Abstract

The disposal of tea leaves discarded in the tea beverage market and clinker from coal-fired power plants has an impact on the environment; however, there are no reported cases of their combination for composting. Therefore, this study evaluated the effect of adding clinker from a coal-fired power plant to compost based on tea leaves, an organic waste product, on the composting rate and quality. The tea leaves-only compost was designated as Clinker 0%, and composts with 20% (w/w), 40% (w/w), and 60% (w/w) tea leaves supplemented with clinker were designated as Clinker 20, 40, and 60%, respectively. Each mixed material was placed in a 35 L polypropylene container with a lid and allowed to compost for 95 days. The composting rate was evaluated by the chemical oxygen demand (COD) in hot water extract and plant tests using juvenile komatsuna (Brassica rapa var. perviridis). The addition of clinker reduced the COD at the beginning of composting by 52.0, 74.3, and 86.7% in Clinker 20, 40, and 60%, respectively, compared to Clinker 0%. Furthermore, root elongation one month after composting was inhibited by Clinker 0% (60.1% relative to distilled water), but not by the addition of clinker (91.7–102.7% relative to distilled water). This suggests that the addition of clinker to tea leaf compost may accelerate composting.

1. Introduction

Recently, the amount of organic and solid waste generated has increased with human population growth [1]. Although these wastes contain nutrients necessary for plants, many of them are disposed of in landfills or incinerated, which not only leads to a loss of opportunity to recycle nutrients, but may also pose a significant threat to the surrounding air, soil, and water quality [2]. One of the best approaches to solve this problem and effectively use waste is composting. Composting is the preferred option for processing organic waste and ultimately obtaining a stable and hygienic product. In addition, composting is one of the few technologies that can be practically applied at any scale [1].

Tea leaves are a waste product generated in the tea beverage market. The global demand for tea has increased, with green tea production projected to increase from 1.5 million tons (2015–2017) to 3.6 million tons (2027), resulting in the generation of large amounts of tea leaves as a consequence of increased tea production [3]. However, most tea leaves are disposed of in landfills or incinerated, which raises concerns about their impact on the environment [3]. Therefore, various effective methods of using tea leaves have been investigated, including their usage for biogas production through co-digestion with cattle manure and organic waste [4,5,6]. Additionally, research has been carried out on the removal of pharmaceuticals [7,8,9,10], aromatic compounds [11,12,13], dyes [14,15,16,17], and heavy metals [18,19,20,21], making tea leaves a waste product of great interest worldwide.

Nitrogen (N) has a significant impact on the yield and quality of tea [22]. Large amounts of N are used for tea cultivation, and the N content in tea leaves is generally high [23]. Therefore, compost made from tea leaves is known to be rich in N [24], and many examples of composting using tea leaves have been reported [25,26,27,28]. However, tea leaves also contain large amounts of polyphenols with antimicrobial activity [29], suggesting that the contribution of microbial decomposition during the composting process is low in compost made solely from tea leaves, resulting in slow composting progress. Materials with low C/N ratios experience higher N losses associated with the composting process than those with high C/N ratios [30]. These findings suggest that composting tea leaves alone may delay the composting rate and cause nutrient loss during the composting process, which may hinder efficient compost production. Therefore, it is desirable to compost tea leaves by adding secondary materials or by co-composting with other materials.

Coal-fired power plants release fly ash and clinker as byproducts. While fly ash is effectively used as an additive to cement, clinker is not effectively reused, and there are concerns about socioeconomic and environmental issues if it is disposed of in landfills [31]. The particle surface of clinker is characterized by a porous structure, which has been used for applications in soil to improve its physicochemical properties [32,33], adsorb inorganic N and chemical oxygen demand (COD) in water [34,35], remove pathogenic microorganisms [36], and establish bacteria to restore desertified soil [37]. Clinker has also been used as a secondary material in cattle manure compost to improve drainage and aeration [38]. Therefore, it is suggested that clinker may improve the physical properties of compost materials with high moisture content and poor drainage, such as tea leaves. Based on the above, the use of clinker as a compost material is expected to foster the supply of oxygen by improving the physical properties, thereby promoting composting by increasing microbial activity, and reducing nutrient loss by retaining nutrients in the clinker. Previous studies have not investigated the novel use of clinker as an additive in tea leaf composting. Combining waste materials has the potential to inform more sustainable waste management practices that promote nutrient recycling and divert industrial waste from landfills. In addition, the unique combination of clinker and tea leaves has the potential to achieve environmental benefits in the energy and beverage sectors.

Therefore, this study evaluated the effect of clinker addition on the composting rate and quality of tea leaf compost based on its chemical parameters. The nutrient balances of N and carbon (C) before and after composting were calculated, and the effect of clinker addition on reducing nutrient loss was also examined.

2. Materials and Methods

2.1. Study Site and Test Materials

This study was conducted at the greenhouse of the Faculty of Agriculture, Ehime University (33°50′17″ N, 132°47′30″ E). Table 1 lists the physico-chemical properties of the clinker and tea leaves used as test materials. The clinker was coal ash produced after coal combustion at power plants, had a grain size of 3 mm or less and was provided by Nishinihon Saiseki Co., Ltd. (Ehime, Japan) on 30 June 2015. The tea leaves were provided by Shikoku Coca-Cola Bottling Co. Komatsu No. 2 Plant (Ehime, Japan) on 15 July, and were used under fresh conditions.

Table 1.

Physico-chemical properties of clinker and tea leaves.

2.2. Treatments and Compost Management

In this study, the ratio of clinker to tea leaves by weight varied, with four treatments of Clinker 0, 20, 40, and 60%. The total weight of the clinker and tea leaves in each treatment was 10 kg, and 0.5 kg of bark compost, 5% (w/w) of the total weight, was added to supply microorganisms. Two replicates from each treatment area were used for composting. The compost materials were weighed and mixed on 16 July 2015. Each mixed material was placed in a 35 L polypropylene container (400 W × 300 D × 565 H) with a lid and allowed to compost for 95 days. The compost was turned over approximately once every two weeks on 30 July, 16, 30 August, 16 September, and 2 October (approximately 2, 4, 6, 9, and 11 weeks after composting, respectively). Throughout the composting process, no watering was performed in all treatments. If wastewater was observed at the bottom of the container, it was collected immediately prior to compost turning.

