Abstract

This review aims to streamline the approach to assessing the most used valorization methods for fruit and vegetable waste (FVW) that are eco-friendly, cost-effective, and sustainable within a circular economy framework. Green processing technologies for the extraction of bioactive compounds from FVW, their applications, and the technico-economical assessment of FVW’ biorefinery to support circular economy are highlighted. Important value-added products generated by FVW include bioactive compounds, pectin, protein isolates, such as soy, natural pigments such as anthocyanins, quinones, carotenoids, betalains, and chlorophyll. At this time, the prospects of using FVW have increased in the food supplements, bioactive and edible food packaging, agriculture, energy, and water purification fields. The findings report that proper management of FVW not only minimizes their addition to landfills in the absence of composting, but also promotes the efficient utilization of resources for the development of innovative materials with a wide range of beneficial applications. Implementing the possible solutions described in this paper would not only reduce environmental impact, but also open up new economic opportunities through the valorization of FVW.

1. Introduction

Fruits and vegetables are among the most widely consumed commodities worldwide [1]. In 2001, the most produced fruits worldwide were apples, bananas, watermelons, grapes, oranges, and mangoes, while the most produced vegetables were tomatoes, cucumbers, cabbages, onions, eggplants, and carrots [2]. As outlined in the 2019 research report by the Food and Agricultural Organization (FAO) of the United Nations, approximately 14% of food produced in the world was lost or wasted post-harvest [3]. Moreover, according to the United Nations (UN) Environment Programme’s Food Waste Index Report 2021, 931 million tons are lost annually due to food wastage [4]. Goal 12 of the Sustainable Development Goals (SDGs) incorporated into the 2030 Agenda encompasses the main objectives related to food waste, which involve halving the global amount of wasted food per capita through retail sales and consumption, as well as reducing food loss in the production and distribution processes [4,5,6] to ensure sustainable consumption and production patterns [7]. Fruit and vegetable loss occurs at various stages of the food supply chain, during the production, storage, processing, and distribution stages before consumption [8,9].

Waste from fruits and vegetables makes up approximately 16% of the overall food waste and contributes around 6% to global greenhouse gas emissions [10]. Fruit and vegetable waste is usually discarded or left to spoil at the consumer, retail, or other food outlet levels [1]. In this paper, the expression ’’fruit and vegetable waste’’ (FVW) refers to all parts of fruit and vegetable waste, which occurs through harvesting by the farmer, uneaten food from retail and food services, processing food facilities, preservation, packaging, and end consumers, and which can be further processed and recovered in several ways [11]. By-products in the form of non-edible parts, such as peels, seeds, pomace, and stems generated from industrial processing of fruits and vegetables, are included in FVW.

The beneficial properties of fruit and vegetable waste (FVW), such as biodegradability, cost-effectiveness durability, and lighter weight, underscore their potential for valorization.

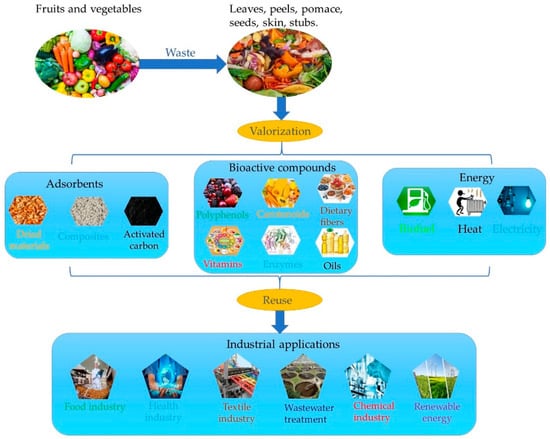

Figure 1 illustrates the valorization pathways of the main types of waste, i.e., leaves, peels, pomace, seeds, skin, and roots, resulting from the processing or discarding of FVW prior to reaching the retail phase.

Figure 1.

Conversion of FVW into sustainable and value-added materials [12].

The conversion of fruit waste (such as citrus, banana, apple, grape, and mango) and vegetable waste (including potato, tomato, cabbage, carrot, cauliflower, and broccoli) to adsorbents for water purification has been documented [12].

These raw materials contain ample reserves of valuable molecules, such as phytochemicals, minerals, vitamins, oils, nutrients, and other bioactive compounds recognized for their health advantages [2,11] and food packaging applications [13,14]. These health benefits encompass disease prevention, immune system enhancement, regulation of gastrointestinal transit, and various others [10]. The recovering of fiber and phytochemicals from the peel fractions, pulps, pomace, and seeds provides an integrated perspective for their incorporation into human, animal [15], and fish feed [7,13,16], as well as pharmaceutical and cosmeceutical products [10,17]. The innovative conversion technologies of FVW into high-value-added molecules such as bioactive compounds, pectin, carotenoids, anthocyanins, antioxidants, phenols, flavonoids, proteins, polysaccharides, dietary fibers, or oils are ultrasound-assisted extraction (UAE) [5,18,19], microwave-assisted extraction (MWAE) [20], supercritical fluid extraction (SFE) [5,20], pressurized hot water extraction (PHWE) [20,21,22,23], pressurized liquid extraction (PLE) [5,20,24], supercritical fluid extraction (SFE) [5,20], pulsed electric field-assisted extraction (PEFAE) [5], ohmic heating-assisted extraction (OHAE) [25,26], and enzyme-assisted extraction (EAE) [5].

Also, these leftover biomass materials offer a feasible alternative feedstock for the generation of diverse biofuels, such as biogas, biodiesel, biohydrogen, and fuel pellets [27].

It has been recorded that the inadequate handling of FVW due to their high perishability leads to the escalation of the climate change crisis with considerable GHG emissions. With the disposal of fruit waste in landfills or through composting, greenhouse gases such as CH4 and nitrous oxides (N2O) are released, which have more potent warming effects compared to CO2 [28]. Also, the biodiversity near farmland is damaged, posing a significant threat to human health.

In a study conducted in the United States on the water and carbon footprint emissions associated with the loss and waste of grains, vegetables, and fruits from 1970 to 2017, it was stated that the level of vegetable food waste was five times higher than that of grains and twice as high as that of fruits [6]. These data led to the conclusion that the focus on mitigating food waste should prioritize vegetables. When considering the overall CO2 emissions due to food loss and waste, vegetables accounted for 50%, grains for 31%, and fruits for 19% of the total emissions. Furthermore, food waste accounted for 29%, 47%, and 24% of the total wasted water [6].

In this context, the aim of this paper is to explore the reintegration of valuable products obtained from FVW into specific applications, as well as to highlight green extraction technologies for valuable molecules, in line with economic circularity.

2. Sources of FVW

2.1. Industrial Processing Facilities

Every day, food processing industries generate a significant amount of fruit and vegetable waste, including skins, seeds, cores, rinds, pomace, etc. [29]. Engineering processes such as oil extraction from papaya seeds [30], citrus peels [31], juice manufacturing [32,33], and sugar refining are significant contributors to food waste [14]. During industrial operation of fruits and vegetables, about 50% of the waste is discarded [33]. For example, 50–65% of waste is produced during the extraction of bergamot essential oil from the pomace of a hybrid plant of lemon and sour orange [34]. In addition, more than 50% of fresh citrus fruits (including tangerines, lemons, oranges, and limes) are made up of the peel, membranes, and seeds [2].

The waste generated from fruit and vegetable sources contains isoflavones and phenolic compounds, carotenes, minerals, oils, enzymes, alkaloids, and vitamins, all of which possess diverse health-promoting properties [35,36,37].

2.2. Retail Sectors

Unsold and abnormal fruit and vegetables, which have equivalent nutritional value to their visually attractive counterparts, are often discarded because of their less-than-perfect appearance for retail purposes [38,39,40]. In addition, 83.9% of produce vendors report that the vegetable leaves make up the largest portion of their waste [41].

The study conducted by Yenerall and Chen [42] on food retailers from the United States identified online grocery shopping and restaurants as the main sources of FVW.

Employees are essential to the retail sector, as they actively address the causes of food waste and are trained to implement various precautionary measures to prevent and reduce it. From the employees’ perspective, the combination of policy, practice, people, and product themes are the main causes of the generation of FVW in supermarkets [43].

The influence of culture and social economy aspects on consumers’ willingness to buy fruits and vegetables with unconventional shapes was investigated by Campos et al. [40]. The authors demonstrated that elevated cultural levels positively influence the consumer’s willingness to buy them, whereas lower socio-economic aspects of a nation have a negative impact on their willingness to make such purchases.

The best methods to reduce FVW include extra care in fruit and vegetable handling, proper packaging, and facilities such as cold rooms and shelving [44]. In addition, effective supply chain management, information sharing, and collaborative partnerships, as well as consumer education and awareness, are also key strategies.

2.3. Consumers Households

Usually, consumers do not consume all parts of fruits and vegetables, with waste encompassing seed coats, hulls, husks, peels, seeds, and pomace, leading to the generation of significant amounts of food waste on a global scale. Regarding the overall waste incidence rate, food waste occurs in most households, with an incidence rate of approximately 90.7%. Fruits and vegetables have the highest incidence rate of food waste, at around 87.7% [45]. The literature suggests that routines relating to planning and shopping for fruits and vegetables are the main factors in waste production, in addition to perceived behavioral control [46].

According to the empirical results, consumers should first be educated about food expiration date labels to correct misinterpretations of these labels’ definitions and, furthermore, to avoid the resulting inappropriate discarding behavior [47,48]. Second, the outer packaging labels of pre-packaged food should be improved. Moreover, new labeling technologies should be used. For example, intelligent freshness monitoring labels can show the current quality status of food and the conditions under which it can no longer be consumed [49].

