Industrial Food Waste Screening in Emilia-Romagna and the Conceptual Design of a Novel Process for Biomethane Production

Abstract

1. Introduction

2. Approach and Methodology

2.1. Screening of Food Waste Production in Emilia-Romagna Region

2.2. Conceptual Design of Alternative Waste-to-Value Process

3. Food Waste Screening: The Emilia-Romagna Region Case Study

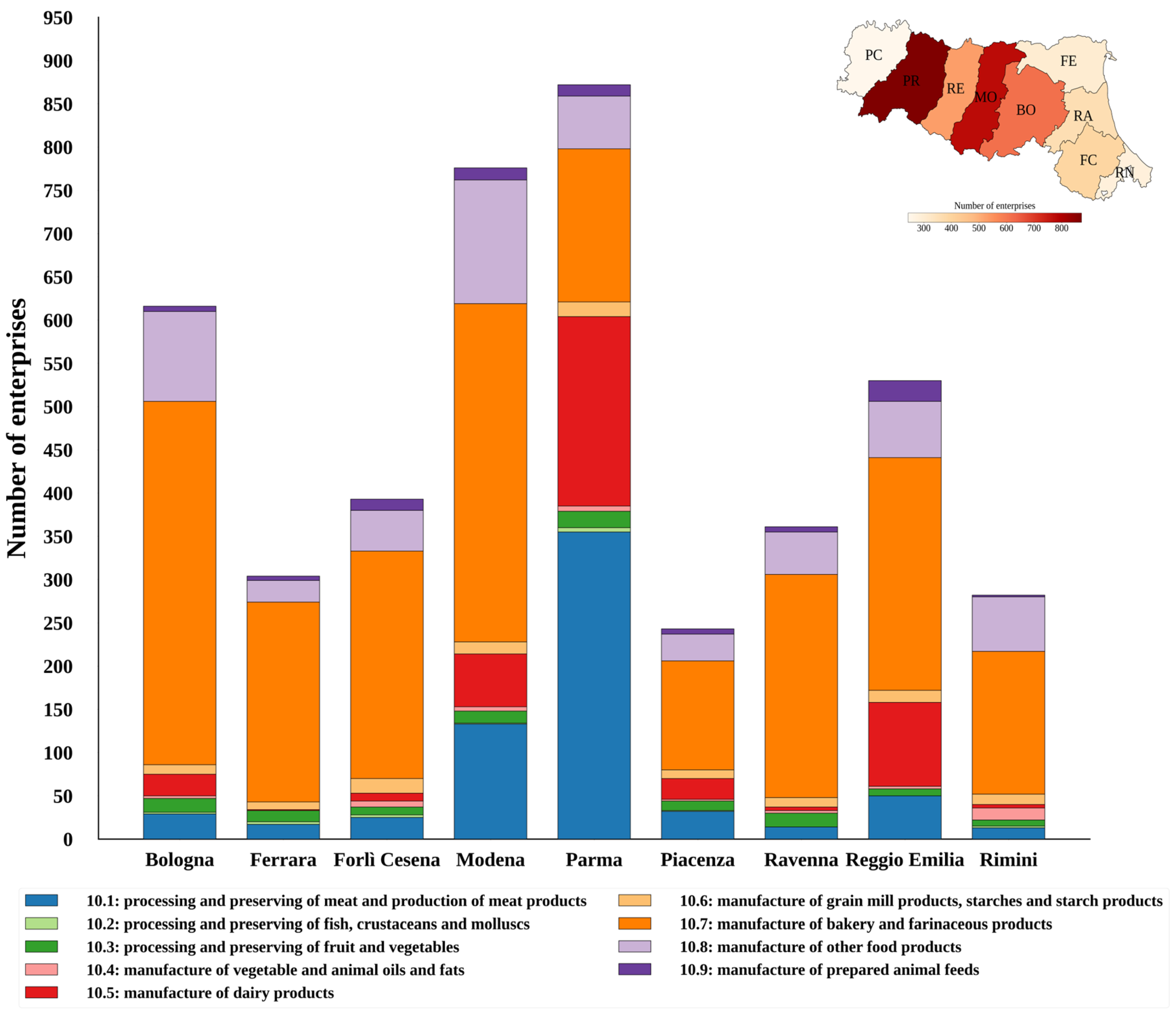

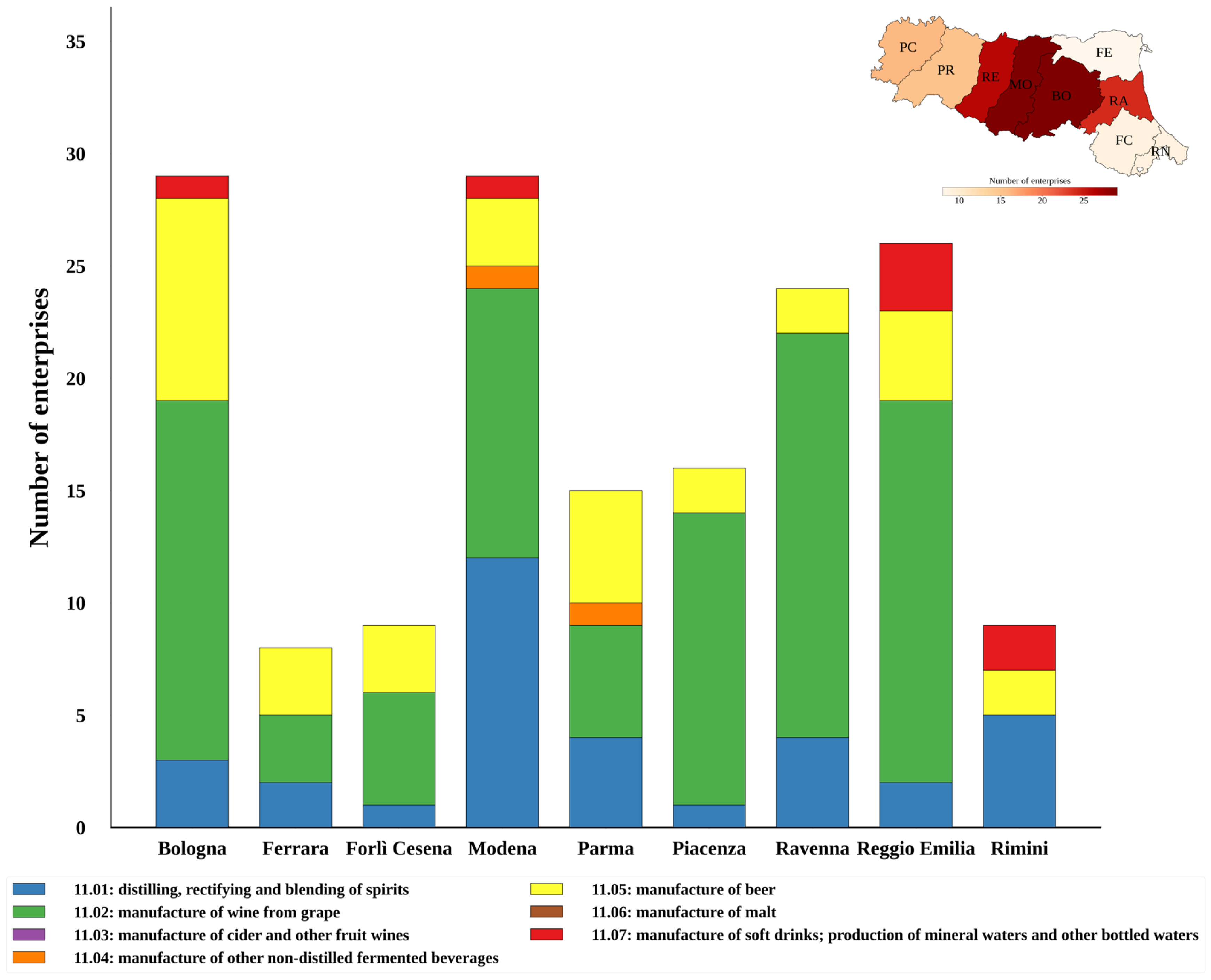