2.3. Measurement of Chemical Properties in Compost and Compost-Derived Wastewater

The compost was collected on 16 August, 16 September, and 19 October 2015 (approximately one, two, and three months after composting, respectively). The pH and EC of the compost were measured by adding 100 mL of distilled water (raw compost:distilled water = 1:5 (w/v)) to 20 g of raw compost, shaking (180 rpm, 1 h), and measuring the pH (Twin pH-B-212, HORIBA, Kyoto, Japan) and EC (conductivity meter, HORIBA, Kyoto, Japan). For NH4+-N and NO3−-N content, 100 mL of 2M KCl was added to 10 g of raw compost, shaken (180 rpm, 1 h), and filtered through a filter paper to obtain the extract. NO3−-N content was determined using a colorimetric method using vanadium (III) chloride and NH4+-N content using the indophenol blue colorimetric method at wavelengths of 540 and 630 nm, respectively, using a spectrophotometer (UV-visible spectrophotometer V-630, Jasco Corporation, Tokyo, Japan). The compost was dried in a ventilated dryer at 70–80 °C for at least 48 h and finely ground samples were prepared using a high-speed vibrating sample mill (CMT Co., Ltd., Tokyo, Japan). The finely ground samples were analyzed for total N (TN) and C (TC) content in the compost using an automatic NC analyzer (Sumigraph NC-80 auto, Sumika Chemical Analysis Service, Osaka, Japan) and a gas chromatograph (GC-8A, SHIMADZU Co., Ltd., Kyoto, Japan). In addition, wastewater collected from the bottom of the container during the composting process was dried at 105 °C for 24 h, and its N and C content were determined in the same manner as for the compost.

2.4. Determination of Compost Maturity

To evaluate the maturity of the compost, chemical oxygen demand (COD) measurements of the hot water extracts of the compost and juvenile plant tests using komatsuna (Brassica rapa var. perviridis) were conducted. COD is the amount of oxygen consumed by an oxidant when an oxidant such as potassium permanganate is added and reacts under certain conditions. As it is mainly used as an indicator of the amount of organic matter in water, it is considered an indicator of easily degradable organic matter in compost. The compost extract solution for COD measurements was obtained using the hot water extraction method at 80 °C for 16 h [39]. Raw compost (2.5 g) and distilled water (25 mL) were weighed into a 50 mL centrifuge tube, and the test solution temperature was adjusted to 80 °C using an aluminum block thermostatic oven (Dry Thermo Unit DTU-2C, TAITEC, Corp, Saitama, Japan) and allowed to stand for 16 h. Subsequently, the sample was shaken by hand for 30 s, allowed to cool for approximately 2 h, 0.15 g KCl was added, shaken again by hand for 30 s, and filtered through filter paper (No. 2) to obtain the extract. The resulting extract was analyzed using a COD pack test (KR-COD; Kyoritsu Chemical Check Lab., Yokohama, Japan). While pack tests are generally analyzed qualitatively in terms of shade color and degree of discoloration, this study attempted to obtain numerical data from the compost extracts that reacted in pack tests using a spectrophotometer and quantified using a calibration curve for glucose. For this specific operation, the tip of the pack test tube was cut off and compost extract (1.5 mL) was added to the tube. The entire extract solution, which was stirred and mixed by pipetting, was transferred to a 2.5 mL plastic cell. Five minutes after the addition of the compost extract, a spectrophotometer was used to measure the oxygen consumption at a wavelength of 525 nm. It is known that the degradation rate of the potassium permanganate COD measurement method in general sulfuric acidification varies depending on the type of organic compound, and is reported to be approximately 60% for glucose and sucrose and approximately 50% for soluble starch and amylopectin [40]. Therefore, the oxygen consumption of the compost extract was calculated in this study assuming a degradation rate of 56% for glucose.

The extract for the komatsuna juvenile plant test was a water extract prepared by adding 100 mL distilled water to raw compost (equivalent to 10 g dry weight), shaking (180 rpm, 30 min), and filtering through two layers of gauze. After placing 14 seeds of komatsuna (cv. Natsurakuten) evenly in a seed pack (Fujihira Industry, Kogyo Co., Ltd., Tokyo, Japan), 30 mL of the water extract of the compost was added to the bottom of the seed pack. As a control, only distilled water was added, and after 5 days of standing in the dark at 25 °C, the plant height and root length of each seed were measured and compared to the treatments and distilled water.

2.5. Statistical Analysis

Statistical analysis of plant height and root length obtained from juvenile plant trials with komatsuna was performed using one-way analysis of variance (ANOVA) and Tukey’s method was used for multiple comparison test. Excel was used for statistical analysis.

3. Results

3.1. pH and EC of Tea Leaf Compost with Clinker

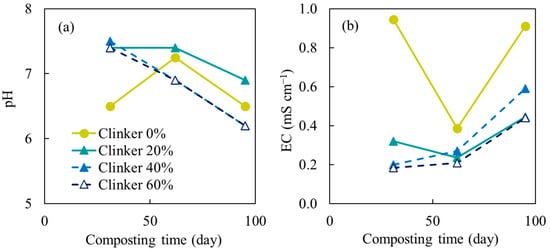

The pH and EC during the composting period are shown in Figure 1. The pH was in the range of 6.0–7.5 throughout the composting period. The pH with Clinker 0% was 6.5 after a month of composting; it increased marginally after two months, but dropped again to 6.5 after three months. With the addition of the clinker, the pH was 7.4–7.5 after one month of composting. It decreased throughout the composting process to 6.9, 6.2, and 6.2 for Clinker 20, 40, and 60%, respectively. The EC of Clinker 0% was 0.95 mS cm−1 after one month of composting, decreased after two months, and increased to 0.91 mS cm−1 after 3 months. When the clinker was added, the EC changed only slightly after one and two months of composting but increased after three months to 0.45, 0.59, and 0.44 mS cm−1 for Clinker 20, 40, and 60%, respectively.

Figure 1.

Changes in compost pH (a) and EC (b) in different treatments during composting process. Values are mean (n = 2).