A survey conducted in Pakistan showed that the financial losses from food waste per person per year were USD 12.8, and were greater in wealthy households compared to lower-income households [50].

3. Potential Uses of Some FVW as Sustainable and Value-Added Materials

Conventional methods for disposal of FVW include briquetting, landfills, anaerobic digestion, incineration, and composting [1,51,52,53]. Each technology has disadvantages in terms of environmental pollution, the high cost of acquiring equipment, and potential harm to animals’ food and human health.

Table 1 illustrates different solutions for reducing the amount of FVW by using innovative applications.

Table 1.

Potential applications of FVW.

3.1. Value-Added Products

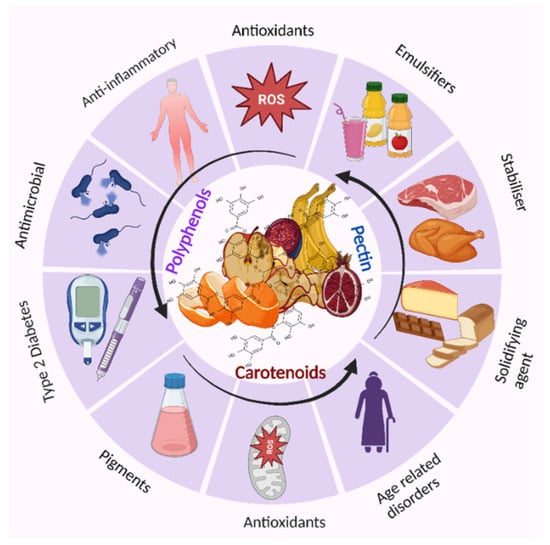

Figure 2 depicts some industrial applications of polyphenols, pectin, and carotenoids extracted from FVW.

Figure 2.

Some applications of value-added products extracted from FVW. Reproduced from [17] with permission from Elsevier. ROS means reactive oxygen species.

3.1.1. Bioactive Compounds

Bioactive compounds include phenolics, carotenoids, flavoring (anthocyanins), chlorophylls, and betalains [70], with potential applications for people’s health, functional food, cosmetics, and pharmaceuticals [17,23,70,71]. Dhalaria et al. [72] evidenced the roles of antioxidants, nutraceuticals, and phenolic acids extracted from the waste of many fruits for their health benefits. Bioactive compounds isolated from FVW have been reported to be suitable for food emulsion stability, textural qualities, and food preservation due to their antimicrobial properties [36].

Bioactive compounds extracted from apple and carrot by-products have been effectively employed in the nutrition of post-weaning piglets. This use resulted in decreased oxidant and inflammatory processes, along with positive modulation of the microbiota. These compounds served as valuable alternatives to pharmaceutical ZnO and in-feed antibiotics [73]. Similar, citrus pulp and grape pomace were demonstrated as novel, cost-effective, and natural sources of cellulose, polyunsaturated fatty acids, and phytochemicals which are beneficial for the ruminant livestock industry [74]. These components possess nutritional value along with anthelmintic, antioxidant, and antimicrobial properties.

The mango seed kernel contains phenolic compounds that have shown antifungal properties against postharvest pathogens, which pose a major risk to the global food supply chain [75].

Natural pigments (colorants) extracted from vegetable waste are acknowledged for their numerous advantages, such as enhancing consumer acceptance; boosting the nutritional content of processed foods; and decreasing the use of synthetic dyes that can cause various side effects such as food allergies, respiratory, and cardiovascular problems [76]. Also, natural pigments incorporated into food products not only enhance the color of foods, but also increase their antioxidant capacity. This process helps to chelate free radicals from the body, providing health benefits when included in the diet. Additionally, it improves the aesthetic appeal for consumers, increases profitability for manufacturers, and benefits the environment by reducing industry biomass waste [77]. A variety of FVWs have been used for extraction of natural pigments [77,78,79]. For instance, apple peel, eggplant peel, banana peel, and grape skin have been exploited for the extraction of anthocyanins, which have shown high antioxidant capacity and are useful in health care.

Lombardelli et al. [80] investigated the recovery of betalains (in amount of 200 g) from unsold red beets using the enzyme-assisted extraction (EAE) method, which operates at a temperature of 25 °C and for a duration of 240 min.

An integrated method for the simultaneous extraction of betalains and chlorophylls pigments from red beet stems and leaves using reversible aqueous biphasic systems (ABSs) containing ionic liquids (ILs) was conducted by Rosa et al. [81]. The highest extraction yields achieved were 6.67 wt% for betalains and 1.82 wt% for chlorophylls (per unit weight of biomass).

A review by Phan et al. [82] highlighted the prevalence of natural dyes like anthocyanins, quinones, and carotenoids, extracted in crude form from FVW, and their use in small-scale applications. Carotenoids are primarily stored in the peels of edible and non-edible parts of vegetables and fruits such as tomatoes, oranges, grapes, and carrots, which are often discarded [5]. Carotenoids are used as natural colorants or for combating vitamin A deficiencies in children and pregnant woman [83].

Powders derived from vegetable waste could also serve as coloring and flavoring agents or as natural preservatives in the food industry, or could be used to reformulate processed foods to enhance their nutritional profiles [84].

Waste and by-products of plants (fruits, exotic fruits, vegetables and seeds) have been valorized as bioactive compounds [85] or incorporated in natural-derived matrices to obtain green composites with performant properties [86,87].

3.1.2. Biopolymers

FVW is among the most promising prospects in the next generation of raw materials for obtaining biopolymers because not only are they naturally biodegradable and produced using renewable resources, but they can also be edible, meeting nutritional needs for the expanding population. Examples of biopolymers extracted from FVW include pectin; carbohydrates such as starch, sugars, and dietary fibers; nanocellulose; and proteins. Biopolymers from FVW offer sustainable alternatives to synthetic materials, contributing to waste valorization and the development of new food ingredients [88,89], as well as eco-friendly products.

Pectin is a valuable polysaccharide extracted from the cell walls of many fruits, especially citrus peels and apple pomace, which possess interesting features such as retaining moisture, oil, and aroma barriers and diminishing the respiration rate and food oxidation in food packaging [90,91]. Other FVW investigated for pectin extraction are watermelon rind [92], banana and papaya peels [93], and beetroot and red cabbage powder, which are obtained as by-products [94]. Future prospects include the application of pectin in the pharmaceutical and paper industries as a foam or a plasticizer [95].

The prebiotics promoting the growth of useful bacteria in the colon have been identified as novel applications of compounds of fructooligosaccharide (FOS), a carbohydrate extracted from FVW [96]. In a same line, a review paper by Freire et al. [97] showed that Limosilactobacillus (L.) fermentum strains isolated from by-products of fruit processing have shown probiotic properties that promote host health benefits.

Many fruits and vegetables contain starch, a polysaccharide carbohydrate that can serve as a primary ingredient for bioplastic production [98]. Starch can be extracted from various wastes of apple, kiwifruit, annatto, pineapple, mango, tamarind, litchi, longan, loquat, jackfruit, avocado, and banana through various methods, such as grinding, washing, and enzymatic treatment [99].

Nanocellulose is a natural biopolymer that can be synthesized from several FVWs, such as nut biomass, kiwi pruning residues, pineapple leaf and peel, and carrot root and pomace [100]. Diverse applications of nanocellulose have been disclosed, including its use in various functional composite materials, aerogels, and drug-delivery systems. Abdullah et al. [55] extracted cellulose from the rachis of banana fruit (Musa sapientum L. cv. Mali-Ong) and converted it into carboxymethyl cellulose (CMC), resulting in its successful use as an innovative edible coating to retard the aging and extend the shelf life of strawberry fruit.

Proteins extracted from waste plants such as corn, wheat, soybean, peanuts, cottonseed, and rice remain suitable and acceptable for individuals adhering to a vegetarian diet [101].

Resent research on the use of FVW has described the isolation of unconventional vegetable protein (UVP) from leaves, roots, and stems using the enzyme-assisted extraction (EAE) method [102]. The principle involves the breakdown of cellulose, hemicellulose, and pectin components in plant cell walls by the enzyme or a complex enzyme mixture, thereby impairing cell wall integrity and aiding in the release of proteins from the plant matrix. At present, the use of EAE techniques in UVP remains in the experimental phase rather than the commercial expansion stage because of its high expenses. Furthermore, variable outcomes and intricate purification processes also pose challenges to industrial production [102].

Onion peels, orange peels, and pea pods have been investigated for the production of single-cell protein (SCP) using a specific strain of Lactobacillus sp. as an alternative to conventional protein sources [89]. A maximum SCP yield of 8.6 g was achieved. The nutritional properties revealed a protein content of 48.34 ± 0.05%, a fat content of 2.44 ± 0.2%, and a fiber content of 2.97 ± 0.16%.

The amphiphilic nature of soy protein enables the formation of a stable network through denaturation. According to de Oliveira et al. [103], soy protein can interact with carboxymethylcellulose (CMC), enhancing the mechanical strength and oxygen permeability of edible films.

3.2. Food and Food Packaging

According to the UN’s projection, the global population is expected to reach about 9.8 billion people by the year 2050, suggesting that food production will need to increase by around 50–60% to meet the growing demand [104]. Promising opportunities for reducing food waste, promoting sustainability, and enhancing food quality and safety can include the development of edible food packaging and oil.