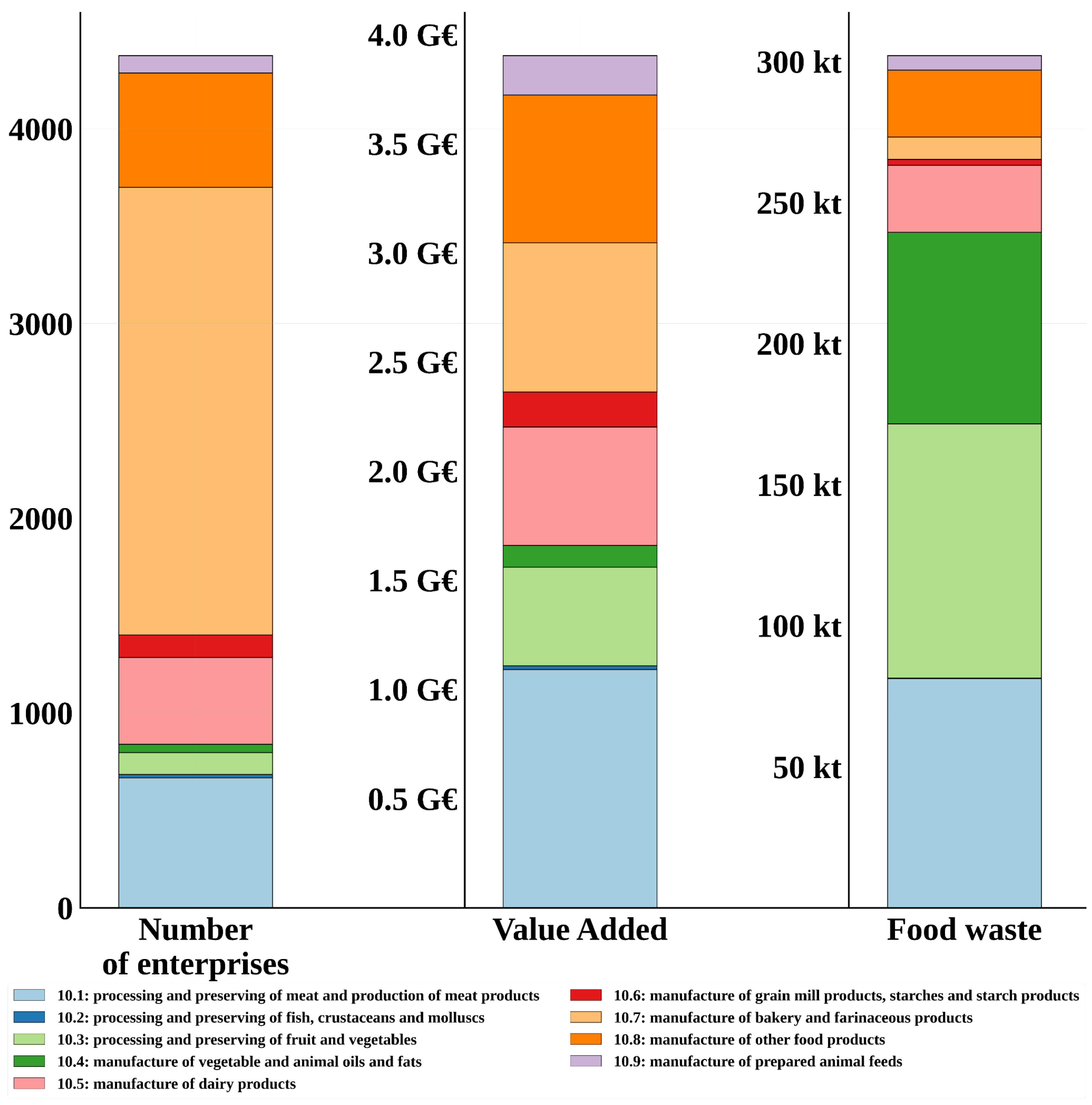

3.1. Food and Beverage Industry: Number of Enterprises Operating in Emilia-Romagna

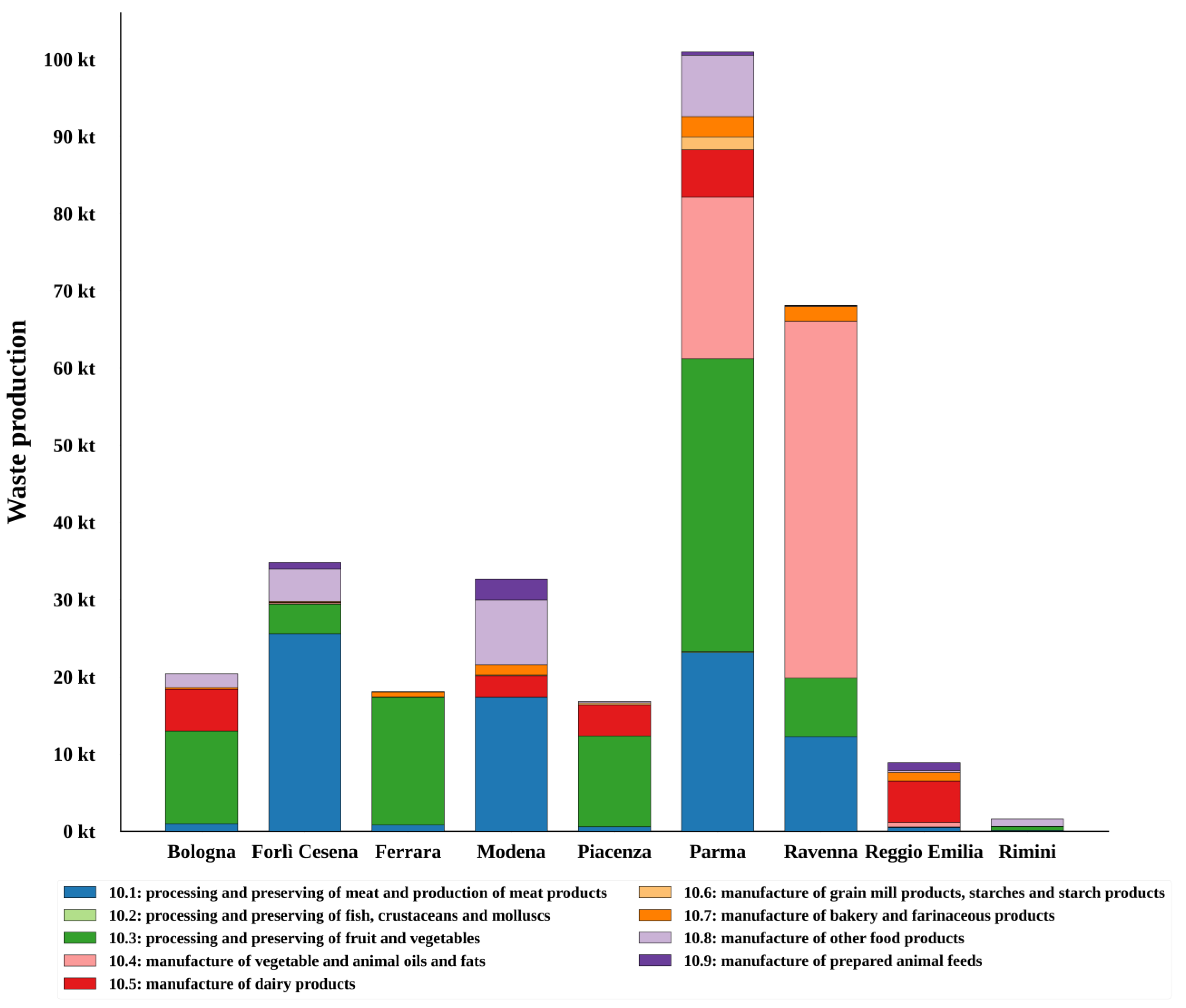

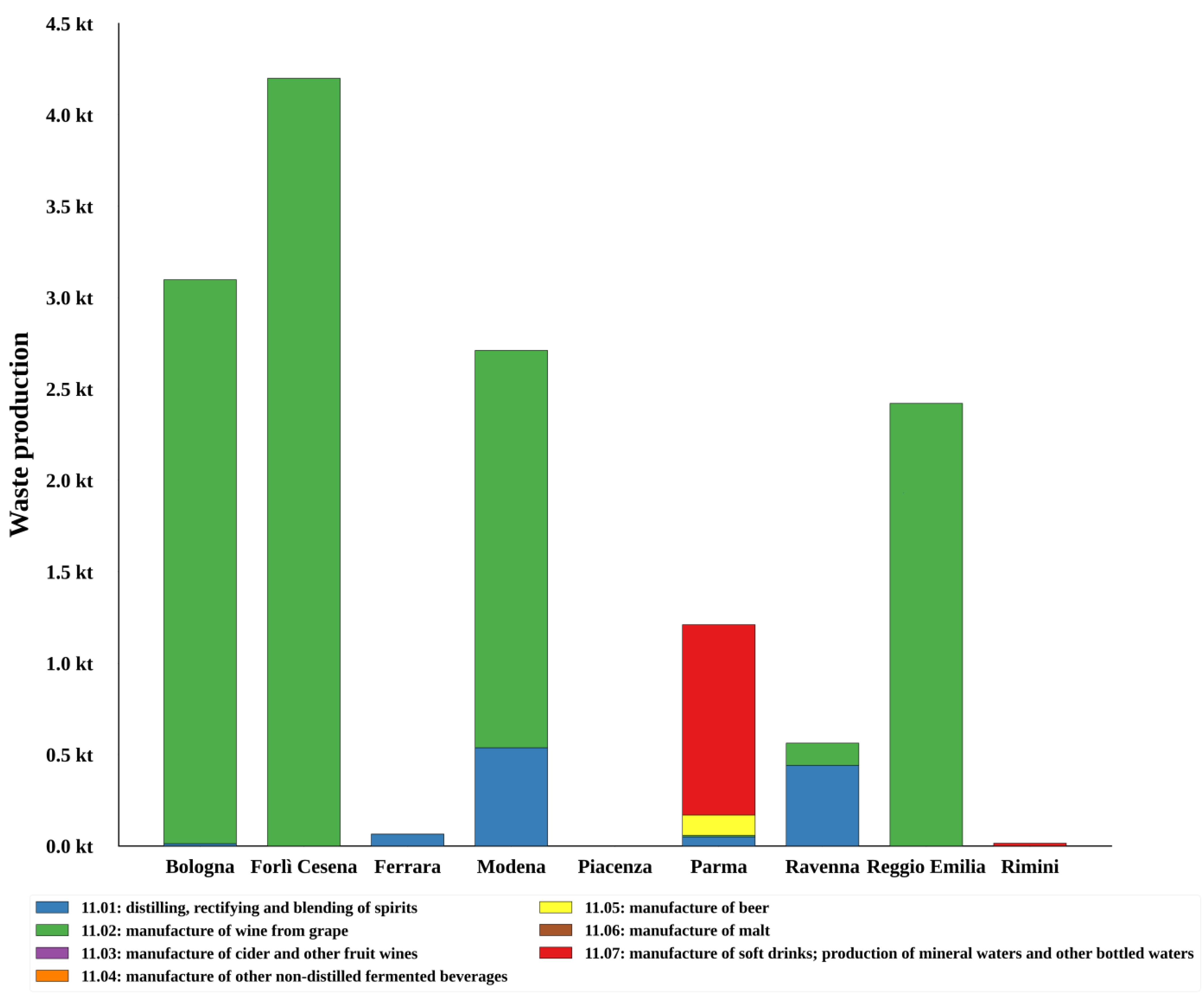

3.2. Food and Beverage Waste Production in Emilia-Romagna

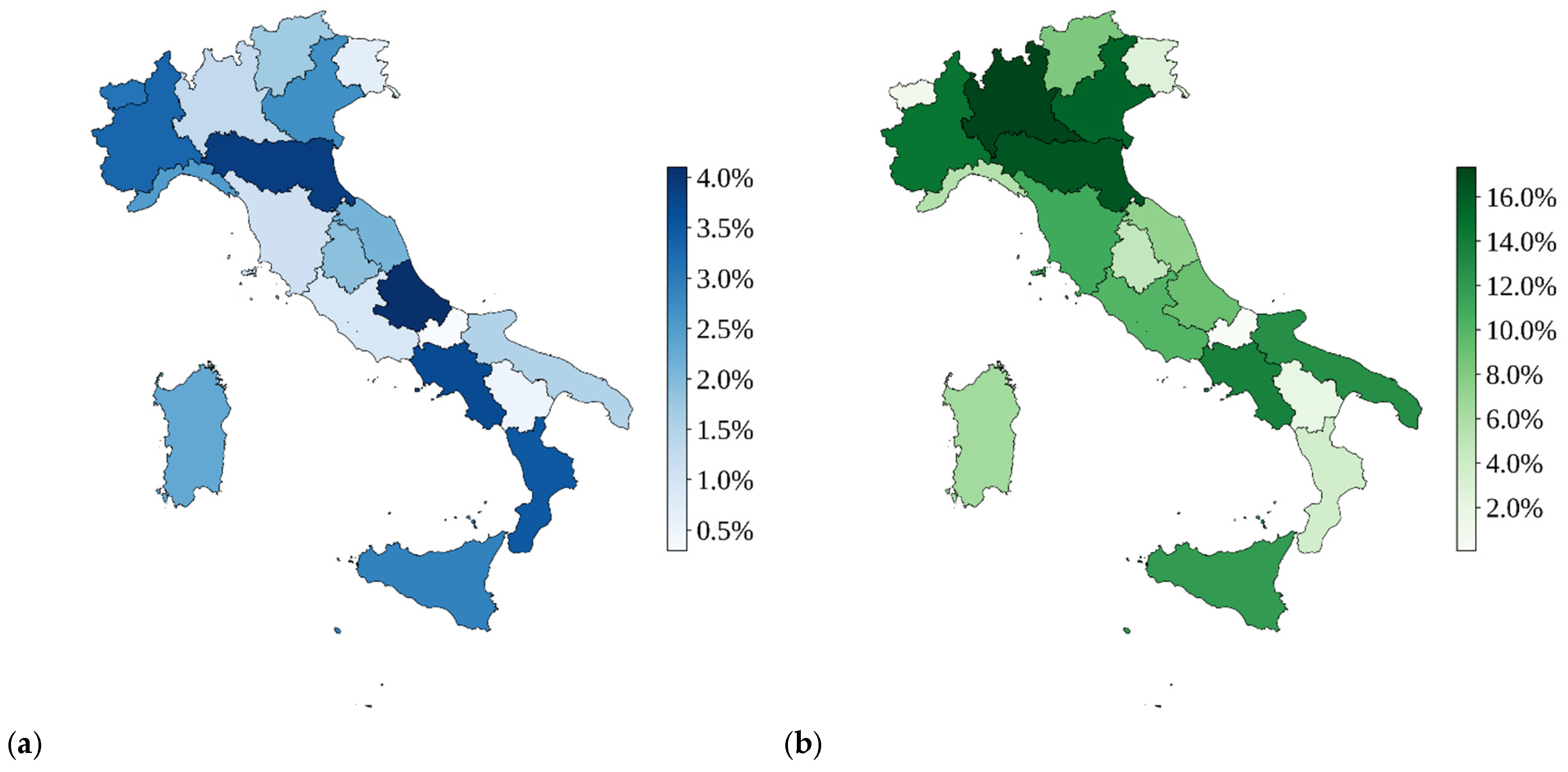

3.3. Food and Beverage Industry Characterization by Value Added

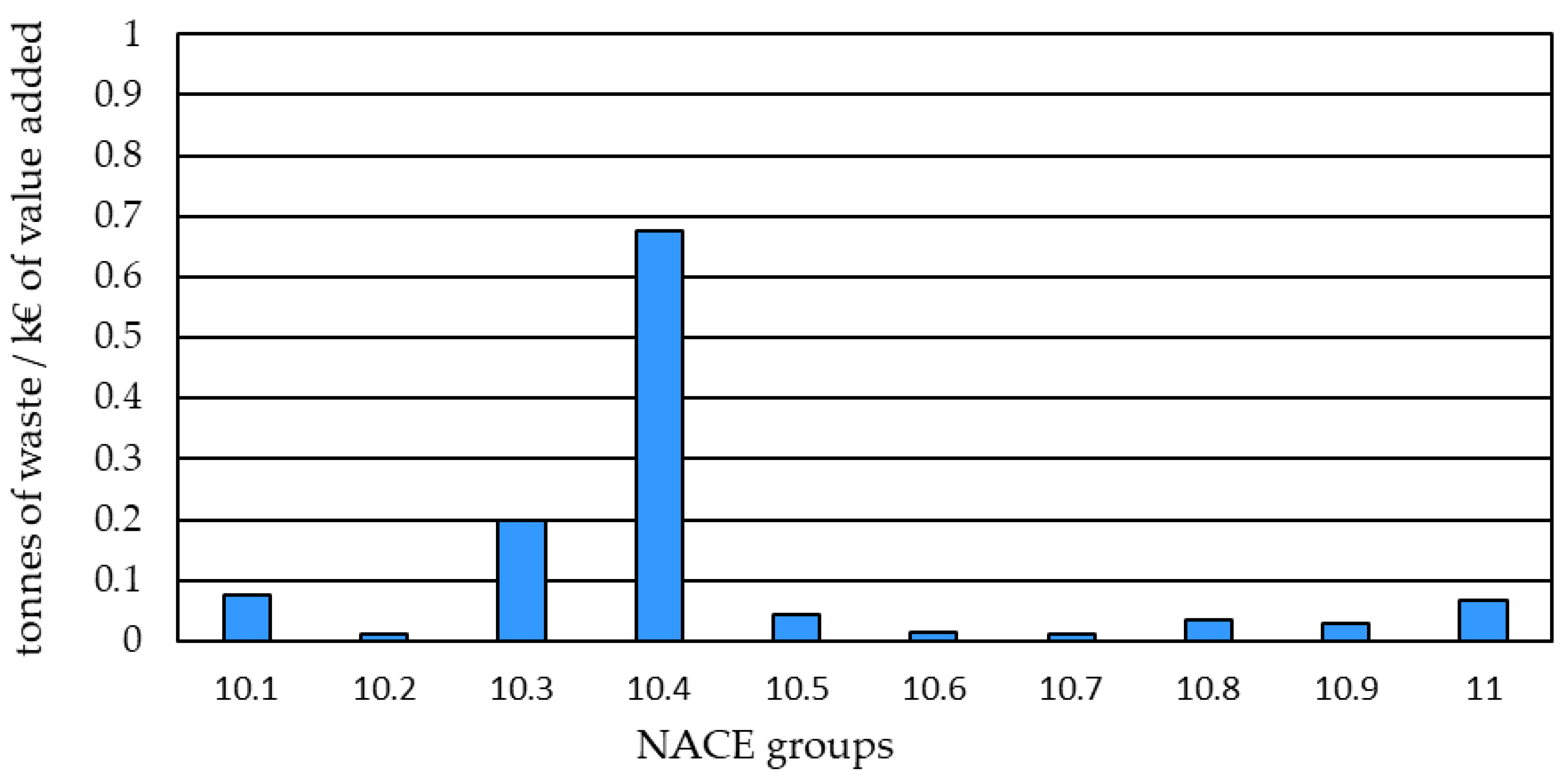

3.4. Regional Scenario Based on Selected Figures

