Influences of Management Practices and Methodological Choices on Life Cycle Assessment Results of Composting Mixtures of Biowaste and Green Cuts

Abstract

:1. Introduction

- To investigate the influence of the biowaste and the green cut waste composition;

- To assess the influence of management practices;

- To estimate the environmental impacts of using alternative substituted products.

2. Materials and Methods

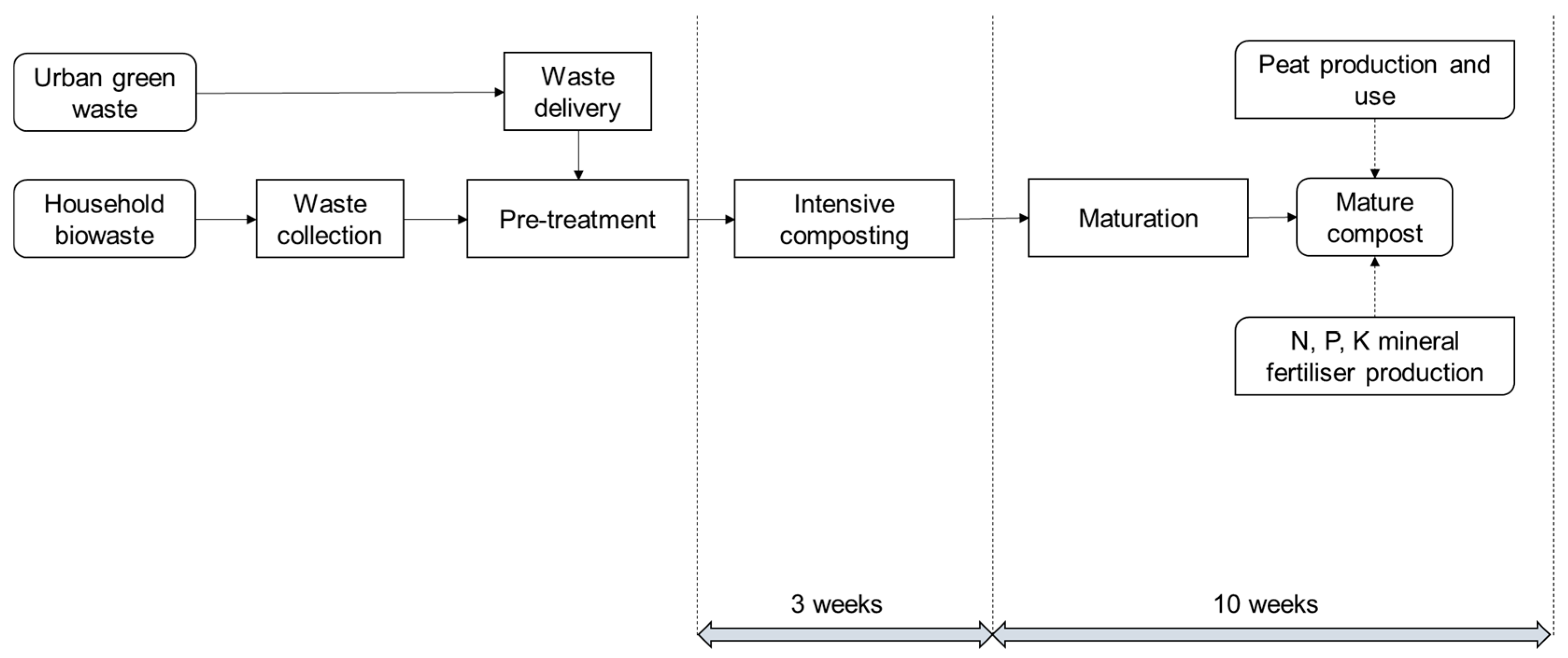

2.1. Investigated Composting Systems

2.2. Life Cycle Assessment (LCA)

2.2.1. Goal Definition

2.2.2. Scope Definition

2.2.3. Life Cycle Inventory Modelling and Data Collection

2.2.4. Impact Assessment

2.3. Multi-Functionality and Scenario Definition

2.3.1. Multi-Functional Processes and Defining Marginal Products

2.3.2. Scenario Definition

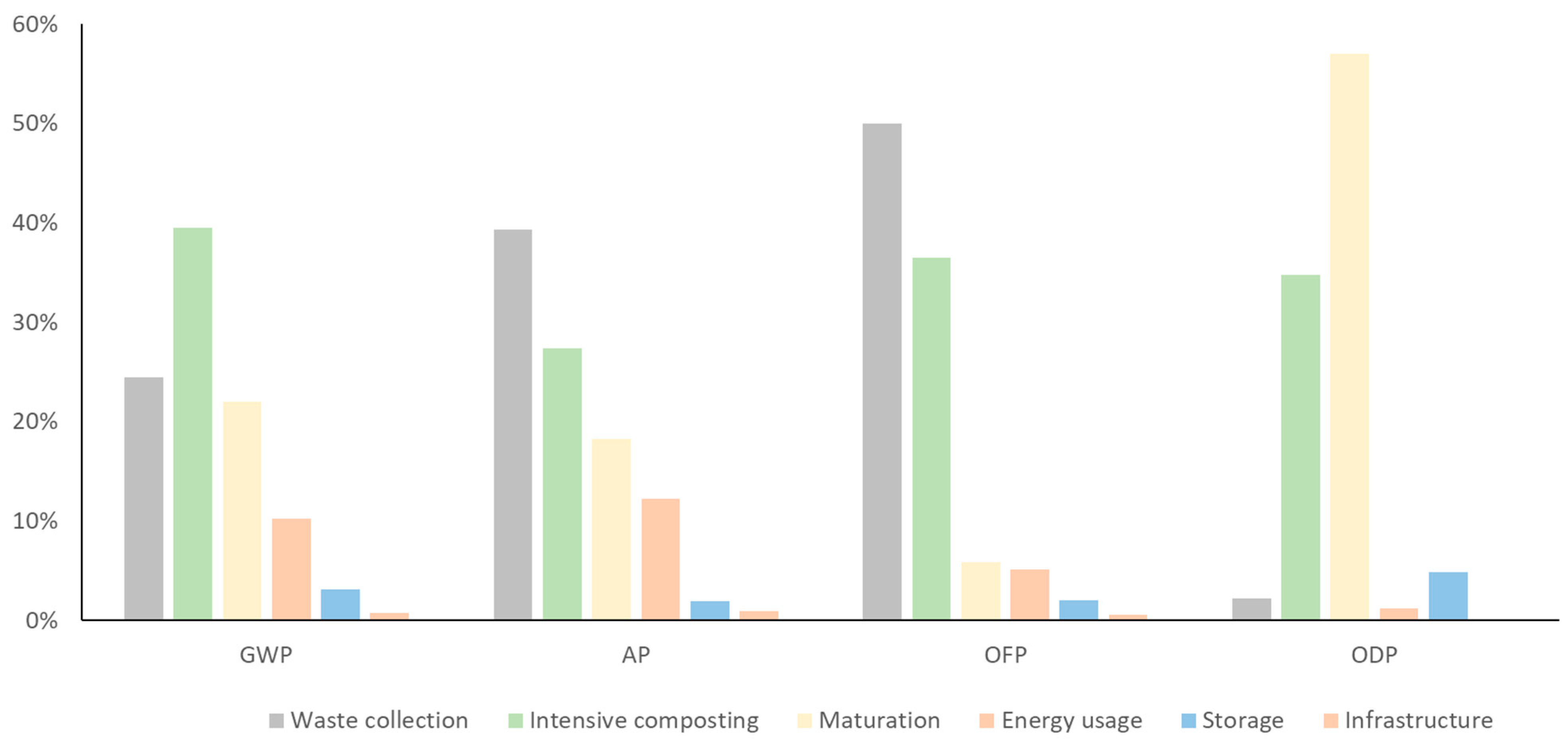

3. Results