3.2. NH4+-N and NO3–-N Content in Tea Leaf Compost with Clinker

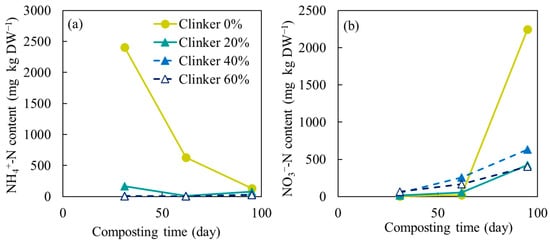

Figure 2 shows the changes in NH4+-N and NO3−-N content during the composting period. The NH4+-N content of Clinker 0% was 2400, 633, and 130 mg kg DW−1 at one, two, and three months after composting, respectively, and decreased with composting time. The NO3−-N content of Clinker 0% remained low after one and two months of composting, but increased to 2250 mg kg DW−1 after three months of composting. However, the NH4+-N content of Clinker 20, 40, and 60% ranged from 1.74 to 164 mg kg DW−1 during the composting. The NO3−-N content of these treatment groups tended to increase during the composting, with an NO3−-N content of 425, 634, and 401 mg kg DW−1 after three months of composting, respectively.

Figure 2.

Changes in compost NH4+-N (a) and NO3−-N (b) content in different treatments during composting process. Values are mean (n = 2).

3.3. Nitrogen and Carbon Balance in Compost

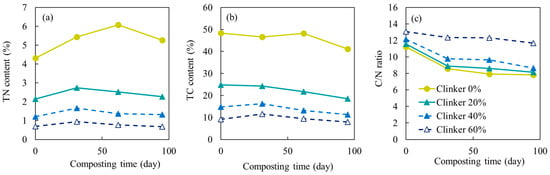

The TN content, TC content, and C/N ratio during the composting period are shown in Figure 3. The TN content in the compost tended to increase from 4.31% at the beginning to 5.26% at the end of composting for Clinker 0%. The TN content after three months of composting was 2.28, 1.32, and 0.683% for the Clinker 20, 40, and 60% treatments, respectively, which were close to the initial TN content. The TC content of each treatment tended to decrease, with 48.3, 24.8, 14.8, and 9.2% at the beginning of composting and 41.1, 18.5, 11.3, and 7.9% after three months in Clinker 0, 20, 40, and 60%, respectively. The N content increased or remained constant throughout the composting period, whereas the C content tended to decrease, resulting in a decreasing trend in the C/N ratio for each treatment.

Figure 3.

Changes in compost TN content (a), TC content (b), and C/N ratio (c) in different treatments during composting process. Values are mean (n = 2).

The N and C balances calculated from the compost weight and the N and C contents at the beginning and end of composting are shown in Table 2. The results showed that the amounts of N and C at the beginning of composting decreased as the amount of clinker increased, and the loss of N and C in the case of clinker addition was 30–48% and 39–67%, respectively, compared to Clinker 0%. Thus, the addition of clinker to tea leaf composting is expected to effectively reduce nutrient loss during composting.

Table 2.

N and C balance before and after composting.

In addition, drainage was collected from the bottom of the containers for Clinker 0 and 20% at compost turnings of 2, 4, and 6 weeks after composting to determine the amount of N and C lost as drainage. The amounts of N in the drainage were approximately 300 mg and 100 mg for 0% and 20% Clinker, respectively, and the amounts of C in the drainage were approximately 3000 mg and 800 mg, respectively. Compared with the weight of N and C lost throughout the composting period, the loss of N and C by drainage was lower, at approximately 0.5–2%.

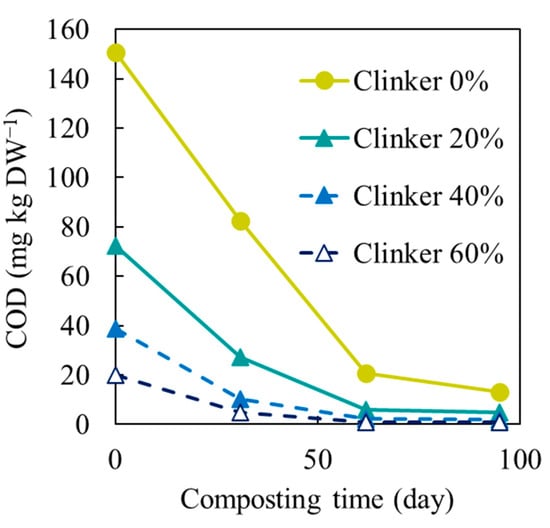

3.4. COD in Compost Extracted by 16 h Hot Water Extraction

The COD of the compost obtained from the hot water extracts at 80 °C for 16 h is shown in Figure 4. The COD at the beginning of composting was 52.0, 74.3, and 86.7% lower at Clinker 20, 40, and 60%, respectively, than at Clinker 0%. The percentage decreases in the COD after one month relative to the beginning of composting were 45.2, 62.4, 73.6, and 76.4% for Clinker 0, 20, 40, and 60%, respectively. The percentage decrease in the COD during the early stages of composting was greater when the clinker was added.

Figure 4.

Changes in compost COD in different treatments during composting process. Values are mean (n = 2).

3.5. Komatsuna Juvenile Plant Test Using Compost Water Extract

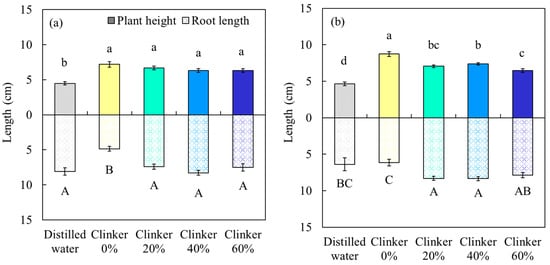

The plant height and root length, as measured by the komatsuna juvenile plant test using the compost extract after one and three months of composting, are shown in Figure 5. The plant height was significantly higher in all the treatments than in the distilled water and was the highest in Clinker 0%. After one month of composting, the root length in Clinker 0% was 60.1% of that in the distilled water, whereas that in the clinker added was 91.7–102.7% of that in the distilled water, which was significantly lower in Clinker 0% than in the clinker-added and distilled water treatments. In contrast, after three months of composting, the root length in the Clinker 0% was 96.5% relative to the distilled water, whereas that in the clinker-added treatments was 123.1–130.9%, which was still significantly higher than in Clinker 0%.