Utilizing vegetable waste as a growth substrate for cultivating fresh earthworms with the aim of producing dried meal for both feed and food purposes can be considered a practical and sustainable solution [105]. In comparison to the conventional meal used as feed, earthworm meal exhibits a greater environmental impact, which can be attributed to its higher economic value and the increased electrical consumption during the freeze-drying process [105].

FVW from markets has become a rearing substrate for Hermetia illucens (BSF black soldier fly) [106]. Meal insects can be used as fish feed to increase the sustainability of aquaculture. Recently, Yu et al. [57] used orange peel and apple pomace as substrates for microbial growth.

Producing functional powders from a variety of vegetable wastes, including carrot, leek, celery, and cabbage sourced from both fresh products and ready-to-eat lines of the cooperative to be utilized as functional food ingredients, will contribute to a circular economy [16].

It has been demonstrated that the natural antioxidants derived from FVW can serve as edible oil alternatives to artificial antioxidants, which may have detrimental impacts on human health [107].

Pomelo peel-derived carbon dots synthesized through a hydrothermal method were introduced, up to 3 wt%, into a biopolymeric matrix based on fish scale gelatin/alginate dialdehyde [108]. This composite film showed significant antioxidant and antimicrobial effects.

An extension of the shelf-life of strawberries by 24 days was reported when a coating with pectin, pullulan, and phenolic compounds extracted from apple pomace was made [56]. By incorporating phenolic compounds, tocopherols, and carotenoids, which help to protect cells from oxidative damage and inflammation, into edible oil, manufacturers can enhance the stability and shelf life of food products, promoting sustainability and reduces environmental impact by utilizing FVW that would otherwise be discarded.

3.3. Agriculture

FVW subjected to the drying process as well as milling of particles with sizes less than 50 μm was used to achieve biofertilizers through melting technology [58]. Compared with traditional fertilizers, such biofertilizers offer numerous benefits, such as cost-effectiveness, greater nutrient availability, improved soil fertility, protection of crops from soil-borne pathogens, viable agricultural production, increased tolerance to biotic and abiotic stresses, stimulation of phytohormone production, better soil health, and significantly reduced environmental contamination [109].

The fabricated biocomposites based on PLA and 20 wt% spinach stems (SS) designed for mulch film fabrication reached nearly 40 wt% biodegradation after 6 months, and they provided micro- and macronutrients such as P, K, B, Ca, Cu, Fe, Mn, Mg, S, and Zn for plant growth [58].

Biochar derived from FVW has been used as a soil amendment, which assures the proper pH and CEC for the growing plant. This is another innovative application of FVW [61].

3.4. Energy

Improper landfill disposal of biodegradable FVW contributes substantially to climate change and leachate. This happens because the waste releases various greenhouse gases and particles into the atmosphere [28]. FVWs are valuable feedstocks for producing renewable hydrogen through fermentation [62] and dark fermentation (DF) processes [64], as well as biomethane [65,110], offering a potentially efficient method for generating renewable energy and, thus, decreasing the use of non-renewable energy sources.

A major challenge in sustainable bioenergy production and supply is feedstock availability. It has been proven that the anaerobic digestion (AD) of FVW alone is not adequate, as it can cause harmful levels of acidification due to the rapid generation and buildup of volatile fatty acids, which negatively affect methane production [111]. Instead, using FVW as a co-substrate in the aerobic digestion of municipal sewage sludge can positively impact the energetic self-sustainability of wastewater treatment facilities [111]. This approach increases the biodegradability of municipal sewage sludge and leverages the unused capacity of current infrastructure to improve both the amount and quality of the generated biogas.

It has been found that 20% and 30% of sludge contents can be considered as a source of microorganisms, and 80% and 75% of mixed FVW collected from the University of Texas at Arlington (UTA) Compost Center were introduced into a digestor for degradation in the absence of oxygen via enzymatic and bacterial activities. The digestor operated at 37 °C for about five months [110]. KOH was added to increase the pH value. The rate of methane production was 14.77 L of methane per kg of food waste.

3.5. Water Purification

Water purification of industrial and pharmaceutical contaminants [66,69,112,113] and soil remediation of heavy metals [114] demonstrate that the FVW consists of promising materials for these environmental applications. The binding capacities of biosorbents based on FVW depend on various factors, including their source, chemical structure, type of metal, modification technology used, and the process conditions applied to enhance their functionality [114]. It has been observed that the modified fibers extracted from vegetable waste lead to better results than unmodified fibers. Various treatments, such as physical, enzymatic, bacterial, and chemical modifications, can enhance fiber porosity and surface area, thus increasing the number of adsorption sites, favoring the retention of heavy metals on biosorbent surfaces [114]. The greatest challenge posed by biosorbents after chemical neutralization is their disposal method in landfills, which brings a potential risk of secondary contamination to the soil, groundwater, surface water, and air due to the leaching process.

3.6. Other Applications

Patil et al. [115] introduced 5% fruit vegetable waste powder into a composition based on acrylic polymer resin, glycerol, and polyvinyl acetate for the purpose of fabricating a semi-synthetic leather, which exhibited an abrasion resistance of 20,000 abrasion cycles.

An innovative application of fresh kitchen waste, such as vegetable and fruit peels, in the production of eco-enzymes was revealed by Benny et al. [116]. The fermentation of a mixture of sugar, citrus peels, and water in a ratio of 1:3:10 was carried out for three months at a temperature of 27 °C. This eco-enzyme offers multiple potential applications, including cleaning and disinfection for floors, utensils, gardening, wastewater treatment, and plant growth.

4. Extraction Methods

Conventional methods for extracting bioactive compounds, pectin, carotenoids, anthocyanins, antioxidants, phenols, flavonoids, proteins, polysaccharides, dietary fibers, or oils from FVW, such as Soxhlet extraction, maceration, and steam distillation, usually involve the use of hydroethanolic mixtures as solvents and are time-consuming [36,117]. Usually, the conventional extraction systems of valuable compounds from FVW involve the use of organic solvents and heating for prolonged periods of time, promoting the degradation of compounds of interest. This highlights the necessity of developing innovative techniques for retaining high-value-added molecules from FVW, such as ultrasound-assisted extraction (UAE), microwave-assisted extraction (MWAE), supercritical fluid extraction (SFE), pressurized hot water extraction (PHWE), pressurized liquid extraction (PLE), supercritical fluid extraction (SFE), pulsed electric field-assisted extraction (PEFAE), ohmic heating-assisted extraction (OHAE), and enzyme-assisted extraction (EAE) [5,18,19,20,21,25,118,119].

Table 2 illustrates the advantages and barriers encountered by various methods applied for the extraction of bioactive compounds from FVW.

Table 2.

Green methods applied for extraction of high-value compounds from FVW.

4.1. Ultrasound-Assisted Extraction (UAE) and Microwave-Assisted Extraction (MWAE)

With the ultrasound-assisted extraction (UAE) method, acoustic waves generated in the solvent induce cavitation bubbles, which burst at the surface of the FVW, causing disruption to the cell wall. Furthermore, this disruption facilitates the release of phenolic bioactive compounds into the solvent. This technique is optimized by controlling the solvent concentrations, solvent-to-sample ratio, extraction time, temperature, frequency, and power [19].

UAE is applied as an environmentally friendly technology to recover valuable components from polysaccharides, pectin, essential oils, polyphenols, flavonoids, anthocyanins, lycopene, carotenoids, and related antioxidant extracts from FVW [18]. Furthermore, ultrasound extraction aids in the elimination of toxic and persistent pollutants, such as aromatics, surfactants, and dyes, from the wastewater produced during the extraction of biocompounds, which is achieved through the oxidative breakdown of these substances.

The extraction of phenolic compounds from mango peels by this technique in the presence of 50% aqueous ethanol solution, with a solid-to-liquid ratio of 1:30, a temperature of 45 °C, and 30% of ultrasound amplitude after a treatment time of 10 min, resulted in the highest phenolic content of 35.5 mg GAE/g and 92% antioxidant activity [120].

Compared to the UAE method, microwave-pretreated ultrasound-assisted extraction was found to release less CO2 into the atmosphere and had a shorter extraction duration when isolating bioactive compounds from papaya fruit peel [121].

4.2. Supercritical Fluid Extraction (SFE)

Supercritical fluid extraction (SFE) is primarily employed for the extraction of volatile compounds. It involves utilizing supercritical fluids, such as CO2 and H2O, at or near their critical temperature and pressure to recover extracts from solid plant matrices [122]. For the optimal extraction of valuable compounds from fruit waste, pre-treatment steps such as microwave, ultrasound, and enzymatic pre-treatments for preparing the substrate for SFE are necessary [122].

In an experiment, 12 g of tomato peel and seed acquired from a ketchup plant in California was used for lycopene extraction using supercritical carbon dioxide (SC–CO2) at 30 MPa and 80 °C for 4 h as well as the Soxhlet (hexane) method [123]. The bioaccessibility of lycopene in the extracts was 11.5% using the SC-CO2 technique, compared with 3.5% with the conventional extraction method. This demonstrates the significant potential of the SC-CO2 technique to enhance the health and wellness benefits of lycopene by improving its bioavailability due to the higher (Z)-lycopene content.

4.3. Pressurized Liquid Extraction (PLE) and Hot Water Extraction (PHWE)

When the efficiencies the of pressurized liquid extraction (PLE), Soxhlet, and maceration techniques were compared during isolation of bioactive compounds from passionfruit rinds, PLE was found to be the most economical at a temperature of 60 °C and 70% ethanol [124]. At this concentration of ethanol, a pipeline blockage was observed due to the gelatinization of pectin found in the passionfruit rinds. A step to extract pectin was proposed.