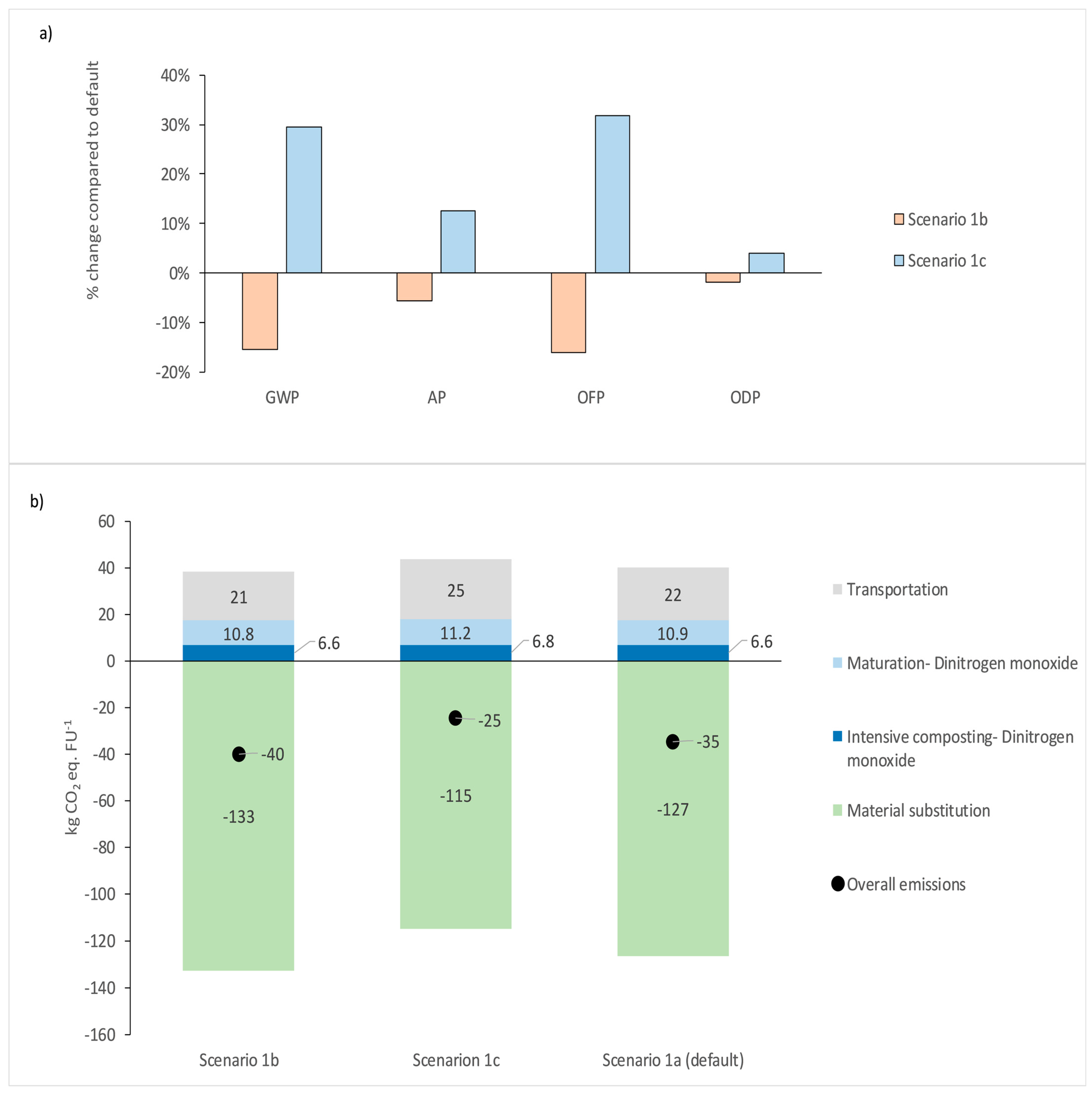

3.1. Influence of Biowaste Composition Simulated by Using Different Mixing Ratios

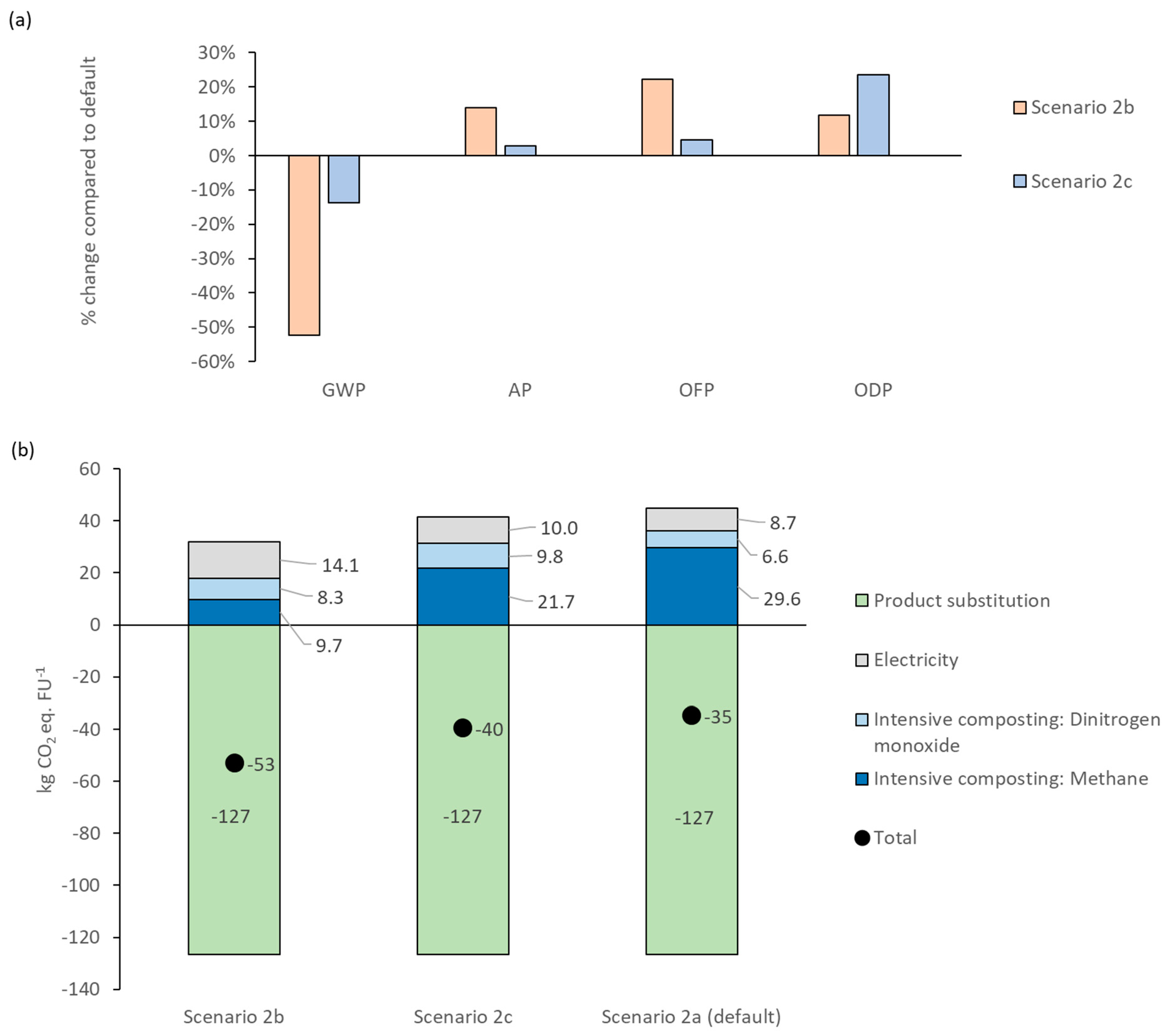

3.2. Influence of Turning Frequency

3.3. Influence of Biofilter Maintenance

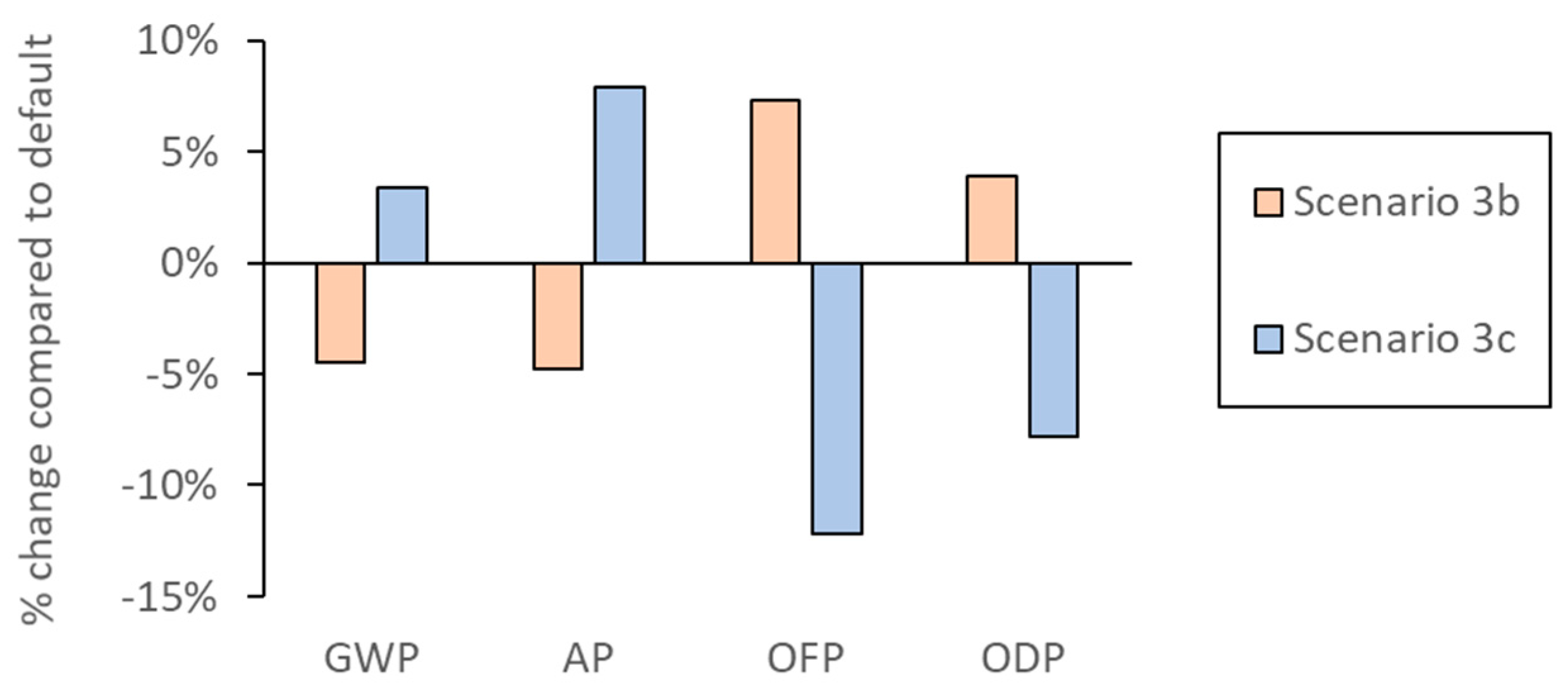

3.4. Influence of Alternative Products for Substitution

4. Discussion

4.1. Waste Composition

4.2. Management Practices

4.3. Choice of Substitution Product

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Allesch, A.; Brunner, P.H. Assessment methods for solid waste management: A literature review. Waste Manag. Res. 2014, 32, 461–473. [Google Scholar] [CrossRef] [PubMed]

- Vergara, S.E.; Silver, W.L. Greenhouse gas emissions from windrow composting of organic wastes: Patterns and emissions factors. Environ. Res. Lett. 2019, 14, 124027. [Google Scholar] [CrossRef]