Figure 5.

Plant height and root length in komatsuna juvenile plant test in composts with different amounts of clinker treatments and distilled water after one month (a) and three months (b) composting. Values are mean ± standard error. The sample size was 28 for Clinker 0, 20, 40, and 60% and 14 for distilled water. Different lowercase and capital letters on each sampling day indicate significant differences (p < 0.05) between treatments, according to Tukey’s test for plant height and root length, respectively.

4. Discussion

4.1. Effect of Clinker Addition on Composting Acceleration of Tea Leaf Compost

Although chemical and biological methods are generally employed to determine compost maturity, the germination index is often used to determine the phytotoxicity of compost because different types of compost materials have variable effects that delay seed germination and plant growth [41]. It has been suggested that it is difficult to evaluate the stability of compost using only one parameter [42]; therefore, two parameters were used in this study: the COD of the hot water extracts of compost and juvenile plant tests using komatsuna.

In this study, the COD at the start of composting decreased by 52.0, 74.3, and 86.7% for Clinker 20, 40, and 60%, respectively, compared to Clinker 0%. Furthermore, the COD at 1 month relative to the start of composting was 45.2, 62.4, 73.6, and 76.4% for Clinker 0, 20, 40, and 60%, respectively. The COD of the clinker was as low as 0.048 mg kg DW−1, suggesting that the COD at the start of composting decreased with the amount of clinker. However, the COD in the compost decreased with the addition of clinker, which may be due to the COD adsorption capacity of the clinker. It has been reported that palm oil clinker used in wastewater treatment can remove 96% of the COD in wastewater [43]. This could explain the decrease in the COD during the composting period caused by an increase in the amount of clinker added. Since the COD is derived from readily degradable organic matter in the compost, the decrease in the COD could be interpreted as being related to the progress of the composting process. Therefore, it is suggested that the addition of clinker to tea leaf compost may reduce the amount of biodegradable organic matter in the compost and promote composting. Previous studies have shown that composting was accelerated by the addition of secondary materials. Wong et al. (2009) [44] reported that the addition of 1.5–3.0% lime and 5–10% fly ash to food waste increased the decomposition efficiency and reduced the composting time by 35%. The addition of lime and fly ash to the compost containing municipal solid residues and kitchen waste resulted in higher germination indices of over 80% [45,46]. In this study, after one month of composting, the relative root length in Clinker 0% was 60.1% of that of the distilled water, whereas that in the clinker added was 91.7–102.7% of that in the distilled water. Jarboui et al. [47] suggested that a decrease in the concentration of the compost extract led to a decrease in the concentration of toxic compounds and improved seed germination. Many studies have also reported that toxic compounds such as soluble C and phenolic compounds decrease during composting, which in turn increases the germination index and root length of young plants [48,49]. Therefore, the lower root elongation in the Clinker 0% in this study could also be attributed to the higher concentration of toxic compounds in the compost. In a study that confirmed the response of spent litter compost extracts from piggeries to young plants, root elongation was reported to be a more sensitive indicator of phytotoxicity than germination [50,51], suggesting that root elongation is an important indicator of compost maturity. In contrast, tea leaves contain compounds that chelate metals [52], and the shoot sensitivity of young plants to heavy metals is lower than that of the roots [53]. This supports the finding that root elongation was suppressed at Clinker 0% in this study, whereas root elongation at the top was not.

The percentage of COD reduction in the initial stage of composting was greater when the clinker was added than when no clinker was added, suggesting that the addition of the clinker is expected to reduce the amount of easily degradable organic matter more than the dilution effect and accelerate the composting period. This suggests that the addition of clinker reduces the amount of easily degradable organic matter and shortens the composting period more than dilution. Clinker is known to physically adsorb dissolved organic matter from landscape water [54]. Palm oil clinker, a byproduct of palm oil manufacturing plants, has also been reported to reduce organic pollutants such as the COD in wastewater when used as a growth medium in attachment growth systems [34,43,55]. Based on these findings, it was inferred that the decrease in the COD identified with the addition of the clinker was due to adsorption to the clinker and an increase in the number and activity of the microorganisms present. Indeed, many composting trials have shown the rapid decomposition of easily biodegradable organic matter [56] and intense enzymatic activity [57] in the first two to three weeks of composting, independent of the compost material. It has also been reported that clinker has the ability to remove microorganisms from water [36] and that many bacteria have been observed on the porous surface and inside particles of coal ash, such as clinker [37]. Given these facts, the addition of the clinker in the composting of the tea leaves in this study may have contributed to the reduction in the easily degradable organic matter in the early stages of composting through its effect on microbial activity.

4.2. Effect of Clinker Addition on Compost Quality of Tea Leaf Compost

The compost mixture of the tea leaves and clinker did not exhibit significant pH fluctuations during the composting period. The EC with the clinker was approximately half that with Clinker 0%. Sundberg et al. [58] reported that during the composting of household waste, high temperatures and a pH below 6 reduced the respiration rate during the early composting stage. In addition, the high salt concentrations in compost limit microbial activity [59] and adversely affect plants [60,61]. Clinker-added compost was found to be neutral to slightly acidic, preventing excessive salt supply. Therefore, this study suggests that clinker addition not only does not limit microbial activity during the composting process, but may also mitigate the adversely effects on the plant when applied to the soil. Compared with the addition of the clinker, the NH4+-N and NO3−-N content of Clinker 0% increased significantly after 1 and 3 months of composting, respectively. This suggests that the nitrogenous organic matter in the compost was decomposed by microorganisms into ammonia-form N, which was then converted into nitrate-form N by supplying oxygen during the compost-turning process. This change in N morphology was pronounced with Clinker 0% in this study, but no significant change was observed with the addition of clinker. Clinkers and palm oil clinkers have been studied for N removal from water because of their porous structure [62,63], and their adsorption effects on inorganic N, such as NH4+-N and NO3−-N, are also known [35]. This suggests that inorganic N adsorption onto the clinker was the reason for the relatively low abundance of inorganic N when the clinker was added in this study.