Pressurized hot water extraction (PHWE) employs only liquid water as an extraction solvent at temperatures exceeding the atmospheric boiling point of water (100 °C, 0.1 MPa), but remaining below its critical point (374 °C, 22.1 MPa) [22]. Pagano et al. [125] found PHWE to be an excellent and environmentally friendly method for reclaiming bioactive compounds from artichoke agro-industrial residues, demonstrating recoveries of 93–105% and 90–105% for caffeoylquinic acids (CQAs) and flavone glycosides (FLs), respectively.

4.4. Ohmic Heating-Assisted Extraction (OHAE)

Ohmic heating is a sustainable and green technology based on the utilization of electric energy, which is converted into thermal energy to heat the substance [25]. Microwave-assisted extraction (MWAE) and ohmic heating-assisted extraction (OHAE) were concurrently employed for phenolic extraction from avocado leaves [126]. Although both methods resulted in high values for total phenolic content (TPC), 2,2-diphenyl-1-picrylhydrazyl (DPPH) scavenging, and antidiabetic activities, the OHAE approach was found to be superior to MWAE. The optimal OHAE conditions were a 9.38 V/cm voltage gradient, a 6 min extraction time, a temperature of 60 °C, 5 min, and 1 g dried leaf/100 mL water [126].

4.5. Enzyme-Assisted Extraction (EAE)

The need for targeted extraction by specific bacteria, fungi, nematodes, or earthworms arises from their unique abilities to break down complex organic matter and extract valuable molecules, thus efficiently controlling postharvest fungal infection.

To evaluate the extraction performance of oil and polyphenols from raspberry pomace through EAE compared with conventional extraction methods, four proteases—Alcalase 2.4 L, a thermostable alkaline protease from Bacillus licheniformis; Neutrase from Bacillus amyloliquefaciens; pepsin from porcine gastric mucosa; and papain, a cysteine protease from Carica papaya latex—were used simultaneously [127]. Three carbohydrates were also employed: cellulase from Trichoderma reesei, pectinase from Aspergillus aculeatus, and xylanase from Trichoderma viride. The recovery rates of polyphenols and antioxidant activity were 48% and 25% higher for EAE, respectively, compared to extraction with a methanol/acetone/water mixture.

5. Techno-Economic Assessment

Within the scope of the circular economy, valorization of fruit and vegetable waste would be advantageous for reducing the amount of these wastes, recycling them into innovative value-added materials, and addressing environmental problems. Due to the high moisture content of this waste, which affects its perishability, quality, storage, and transportation, a proposed strategy involves reducing the water content through pressing [15]. Consequently, various drying methods have been explored as means to mitigate or prevent potential waste, such as sun-drying, solar drying, convective air-drying, hybrid drying, spray-drying, drum-drying, vacuum-drying, freeze-drying, and refractance window drying for food valorization [4]. Drying techniques have been effectively utilized to convert different types of fermented vegetable residues into nutrient-dense flours. For example, fermented grape residue has been processed into a fortified flour that can be used to boost the nutrient content of various foods [128]. Likewise, this approach can be applied to other vegetable residues, such as beetroot, red pepper, and carrot pomace, transforming them into valuable components for food enhancement [129].

Soltan et al. [62] performed fermentation and pyrolysis experiments with fruit and vegetable peels in 200 mL batch reactors with working volumes of 150 mL and found a maximum net profit for multi-fermentation and pyrolysis processes of USD 4.11 per kg feedstock for a mixture of 25% pea, 25% tomato, 25% banana, and 25% orange, and USD 4.13 per kg feedstock for the digestate of orange, respectively.

Fermentation and freeze-drying processes are old approaches to avoid spoiling and the need for refrigeration storage for pickled dried vegetables [130]. These methods contribute to reducing vegetable waste as well as the prolonging the shelf lives of these vegetables.

At an industrial scale, lettuce waste has been efficiently converted using innovative technologies into antioxidant extract through the implementation of a decision support system (DSS) [131]. The structure of the DSS model employed for the valorization of lettuce waste comprised three main phases: an investigative phase, incorporating tools such as material flow analysis (MFA) and techno-economic and profitability assessments; a design phase; and scenario analysis. It was demonstrated that, through the application of homogenization, supercritical CO2 drying, and bioactive extraction processes on 40% of lettuce waste, a reduction in greenhouse gas emissions (CO2RED) of 124.4 tons CO2 per year and a primary energy saving (PES) of 55.1 tons per year were achieved [131]. These innovative processes maximized the economic performances of lettuce waste valorization compared with traditional approaches, such as anaerobic digestion, composting, and carbonization.

Green extraction methods applied to extract bioactive compounds from fruit and vegetable waste processing address market demands and align with the global goals of Agenda 2030 concerning the sustainability of food systems. They boast shorter extraction times for biologically active compounds, resulting in lower energy consumption. Moreover, they eliminate the need for petrochemical solvents, greatly reducing environmental harm and eliminating the issue of disposing of toxic waste afterward.

A life cycle assessment (LCA) demonstrated that, in the EU-28, for an annual production exceeding 0.1 million metric tons (Mt), the quantities of anthocyanins, quinones, and carotenoids were 56 kg/t of dry weight, 18 kg/t of dry weight, and 593 kg/t of dry weight, respectively [5].

Joensuu et al. [132] proposed a holistic approach using carrot peel compounds, such as vitamins A and E, to nourish the skin by producing artisan soap. The profit margin for a 100 g soap piece was estimated to be approximately EUR 5.5, with a selling price of EUR 9 per piece (compared to similar products in the market).

However, some limitations need still to be resolved in this area. Most of the eco-friendly technologies proposed for the recovery of bioactive compounds such as polyphenols, flavonoids, colorants, pectin, and essential oils are still either at the laboratory scale or the pilot scale, showing a moderate technology readiness level (TRL 5 to 7) [133]. The surface areas of large-scale bioreactors, flow dynamics, and purification expenses serve as limitations in designing a scale-up process for enhanced productivity [75].

Managing FVW in the food processing industry is a significant challenge that involves substantial capital investment, primarily due to the transportation costs. Transporting waste to disposal or processing facilities is costly, largely due to the bulk and weight of the waste, which often contains a high water content [52].

Special attention should be paid to the education of consumers and businesses on reducing FVW, and regulatory bodies and policymakers should encourage more sustainable waste valorization practices in circular economy models.

Overall, the valorization of fruit and vegetable waste can open great market opportunities if it is efficiently exploited.

6. Conclusions and Perspectives

Fruit and vegetable waste is highly perishable, leading to quick degradation and potential environmental hazards if it is not managed promptly. Improper disposal can lead to emissions of methane, a potent greenhouse gas, and other environmental issues such as water pollution.

The primary sources of fruit and vegetable waste arise from industrial processing, which can be exploited for the valorization of bioactive functional molecules.

As compared with traditional extraction methods of valuable compounds from FVW technologies, the green extraction methods investigated herein are promising for the separation of various bioactive compounds (for example, pectin, carotenoids, polyphenols, proteins) from FVW, in line with the circularity of resources and sustainability. Other potential solutions for processing and valorization of FVW involve converting them into biogas and organic fertilizers, developing animal feed and innovative food packaging that extends the shelf lives of fruits and vegetables, and creating high-performance materials with applications in construction and water purification.

However, more research is needed to optimize the extraction process parameters, as they directly impact the final quality of bioactive compounds. In addition, the industry should address more sustainable and cost-effective FVW management practices. Some data have shown promise, and exploitation is limited with a low amount of raw material.

Implementing the possible solutions described in this paper would not only reduce environmental impact, but would also open up new economic opportunities through the valorization of FVW.

Author Contributions

Conceptualization, M.R.; investigation, R.N.D.-N. and G.C.; methodology, M.R. and R.N.D.-N.; resources, G.C.; software, G.C.; validation, R.N.D.-N.; writing—original draft, M.R.; writing—review and editing, M.R., R.N.D.-N., and G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available upon request due to privacy.

Acknowledgments

G. Coman acknowledges the National Program for Research of the National Association of Technical Universities—GNAC ARUT 2023. R.N. Darie-Niță acknowledges the Romanian Academy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ganesh, K.S.; Sridhar, A.; Vishali, S. Utilization of fruit and vegetable waste to produce value-added products: Conventional utilization and emerging opportunities-A review. Chemosphere 2022, 287, 132221. [Google Scholar] [CrossRef]

- Mateus, A.R.S.; Pena, A.; Sanches-Silva, A. Unveiling the potential of bioactive compounds in vegetable and fruit by-products: Exploring phytochemical properties, health benefits, and industrial. Curr. Opin. Green Sustain. Chem. 2024, 48, 100938. [Google Scholar] [CrossRef]

- Zhu, Y.D.; Luan, Y.T.; Zhao, Y.N.; Liu, J.L.; Duan, Z.Q.; Ruan, R.G. Current Technologies and Uses for Fruit and Vegetable Wastes in a Sustainable System: A Review. Foods 2023, 12, 1949. [Google Scholar] [CrossRef]

- Tan, C.H.; Hii, C.L.; Borompichaichartkul, C.; Phumsombat, P.; Kong, I.; Pui, L.P. Valorization of fruits, vegetables, and their by-products: Drying and bio-drying. Dry. Technol. 2022, 40, 1514–1538. [Google Scholar] [CrossRef]

- Kultys, E.; Kurek, M.A. Green Extraction of Carotenoids from Fruit and Vegetable Byproducts: A Review. Molecules 2022, 27, 518. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.H.; Sun, Y.C.; Jin, M.Z.; Ripp, S.A.; Sayler, G.S.; Zhuang, J. Domestic plant food loss and waste in the United States: Environmental footprints and mitigation strategies. Waste Manag. 2022, 150, 202–207. [Google Scholar] [CrossRef] [PubMed]

