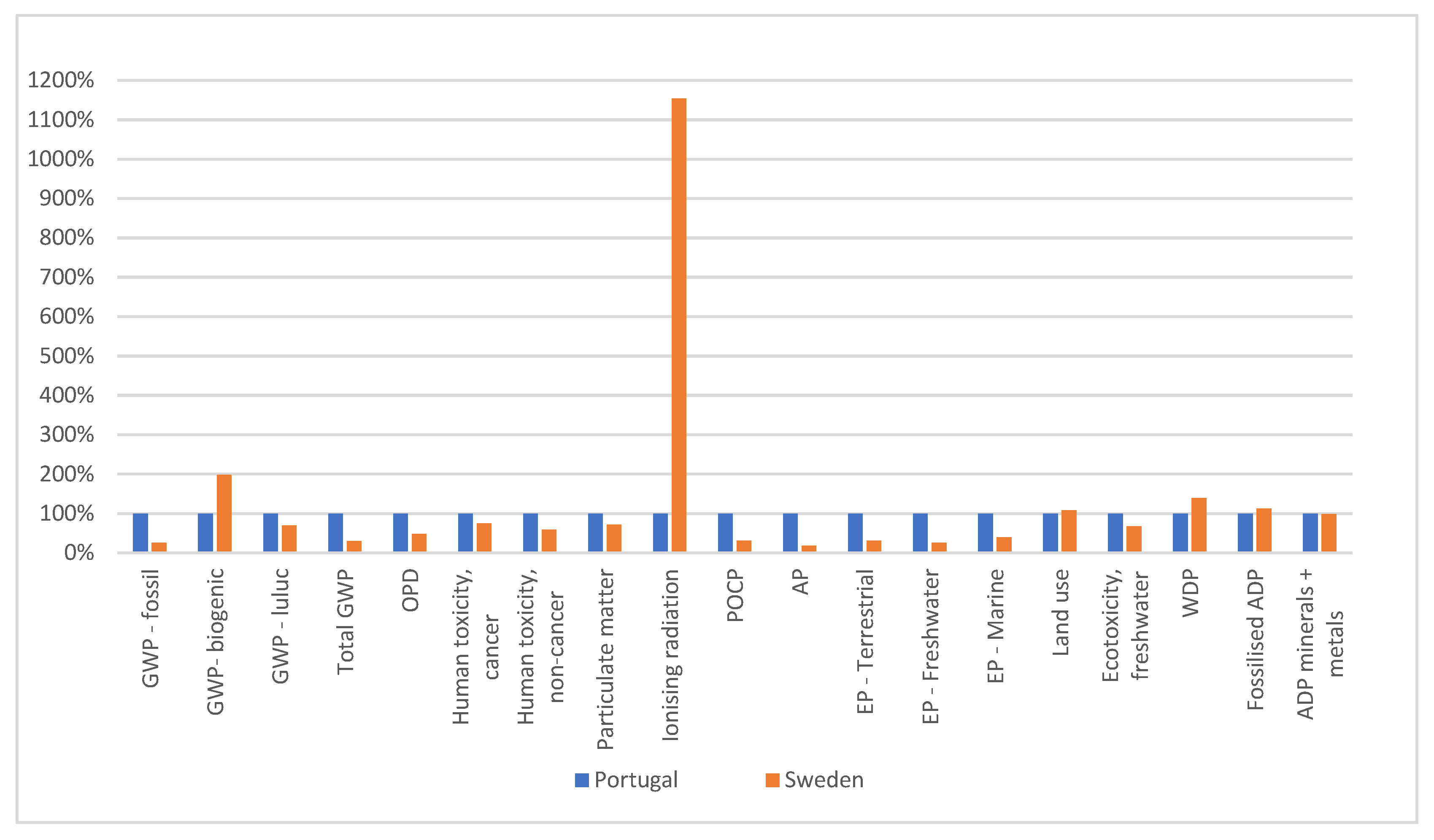

Variations in the electricity source were tested to determine the most likely origin of the increase in GWP-biogenic observed during the reconditioning process and to assess the effects on environmental impacts. Three alternative energy sources were modelled: the Swedish electricity mix, photovoltaic energy produced in Portugal, and photovoltaic energy produced in Sweden. Swedish data was considered, given that the EPD study used here as a benchmark was performed in that country. The comparison of the impacts of the Portuguese and Swedish electricity mixes is presented in

Figure 5.

We can see that when we replace the Portuguese mix with the Swedish mix, keeping the rest of the data unchanged, there is a significant increase in GWP-biogenic (98.29%) and Ionizing radiation (1054,09%) and a reduction in the indicators GWP fossil (−74.63%), GWP total (−70.29%), POCP (−69.17%), AP (−82.16%), EP-terrestrial (−68.96%), EP-freshwater (−74.74%) and EP-marine (−60.21%).

The variations observed in the indicators were attributed to the differences in the origin of electricity production in the two countries, with the Portuguese mix being mostly made up of fossil fuels, wind, and hydroelectric power [

25] and the Swedish mix being made up of wind, hydroelectric, and nuclear power [

26]. Production data from 2018 were used, as the period covered by the version of the database used in the study.