4.3. Nitrogen and Carbon Balance

The compost C/N ratio was low from the beginning of composting because tea leaves and clinker, which have relatively low C/N ratios, were used as materials in this study. The C/N ratio is generally used as an indicator of compost maturity. However, in some cases, the C/N ratio of the solid phase is not a valid parameter for evaluating maturity depending on the compost material [64]. The slow decrease in the C/N ratio in all the treatments made it inappropriate to use the C/N ratio as an indicator of the compost maturity in this study. In any case, the C/N ratio after three months of composting was approximately 10, suggesting that compost made from tea leaves and clinker may have little effect on N starvation when applied to the soil. Zhu [30] reported that a low C/N ratio in the early stages of composting results in less N loss than a high C/N ratio. In contrast, Han et al. [61] suggested that low C/N ratios may result in the volatilization and loss of NH3 and N2O throughout the composting process. These contrasting views suggest that the composting process depends on the properties of the compost material. In general, the composting process inevitably releases gases containing N and C, resulting in N and C losses [65].

In this study, N and C balances were calculated at the beginning and end of composting. The results showed that the loss rate of N and C in the case of clinker addition was 30–48% and 39–67%, respectively, compared to Clinker 0%. Thus, the addition of clinker to tea leaf composting is expected to effectively reduce nutrient loss during composting. Yılmaz et al. [66] reported the lowest N and organic C losses for a 25% tea leaf combination compared with tea leaves alone in their study on co-composting tea leaves and food waste, suggesting that composting tea leaves alone may result in greater nutrient losses. There have also been reports of reduced N loss during composting by mixing bagasse with filter cake, a by-product of the sugar industry [67], and by mixing raw compost with aged compost [68]. This may be due to the relatively low fraction of easily degradable organic matter lost during composting. In this study, it was suggested that the clinker may have contributed to the reduction in the N and C losses during composting by the adsorption of inorganic N and easily degradable organic matter, and the microbial uptake of the N and C fractions, in addition to having a high fraction that was not easily degraded. Additionally, Yang et al. [68] reported a 44.8% and 73.6% reduction in the emissions of greenhouse gases, such as CH4 and N2O, owing to lower N and C losses. In summary, the addition of clinker in composting not only contributes to efficient compost production with less nutrient loss but is also expected to be effective in reducing environmental impacts such as nutrient and greenhouse gas emissions into the atmosphere.

4.4. Practical Implications

The findings of this study have several important practical implications. Landfilling clinker, a byproduct from coal-fired power plants, can lead to environmental problems [31]. However, large quantities of spent tea leaves generated by the beverage industry are often disposed of in landfills, resulting in nutrient loss [3]. Therefore, combining these wastes for composting not only reduces the amount of waste and thus the environmental impact, but also has the advantage of returning nutrients to the agricultural soil as compost.

In this study, composting the tea leaves alone required at least three months of composting time, but when clinker was added, the tea leaves matured to a plant-safe level in approximately one month of composting time. Accelerated composting means the more frequent and effective use of waste, thus reducing the percentage of waste in landfills while simultaneously allowing for the more efficient recycling of tea nutrients. In addition, this study found that the addition of clinker reduced nitrogen and carbon losses during tea leaf composting. Lower nutrient loss means that more nutrients are retained in the final compost, which improves the quality of the product. The retention of nutrients in the compost also reduces the nutrient contamination of air and water that can occur during composting.

Overall, the key finding that the addition of clinker to tea leaf compost enhances composting and reduces nutrient losses suggests that there are environmental benefits from the efficient use of the waste, as it reduces the amount of waste sent to landfills and the amount of nutrients released into the environment during the composting process. The practical application of this research could improve the sustainability of waste management in the coal-fired power generation and beverage industries. Promoting nutrient recycling and preventing pollution are consistent with circular economic principles.

5. Conclusions

In this study, composting tea leaves with clinker decreased the COD at the beginning of composting by 52.0, 74.3, and 86.7% in Clinker 20, 40, and 60%, respectively, compared to Clinker 0%. In the plant tests using juvenile komatsuna, the root elongation one month after composting was inhibited by Clinker 0% (60.1% relative to distilled water) but not by the addition of clinker (91.7–102.7% relative to distilled water). These findings suggest that the addition of clinker in tea leaf composting may accelerate composting. In addition, the addition of clinker reduced the amount of N and C loss during the composting process, suggesting that the use of clinker as a composting material can contribute to the efficient and environmentally friendly production of compost. The promotion of composting and reduction in nutrient loss by the addition of clinker may be due to the adsorption of inorganic N and xenobiotic organic matter on the clinker surface with its porous structure and the improvement of microbial activity by the fixation of microorganisms. Therefore, in future research, it is necessary to clarify the microbial activity in the compost when clinker is added.

Author Contributions

All the authors conceived and designed the experiments; all the authors performed the experiments and analyzed the data; all the authors contributed reagents/materials/analysis tools and wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This study was partly supported by Nishinihon Saiseki Co., Ltd., Japan.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are contained within the article.

Acknowledgments

We would like to thank Nishinihon Saiseki Co., Ltd. for providing the clinker and financial support for this study, and Shikoku Coca-Cola Products Co., Ltd. for providing tea leaves for this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sayara, T.; Basheer-Salimia, R.; Hawamde, F.; Sánchez, A. Recycling of organic wastes through composting: Process performance and compost application in agriculture. Agronomy 2020, 10, 1838. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, N.; Lin, Y.; Zhan, Y.; Ding, X.; Liu, Y.; Zhang, A.; Ding, G.; Xu, T.; Li, J. Recycling of nutrients from organic waste by advanced compost technology—A case study. Bioresour. Technol. 2021, 337, 125411. [Google Scholar] [CrossRef]

- Debnath, B.; Haldar, D.; Purkait, M.K. Potential and sustainable utilization of tea waste: A review on present status and future trends. J. Environ. Chem. Eng. 2021, 9, 106179. [Google Scholar] [CrossRef]

- Khayum, N.; Anbarasu, S.; Murugan, S. Biogas potential from spent tea waste: A laboratory scale investigation of co-digestion with cow manure. Energy 2018, 165, 760–768. [Google Scholar] [CrossRef]

- Khurshid, H.; Mustafa, M.R.U.; Rashid, U.; Isa, M.H.; Ho, Y.C.; Shah, M.M. Adsorptive removal of COD from produced water using tea waste biochar. Environ. Technol. Innov. 2021, 23, 101563. [Google Scholar] [CrossRef]