- Lau, K.Q.; Sabran, M.R.; Shafie, S.R. Utilization of Vegetable and Fruit By-products as Functional Ingredient and Food. Front. Nutr. 2021, 8, 661693. [Google Scholar] [CrossRef] [PubMed]

- Sagar, N.; Pareek, S.; Sharma, S.; Yahia, E.; Lobo, M. Fruit and Vegetable Waste: Bioactive Compounds, Their Extraction, and Possible Utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef]

- Esparza, I.; Jiménez-Moreno, N.; Bimbela, F.; Ancín-Azpilicueta, C.; Gandía, L. [Fruit and vegetable waste management: Conventional and emerging approaches]. J. Environ. Manag. 2020, 265, 110510. [Google Scholar] [CrossRef]

- Cassani, L.; Gomez-Zavaglia, A. Sustainable Food Systems in Fruits and Vegetables Food Supply Chains. Front. Nutr. 2022, 9, 829061. [Google Scholar] [CrossRef]

- Ueda, J.M.; Pedrosa, M.C.; Heleno, S.A.; Carocho, M.; Ferreira, I.; Barros, L. Food Additives from Fruit and Vegetable By-Products and Bio-Residues: A Comprehensive Review Focused on Sustainability. Sustainability 2022, 14, 5212. [Google Scholar] [CrossRef]

- Matei, E.; Rapa, M.; Predescu, A.M.; Turcanu, A.A.; Vidu, R.; Predescu, C.; Bobirica, C.; Bobirica, L.; Orbeci, C. Valorization of Agri-Food Wastes as Sustainable Eco-Materials for Wastewater Treatment: Current State and New Perspectives. Materials 2021, 14, 4581. [Google Scholar] [CrossRef] [PubMed]

- Augustin, M.A.; Sanguansri, L.; Fox, E.M.; Cobiac, L.; Cole, M.B. Recovery of wasted fruit and vegetables for improving sustainable diets. Trends Food Sci. Technol. 2020, 95, 75–85. [Google Scholar] [CrossRef]

- Dilucia, F.; Lacivita, V.; Conte, A.; Del Nobile, M.A. Sustainable Use of Fruit and Vegetable By-Products to Enhance Food Packaging Performance. Foods 2020, 9, 857. [Google Scholar] [CrossRef] [PubMed]

- Tedesco, D.E.A.; Scarioni, S.; Tava, A.; Panseri, S.; Zuorro, A. Fruit and Vegetable Wholesale Market Waste: Safety and Nutritional Characterisation for Their Potential Re-Use in Livestock Nutrition. Sustainability 2021, 13, 9478. [Google Scholar] [CrossRef]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Segui, L. Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry. Sustainability 2020, 12, 1284. [Google Scholar] [CrossRef]

- Noor, A.; Moyle, P.M.; Malik, A.; Ziora, Z.M.; Pant, K.K. Transformative upcycling of fruit-vegetable waste for nutraceutical and pharmaceutical breakthroughs and circular economy evolution. Process Saf. Environ. Prot. 2024, 187, 1022–1036. [Google Scholar] [CrossRef]

- Nabi, B.G.; Mukhtar, K.; Ansar, S.; Hassan, S.A.; Hafeez, M.A.; Bhat, Z.F.; Khaneghah, A.M.; Ul Haq, A.; Aadil, R.M. Application of ultrasound technology for the effective management of waste from fruit and vegetable. Ultrason. Sonochem. 2024, 102, 106744. [Google Scholar] [CrossRef]

- Basri, M.S.M.; Shah, N.; Sulaiman, A.; Tawakkal, I.; Nor, M.Z.M.; Ariffin, S.H.; Ghani, N.H.A.; Salleh, F.S.M. Progress in the Valorization of Fruit and Vegetable Wastes: Active Packaging, Biocomposites, By-Products, and Innovative Technologies Used for Bioactive Compound Extraction. Polymers 2021, 13, 3503. [Google Scholar] [CrossRef]

- Rifna, E.J.; Misra, N.N.; Dwivedi, M. Recent advances in extraction technologies for recovery of bioactive compounds derived from fruit and vegetable waste peels: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 719–752. [Google Scholar] [CrossRef]

- Plaza, M.; Marina, M.L. Pressurized hot water extraction of bioactives. TRAC-Trends Anal. Chem. 2023, 166, 117201. [Google Scholar] [CrossRef]

- Plaza, M.; Turner, C. Pressurized hot water extraction of bioactives. TRAC-Trends Anal. Chem. 2015, 71, 39–54. [Google Scholar] [CrossRef]

- Tan, S.S.Y.; Shanmugham, M.; Chin, Y.L.; An, J.; Chua, C.K.; Ong, E.S.; Leo, C.H. Pressurized Hot Water Extraction of Mangosteen Pericarp and Its Associated Molecular Signatures in Endothelial Cells. Antioxidants 2023, 12, 1932. [Google Scholar] [CrossRef] [PubMed]

- Visnjevec, A.M.; Barp, L.; Lucci, P.; Moret, S. Pressurized liquid extraction for the determination of bioactive compounds in plants with emphasis on phenolics. TRAC-Trends Anal. Chem. 2024, 173, 117620. [Google Scholar] [CrossRef]

- Khalid, S.; Hassan, S.A.; Altemimi, A.B.; Chaudhary, K.; Raana, S.; Javaid, H.; Naeem, M.; Bhat, Z.F.; Aadil, R.M. Recovery of valuable substances from food waste by ohmic heating assisted extraction -A step towards sustainable production. Future Foods 2024, 9, 100365. [Google Scholar] [CrossRef]

- Ferreira-Santos, P.; Nobre, C.; Rodrigues, R.M.; Genisheva, Z.; Botelho, C.; Teixeira, J.A. Extraction of phenolic compounds from grape pomace using ohmic heating: Chemical composition, bioactivity and bioaccessibility. Food Chem. 2024, 436, 137780. [Google Scholar] [CrossRef] [PubMed]

- Gebre, G.D.; Gebremariam, S.N.; Keneni, Y.G.; Marchetti, J.M. Valorization of tropical fruit-processing wastes and byproducts for biofuel production. Biofuels Bioprod. Biorefining 2023, 17, 1807–1842. [Google Scholar] [CrossRef]

- Adamu, H.; Bello, U.; Yuguda, A.U.; Tafida, U.I.; Jalam, A.M.; Sabo, A.; Qamar, M. Production processes, techno-economic and policy challenges of bioenergy production from fruit and vegetable wastes. Renew. Sustain. Energy Rev. 2023, 186, 113686. [Google Scholar] [CrossRef]

- Hasan, M.M.; Islam, M.R.; Haque, A.R.; Kabir, M.R.; Khushe, K.J.; Hasan, S.M.K. Trends and challenges of fruit by-products utilization: Insights into safety, sensory, and benefits of the use for the development of innovative healthy food: A review. Bioresour. Bioprocess. 2024, 11, 10. [Google Scholar] [CrossRef]

- Tan, C.X.; Tan, S.T.; Tan, S.S. An overview of papaya seed oil extraction methods. Int. J. Food Sci. Technol. 2020, 55, 1506–1514. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.P.; Kaur, A.; Yadav, M.P. Insights into the chemical composition and bioactivities of citrus peel essential oils. Food Res. Int. 2021, 143, 110231. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, T.; Chowdhary, P.; Chaurasia, D.; Gnansounou, E.; Pandey, A.; Chaturvedi, P. Sustainable green processing of grape pomace for the production of value-added products: An overview. Environ. Technol. Innov. 2021, 23, 101592. [Google Scholar] [CrossRef]

- Pérez-Marroquín, X.A.; Estrada-Fernández, A.G.; García-Ceja, A.; Aguirre-Alvarez, G.; León-López, A. Agro-Food Waste as an Ingredient in Functional Beverage Processing: Sources, Functionality, Market and Regulation. Foods 2023, 12, 1583. [Google Scholar] [CrossRef] [PubMed]

- Gattuso, A.; Piscopo, A.; Romeo, R.; De Bruno, A.; Poiana, M. Recovery of Bioactive Compounds from Calabrian Bergamot Citrus Waste: Selection of Best Green Extraction. Agriculture 2023, 13, 1095. [Google Scholar] [CrossRef]

- Arias, A.; Feijoo, G.; Moreira, M.T. Exploring the potential of antioxidants from fruits and vegetables and strategies for their recovery. Innov. Food Sci. Emerg. Technol. 2022, 77, 102974. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Khanashyam, A.C.; Mundanat, A.S.; Shah, K.; Babu, K.S.; Thorakkattu, P.; Al-Asmari, F.; Pandiselvam, R. Valorization of Fruit Waste for Bioactive Compounds and Their Applications in the Food Industry. Foods 2023, 12, 556. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Chen, G.; Diao, J.; Wang, C. Recent advances in exploring and exploiting soybean functional peptides-a review. Front. Nutr. 2023, 10, 1185047. [Google Scholar] [CrossRef] [PubMed]

- Stockli, S.; Dorn, M. Awareness, intention, and behavior: Three empirical perspectives on predicting the purchase of abnormally shaped fruits and vegetables. Resour. Conserv. Recycl. 2021, 168, 105431. [Google Scholar] [CrossRef]

- Tu, J.C.; Lee, Y.L.; Wei, M.Y. Analysis and Research on the Key Success Factors of Marketing Ugly Fruits and Vegetables. Sustainability 2018, 10, 2783. [Google Scholar] [CrossRef]