- Dhamodharan, K.; Varma, V.S.; Veluchamy, C.; Pugazhendhi, A.; Rajendran, K. Emission of volatile organic compounds from composting: A review on assessment, treatment and perspectives. Sci. Total Environ. 2019, 695, 133725. [Google Scholar] [CrossRef] [PubMed]

- Sayara, T.; Sánchez, A. Gaseous Emissions from the Composting Process: Controlling Parameters and Strategies of Mitigation. Processes 2021, 9, 1844. [Google Scholar] [CrossRef]

- UBA. Aufwand und Nutzen Einer Optimierten Bioabfallverwertung Hinsichtlich Energieeffizienz, Klima- und Ressourcenschutz, Dessau-Roßlau, 2010. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/461/publikationen/4010_0.pdf (accessed on 15 October 2023).

- Waqas, M.; Nizami, A.S.; Aburiazaiza, A.S.; Barakat, M.A.; Rashid, M.I.; Ismail, I. Optimizing the process of food waste compost and valorizing its applications: A case study of Saudi Arabia. J. Clean. Prod. 2018, 176, 426–438. [Google Scholar] [CrossRef]

- Colón, J.; Martínez-Blanco, J.; Gabarrell, X.; Rieradevall, J.; Font, X.; Artola, A.; Sánchez, A. Performance of an industrial biofilter from a composting plant in the removal of ammonia and VOCs after material replacement. J. Chem. Technol. Biotechnol. 2009, 84, 1111–1117. [Google Scholar] [CrossRef]

- Aziz, R.; Chevakidagarn, P.; Danteravanich, S. Composting system improvement by life cycle assessment approach on community composting of agricultural and agro industrial wastes. Indones. J. Environ. Manag. Sustain. 2018, 3, 69–75. [Google Scholar] [CrossRef]

- Lam, K.L.; Solon, K.; Jia, M.; Volcke, E.I.P.; van der Hoek, J.P. Life Cycle Environmental Impacts of Wastewater-Derived Phosphorus Products: An Agricultural End-User Perspective. Environ. Sci. Technol. 2022, 56, 10289–10298. [Google Scholar] [CrossRef]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Andreasi Bassi, S.; Christensen, T.H.; Damgaard, A. Environmental performance of household waste management in Europe—An example of 7 countries. Waste Manag. 2017, 69, 545–557. [Google Scholar] [CrossRef]

- Hansen, R.N.; Rasmussen, F.N.; Ryberg, M.; Birgisdottir, H. Wood as a carbon mitigating building material: A review of consequential LCA and biogenic carbon characteristics. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 12066. [Google Scholar] [CrossRef]

- Weidema, B.P.; Ekvall, T.; Heijungs, R. Guidelines for application of deepened and broadened LCA. Deliv. D18 Work. Package 2009, 5, 17. [Google Scholar]

- Kranert, M.; Cord-Landwehr, K. Sammlung und Transport. In Einführung in Die Abfallwirtschaft; Kranert, M., Cord-Landwehr, K., Eds.; Vieweg+Teubner: Wiesbaden, Germany, 2010; pp. 91–133. ISBN 978-3-8351-0060-2. [Google Scholar]