- Thanarasu, A.; Periyasamy, K.; Devaraj, K.; Periyaraman, P.; Palaniyandi, S.; Subramanian, S. Tea powder waste as a potential co-substrate for enhancing the methane production in anaerobic digestion of carbon-rich organic waste. J. Clean. Prod. 2018, 199, 651–658. [Google Scholar] [CrossRef]

- Ahsan, M.A.; Katla, S.K.; Islam, M.T.; Hernandez-Viezcas, J.A.; Martinez, L.M.; Díaz-Moreno, C.A.; Lopez, J.; Singamaneni, S.R.; Banuelos, J.; Gardea-Torresdey, J.G.; et al. Adsorptive removal of methylene blue, tetracycline and Cr(VI) from water using sulfonated tea waste. Environ. Technol. Innov. 2018, 11, 23–40. [Google Scholar] [CrossRef]

- He, X.; Li, J.; Meng, Q.; Guo, Z.; Zhang, H.; Liu, Y. Enhanced adsorption capacity of sulfadiazine on tea waste biochar from aqueous solutions by the two-step sintering method without corrosive activator. J. Environ. Chem. Eng. 2021, 9, 104898. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Y.; Xu, J.; Mei, Y.; Fan, S.; Xu, H. Effect of carbonization methods on the properties of tea waste biochars and their application in tetracycline removal from aqueous solutions. Chemosphere 2021, 267, 129283. [Google Scholar] [CrossRef]

- Patil, C.S.; Gunjal, D.B.; Naik, V.M.; Harale, N.S.; Jagadale, S.D.; Kadam, A.N.; Patil, P.S.; Kolekar, G.B.; Gore, A.H. Waste tea residue as a low cost adsorbent for removal of hydralazine hydrochloride pharmaceutical pollutant from aqueous media: An environmental remediation. J. Clean. Prod. 2019, 206, 407–418. [Google Scholar] [CrossRef]

- Daware, G.B.; Gogate, P.R. Removal of pyridine using ultrasound assisted and conventional batch adsorption based on tea waste residue as biosorbent. Environ. Technol. Innov. 2021, 21, 101292. [Google Scholar] [CrossRef]

- Inbaraj, B.S.; Sridhar, K.; Chen, B.H. Removal of polycyclic aromatic hydrocarbons from water by magnetic activated carbon nanocomposite from green tea waste. J. Hazard. Mater. 2021, 415, 125701. [Google Scholar] [CrossRef] [PubMed]

- Keerthanan, S.; Bhatnagar, A.; Mahatantila, K.; Jayasinghe, C.; Ok, Y.S.; Vithanage, M. Engineered tea-waste biochar for the removal of caffeine, a model compound in pharmaceuticals and personal care products (PPCPs), from aqueous media. Environ. Technol. Innov. 2020, 19, 100847. [Google Scholar] [CrossRef]

- Fan, S.; Tang, J.; Wang, Y.; Li, H.; Zhang, H.; Tang, J.; Wang, Z.; Li, X. Biochar prepared from co-pyrolysis of municipal sewage sludge and tea waste for the adsorption of methylene blue from aqueous solutions: Kinetics, isotherm, thermodynamic and mechanism. J. Mol. Liq. 2016, 220, 432–441. [Google Scholar] [CrossRef]

- Jain, S.N.; Tamboli, S.R.; Sutar, D.S.; Jadhav, S.R.; Marathe, J.V.; Shaikh, A.A.; Prajapati, A.A. Batch and continuous studies for adsorption of anionic dye onto waste tea residue: Kinetic, equilibrium, breakthrough and reusability studies. J. Clean. Prod. 2020, 252, 119778. [Google Scholar] [CrossRef]

- Mu, Y.; Ma, H. NaOH-modified mesoporous biochar derived from tea residue for methylene Blue and Orange II removal. Chem. Eng. Res. Des. 2021, 167, 129–140. [Google Scholar] [CrossRef]

- Tuli, F.J.; Hossain, A.; Kibria, A.K.M.F.; Tareq, A.R.M.; Mamun, S.M.M.A.; Ullah, A.K.M.A. Removal of methylene blue from water by low-cost activated carbon prepared from tea waste: A study of adsorption isotherm and kinetics. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100354. [Google Scholar] [CrossRef]

- Joshi, S.; Kataria, N.; Garg, V.K.; Kadirvelu, K. Pb2+ and CD2+ recovery from water using residual tea waste and SiO2@TW nanocomposites. Chemosphere 2020, 257, 127277. [Google Scholar] [CrossRef]

- Pal, D.; Maiti, S.K. Abatement of cadmium (Cd) contamination in sediment using tea waste biochar through meso-microcosm study. J. Clean. Prod. 2019, 212, 986–996. [Google Scholar] [CrossRef]

- Wen, T.; Wang, J.; Li, X.; Huang, S.; Chen, Z.; Wang, S.; Hayat, T.; Alsaedi, A.; Wang, X. Production of a generic magnetic Fe3O4 nanoparticles decorated tea waste composites for highly efficient sorption of Cu(II) and Zn(II). J. Environ. Chem. Eng. 2017, 5, 3656–3666. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, C.; Yuan, Y.; Fan, M.; Zhang, D.; Wang, D.; Xu, Y. Selective, highly efficient extraction of Cr(III), Pb(II) and Fe(III) from complex water environment with a tea residue derived porous gel adsorbent. Bioresour. Technol. 2020, 311, 123520. [Google Scholar] [CrossRef] [PubMed]

- Xiao, F.; Yang, Z.; Huang, H.; Yang, F.; Zhu, L.; Han, D. Nitrogen fertilization in soil affects physiological characteristics and quality of green tea leaves. HortScience 2018, 53, 715–722. [Google Scholar] [CrossRef]

- Kondo, M.; Kita, K.; Yokota, H.O. Effects of tea leaf waste of green tea, oolong tea, and black tea addition on Sudan grass silage quality and in vitro gas production. J. Sci. Food Agric. 2004, 84, 721–727. [Google Scholar] [CrossRef]