- Campos, A.C.; Santini, F.D.; Perin, M.G.; Ladeira, W. Effects of abnormally shaped fruits and vegetables on consumer’s willingness to buy: A meta-analytic study. J. Soc. Mark. 2022, 12, 556–586. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Y.F.; Wang, Q.Y.; Zhang, S.; Wang, M.Z.; Feng, H.J.; Jiang, J.; Qiu, X.P.; Zhang, Y.F.; Chen, T. Generation of fruit and vegetable wastes in the farmers’ market and its influencing factors: A case study from Hangzhou, China. Waste Manag. 2022, 154, 331–339. [Google Scholar] [CrossRef]

- Yenerall, J.; Chen, R.T. Food Retailer, Restaurant, and Online Grocery Shopping Use and Household Food Waste: Evidence from US Households in 2022. J. Food Prod. Mark. 2023, 29, 232–254. [Google Scholar] [CrossRef]

- Mattsson, L.; Williams, H. Avoidance of Supermarket Food Waste-Employees’ Perspective on Causes and Measures to Reduce Fruit and Vegetables Waste. Sustainability 2022, 14, 10031. [Google Scholar] [CrossRef]

- Guarnieri, P.; de Aguiar, R.C.C.; Thome, K.M.; Watanabe, E.A.D. The Role of Logistics in Food Waste Reduction in Wholesalers and Small Retailers of Fruits and Vegetables: A Multiple Case Study. Logistics 2021, 5, 77. [Google Scholar] [CrossRef]

- Li, X.L.; Jiang, Y.; Qing, P. Estimates of Household Food Waste by Categories and Their Determinants: Evidence from China. Foods 2023, 12, 776. [Google Scholar] [CrossRef]

- Stancu, V.; Haugaard, P.; Lahteenmaki, L. Determinants of consumer food waste behaviour: Two routes to food waste. Appetite 2016, 96, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Kavanaugh, M.; Quinlan, J.J. Consumer knowledge and behaviors regarding food date labels and food waste. Food Control 2020, 115, 107285. [Google Scholar] [CrossRef]

- Karanth, S.; Feng, S.; Patra, D.; Pradhan, A.K. Linking microbial contamination to food spoilage and food waste: The role of smart packaging, spoilage risk assessments, and date labeling. Front. Microbiol. 2023, 14, 1198124. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Zhu, Q.; Adhikari, B. Intelligent vegetable freshness monitoring system developed by integrating eco-friendly fluorescent sensor arrays with deep convolutional neural networks. Chem. Eng. J. 2024, 488, 150739. [Google Scholar] [CrossRef]

- Khalid, S.; Malik, A.U.; Ullah, M.I.; Khalid, M.S.; Javeed, H.M.R.; Naeem, M.A.; Naseer, A. Food waste: Causes and economic losses estimation at household level in Pakistan. Environ. Sci. Pollut. Res. 2023, 30, 99284–99297. [Google Scholar] [CrossRef]

- Liu, Z. A review on the emerging conversion technology of cellulose, starch, lignin, protein and other organics from vegetable-fruit-based waste. Int. J. Biol. Macromol. 2023, 242, 124804. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, S.; Parthasarathy, P.; Mackey, H.R.; Al-Ansari, T.; McKay, G. Food waste biochar: A sustainable solution for agriculture application and soil–water remediation. Carbon Res. 2024, 3, 1–29. [Google Scholar] [CrossRef]

- Ahmad, I.K.; Mohamed, Z.S.; Amrul, N.F.; Quan, C.W.; Jalil, B.A.A.; Basri, N.E.A.; Azmi, M.R. Composting Fruit and Vegetable Waste Using Black Soldier Fly Larvae. J. Kejuruter. 2021, 33, 837–843. [Google Scholar] [CrossRef]

- Zhang, S.K.; Fu, Q.B.; Li, H.S.; Wu, P.; Waterhouse, G.I.N.; Li, Y.J.; Ai, S.Y. A pectocellulosic bioplastic from fruit processing waste: Robust, biodegradable, and recyclable. Chem. Eng. J. 2023, 463, 142452. [Google Scholar] [CrossRef]

- Abdullah, A.H.; Awad-Allah, M.A.A.; Abd-Elkarim, N.A.A.; Ahmed, Z.F.R.; Taha, E.M.A. Carboxymethyl Cellulose from Banana Rachis: A Potential Edible Coating to Extend the Shelf Life of Strawberry Fruit. Agriculture 2023, 13, 1058. [Google Scholar] [CrossRef]

- Salimi, A.; Khodaiyan, F.; Askari, G.; Hosseini, S.S. A zero-waste approach towards a sustainable waste management of apple: Extraction of value-added products and their application as edible coating. Food Hydrocoll. 2024, 147, 109304. [Google Scholar] [CrossRef]

- Yu, J.; Fang, L.; Kim, S.; Kim, K.; Kim, M.; Lee, T. Valorization of fruit and vegetable byproducts for the beta-glucan production from Euglena gracilis. Bioresour. Technol. 2024, 394, 130213. [Google Scholar] [CrossRef]

- Merino, D.; Zych, A.; Athanassiou, A. Biodegradable and Biobased Mulch Films: Highly Stretchable PLA Composites with Different Industrial Vegetable Waste. ACS Appl. Mater. Interfaces 2022, 14, 46920–46931. [Google Scholar] [CrossRef]

- Ramamoorthy, K.; Dhanraj, R.; Vijayakumar, N.; Ma, Y.; Al Obaid, S.; Narayanan, M. Vegetable and fruit wastes: Valuable source for organic fertilizer for effective growth of short-term crops: Solanum lycopersicum and Capsicum annum. Environ. Res. 2024, 251, 118727. [Google Scholar] [CrossRef] [PubMed]

- Wu, R.; Chen, M.; Qin, Y.; Liu, S.; Li, X. Combined hydrothermal and biological treatments for valorization of fruit and vegetable waste into liquid organic fertilizer. Environ. Res. 2023, 221, 115262. [Google Scholar] [CrossRef]

- Pradhan, S.; Abdelaal, A.H.; Mroue, K.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Biochar from vegetable wastes: Agro-environmental characterization. Biochar 2020, 2, 439–453. [Google Scholar] [CrossRef]

- Soltan, M.; Elsamadony, M.; Mostafa, A.; Awad, H.; Tawfik, A. Harvesting zero waste from co-digested fruit and vegetable peels via integrated fermentation and pyrolysis processes. Environ. Sci. Pollut. Res. 2019, 26, 10429–10438. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, B.; Mazumder, D. Valorization of fruit and vegetable waste in a novel three-stage hybrid anaerobic digester for enhanced biogas production: Performance study and microbial community analysis. Biochem. Eng. J. 2024, 209, 109403. [Google Scholar] [CrossRef]

- Martinez-Mendoza, L.J.; Lebrero, R.; Munoz, R.; Garcia-Depraect, O. Influence of key operational parameters on biohydrogen production from fruit and vegetable waste via lactate-driven dark fermentation. Bioresour. Technol. 2022, 364, 128070. [Google Scholar] [CrossRef] [PubMed]

- Korai, M.S.; Noonari, A.A.; Ali, M.; Rabab, N.; Rasheed, R.; Solangi, Z.A.; Bhatti, Z.A. Anaerobic Biodegradability and Biomethanation Potential of Fruit-Vegetable Wastes at Sindh, Pakistan. Pak. J. Anal. Environ. Chem. 2023, 24, 145–154. [Google Scholar] [CrossRef]

- Zaidi, Z.; Manchanda, A.; Sharma, A.; Shehnaz; Choudhry, A.; Sajid, M.; Khan, S.A.; Khan, A.; Chaudhry, S.A. Adsorptive removal of Methylene blue using fruit waste activated carbon and its binary metal oxide nanocomposite. Chem. Eng. J. Adv. 2023, 16, 100571. [Google Scholar] [CrossRef]

- Vaishna, V.R.; Sam, J.; Nair, R.R.; Akhina, M.K.; Haritha, K.; Prathish, K.P. Sustainable utilization of nutmeg fruit rind waste for Cr(VI) removal and resource recovery from industrial wastewater: An integrated approach. J. Environ. Chem. Eng. 2023, 11, 111495. [Google Scholar] [CrossRef]

- Negroiu, M.; Turcanu, A.A.; Matei, E.; Rapa, M.; Covaliu, C.I.; Predescu, A.M.; Pantilimon, C.M.; Coman, G.; Predescu, C. Novel Adsorbent Based on Banana Peel Waste for Removal of Heavy Metal Ions from Synthetic Solutions. Materials 2021, 14, 3946. [Google Scholar] [CrossRef]

- Țurcanu, A.A.; Matei, E.; Râpă, M.; Predescu, A.M.; Berbecaru, A.C.; Coman, G.; Predescu, C. Walnut Shell Biowaste Valorization via HTC Process for the Removal of Some Emerging Pharmaceutical Pollutants from Aqueous Solutions. Int. J. Mol. Sci. 2022, 23, 11095. [Google Scholar] [CrossRef]

- Zin, M.M.; Anucha, C.B.; Banvölgyi, S. Recovery of Phytochemicals via Electromagnetic Irradiation (Microwave-Assisted-Extraction): Betalain and Phenolic Compounds in Perspective. Foods 2020, 9, 918. [Google Scholar] [CrossRef]