- Friedrich, J. Nachhaltigkeitsbewertung von Systemalternativen zur Transformation des Wasser-Energie-Nexus im Städtischen Gebäudebestand; Karlsruhe Institute of Technology: Karlsruhe, Germany, 2020. [Google Scholar]

- Kranert, M.; Cord-Landwehr, K. Biologische Verfahren. In Einführung in Die Abfallwirtschaft; Kranert, M., Cord-Landwehr, K., Eds.; Vieweg+Teubner: Wiesbaden, Germany, 2010; pp. 185–291. ISBN 978-3-8351-0060-2. [Google Scholar]

- Sánchez, A.; Artola, A.; Font, X.; Gea, T.; Barrena, R.; Gabriel, D.; Sánchez-Monedero, M.Á.; Roig, A.; Cayuela, M.L.; Mondini, C. Greenhouse gas emissions from organic waste composting. Environ. Chem. Lett. 2015, 13, 223–238. [Google Scholar] [CrossRef]

- Epstein, E. Industrial Composting: Environmental Engineering and Facilities Management; CRC Press: Boca Raton, FL, USA, 2011; ISBN 9781439845318. [Google Scholar]

- UBA. Ermittlung der Emissionssituation Bei der Verwertung Von Bioabfällen. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/texte_39_2015_ermittlung_der_emissionssituation_bei_der_verwertung_von_bioabfaellen.pdf (accessed on 10 September 2021).

- RAL. RAL-GZ 251, Güte-und Prüfbestimmungen für Kompost; Deutsches Institut für Gütesicherungund Kennzeichnung e.V: Berlin, Germany, 2007. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Laurent, A.; Clavreul, J.; Bernstad, A.; Bakas, I.; Niero, M.; Gentil, E.; Christensen, T.H.; Hauschild, M.Z. Review of LCA studies of solid waste management systems–part II: Methodological guidance for a better practice. Waste Manag. 2014, 34, 589–606. [Google Scholar] [CrossRef] [PubMed]

- Stichnothe, H.; Schuchardt, F. Comparison of different treatment options for palm oil production waste on a life cycle basis. Int. J. Life Cycle Assess. 2010, 15, 907–915. [Google Scholar] [CrossRef]

- Luo, Y.; Stichnothe, H.; Schuchardt, F.; Li, G.; Huaitalla, R.M.; Xu, W. Life cycle assessment of manure management and nutrient recycling from a Chinese pig farm. Waste Manag. Res. 2014, 32, 4–12. [Google Scholar] [CrossRef]

- Clemens, J.; Cuhls, C. Greenhouse gas emissions from mechanical and biological waste treatment of municipal waste. Environ. Technol. 2003, 24, 745–754. [Google Scholar] [CrossRef]

- Hansen, T.L.; Bhander, G.S.; Christensen, T.H.; Bruun, S.; Jensen, L.S. Life cycle modelling of environmental impacts of application of processed organic municipal solid waste on agricultural land (EASEWASTE). Waste Manag. Res. 2006, 24, 153–166. [Google Scholar] [CrossRef]

- Sardarmehni, M.; Levis, J.W.; Barlaz, M.A. What Is the Best End Use for Compost Derived from the Organic Fraction of Municipal Solid Waste? Environ. Sci. Technol. 2021, 55, 73–81. [Google Scholar] [CrossRef]

- Boldrin, A.; Hartling, K.R.; Laugen, M.; Christensen, T.H. Environmental inventory modelling of the use of compost and peat in growth media preparation. Resour. Conserv. Recycl. 2010, 54, 1250–1260. [Google Scholar] [CrossRef]

- Stichnothe, H. Life cycle assessment of peat for growing media and evaluation of the suitability of using the Product Environmental Footprint methodology for peat. Int. J. Life Cycle Assess. 2022, 27, 1270–1282. [Google Scholar] [CrossRef]

- Kokkora, M.I. Biowaste and Vegetable Waste Compost Application to Agriculture; Cranfield University: Cranfield, UK, 2008. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Tonini, D.; Hamelin, L.; Wenzel, H.; Astrup, T. Bioenergy production from perennial energy crops: A consequential LCA of 12 bioenergy scenarios including land use changes. Environ. Sci. Technol. 2012, 46, 13521–13530. [Google Scholar] [CrossRef] [PubMed]

- de Vries, J.W.; Groenestein, C.M.; de Boer, I.J.M. Environmental consequences of processing manure to produce mineral fertilizer and bio-energy. J. Environ. Manage. 2012, 102, 173–183. [Google Scholar] [CrossRef]

- Ahlgren, S.; Baky, A.; Bernesson, S.; rdberg, Å.; Norén, O.; Hansson, P.-A. Green Nitrogen-Possibilities for Production of Mineral Nitrogen Fertilisers Based on Renewable Resources in Sweden, 2011. Available online: https://pub.epsilon.slu.se/13703/11/ahlgren_s_et_al_161230.pdf (accessed on 11 November 2023).