4. Results and Discussion

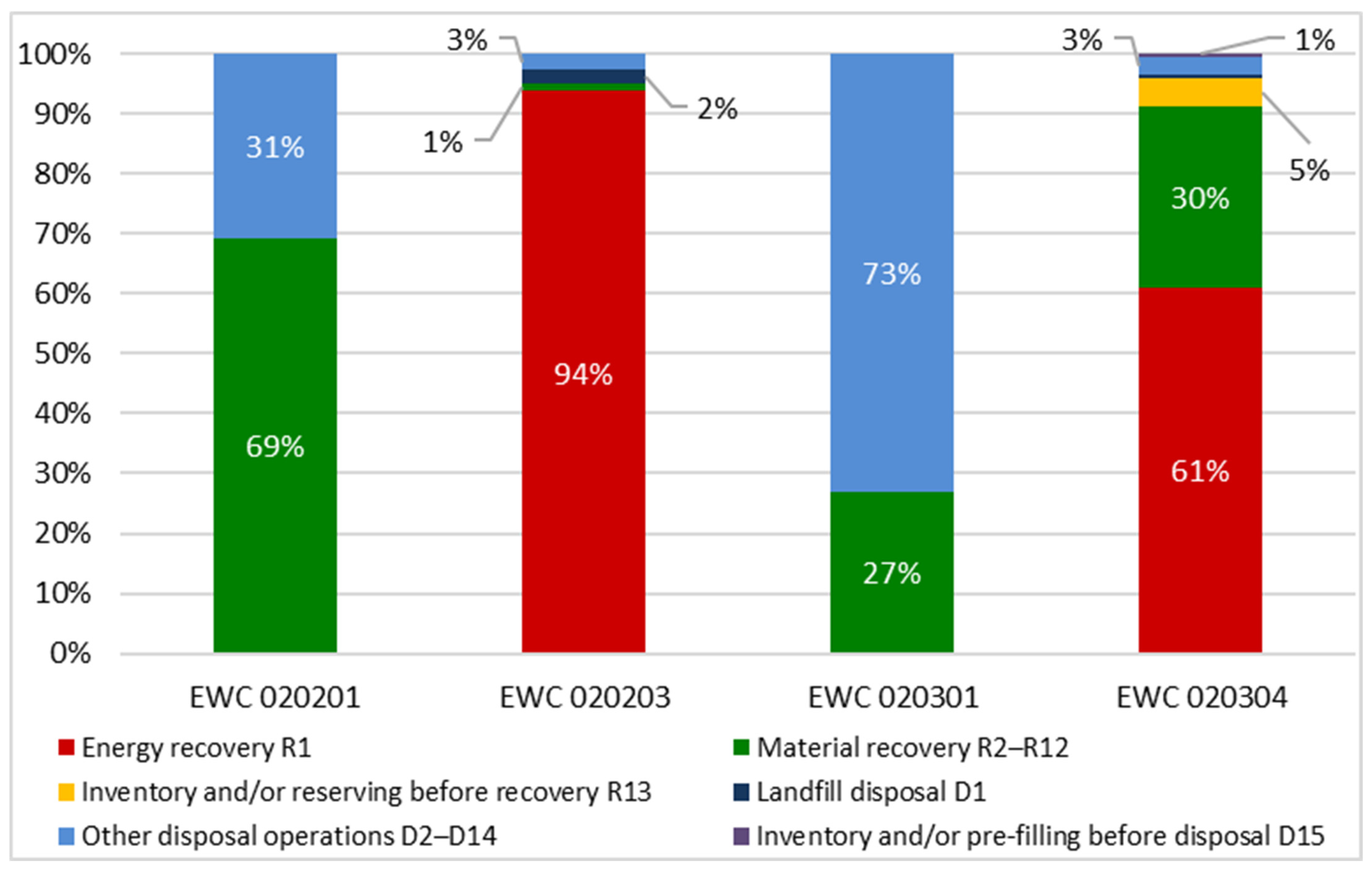

4.1. Selection of Industrial Food Waste Streams of Interest

4.2. Conceptual Design of Integrated Waste-to-Value Process

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| ARPAE | Agenzia regionale per la prevenzione, l’ambiente e l’energia Emilia-Romagna |

| ASIA | Archivio statistico delle imprese attive |

| BO | Bologna |

| EWC | European Waste Catalogue |

| FAO | Food and Agricultural Organization |

| FC | Forlì-Cesena |

| FE | Ferrara |

| FVS | Fruit and vegetable sludges |

| FVSW | Fruit and vegetable solid waste |

| HTC | Hydrothermal carbonization |

| ISPRA | Istituto superiore per la protezione e la ricerca ambientale |

| ISTAT | Istituto nazionale di statistica |

| MO | Modena |

| NACE | Statistical classification of economic activities in the European Community |