- Iqbal Khan, M.A.I.; Ueno, K.; Horimoto, S.; Komai, F.; Tanaka, K.; Ono, Y. Evaluation of the physio-chemical and microbial properties of green tea waste-rice bran compost and the effect of the compost on spinach production. Plant Prod. Sci. 2007, 10, 391–399. [Google Scholar] [CrossRef]

- Gülser, C.; Pekşen, A. Using tea waste as a new casing material in mushroom (Agaricus bisporus (L.) Sing.) cultivation. Bioresour. Technol. 2003, 88, 153–156. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.I.; Ueno, K.; Horimoto, S.; Komai, F.; Tanaka, K.; Ono, Y. Physicochemical, including spectroscopic, and biological analyses during composting of green tea waste and rice bran. Biol. Fertil. Soils 2009, 45, 305–313. [Google Scholar] [CrossRef]

- Maharjan, K.K.; Noppradit, P.; Techato, K.; Gyawali, S. Recycling of mixed food waste and tea waste through tub basin composting. Biomass Convers. Biorefin. 2023, 13, 15039–15049. [Google Scholar] [CrossRef]

- Yigitbasi, O.N.; Baysal, E.; Colak, M.; Toker, H.; Simsek, H.; Yilmaz, F. Cultivation of Agaricus bisporus on some compost formulas and locally available casing materials. Part II: Waste tea leaves based compost formulas and locally available casing materials. Afr. J. Biotechnol. 2007, 6, 2225–2230. [Google Scholar] [CrossRef]

- An, B.J.; Kwak, J.H.; Son, J.H.; Park, J.M.; Lee, J.Y.; Jo, C.; Byun, M.W. Biological and anti-microbial activity of irradiated green tea polyphenols. Food Chem. 2004, 88, 549–555. [Google Scholar] [CrossRef]

- Zhu, N. Effect of low initial C/N ratio on aerobic composting of swine manure with rice straw. Bioresour. Technol. 2007, 98, 9–13. [Google Scholar] [CrossRef]

- Winter, M.J.; Hyodo, M.; Wu, Y.; Yoshimoto, N.; Hasan, M.B.; Matsui, K. Influences of particle characteristic and compaction degree on the shear response of clinker ash. Eng. Geol. 2017, 230, 32–45. [Google Scholar] [CrossRef]

- Klõšeiko, J.; Ots, K.; Kuznetsova, T.; Pärn, H.; Mandre, M. Short-term responses of soil chemistry, needle macronutrients and tree growth to clinker dust and fertiliser in a stand of Scots pine. Environ. Monit. Assess. 2011, 181, 83–99. [Google Scholar] [CrossRef] [PubMed]

- Kubotera, H. Analysis of problems in certain soils of the Kyushu Okinawa region for suitable management. Soil Sci. Plant Nutr. 2020, 66, 15–20. [Google Scholar] [CrossRef]

- Al-dhawi, B.N.S.; Kutty, S.R.M.; Ghaleb, A.A.S.; Almahbashi, N.M.Y.; Saeed, A.A.H.; Al-Mekhlafi, A.B.A.; Alsaeedi, Y.A.A.; Jagaba, A.H. Pretreated palm oil clinker as an attached growth media for organic matter removal from synthetic domestic wastewater in a sequencing batch reactor. Case Stud. Chem. Environ. Eng. 2023, 7, 100294. [Google Scholar] [CrossRef]

- Okazawa, H.; Fujikawa, T. Nitrogen adsorption ability in clinker ash and utilization of nitrogen-adsorbed clinker ash to promote vegetation growth. Poljopr. i Sumar. 2014, 60, 15. [Google Scholar]

- Letshwenyo, M.W.; Lebogang, L. Assessment of roughing and slow sand filter modified with slag and clinker ash for removal of microorganisms from secondary effluent. Environ. Technol. 2020, 41, 3004–3015. [Google Scholar] [CrossRef]

- Mitsuno, M.; Tazaki, K.; Fyfe, W.S.; Powell, M.A.; Hart, B.; Daishng, S.; Li, S.R. Influence of coal ash on microorganisms and applicability of coal ash to remediate desertificated soil: In the case of desertificated land in Inner Mongolia of China. Clay Sci. 2001, 11, 503–515. [Google Scholar] [CrossRef]

- Minato, K.; Watanobe, K.; Tamura, T.; Abe, H. Utility of coal combustion clinker ash as a sub material in cattle manure composting. Bull. Hokkaido Animal Res. Cent. 2007, 26, 24–30. [Google Scholar]

- Uezono, I. Applicability of rapid analysis by 80 °C-16 h hot water extraction for estimating available nitrogen in upland soil in Japan. Jpn. J. Soil Sci. Plant Nutr. 2010, 81, 39–43. [Google Scholar]

- Kikuchi, Y.; Kakizaki, S.; Koizumi, R. Decomposition characteristics of various organic compounds in chemical oxygen demand measurement. Bunseki Kagaku 2007, 56, 857–862. [Google Scholar] [CrossRef][Green Version]

- Selim, S.M.; Zayed, M.S.; Atta, H.M. Evaluation of phytotoxicity of compost during composting process. Nat. Sci. 2012, 10, 69–77. [Google Scholar]

- Riffaldi, R.; Levi-Minzi, R.; Pera, A.; de Bertoidi, M. Evaluation of compost maturity by means of chemical and microbial analyses. Waste Manag. Res. 1986, 4, 387–396. [Google Scholar] [CrossRef]

- Al-dhawi, B.N.S.; Kutty, S.R.M.; Baloo, L.; Almahbashi, N.M.Y.; Ghaleb, A.A.S.; Jagaba, A.H.; Kumar, V.; Saeed, A.A.H. Treatment of synthetic wastewater by using submerged attached growth media in continuous activated sludge reactor system. Int. J. Sustain. Build. Technol. Urban Dev. 2022, 13, 2–10. [Google Scholar] [CrossRef]

- Wong, J.W.C.; Fung, S.O.; Selvam, A. Coal fly ash and lime addition enhances the rate and efficiency of decomposition of food waste during composting. Bioresour. Technol. 2009, 100, 3324–3331. [Google Scholar] [CrossRef]

- Mohee, R.; Boojhawon, A.; Sewhoo, B.; Rungasamy, S.; Somaroo, G.D.; Mudhoo, A. Assessing the potential of coal ash and bagasse ash as inorganic amendments during composting of municipal solid wastes. J. Environ. Manag. 2015, 159, 209–217. [Google Scholar] [CrossRef]