- Nath, P.C.; Ojha, A.; Debnath, S.; Neetu, K.; Bardhan, S.; Mitra, P.; Sharma, M.; Sridhar, K.; Nayak, P.K. Recent advances in valorization of pineapple (Ananas comosus) processing waste and by-products: A step towards circular bioeconomy. Trends Food Sci. Technol. 2023, 136, 100–111. [Google Scholar] [CrossRef]

- Dhalaria, R.; Verma, R.; Kumar, D.; Puri, S.; Tapwal, A.; Kumar, V.; Nepovimova, E.; Kuca, K. Bioactive Compounds of Edible Fruits with Their Anti-Aging Properties: A Comprehensive Review to Prolong Human Life. Antioxidants 2020, 9, 1123. [Google Scholar] [CrossRef] [PubMed]

- Pistol, G.C.; Pertea, A.M.; Taranu, I. The Use of Fruit and Vegetable by-Products as Enhancers of Health Status of Piglets after Weaning: The Role of Bioactive Compounds from Apple and Carrot Industrial Wastes. Vet. Sci. 2024, 11, 15. [Google Scholar] [CrossRef] [PubMed]

- Tayengwa, T.; Mapiye, C. Citrus and Winery Wastes: Promising Dietary Supplements for Sustainable Ruminant Animal Nutrition, Health, Production, and Meat Quality. Sustainability 2018, 10, 3718. [Google Scholar] [CrossRef]

- Martí-Quijal, F.J.; Khubber, S.; Remize, F.; Tomasevic, I.; Roselló-Soto, E.; Barba, F.J. Obtaining Antioxidants and Natural Preservatives from Food By-Products through Fermentation: A Review. Fermentation 2021, 7, 106. [Google Scholar] [CrossRef]

- Santamarina, A.B.; Mesquita, L.M.; Casagrande, B.P.; Sertorio, M.N.; de Souza, D.V.; Mennitti, L.V.; Ribeiro, D.A.; Estadella, D.; Ventura, S.P.M.; de Rosso, V.V.; et al. Supplementation of carotenoids from peach palm waste (Bactris gasipaes) obtained with an ionic liquid mediated process displays kidney anti-inflammatory and antioxidant outcomes. Food Chem. -X 2022, 13, 100245. [Google Scholar] [CrossRef] [PubMed]

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of fruits and vegetable wastes and by-products to produce natural pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563. [Google Scholar] [CrossRef] [PubMed]

- Carrillo, C.; Nieto, G.; Martínez-Zamora, L.; Ros, G.; Kamiloglu, S.; Munekata, P.E.S.; Pateiro, M.; Lorenzo, J.M.; Fernández-López, J.; Viuda-Martos, M.; et al. Novel Approaches for the Recovery of Natural Pigments with Potential Health Effects. J. Agric. Food Chem. 2022, 70, 6864–6883. [Google Scholar] [CrossRef]

- Lombardelli, C.; Benucci, I.; Mazzocchi, C.; Esti, M. Green Enzymatic Recovery of Functional Bioactive Compounds from Unsold Vegetables: Storability and Potential Health Benefits. Appl. Sci. 2022, 12, 12249. [Google Scholar] [CrossRef]

- Lombardelli, C.; Benucci, I.; Mazzocchi, C.; Esti, M. A Novel Process for the Recovery of Betalains from Unsold Red Beets by Low-Temperature Enzyme-Assisted Extraction. Foods 2021, 10, 236. [Google Scholar] [CrossRef]

- Rosa, M.E.; Ferreira, A.M.; Neves, C.; Almeida, M.R.; Barros, R.; Cristovao, A.C.; Sousa, A.C.A.; Reis, P.M.; Rebelo, L.P.N.; Esperança, J.; et al. Valorisation of red beet waste: One-step extraction and separation of betalains and chlorophylls using thermoreversible aqueous biphasic systems. Green Chem. 2023, 25, 1852–1864. [Google Scholar] [CrossRef]

- Phan, K.; Raes, K.; Van Speybroeck, V.; Roosen, M.; De Clerck, K.; De Meester, S. Non-food applications of natural dyes extracted from agro-food residues: A critical review. J. Clean. Prod. 2021, 301, 126920. [Google Scholar] [CrossRef]

- Tiwari, S.; Yawale, P.; Upadhyay, N. Carotenoids: Extraction strategies and potential applications for valorization of under-utilized waste biomass. Food Biosci. 2022, 48, 101812. [Google Scholar] [CrossRef]

- Kainat, S.; Arshad, M.S.; Khalid, W.; Zubair Khalid, M.; Koraqi, H.; Afzal, M.F.; Noreen, S.; Aziz, Z.; Al-Farga, A. Sustainable novel extraction of bioactive compounds from fruits and vegetables waste for functional foods: A review. Int. J. Food Prop. 2022, 25, 2457–2476. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Joudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. [Google Scholar] [CrossRef] [PubMed]

- Spiridon, I.; Darie-Nita, R.N.; Hitruc, G.E.; Ludwiczak, J.; Spiridon, I.A.C.; Niculaua, M. New opportunities to valorize biomass wastes into green materials. J. Clean. Prod. 2016, 133, 235–242. [Google Scholar] [CrossRef]

- Spiridon, I.; Anghel, N.C.; Darie-Nita, R.N.; Iwanczuk, A.; Ursu, R.G.; Spiridon, I.A. New composites based on starch/Ecoflex®/biomass wastes: Mechanical thermal, morphological and antimicrobial properties. Int. J. Biol. Macromol. 2020, 156, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Syed, R.; Ding, H.H.; Hui, D.F.; Wu, Y. Physicochemical and functional properties of pigeon pea (Cajanus cajan) protein and non-starch polysaccharides. Bioact. Carbohydr. Diet. Fibre 2022, 28, 100317. [Google Scholar] [CrossRef]

- Kaur, N.; Chavan, A. Production of Single-Cell Protein from Fruit and Vegetable Waste Using an Isolated Strain of Lactobacillus sp. Ind. Biotechnol. 2022, 18, 304–313. [Google Scholar] [CrossRef]

- Hoorfar, J. Global Safety of Fresh Produce: A Handbook of Best Practice, Innovative Commercial Solutions and Case Studies; Woodhead Publishing: Sawston, UK, 2014; Volume 260, pp. 1–436. [Google Scholar]

- Kumar, S.; Reddy, A.R.L.; Basumatary, I.B.; Nayak, A.; Dutta, D.; Konwar, J.; Das Purkayastha, M.; Mukherjee, A. Recent progress in pectin extraction and their applications in developing films and coatings for sustainable food packaging: A review. Int. J. Biol. Macromol. 2023, 239, 124281. [Google Scholar] [CrossRef]

- Alexander Mendez, D.; Jose Fabra, M.; Gomez-Mascaraque, L.; Lopez-Rubio, A.; Martinez-Abad, A. Modelling the Extraction of Pectin towards the Valorisation of Watermelon Rind Waste. Foods 2021, 10, 738. [Google Scholar] [CrossRef]

- Mada, T.; Duraisamy, R.; Guesh, F. Optimization and characterization of pectin extracted from banana and papaya mixed peels using response surface methodology. Food Sci. Nutr. 2022, 10, 1222–1238. [Google Scholar] [CrossRef] [PubMed]

- Otalora Gonzalez, C.M.; De’Nobili, M.D.; Rojas, A.M.; Basanta, M.F.; Gerschenson, L.N. Development of functional pectin edible films with fillers obtained from red cabbage and beetroot. Int. J. Food Sci. Technol. 2021, 56, 3662–3669. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Mishra, S.; Mohanty, P.; Singh, P.K.; Srivastava, R.K.; Pattnaik, R.; Adhya, T.K.; Das, T.; Lenka, B.; Gupta, V.K.; et al. Food and fruit waste valorisation for pectin recovery: Recent process technologies and future prospects. Int. J. Biol. Macromol. 2023, 235, 123929. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, L.; Sarangi, P.K.; Singh, A.K.; Srivastava, R.K.; Chandel, A.K. Pre-, Pro-, and Postbiotics Development from Vegetable, Fruit, and Lignocellulosic Biomass: A Perspective. Food Biosci. 2024, 61, 104589. [Google Scholar] [CrossRef]

- Freire, M.O.D.; Neto, J.; Lemos, D.E.D.; de Albuquerque, T.M.R.; Garcia, E.F.; de Souza, E.L.; Alves, J.L.D. Limosilactobacillus fermentum Strains as Novel Probiotic Candidates to Promote Host Health Benefits and Development of Biotherapeutics: A Comprehensive Review. Probiotics Antimicrob. Proteins 2024. [Google Scholar] [CrossRef]

- Das, S.; Kalyani, M.I. From trash to treasure: Review on upcycling of fruit and vegetable wastes into starch based bioplastics. Prep. Biochem. Biotechnol. 2023, 53, 713–727. [Google Scholar] [CrossRef] [PubMed]

- Kringel, D.H.; Dias, A.R.G.; Zavareze, E.d.R.; Gandra, E.A. Fruit Wastes as Promising Sources of Starch: Extraction, Properties, and Applications. Starch-Starke 2020, 72. [Google Scholar] [CrossRef]

- Jayanthi, B.; Vinoth, S.; Hariharan, M.; Raja, R.K.; Kamaraj, C.; Narayanan, M. Valorization of agro-industry wastes for nanocellulose fabrication and its multifunctional applications. Biocatal. Agric. Biotechnol. 2024, 57, 103124. [Google Scholar] [CrossRef]

- Langyan, S.; Yadava, P.; Khan, F.N.; Dar, Z.A.; Singh, R.; Kumar, A. Sustaining Protein Nutrition Through Plant-Based Foods. Front. Nutr. 2022, 8, 772573. [Google Scholar] [CrossRef]