- Petersen, B.M. Life Cycle Assessment of Slurry Management Technologies, 2009. Available online: https://www2.mst.dk/udgiv/publications/2009/978-87-92548-20-7/pdf/978-87-92548-21-4.pdf (accessed on 11 November 2023).

- Weidema, B.P. Market Information in LCA, Environmental Project no. 863. Dan. Environ. Prot. Agency Cph. Den. 2003. Available online: https://www2.mst.dk/Udgiv/publications/2003/87-7972-991-6/pdf/87-7972-992-4.pdf (accessed on 11 November 2023).

- Nemecek, T.; Kägi, T.; Blaser, S. Life cycle inventories of agricultural production systems. Final Rep. Ecoinvent 2007, 15, 1–360. [Google Scholar]

- Pagans, E.; Font, X.; Sánchez, A. Biofiltration for ammonia removal from composting exhaust gases. Chem. Eng. J. 2005, 113, 105–110. [Google Scholar] [CrossRef]

- Helm, M. Prozeßführung Bei der Kompostierung von Organischen Reststoffen Aus Haushalten; Technische Universität München: München, Germany, 1995. [Google Scholar]

- Cuhls, C. Schadstoffbilanzierung und Emissionsminderung Bei der Mechanisch-Biologischen Abfallbehandlung; ISAH: Hannover, Germany, 2001; ISBN 3921421438. [Google Scholar]

- Amlinger, F.; Peyr, S.; Cuhls, C. Green house gas emissions from composting and mechanical biological treatment. Waste Manag. Res. 2008, 26, 47–60. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Cuhls, C. Methane removal using materials from biofilters at composting plants. J. Vietnam. Environ. 2018, 10, 22–26. [Google Scholar] [CrossRef]

- Konstantzos, G.E.; Malamis, D.; Sotiropoulos, A.; Loizidou, M. Environmental profile of an innovative household biowaste dryer system based on Life Cycle Assessment. Waste Manag. Res. 2019, 37, 48–58. [Google Scholar] [CrossRef] [PubMed]

- Sommer, S.G.; Moller, H.B. Emission of greenhouse gases during composting of deep litter from pig production–effect of straw content. J. Agric. Sci. 2000, 134, 327–335. [Google Scholar] [CrossRef]

- He, Y.; Inamori, Y.; Mizuochi, M.; Kong, H.; Iwami, N.; Sun, T. Nitrous oxide emissions from aerated composting of organic waste. Environ. Sci. Technol. 2001, 35, 2347–2351. [Google Scholar] [CrossRef] [PubMed]

- Czekała, W.; Janczak, D.; Pochwatka, P.; Nowak, M.; Dach, J. Gases Emissions during Composting Process of Agri-Food Industry Waste. Appl. Sci. 2022, 12, 9245. [Google Scholar] [CrossRef]

- Chadwick, D. Emissions of ammonia, nitrous oxide and methane from cattle manure heaps: Effect of compaction and covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Phong, N.T. Greenhouse Gas Emissions from Composting and Anaerobic Digestion Plants. Ph.D. Thesis, Rheinischen Friedrich-Wilhelms University of Bonn, Bonn, Germany, 2012. Available online: https://bonndoc.ulb.uni-bonn.de/xmlui/bitstream/handle/20.500.11811/5130/3002.pdf (accessed on 11 November 2023).

- Althaus, H.-J.; Chudacoff, M.; Hischier, R.; Jungbluth, N.; Osses, M.; Primas, A. Life Cycle Inventories of Chemicals: Ecoinvent Report No. 8, v2.0., 2007. Available online: https://db.ecoinvent.org/reports/08_Chemicals.pdf (accessed on 11 November 2023).