- Muhammad, T.; Jiang, C.; Li, Y.; Manan, I.; Ma, C.; Geng, H.; Fatima, I.; Adnan, M. Impacts and mechanisms of coal fly ash on kitchen waste composting performance: The perspective of microbial community. Chemosphere 2023, 350, 141068. [Google Scholar] [CrossRef]

- Jarboui, R.; Dhouib, B.; Ammar, E. Effect of food waste compost (FWC) and its non-aerated fermented extract (NFCE) on seeds germination and plant growth. Open J. Soil Sci. 2021, 11, 122–138. [Google Scholar] [CrossRef]

- Pascual, J.A.; Ayuso, M.; Garcia, C.; Hernández, T. Characterization of urban wastes according to fertility and phytotoxicity parameters. Waste Manag. Res. 1997, 15, 103–112. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Gonzálvez, J.; García, D.; Cegarra, J. Measuring detoxification and maturity in compost made from “alperujo”, the solid by-product of extracting olive oil by the two-phase centrifugation system. Chemosphere 2006, 64, 470–477. [Google Scholar] [CrossRef] [PubMed]

- Tam, N.F.Y.; Tiquia, S. Assessing toxicity of spent pig litter using a seed germination technique. Resour. Conserv. Recycl. 1994, 11, 261–274. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Tam, N.F.Y.; Hodgkiss, I.J. Effects of composting on phytotoxicity of spent pig-manure sawdust litter. Environ. Pollut. 1996, 93, 249–256. [Google Scholar] [CrossRef]

- Morikawa, C.K.; Saigusa, M. Recycling coffee and tea wastes to increase plant available Fe in alkaline soils. Plant Soil 2008, 304, 249–255. [Google Scholar] [CrossRef]

- Cheung, Y.H.; Wong, M.H.; Tam, N.F.Y. Root and shoot elongation as an assessment of heavy metal toxicity and ‘Zn equivalent value’ of edible crops. Hydrobiologia 1989, 188, 377–383. [Google Scholar] [CrossRef]

- Jiping, H.; Chengjian, Y. Dynamic adsorption and re-adsorption characteristics of dissolved organic matter on clinker. In Proceedings of the 2019 International Conference on Biology, Chemistry and Medical Engineering, Hefei, China, 29–30 June 2019; pp. 174–181. [Google Scholar]

- Al-dhawi, B.N.; Kutty, S.R.; Almahbashi, N.M.; Noor, A.; Jagaba, A.H. Organics removal from domestic wastewater utilizing palm oil clinker (POC) media in a submerged attached growth systems. Int. J. Civ. Eng. Technol. 2020, 11, 1–7. [Google Scholar]

- Zbytniewski, R.; Buszewski, B. Characterization of natural organic matter (NOM) derived from sewage sludge compost. Part 1: Chemical and spectroscopic properties. Bioresour. Technol. 2005, 96, 471–478. [Google Scholar] [CrossRef] [PubMed]

- Jurado, M.M.; Suárez-Estrella, F.; Vargas-García, M.C.; López, M.J.; López-González, J.A.; Moreno, J. Evolution of enzymatic activities and carbon fractions throughout composting of plant waste. J. Environ. Manag. 2014, 133, 355–364. [Google Scholar] [CrossRef] [PubMed]

- Sundberg, C.; Smårs, S.; Jönsson, H. Low pH as an inhibiting factor in the transition from mesophilic to thermophilic phase in composting. Bioresour. Technol. 2004, 95, 145–150. [Google Scholar] [CrossRef]

- Huang, G.F.; Wong, J.W.C.; Wu, Q.T.; Nagar, B.B. Effect of C/N on composting of pig manure with sawdust. Waste Manag. 2004, 24, 805–813. [Google Scholar] [CrossRef]

- Diaz, M.J.; Madejón, E.; López, F.; López, R.; Cabrera, F. Optimization of the rate vinasse/grape marc for co-composting process. Process Biochem. 2002, 37, 1143–1150. [Google Scholar] [CrossRef]

- Han, W.; Clarke, W.; Pratt, S. Composting of waste algae: A review. Waste Manag. 2014, 34, 1148–1155. [Google Scholar] [CrossRef]

- Chew, Y.Z.; Yap, Z.K.; Kutty, S.R.M.; Ghaleb, A.A.S.; Almahbashi, N.M.Y. Removal of ammonia by palm oil clinker (POC) as submerged fixed media in sequence batch reactor (SBR) mode. IOP Conf. Ser. Mater. Sci. Eng. 2020, 849, 012024. [Google Scholar] [CrossRef]

- Yamamoto, H.; Okazawa, H.; Ohtaka, Y.; Takeuchi, Y.; Murakami, Y. Fundamental study on nitrogen removal from paddy drainage using clinker ash. Int. J. Environ. Rural Dev. 2011, 2, 54–58. [Google Scholar]

- Iglesias Jiménez, E.; Pérez García, V. Composting of domestic refuse and sewage sludge. I. Evolution of temperature, pH, C/N ratio and cation-exchange capacity. Resour. Conserv. Recycl. 1991, 6, 45–60. [Google Scholar] [CrossRef]

- Huang, D.; Gao, L.; Cheng, M.; Yan, M.; Zhang, G.; Chen, S.; Du, L.; Wang, G.; Li, R.; Tao, J.; et al. Carbon and N conservation during composting: A review. Sci. Total Environ. 2022, 840, 156355. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, E.C.; Aydın Temel, F.; Cagcag Yolcu, O.; Turan, N.G. Modeling and optimization of process parameters in co-composting of tea waste and food waste: Radial basis function neural networks and genetic algorithm. Bioresour. Technol. 2022, 363, 127910. [Google Scholar] [CrossRef] [PubMed]

- Meunchang, S.; Panichsakpatana, S.; Weaver, R.W. Co-composting of filter cake and bagasse; by-products from a sugar mill. Bioresour. Technol. 2005, 96, 437–442. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Li, Y.; Han, Y.; Qian, W.; Li, G.; Luo, W. Performance of mature compost to control gaseous emissions in kitchen waste composting. Sci. Total Environ. 2019, 657, 262–269. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).