| PC | Piacenza |

| PR | Parma |

| RA | Ravenna |

| RE | Reggio Emilia |

| RN | Rimini |

| SHS | Slaughterhouse sludges |

| SHSW | Slaughterhouse solid waste |

| TS | Total solid |

| VS | Volatile solid |

Appendix A

| Province | NACE 10 | NACE 10 Groups | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10.1 | 10.2 | 10.3 | 10.4 | 10.5 | 10.6 | 10.7 | 10.8 | 10.9 | ||

| Bologna | 616 | 29 | 2 | 16 | 3 | 25 | 11 | 420 | 104 | 6 |

| Ferrara | 304 | 17 | 3 | 13 | 0 | 1 | 9 | 231 | 25 | 5 |

| Forlì Cesena | 393 | 25 | 3 | 9 | 7 | 9 | 17 | 263 | 47 | 13 |

| Modena | 776 | 133 | 1 | 14 | 5 | 61 | 14 | 391 | 143 | 14 |

| Parma | 872 | 355 | 5 | 19 | 6 | 219 | 17 | 177 | 61 | 13 |

| Piacenza | 243 | 32 | 1 | 11 | 2 | 24 | 10 | 126 | 31 | 6 |

| Ravenna | 361 | 14 | 0 | 16 | 3 | 4 | 11 | 258 | 49 | 6 |

| Reggio Emilia | 530 | 50 | 0 | 8 | 3 | 97 | 14 | 269 | 65 | 24 |

| Rimini | 282 | 13 | 2 | 7 | 14 | 4 | 12 | 165 | 63 | 2 |

| Total | 4377 | 668 | 17 | 113 | 43 | 444 | 115 | 2300 | 588 | 89 |

| Province | NACE 11 | NACE 11 Groups | ||||||

|---|---|---|---|---|---|---|---|---|

| 11.01 | 11.02 | 11.03 | 11.04 | 11.05 | 11.06 | 11.07 | ||

| Bologna | 29 | 3 | 16 | 0 | 0 | 9 | 0 | 1 |

| Ferrara | 8 | 2 | 3 | 0 | 0 | 3 | 0 | 0 |

| Forlì Cesena | 9 | 1 | 5 | 0 | 0 | 3 | 0 | 0 |

| Modena | 29 | 12 | 12 | 0 | 1 | 3 | 0 | 1 |

| Parma | 15 | 4 | 5 | 0 | 1 | 5 | 0 | 0 |

| Piacenza | 16 | 1 | 13 | 0 | 0 | 2 | 0 | 0 |

| Ravenna | 24 | 4 | 18 | 0 | 0 | 2 | 0 | 0 |

| Reggio Emilia | 26 | 2 | 17 | 0 | 0 | 4 | 0 | 3 |

| Rimini | 9 | 5 | 0 | 0 | 0 | 2 | 0 | 2 |

| Total | 165 | 34 | 89 | 0 | 2 | 33 | 0 | 7 |

| Province | Waste Production NACE 10 [t/y] | NACE 10 Groups [t/y] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10.1 | 10.2 | 10.3 | 10.4 | 10.5 | 10.6 | 10.7 | 10.8 | 10.9 | ||

| Bologna | 20,402 | 984 | - | 11,981 | - | 5396 | 1 | 243 | 1798 | - |

| Forlì Cesena | 34,793 | 25,561 | - | 3839 | 154 | 33 | 25 | 110 | 4183 | 880 |

| Ferrara | 18,067 | 797 | - | 16,556 | - | - | 69 | 600 | - | 45 |

| Modena | 32,590 | 17,347 | - | - | 35 | 2773 | 99 | 1319 | 8331 | 2686 |

| Piacenza | 16,800 | 548 | - | 11,796 | - | 4046 | 227 | - | 177 | 6 |

| Parma | 100,926 | 23,134 | 109 | 37,946 | 20,910 | 6141 | 1694 | 2622 | 7955 | 414 |

| Ravenna | 68,076 | 12,237 | - | 7598 | 46,213 | - | 8 | 1873 | 83 | 65 |

| Reggio Emilia | 8903 | 450 | 68 | - | 639 | 5334 | 8 | 1126 | 233 | 1045 |

| Rimini | 1578 | 104 | 5 | 455 | - | - | - | 32 | 982 | - |

| Total | 302,128 | 81,162 | 182 | 90,172 | 67,952 | 23,723 | 2130 | 7925 | 23,742 | 5141 |

| Province | Waste Production NACE 11 [t/y] | NACE 11 Groups [t/y] | ||||||

|---|---|---|---|---|---|---|---|---|

| 11.01 | 11.02 | 11.03 | 11.04 | 11.05 | 11.06 | 11.07 | ||

| Bologna | 3098 | 13 | 3085 | 0 | 0 | 0 | 0 | 0 |

| Forlì Cesena | 4200 | 0 | 4200 | 0 | 0 | 0 | 0 | 0 |

| Ferrara | 65 | 65 | 0 | 0 | 0 | 0 | 0 | 0 |

| Modena | 2711 | 537 | 2173 | 0 | 0 | 0 | 0 | 0 |

| Piacenza | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Parma | 1211 | 50 | 8 | 0 | 0 | 111 | 0 | 1042 |

| Ravenna | 563 | 441 | 122 | 0 | 0 | 0 | 0 | 0 |

| Reggio Emilia | 2421 | 0 | 2421 | 0 | 0 | 0 | 0 | 0 |

| Rimini | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 15 |

| Total | 14,284 | 1107 | 12,009 | 0 | 0 | 111 | 0 | 1057 |

| NACE Code | Value Added [k€] | |

|---|---|---|

| 10. | manufacture of food products. | 3,903,329 |

| 10.1. | processing and preserving of meat and production of meat products. | 1,089,942 |

| 10.2. | processing and preserving of fish, crustaceans, and mollusks. | 16,945 |

| 10.3. | processing and preserving of fruit and vegetables. | 452,546 |

| 10.4. | manufacture of vegetable and animal oils and fats. | 100,393 |

| 10.5. | manufacture of dairy products. | 541,288 |

| 10.6. | manufacture of grain mill products, starches, and starch products. | 161,263 |

| 10.7. | manufacture of bakery and farinaceous products. | 683,122 |

| 10.8. | manufacture of other food products. | 676,857 |

| 10.9. | manufacture of prepared animal feeds. | 180,972 |

| 11. | manufacture of beverages. | 209,551 |

| NACE Code and Relative Classes | |||||||||||

| 10.1—Processing and preserving of meat and production of meat products 10.11.00. Processing and preserving of meat (excluding poultry meat); 10.12.00. Processing and preserving of poultry meat; 10.13.00. Production of meat and poultry meat products. | |||||||||||

| 10.3—Processing and preserving of fruit and vegetables 10.31.00. Processing and preserving of potatoes; 10.32.00. Manufacture of fruit and vegetable juice; 10.39.00. Other processing and preserving of fruit and vegetables. | |||||||||||

| 10.4—Manufacture of vegetable and animal oils and fats 10.41.00. Production of oils and fats; 10.41.10. Production of olive oil from predominantly non-self-produced olives; 10.41.20. Production of refined or crude oil from oilseeds or oil fruits, primarily not self-produced; 10.41.30. Production of crude or refined animal oils and fats; 10.42.00. Manufacture of margarine and similar edible fats. | |||||||||||

| NACE Code | EWC—Description | Total (t/y) | Provinces | ||||||||

| BO | FC | MO | PC | PR | RA | RE | RN | FE | |||

| 10.11.00 | 020201—sludges from washing and cleaning | 8853 | 105 | 8433 | 130 | 0 | 17 | 0 | 63 | 104 | 0 |

| 020203—materials unsuitable for consumption or processing | 412 | 0 | 0 | 0 | 0 | 411 | 0 | 0 | 0 | 0 | |