- Liu, X.; Elgowainy, A.; Wang, M. Life cycle energy use and greenhouse gas emissions of ammonia production from renewable resources and industrial by-products. Green Chem. 2020, 22, 5751–5761. [Google Scholar] [CrossRef]

| N Fertiliser | P Fertiliser | K Fertiliser |

|---|---|---|

| Ammonium Nitrate (35% N) | Single Superphosphate (21% P2O5) | Potassium Chloride (60% K2O) |

| Ammonium Sulphate (21% N) | Triple Superphosphate (48% P2O5) | Potassium Sulphate (50% K2O) |

| Calcium Ammonium Nitrate (26.5% N) | ||

| Calcium Nitrate (11.86% N) | ||

| Urea Ammonium Nitrate (32% N) | ||

| Urea (46% N) |

| Default | Alternate Scenario | Alternate Scenario | |

|---|---|---|---|

| SG1: Mixing ratio (BW:GW) | 1a: 70:30 | 1b: 60:40 | 1c: 90:10 |

| SG2: Turning frequency | 2a: 7-day interval | 2b: 3-day interval | 2c: 1-day interval |

| SG3: Biofilter maintenance | 3a: Default maintenance | 3b: Optimal maintenance | 3c: Inadequate maintenance |

| SG4: Fertiliser substitution | 4a: UAN/ TSP | 4b: CAN/ TSP | 4c: UAN/ SSP |

| SG5: Peat substitution | 5a: Unspecified peat | 5b: White peat | 5c: Black peat |

| Mixing Ratio (BW:GW) | C/N Ratio | Moisture Content | EF_CH4 | EF_N2O | EF_NH3 | |

|---|---|---|---|---|---|---|

| Unit | % | g/t FM | g/t FM | g/t FM | ||

| SG1: Composition | ||||||

| 1a. 70:30 scenario | 70:30 | 29 | 61.3 | 1200 | 62.0 | 22.9 |

| 1b. 60:40 scenario | 60:40 | 31 | 60.0 | 1200 | 61.3 | 22.6 |

| 1c. 90:10 scenario | 90:10 | 24 | 64.0 | 1200 | 63.4 | 23.4 |

| SG2: Turning frequency | ||||||

| 2a. 7-day interval | 70:30 | 29 | 61.3 | 1200 | 62.0 | 22.9 |

| 2b. 1-day interval | 70:30 | 29 | 61.3 | 393 | 68.0 | 33.0 |

| 2c. 3-day interval | 70:30 | 29 | 61.3 | 879 | 110.0 | 25.0 |

| SG3: Biofilter maintenance | ||||||

| 3a. default maintenance | 70:30 | 29 | 61.3 | 1200 | 62.0 | 22.9 |

| 3b. Optimal maintenance | 70:30 | 29 | 61.3 | 1135 | 64.0 | 17.0 |

| 3c. Inadequate maintenance | 70:30 | 29 | 61.3 | 1267 | 59.0 | 33.0 |

| GWP (kg CO2 eq.) | AP (kg SO2 eq.) | OFP (kg NOx eq.) | ODP (kg CFC11 eq.) | |

|---|---|---|---|---|

| Emissions | ||||

| Collection | 22.4 | 0.06 | 0.15 | 2 × 10−5 |

| Pre-treatment | 2.7 | 0.01 | 0.00 | 2 × 10−6 |

| Composting | ||||

| Intensive composting | 43.0 | 0.06 | 0.09 | 3 × 10−4 |

| Maturation | 20.9 | 0.04 | 0.02 | 4 × 10−4 |

| Storage | 2.8 | 0.00 | 0.01 | 3 × 10−5 |

| Credits | ||||

| N fertiliser replacement | −5.4 | 0.01 | −0.01 | −9 × 10−5 |

| P fertiliser replacement | −3.1 | −0.03 | −0.01 | −1 × 10−6 |

| K fertiliser replacement | −5.6 | 0.02 | −0.01 | −8 × 10−5 |

| Peat replacement | −112.5 | −0.03 | −0.08 | −2 × 10−5 |

| Net impact | −34.8 | 0.14 | 0.15 | 5 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joseph, B.; Stichnothe, H. Influences of Management Practices and Methodological Choices on Life Cycle Assessment Results of Composting Mixtures of Biowaste and Green Cuts. Waste 2023, 1, 919-934. https://doi.org/10.3390/waste1040053

Joseph B, Stichnothe H. Influences of Management Practices and Methodological Choices on Life Cycle Assessment Results of Composting Mixtures of Biowaste and Green Cuts. Waste. 2023; 1(4):919-934. https://doi.org/10.3390/waste1040053

Chicago/Turabian StyleJoseph, Ben, and Heinz Stichnothe. 2023. "Influences of Management Practices and Methodological Choices on Life Cycle Assessment Results of Composting Mixtures of Biowaste and Green Cuts" Waste 1, no. 4: 919-934. https://doi.org/10.3390/waste1040053

APA StyleJoseph, B., & Stichnothe, H. (2023). Influences of Management Practices and Methodological Choices on Life Cycle Assessment Results of Composting Mixtures of Biowaste and Green Cuts. Waste, 1(4), 919-934. https://doi.org/10.3390/waste1040053