When biomass, biogas, and waste are burned to produce electricity, significant quantities of biogenic carbon are emitted. In addition, hydroelectric power, despite being considered a low-carbon source, is responsible for the generation of biogenic carbon in both the dam construction process and the degradation of biomass during the creation of reservoirs [

27]. The biofuel and waste burning component is higher, just as the contribution of hydroelectric power is much more relevant in Sweden’s mix and can explain the higher GWP-biogenic values observed.

As a result, the Swedish electricity mix has a greater impact on GWP-biogenic emissions than the Portuguese mix. This contradiction may indicate that the electricity used in the production of Swedish beams comes from other renewable sources.

To test this hypothesis, new modelling was carried out, using only photovoltaic electricity, to assess the influence on the GWP-biogenic indicator. The reconditioning process using the Portuguese mix and using photovoltaic electricity produced in Portugal and Sweden was compared.

Figure 6 highlights the results of this comparison, showing a reduction in the GWP-biogenic indicator of between 82% and 83% when the reconditioning process utilizes photovoltaic electricity. Additionally, there is an increase of between 350% and 450% in the Land use indicator, attributed to the installation of photovoltaic plants.

When we analyzed the modelling with Portuguese and Swedish photovoltaic energy, the environmental impacts were similar, with the indicators being slightly higher in Sweden. In general, photovoltaic generation has considerably lower environmental impacts in several impact indicators compared to the electricity mix, the main ones being GWP, AP, EP, and ADP fossil.

The significant variation shown in the different electricity use scenarios may indicate the cause of the difference found in the GWP-biogenic values in the production processes evaluated. The most likely scenario is that a significant part of the electricity used in the Swedish process comes from photovoltaics or another non-biogenic renewable source.

3.3.2. Influence of Distance

As with electricity, variations in the distance from the storage centers (SC) to the plant were tested to assess the impacts of transport on the A2 stage. This transport stage is the most significant due to the distribution of the various storage centers across the country.

Two SC were selected, the closest to the factory, SC02 (37 km), and the furthest, SC03 (420 km), for comparison with the storage center considered in the study, SC01 (70 km). The comparison of the impacts when distances to storage centers are changed is presented in

Figure 7.

We can see that there is a significant influence of transport on the impacts observed on the scenarios considered. As expected, impacts are proportional to distance.

When compared to the one used in the study (SC01), SC02 showed more significant variations in the OPD, Particulate matter, and Land use indicators, with reductions of 5.78%, 6.57%, and 6.75%, respectively. The remaining indicators showed a reduction ranging from 0.07% to 2.48%.

The comparison with SC03 shows more clearly the magnitude of the impacts associated with transporting the beams in the reconditioning process. The impacts associated with transport from CA02 showed an increase in the same indicators, in proportion to the distance travelled. The increases in the OPD, Particulate matter, and Land use indicators were 61.3%, 69.72%, and 71.63%, respectively, while the other indicators ranged from 0.76% to 26.33%.

The result of the LCA showed that the biggest contribution to the impacts of the reconditioning process is related to electricity consumption, but the impact of transporting the beams in A2 stage should not be underestimated, as observed in the alternative modelling. This data can help decision-makers adopt more efficient transport logistics to minimize the impacts observed.

4. Conclusions

The primary objective of this study was to assess the environmental sustainability of a prototyping project aimed at reconditioning road safety guardrail beams. The environmental impacts of the process under development were studied and then compared with the impacts of the traditional production process using a Life Cycle Assessment (LCA) approach.

LCA studies of road guardrails are scarce in scientific literature. Comprehensive studies on beams were not found. To fill this gap, LCA data from the beam reconditioning process were compared with data obtained from an Environmental Product Declaration for an equivalent material.

The study showed that most of the impacts of the reconditioning process derive from the use of electricity. The comparison with the traditional beam production process revealed that when primary raw materials are replaced by secondary raw materials, the environmental impacts associated with the production process decrease significantly. Of the 19 impact indicators assessed, 18 were lower, and 17 had a drop of more than 90% compared to the traditional production process. The reduction in impacts was most pronounced in indicators related to human health, followed by those of air and water pollution, the use of fossil fuels, mineral resources, and climate change. The only exception was the increase in biogenic carbon emissions, which was attributed to the use of the Portuguese energy mix.

The process under development could be improved by increasing the contribution of renewable energy sources to the electricity mix (for example, by the installation of photovoltaic panels), which would have a beneficial impact by reducing biogenic carbon emissions. The stage of transporting the beams from the operational centers to the factory should not be underestimated, as it can have significant impacts. A careful study of transport logistics is recommended, with the storage of the reconditioned beams in locations closer to the factory.

The results clearly show that the reconditioning process is associated with lower environmental impacts by avoiding the consumption and transportation of primary raw materials, which have been identified as the main sources of the impacts of the traditional production process, as well as minimizing waste generation.

This study also helped to prove that the reuse of secondary materials can substantially reduce the environmental impacts of the production chain, contributing to the effort to implement the Circular Economy.

As we have seen, Portugal has one of the lowest rates of material circularity in the EU, largely due to the low incorporation of waste in its production processes. Advancing the implementation of the Circular Economy in Portugal is fundamental to aligning with the EU’s carbon neutrality objectives and combating climate change.

To more comprehensively assess the environmental benefits of the reconditioning process, further studies are needed, with the system boundaries expanded and all stages of the life cycle evaluated. In this sense, the process under development must be more mature in order to provide more detailed information on the end-of-life stage. In future studies, it is recommended that primary beam production data or detailed secondary data be used to access Life Cycle Inventory data.