| Total for 10.11.00 | 9265 | 105 | 8433 | 130 | 0 | 428 | 0 | 63 | 104 | 0 | |

| 10.13.00 | 020201—sludges from washing and cleaning | 2812 | 145 | 0 | 1468 | 45 | 1095 | 28 | 31 | 0 | 0 |

| 020202—animal-tissue waste | 107 | 0 | 0 | 0 | 0 | 107 | 0 | 0 | 0 | 0 | |

| 020203—materials unsuitable for consumption or processing | 994 | 0 | 0 | 33 | 0 | 960 | 0 | 0 | 0 | 0 | |

| Total for 10.13.00 | 3913 | 145 | 0 | 1501 | 45 | 2163 | 28 | 31 | 0 | 0 | |

| 10.3X.00 | 020304—materials unsuitable for consumption or processing | 1721 | 0 | 0 | 0 | 6 | 1150 | 68 | 0 | 0 | 497 |

| 10.31.00 | 020304—materials unsuitable for consumption or processing | 4286 | 4286 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 10.32.00 | 020301—sludges from washing, cleaning, peeling, centrifuging and separation | 49 | 0 | 0 | 0 | 0 | 0 | 49 | 0 | 0 | 0 |

| 020304—materials unsuitable for consumption or processing | 3741 | 23 | 0 | 0 | 0 | 457 | 3261 | 0 | 0 | 0 | |

| Total for 10.32.00 | 3790 | 23 | 0 | 0 | 0 | 457 | 3310 | 0 | 0 | 0 | |

| 10.39.00 | 020301—sludges from washing, cleaning, peeling, centrifuging and separation | 1018 | 946 | 26 | 0 | 0 | 45 | 0 | 0 | 0 | 0 |

| 020304—materials unsuitable for consumption or processing | 12,231 | 624 | 159 | 0 | 545 | 10,184 | 189 | 0 | 455 | 76 | |

| Total for 10.39.00 | 13,249 | 1570 | 185 | 0 | 545 | 10,229 | 189 | 0 | 455 | 76 | |

| 10.41.10 | 020301—sludges from washing, cleaning, peeling, centrifuging and separation | 485 | 0 | 43 | 0 | 0 | 441 | 0 | 0 | 0 | 0 |

| 020304—materials unsuitable for consumption or processing | 4 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | |

| Total for 10.41.10 | 489 | 0 | 43 | 0 | 0 | 446 | 0 | 0 | 0 | 0 | |

| 10.41.20 | 020304—materials unsuitable for consumption or processing | 36,132 | 0 | 0 | 0 | 0 | 0 | 36,132 | 0 | 0 | 0 |

| 10.41.30 | 020201—sludges from washing and cleaning | 9677 | 0 | 0 | 0 | 0 | 9502 | 0 | 175 | 0 | 0 |

| 020203—materials unsuitable for consumption or processing | 10,747 | 0 | 0 | 0 | 0 | 10,747 | 0 | 0 | 0 | 0 | |

| Total for 10.41.30 | 20,424 | 20,249 | 175 | ||||||||

| 10.42.00 | 020304—materials unsuitable for consumption or processing | 215 | 0 | 0 | 0 | 0 | 215 | 0 | 0 | 0 | 0 |

References

- Tsegaye, B.; Jaiswal, S.; Jaiswal, A.K. Food Waste Biorefinery: Pathway towards Circular Bioeconomy. Foods 2021, 10, 1174. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations (FAO). Global Food Losses and Food Waste—Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2011. [Google Scholar]

- Caldeira, C.; Vlysidis, A.; Fiore, G.; De Laurentiis, V.; Vignali, G.; Sala, S. Sustainability of food waste biorefinery: A review on valorisation pathways, techno-economic constraints, and environmental assessment. Bioresour. Technol. 2020, 312, 123575. [Google Scholar] [CrossRef] [PubMed]

- Bastidas-Oyanedel, J.-R.; Schmidt, J.E. (Eds.) Biorefinery; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A Sustainable Bioeconomy for Europe: Strengthening the Connection Between Economy, Society and the Environment; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A New Circular Economy Action Plan For a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Guidehouse and European Biogas Association (EBA). Biogases Towards 2040 and Beyond—A Realistic and Resilient Path to Climate Neutrality; Guidehouse and European Biogas Association (EBA): Brussels, Belgium, 2024. [Google Scholar]

- European Commission. Commission Staff Working Document—Implementing the REPowerEU Action Plan: Investment Needs, Hydrogen Accelerator and Achieving the Bio-Methane Targets; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Bataglia, L.; Conversano, A.; Di Bona, D.; Sogni, D.; Voccia, D.; Mazzoni, E.; Lamastra, L. Recent Developments, Challenges, and Environmental Benefits of Using Hermetia illucens for Bioenergy Production Within a Circular Economy Approach. Energies 2025, 18, 2826. [Google Scholar] [CrossRef]

- Conversano, A.; Zatti, M.; Sogni, D.; Consonni, S. Energy storage scenarios and design of a new Italian innovation infrastructure for energy transition. J. Phys. Conf. Ser. 2024, 2893, 012005. [Google Scholar] [CrossRef]

- Regione Emilia-Romagna e ART-ER—Attrattività Ricerca Territorio Emilia Romagna. Analisi del Sistema Agricolo, Agroindustriale e del Territorio Rurale dell’Emilia-Romagna; Regione Emilia-Romagna: Bologna, Italy, 2021; Available online: https://agricoltura.regione.emilia-romagna.it/pac-2023-2027/documenti/analisi-del-sistema/analisi-contesto.pdf (accessed on 23 September 2025).

- European Union. The European Parliament and the Council Directive 2008/98/EC of the European Parliament and of the Council on Waste and Repealing Certain Directives; European Union: Brussels, Belgium, 2008. [Google Scholar]

- Eurostat—European Commission. NACE Rev. 2—Statistical Classification of Economic Activities in the European Community; Eurostat—European Commission: Luxembourg, 2008; ISBN 978-92-79-04741-1. [Google Scholar]

- ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale. Catasto Rifiuti—Sezione Nazionale. 2024. Available online: https://www.catasto-rifiuti.isprambiente.it (accessed on 11 December 2024).

- ARPAE—Agenzia Regionale per la Protezione Ambientale dell’Emilia Romagna. Rifiuti Speciali—Dataset. 2024. Available online: https://dati.arpae.it/dataset/rifiuti-speciali-per-comune (accessed on 11 December 2024).

- Official Journal of the European Communities. Commission Decision of 3 May 2000; European Union: Brussels, Belgium, 2008. [Google Scholar]

- ISTAT—Istituto Nazionale di Statistica. Glossario Statistico. Available online: https://www.istat.it/classificazioni-e-strumenti/glossario/ (accessed on 5 June 2025).

- Ischia, G.; Fiori, L. Hydrothermal Carbonization of Organic Waste and Biomass: A Review on Process, Reactor, and Plant Modeling. Waste Biomass Valorization 2021, 12, 2797–2824. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D.-J. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2021, 323, 124626. [Google Scholar] [CrossRef] [PubMed]

- ISTAT—Istituto Nazionale di Statistica Enterprises and Persons Employed. 2024. Available online: http://dati.istat.it/Index.aspx?QueryId=20771# (accessed on 11 December 2024).