- Fang, B.C.; Peng, Z.C.; Chen, B.C.; Rao, J.J. Unconventional sources of vegetable proteins: Technological properties. Curr. Opin. Food Sci. 2024, 57, 101150. [Google Scholar] [CrossRef]

- Luthria, D.L.; Lu, Y.J.; John, K.M.M. Bioactive phytochemicals in wheat: Extraction, analysis, processing, and functional properties. J. Funct. Foods 2015, 18, 910–925. [Google Scholar] [CrossRef]

- Pereira, J.A.M.; Berenguer, C.V.; Andrade, C.F.P.; Camara, J.S. Unveiling the Bioactive Potential of Fresh Fruit and Vegetable Waste in Human Health from a Consumer Perspective. Appl. Sci. 2022, 12, 2747. [Google Scholar] [CrossRef]

- Tedesco, D.E.A.; Conti, C.; Lovarelli, D.; Biazzi, E.; Bacenetti, J. Bioconversion of fruit and vegetable waste into earthworms as a new protein source: The environmental impact of earthworm meal production. Sci. Total Environ. 2019, 683, 690–698. [Google Scholar] [CrossRef] [PubMed]

- Cappellozza, S.; Leonardi, M.G.; Savoldelli, S.; Carminati, D.; Rizzolo, A.; Cortellino, G.; Terova, G.; Moretto, E.; Badaile, A.; Concheri, G.; et al. A First Attempt to Produce Proteins from Insects by Means of a Circular Economy. Animals 2019, 9, 278. [Google Scholar] [CrossRef] [PubMed]

- Zahid, M.; Khalid, S.; Raana, S.; Amin, S.; Javaid, H.; Arshad, R.; Jahangeer, A.; Ahmad, S.; Hassan, S.A. Unveiling the anti-oxidative potential of fruits and vegetables waste in prolonging the shelf stability of vegetable oils. Future Foods 2024, 10, 100328. [Google Scholar] [CrossRef]

- Li, Y.S.; Yang, J.X.; Sun, L.P.; Liu, B.Z.; Li, H.; Peng, L.C. Crosslinked fish scale gelatin/alginate dialdehyde functional films incorporated with carbon dots derived from pomelo peel waste for active food packaging. Int. J. Biol. Macromol. 2023, 253, 127290. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Urena, L.J.; Batlles-delaFuente, A.; Camacho-Ferre, F. Management of Agricultural Waste Biomass: A case study of Fruit and Vegetable Producer Organizations in southeast Spain. J. Clean. Prod. 2022, 359, 131972. [Google Scholar] [CrossRef]

- Latif, M.B.; Islam, M.A.; Hossain, M.S.; Aurpa, S.S. Effect of Sludge Content on the Decomposition of Different Types of Food Waste. Sustainability 2023, 15, 2782. [Google Scholar] [CrossRef]

- Azevedo, A.; Lapa, N.; Moldao, M.; Duarte, E. Opportunities and challenges in the anaerobic co-digestion of municipal sewage sludge and fruit and vegetable wastes: A review. Energy Nexus 2023, 10, 100202. [Google Scholar] [CrossRef]

- Younas, F.; Younas, S.; Bibi, I.; Farooqi, Z.U.R.; Hameed, M.A.; Mohy-Ud-Din, W.; Shehzad, M.T.; Hussain, M.M.; Shakil, Q.; Shahid, M.; et al. A critical review on the separation of heavy metal(loid)s from the contaminated water using various agricultural wastes. Int. J. Phytoremediation 2024, 26, 349–368. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Rosero, J.; Urbina-López, M.E.; Rodríguez-González, B.E.; León-Villegas, S.X.; Luna-Cruz, I.E.; Cárdenas-Chávez, D.L. Development and Characterization of Bioadsorbents Derived from Different Agricultural Wastes for Water Reclamation: A Review. Appl. Sci. 2022, 12, 2740. [Google Scholar] [CrossRef]

- Karim, A.; Raji, Z.; Karam, A.; Khalloufi, S. Valorization of Fibrous Plant-Based Food Waste as Biosorbents for Remediation of Heavy Metals from Wastewater-A Review. Molecules 2023, 28, 4205. [Google Scholar] [CrossRef] [PubMed]

- Patil, H.; Patil, Y.; Maiti, S.; Athalye, A.; Adivarekar, R.V. Valorization of fruit vegetable waste for semi-synthetic leather. Iran. Polym. J. 2024, 33, 597–605. [Google Scholar] [CrossRef]

- Benny, N.; Shams, R.; Dash, K.K.; Pandey, V.K.; Bashir, O. Recent trends in utilization of citrus fruits in production of eco-enzyme. J. Agric. Food Res. 2023, 13, 100657. [Google Scholar] [CrossRef]

- Martins, R.; Barbosa, A.; Advinha, B.; Sales, H.; Pontes, R.; Nunes, J. Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review. Processes 2023, 11, 2255. [Google Scholar] [CrossRef]

- Kumar, K.; Srivastav, S.; Sharanagat, V.S. Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrason. Sonochem. 2021, 70, 105325. [Google Scholar] [CrossRef] [PubMed]

- Dash, D.R.; Pathak, S.S.; Pradhan, R.C. Improvement in novel ultrasound-assisted extraction technology of high value-added components from fruit and vegetable peels. J. Food Process Eng. 2021, 44, 13658. [Google Scholar] [CrossRef]

- Kaur, B.; Panesar, P.S.; Anal, A.K. Standardization of ultrasound assisted extraction for the recovery of phenolic compounds from mango peels. J. Food Sci. Technol. -Mysore 2022, 59, 2813–2820. [Google Scholar] [CrossRef]

- Biswas, R.; Sarkar, A.; Alam, M.; Roy, M.; Hasan, M.M.M. Microwave and ultrasound-assisted extraction of bioactive compounds from Papaya: A sustainable green process. Ultrason. Sonochem. 2023, 101, 106677. [Google Scholar] [CrossRef]

- Ray, A.; Dubey, K.K.; Marathe, S.J.; Singhal, R. Supercritical fluid extraction of bioactives from fruit waste and its therapeutic potential. Food Biosci. 2023, 52, 102418. [Google Scholar] [CrossRef]

- Ubeyitogullari, A.; Ciftci, O.N. Enhancing the bioaccessibility of lycopene from tomato processing byproducts via supercritical carbon dioxide extraction. Curr. Res. Food Sci. 2022, 5, 553–563. [Google Scholar] [CrossRef]

- Vigano, J.; Brumer, I.Z.; de Campos Braga, P.A.; da Silva, J.K.; Marostica Junior, M.R.; Reyes Reyes, F.G.; Martinez, J. Pressurized liquids extraction as an alternative process to readily obtain bioactive compounds from passion fruit rinds. Food Bioprod. Process. 2016, 100, 382–390. [Google Scholar] [CrossRef]

- Pagano, I.; Piccinelli, A.L.; Celano, R.; Campone, L.; Gazzerro, P.; Russo, M.; Rastrelli, L. Pressurized hot water extraction of bioactive compounds from artichoke by-products. Electrophoresis 2018, 39, 1899–1907. [Google Scholar] [CrossRef]

- Gumustepe, L.; Kurt, N.; Aydin, E.; Ozkan, G. Comparison of ohmic heating- and microwave-assisted extraction techniques for avocado leaves valorization: Optimization and impact on the phenolic compounds and bioactivities. Food Sci. Nutr. 2023, 11, 5609–5620. [Google Scholar] [CrossRef]

- Saad, N.; Louvet, F.; Tarrade, S.; Meudec, E.; Grenier, K.; Landolt, C.; Ouk, T.S.; Bressollier, P. Enzyme-Assisted Extraction of Bioactive Compounds from Raspberry (Rubus idaeus L.) Pomace. J. Food Sci. 2019, 84, 1371–1381. [Google Scholar] [CrossRef] [PubMed]

- Pires, J.A.; Gomes, W.P.C.; Teixeira, N.N.; Melchert, W.R. Effect of drying methods on nutritional constitutes of fermented grape residue. J. Food Sci. Technol. -Mysore 2022, 59, 3458–3463. [Google Scholar] [CrossRef] [PubMed]

- Janiszewska-Turak, E.; Kolakowska, W.; Pobiega, K.; Gramza-Michalowska, A. Influence of Drying Type of Selected Fermented Vegetables Pomace on the Natural Colorants and Concentration of Lactic Acid Bacteria. Appl. Sci. 2021, 11, 7864. [Google Scholar] [CrossRef]

- Janiszewska-Turak, E.; Rybak, K.; Pobiega, K.; Nikodem, A.; Gramza-Michalowska, A. Sustainable Production and Characteristics of Dried Fermented Vegetables. Fermentation 2022, 8, 659. [Google Scholar] [CrossRef]

- Plazzotta, S.; Cottes, M.; Simeoni, P.; Manzocco, L. Evaluating the environmental and economic impact of fruit and vegetable waste valorisation: The lettuce waste study-case. J. Clean. Prod. 2020, 262, 121435. [Google Scholar] [CrossRef]

- Joensuu, K.; Harrison, E.; Hartikainen, H. What to Do with Food Waste? A Holistic Feasibility Framework to Evaluate Different Solutions. Sustainability 2022, 14, 3004. [Google Scholar] [CrossRef]

- More, P.R.; Jambrak, A.R.; Arya, S.S. Green, environment-friendly and sustainable techniques for extraction of food bioactive compounds and waste valorization. Trends Food Sci. Technol. 2022, 128, 296–315. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).