- Edwiges, T.; Frare, L.; Mayer, B.; Lins, L.; Mi Triolo, J.; Flotats, X.; de Mendonça Costa, M.S.S. Influence of chemical composition on biochemical methane potential of fruit and vegetable waste. Waste Manag. 2018, 71, 618–625. [Google Scholar] [CrossRef] [PubMed]

- Miramontes-Martínez, L.R.; Rivas-García, P.; Albalate-Ramírez, A.; Botello-Álvarez, J.E.; Escamilla-Alvarado, C.; Gomez-Gonzalez, R.; Alcalá-Rodríguez, M.M.; Valencia-Vázquez, R.; Santos-López, I.A. Anaerobic co-digestion of fruit and vegetable waste: Synergy and process stability analysis. J. Air Waste Manag. Assoc. 2021, 71, 620–632. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Mu, H.; Zhao, Y.; Wang, L.; Zuo, B. Microbial characteristics analysis and kinetic studies on substrate composition to methane after microbial and nutritional regulation of fruit and vegetable wastes anaerobic digestion. Bioresour. Technol. 2018, 249, 315–321. [Google Scholar] [CrossRef] [PubMed]

- Nielfa, A.; Cano, R.; Pérez, A.; Fdez-Polanco, M. Co-digestion of municipal sewage sludge and solid waste: Modelling of carbohydrate, lipid and protein content influence. Waste Manag. Res. J. Sustain. Circ. Econ. 2015, 33, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Hejnfelt, A.; Angelidaki, I. Anaerobic digestion of slaughterhouse by-products. Biomass Bioenergy 2009, 33, 1046–1054. [Google Scholar] [CrossRef]

- Handous, N.; Gannoun, H.; Hamdi, M.; Bouallagui, H. Two-Stage Anaerobic Digestion of Meat Processing Solid Wastes: Methane Potential Improvement with Wastewater Addition and Solid Substrate Fermentation. Waste Biomass Valorization 2019, 10, 131–142. [Google Scholar] [CrossRef]

- Palatsi, J.; Viñas, M.; Guivernau, M.; Fernandez, B.; Flotats, X. Anaerobic digestion of slaughterhouse waste: Main process limitations and microbial community interactions. Bioresour. Technol. 2011, 102, 2219–2227. [Google Scholar] [CrossRef] [PubMed]

- Cuetos, M.J.; Gómez, X.; Otero, M.; Morán, A. Anaerobic digestion of solid slaughterhouse waste (SHW) at laboratory scale: Influence of co-digestion with the organic fraction of municipal solid waste (OFMSW). Biochem. Eng. J. 2008, 40, 99–106. [Google Scholar] [CrossRef]

- Bayr, S. Biogas Production from Meat and Pulp and Paper Industry By-Products; University of Jyväskylä: Jyväskylä, Finland, 2014; Available online: https://jyx.jyu.fi/dspace/bitstream/handle/123456789/43316/978-951-39-5680-6_vaitos23052014.pdf?sequence=1 (accessed on 23 September 2025).

- Lombardelli, G.; Scaccabarozzi, R.; Conversano, A.; Gatti, M. Bio-methanol with negative CO2 emissions from residual forestry biomass gasification: Modelling and techno-economic assessment of different process configurations. Biomass Bioenergy 2024, 188, 107315. [Google Scholar] [CrossRef]

- Lombardelli, G.; Consonni, S.; Conversano, A.; Mureddu, M.; Pettinau, A.; Gatti, M. Process Design and Techno-Economic Assessment of biogenic CO 2 Hydrogenation-to-Methanol with innovative catalyst. J. Phys. Conf. Ser. 2022, 2385, 012038. [Google Scholar] [CrossRef]

| Section C—Manufacturing | ||

|---|---|---|

| Division 10—Manufacture of Food Products | ||

| Group | Class | Title |

| 10.1 | Processing and preserving of meat and production of meat products | |

| 10.11 | Processing and preserving of meat | |

| 10.12 | Processing and preserving of poultry meat | |

| 10.13 | Production of meat and poultry meat products | |

| 10.2 | Processing and preserving of fish, crustaceans and mollusks | |

| 10.20 | Processing and preserving of fish, crustaceans and mollusks | |

| 10.3 | Processing and preserving of fruit and vegetables | |

| 10.31 | Processing and preserving of potatoes | |

| 10.32 | Manufacture of fruit and vegetable juice | |

| 10.39 | Other processing and preserving of fruit and vegetables | |

| 10.4 | Manufacture of vegetable and animal oils and fats | |

| 10.41 | Manufacture of oils and fats | |

| 10.42 | Manufacture of margarine and similar edible fats | |

| 10.5 | Manufacture of dairy products | |

| 10.51 | Operation of dairies and cheese making | |

| 10.52 | Manufacture of ice cream | |

| 10.6 | Manufacture of grain mill products, starches and starch products | |

| 10.61 | Manufacture of grain mill products | |

| 10.62 | Manufacture of starches and starch products | |

| 10.7 | Manufacture of bakery and farinaceous products | |

| 10.71 | Manufacture of bread; manufacture of fresh pastry goods and cakes | |

| 10.72 | Manufacture of rusks and biscuits; manufacture of preserved pastry goods and cakes | |

| 10.73 | Manufacture of macaroni, noodles, couscous and similar farinaceous products | |

| 10.8 | Manufacture of other food products | |

| 10.81 | Manufacture of sugar | |

| 10.82 | Manufacture of cocoa, chocolate and sugar confectionery | |

| 10.83 | Processing of tea and coffee | |

| 10.84 | Manufacture of condiments and seasonings | |

| 10.85 | Manufacture of prepared meals and dishes | |

| 10.86 | Manufacture of homogenized food preparations and dietetic food | |

| 10.89 | Manufacture of other food products not elsewhere classified | |

| 10.9 | Manufacture of prepared animal feeds | |

| 10.91 | Manufacture of prepared feeds for farm animals | |

| 10.92 | Manufacture of prepared pet foods | |

| Division 11—Manufacture of beverages | ||

| Group | Class | Title |

| 11.0 | Manufacture of beverages | |

| 11.01 | Distilling, rectifying and blending of spirits | |

| 11.02 | Manufacture of wine from grape | |

| 11.03 | Manufacture of cider and other fruit wines | |

| 11.04 | Manufacture of other non-distilled fermented beverages | |

| 11.05 | Manufacture of beer | |

| 11.06 | Manufacture of malt | |

| 11.07 | Manufacture of soft drinks; production of mineral waters and other bottled waters | |

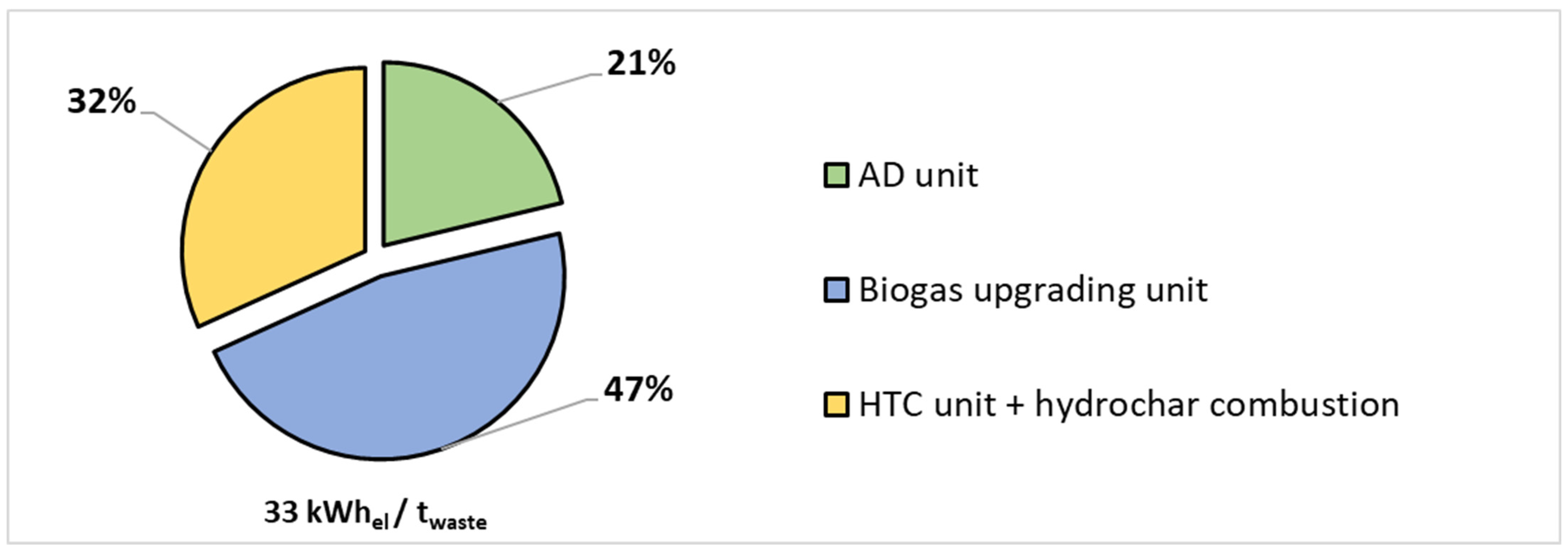

| Anaerobic Digestion (AD) Unit | |

| %VS—Volatile solid mass percentage | 11%w |

| Specific biogas production from AD (i.e., kg of biogas per kg of AD inlet) | 0.043 kg/kg |

| Inlet AD moisture | >87%w |

| Overall pump efficiency | 73% |

| Biogas upgrading unit | |

| Specific electric consumption with reference to biogas production | 0.3 kWh/Nm3 |

| HTC unit and hydrochar combustion unit | |

| Specific electric consumption with reference to total inlet waste in the process | 11 kWhel/twaste |

| Region | Waste Production in Food and Beverage Industries (t/y) | Total Industrial Waste Production (t/y) | Regional % of Food and Beverage Industrial Waste in Terms of Total Regional Industrial Waste | Regional % of Industrial Waste Production for Food and Beverage Industry over National Industrial Food and Beverage Waste |

|---|---|---|---|---|

| Abruzzo | 120,290 | 2,934,286 | 4.10% | 3.57% |

| Basilicata | 31,523 | 2,314,039 | 1.36% | 0.94% |

| Calabria | 58,650 | 2,212,084 | 2.65% | 1.74% |

| Campania | 268,370 | 8,436,752 | 3.18% | 7.98% |

| Emilia-Romagna | 450,739 | 13,832,669 | 3.26% | 13.39% |

| Friuli Venezia Giulia | 58,372 | 4,218,735 | 1.38% | 1.73% |

| Lazio | 150,106 | 10,164,452 | 1.48% | 4.46% |

| Liguria | 65,361 | 2,834,408 | 2.31% | 1.94% |

| Lombardia | 583,028 | 33,540,168 | 1.74% | 17.33% |

| Marche | 82,223 | 3,743,696 | 2.20% | 2.44% |

| Molise | 1783 | 601,719 | 0.30% | 0.05% |

| Piemonte | 303,313 | 11,896,872 | 2.55% | 9.01% |

| Puglia | 204,122 | 11,388,162 | 1.79% | 6.07% |

| Sardegna | 68,707 | 3,070,948 | 2.24% | 2.04% |

| Sicilia | 182,281 | 7,373,307 | 2.47% | 5.42% |

| Toscana | 169,661 | 10,086,823 | 1.68% | 5.04% |

| Trentino Alto Adige | 89,331 | 4,686,283 | 1.91% | 2.65% |

| Umbria | 61,553 | 3,001,267 | 2.05% | 1.83% |

| Valle d’Aosta | 7444 | 292,639 | 2.54% | 0.22% |

| Veneto | 408,277 | 17,345,015 | 2.35% | 12.13% |

| Total | 3,365,134 | 153,974,324 | 2.19% | 100.00% |

| Stream ID | EWC Code and Description | NACE Code | Amount [t] | Total Amount [t] |

|---|---|---|---|---|

| FVSW Fruit and Vegetable Solid Waste | 020304—materials unsuitable for consumption or processing | 10.3X.00 | 1721 | 58,332 |

| 10.31.00 | 4286 | |||

| 10.32.00 | 3741 | |||

| 10.39.00 | 12,231 | |||

| 10.41.10 | 4 | |||

| 10.41.20 | 36,132 | |||

| 10.42.00 | 215 | |||

| FVS Fruit and Vegetable Sludges | 020301—sludges from washing, cleaning, peeling, centrifuging and separation | 10.32.00 | 49 | 1552 |

| 10.39.00 | 1018 | |||

| 10.41.10 | 485 | |||

| SHSW Slaughterhouse Solid Waste | 020202—animal tissue 020203—materials unsuitable for consumption or processing | 10.11.00 | 412 | 12,260 |

| 10.13.00 | 1101 | |||

| 10.41.30 | 10,747 | |||

| SHS Slaughterhouse Sludges | 020201—sludges from washing and cleaning | 10.11.00 | 8853 | 21,342 |

| 10.13.00 | 2812 | |||

| 10.41.30 | 9677 | |||

| Total (sludges + solid waste) | 93,486 | |||

| FVSW Composition | Moisture | Ashes | Lipids | Proteins | Carbohydrates |

| Edwiges et al. [21] | 90.5% | 0.8% | 0.4% | 1.4% | 7.0% |

| Miramontes-Martínez et al. [22] | 89.1% | 0.8% | 0.6% | 0.7% | 8.8% |

| Zhao et al. [23] | 52.2% | 0.2% | 0.9% | 7.7% | 39.1% |

| FVS composition | Moisture | Ashes | Lipids | Proteins | Carbohydrates |

| Nielfa et al. [24] | 92.8% | 1.5% | 0.2% | 3.3% | 2.2% |

| SHSW composition | Moisture | Ashes | Lipids | Proteins | Carbohydrates |

| Miramontes-Martínez et al. [22] | 88.2% | 0.6% | 4.6% | 5.5% | 1.1% |

| Hejnfelt et al. [25] | 73.1% | 3.7% | 5.5% | 17.2% | 0.6% |

| Handous et al. [26] | 74.5% | 5.0% | 5.6% | 14.5% | 0.4% |

| Palatsi et al. [27] | 47.3% | 0.6% | 43.2% | 6.5% | 2.4% |

| Palatsi et al. [27] | 62.5% | 0.8% | 24.9% | 7.0% | 4.8% |

| Cuetos et al. [28] | 71.7% | 2.3% | 10.5% | 10.1% | 5.4% |

| SHS composition | Moisture | Ashes | Lipids | Proteins | Carbohydrates |

| Handous et al. [26] | 91.9% | 1.1% | 0.0% | 6.9% | 0.1% |

| Palatsi et al. [27] | 75.8% | 0.9% | 10.7% | 6.8% | 5.8% |

| Palatsi et al. [27] | 90.4% | 1.3% | 5.0% | 3.1% | 0.1% |

| Bayr [29] | 97.8% | 0.2% | 1.6% | 0.2% | 0.2% |

| Bayr [29] | 99.0% | 0.1% | 0.1% | 0.8% | 0.0% |

| Stream | Description | Value | Unit |

| 1 | FVSW | 58,332 | t/y |

| 2 | SHSW | 12,260 | t/y |

| 5 | FVS | 1552 | t/y |

| 6 | SHS | 21,342 | t/y |

| waste | Total inlet waste (stream n.1 + 2 + 5 + 6) | 93,486 | t/y |

| Indicator | Description | Value | Unit |

| BMP | Biomethane potential | 0.233 | Nm3/kgVS(ADin) |

| Yhydrochar | Net hydrochar yield (i.e., hydrochar to storage) | 130 | kghydrochar/twaste |

| Wel | Specific electric consumption | 33 | kWhel/twaste |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conversano, A.; Alemanno, S.; Sogni, D.; Di Bona, D. Industrial Food Waste Screening in Emilia-Romagna and the Conceptual Design of a Novel Process for Biomethane Production. Waste 2025, 3, 33. https://doi.org/10.3390/waste3040033

Conversano A, Alemanno S, Sogni D, Di Bona D. Industrial Food Waste Screening in Emilia-Romagna and the Conceptual Design of a Novel Process for Biomethane Production. Waste. 2025; 3(4):33. https://doi.org/10.3390/waste3040033

Chicago/Turabian StyleConversano, Antonio, Samuele Alemanno, Davide Sogni, and Daniele Di Bona. 2025. "Industrial Food Waste Screening in Emilia-Romagna and the Conceptual Design of a Novel Process for Biomethane Production" Waste 3, no. 4: 33. https://doi.org/10.3390/waste3040033

APA StyleConversano, A., Alemanno, S., Sogni, D., & Di Bona, D. (2025). Industrial Food Waste Screening in Emilia-Romagna and the Conceptual Design of a Novel Process for Biomethane Production. Waste, 3(4), 33. https://doi.org/10.3390/waste3040033